Introduction: Navigating the Global Market for what does an alternator do

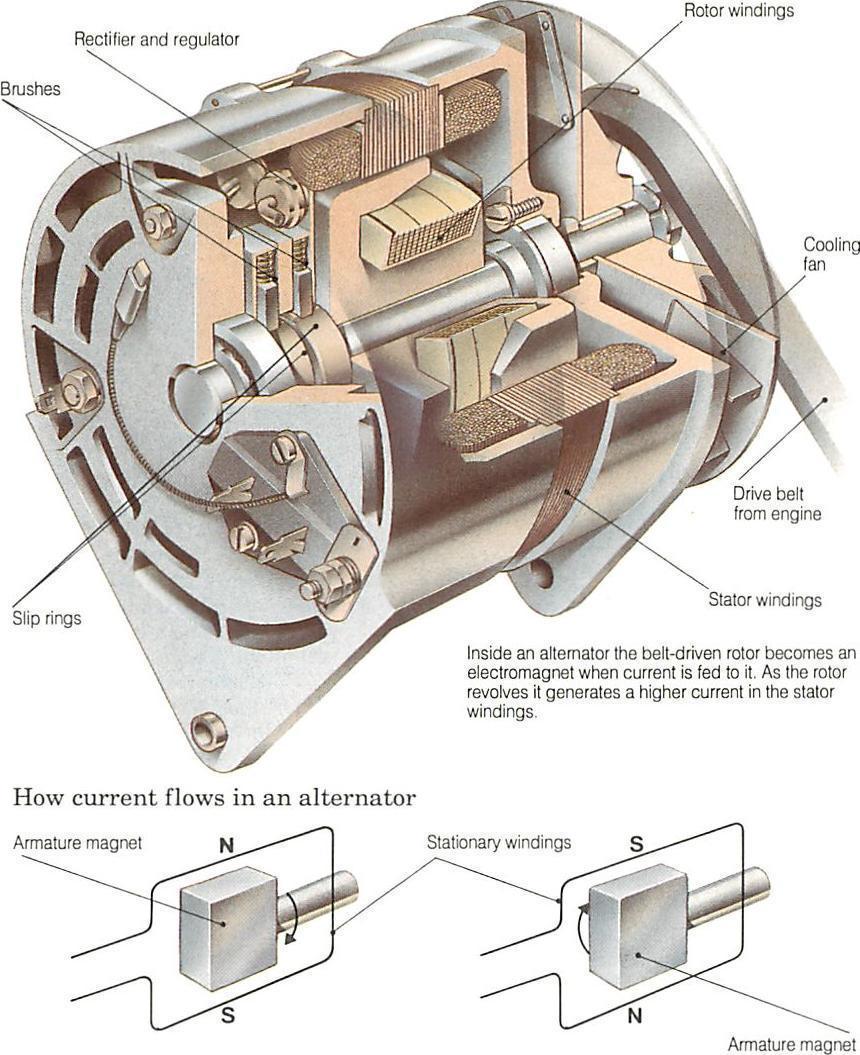

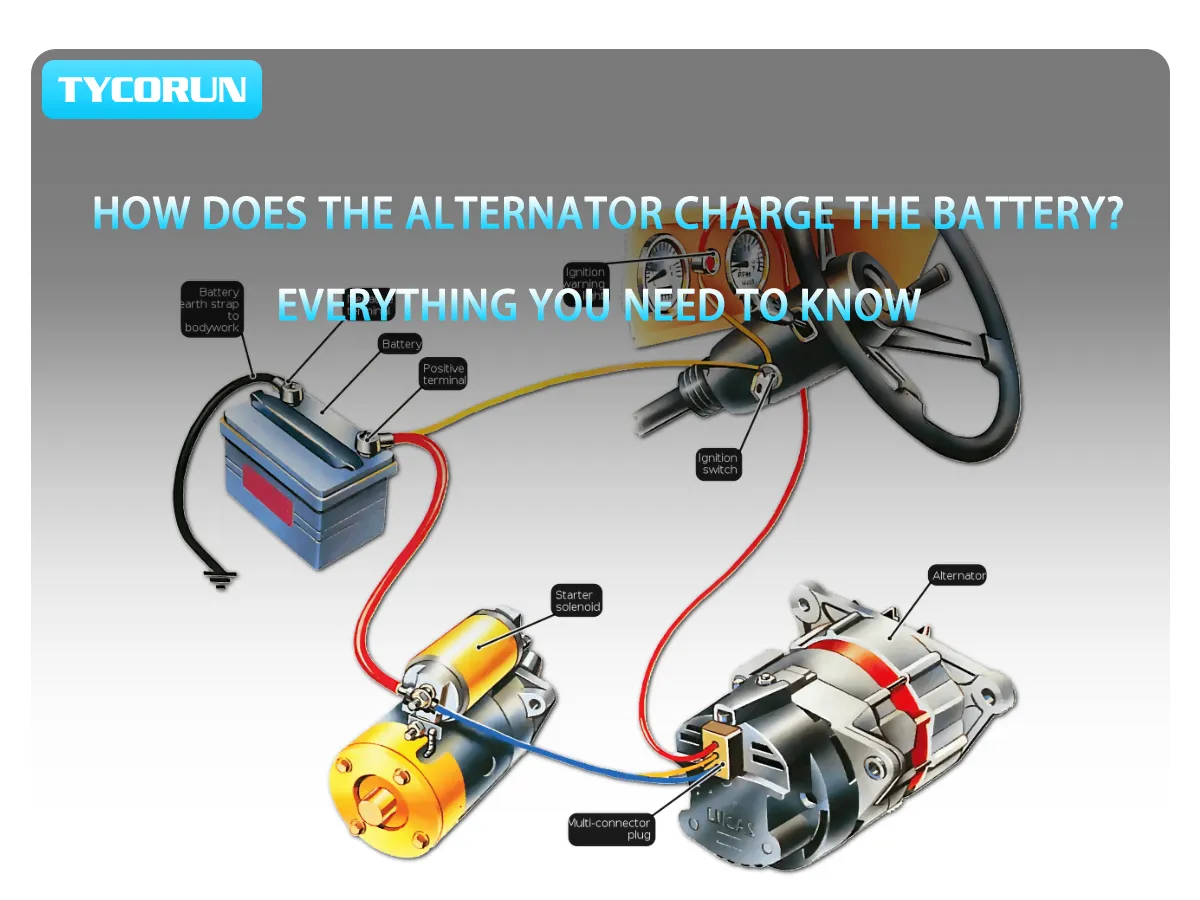

In the complex landscape of automotive components, understanding what an alternator does is crucial for B2B buyers involved in vehicle maintenance and parts sourcing. Alternators play a pivotal role in converting mechanical energy into electrical energy, ensuring that all electrical systems in vehicles operate smoothly. As global markets continue to evolve, especially in regions such as Africa, South America, the Middle East, and Europe, sourcing reliable alternators becomes increasingly important. However, challenges such as varying quality standards, fluctuating costs, and diverse supplier capabilities can complicate the purchasing process.

This comprehensive guide addresses these challenges by delving into the functionalities of alternators, their various types, and applications across different vehicle models. Additionally, it offers insights into effective supplier vetting processes, cost considerations, and best practices for maintenance. By providing actionable information and expert advice, this guide empowers international B2B buyers to make informed purchasing decisions, ensuring they select high-quality alternators that meet their operational needs. Whether you are in a bustling market in Vietnam or navigating the automotive landscape in Saudi Arabia, understanding the intricacies of alternators will enhance your procurement strategy and support the reliability of your automotive fleet.

Table Of Contents

- Top 3 What Does An Alternator Do Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what does an alternator do

- Understanding what does an alternator do Types and Variations

- Key Industrial Applications of what does an alternator do

- 3 Common User Pain Points for ‘what does an alternator do’ & Their Solutions

- Strategic Material Selection Guide for what does an alternator do

- In-depth Look: Manufacturing Processes and Quality Assurance for what does an alternator do

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what does an alternator do’

- Comprehensive Cost and Pricing Analysis for what does an alternator do Sourcing

- Alternatives Analysis: Comparing what does an alternator do With Other Solutions

- Essential Technical Properties and Trade Terminology for what does an alternator do

- Navigating Market Dynamics and Sourcing Trends in the what does an alternator do Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what does an alternator do

- Strategic Sourcing Conclusion and Outlook for what does an alternator do

- Important Disclaimer & Terms of Use

Understanding what does an alternator do Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Alternator | Uses electromagnetic induction to generate electricity | Automotive manufacturing and repair | Pros: Widely available, cost-effective. Cons: Limited efficiency under extreme conditions. |

| High-Output Alternator | Designed for high-performance applications, providing increased current | Racing, heavy-duty vehicles, custom builds | Pros: Enhanced power output, supports advanced electronics. Cons: Higher cost, may require additional modifications. |

| Smart Alternator | Incorporates advanced technology for energy management | Electric vehicles, hybrid systems | Pros: Improves fuel efficiency, optimizes battery life. Cons: More complex, potentially higher initial investment. |

| Diesel Alternator | Specifically designed for diesel engines, robust construction | Commercial vehicles, heavy machinery | Pros: Durable, reliable under heavy loads. Cons: Heavier, can be more expensive. |

| Portable Alternator | Compact and mobile, ideal for temporary power needs | Construction sites, outdoor events | Pros: Versatile, easy to transport. Cons: Limited power output, not suitable for permanent installations. |

What are the Characteristics of Conventional Alternators?

Conventional alternators are the most common type found in standard vehicles. They utilize electromagnetic induction to convert mechanical energy from the engine into electrical energy. These units are typically reliable and can last between 7 to 10 years under normal driving conditions. B2B buyers in the automotive manufacturing and repair sectors often prefer these alternators due to their cost-effectiveness and widespread availability. However, they may not perform optimally in extreme environments, which can be a consideration for companies operating in diverse climatic conditions.

How Do High-Output Alternators Benefit Performance Applications?

High-output alternators are engineered for applications requiring increased electrical power, such as racing or heavy-duty vehicles. They deliver a higher current output, which is essential for powering advanced electronics and performance modifications. Businesses involved in motorsports or custom vehicle builds often seek these alternators to meet the demands of high-performance engines. While they provide significant advantages in power supply, they come at a higher price point and may necessitate additional modifications to the vehicle.

What Makes Smart Alternators a Smart Choice for Modern Vehicles?

Smart alternators feature advanced technology that allows for better energy management, making them ideal for electric and hybrid vehicles. These alternators adjust their output based on the vehicle’s energy demands, enhancing fuel efficiency and prolonging battery life. B2B buyers in the electric vehicle and hybrid markets should consider investing in smart alternators for their innovative design and energy-saving capabilities. However, the complexity of these systems may lead to higher initial costs, which could be a barrier for some businesses.

Why Are Diesel Alternators Essential for Heavy Machinery?

Diesel alternators are specifically designed to cater to the unique needs of diesel engines, providing robust power generation for commercial vehicles and heavy machinery. Their durability makes them suitable for high-load applications, ensuring reliable performance in demanding environments. Companies in the construction and transportation industries often prioritize diesel alternators for their resilience and efficiency. The trade-off is that these units tend to be heavier and more expensive than their conventional counterparts, which could impact overall vehicle weight and budget considerations.

How Do Portable Alternators Serve Diverse Applications?

Portable alternators are designed for versatility and ease of transport, making them ideal for temporary power needs at construction sites or outdoor events. Their compact size and lightweight construction allow for easy mobility, catering to businesses that require power on the go. However, their limited power output means they are not suitable for permanent installations or high-demand applications. B2B buyers should evaluate their specific power needs and consider the trade-offs between portability and power capacity when selecting a portable alternator.

Key Industrial Applications of what does an alternator do

| Industry/Sector | Specific Application of what does an alternator do | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Power supply for vehicle electrical systems | Ensures reliable vehicle operation and customer satisfaction | Quality assurance, compatibility with various vehicle models, and cost-effectiveness |

| Heavy Equipment | Electrical power generation in construction machinery | Enhances operational efficiency and reduces downtime | Durability, resistance to harsh environments, and availability of replacement parts |

| Marine Industry | Powering onboard electrical systems in vessels | Improves safety and functionality of marine operations | Corrosion resistance, size constraints, and compliance with maritime regulations |

| Renewable Energy | Integration in hybrid and electric vehicle systems | Supports the transition to sustainable energy solutions | Advanced technology, performance metrics, and supplier reliability |

| Agriculture | Powering irrigation and farming equipment | Increases productivity and operational reliability | Adaptability to agricultural environments, maintenance support, and warranty terms |

How Does an Alternator Function in Automotive Manufacturing?

In the automotive manufacturing sector, alternators are crucial for supplying power to a vehicle’s electrical systems, including lights, infotainment systems, and safety features. A reliable alternator ensures that vehicles operate smoothly, enhancing customer satisfaction and reducing warranty claims. For international buyers, particularly in regions like Africa and South America, sourcing high-quality alternators that are compatible with various vehicle models is essential. Businesses should prioritize suppliers that offer robust quality assurance processes and competitive pricing to meet diverse market needs.

What Role Does an Alternator Play in Heavy Equipment?

Heavy equipment, such as bulldozers and excavators, relies on alternators to generate electrical power for various functions, including hydraulic systems and operator controls. A dependable alternator minimizes downtime, which is critical in construction projects where delays can lead to significant financial losses. When sourcing alternators for heavy machinery, buyers should consider factors like durability and resistance to extreme conditions, ensuring that the components can withstand the rigors of construction sites while maintaining performance.

How is an Alternator Used in the Marine Industry?

In the marine industry, alternators are essential for powering onboard electrical systems, including navigation, communication, and safety equipment. A malfunctioning alternator can compromise the safety and functionality of a vessel, making it vital for maritime operators to invest in high-quality components. Buyers in this sector must look for alternators that offer corrosion resistance and comply with maritime regulations, ensuring long-term reliability in harsh marine environments.

What is the Importance of Alternators in Renewable Energy Applications?

As the demand for hybrid and electric vehicles increases, alternators play a significant role in these systems by converting mechanical energy into electrical energy. This conversion is vital for recharging batteries and powering electric motors, facilitating the transition to sustainable energy solutions. Buyers in this market should focus on advanced technology and performance metrics when sourcing alternators, as these factors are critical for the efficiency and effectiveness of hybrid systems.

How Do Alternators Benefit Agriculture?

In agriculture, alternators are used to power irrigation systems and various farming equipment, ensuring that operations run smoothly and efficiently. A reliable power supply can significantly increase productivity, reducing the risk of crop failure due to equipment malfunction. When sourcing alternators for agricultural applications, businesses should consider adaptability to different environments, availability of maintenance support, and favorable warranty terms to ensure long-term operational reliability.

3 Common User Pain Points for ‘what does an alternator do’ & Their Solutions

Scenario 1: Understanding Alternator Functionality in Fleet Management

The Problem:

B2B buyers managing fleets often struggle with understanding the role of alternators in vehicle performance and reliability. Fleet managers may experience vehicle breakdowns due to alternator failures, leading to unexpected downtime and increased operational costs. This lack of knowledge can result in delayed maintenance schedules or misdiagnosis of electrical issues, causing unnecessary replacements or repairs.

The Solution:

To effectively manage alternator-related issues, fleet managers should prioritize training for their maintenance teams on the electrical systems of vehicles, specifically the function and importance of alternators. Implementing a regular inspection schedule can help detect early signs of alternator failure, such as dimming lights or battery warning indicators. Additionally, investing in diagnostic tools can aid in accurately pinpointing whether issues stem from the alternator or the battery. By establishing relationships with reputable suppliers, fleet managers can ensure they have access to high-quality alternators and components, which will enhance the overall reliability of their fleet.

Scenario 2: Cost Management and Budgeting for Alternator Replacements

The Problem:

B2B buyers often face budget constraints when it comes to vehicle maintenance, particularly with high-value components like alternators. The cost of alternator replacement can vary significantly based on the vehicle model and the supplier, and unexpected failures can strain financial resources. This unpredictability makes it challenging for businesses to allocate funds effectively, especially in regions with fluctuating import costs or supply chain disruptions.

The Solution:

To manage costs effectively, businesses should conduct thorough market research to understand the price range for alternators across different suppliers and regions. Creating a budget that includes both routine maintenance and potential replacement costs will provide a financial buffer for unexpected failures. Additionally, forming partnerships with local suppliers can reduce shipping costs and lead times, ensuring that replacements are available without significant financial strain. Implementing a preventative maintenance program that includes regular alternator checks can also help extend the lifespan of the component, reducing the frequency of replacements.

Scenario 3: Recognizing Signs of Alternator Failure in Diverse Operating Conditions

The Problem:

For B2B buyers operating in diverse environments—from urban settings with stop-and-go traffic to rural areas with rough terrain—recognizing the signs of alternator failure can be challenging. Variations in driving conditions can mask symptoms, leading to abrupt vehicle failures. This uncertainty can result in operational disruptions, especially in industries reliant on timely deliveries or services.

The Solution:

Educating drivers on the signs of alternator failure is crucial. Implementing a training program that covers symptoms such as dashboard warning lights, dimming headlights, or unusual noises can empower drivers to report issues before they escalate. Additionally, utilizing telematics systems can provide real-time data on vehicle performance, helping to identify potential electrical issues early. By tracking vehicle performance metrics, businesses can establish maintenance protocols tailored to the specific operating conditions of their fleets, ultimately improving reliability and reducing downtime. Regularly scheduled maintenance checks that include alternator inspections will ensure that any potential issues are addressed proactively, maintaining seamless operations.

Strategic Material Selection Guide for what does an alternator do

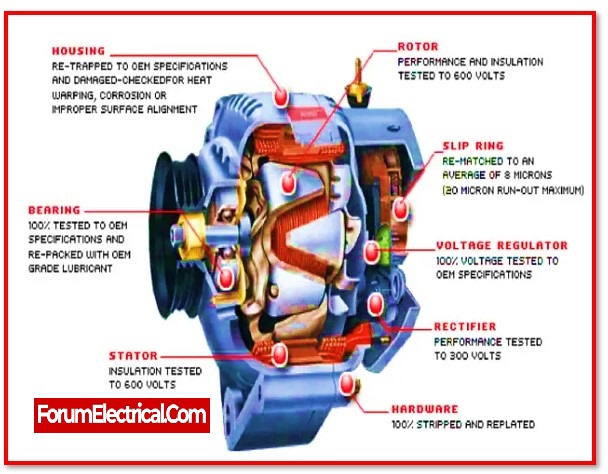

What Materials Are Commonly Used in Alternators and Their Performance?

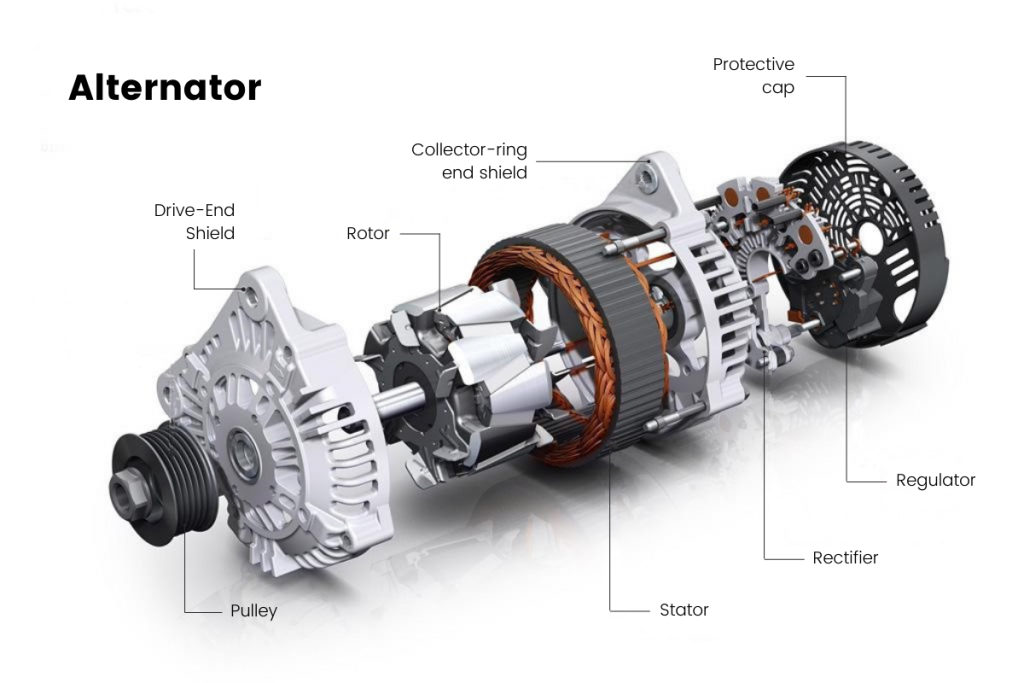

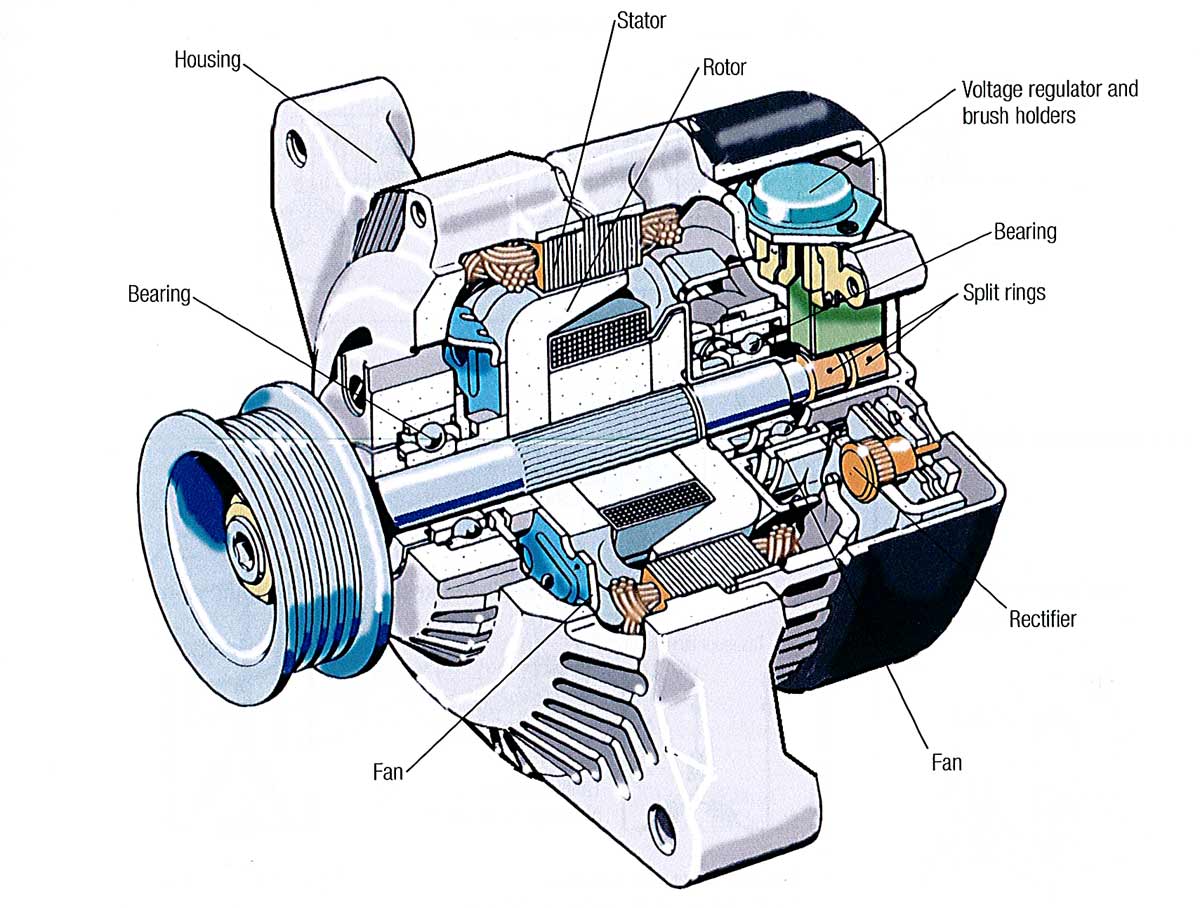

When considering the materials used in alternators, it is essential to focus on those that enhance performance, durability, and compatibility with various operating conditions. The primary materials include aluminum, copper, steel, and plastic composites. Each material has unique properties that affect the alternator’s efficiency, longevity, and overall functionality.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is known for its excellent corrosion resistance and lightweight characteristics. It can withstand moderate temperatures, typically up to 150°C (302°F), making it suitable for automotive applications.

Pros & Cons: The advantages of aluminum include its low weight, which contributes to overall vehicle efficiency, and its resistance to corrosion, reducing maintenance needs. However, it can be less durable than other metals under high-stress conditions and may require additional coatings for enhanced performance.

Impact on Application: In alternators, aluminum is often used for the housing and some internal components. Its lightweight nature helps improve fuel efficiency but may not be suitable for high-performance applications requiring extreme durability.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should consider local environmental conditions, such as humidity and temperature extremes, when selecting aluminum components. Compliance with international standards like ASTM can also influence material selection.

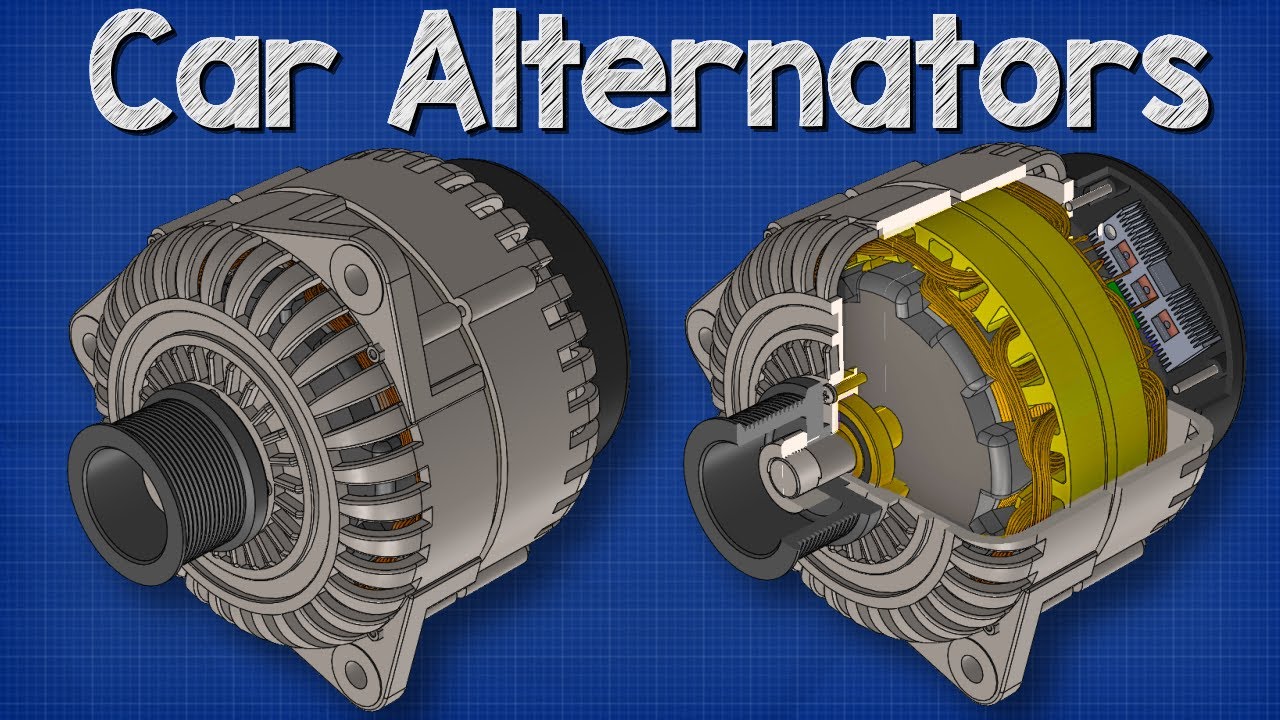

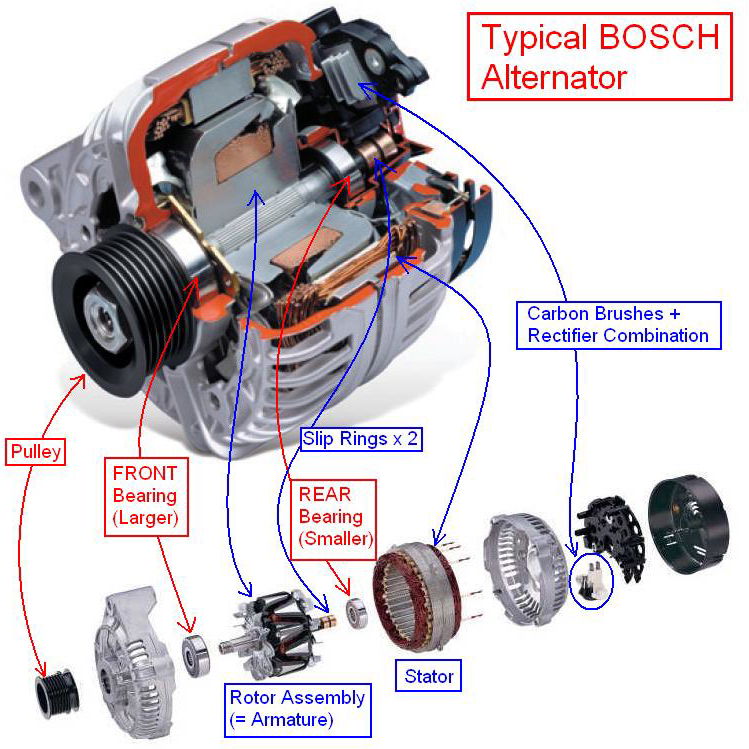

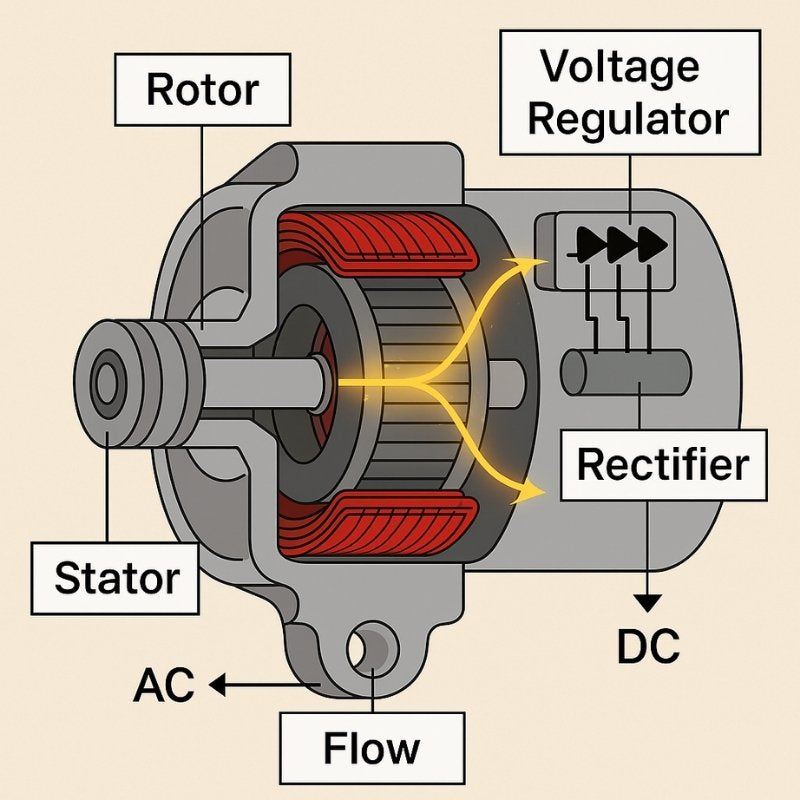

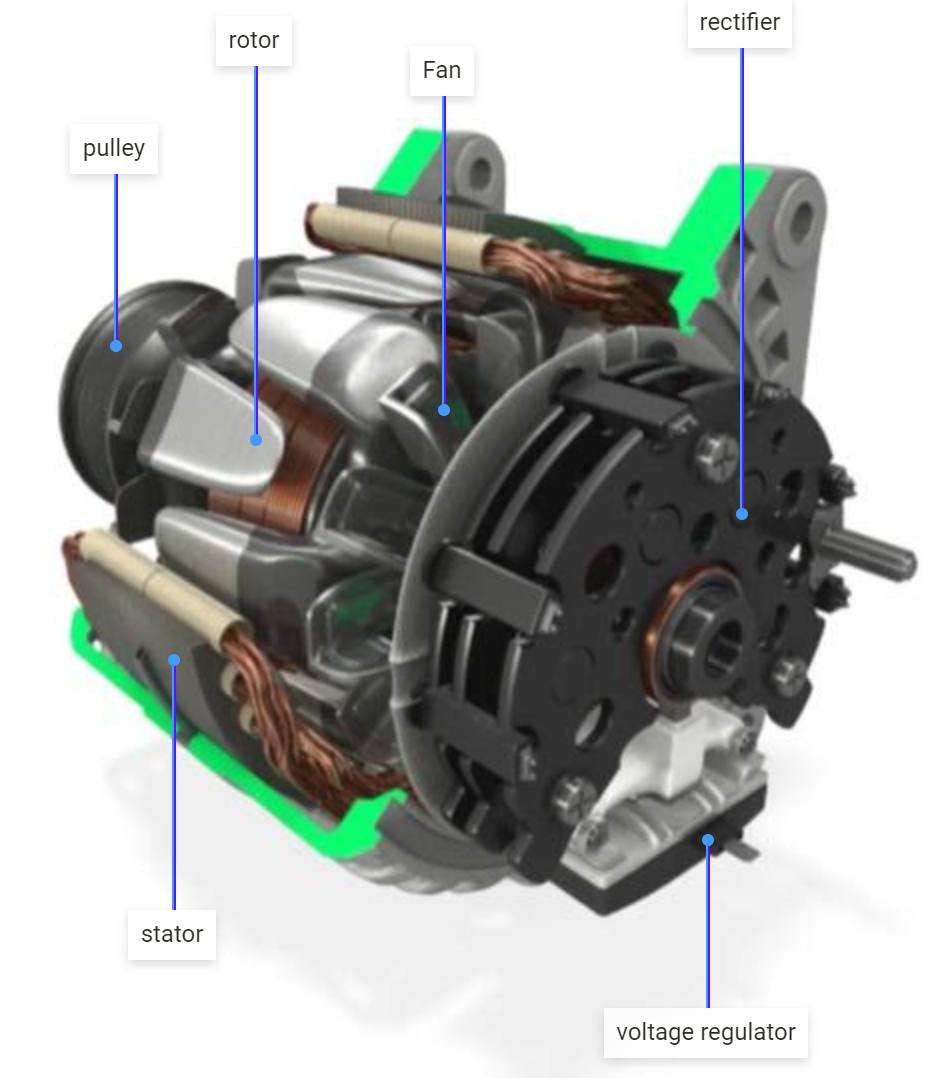

Illustrative image related to what does an alternator do

Copper: Superior Conductivity

Key Properties: Copper is renowned for its excellent electrical conductivity, with a conductivity rating of 97% IACS (International Annealed Copper Standard). It can handle high temperatures up to 200°C (392°F) without significant degradation.

Pros & Cons: The primary advantage of copper is its superior ability to conduct electricity, which enhances the efficiency of the alternator. However, copper is heavier than aluminum and more expensive, which can increase the overall cost of the alternator.

Impact on Application: Copper is predominantly used in the windings of the alternator, where efficient energy transfer is critical. Its high conductivity ensures that the alternator can effectively charge the battery and power electrical components.

Illustrative image related to what does an alternator do

Considerations for International Buyers: In markets like South America and Europe, the demand for copper components may be influenced by local supply chains and pricing fluctuations. Buyers should also be aware of recycling regulations, as copper is a valuable material in sustainability practices.

Steel: Strength and Durability

Key Properties: Steel offers high tensile strength and can withstand significant mechanical stress. Its temperature resistance varies but generally can handle up to 300°C (572°F) in automotive applications.

Pros & Cons: The main advantage of steel is its durability, making it ideal for structural components in alternators. However, steel is prone to corrosion if not properly treated, and it is heavier than aluminum, which can affect overall vehicle weight.

Impact on Application: Steel is often used in the rotor and stator components of the alternator, where strength is crucial. Its durability ensures long-lasting performance under demanding conditions.

Considerations for International Buyers: Buyers should consider the availability of high-quality steel in their region, as well as compliance with international standards such as DIN. Corrosion resistance treatments may be necessary in humid climates, particularly in Africa and Southeast Asia.

Illustrative image related to what does an alternator do

Plastic Composites: Lightweight and Versatile

Key Properties: Plastic composites are lightweight and can be engineered for specific thermal and mechanical properties. They typically withstand temperatures up to 120°C (248°F).

Pros & Cons: The advantages of plastic composites include their lightweight nature and resistance to corrosion. However, they may not offer the same level of strength as metals and can be susceptible to deformation under high heat.

Impact on Application: Plastic composites are often used for non-structural components, such as covers and insulators, in alternators. Their lightweight properties contribute to overall vehicle efficiency.

Considerations for International Buyers: In regions with stringent regulations on materials, such as Europe, compliance with environmental standards is crucial. Buyers should also consider the long-term durability of plastic composites in their specific applications.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for what does an alternator do | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and internal components | Lightweight and corrosion-resistant | Less durable under high stress | Medium |

| Copper | Windings | Superior electrical conductivity | Heavier and more expensive | High |

| Steel | Rotor and stator components | High strength and durability | Prone to corrosion | Medium |

| Plastic Composites | Covers and insulators | Lightweight and versatile | Lower strength than metals | Low |

This analysis provides a comprehensive overview of the materials used in alternators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers. Understanding these factors is crucial for making informed purchasing decisions in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for what does an alternator do

What Are the Key Stages in the Manufacturing Process of Alternators?

The manufacturing process of alternators is a complex operation that requires precision engineering and high-quality materials to ensure reliability and efficiency. The main stages of manufacturing alternators typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Alternator Manufacturing?

Material preparation is the foundational step in alternator manufacturing. High-quality materials, such as aluminum for housings, copper for windings, and steel for rotor components, are sourced from reputable suppliers. The materials undergo rigorous testing to ensure they meet specific mechanical and electrical properties. This stage may also involve the use of Computer Numerical Control (CNC) machining to cut and shape components to precise specifications.

Illustrative image related to what does an alternator do

What Techniques Are Used in the Forming Stage of Alternator Production?

In the forming stage, the prepared materials are shaped into their final forms. This involves various techniques, including die casting for the aluminum housing and stamping for the steel components. Advanced forming methods like injection molding may also be used for plastic parts, which are increasingly utilized in modern alternator designs for weight reduction and cost efficiency. The choice of technique can significantly impact the durability and performance of the alternator.

How Does the Assembly Process Work for Alternators?

Assembly is a critical phase where all the components come together. Skilled technicians or automated systems assemble the rotor and stator, ensuring proper alignment and fit. The assembly process often employs techniques like soldering for electrical connections and torque specifications for mechanical fastenings. Quality control checks are integrated at this stage to detect any assembly defects that could lead to performance issues.

What Finishing Processes Are Essential for Alternators?

Finishing processes include painting, coating, and surface treatment to enhance durability and resistance to environmental factors. These treatments are crucial for alternators operating in diverse conditions, particularly in regions with extreme temperatures or humidity, such as parts of Africa and the Middle East. Finishing also involves final inspections to ensure that the alternator meets the required aesthetic and functional standards before shipping.

What Quality Assurance Practices Are Implemented in Alternator Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that alternators perform reliably and meet international standards. Various QA practices are employed throughout the manufacturing stages, with checkpoints established to monitor quality at different phases.

Which International Standards Govern Alternator Quality Assurance?

Compliance with international standards is essential for B2B buyers looking to ensure product reliability. The ISO 9001 standard is a widely recognized framework that outlines requirements for a quality management system. Manufacturers often seek certification to demonstrate their commitment to quality and continuous improvement. Additionally, industry-specific standards like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) certifications for specific applications may apply.

What Are the Key Quality Control Checkpoints in Alternator Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components before they enter production. Ensuring that these materials meet specified standards is crucial for the overall quality of the alternator.

-

In-Process Quality Control (IPQC): During assembly, ongoing inspections are conducted to monitor the assembly process and detect any deviations from specified tolerances. This step helps prevent defects from progressing further down the production line.

-

Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is performed on the final product. This includes functional testing to verify that the alternator operates within its designated parameters.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control measures is vital for ensuring product reliability. Here are several approaches:

-

Conducting Audits: Buyers can request to conduct audits of the manufacturing facility to observe quality control processes in action. This direct assessment allows buyers to evaluate the supplier’s commitment to quality and compliance with international standards.

-

Reviewing Quality Reports: Suppliers should provide detailed quality reports that document the results of inspections and tests conducted throughout the manufacturing process. These reports should outline any corrective actions taken in response to identified defects.

-

Utilizing Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality control practices. These agencies can perform inspections at various stages of production and offer certification of compliance with international standards.

What Testing Methods Are Commonly Used to Ensure Alternator Quality?

Testing is a critical component of the quality assurance process. Various testing methods are employed to evaluate the performance, durability, and safety of alternators:

-

Electrical Testing: This includes measuring output voltage, current, and resistance to ensure the alternator meets performance specifications. Tests are conducted under various load conditions to simulate real-world usage.

-

Thermal Testing: Alternators must withstand heat generated during operation. Thermal testing assesses the component’s ability to operate within acceptable temperature ranges without failure.

-

Vibration and Shock Testing: Given that vehicles experience various vibrations and shocks during operation, alternators are subjected to these tests to ensure they can endure such conditions without compromising performance.

How Do Quality Control Nuances Affect International B2B Transactions?

When engaging in international B2B transactions, quality control nuances can vary significantly based on regional standards and practices. Buyers from Africa, South America, the Middle East, and Europe should consider the following:

Illustrative image related to what does an alternator do

-

Cultural Differences: Understanding the cultural context can influence communication and expectations regarding quality. Establishing clear agreements on quality standards and specifications is essential.

-

Regulatory Compliance: Each region may have specific regulatory requirements that manufacturers must meet. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Supply Chain Considerations: Global supply chains can introduce variability in quality. Buyers should assess the entire supply chain, from raw material sourcing to final assembly, to ensure consistency in quality across the board.

In conclusion, the manufacturing processes and quality assurance practices for alternators are critical for ensuring product reliability and performance. B2B buyers must engage in thorough due diligence to verify suppliers’ quality control measures, ensuring that they procure alternators that meet their operational needs and comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what does an alternator do’

Introduction

This practical sourcing guide serves as a checklist for B2B buyers seeking to understand the function of an alternator and to procure the appropriate components for their automotive needs. An alternator is critical for converting mechanical energy into electrical energy, powering the vehicle’s electrical systems, and maintaining battery charge. Understanding its role and the procurement process can lead to better purchasing decisions, ensuring reliability and performance in vehicles.

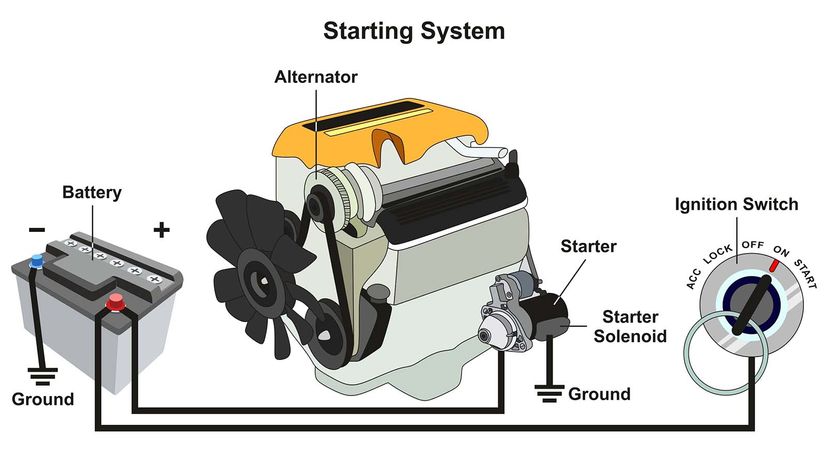

Step 1: Understand the Alternator’s Role

Before sourcing, familiarize yourself with what an alternator does. It converts mechanical energy from the engine into electrical energy, charging the vehicle’s battery and powering electrical components. Recognizing this function is essential for identifying the right specifications and potential issues that may arise with subpar products.

Step 2: Define Your Technical Specifications

Clearly outline your technical requirements for the alternators you intend to procure. Consider factors such as voltage output, power capacity, and compatibility with specific vehicle models. This clarity will help you communicate effectively with suppliers and ensure that you receive products that meet your operational needs.

Illustrative image related to what does an alternator do

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Investigate their company profiles, check for industry certifications, and request references from other buyers in similar markets. A robust supplier background can indicate reliability and quality assurance, which is crucial for maintaining operational efficiency.

- Check for Certifications: Ensure the supplier complies with international standards such as ISO or specific automotive industry certifications.

- Review Case Studies: Look for documented successes with similar clients to gauge their expertise.

Step 4: Assess Product Quality and Warranty

Quality should be a top priority when sourcing alternators. Request samples or detailed specifications to evaluate the materials used and the manufacturing process. Additionally, inquire about warranty terms to understand the supplier’s confidence in their product and the protection offered against defects.

- Material Inspection: Consider the durability of components like the rotor and stator, as these significantly impact performance.

- Warranty Coverage: Ensure that warranties cover both parts and labor to safeguard your investment.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to understand market pricing for alternators. While cost is an important factor, consider the total value offered, including warranty, support, and product quality. Additionally, clarify payment terms to ensure they align with your budget and cash flow management.

- Transparent Pricing: Look for itemized quotes that break down costs to avoid hidden fees.

- Flexible Payment Options: Some suppliers may offer financing options that can be beneficial for large orders.

Step 6: Confirm Logistics and Delivery Times

Once you have selected a supplier, confirm the logistics involved in the delivery of the alternators. Understand shipping methods, lead times, and any potential customs regulations, especially if sourcing internationally. Timely delivery is crucial to maintaining your operations without interruption.

- Shipping Methods: Evaluate the reliability of the shipping options provided by the supplier.

- Lead Times: Ensure the delivery schedule aligns with your operational timelines to avoid downtime.

Step 7: Establish Communication and Support Channels

Finally, set up clear communication channels with your supplier. Establishing a point of contact for support can streamline the resolution of any issues that may arise post-purchase. Regular communication will also help you stay informed about product updates or changes in availability.

Illustrative image related to what does an alternator do

- Dedicated Support: Ensure you have access to technical support for any installation or operational queries.

- Feedback Mechanism: Create a system for providing feedback on product performance to foster a collaborative relationship with the supplier.

By following this checklist, B2B buyers can effectively navigate the procurement process for alternators, ensuring they make informed decisions that enhance their operational capabilities.

Comprehensive Cost and Pricing Analysis for what does an alternator do Sourcing

What are the Key Cost Components for Sourcing Alternators?

When sourcing alternators, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The quality of raw materials used in alternators significantly influences costs. Common materials include copper for windings, aluminum for housings, and various plastics for components. Higher quality materials can enhance durability and performance but may lead to increased costs.

-

Labor: Labor costs vary based on the region and the complexity of the alternator design. Regions with higher labor costs may lead to increased pricing, while manufacturers in lower-cost regions might offer more competitive rates. Skilled labor is particularly important for ensuring high-quality assembly and adherence to specifications.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, thereby impacting the final price of the alternator.

-

Tooling: The initial investment in tooling for manufacturing alternators can be significant. Custom tooling for specialized designs or high-volume production can amortize costs over larger production runs, which may lower per-unit pricing.

-

Quality Control (QC): Rigorous QC processes are essential to ensure that alternators meet industry standards and performance expectations. Enhanced QC measures may increase costs but are vital for reducing warranty claims and ensuring customer satisfaction.

-

Logistics: Transportation and shipping costs play a significant role in overall pricing, especially for international buyers. Factors such as distance, shipping method, and import duties can affect the total landed cost of alternators.

-

Margin: The manufacturer’s profit margin is typically included in the final price. This margin can vary based on competition, brand reputation, and market demand.

What Influences the Pricing of Alternators?

Several factors can influence the pricing of alternators beyond the basic cost components. Understanding these can help buyers make informed purchasing decisions.

-

Volume/MOQ: Purchasing in larger volumes often allows buyers to negotiate better pricing. Manufacturers are typically more willing to offer discounts for bulk orders, which can significantly reduce the cost per unit.

-

Specifications and Customization: Customized alternators designed for specific applications may incur higher costs due to unique materials or engineering requirements. Standardized products generally offer more competitive pricing.

-

Quality and Certifications: Alternators that meet specific quality standards or certifications (e.g., ISO, SAE) may come at a premium. Buyers must weigh the benefits of certification against cost when selecting suppliers.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge higher prices but offer better service and support.

-

Incoterms: Understanding Incoterms is vital for international buyers. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) dictate shipping responsibilities and costs, affecting the total landed price.

What Tips Can Help Buyers Negotiate Better Prices for Alternators?

For B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, negotiation strategies can lead to better pricing and cost efficiency.

-

Leverage Total Cost of Ownership (TCO): When evaluating alternators, consider not only the purchase price but also factors such as maintenance costs, warranty, and longevity. A higher initial cost may be justified by lower TCO over the product’s lifespan.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and warranty conditions. Flexible terms can enhance the overall value of the purchase.

-

Research Market Prices: Familiarize yourself with the market prices for alternators to establish a baseline for negotiations. This knowledge can empower you to negotiate more effectively.

-

Explore Multiple Suppliers: Engaging with multiple suppliers can create competitive pressure, leading to better pricing. Request quotes from various manufacturers to compare costs and services.

-

Consider Local Suppliers: Local sourcing can reduce logistics costs and lead times, potentially offering more competitive pricing compared to importing alternators.

Disclaimer

Prices for alternators can fluctuate based on market conditions, regional economic factors, and changes in raw material costs. It is advisable to obtain current quotes from suppliers to get an accurate picture of pricing for your specific needs.

Alternatives Analysis: Comparing what does an alternator do With Other Solutions

Introduction to Alternatives in Automotive Power Generation

In the automotive industry, the alternator plays a critical role by converting mechanical energy into electrical energy, powering essential components in vehicles. However, there are alternative solutions that can achieve similar outcomes. Understanding these alternatives helps B2B buyers make informed decisions, particularly when considering the specific needs and conditions in diverse markets like Africa, South America, the Middle East, and Europe.

Comparison of Automotive Power Solutions

| Comparison Aspect | What Does An Alternator Do | Alternative 1: Battery-Only Systems | Alternative 2: Solar Power Systems |

|---|---|---|---|

| Performance | Efficiently powers electrical systems while engine runs | Limited to battery capacity; performance declines as charge depletes | Can provide continuous power in sunlight; dependent on solar conditions |

| Cost | Replacement costs range from $500 to $1,000 | Initial low cost but requires frequent battery replacements | Higher initial investment; potential long-term savings on energy costs |

| Ease of Implementation | Standard installation in most vehicles; minimal training required | Simple to replace batteries; widely understood technology | Requires knowledge of solar installation; potential regulatory hurdles |

| Maintenance | Generally low; lasts 7-10 years but needs inspection | High; batteries need regular checks and replacements | Moderate; solar panels require occasional cleaning and monitoring |

| Best Use Case | Ideal for conventional combustion engine vehicles | Suitable for short trips and low-power vehicles | Excellent for eco-friendly vehicles or in areas with abundant sunlight |

Detailed Breakdown of Alternatives

1. Battery-Only Systems

Battery-only systems rely solely on the vehicle’s battery to power electrical components when the engine is off. While this method is straightforward and cost-effective initially, its performance is limited by the battery’s charge capacity. As the vehicle is used, the battery depletes, leading to potential issues such as difficulty starting the engine or powering accessories. This solution is best suited for vehicles that operate on short trips or require minimal electrical power. However, B2B buyers should consider the ongoing costs of battery maintenance and replacement, which can accumulate over time.

Illustrative image related to what does an alternator do

2. Solar Power Systems

Solar power systems harness renewable energy to provide electrical power to vehicles. This alternative can be particularly advantageous in regions with ample sunlight. Solar panels can continuously charge the vehicle’s battery, offering a sustainable solution with lower long-term energy costs. However, the initial investment for solar technology can be significant, and the effectiveness can be diminished on cloudy days or in less sunny regions. Moreover, installation might require specialized knowledge, and buyers should be aware of any local regulations regarding solar energy usage.

Conclusion: Choosing the Right Power Solution for Your Needs

When selecting a power generation solution for vehicles, B2B buyers should evaluate their specific requirements, budget constraints, and regional conditions. An alternator remains a robust choice for conventional combustion engine vehicles, ensuring reliable performance and low maintenance. However, for those interested in innovative alternatives, battery-only systems and solar power solutions present viable options that cater to particular use cases. By considering these factors, businesses can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for what does an alternator do

What Are the Key Technical Properties of an Alternator and Their Importance in B2B Transactions?

Understanding the technical specifications of alternators is crucial for B2B buyers, particularly when sourcing components for vehicle manufacturing, maintenance, or repair. Here are some essential properties to consider:

1. Material Grade

The materials used in an alternator, such as aluminum for the housing and copper for the windings, significantly affect its durability and performance. High-grade materials can enhance resistance to corrosion and wear, thus prolonging the life of the component. For international buyers, selecting alternators made from superior materials is vital to ensure reliability, especially in challenging environments found in regions like Africa and South America.

Illustrative image related to what does an alternator do

2. Output Voltage

An alternator typically produces between 12V to 14.5V of direct current (DC). This voltage is essential for charging the vehicle’s battery and powering electrical systems. Understanding the output voltage is crucial for ensuring compatibility with various vehicle models and electrical accessories. For B2B buyers, confirming the output voltage can prevent costly mismatches and ensure optimal performance.

3. Amperage Rating

The amperage rating of an alternator indicates how much electrical current it can provide. This specification is critical for ensuring that all electrical components in a vehicle operate efficiently. For B2B transactions, knowing the amperage requirements of specific vehicle models helps buyers select alternators that meet operational demands without risking electrical overloads.

4. Regulator Type

Alternators can feature either internal or external voltage regulators. Internal regulators are more common in modern vehicles, offering easier installation and reduced complexity. Understanding the type of regulator is essential for B2B buyers, as it affects installation processes and maintenance requirements. Buyers must assess their needs based on vehicle types and electrical system configurations.

5. Rotational Speed

The efficiency of an alternator is often measured by its ability to generate power at varying engine speeds. A typical automotive alternator operates effectively between 1,000 to 6,000 RPM. For international buyers, understanding rotational speed can guide the selection of alternators suited for specific vehicle types and driving conditions, thus optimizing performance.

6. Warranty Period

The warranty period offered by manufacturers is a vital consideration for B2B buyers. A longer warranty often indicates confidence in product quality and can mitigate risks associated with component failures. For businesses operating in regions with challenging logistics, a robust warranty can also reduce potential downtime and costs related to replacements.

What Are Common Trade Terms Related to Alternators in B2B Transactions?

Navigating the landscape of alternator procurement requires familiarity with specific trade terminology. Here are some common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to components made by the manufacturer of the original vehicle parts. For buyers, sourcing OEM alternators ensures compatibility and reliability, as these parts are designed to meet the specific standards of vehicle manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers, as it affects inventory management and purchasing strategies. Buyers should negotiate MOQs that align with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For alternators, submitting an RFQ allows buyers to compare offers and ensure they are getting competitive pricing and favorable terms.

Illustrative image related to what does an alternator do

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in a transaction. They clarify who bears the risk at various stages of shipping and delivery. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings in logistics and cost responsibilities.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for B2B buyers to plan their inventory and maintenance schedules effectively, especially when sourcing alternators from international suppliers.

6. Aftermarket

Aftermarket parts refer to components made by companies other than the original manufacturer. For B2B buyers, understanding the aftermarket landscape can provide additional options for sourcing alternators, often at competitive prices, while still ensuring quality and compatibility.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the what does an alternator do Sector

What Are the Current Market Dynamics and Key Trends in the Alternator Sector?

The global alternator market is witnessing significant growth, driven by the increasing demand for automotive vehicles, particularly in emerging markets in Africa, South America, the Middle East, and parts of Europe. The rise in vehicle production, coupled with the growing trend of electric and hybrid vehicles, is reshaping the alternator landscape. In these regions, international B2B buyers are particularly focused on sourcing high-quality alternators that meet evolving standards of performance and efficiency.

Illustrative image related to what does an alternator do

Emerging technologies such as advanced manufacturing processes, including automation and artificial intelligence, are streamlining production and reducing costs. These innovations are critical for suppliers aiming to maintain competitive pricing while ensuring product reliability. Additionally, the integration of smart technologies into vehicles is prompting a shift towards alternators that can handle higher electrical loads, making it essential for manufacturers to adapt their offerings accordingly.

B2B buyers are increasingly prioritizing suppliers who can provide detailed product specifications and robust warranties. There is also a growing emphasis on aftermarket services, which enhance the overall value proposition. By understanding these dynamics, international buyers can make informed sourcing decisions that align with their operational needs and market expectations.

How Are Sustainability and Ethical Sourcing Influencing the Alternator Industry?

Sustainability is becoming a cornerstone of the B2B landscape, and the alternator sector is no exception. The environmental impact of manufacturing processes, resource extraction, and end-of-life disposal is garnering attention from both consumers and regulators. For international buyers, sourcing alternators from manufacturers that adhere to sustainable practices is not just a preference but increasingly a necessity to comply with local and international regulations.

Ethical supply chains are also gaining traction, with a focus on transparency and social responsibility. Buyers are seeking suppliers that can demonstrate responsible sourcing of raw materials, particularly metals and rare earth elements used in alternators. Certifications such as ISO 14001 for environmental management systems and adherence to the principles of the Global Reporting Initiative (GRI) can provide buyers with assurance of a supplier’s commitment to sustainability.

Moreover, the demand for ‘green’ certifications and materials is on the rise. Buyers are looking for alternators that not only perform well but also contribute to reducing the overall carbon footprint of their vehicles. As sustainability becomes a key differentiator in the automotive industry, suppliers who prioritize eco-friendly practices will likely gain a competitive edge.

What Is the Brief Evolution and History of Alternators in the Automotive Sector?

The evolution of alternators has been marked by significant technological advancements since their inception in the early 20th century. Initially, vehicles relied on generators, which were less efficient and required regular maintenance. The introduction of the alternator in the 1960s revolutionized automotive electrical systems by providing a more efficient means of generating electricity.

As vehicles became more complex, with increasing electrical demands from accessories and systems, alternators evolved to accommodate these needs. Modern alternators are equipped with advanced features such as voltage regulation and integrated electronics, which enhance their functionality and reliability. This evolution continues today, with ongoing innovations aimed at improving energy efficiency and performance, particularly in hybrid and electric vehicles.

For B2B buyers, understanding the historical context of alternators provides valuable insights into current product offerings and technological advancements, helping them make informed sourcing decisions in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of what does an alternator do

-

How do I identify if an alternator is failing in my vehicle fleet?

To identify a failing alternator, monitor for several key indicators: dim or flickering dashboard lights, difficulty starting vehicles, or a battery warning light illuminated on the dashboard. Additionally, listen for unusual noises, such as whining or screeching sounds from the engine compartment. Conduct regular inspections of the alternator’s performance during routine vehicle maintenance to preemptively address potential issues, ensuring the reliability of your fleet. -

What is the average lifespan of an alternator, and when should I consider replacement?

An alternator typically lasts between 7 to 10 years, depending on usage and driving conditions. Factors such as frequent short trips, heavy electrical loads, and extreme weather can shorten its lifespan. Regularly check the alternator’s performance and consider replacement if you notice signs of wear, such as dimming lights or frequent battery issues, to avoid unexpected vehicle downtime. -

What are the typical costs associated with purchasing an alternator?

The cost of an alternator can range from $500 to $1,000, depending on the vehicle model and region. Prices may fluctuate due to international trade policies, shipping costs, and supplier pricing strategies. When sourcing alternators, request quotes from multiple suppliers to compare prices and negotiate better terms, ensuring you achieve the best value for your investment. -

How can I vet suppliers for alternators in international markets?

To effectively vet suppliers, start by researching their reputation and experience in the industry. Check for certifications, customer reviews, and case studies that demonstrate their reliability. Additionally, request samples and assess their quality control processes. Establish communication channels to discuss terms, logistics, and after-sales support to ensure a long-term, trustworthy partnership. -

What customization options are available for alternators?

Many manufacturers offer customization options to meet specific requirements, such as varying voltage outputs, sizes, and mounting configurations. When sourcing alternators, inquire about available modifications to ensure compatibility with your vehicle specifications. Customization may also include branding opportunities, which can enhance your business identity in the marketplace. -

What are the minimum order quantities (MOQs) for purchasing alternators?

MOQs can vary significantly between suppliers based on production capabilities and inventory levels. Some manufacturers may offer flexible MOQs for new customers or bulk orders, while others may have strict minimums. When negotiating with suppliers, clarify MOQ terms to align with your purchasing strategy and ensure adequate stock levels for your operations. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms can vary widely based on supplier policies, the size of the order, and your relationship with the supplier. Common terms include payment upfront, net 30, or letter of credit arrangements for larger transactions. Discuss payment options early in negotiations to establish mutually agreeable terms that support your cash flow management and minimize financial risk. -

How can I ensure quality assurance (QA) for alternators I source?

To ensure quality assurance, request detailed specifications and certifications from suppliers, outlining their manufacturing processes and quality control measures. Implement a robust inspection protocol upon receipt of products, including testing functionality and durability. Establish clear communication with suppliers regarding your QA standards and expectations to foster accountability and ensure consistent product quality.

Top 3 What Does An Alternator Do Manufacturers & Suppliers List

1. Turner Chevrolet – Alternator Services

Domain: turnerchevrolet.com

Registered: 2000 (25 years)

Introduction: The alternator is a central component in gas-powered vehicles, responsible for keeping the car’s electrical systems functioning while the engine is running. Signs of a failing alternator include dimmer dash lights, illuminated service engine light, strange noises, issues with the car’s electrical system, difficulties starting the car, and a dead battery. New alternators typically cost between $500…

2. Kia – Alternator

Domain: kia.com

Registered: 1996 (29 years)

Introduction: An alternator is an integral part of every combustion engine vehicle, responsible for converting chemical energy to electrical energy to charge and replenish the battery and other electrical components in a car. It works within the vehicle’s charging system, which includes the car battery, voltage regulator, and alternator itself. The alternator converts mechanical energy to electrical energy usin…

3. Savannah Toyota – Alternator Services

Domain: savannahtoyota.com

Registered: 1996 (29 years)

Introduction: The alternator powers all electronics in a vehicle while the engine is running, functioning as a generator using the gas engine as its energy source. Signs of a failing alternator include a battery warning light, dim headlights, burning rubber smell, devices not charging, whining sounds, and inability to start the vehicle. Most alternators last between 80,000 and 150,000 miles or about seven years…

Strategic Sourcing Conclusion and Outlook for what does an alternator do

In summary, understanding the function and importance of an alternator is essential for international B2B buyers involved in automotive sourcing. The alternator plays a pivotal role in converting mechanical energy into electrical energy, ensuring that vehicles operate efficiently and reliably. Recognizing the signs of a failing alternator—such as dim lights, starting issues, and electrical malfunctions—can lead to timely interventions, minimizing downtime and maintenance costs.

Strategic sourcing of quality alternators is not just about cost; it involves assessing durability, compatibility, and supplier reliability. As global supply chains evolve, particularly in regions like Africa, South America, the Middle East, and Europe, establishing partnerships with reputable manufacturers can enhance operational efficiency and reduce risks associated with sourcing components.

Looking ahead, the automotive industry is poised for further innovation, and the demand for high-quality, efficient alternators will only increase. We encourage B2B buyers to actively engage with suppliers, explore advanced technologies, and consider long-term partnerships that can support sustainable growth. By prioritizing strategic sourcing, businesses can not only secure high-performance components but also gain a competitive edge in an ever-evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to what does an alternator do

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.