Introduction: Navigating the Global Market for how long does an alternator last

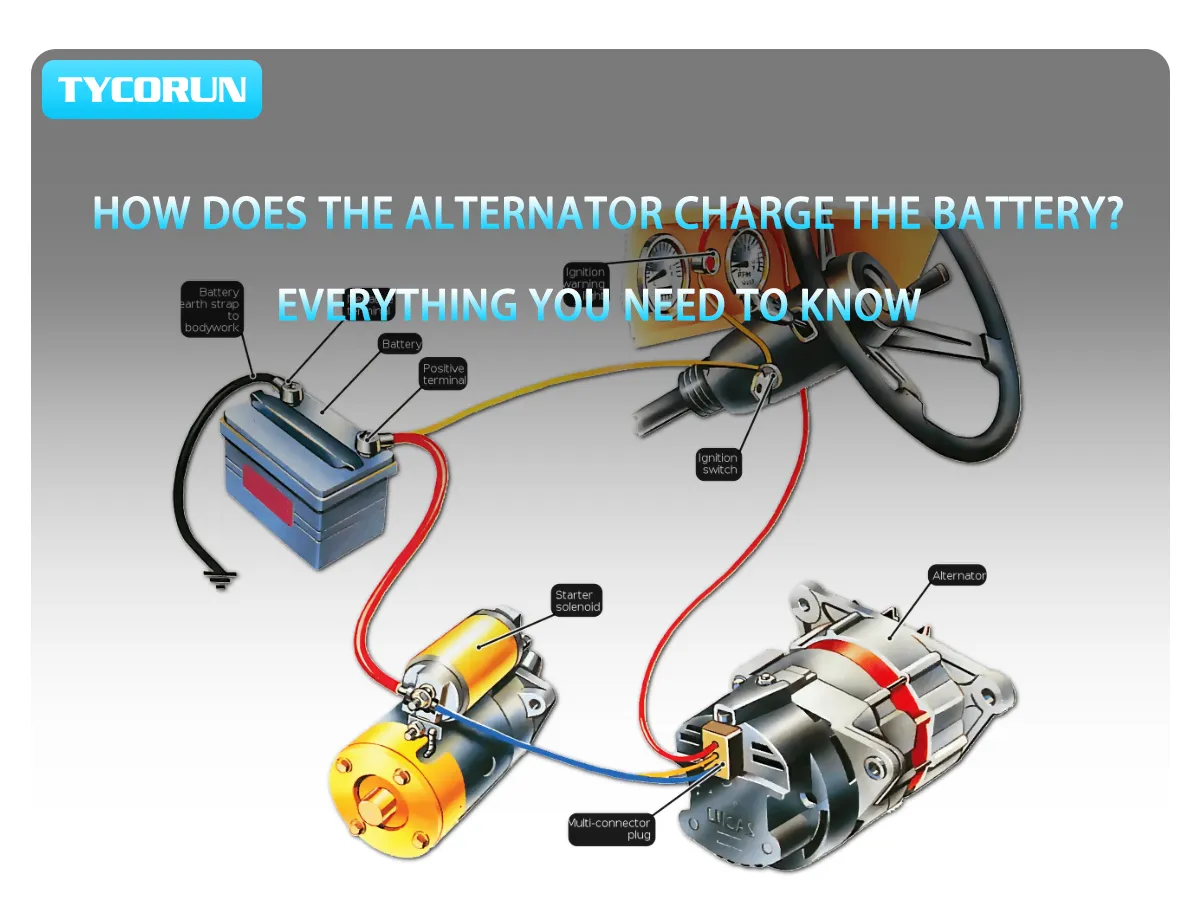

Understanding the longevity of an alternator is crucial for international B2B buyers seeking to maintain their fleets and ensure operational efficiency. As businesses expand across diverse markets—from the bustling cities of Nigeria to the industrial hubs of Brazil—sourcing reliable automotive components becomes a fundamental challenge. This guide delves into the average lifespan of alternators, typically ranging from seven years or 150,000 miles, while highlighting the factors influencing their durability, such as vehicle type, usage patterns, and environmental conditions.

In this comprehensive resource, we will explore various types of alternators, their applications across different vehicle models, and the importance of supplier vetting to ensure quality and reliability. Additionally, we will provide insights into cost considerations and maintenance practices that can extend the life of these essential components. By equipping international B2B buyers with actionable knowledge, this guide empowers you to make informed purchasing decisions that enhance the longevity of your automotive assets.

Whether you are a fleet manager in the Middle East or a procurement officer in Europe, understanding how to assess alternator performance and longevity can save your business significant downtime and repair costs. With this guide, you will navigate the complexities of the global market for alternators with confidence, ensuring your operations remain smooth and efficient across borders.

Table Of Contents

- Top 2 How Long Does An Alternator Last Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long does an alternator last

- Understanding how long does an alternator last Types and Variations

- Key Industrial Applications of how long does an alternator last

- 3 Common User Pain Points for ‘how long does an alternator last’ & Their Solutions

- Strategic Material Selection Guide for how long does an alternator last

- In-depth Look: Manufacturing Processes and Quality Assurance for how long does an alternator last

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does an alternator last’

- Comprehensive Cost and Pricing Analysis for how long does an alternator last Sourcing

- Alternatives Analysis: Comparing how long does an alternator last With Other Solutions

- Essential Technical Properties and Trade Terminology for how long does an alternator last

- Navigating Market Dynamics and Sourcing Trends in the how long does an alternator last Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long does an alternator last

- Strategic Sourcing Conclusion and Outlook for how long does an alternator last

- Important Disclaimer & Terms of Use

Understanding how long does an alternator last Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternators | Typically last 5-7 years or 100,000-150,000 miles. | General automotive repair shops, fleet services. | Pros: Cost-effective, widely available. Cons: May require frequent replacements in harsh conditions. |

| Heavy-Duty Alternators | Designed for high-load applications, longer lifespan. | Commercial trucks, construction equipment. | Pros: More durable, handles increased electrical demand. Cons: Higher initial cost, heavier weight. |

| High-Performance Alternators | Enhanced output for vehicles with numerous electronics. | Performance automotive shops, racing teams. | Pros: Improved efficiency, supports advanced systems. Cons: More expensive, may require specialized installation. |

| Remanufactured Alternators | Rebuilt from used parts, often at a lower price. | Budget-conscious repair shops, used vehicle markets. | Pros: Lower cost, eco-friendly option. Cons: Potential quality variability, shorter lifespan than new. |

| Smart Alternators | Incorporate advanced technology for improved efficiency. | Electric vehicles, hybrid systems. | Pros: Optimizes energy usage, enhances battery life. Cons: Higher complexity, may require specialized knowledge for installation. |

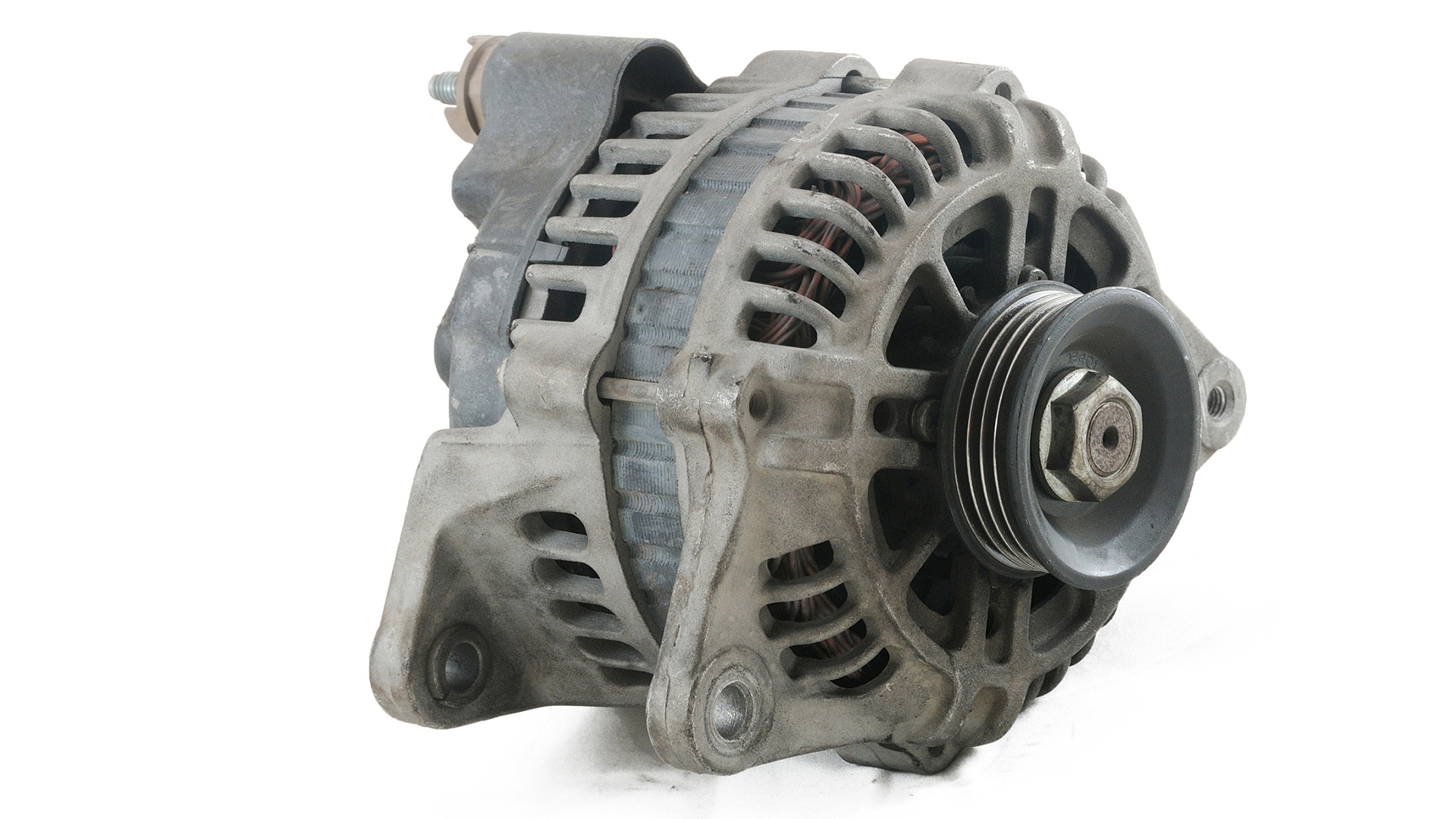

What Are the Characteristics of Standard Alternators?

Standard alternators are the most common type found in conventional vehicles, typically lasting between 5 to 7 years or approximately 100,000 to 150,000 miles under normal driving conditions. They are suitable for general automotive applications and are widely used in repair shops and fleet services. When purchasing, B2B buyers should consider the vehicle’s electrical load and typical usage patterns, as extreme conditions can lead to premature failure. Their cost-effectiveness makes them a go-to choice for many businesses, although they may require more frequent replacements in harsher environments.

How Do Heavy-Duty Alternators Differ from Standard Ones?

Heavy-duty alternators are engineered for vehicles that operate under high-load conditions, such as commercial trucks and construction equipment. They generally have a longer lifespan due to their robust construction and ability to handle increased electrical demands. B2B buyers in the transportation and construction sectors should prioritize these alternators for their durability and reliability. While they come at a higher initial cost, the investment pays off through reduced downtime and lower maintenance costs, making them a practical choice for businesses that rely on heavy machinery.

What Are the Benefits of High-Performance Alternators?

High-performance alternators are tailored for vehicles with extensive electronic systems, such as racing cars or modified street vehicles. They offer enhanced output and efficiency, making them ideal for performance automotive shops and racing teams. When considering a purchase, B2B buyers should evaluate the specific electrical requirements of their vehicles. Although they are more expensive, the benefits of improved efficiency and support for advanced electronics can justify the investment for businesses focused on performance.

Why Choose Remanufactured Alternators?

Remanufactured alternators present a budget-friendly alternative for businesses, particularly those in the used vehicle market or budget-conscious repair shops. These alternators are rebuilt from used parts and typically come at a lower price point. However, B2B buyers should be aware of potential quality variability and the shorter lifespan compared to new units. This option is best suited for businesses looking to minimize costs while still providing reliable service.

What Makes Smart Alternators a Cutting-Edge Choice?

Smart alternators incorporate advanced technology to optimize energy usage, making them particularly beneficial for electric and hybrid vehicles. They are designed to enhance battery life and overall vehicle efficiency. B2B buyers in the electric vehicle sector should consider these alternatives for their innovative features. While they may require specialized installation and come at a higher cost, the long-term benefits of improved performance and energy management can lead to significant savings and operational efficiencies.

Key Industrial Applications of how long does an alternator last

| Industry/Sector | Specific Application of how long does an alternator last | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Maintenance scheduling for fleet vehicles | Reduces downtime and enhances operational efficiency | Quality of alternators, availability of parts, warranty terms |

| Transportation & Logistics | Power management in commercial vehicles | Ensures reliability and safety in long-haul operations | Compatibility with existing systems, supplier reliability |

| Agriculture | Power supply for agricultural machinery | Maintains productivity and reduces repair costs | Durability in harsh conditions, sourcing from reputable manufacturers |

| Construction | Power generation for heavy equipment | Minimizes project delays and operational interruptions | Performance under load, service support, and parts availability |

| Mining | Electrical systems in mining vehicles | Enhances safety and operational continuity | Resistance to extreme conditions, compliance with local regulations |

How is ‘how long does an alternator last’ relevant in the automotive repair industry?

In the automotive repair sector, understanding the lifespan of alternators is crucial for fleet management. Regular maintenance scheduling based on alternator longevity ensures that vehicles are serviced before failures occur, reducing unexpected breakdowns and enhancing operational efficiency. Fleet managers must consider the quality of alternators sourced, as well as warranty terms, to ensure they are investing in reliable components that minimize downtime.

Why is alternator longevity critical for transportation and logistics?

In the transportation and logistics industry, the reliability of commercial vehicles is paramount. The alternator’s lifespan directly affects the vehicle’s power management, impacting everything from navigation systems to cargo refrigeration. A failing alternator can lead to safety risks and operational delays. Buyers in this sector should prioritize sourcing alternators that are compatible with their vehicle systems and ensure suppliers have a proven track record of reliability.

How does alternator lifespan impact agricultural operations?

For the agriculture industry, alternators power essential machinery such as tractors and irrigation systems. Understanding how long an alternator lasts helps farmers plan for maintenance and avoid costly downtime during critical planting or harvesting periods. Buyers should focus on sourcing durable alternators that can withstand harsh environmental conditions, ensuring that their agricultural operations remain productive and cost-effective.

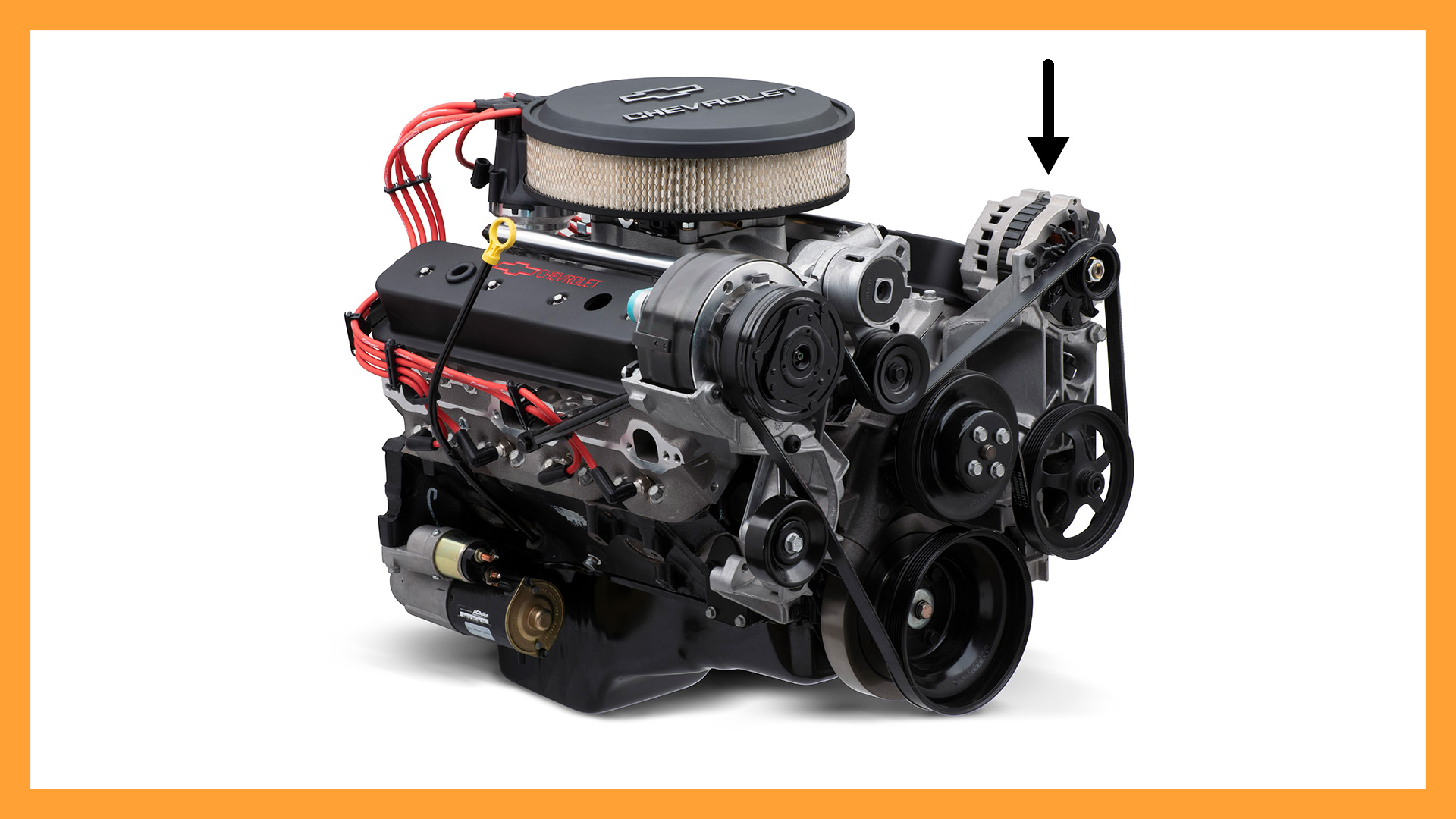

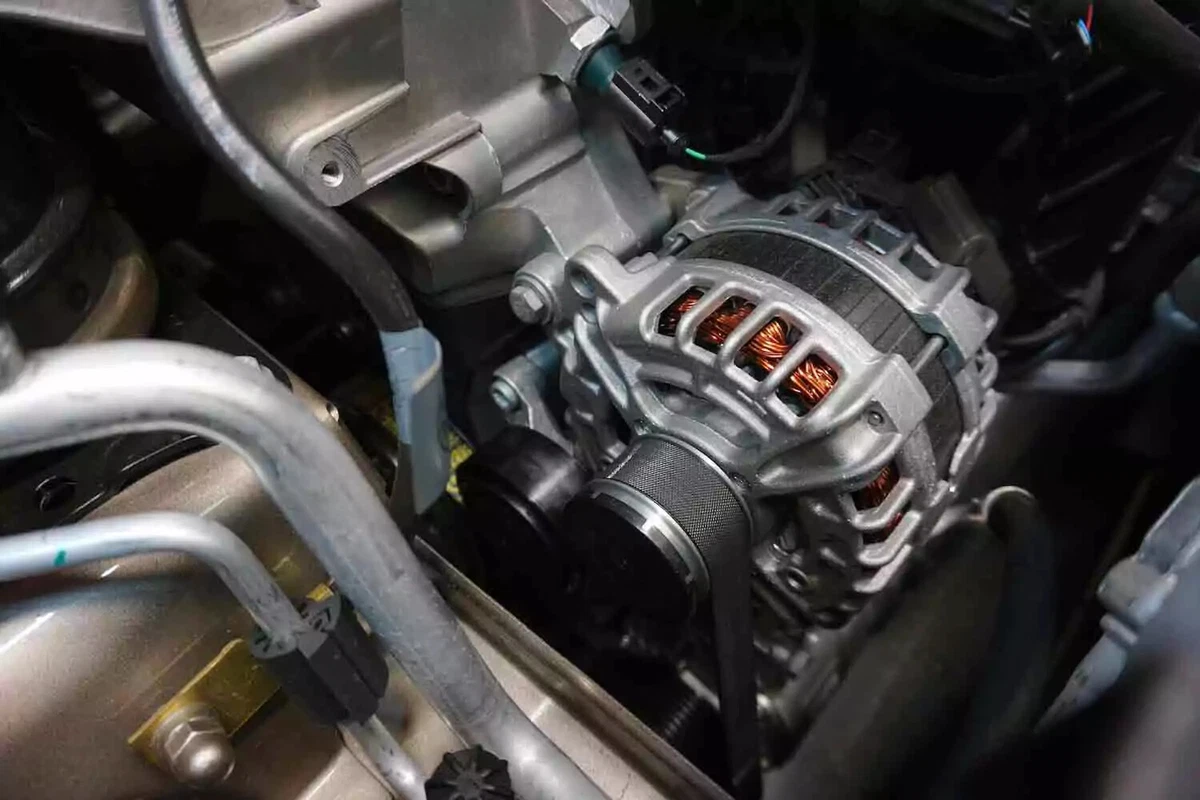

Illustrative image related to how long does an alternator last

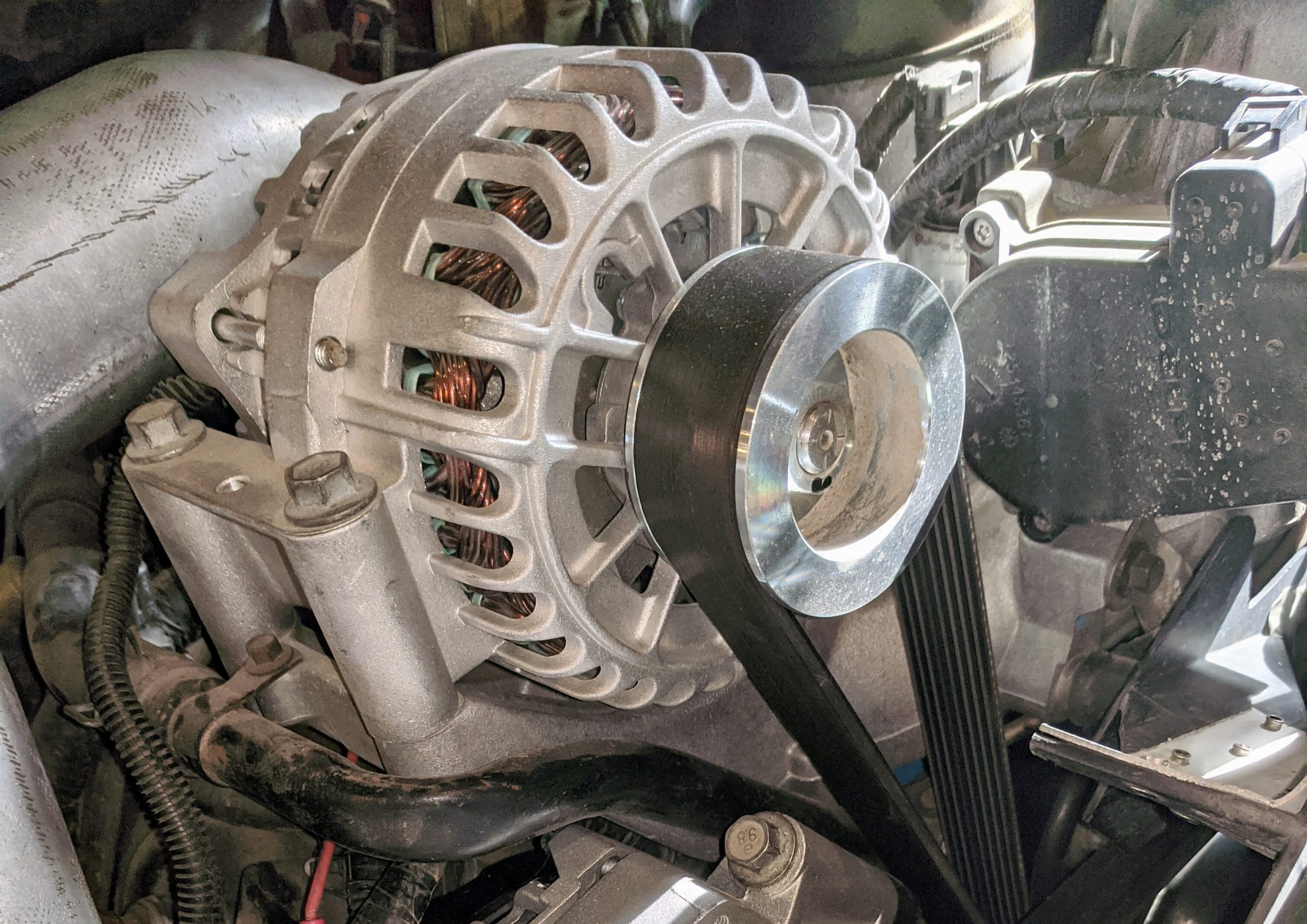

What role does alternator longevity play in construction projects?

In construction, heavy equipment relies on efficient electrical systems, where alternators are vital for power generation. Knowledge of alternator lifespan aids project managers in minimizing delays caused by equipment failures. By ensuring that they source high-performance alternators with strong service support, construction companies can maintain productivity and avoid costly interruptions in their project timelines.

How does mining benefit from understanding alternator lifespan?

Mining operations often involve extreme conditions, making the reliability of electrical systems critical. An alternator’s lifespan can directly affect the safety and operational continuity of mining vehicles. Buyers in this sector must consider sourcing alternators that are not only durable but also compliant with local regulations. This ensures that their equipment remains functional and safe, even in the most challenging environments.

3 Common User Pain Points for ‘how long does an alternator last’ & Their Solutions

Scenario 1: Unpredictable Vehicle Downtime Affects Operations

The Problem: For fleet managers in industries such as logistics or transportation, the reliability of vehicles is paramount. A sudden alternator failure can lead to unplanned downtime, disrupting schedules and incurring significant costs. If an alternator lasts only a few years or 150,000 miles—factors such as driving conditions, vehicle load, and maintenance history can affect this lifespan—fleet managers must remain vigilant. They may face the challenge of balancing cost-effective maintenance with the need to prevent breakdowns.

The Solution: To mitigate the risk of alternator failures, fleet managers should implement a proactive maintenance schedule that includes regular inspections of the charging system. Utilizing telematics systems can help track vehicle performance and alert managers to potential alternator issues before they lead to breakdowns. Establishing partnerships with reliable suppliers who provide high-quality alternators and training staff on recognizing early signs of alternator failure can also be crucial. By keeping detailed records of each vehicle’s maintenance history, managers can identify patterns and anticipate when specific vehicles may need their alternators replaced, thereby minimizing downtime.

Scenario 2: Sourcing Quality Alternators in Diverse Markets

The Problem: B2B buyers, especially those in emerging markets such as Nigeria or Brazil, often face challenges in sourcing quality automotive parts like alternators. The availability of counterfeit or subpar products can lead to premature failures, leaving businesses with unexpected repair costs and operational disruptions. Additionally, varying standards and regulations across regions can complicate the purchasing process, making it difficult to know what to trust.

The Solution: To address this sourcing challenge, businesses should conduct thorough due diligence when selecting suppliers. This includes verifying certifications, checking reviews from other B2B buyers, and understanding the warranty and return policies of the products offered. Engaging with manufacturers directly or through reputable distributors can provide more assurance of quality. Establishing long-term relationships with trusted suppliers can also facilitate better pricing, improved service levels, and access to genuine parts. Conducting regular market research can help identify reputable suppliers in different regions, ensuring that businesses can source reliable alternators that meet local standards.

Scenario 3: Managing Maintenance Costs While Ensuring Performance

The Problem: Businesses operating in sectors like construction or emergency services must frequently assess the performance of their vehicles to ensure they remain operational. The cost of replacing alternators can be a burden, especially if replacements are needed sooner than expected. For these buyers, understanding how long an alternator lasts and the associated costs is crucial to budgeting and financial planning.

The Solution: To manage maintenance costs effectively, businesses should invest in preventive maintenance programs that include regular alternator checks and servicing of related components, such as belts and batteries. Educating staff on proper vehicle usage—like avoiding excessive electrical loads and ensuring proper jump-start procedures—can extend the life of alternators. Additionally, businesses should consider investing in higher-quality alternators, which may have a higher upfront cost but offer better longevity and reliability. By keeping detailed records of alternator performance and replacement history, businesses can create more accurate forecasts for future maintenance budgets, allowing for better financial planning and resource allocation.

Strategic Material Selection Guide for how long does an alternator last

What Materials Are Commonly Used in Alternators and How Do They Affect Lifespan?

When considering the lifespan of an alternator, the materials used in its construction play a crucial role. The most common materials include aluminum, copper, steel, and plastic. Each of these materials has distinct properties that influence the performance, durability, and overall effectiveness of the alternator.

How Does Aluminum Impact the Lifespan of an Alternator?

Aluminum is frequently used in the casing and components of alternators due to its lightweight nature and excellent thermal conductivity. It can withstand moderate temperatures, making it suitable for automotive applications. The corrosion resistance of aluminum is another key property, which helps in maintaining the integrity of the alternator over time.

Pros: Aluminum is cost-effective, lightweight, and has good thermal properties. Its resistance to corrosion helps prolong the alternator’s lifespan.

Illustrative image related to how long does an alternator last

Cons: While aluminum is durable, it can be less robust than other metals under high-stress conditions. It may also be susceptible to wear and tear from exposure to harsh environmental factors.

Impact on Application: Aluminum is ideal for applications where weight reduction is essential, such as in performance vehicles. However, in regions with extreme temperatures or high humidity, additional protective coatings may be necessary.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the aluminum used complies with local standards for automotive parts, such as ASTM or ISO certifications.

What Role Does Copper Play in Alternator Performance?

Copper is predominantly used in the windings of the alternator due to its superior electrical conductivity. This property allows for efficient power generation and minimizes energy loss, which is vital for the alternator’s performance.

Illustrative image related to how long does an alternator last

Pros: Copper has excellent electrical conductivity, which enhances the efficiency of the alternator. Its durability ensures a long service life when properly maintained.

Cons: The primary drawback of copper is its higher cost compared to aluminum. Additionally, copper is prone to corrosion if not adequately insulated or protected.

Impact on Application: Copper windings are essential for high-performance alternators, particularly in vehicles with extensive electrical systems. However, in humid climates, corrosion-resistant coatings are advisable.

Considerations for International Buyers: Buyers should verify that the copper used meets international standards, such as JIS or DIN, to ensure quality and reliability.

How Does Steel Contribute to Alternator Durability?

Steel is often employed in the construction of brackets and internal components of alternators due to its high strength and durability. It can withstand significant mechanical stress, making it suitable for heavy-duty applications.

Illustrative image related to how long does an alternator last

Pros: Steel’s robustness provides excellent structural integrity, ensuring that the alternator can handle vibrations and shocks from the vehicle’s operation.

Cons: While steel is strong, it is heavier than aluminum and can be prone to rust if not properly treated or coated.

Impact on Application: Steel is ideal for alternators used in trucks and heavy machinery, where durability is paramount. However, its weight may be a disadvantage in performance-focused vehicles.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure that the steel used complies with regional standards for automotive components, focusing on corrosion resistance.

Illustrative image related to how long does an alternator last

What About the Use of Plastic in Alternators?

Plastic is commonly used for insulating components and housings in alternators. Its lightweight nature and resistance to electrical conductivity make it a suitable choice for certain parts.

Pros: Plastic is lightweight and can be molded into complex shapes, allowing for design flexibility. It also provides effective insulation against electrical currents.

Cons: The main limitation of plastic is its susceptibility to heat and UV degradation, which can lead to premature failure in high-temperature environments.

Impact on Application: Plastic components are best suited for alternators in vehicles operating in moderate climates. In extreme heat or direct sunlight, alternative materials may be more appropriate.

Illustrative image related to how long does an alternator last

Considerations for International Buyers: Buyers should assess the quality of plastics used, ensuring they meet relevant standards for heat resistance and durability, particularly in regions with extreme weather conditions.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for how long does an alternator last | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Casing and components for lightweight vehicles | Corrosion resistance and lightweight | Less robust under high stress | Medium |

| Copper | Windings for efficient power generation | Excellent electrical conductivity | Higher cost and prone to corrosion | High |

| Steel | Brackets and internal components for heavy-duty applications | High strength and durability | Heavier and prone to rust | Medium |

| Plastic | Insulating components and housings | Lightweight and design flexibility | Susceptible to heat and UV degradation | Low |

This analysis highlights the importance of material selection in the design and longevity of alternators. By understanding the properties and implications of each material, B2B buyers can make informed decisions that align with their operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for how long does an alternator last

What Are the Key Stages in the Manufacturing Process of an Alternator?

The manufacturing process of an alternator involves several critical stages that ensure its reliability and longevity. Understanding these stages can help B2B buyers assess the quality of the alternators they plan to procure.

Material Preparation: What Materials Are Used in Alternator Production?

The first stage involves selecting high-quality materials that will contribute to the alternator’s durability. Common materials include:

Illustrative image related to how long does an alternator last

- Copper: Used for windings due to its excellent electrical conductivity.

- Aluminum: Typically used for the housing and rotor components, providing a balance of strength and weight.

- Steel: Often utilized for the frame and other structural components, ensuring robustness.

- Insulation materials: Essential for protecting electrical components from heat and electrical shorts.

Suppliers should ensure that the materials meet relevant international standards for quality and safety, which can significantly influence the lifespan of the alternator.

How Is the Forming Process Conducted in Alternator Manufacturing?

Once the materials are prepared, they undergo various forming processes. Key techniques include:

- Stamping: Metal sheets are stamped into specific shapes required for the alternator’s casing and other components.

- Winding: Copper wire is wound into coils, which are essential for generating electricity. The precision of the winding process is crucial for efficiency.

- Casting: Some parts, like the rotor, may be cast to achieve specific geometries that are difficult to create through other methods.

These forming techniques are critical as they directly affect the alternator’s performance and durability.

What Does the Assembly Process Involve for Alternators?

The assembly stage is where individual components come together to form a complete alternator. This process typically includes:

- Component assembly: The stator, rotor, and other parts are assembled in a clean environment to prevent contamination.

- Electrical connections: Ensuring that all electrical connections are secure and properly insulated to prevent shorts and failures.

- Quality checks: Throughout assembly, manufacturers perform in-process quality control (IPQC) to catch defects early.

Effective assembly techniques contribute to the overall reliability of the alternator and its ability to perform under various conditions.

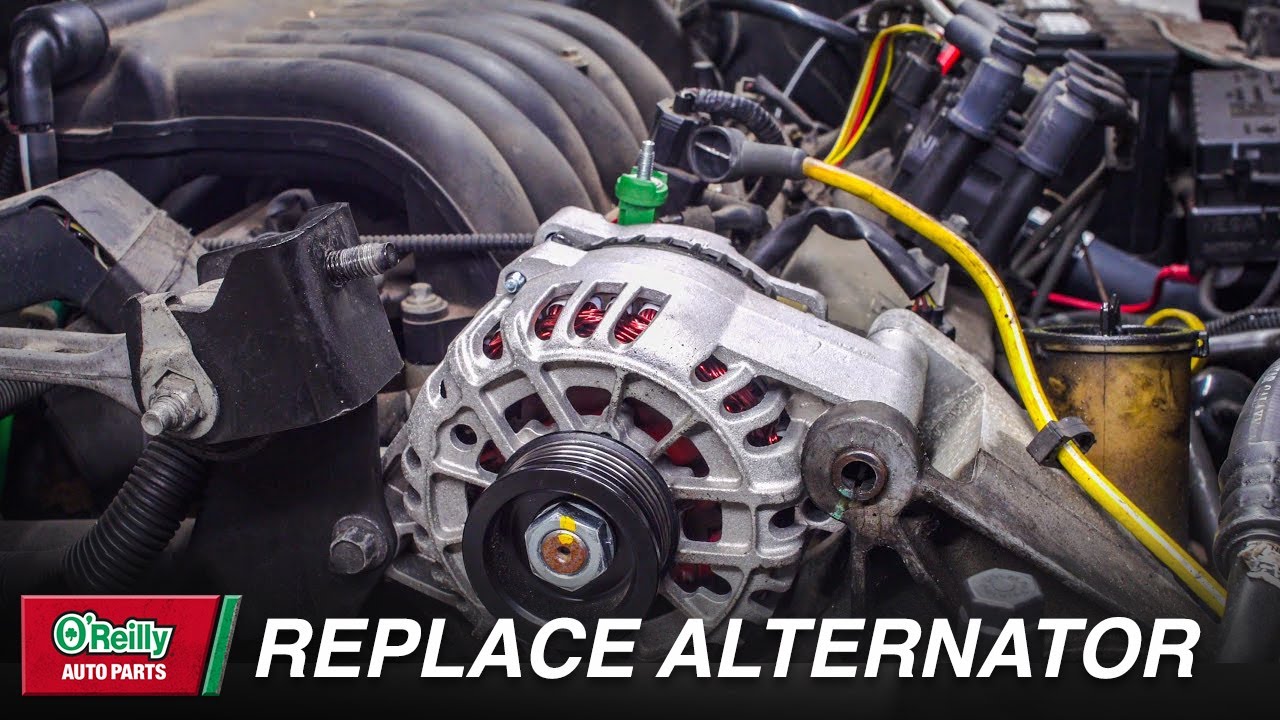

Illustrative image related to how long does an alternator last

How Are Alternators Finished and Prepared for Quality Assurance?

The finishing stage involves several steps to prepare the alternator for testing and distribution:

- Surface treatment: Components may undergo treatments such as anodizing or powder coating to enhance corrosion resistance.

- Final assembly: The alternator is fully assembled, and any additional components, such as bearings and seals, are installed.

- Testing: Before shipping, alternators are subjected to rigorous tests to ensure they meet performance standards.

These finishing processes are essential for the alternator’s longevity and reliability in diverse operating conditions.

What Quality Assurance Standards Are Relevant for Alternator Manufacturing?

Quality assurance is paramount in the manufacturing of alternators, particularly for B2B buyers who prioritize long-lasting products. Key international and industry-specific standards include:

- ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers aiming to maintain consistent quality.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Specifications: Relevant for alternators used in specific industrial applications, ensuring they meet industry performance standards.

Adherence to these standards can significantly influence the lifespan and reliability of alternators.

What Are the Key Quality Control Checkpoints in Alternator Production?

Quality control (QC) is integral to the manufacturing process, with several checkpoints established to ensure product integrity:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing process help catch defects early, reducing waste and improving efficiency.

- Final Quality Control (FQC): After assembly, the finished alternators undergo comprehensive testing to ensure they meet performance standards.

B2B buyers should inquire about these QC checkpoints when evaluating potential suppliers.

What Testing Methods Are Commonly Used for Alternators?

Various testing methods are employed to validate the performance and reliability of alternators, including:

- Electrical testing: Measures output voltage and current to ensure the alternator meets specified performance criteria.

- Mechanical testing: Assesses the structural integrity of components under simulated operating conditions.

- Thermal testing: Evaluates how the alternator performs under high-temperature conditions, which is critical for longevity.

Understanding these testing methods can help B2B buyers assess the quality and reliability of alternators from potential suppliers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure the longevity of the alternators. Key strategies include:

- Supplier audits: Conducting on-site audits of the manufacturing facility to assess compliance with quality standards.

- Requesting quality reports: Suppliers should provide documentation detailing their quality control processes and results from testing.

- Third-party inspections: Engaging third-party inspectors to evaluate the manufacturing processes and quality control measures can provide an unbiased assessment.

For buyers from regions such as Africa, South America, the Middle East, and Europe, these practices are crucial in establishing a reliable supply chain.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must navigate various nuances in quality control and certification when sourcing alternators. These include:

- Regulatory compliance: Understanding local regulations in different markets to ensure products meet specific requirements.

- Cultural considerations: Different regions may have varying expectations regarding quality, which can impact supplier selection.

- Documentation requirements: Buyers should be aware of the necessary documentation for customs clearance and compliance verification.

By considering these factors, B2B buyers can make informed decisions that enhance their supply chain’s reliability and product quality.

Conclusion

The manufacturing processes and quality assurance measures for alternators are crucial for determining their lifespan and performance. B2B buyers should prioritize suppliers who adhere to rigorous quality standards and employ effective manufacturing practices. By understanding these processes, buyers can make informed procurement decisions that ensure they receive high-quality, reliable alternators that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does an alternator last’

To assist B2B buyers in making informed decisions regarding alternators, this guide offers a step-by-step checklist focused on understanding the lifespan and performance factors of alternators. This information is crucial for ensuring the reliability of vehicle operations and minimizing unexpected downtimes.

Step 1: Understand the Average Lifespan of Alternators

Knowing the typical lifespan of an alternator, which averages around seven years or 150,000 miles, is essential. This baseline helps you plan for replacements and budget for maintenance. Factors like vehicle usage, environmental conditions, and electrical load impact longevity, making it vital to assess these elements in your fleet.

Step 2: Identify Key Performance Indicators

Establish specific performance metrics for the alternators you are considering. Look for indicators such as voltage output, efficiency ratings, and compatibility with your vehicle types. This will help you ensure that the alternators meet the electrical demands of modern vehicles, especially those with advanced electronic systems.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that your suppliers have relevant certifications and quality assurance processes in place. Look for ISO certifications or other industry-standard endorsements that validate their manufacturing and testing processes. This step ensures that you are sourcing high-quality alternators that meet safety and performance standards.

Step 4: Assess Warranty and After-Sales Support

A robust warranty can protect your investment and provide peace of mind. Inquire about the duration and terms of the warranty, as well as the availability of after-sales support. Reliable support can help you address any issues promptly, minimizing downtime and operational disruptions.

Step 5: Research Supplier Reputation and Reviews

Investigate the reputation of potential suppliers by checking customer reviews and testimonials. Look for feedback from businesses in similar industries or regions to gauge reliability and customer service. A supplier with a strong track record is more likely to provide quality products and support.

Step 6: Consider Bulk Procurement Options

If your business operates a fleet or has high-volume needs, explore bulk purchasing options. Many suppliers offer discounts or favorable terms for large orders. This not only reduces per-unit costs but also ensures consistency in the products used across your fleet.

Step 7: Plan for Regular Maintenance and Inspections

Finally, establish a maintenance schedule for your alternators. Regular inspections can help identify potential issues before they lead to failures, extending the lifespan of your alternators. Ensure your maintenance team is trained to recognize early warning signs of alternator problems, such as unusual noises or electrical malfunctions.

Illustrative image related to how long does an alternator last

By following this checklist, B2B buyers can make informed decisions about procuring alternators that meet their operational needs, ensuring reliability and efficiency in their vehicle fleets.

Comprehensive Cost and Pricing Analysis for how long does an alternator last Sourcing

What Are the Key Cost Components for Sourcing Alternators?

When sourcing alternators, it’s essential to understand the various cost components involved. These include:

-

Materials: The primary materials used in alternator manufacturing include copper wire, steel, aluminum, and plastic. The cost of these materials can fluctuate based on market demand and availability. For international buyers, understanding local sourcing options can lead to cost savings.

-

Labor: Labor costs can vary significantly depending on the region. Countries with lower labor costs might provide a competitive advantage, but it’s crucial to evaluate the skill level and training of the workforce, which can impact the quality of the alternators produced.

-

Manufacturing Overhead: This includes costs related to utilities, equipment depreciation, and facility maintenance. A manufacturer with optimized processes may offer better pricing due to lower overhead costs.

-

Tooling: Specialized tools and machinery required for production can be a substantial investment. Suppliers that produce a high volume of alternators may spread these costs over more units, thereby reducing the price per unit.

-

Quality Control (QC): QC processes ensure that the alternators meet specific performance standards. Suppliers with stringent QC measures may charge higher prices, but this can lead to long-term savings by reducing warranty claims and failures.

-

Logistics: Shipping costs, including freight and customs duties, are critical in pricing, especially for international transactions. Buyers should consider the total logistics cost when evaluating suppliers.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the typical margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Affect Alternator Sourcing?

Several factors can influence the final pricing of alternators:

-

Volume/MOQ: Suppliers often provide discounts for bulk purchases. Understanding the Minimum Order Quantity (MOQ) can help in negotiating better pricing, especially for larger orders.

-

Specifications and Customization: Customized alternators that meet specific vehicle requirements can increase costs. Buyers should clearly define their specifications to avoid unnecessary expenses.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., ISO standards) often come at a premium. Buyers should balance the need for quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding Incoterms is vital for international buyers as they dictate who bears the costs and risks during transportation. Choosing favorable terms can reduce overall costs.

What Buyer Tips Can Help in Negotiating Alternator Prices?

To optimize sourcing strategies, international B2B buyers should consider the following tips:

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing. Highlighting long-term partnership potential can lead to better pricing arrangements.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors like durability, warranty, and maintenance costs to make a more informed decision.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing structures due to local economic conditions, tariffs, and regulations. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to identify competitive pricing.

-

Request Samples: Before committing to a large order, request samples to assess quality. This can prevent costly mistakes and ensure that the alternators meet your specifications.

-

Leverage Local Suppliers: In regions like Nigeria or Brazil, local suppliers may offer more competitive pricing due to lower shipping costs and tariffs. Assessing local manufacturing capabilities can lead to significant savings.

Disclaimer on Indicative Prices

Prices for alternators can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes from different suppliers to ensure competitive pricing. Always consider the long-term value and reliability of the alternators when making purchasing decisions.

Alternatives Analysis: Comparing how long does an alternator last With Other Solutions

In the automotive industry, understanding the lifespan of an alternator is essential for vehicle maintenance and operational efficiency. However, it’s equally important for B2B buyers to explore alternative solutions that can either complement or replace the function of an alternator. This section will compare the longevity and performance of traditional alternators with two viable alternatives: solar power systems and battery management systems.

| Comparison Aspect | How Long Does An Alternator Last | Solar Power Systems | Battery Management Systems |

|---|---|---|---|

| Performance | Typically lasts 7 years or 150,000 miles | Provides renewable energy, but dependent on sunlight | Extends battery life and efficiency |

| Cost | Average replacement cost: $500 – $1,000 | Initial setup cost: $1,000 – $3,000 | Varies widely, generally $200 – $800 |

| Ease of Implementation | Moderate; requires mechanical expertise | High; installation requires specialized knowledge | Moderate; can be integrated into existing systems |

| Maintenance | Regular checks needed; can fail suddenly | Low; minimal upkeep, mostly cleaning | Requires software updates and occasional hardware checks |

| Best Use Case | Ideal for conventional vehicles | Best for electric vehicles or off-grid systems | Great for optimizing battery performance in hybrid and electric vehicles |

What Are the Advantages and Disadvantages of Solar Power Systems?

Solar power systems harness energy from the sun to provide electricity for vehicles, especially electric ones. The primary advantage is that they are a renewable energy source, reducing dependency on fossil fuels and offering sustainability. However, their performance is heavily reliant on weather conditions; insufficient sunlight can lead to inadequate charging. Moreover, the initial investment can be significantly higher than that of traditional alternators, making it less appealing for conventional vehicles.

How Do Battery Management Systems Improve Vehicle Efficiency?

Battery management systems (BMS) are designed to monitor and manage battery performance, particularly in electric and hybrid vehicles. They help to optimize battery life by preventing overcharging and deep discharging, thus extending overall battery longevity. While BMS can be integrated into existing vehicle systems, they require a certain level of technical expertise to install and maintain. This can pose challenges for businesses that lack in-house technical resources or prefer simpler solutions.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When deciding between an alternator and alternative solutions like solar power systems or battery management systems, B2B buyers should consider several factors. The choice largely depends on the type of vehicles in their fleet, budget constraints, and long-term sustainability goals. For traditional vehicles, a reliable alternator remains the best choice due to its proven track record and lower initial costs. Conversely, businesses looking to invest in electric or hybrid vehicles may find that solar power systems or battery management systems provide better long-term benefits, despite higher upfront costs. Ultimately, the decision should align with the company’s operational strategy and financial considerations.

Essential Technical Properties and Trade Terminology for how long does an alternator last

What Are the Key Technical Properties of an Alternator and Their B2B Significance?

Understanding the essential technical properties of an alternator is crucial for B2B buyers, especially when assessing product quality and suitability for specific applications. Here are several critical specifications to consider:

1. Material Grade

The material composition of an alternator, typically aluminum or high-grade steel, significantly influences its durability and resistance to environmental factors. A higher material grade can lead to a longer lifespan, making it an essential consideration for buyers seeking long-term value. In regions with extreme temperatures or corrosive environments, investing in alternators made from superior materials can reduce replacement costs over time.

2. Voltage Output

An alternator’s voltage output, usually around 12-14 volts for most automotive applications, is a critical specification. This measure determines how effectively the alternator can recharge the battery and power the vehicle’s electrical systems. Understanding the voltage output is vital for ensuring compatibility with the vehicle’s electrical requirements, preventing potential failures that could lead to costly repairs.

3. Current Rating (Amperage)

The current rating, measured in amperes (amps), indicates the maximum electrical current the alternator can supply. This specification is essential for determining whether the alternator can handle the electrical load of a vehicle, especially in modern cars equipped with numerous electronic systems. For B2B buyers, selecting an alternator with an appropriate amperage rating ensures reliable performance under varying conditions and loads.

4. Bearing Type

Alternators typically utilize either ball bearings or bushings. The bearing type affects the alternator’s rotational efficiency and noise levels. Ball bearings generally provide better performance and longevity, which can be a deciding factor for businesses focused on maintenance costs and operational noise in their fleets.

5. Rotational Speed (RPM)

The operational RPM of an alternator indicates how fast it must rotate to produce its rated output. This specification is crucial in determining compatibility with different engine types and driving conditions. Buyers should consider the RPM range to ensure optimal performance and reliability, especially in high-demand applications.

6. Cooling Method

Alternators may feature different cooling methods, such as air-cooled or liquid-cooled designs. The cooling method impacts the alternator’s efficiency and lifespan. For B2B buyers in hot climates or heavy-duty applications, selecting an alternator with an effective cooling system can prevent overheating and enhance performance.

Illustrative image related to how long does an alternator last

What Are Common Trade Terms Related to Alternators in B2B Transactions?

Understanding industry jargon is essential for effective communication and decision-making in B2B transactions. Here are several common terms related to alternators:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of alternators, OEM parts are made to the specifications of the original vehicle manufacturer. B2B buyers often prefer OEM parts for their guaranteed compatibility and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products a supplier is willing to sell. For alternators, knowing the MOQ helps buyers plan inventory and manage costs effectively. This term is crucial for businesses looking to optimize their supply chain and reduce excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to suppliers to request pricing and availability for specific products. When sourcing alternators, a well-prepared RFQ can lead to better pricing and terms, making it an essential step in the procurement process.

Illustrative image related to how long does an alternator last

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping costs, risk management, and logistics when procuring alternators from different countries.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For alternators, understanding lead times is critical for inventory management and ensuring that vehicles remain operational without unnecessary downtime.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, ultimately leading to improved operational efficiency and cost savings in their automotive fleets.

Navigating Market Dynamics and Sourcing Trends in the how long does an alternator last Sector

Market Overview & Key Trends in the Alternator Lifespan Sector

The global automotive parts market, particularly regarding alternators, is experiencing significant shifts driven by technological advancements, consumer behavior changes, and emerging markets. With an average lifespan of approximately seven years or 150,000 miles, the demand for reliable and durable alternators remains high. Factors influencing this market include increasing vehicle sales in emerging economies such as Brazil and Nigeria, where a growing middle class is investing in personal transportation. Additionally, the rise in electric vehicles (EVs) introduces new dynamics, as traditional alternators are replaced or modified to meet the demands of EV power systems.

Current B2B sourcing trends highlight a shift towards integrated supply chain solutions that offer real-time tracking and enhanced transparency. Buyers are increasingly seeking suppliers that can provide not only high-quality alternators but also comprehensive support services, including diagnostics and maintenance. The adoption of Industry 4.0 technologies, such as IoT and AI, is also transforming how manufacturers monitor alternator performance and predict failures, thereby enhancing product longevity and customer satisfaction.

Furthermore, international buyers are prioritizing suppliers that can demonstrate resilience in supply chains, particularly in light of recent global disruptions. Sourcing from regions with stable political and economic climates is becoming a vital consideration for B2B buyers looking to mitigate risks associated with production delays and quality control.

How Does Sustainability & Ethical Sourcing Impact the Alternator Market?

In the context of the automotive parts industry, sustainability and ethical sourcing have become paramount. The environmental impact of alternator manufacturing and disposal processes is under scrutiny as global awareness of climate change rises. B2B buyers are increasingly looking for suppliers who utilize sustainable practices, such as recycling materials and employing eco-friendly manufacturing processes. The use of ‘green’ certifications, such as ISO 14001, can enhance a supplier’s appeal, demonstrating their commitment to reducing environmental footprints.

Ethical supply chains are equally important. Buyers are demanding transparency regarding labor practices and sourcing materials. Ensuring that suppliers adhere to ethical labor standards not only aligns with corporate social responsibility goals but also mitigates risks associated with reputational damage. The shift towards circular economies, where components like alternators are designed for longevity and recyclability, is becoming a focal point. This trend encourages manufacturers to innovate and create products that not only last longer but are also easier to disassemble and recycle at the end of their lifecycle.

What is the Brief Evolution of the Alternator in the Automotive Industry?

The alternator has undergone significant evolution since its inception in the early 20th century. Initially, vehicles relied on direct current (DC) generators, which were less efficient and required regular maintenance. The introduction of the alternator in the 1960s revolutionized automotive electrical systems, offering higher efficiency and reduced weight. This advancement enabled cars to support more electrical components, paving the way for the modern vehicles we see today, equipped with advanced electronics and comfort features.

As the automotive industry continues to evolve, the role of the alternator is adapting to include hybrid and electric vehicle applications. The shift towards electrification is driving innovation in alternator design and function, necessitating partnerships between manufacturers and suppliers to meet the increasing demands for efficiency and performance. This evolution presents an opportunity for B2B buyers to engage with forward-thinking suppliers that are prepared to navigate these changes and contribute to a more sustainable automotive future.

Frequently Asked Questions (FAQs) for B2B Buyers of how long does an alternator last

-

How do I determine the lifespan of an alternator for my fleet vehicles?

The average lifespan of an alternator is typically around 7 years or approximately 150,000 miles, but this can vary based on usage, environmental conditions, and maintenance practices. For fleet vehicles, regular inspections and preventive maintenance can significantly extend the lifespan. Monitoring performance indicators like dimming lights or starting issues can help identify problems early. Additionally, investing in high-quality alternators and ensuring proper installation can lead to longer service life, minimizing downtime and replacement costs. -

What are the common signs of a failing alternator that I should watch for?

Common indicators of a failing alternator include difficulty starting the vehicle, dimming headlights, unusual sounds like squealing or whining, and dashboard warning lights. If your vehicles are experiencing frequent electrical issues, such as malfunctioning electronics or needing jump-starts, these could also signal alternator problems. Regular maintenance checks and technician inspections can help catch these signs early, allowing for timely repairs or replacements, thus maintaining fleet reliability. -

How can I ensure the quality of alternators when sourcing from international suppliers?

To ensure quality, vet suppliers by checking their certifications, production processes, and customer reviews. Request samples and conduct quality assurance (QA) tests to evaluate the alternators before bulk purchasing. It’s also beneficial to establish a clear agreement on quality standards and warranties. Consider suppliers with a proven track record in your region, and build relationships for better communication and support throughout the sourcing process. -

What customization options are available for alternators, and how do they impact pricing?

Customization options for alternators may include variations in output voltage, size, and connector types to meet specific vehicle requirements. Customization can significantly impact pricing, often increasing costs due to additional manufacturing processes and materials. Discuss your needs with potential suppliers to understand the implications for pricing and lead times, and consider balancing customization against standard parts to optimize costs without compromising on performance. -

What are the typical minimum order quantities (MOQs) for alternators in B2B sourcing?

Minimum order quantities for alternators can vary widely based on the supplier and the specific type of alternator. Generally, MOQs can range from a few dozen to several hundred units. When negotiating with suppliers, clarify their MOQ policies and explore options for smaller initial orders to test the market demand. Establishing a good relationship with suppliers can sometimes lead to flexibility in MOQs, especially for long-term partnerships. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms can vary significantly between suppliers and regions. Common practices include advance payments, letters of credit, or payment upon delivery. It’s essential to negotiate terms that mitigate risk for both parties. Consider using escrow services for large orders to ensure compliance with quality standards before payment is finalized. Understanding regional banking practices and currency exchange rates is also crucial for smooth transactions. -

How do logistics and shipping impact the procurement of alternators?

Logistics and shipping play a critical role in the procurement process, affecting lead times and overall costs. Factors such as shipping method, distance, and customs regulations can influence delivery schedules. It is advisable to work with logistics partners experienced in international shipping to navigate potential challenges. Always factor in shipping costs when comparing supplier pricing, and consider incoterms that clearly define responsibilities for shipping, insurance, and tariffs. -

What should I include in a quality assurance checklist for alternators?

A quality assurance checklist for alternators should include inspection criteria for physical dimensions, electrical performance (voltage and current outputs), and visual checks for damage or defects. Ensure that all components meet specified standards and that the alternators pass functional tests before approval. Include documentation requirements, such as compliance certificates and warranty information. Regular audits of the supplier’s production processes can also help maintain quality consistency over time.

Top 2 How Long Does An Alternator Last Manufacturers & Suppliers List

1. Savannah Toyota – Alternator

Domain: savannahtoyota.com

Registered: 1996 (29 years)

Introduction: The alternator powers all electronics in a vehicle while the engine is running, functioning as a generator using the gas engine as its energy source. It typically lasts between 80,000 and 150,000 miles (about seven years). Signs of a failing alternator include a battery warning light, dim headlights, burning rubber smell, devices not charging, whining sounds, and inability to start the vehicle. Th…

2. Facebook – Customer Experience

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Customer Experience, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how long does an alternator last

In summary, understanding the lifespan of an alternator—typically around seven years or 150,000 miles—is crucial for maintaining vehicle reliability and preventing unexpected breakdowns. As B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, investing in high-quality alternators and components can significantly reduce long-term maintenance costs.

Strategic sourcing plays a vital role in securing durable and reliable parts, ensuring that your fleet operates efficiently and minimizes downtime. By evaluating suppliers based on quality, reliability, and service support, businesses can foster partnerships that enhance operational performance.

Looking ahead, as the automotive landscape evolves, the demand for advanced electrical systems will grow. This presents an opportunity for businesses to align with suppliers who prioritize innovation and sustainability in their offerings. We encourage you to explore partnerships that not only meet your immediate needs but also position your company for future advancements in automotive technology. Prioritize quality and strategic sourcing to drive efficiency and reliability in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to how long does an alternator last

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.