Introduction: Navigating the Global Market for battery alternator or starter

Navigating the global market for battery alternators and starters poses unique challenges for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. With a complex interplay of electrical components critical to vehicle performance, understanding how to source high-quality battery alternators and starters is essential for maintaining operational efficiency and minimizing downtime. This guide provides a comprehensive overview of the types of battery alternators and starters available, their various applications, and insights into supplier vetting processes that ensure quality and reliability.

Buyers will gain valuable knowledge about the key indicators of performance and longevity, as well as the common causes of failure that can impact vehicle operations. Additionally, this guide will delve into cost considerations, providing a framework for making informed purchasing decisions that align with budgetary constraints and operational needs. By addressing these critical aspects, this resource empowers international B2B buyers to navigate the complexities of sourcing battery alternators and starters effectively.

Whether you are a fleet manager in Germany, an automotive parts distributor in Brazil, or a vehicle maintenance provider in the Middle East, the insights offered in this guide will equip you with the necessary tools to enhance your procurement strategy and ensure the reliability of your automotive systems.

Table Of Contents

- Top 3 Battery Alternator Or Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for battery alternator or starter

- Understanding battery alternator or starter Types and Variations

- Key Industrial Applications of battery alternator or starter

- 3 Common User Pain Points for ‘battery alternator or starter’ & Their Solutions

- Strategic Material Selection Guide for battery alternator or starter

- In-depth Look: Manufacturing Processes and Quality Assurance for battery alternator or starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘battery alternator or starter’

- Comprehensive Cost and Pricing Analysis for battery alternator or starter Sourcing

- Alternatives Analysis: Comparing battery alternator or starter With Other Solutions

- Essential Technical Properties and Trade Terminology for battery alternator or starter

- Navigating Market Dynamics and Sourcing Trends in the battery alternator or starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of battery alternator or starter

- Strategic Sourcing Conclusion and Outlook for battery alternator or starter

- Important Disclaimer & Terms of Use

Understanding battery alternator or starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lead-Acid Battery | Traditional battery type, widely used, cost-effective | Automotive, industrial equipment | Pros: Affordable, reliable; Cons: Heavier, shorter lifespan |

| Lithium-Ion Battery | Lightweight, higher energy density, longer cycle life | Electric vehicles, renewable energy storage | Pros: Longer lifespan, fast charging; Cons: Higher cost |

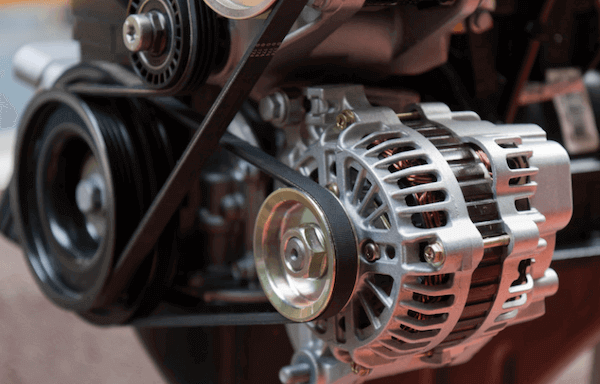

| Alternator (Belt-Driven) | Converts mechanical energy to electrical, typically found in cars | Automotive, marine applications | Pros: Efficient power generation; Cons: Sensitive to wear |

| Starter Motor | Engages engine’s flywheel to start the vehicle | Automotive, heavy machinery | Pros: Critical for engine start; Cons: Prone to wear over time |

| High-Performance Starter | Designed for high-demand applications, robust construction | Racing, heavy-duty vehicles | Pros: Enhanced durability, quick engagement; Cons: More expensive |

What are the Characteristics and Suitability of Lead-Acid Batteries for B2B Buyers?

Lead-acid batteries are the most common type of battery used in vehicles and industrial applications due to their cost-effectiveness and reliability. These batteries operate using lead dioxide and sponge lead, providing a steady voltage output. They are suitable for businesses that require a dependable power source for automotive applications or industrial equipment. However, their weight and relatively short lifespan compared to newer technologies may be a consideration for B2B buyers focused on efficiency and long-term costs.

Why Choose Lithium-Ion Batteries for Advanced Applications?

Lithium-ion batteries are increasingly favored in modern applications due to their lightweight design and high energy density. They offer a longer cycle life and faster charging capabilities, making them ideal for electric vehicles and renewable energy systems. B2B buyers looking for cutting-edge technology should consider lithium-ion batteries for their efficiency and sustainability benefits. However, the higher upfront cost may require careful budget planning for businesses aiming for long-term investment returns.

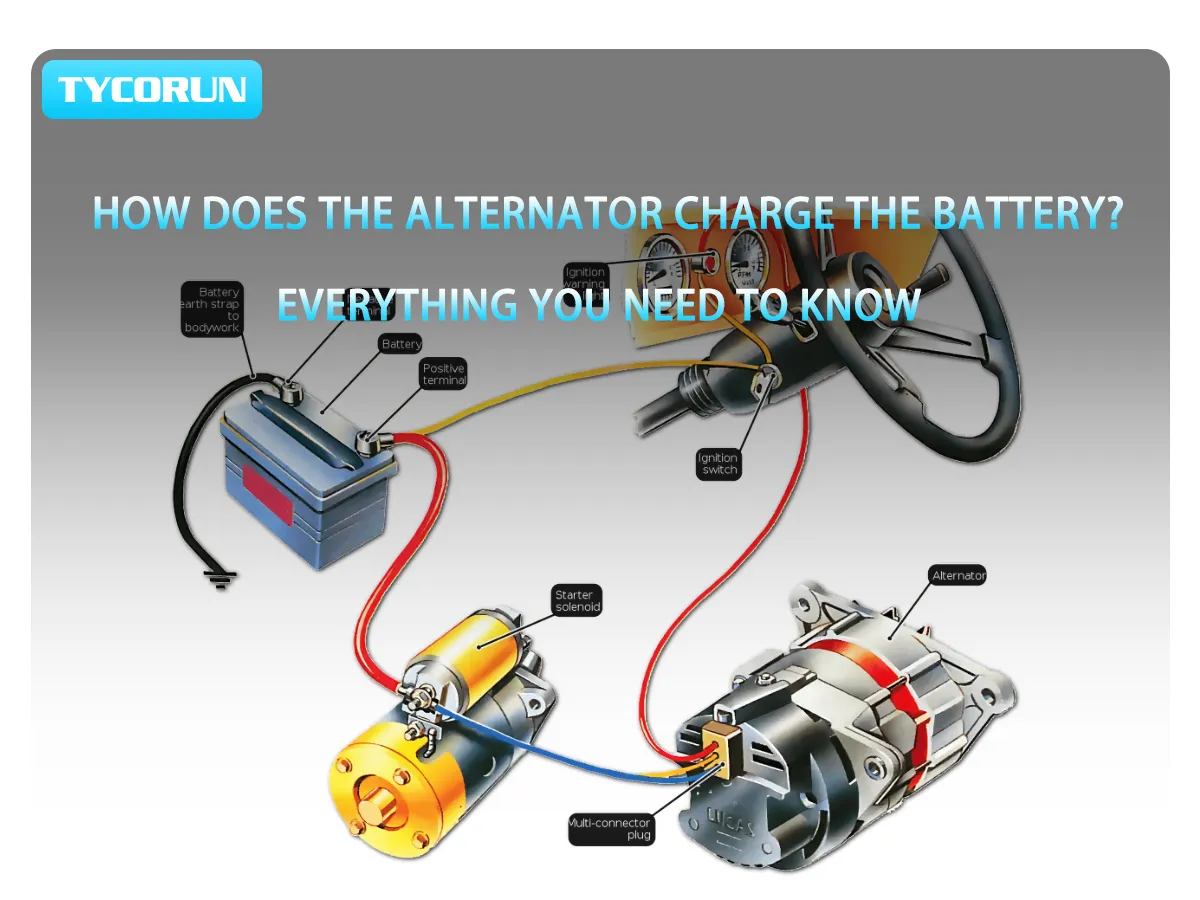

How Does a Belt-Driven Alternator Function in Automotive Applications?

Belt-driven alternators convert mechanical energy generated by the engine into electrical energy to charge the battery and power the vehicle’s electrical systems. They are essential in automotive applications, ensuring that the battery remains charged and operational. For B2B buyers in the automotive sector, the efficiency and reliability of alternators are critical. However, they require regular maintenance as wear can impact performance, leading to potential downtime.

What Role Does a Starter Motor Play in Engine Functionality?

The starter motor is a crucial component that engages the engine’s flywheel to initiate the combustion process. Found in automotive and heavy machinery applications, it is essential for starting engines. B2B buyers should consider the durability and reliability of starter motors, especially in environments where heavy usage is expected. While they are essential for engine functionality, their susceptibility to wear over time necessitates regular maintenance and potential replacement.

When Should You Consider High-Performance Starters for Heavy-Duty Applications?

High-performance starters are designed for applications requiring robust performance, such as racing or heavy-duty vehicles. They feature enhanced construction to withstand extreme conditions and provide quick engagement. For B2B buyers in the automotive racing or heavy machinery sectors, investing in high-performance starters can lead to improved reliability and engine performance. However, the higher cost may be a factor, requiring a clear understanding of the return on investment for specific applications.

Key Industrial Applications of battery alternator or starter

| Industry/Sector | Specific Application of battery alternator or starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Integration in vehicle assembly lines | Ensures reliable vehicle performance and reduces downtime | Quality assurance, compliance with international standards |

| Renewable Energy | Power management in solar or wind systems | Enhances energy efficiency and reliability of power supply | Compatibility with energy storage systems and environmental regulations |

| Agriculture | Starting and powering agricultural machinery | Increases operational efficiency and reduces maintenance costs | Durability in harsh environments and availability of spare parts |

| Construction | Powering construction equipment | Improves productivity and minimizes project delays | Robustness and reliability in extreme conditions |

| Public Transport | Starting systems in buses and trains | Enhances safety and reliability of public transport systems | Compliance with safety standards and long-term performance guarantees |

How is ‘Battery Alternator or Starter’ Used in Automotive Manufacturing?

In the automotive manufacturing sector, battery alternators and starters are integral components for vehicle assembly lines. They ensure that vehicles start reliably and operate smoothly throughout the production process. By using high-quality starters and alternators, manufacturers can minimize downtime due to electrical failures, which can be costly. International buyers should consider sourcing components that meet strict quality standards and are compliant with regional regulations, especially in markets like Germany and Brazil, where automotive standards are rigorously enforced.

What Role Does ‘Battery Alternator or Starter’ Play in Renewable Energy Systems?

Battery alternators and starters are crucial in renewable energy applications, particularly in solar and wind energy systems. These components manage the power generated and ensure that energy is efficiently stored and utilized. They help in maintaining a stable power supply, which is essential for grid stability and energy reliability. Buyers in regions like Africa and the Middle East should prioritize sourcing products that are compatible with energy storage systems and adhere to environmental regulations to ensure sustainability and efficiency.

How are ‘Battery Alternator or Starter’ Utilized in Agriculture?

In agriculture, battery alternators and starters are vital for starting and powering various machinery, such as tractors and harvesters. These components enhance operational efficiency by ensuring that equipment is ready for use at all times, thereby reducing maintenance costs associated with frequent breakdowns. Buyers in South America and Africa should focus on sourcing durable products that can withstand harsh environmental conditions, along with the availability of spare parts to ensure long-term functionality.

What is the Importance of ‘Battery Alternator or Starter’ in Construction?

In the construction industry, battery alternators and starters are essential for powering heavy machinery and equipment. Reliable starting systems improve productivity by reducing the likelihood of equipment failure, which can lead to project delays. When sourcing these components, businesses must ensure they are robust enough to operate in extreme conditions often found on construction sites. This includes considering factors like vibration resistance and the availability of support services for maintenance.

How Does ‘Battery Alternator or Starter’ Impact Public Transport Systems?

Battery alternators and starters play a critical role in the reliability of public transport vehicles, such as buses and trains. A dependable starting system enhances safety and ensures that transport services run smoothly, which is vital for maintaining public confidence. For international buyers in Europe and the Middle East, sourcing high-performance components that comply with safety regulations and offer long-term guarantees is essential to uphold service reliability and operational efficiency.

3 Common User Pain Points for ‘battery alternator or starter’ & Their Solutions

Scenario 1: Difficulty in Diagnosing the Root Cause of Electrical Failures

The Problem:

B2B buyers, particularly those managing fleets or automotive repair shops, often encounter situations where vehicles exhibit electrical issues but fail to clearly indicate whether the problem lies with the battery, alternator, or starter. This ambiguity can lead to misdiagnosis, resulting in unnecessary parts replacements and increased downtime. For instance, if a vehicle won’t start, technicians may replace the battery only to find that the issue persists, leading to frustration and wasted resources.

The Solution:

To accurately diagnose the problem, buyers should invest in comprehensive diagnostic tools that can test the health of the battery, alternator, and starter. These tools typically measure voltage levels and current draw, providing insights into each component’s performance. For instance, a healthy battery should read around 12.6 volts when off and 13.5-14.2 volts when the engine is running. Implementing a standardized troubleshooting protocol that includes checking connections and ensuring proper installation can help pinpoint issues more effectively. Training staff on the use of these diagnostic tools will also minimize misdiagnoses, ensuring that only faulty components are replaced.

Scenario 2: Managing Component Lifespan in Extreme Weather Conditions

The Problem:

In regions with extreme weather, such as the intense heat of Africa or the cold winters in Europe, the lifespan of batteries, alternators, and starters can be severely affected. Businesses may find that vehicles frequently experience electrical failures due to environmental stressors, leading to higher maintenance costs and operational disruptions. For example, batteries in hot climates can degrade faster, while cold weather can impede the efficiency of starters.

The Solution:

To combat these challenges, B2B buyers should source high-quality, climate-appropriate components designed to withstand specific environmental conditions. This may include selecting batteries with enhanced thermal management features or alternators with protective casings that prevent moisture ingress. Establishing a regular maintenance schedule that includes checks on these components can also extend their lifespan. Furthermore, educating staff about the signs of wear specific to different climates can ensure early intervention before failures occur, ultimately reducing downtime and repair costs.

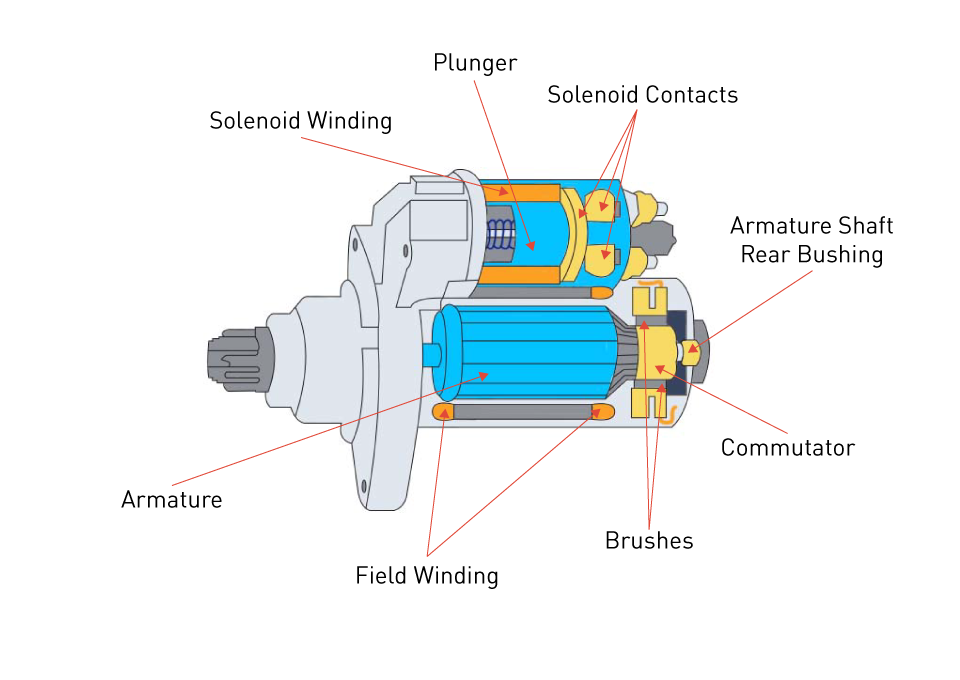

Illustrative image related to battery alternator or starter

Scenario 3: Inefficient Supply Chain Management for Replacement Parts

The Problem:

B2B buyers often struggle with the timely procurement of replacement parts, such as batteries, alternators, and starters, especially in regions with limited access to reliable suppliers. Delays in receiving these critical components can lead to vehicle downtime and lost revenue. For instance, a fleet manager might experience significant disruptions if a supplier fails to deliver a bulk order of starters on time, impacting overall operational efficiency.

The Solution:

To improve supply chain management, businesses should establish relationships with multiple reliable suppliers to ensure a consistent supply of quality components. Implementing a just-in-time inventory system can help minimize stockouts while also reducing excess inventory costs. Additionally, leveraging digital platforms for real-time inventory tracking and automated ordering can streamline the procurement process. B2B buyers should also consider investing in bulk purchasing agreements to secure better pricing and prioritize delivery schedules, ensuring that they have the necessary parts on hand when needed. Regularly reviewing supplier performance and diversifying the supplier base will mitigate risks associated with delays and maintain operational continuity.

Strategic Material Selection Guide for battery alternator or starter

What Materials Are Commonly Used in Battery Alternators and Starters?

When selecting materials for battery alternators and starters, it’s essential to consider their performance characteristics, durability, and cost-effectiveness. Here, we analyze four common materials used in these components: copper, aluminum, steel, and plastic composites. Each material has unique properties that impact their suitability and performance in various applications.

How Does Copper Affect Performance in Battery Alternators and Starters?

Copper is widely recognized for its excellent electrical conductivity, making it a preferred choice for wiring and electrical connections in battery alternators and starters. It can handle high temperatures and pressures, which is crucial for automotive applications.

Pros: Copper’s high conductivity ensures efficient energy transfer, reducing energy loss and improving performance. It also offers good corrosion resistance, which is vital in environments with moisture and varying temperatures.

Illustrative image related to battery alternator or starter

Cons: The primary drawback of copper is its cost, which can be significantly higher than alternatives like aluminum. Additionally, copper is heavier, which may affect the overall weight of the component.

Impact on Application: Copper’s compatibility with high-current applications makes it ideal for starters and alternators that require reliable performance under load. However, buyers must consider the cost implications, especially in regions where budget constraints are prevalent.

What Role Does Aluminum Play in Battery Alternators and Starters?

Aluminum is often used for its lightweight properties and good conductivity, making it a popular choice for housing and structural components in battery alternators and starters.

Pros: The lightweight nature of aluminum reduces the overall weight of the vehicle, contributing to fuel efficiency. It also has decent corrosion resistance, particularly when treated with coatings or anodization.

Cons: While aluminum is less expensive than copper, it has lower conductivity, which may necessitate larger cross-sectional areas for wiring, potentially increasing manufacturing complexity.

Impact on Application: Aluminum is suitable for applications where weight reduction is critical, such as in electric vehicles. However, international buyers must ensure that the aluminum used meets specific standards for strength and conductivity.

How Does Steel Contribute to the Durability of Battery Alternators and Starters?

Steel is commonly utilized for structural components in battery alternators and starters due to its strength and durability.

Illustrative image related to battery alternator or starter

Pros: Steel offers excellent tensile strength and impact resistance, making it ideal for components that endure mechanical stress. It is also generally less expensive than both copper and aluminum.

Cons: Steel is heavier than aluminum and can be prone to corrosion if not adequately treated. This can lead to premature failure in harsh environments.

Impact on Application: Steel is best suited for applications requiring robust mechanical support. Buyers in regions with high humidity or saline environments should consider corrosion-resistant coatings to enhance the longevity of steel components.

What Advantages Do Plastic Composites Offer in Battery Alternators and Starters?

Plastic composites are increasingly being used in battery alternators and starters for non-structural components due to their lightweight and insulating properties.

Pros: These materials are resistant to corrosion and can be molded into complex shapes, allowing for design flexibility. They are also lightweight, which can contribute to overall vehicle efficiency.

Cons: Plastic composites may not withstand high temperatures as effectively as metals, which can limit their application in high-heat areas of the engine.

Impact on Application: Plastic composites are ideal for insulating parts and covers in alternators and starters. International buyers should ensure that the composites used meet relevant standards for thermal and mechanical performance.

Summary Table of Material Selection for Battery Alternators and Starters

| Material | Typical Use Case for battery alternator or starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and electrical connections | Excellent electrical conductivity | High cost and weight | High |

| Aluminum | Housing and structural components | Lightweight and good corrosion resistance | Lower conductivity than copper | Medium |

| Steel | Structural components and supports | High strength and impact resistance | Prone to corrosion without treatment | Low |

| Plastic Composites | Insulating parts and covers | Corrosion-resistant and lightweight | Limited high-temperature tolerance | Medium |

This analysis provides a comprehensive overview of the materials used in battery alternators and starters, highlighting their properties, advantages, and potential limitations. International B2B buyers should carefully consider these factors to ensure optimal performance and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for battery alternator or starter

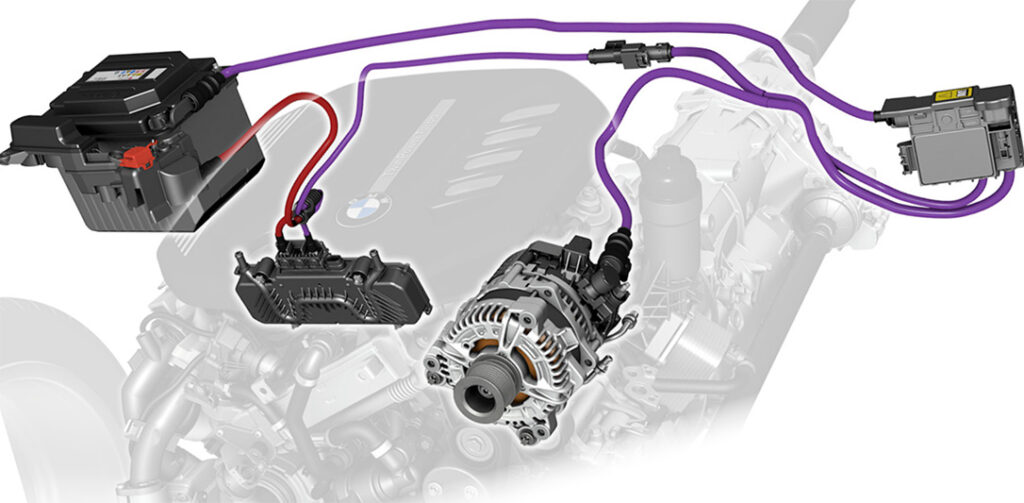

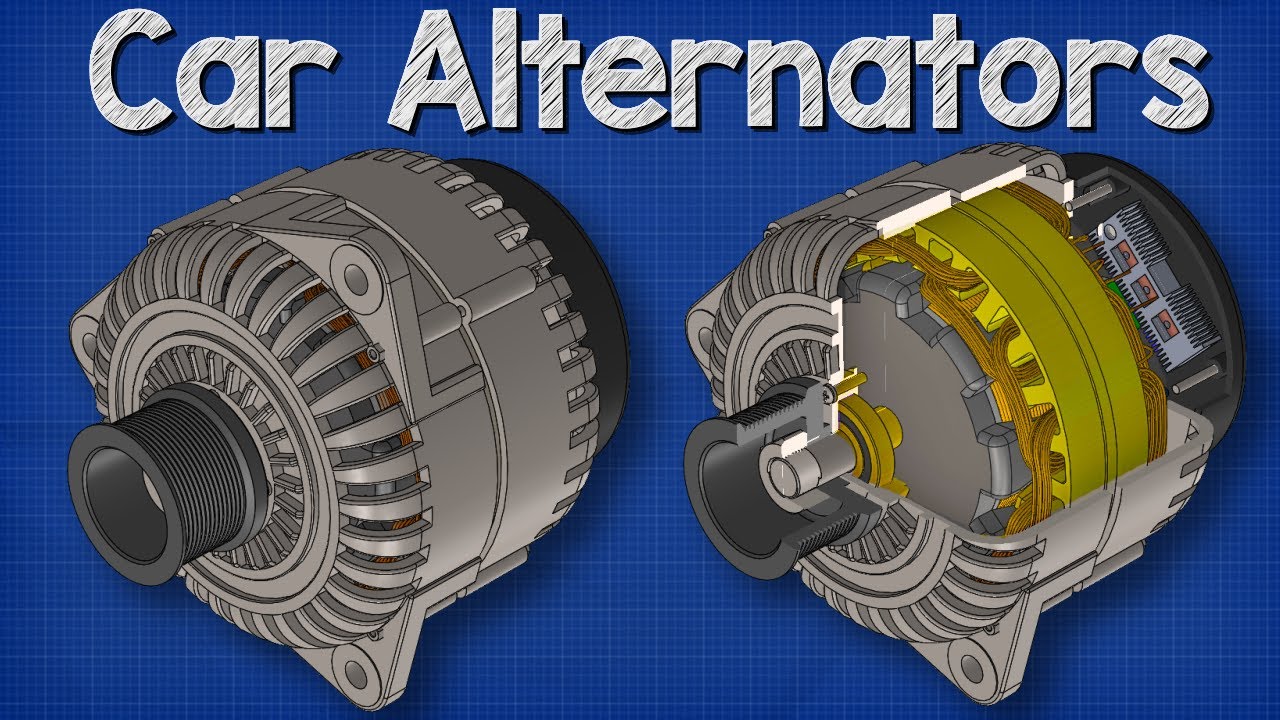

What Are the Main Stages of Manufacturing Battery Alternators and Starters?

The manufacturing process for battery alternators and starters involves several crucial stages that ensure the final product meets performance and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

Illustrative image related to battery alternator or starter

How Is Material Prepared for Battery Alternators and Starters?

Material preparation is the first step in the manufacturing process. High-quality raw materials such as copper for windings, steel for housing, and various plastics for insulation are sourced from reputable suppliers. Rigorous testing is often conducted on these materials to ensure they meet specific performance criteria. This may include checks for conductivity, resistance to corrosion, and mechanical strength, which are essential for durability and efficiency.

What Forming Techniques Are Used in Manufacturing?

Once materials are prepared, the forming stage begins. For battery alternators, this includes processes like stamping and machining to create the various components such as stators, rotors, and housings. Advanced techniques like computer numerical control (CNC) machining are employed to achieve precise dimensions and tolerances, which are critical for the proper functioning of the alternator or starter.

In the case of starters, components like the solenoid and armature are formed through similar machining and molding processes. Heat treatment may also be applied to enhance the mechanical properties of the metal parts, ensuring they can withstand the stresses during operation.

How Is the Assembly Process Conducted?

The assembly stage is where all the individual components come together. Automated assembly lines are often used to improve efficiency and consistency, although some complex assemblies may still require skilled manual labor. Each component is meticulously assembled, and connections are made according to strict specifications to ensure electrical integrity.

During this stage, manufacturers may also incorporate quality checks, such as visual inspections and electrical tests, to catch any defects early in the process. These in-process quality checks (IPQC) are vital for identifying issues before the final product is completed.

Illustrative image related to battery alternator or starter

What Finishing Techniques Enhance Performance and Aesthetics?

The finishing stage encompasses treatments and coatings that enhance both the performance and appearance of the alternators and starters. This may include painting, anodizing, or applying protective coatings to prevent corrosion and wear. Additionally, electrical components are often encapsulated in resin to protect against moisture and dust, particularly for products intended for harsh environments.

What Quality Assurance Measures Are Essential for Battery Alternators and Starters?

Quality assurance (QA) is a critical component of the manufacturing process for battery alternators and starters. It ensures that each product meets international and industry-specific standards, which is particularly important for B2B buyers operating across different markets.

Which International Standards Should Buyers Be Aware Of?

For manufacturers aiming to serve international markets, compliance with standards such as ISO 9001 is essential. This standard focuses on quality management systems and is recognized globally. Additionally, specific certifications like CE marking for European markets, or API standards for automotive components, may also be required, depending on the application.

B2B buyers should seek suppliers who maintain these certifications, as they reflect a commitment to quality and continuous improvement.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival at the manufacturing facility to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify defects early, allowing for corrections before the final assembly.

- Final Quality Control (FQC): After assembly, products undergo rigorous testing, which may include electrical performance tests, durability tests, and safety assessments.

These checkpoints help ensure that any potential issues are addressed promptly, minimizing the risk of defective products reaching the market.

What Testing Methods Are Commonly Used in the Industry?

Various testing methods are employed to verify the performance and safety of battery alternators and starters. Common tests include:

- Electrical Testing: Measuring voltage output, current draw, and resistance to ensure the alternator or starter functions as intended.

- Durability Testing: Subjecting products to extreme conditions, such as temperature fluctuations and vibration, to evaluate their reliability.

- Functional Testing: Running the alternator or starter under load to confirm it operates correctly within specified parameters.

B2B buyers should inquire about the specific testing methods used by suppliers, as this can provide insight into the quality and reliability of the products.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are several strategies to effectively assess supplier quality:

What Steps Can Buyers Take to Conduct Supplier Audits?

Regular audits of potential suppliers can provide a comprehensive view of their manufacturing and QC processes. This can be done through:

- On-Site Visits: Visiting the manufacturing facility allows buyers to observe production practices, QC measures, and the overall working environment.

- Document Reviews: Requesting documentation related to quality certifications, testing protocols, and previous audit results can help validate a supplier’s claims.

How Important Are Third-Party Inspections?

Third-party inspections by accredited agencies can offer an unbiased assessment of a supplier’s manufacturing processes and product quality. These inspections can include checks for compliance with international standards, as well as specific performance tests on the products being supplied.

What Are the Quality Control Nuances for Different Regions?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe may encounter varying standards and practices. It is essential to understand the local regulations and market expectations, as this can impact product quality and compliance. For instance, European markets may have stricter environmental regulations compared to other regions, necessitating additional certifications for products.

Conclusion

Understanding the manufacturing processes and quality assurance measures for battery alternators and starters is essential for B2B buyers. By familiarizing themselves with the stages of production, relevant standards, and effective verification strategies, buyers can make informed decisions and ensure they partner with suppliers who prioritize quality and reliability. This knowledge not only enhances purchasing confidence but also contributes to the long-term success of their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘battery alternator or starter’

In today’s competitive automotive market, sourcing reliable components like battery alternators or starters is crucial for ensuring optimal vehicle performance and customer satisfaction. This guide provides a structured approach to help B2B buyers navigate the procurement process effectively.

Illustrative image related to battery alternator or starter

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for battery alternators and starters. This includes specifications such as voltage ratings, size, and compatibility with various vehicle models.

– Voltage Ratings: Ensure the specifications match the vehicles you service to avoid compatibility issues.

– Size and Weight: Consider dimensions that fit into your vehicle’s design without compromising performance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in battery alternators and starters. Focus on suppliers with a strong reputation in your target markets, such as Africa, South America, the Middle East, and Europe.

– Industry Experience: Look for suppliers with a proven track record in your specific region or industry.

– Product Range: Evaluate their product offerings to ensure they have the components that meet your specifications.

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality standards of potential suppliers. Compliance with international standards, such as ISO or TS certifications, indicates a commitment to quality and reliability.

– Quality Assurance: Ask for documentation that proves adherence to quality management systems.

– Safety Standards: Ensure that the components meet relevant safety regulations for your region.

Step 4: Request Samples and Perform Testing

Once you have shortlisted suppliers, request samples of their products. Testing these samples is critical to ensure they meet your performance criteria.

– Functionality Tests: Conduct tests to assess the performance of battery alternators and starters under different conditions.

– Durability Assessments: Evaluate how well the components withstand environmental factors, especially if operating in extreme temperatures.

Step 5: Compare Pricing and Terms

Obtain quotes from multiple suppliers and compare pricing structures, payment terms, and delivery timelines. This step is vital to ensure you are getting competitive rates without compromising quality.

– Total Cost of Ownership: Consider not only the upfront costs but also the long-term reliability and potential maintenance costs.

– Payment Flexibility: Look for suppliers that offer favorable payment terms to support your cash flow.

Step 6: Assess After-Sales Support

Evaluate the after-sales support provided by your selected suppliers. A strong support system can significantly impact your operations, especially when dealing with faulty components.

– Warranty Options: Ensure they offer comprehensive warranties that cover defects and malfunctions.

– Technical Support: Check if they provide technical assistance for installation and troubleshooting.

Step 7: Finalize Your Supplier Agreement

After thorough evaluation, finalize your agreement with the selected supplier. Ensure all terms are clearly defined in the contract, including delivery schedules, payment terms, and responsibilities.

– Clear Terms: Clearly outline expectations and performance metrics in the contract to avoid disputes.

– Regular Review: Establish a process for reviewing supplier performance and addressing any issues that arise post-purchase.

By following this structured checklist, B2B buyers can make informed decisions when sourcing battery alternators and starters, ensuring they partner with reliable suppliers that meet their operational needs.

Comprehensive Cost and Pricing Analysis for battery alternator or starter Sourcing

What Are the Key Cost Components in Sourcing Battery Alternators or Starters?

When sourcing battery alternators or starters, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. High-quality copper for windings, durable plastics, and corrosion-resistant metals are often used in manufacturing. Fluctuations in raw material prices can affect overall costs, so staying informed about market trends is critical.

-

Labor: Labor costs can vary widely based on the location of manufacturing. Countries with lower labor costs may offer competitive pricing, but this can come at the expense of quality. Conversely, manufacturers in regions with higher labor costs, such as Germany, may provide superior craftsmanship and quality assurance.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

-

Tooling: Initial tooling costs for production can be substantial, especially for custom designs. However, these costs can be amortized over larger production runs, making bulk purchases more cost-effective.

-

Quality Control: Ensuring that products meet industry standards often incurs additional costs. Certifications such as ISO can enhance product value but may also increase prices. Buyers should weigh the benefits of certified products against their budgets.

-

Logistics: Shipping and handling can significantly impact total costs, especially for international shipments. Factors like distance, shipping method, and local import duties should be considered.

-

Margin: Suppliers typically apply a profit margin to cover their costs and ensure profitability. Understanding the market rate for similar products can help buyers negotiate better deals.

How Do Price Influencers Affect Battery Alternator or Starter Costs?

Several factors influence the pricing of battery alternators or starters, which buyers must consider:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders often qualify for volume discounts, making it advantageous for buyers to consolidate purchases when possible.

-

Specifications and Customization: Customized products may incur higher costs due to additional engineering and design work. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Premium materials and certifications can increase product costs but often lead to better performance and longevity, ultimately reducing total cost of ownership.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge more due to their track record of quality and service, while newer companies may offer lower prices to build their customer base.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is crucial for cost management in international transactions. Terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can influence overall pricing.

What Buyer Tips Can Help Optimize Costs for Battery Alternators or Starters?

To ensure cost-effective sourcing of battery alternators or starters, B2B buyers should consider the following strategies:

-

Negotiate Prices: Engage in open discussions with suppliers about pricing. Leverage your purchasing power, especially if you are a repeat buyer or can commit to larger orders.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial price but also the long-term costs associated with maintenance, durability, and efficiency. A slightly higher upfront cost may lead to significant savings over time.

-

Understand Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, local taxes, and tariffs, which can affect the final cost. Building relationships with local suppliers can also help mitigate some of these challenges.

-

Stay Informed on Market Trends: Keep abreast of changes in raw material prices and manufacturing practices. This knowledge can empower buyers during negotiations and decision-making.

Conclusion

Navigating the complexities of cost and pricing in sourcing battery alternators or starters requires a comprehensive understanding of the various components and influencing factors. By leveraging negotiation tactics, focusing on total cost of ownership, and staying informed about market dynamics, international B2B buyers can optimize their purchasing strategies and achieve favorable outcomes. Always remember that indicative prices may vary based on market conditions and supplier agreements.

Illustrative image related to battery alternator or starter

Alternatives Analysis: Comparing battery alternator or starter With Other Solutions

In the realm of automotive solutions, businesses often seek alternatives to traditional battery, alternator, and starter systems. These components are vital for vehicle functionality, but there are other technologies and methods that can achieve similar outcomes. Understanding these alternatives can assist B2B buyers in making informed decisions that align with their operational needs.

| Comparison Aspect | Battery Alternator or Starter | Hybrid Electric System | Capacitor Start System |

|---|---|---|---|

| Performance | High reliability; requires all components to function together | Excellent efficiency; can operate on electric power alone | Quick discharge of energy; useful for short bursts of power |

| Cost | Moderate initial investment; ongoing maintenance costs | Higher upfront costs; potential savings on fuel | Lower initial cost; limited to specific applications |

| Ease of Implementation | Standard installation; requires expertise for optimal setup | Complex installation; may require specialized knowledge | Simple setup; minimal adjustments needed |

| Maintenance | Regular checks needed; wear and tear common | Lower maintenance; fewer moving parts | Minimal maintenance; no wear components |

| Best Use Case | Conventional vehicles needing reliable starting and power generation | Urban environments focusing on fuel efficiency and emissions reduction | Racing or high-performance applications requiring quick power bursts |

What Are the Advantages and Disadvantages of Hybrid Electric Systems?

Hybrid electric systems combine an internal combustion engine with an electric motor, providing enhanced fuel efficiency and reduced emissions. The main advantage is the ability to switch between power sources, which allows for optimal performance based on driving conditions. However, the complexity of installation and higher initial costs can deter some businesses from adopting this technology. Additionally, specialized knowledge may be required for maintenance and repairs.

How Do Capacitor Start Systems Compare?

Capacitor start systems utilize capacitors to provide a quick burst of energy for starting engines. This method is advantageous in applications where immediate power is needed, such as racing or heavy machinery. The simplicity of the setup and lower initial costs make it attractive for specific use cases. However, the limitations of capacitors mean they are not suitable for continuous power needs, making them less versatile than traditional battery and alternator systems.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting a power solution for vehicles or machinery, B2B buyers should carefully evaluate their operational requirements, budget constraints, and maintenance capabilities. Battery, alternator, and starter systems remain a reliable choice for conventional vehicles, while hybrid systems offer innovative efficiency for modern urban environments. Capacitor start systems can be ideal for niche applications requiring quick bursts of power. Ultimately, understanding the specific needs of your fleet and the characteristics of each alternative will guide you in making the best choice for your business.

Essential Technical Properties and Trade Terminology for battery alternator or starter

What Are the Key Technical Properties of Battery, Alternator, and Starter Components?

When evaluating battery, alternator, and starter components for vehicles, several technical properties are critical to ensure reliability and performance. Understanding these specifications can help B2B buyers make informed purchasing decisions.

1. Material Grade

The material grade of components affects their durability and performance. For instance, batteries are often made from lead-acid or lithium-ion, while alternators usually consist of high-grade copper windings and aluminum or steel casings. High-quality materials resist corrosion and withstand extreme temperatures, which is vital in varying climates, particularly in regions like Africa and the Middle East.

2. Current Rating (Amperage)

The current rating, measured in amperes (A), indicates the maximum electrical current a component can handle. For starters, a typical range is between 100 to 200 A, while alternators can range from 30 A in small vehicles to over 200 A in larger systems. Understanding the current rating is essential for ensuring compatibility with the vehicle’s electrical system, particularly for buyers in the automotive repair sector.

3. Voltage Output

The voltage output is crucial for both alternators and batteries, typically standardized at 12 volts for most vehicles. Alternators must produce between 13.5 to 14.5 volts to effectively charge the battery. Buyers should ensure that the voltage specifications meet the requirements of the vehicle, as mismatched voltage can lead to component failure and costly repairs.

4. Tolerance Levels

Tolerance levels define the acceptable variations in measurements, particularly for components like starter motors and alternators. A common tolerance might be ±0.5 mm for physical dimensions. Tight tolerances are essential to ensure proper fit and function, especially in high-performance vehicles. This is particularly relevant for manufacturers and suppliers who need to ensure precision in their products.

Illustrative image related to battery alternator or starter

5. Cycle Life

Cycle life refers to the number of charge and discharge cycles a battery can endure before its capacity significantly diminishes. For lead-acid batteries, this can be around 200-300 cycles, while lithium-ion batteries can achieve over 2,000 cycles. Understanding cycle life is crucial for businesses focused on offering reliable power solutions, especially in markets where battery longevity is a key selling point.

What Common Trade Terms Should B2B Buyers Know in This Industry?

Navigating the B2B landscape for automotive components involves familiarizing oneself with key industry jargon. Here are several essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle’s original manufacturer. These components are often regarded as higher quality and fit better than aftermarket alternatives. B2B buyers should consider OEM parts for maintaining warranty conditions and ensuring reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is vital for inventory management and budgeting, especially for businesses that may not require large quantities of components at once.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This is a critical step in the procurement process, allowing businesses to compare prices and terms from different vendors effectively.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international shipping agreements. Familiarity with these terms helps B2B buyers understand shipping costs, risk transfer, and delivery obligations, which is particularly important when sourcing components from different countries.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. Understanding lead times is essential for inventory management and can affect project timelines and customer satisfaction.

By mastering these technical properties and trade terms, B2B buyers can enhance their procurement strategies and ensure they select the best battery, alternator, and starter components for their needs.

Navigating Market Dynamics and Sourcing Trends in the battery alternator or starter Sector

What Are the Global Drivers Influencing the Battery Alternator or Starter Market?

The battery alternator and starter market is experiencing significant growth, driven by several global factors. First, the increasing demand for vehicles, especially in emerging markets such as Africa and South America, is propelling the need for reliable battery systems. Additionally, the rise of electric vehicles (EVs) is reshaping market dynamics, as manufacturers seek advanced battery technologies to meet stringent performance standards. The transition to electric mobility is also influencing sourcing strategies, prompting buyers to invest in suppliers that specialize in innovative battery solutions.

Emerging technologies such as smart battery management systems (BMS) and regenerative braking systems are becoming more prevalent. These innovations are enhancing the efficiency and longevity of battery systems, which in turn is influencing purchasing decisions among international B2B buyers. Moreover, the demand for higher-quality components to support advanced driver-assistance systems (ADAS) is increasing, leading to a focus on sourcing partnerships that prioritize reliability and performance.

How Are Sustainability and Ethical Sourcing Shaping the Battery Alternator or Starter Sector?

Sustainability is becoming a crucial consideration for B2B buyers in the battery alternator or starter sector. The environmental impact of battery production, particularly concerning lithium extraction and disposal, is prompting companies to seek suppliers committed to ethical sourcing practices. The importance of supply chain transparency is growing, as buyers increasingly demand that their suppliers adhere to sustainability certifications and standards.

The adoption of ‘green’ materials, such as recyclable components and eco-friendly production processes, is also gaining traction. This trend not only addresses environmental concerns but also aligns with regulatory compliance in various markets, particularly in Europe, where stringent regulations govern electronic waste management. As a result, B2B buyers are encouraged to evaluate potential partners based on their commitment to sustainability, ensuring that they contribute positively to the environment while meeting their operational needs.

What Is the Evolution of the Battery Alternator or Starter Technology?

The evolution of battery alternators and starters has been marked by significant technological advancements over the decades. Initially, these components were simple mechanical systems reliant on lead-acid batteries. However, the introduction of more efficient designs, such as the brushless alternator, significantly improved energy conversion rates and durability.

In recent years, advancements in materials science have led to the development of lightweight and more efficient battery technologies, such as lithium-ion and solid-state batteries. These innovations have not only enhanced performance but also reduced the overall environmental impact of battery systems. As the market continues to evolve, B2B buyers must stay informed about emerging technologies and trends to ensure they are sourcing the most effective and sustainable solutions for their operations.

Illustrative image related to battery alternator or starter

Conclusion

In summary, the battery alternator and starter market is poised for growth driven by increasing vehicle demand and technological advancements. B2B buyers must navigate the complexities of sourcing, emphasizing sustainability and ethical practices, while remaining informed about the ongoing evolution of battery technologies. By aligning with innovative suppliers and prioritizing responsible sourcing, businesses can enhance their operational efficiency and contribute to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of battery alternator or starter

-

How do I determine if I need a new battery, alternator, or starter?

To accurately diagnose which component may be failing, conduct a series of tests. For a battery, check if the voltage is around 12.6V when off and 13.5-14.2V when running; if not, the battery may be weak. If the engine clicks but doesn’t crank, the starter might be at fault. If the vehicle starts with a jump but dies when disconnected, the alternator is likely not charging the battery. Always consult a professional technician for a thorough assessment. -

What is the best battery alternator or starter for my vehicle type?

The best battery alternator or starter depends on your vehicle’s specifications, including make, model, and engine type. Research reputable brands known for reliability and performance in your vehicle category. Additionally, consider the climate and typical driving conditions in your region, as these factors can affect component longevity. Consulting with industry experts or suppliers can help identify the most suitable options tailored to your needs. -

What are the typical minimum order quantities (MOQ) for battery alternators and starters?

Minimum order quantities can vary significantly based on the supplier and product type. Typically, for battery alternators and starters, MOQs might range from 50 to 500 units. However, some manufacturers may offer lower MOQs for first-time buyers or smaller businesses. It’s crucial to discuss your specific needs with potential suppliers to negotiate favorable terms that align with your inventory and sales strategies. -

What payment terms should I expect when sourcing battery components internationally?

Payment terms in international B2B transactions can vary widely. Common arrangements include a 30% deposit upon order confirmation, with the remaining balance due before shipment. Some suppliers may offer payment upon delivery or through letters of credit for larger orders. It’s essential to clarify payment terms upfront and ensure they align with your cash flow management strategies to avoid potential disputes. -

How do I vet suppliers for battery alternators and starters?

To vet suppliers, start by checking their certifications, such as ISO 9001, which indicates quality management. Request references from previous clients and review their feedback. Assess their production capabilities, lead times, and after-sales support. Additionally, consider visiting their facilities or utilizing third-party inspection services to ensure they meet your quality standards and operational requirements. -

What customization options are available for battery alternators and starters?

Many manufacturers offer customization options to meet specific performance or design requirements. Common customizations include varying voltage outputs, size adjustments, and branding with your company logo. Discuss your needs with potential suppliers early in the negotiation process to explore available options and ensure the final product aligns with your expectations. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers typically implement robust quality assurance (QA) measures, including incoming material inspections, in-process checks, and final product testing. Request documentation regarding their QA processes, including any certifications and testing standards they adhere to. Additionally, inquire about their warranty policies, which can indicate their confidence in product quality and provide you with added assurance. -

What are the logistics considerations for importing battery components?

When importing battery alternators and starters, consider shipping methods, customs regulations, and duties applicable in your country. Choose a reliable freight forwarder familiar with hazardous materials regulations, as batteries may fall under this category. Evaluate shipping costs, lead times, and the impact of potential delays on your supply chain. It’s essential to have a clear logistics plan to minimize disruptions and ensure timely delivery of your products.

Top 3 Battery Alternator Or Starter Manufacturers & Suppliers List

1. Honda – Starter Troubleshooting

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: 2006 Honda Civic EX 1.8L 4 Cylinder; issues with starting; symptoms include weak cranking, single click when attempting to start; replaced battery; suspected bad starter or alternator; updates indicate it was the starter that was failing.

2. Champion Auto Parts – Batteries and Alternators

Domain: championautoparts.com

Registered: 2002 (23 years)

Introduction: Battery: Typically lasts 3-5 years; easiest and cheapest to replace; essential for starter operation. Symptoms of a dead battery include failure to start. Alternator: Lasts 8-12 years; charges the battery and powers the electrical system; a dead battery may indicate alternator issues. Symptoms of a bad alternator include battery not holding charge. Starter: Responsible for starting the engine; dra…

3. Pontiac Grand Am – Common Cranking Issues

Domain: ifixit.com

Registered: 2001 (24 years)

Introduction: 1999-2005 Pontiac Grand Am; mid-size (and later compact) car; issues with car randomly not cranking; alternator, starter, and battery tested as good; potential causes include neutral safety switches, starter relay, battery cable connections, and starter solenoid.

Strategic Sourcing Conclusion and Outlook for battery alternator or starter

In today’s competitive automotive market, the significance of strategic sourcing for battery, alternator, and starter components cannot be overstated. By leveraging a robust supply chain, international B2B buyers can ensure they source high-quality parts that enhance vehicle performance and reliability. Understanding the interplay between these critical components allows buyers to make informed decisions, minimizing downtime and reducing repair costs.

Moreover, recognizing the common failure causes—such as environmental factors and improper installation—enables buyers to select products that are more durable and suited to their operational conditions. This knowledge not only aids in procurement but also fosters stronger supplier relationships, facilitating better pricing and support.

As we look to the future, the demand for innovative and sustainable automotive solutions is expected to grow, particularly in regions like Africa, South America, the Middle East, and Europe. Buyers are encouraged to explore partnerships with suppliers who prioritize quality and sustainability, ensuring they remain competitive in a rapidly evolving market.

Illustrative image related to battery alternator or starter

Take action today by evaluating your sourcing strategies and aligning with suppliers who can meet your needs for battery, alternator, and starter components. Embrace the opportunity to enhance your operations and drive forward in this dynamic industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.