Introduction: Navigating the Global Market for how does alternator work

In today’s global marketplace, understanding how an alternator works is crucial for businesses sourcing reliable electrical components for their operations. Alternators are essential for converting mechanical energy into electrical energy, primarily in automotive applications, but their functionality extends to various industries. This guide delves into the mechanics of alternators, offering insights into different types, their applications across sectors, and the intricacies of supplier vetting.

As B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complex landscape of sourcing electrical components, this comprehensive resource empowers them to make informed purchasing decisions. From understanding the key components of an alternator—such as the rotor, stator, and rectifier—to evaluating costs and performance metrics, this guide equips buyers with the knowledge needed to assess quality and reliability in suppliers.

Moreover, it addresses common challenges faced in the procurement process, including identifying reputable manufacturers and ensuring compliance with international standards. By leveraging this guide, international buyers can enhance their operational efficiency and secure dependable alternators tailored to their specific needs, ultimately driving business success in their respective markets.

Table Of Contents

- Top 2 How Does Alternator Work Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how does alternator work

- Understanding how does alternator work Types and Variations

- Key Industrial Applications of how does alternator work

- 3 Common User Pain Points for ‘how does alternator work’ & Their Solutions

- Strategic Material Selection Guide for how does alternator work

- In-depth Look: Manufacturing Processes and Quality Assurance for how does alternator work

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how does alternator work’

- Comprehensive Cost and Pricing Analysis for how does alternator work Sourcing

- Alternatives Analysis: Comparing how does alternator work With Other Solutions

- Essential Technical Properties and Trade Terminology for how does alternator work

- Navigating Market Dynamics and Sourcing Trends in the how does alternator work Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how does alternator work

- Strategic Sourcing Conclusion and Outlook for how does alternator work

- Important Disclaimer & Terms of Use

Understanding how does alternator work Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Alternator | Uses a rotating magnetic field to generate AC, then rectifies to DC. | Automotive, Heavy Machinery | Pros: Reliable, widely available. Cons: Can be less efficient at low RPM. |

| High-Output Alternator | Designed for increased power output, often featuring larger windings and advanced cooling. | Performance Vehicles, Heavy-Duty Equipment | Pros: Supports high-demand electrical systems. Cons: Higher cost, may require modifications. |

| Brushless Alternator | Eliminates brushes and slip rings, using permanent magnets instead. | Renewable Energy Systems, Marine Applications | Pros: Lower maintenance, increased durability. Cons: Initial investment can be high. |

| Smart Alternator | Integrated with advanced electronics for real-time monitoring and adjustments. | Modern Automotive, Fleet Management | Pros: Optimizes battery life, enhances efficiency. Cons: Complexity may require specialized knowledge for repairs. |

| Dual-Voltage Alternator | Capable of producing both 12V and 24V outputs, often used in military and specialized applications. | Military Vehicles, Industrial Equipment | Pros: Versatile, can support multiple systems. Cons: May be overkill for standard applications. |

What Are the Characteristics of Conventional Alternators?

Conventional alternators are the most common type found in vehicles, utilizing a rotating magnetic field to generate alternating current (AC) which is then converted to direct current (DC) for charging the battery. They are characterized by their simplicity and reliability, making them a staple in automotive applications. Buyers should consider the compatibility with their vehicle’s electrical system and the availability of replacement parts, as these units are widely produced and supported.

How Do High-Output Alternators Benefit Performance Vehicles?

High-output alternators are engineered for increased power output, often incorporating larger windings and enhanced cooling mechanisms. These units are ideal for performance vehicles or heavy-duty equipment that require substantial electrical power for additional accessories, such as sound systems or winches. While they provide significant advantages in power management, potential buyers should weigh the higher costs and ensure their vehicle can accommodate the increased load.

What Advantages Do Brushless Alternators Offer?

Brushless alternators utilize permanent magnets instead of brushes and slip rings, resulting in lower maintenance requirements and increased durability. They are particularly suitable for renewable energy systems and marine applications where reliability is crucial. Buyers should consider the initial investment cost, which can be higher than traditional models, but the long-term savings on maintenance can offset this.

How Do Smart Alternators Enhance Efficiency?

Smart alternators are equipped with advanced electronics that allow for real-time monitoring and adjustments to optimize performance. These units are becoming increasingly common in modern automotive applications and fleet management, as they enhance battery life and overall efficiency. However, the complexity of these systems may require specialized knowledge for repairs, making it essential for buyers to consider the availability of technical support.

In What Scenarios Are Dual-Voltage Alternators Necessary?

Dual-voltage alternators can produce both 12V and 24V outputs, making them particularly valuable in military vehicles and specialized industrial equipment. Their versatility allows them to support multiple systems effectively. While they offer significant benefits in specific applications, potential buyers should assess whether the added complexity and cost align with their operational needs, as these units may be excessive for standard applications.

Key Industrial Applications of how does alternator work

| Industry/Sector | Specific Application of how does alternator work | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Vehicle electrical systems for charging batteries | Ensures reliable operation of vehicles, reducing downtime and maintenance costs | Quality standards, compatibility with vehicle models, warranty terms |

| Renewable Energy | Wind turbine systems for energy generation | Converts mechanical energy from wind into electrical energy, enhancing energy efficiency | Durability in harsh environments, efficiency ratings, local regulations |

| Agriculture | Agricultural machinery such as tractors and harvesters | Powers electrical systems for improved productivity and efficiency in farming operations | Voltage requirements, environmental resistance, supplier reliability |

| Marine | Shipboard electrical systems for navigation and communication | Guarantees essential systems remain operational, enhancing safety and operational efficiency | Compliance with maritime standards, robustness against corrosion |

| Construction | Generators for construction sites | Provides reliable power supply for tools and equipment, minimizing project delays | Fuel efficiency, power output specifications, support and service options |

How Is ‘How Does Alternator Work’ Applied in the Automotive Industry?

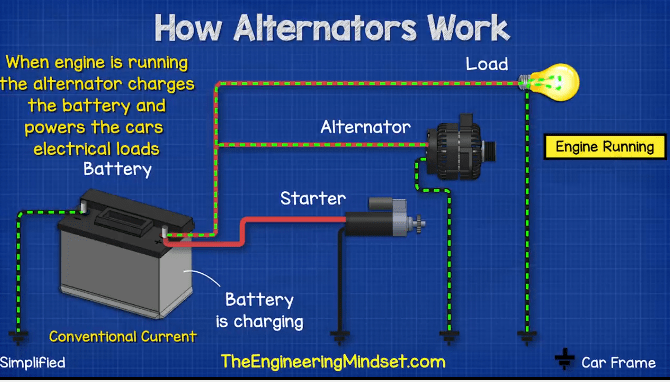

In the automotive sector, alternators are crucial for maintaining the electrical systems of vehicles. They convert mechanical energy from the engine into electrical energy, ensuring that the battery remains charged and that the vehicle’s electrical components function properly. This application is vital for reducing vehicle downtime and maintenance costs, which can be significant in regions with challenging driving conditions, such as those found in Africa and South America. Buyers should consider compatibility with various vehicle models and ensure adherence to quality standards to avoid operational failures.

What Role Do Alternators Play in Renewable Energy Applications?

In renewable energy, particularly in wind turbine systems, alternators convert mechanical energy generated by wind into electrical energy. This process enhances energy efficiency and contributes to sustainable power generation. For international buyers, especially in Europe where renewable energy is a priority, sourcing durable alternators that can withstand harsh environmental conditions is essential. Additionally, ensuring compliance with local regulations and efficiency ratings will maximize the return on investment.

How Are Alternators Utilized in Agricultural Machinery?

Agricultural machinery, such as tractors and harvesters, rely on alternators to power their electrical systems. By ensuring a continuous power supply, these alternators enhance productivity and efficiency during critical farming operations. For buyers in regions like Brazil, where agriculture is a primary industry, it’s important to evaluate voltage requirements and the alternator’s resistance to environmental factors like dust and moisture. Supplier reliability and after-sales support are also critical considerations for maintaining operational efficiency.

Illustrative image related to how does alternator work

In What Ways Do Alternators Support Marine Operations?

In the marine sector, alternators are integral to shipboard electrical systems, powering navigation, communication, and other essential operations. A reliable alternator ensures that these systems remain functional, enhancing both safety and efficiency. International buyers should focus on sourcing alternators that comply with maritime standards and possess robust designs to resist corrosion from saltwater environments. Evaluating the alternator’s performance under various load conditions is also important to ensure operational reliability.

How Do Alternators Contribute to Construction Site Operations?

On construction sites, alternators are used in generators to provide a reliable power supply for tools and equipment. This application minimizes project delays and enhances overall productivity. Buyers in regions facing energy supply challenges, such as parts of Africa and the Middle East, should prioritize sourcing fuel-efficient alternators with appropriate power output specifications. Additionally, understanding the availability of support and service options is crucial for maintaining continuous operations at construction sites.

3 Common User Pain Points for ‘how does alternator work’ & Their Solutions

Scenario 1: Difficulty Understanding Alternator Functionality in Complex Systems

The Problem: Many B2B buyers in sectors such as automotive manufacturing and maintenance often struggle to grasp the intricate workings of alternators, especially when integrated into complex electrical systems. This lack of understanding can lead to misdiagnosis of electrical issues, resulting in costly repairs and downtime. Buyers may find themselves overwhelmed by technical jargon and intricate diagrams that fail to provide a clear understanding of how alternators operate within larger systems. This confusion can also hinder their ability to effectively communicate specifications and requirements to suppliers and technicians.

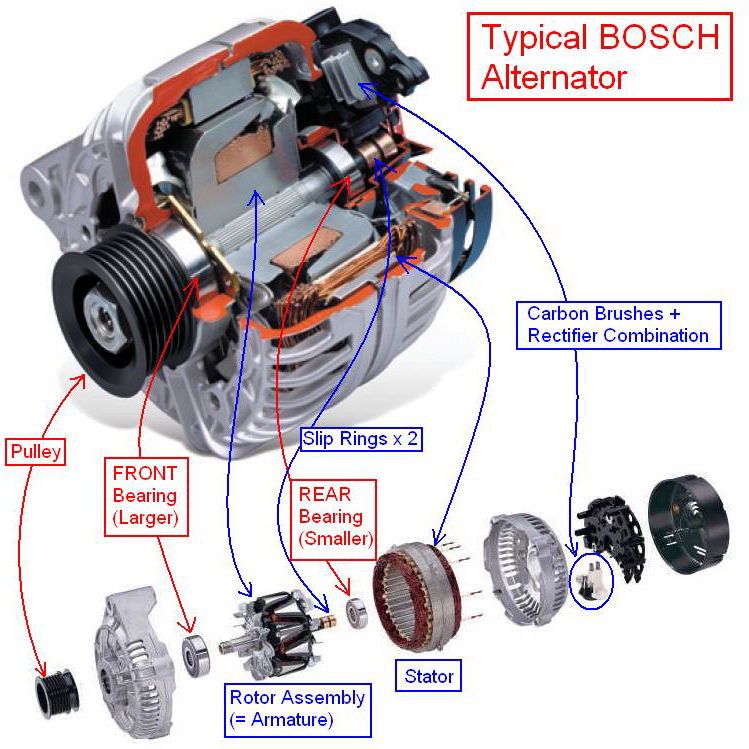

The Solution: To overcome this challenge, B2B buyers should invest in comprehensive training resources or workshops that focus on the fundamentals of alternator functionality. Engaging with expert-led sessions that break down the components—such as rotors, stators, and rectifiers—and their roles in power generation can demystify the process. Additionally, buyers can utilize visual aids, such as simplified diagrams or videos, that illustrate the alternator’s operation in real-time. Collaborating with suppliers who offer detailed technical documentation and support can further enhance understanding and improve communication regarding specifications and requirements.

Scenario 2: Sourcing Quality Alternators and Components

The Problem: In markets across Africa, South America, the Middle East, and Europe, B2B buyers often face challenges in sourcing high-quality alternators and components that meet their operational needs. The risk of encountering counterfeit or substandard products is high, leading to increased maintenance costs and reliability issues. Buyers may also struggle to find suppliers who can provide the specific technical specifications required for their applications, resulting in delays and inefficiencies.

The Solution: To mitigate these sourcing challenges, buyers should establish strong relationships with reputable suppliers known for their quality assurance processes. Conducting thorough research to identify suppliers with a proven track record in the industry is essential. Buyers can request certifications, such as ISO 9001, which indicate adherence to quality management standards. Additionally, leveraging online platforms that specialize in B2B transactions can help buyers compare specifications, read reviews, and verify supplier credibility. Implementing a robust vendor assessment process that includes quality checks and performance reviews will ensure that only reliable alternators and components are sourced.

Scenario 3: Implementing Effective Maintenance Protocols for Alternators

The Problem: B2B buyers in the automotive and industrial sectors often encounter difficulties in establishing effective maintenance protocols for alternators. Without proper maintenance, alternators can fail prematurely, leading to significant operational disruptions and increased costs. Buyers may lack the knowledge to implement preventive measures or may not have access to the necessary tools and resources to conduct regular checks and maintenance.

The Solution: To develop an effective maintenance protocol, buyers should prioritize training for their technical teams on the specific maintenance needs of alternators. This can include regular inspections of key components such as the rotor and rectifier, monitoring voltage output, and checking for signs of wear and tear. Implementing a scheduled maintenance plan that includes documented procedures and checklists can streamline the process. Additionally, partnering with suppliers who offer maintenance services or products can provide access to the necessary tools and expertise. Utilizing technology, such as predictive maintenance software, can also enhance monitoring efforts and help anticipate potential failures before they occur, ensuring the longevity and reliability of alternators.

Illustrative image related to how does alternator work

Strategic Material Selection Guide for how does alternator work

What Materials Are Commonly Used in Alternator Production?

When selecting materials for alternators, it is essential to consider properties that impact performance, durability, and manufacturing complexity. Here, we analyze four common materials used in alternator components, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Copper in Alternators?

Copper is widely used for windings in alternators due to its excellent electrical conductivity and thermal properties. With a high melting point (around 1,984°F or 1,085°C) and good resistance to corrosion, copper effectively supports the high current demands of alternators.

Pros: Copper’s high conductivity ensures minimal energy loss, enhancing the alternator’s efficiency. It is relatively easy to work with, making it suitable for various manufacturing processes.

Cons: The primary downside is its cost, as copper is more expensive than alternatives like aluminum. Additionally, copper is heavier, which can impact the overall weight of the alternator.

Impact on Application: Copper’s compatibility with high temperatures and electrical loads makes it ideal for automotive applications where reliability is crucial.

Considerations for International Buyers: Compliance with international standards such as ASTM B170 for copper wire is essential, particularly for buyers in regions like Africa and South America, where sourcing quality materials can vary.

How Does Aluminum Compare as an Alternator Material?

Aluminum is often used as a cost-effective alternative to copper in alternator windings and housings. It has a lower density, which can reduce the overall weight of the alternator.

Pros: Aluminum is cheaper than copper and offers good corrosion resistance, making it suitable for various environments. Its lightweight nature can improve vehicle fuel efficiency.

Cons: While aluminum has decent conductivity, it is not as efficient as copper. This can lead to higher energy losses, potentially reducing the alternator’s overall performance.

Illustrative image related to how does alternator work

Impact on Application: Aluminum is particularly useful in applications where weight reduction is a priority, such as in electric vehicles.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards, such as ASTM B221 for aluminum extrusions, to guarantee quality and performance.

What Role Does Steel Play in Alternator Construction?

Steel is primarily used for the structural components of alternators, including the frame and rotor shaft. Its strength and durability make it a popular choice.

Pros: Steel offers excellent mechanical properties, including high tensile strength and resistance to deformation. It is also relatively inexpensive compared to other metals.

Cons: Steel can be prone to corrosion if not properly treated, which may lead to premature failure in harsh environments. Additionally, its weight can be a drawback for applications prioritizing lightweight components.

Impact on Application: Steel’s robustness makes it suitable for heavy-duty applications, but its weight may limit its use in performance-oriented designs.

Illustrative image related to how does alternator work

Considerations for International Buyers: Compliance with standards like ASTM A36 for structural steel is critical, especially in regions with varying quality control practices.

How Does Plastic Contribute to Alternator Performance?

Plastics are increasingly used for non-structural components, such as housings and insulation. They offer versatility and can be molded into complex shapes.

Pros: Plastics are lightweight, corrosion-resistant, and can be produced at a lower cost. They also provide good electrical insulation, which is vital for safety.

Cons: Plastics generally have lower thermal resistance compared to metals, which can limit their use in high-temperature applications. They may also degrade over time when exposed to UV light.

Impact on Application: Plastics are suitable for components that do not experience high thermal or mechanical stress, making them ideal for housings.

Considerations for International Buyers: Buyers should look for plastics that meet standards such as ISO 9001 for quality management systems, ensuring reliability in various applications.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for how does alternator work | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings in alternators | Excellent electrical conductivity | High cost and weight | High |

| Aluminum | Windings and housings | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Steel | Structural components | High strength and durability | Prone to corrosion and heavier | Low |

| Plastic | Non-structural components (housings) | Lightweight and corrosion-resistant | Lower thermal resistance | Low |

This guide provides essential insights for B2B buyers considering material selection for alternators, highlighting the importance of balancing performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how does alternator work

What Are the Main Stages of Alternator Manufacturing Processes?

The manufacturing of alternators involves several critical stages, each designed to ensure optimal performance and quality. Understanding these stages is essential for B2B buyers looking to source reliable alternators for various applications.

How Are Materials Prepared for Alternator Manufacturing?

The first step in the manufacturing process is material preparation. Key materials for alternators include high-grade steel for the rotor and stator, copper for winding, and silicon for the rectifier diodes. These materials undergo stringent quality checks upon arrival, ensuring they meet specified standards.

-

Material Selection: Suppliers must source materials that comply with international standards such as ISO 9001. This ensures durability and efficiency.

-

Pre-processing: Materials are cut, cleaned, and treated to remove impurities. This step enhances the longevity and performance of the components.

-

Testing: Material properties are tested for conductivity, tensile strength, and magnetic permeability. This guarantees that only high-quality materials proceed to the next stage.

What Techniques Are Used in Forming Alternator Components?

Forming techniques play a significant role in shaping the individual components of an alternator.

-

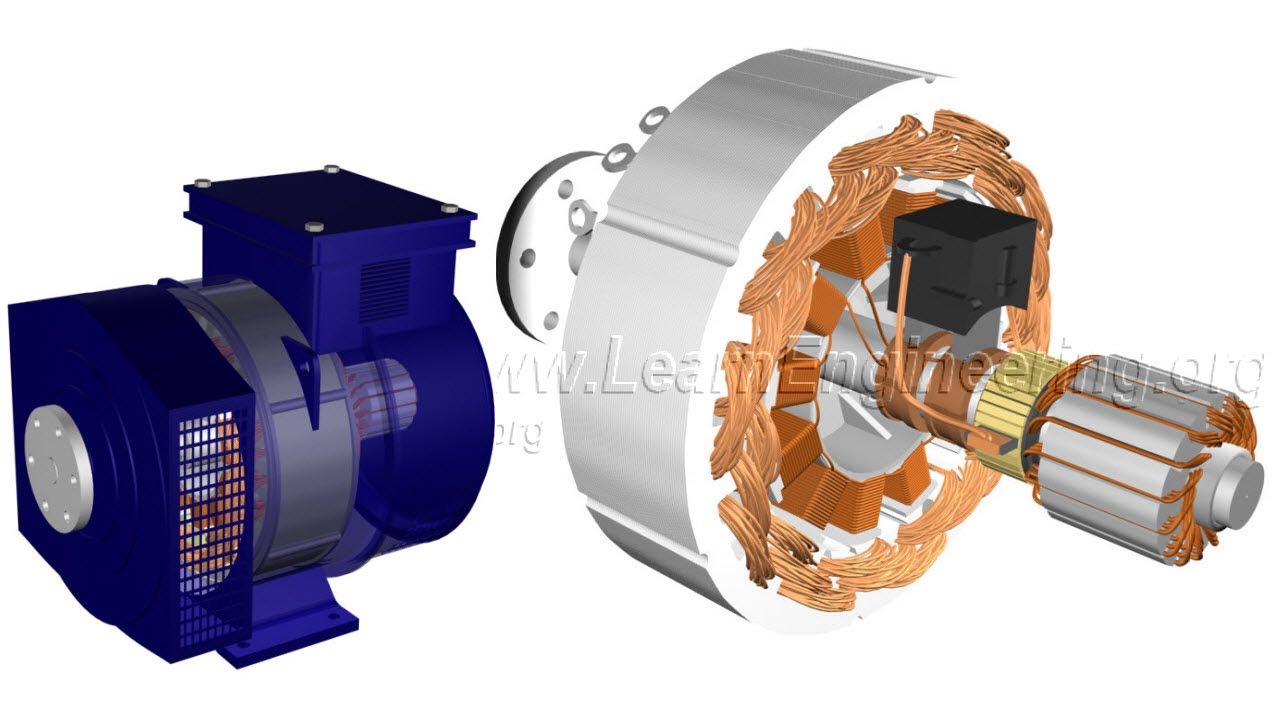

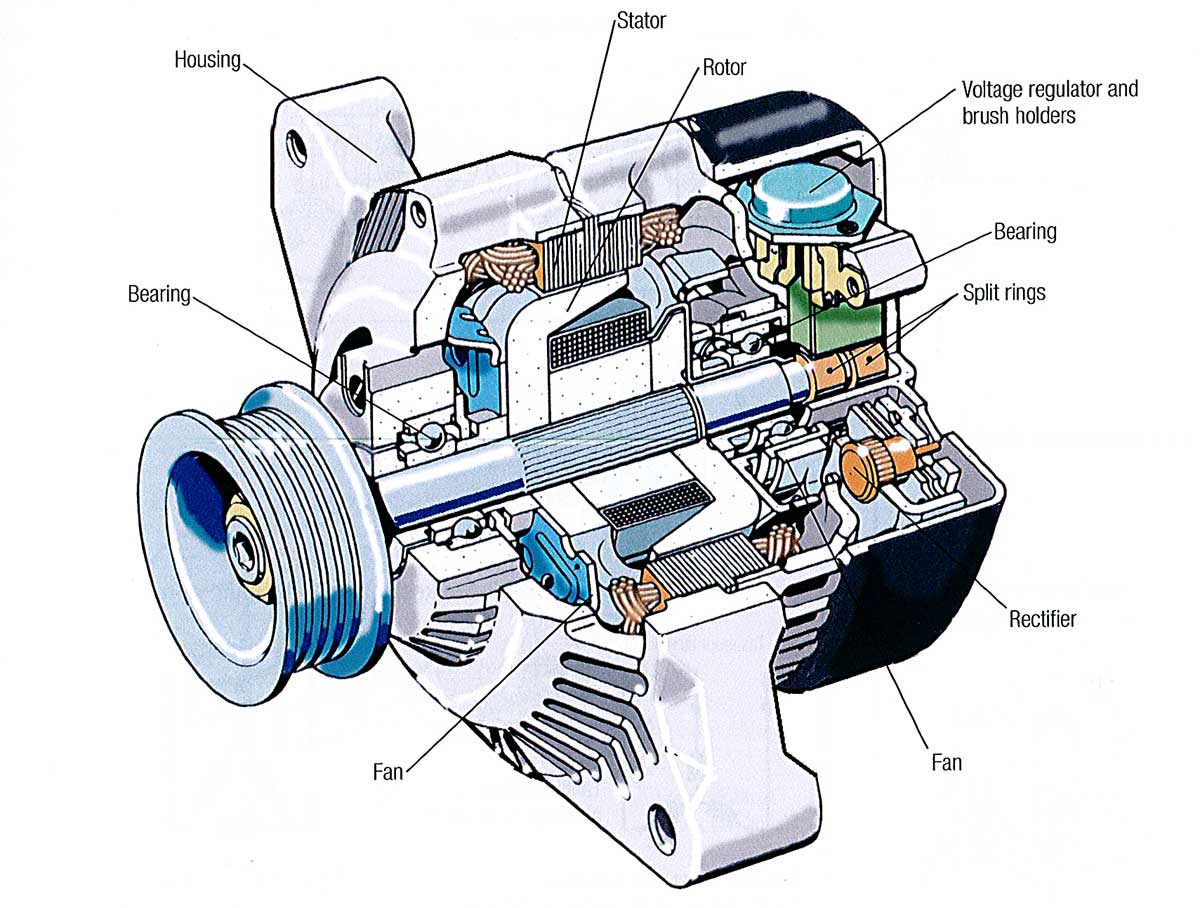

Stator and Rotor Fabrication: The stator and rotor are typically fabricated using stamping and machining processes. Stamping forms the essential shapes, while machining ensures precision dimensions.

-

Winding: The copper wire is wound around the stator to create the electromagnetic coils. Automated winding machines ensure uniformity and consistency in the number of turns.

-

Assembly of Components: The formed components are assembled meticulously. Robotic arms may assist in positioning, ensuring alignment and reducing human error.

How Is Assembly Managed in the Alternator Manufacturing Process?

Assembly is a critical phase that combines all individual components into a functioning alternator.

-

Component Integration: The rotor is fitted into the stator, followed by the installation of the rectifier and voltage regulator. Each component must be properly secured to avoid malfunctions.

-

Quality Control Points: At this stage, several quality control checks are performed, including visual inspections and functional tests to ensure correct assembly.

-

Testing for Functionality: Initial tests are conducted to check for electrical continuity, mechanical integrity, and overall functionality. This ensures the alternator operates as intended before moving to the finishing stage.

What Finishing Processes Are Involved in Alternator Manufacturing?

The finishing stage enhances the alternator’s durability and aesthetic appeal.

-

Surface Treatment: Components undergo surface treatments such as anodizing or powder coating to improve corrosion resistance and enhance appearance.

-

Final Assembly: The alternator is fully assembled, including the installation of protective covers and labeling according to international standards.

-

Packaging: Finished alternators are carefully packaged to avoid damage during transit. Packaging must comply with international shipping standards to ensure safe delivery to buyers.

What Quality Assurance Standards Are Relevant for Alternator Manufacturing?

Quality assurance is crucial in alternator manufacturing, ensuring that products meet customer expectations and regulatory requirements.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are essential for manufacturers to achieve and maintain high quality in their processes. Compliance with these standards indicates that the manufacturer has a quality management system in place, ensuring consistency and reliability in production.

-

ISO 9001: This standard emphasizes the importance of a systematic approach to managing processes and ensuring continuous improvement.

-

CE Marking: For alternators sold in Europe, CE marking signifies compliance with EU safety and environmental regulations.

-

API Standards: For alternators used in industrial applications, compliance with American Petroleum Institute (API) standards may be necessary.

What Are Key Quality Control Checkpoints in Alternator Manufacturing?

Quality control checkpoints are critical throughout the manufacturing process, ensuring that each alternator meets specific quality standards.

-

Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): Ongoing inspections during production help catch any defects early, minimizing waste and rework.

-

Final Quality Control (FQC): Before shipping, each alternator undergoes comprehensive testing to confirm that it meets performance specifications and regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, ensuring supplier quality is paramount to avoid costly failures and enhance supply chain reliability.

What Verification Methods Can Buyers Use?

-

Supplier Audits: Conducting audits of the manufacturing facilities can provide insights into the quality management practices in place. This includes evaluating adherence to ISO standards and checking for necessary certifications.

-

Quality Reports: Requesting quality reports can help buyers understand the supplier’s performance over time, including defect rates and customer feedback.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and final product quality. These services often include detailed reporting and certification.

What Quality Control Nuances Should International Buyers Be Aware Of?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances when sourcing alternators.

-

Regulatory Compliance: Different regions may have distinct regulatory requirements that must be met for importation. Understanding these can prevent delays and additional costs.

-

Cultural Considerations: Communication styles and business practices may vary across cultures. Building strong relationships with suppliers can enhance transparency and trust.

-

Logistics and Shipping Standards: Ensure that suppliers adhere to international shipping standards to avoid damage during transit. This includes proper packaging and labeling of products.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing alternators, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how does alternator work’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to understand the workings of alternators and the critical factors to consider when procuring them. Whether you are involved in automotive manufacturing, maintenance, or other applications requiring reliable electrical systems, this checklist will help you navigate the complexities of alternator technology and supplier selection.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the alternators you need, including voltage ratings, power output, and compatibility with existing systems. Understanding these specifications is vital to ensure that the alternators meet your operational needs and can perform reliably under various conditions.

- Consider application needs: Different applications may require specific types of alternators, such as those designed for automotive or industrial use.

- Identify environmental factors: Temperature, humidity, and exposure to contaminants can affect alternator performance.

Step 2: Research Available Technologies

Investigate the various technologies used in alternators, such as brushless versus brushed systems, and the differences between traditional and modern designs. This knowledge will help you make informed decisions based on efficiency, durability, and maintenance requirements.

- Evaluate efficiency ratings: Higher efficiency translates to lower operational costs and better performance.

- Consider maintenance needs: Some designs may require more frequent maintenance, impacting your total cost of ownership.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thoroughly vet their capabilities and reliability. Request company profiles, product catalogs, and case studies, and seek references from buyers in similar industries or regions.

Illustrative image related to how does alternator work

- Check industry certifications: Look for suppliers with ISO certifications or other relevant industry standards, which can indicate quality and reliability.

- Analyze customer feedback: Reviews and testimonials can provide insights into the supplier’s product performance and service quality.

Step 4: Request Samples and Technical Documentation

Always request samples of the alternators and any accompanying technical documentation, including installation guides and user manuals. This step is essential for assessing product quality and ensuring compatibility with your requirements.

- Conduct performance testing: Evaluate the samples under your specific operating conditions to verify their performance.

- Review technical documentation: Ensure that the documentation is comprehensive and easy to understand for your engineering and maintenance teams.

Step 5: Negotiate Terms and Conditions

Engage in discussions with potential suppliers to negotiate favorable terms regarding pricing, warranty, delivery schedules, and after-sales support. Establishing clear terms is crucial to protect your investment and ensure a smooth procurement process.

- Assess warranty options: A robust warranty can safeguard against defects and performance issues.

- Clarify delivery timelines: Ensure that the supplier can meet your delivery requirements to avoid potential project delays.

Step 6: Implement a Quality Control Process

Once you have selected a supplier, establish a quality control process to monitor the performance of the alternators upon delivery and during operation. This proactive approach can help identify and mitigate any issues early on.

- Conduct regular inspections: Implement routine checks to ensure that the alternators are functioning as expected.

- Gather performance data: Collect data on efficiency and reliability to inform future purchasing decisions.

Step 7: Build Long-Term Supplier Relationships

Consider developing long-term relationships with reliable suppliers to benefit from better pricing, service, and product innovations. Strong partnerships can enhance supply chain resilience and ensure you have access to the latest advancements in alternator technology.

- Engage in regular communication: Keep lines of communication open for feedback and updates on product offerings.

- Collaborate on product development: Work with suppliers to tailor products that meet your evolving needs.

By following this checklist, you can ensure a comprehensive understanding of how alternators work and make informed procurement decisions that align with your business objectives.

Illustrative image related to how does alternator work

Comprehensive Cost and Pricing Analysis for how does alternator work Sourcing

When considering the sourcing of alternators, a comprehensive understanding of the cost structure and pricing dynamics is crucial for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

What are the Major Cost Components in Alternator Manufacturing?

-

Materials: The primary materials involved in alternator production include copper for wiring, steel for the rotor and stator, and various plastics for housing and insulation. The prices of these materials can fluctuate significantly based on global supply chain conditions and market demand.

-

Labor: Labor costs vary widely depending on the region of production. Countries with lower labor costs may offer more competitive pricing, but it’s essential to consider the skill level of the workforce, as experienced technicians can lead to higher quality manufacturing.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these costs, impacting the overall pricing structure.

-

Tooling: Specialized equipment and molds are often required for producing alternators. The initial investment in tooling can be substantial, but it is amortized over the production volume. Custom tooling for specific designs may also increase costs.

-

Quality Control (QC): Ensuring that the alternators meet industry standards requires rigorous QC processes. The costs associated with testing and certification (such as ISO standards) can affect pricing but are critical for maintaining product reliability.

-

Logistics: Transportation costs, including shipping and handling, can significantly impact the final price, particularly for international buyers. Factors such as distance, mode of transport, and tariffs must be carefully considered.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on competition, market demand, and the supplier’s position in the supply chain.

How Do Pricing Influencers Affect Alternator Sourcing?

-

Volume and Minimum Order Quantity (MOQ): Higher volume orders often lead to lower unit costs due to economies of scale. Negotiating MOQs can help buyers achieve better pricing.

-

Specifications and Customization: Customized alternators may incur additional costs due to unique design requirements. Buyers should clearly define specifications to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (like CE or UL) may raise costs but can lead to enhanced performance and reliability, which is vital for long-term value.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better quality assurance and customer support.

-

Incoterms: The chosen Incoterms can significantly impact the total cost. Buyers should understand the responsibilities for shipping, insurance, and tariffs associated with their chosen terms to avoid hidden costs.

What Are Effective Buyer Tips for Negotiating Costs?

-

Negotiation Strategies: Engage suppliers in discussions about pricing, especially if you can commit to larger volumes or longer-term contracts. Highlighting your reliability as a buyer can also strengthen your negotiating position.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the upfront cost. Consider factors such as durability, maintenance, and performance to determine the best value.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa and South America, consider potential additional costs such as import duties, taxes, and currency fluctuations. Understanding local market dynamics can aid in more effective negotiations.

-

Quality vs. Price: While lower prices are attractive, they may compromise quality. Striking a balance between cost and quality is vital for ensuring long-term operational success.

Conclusion

Navigating the complexities of alternator sourcing requires a comprehensive understanding of the cost structure and pricing dynamics. By considering various cost components, recognizing pricing influencers, and employing effective negotiation strategies, B2B buyers can make informed decisions that align with their operational needs and budget constraints. While this analysis provides a foundational understanding, actual prices may vary significantly based on supplier and market conditions, thus necessitating careful research and negotiation.

Alternatives Analysis: Comparing how does alternator work With Other Solutions

Introduction to Alternatives in Power Generation

When evaluating power generation solutions, particularly for automotive and industrial applications, understanding the operational mechanics and comparative advantages of various technologies is crucial. The alternator, a widely adopted device for converting mechanical energy into electrical energy, faces competition from several alternatives. This analysis compares the workings of the alternator against other viable solutions, highlighting performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | How Does Alternator Work | Alternative 1 Name: Generator | Alternative 2 Name: Battery System |

|---|---|---|---|

| Performance | High efficiency in charging and power supply; generates AC to DC effectively. | Versatile; can produce AC or DC but less efficient at low RPMs. | Limited to stored energy; not a primary power source. |

| Cost | Moderate initial investment; long lifespan. | Higher upfront cost; variable based on capacity. | Lower initial cost; requires frequent replacement. |

| Ease of Implementation | Simple installation; widely supported by manufacturers. | Requires more technical expertise; installation complexity varies. | Plug-and-play options available, but integration can be tricky. |

| Maintenance | Low maintenance; periodic checks needed. | Regular maintenance required; oil changes and part replacements are common. | Minimal maintenance; replacement depends on usage and technology. |

| Best Use Case | Ideal for vehicles and applications needing consistent power supply. | Suitable for remote locations and industrial applications requiring high power. | Best for applications needing temporary power or backup solutions. |

Detailed Breakdown of Alternatives

Generator

Generators function similarly to alternators but are capable of producing both AC and DC power. They are often used in remote applications or as backup power sources. The main advantage of generators is their versatility and ability to operate independently of an engine, making them suitable for a variety of situations. However, they can be less efficient at lower RPMs and typically require more maintenance, including regular oil changes and component replacements. This added complexity can lead to higher operational costs.

Battery System

Battery systems, particularly in the context of electric vehicles or portable power applications, store electrical energy for later use. They are advantageous for their lower initial cost and ease of integration in certain applications. However, batteries have limited lifespans and can require frequent replacements, especially in high-use scenarios. While they are excellent for backup power or short-term energy storage, they are not designed to be a primary power source and can lead to higher long-term costs due to replacement needs.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the right power generation solution depends on specific operational requirements, budget constraints, and maintenance capabilities. The alternator offers a balanced approach for automotive applications, combining efficiency, moderate cost, and low maintenance needs. On the other hand, generators provide flexibility in power generation, making them suitable for diverse applications, albeit at a higher maintenance cost. Battery systems, while cost-effective for short-term use, may not be ideal for continuous power demands. Ultimately, understanding the unique advantages and limitations of each solution will empower buyers to make informed decisions tailored to their operational needs.

Illustrative image related to how does alternator work

Essential Technical Properties and Trade Terminology for how does alternator work

What Are the Key Technical Properties of an Alternator?

Understanding the technical properties of alternators is crucial for B2B buyers, especially when making purchasing decisions for automotive or industrial applications. Here are some critical specifications to consider:

-

Material Grade

Alternators are typically constructed from high-grade aluminum or steel for the housing, while copper is used for the winding coils. The material grade affects durability, weight, and thermal conductivity. For B2B buyers, selecting alternators with superior materials ensures longevity and reliability, particularly in demanding environments like heavy machinery or vehicles operating in extreme conditions. -

Output Voltage

The standard output voltage for automotive alternators is typically between 12V to 14.5V, while industrial models may produce higher voltages. Understanding output voltage is essential for ensuring compatibility with the battery and electrical systems. Buyers should ensure that the alternator’s output meets the operational requirements of their specific applications to avoid potential electrical failures. -

Power Rating (Wattage)

Alternators are rated based on their power output, usually measured in watts or amperes. This rating determines how much electrical load an alternator can handle, which is vital for running multiple electrical systems simultaneously. B2B buyers should assess their electrical needs to select an alternator with an adequate power rating, ensuring efficient performance without overloading the system. -

Efficiency Rating

The efficiency of an alternator refers to its ability to convert mechanical energy into electrical energy without excessive heat loss. An efficient alternator reduces fuel consumption and operational costs, making it an important factor for businesses concerned with sustainability and cost-effectiveness. Opting for high-efficiency models can lead to significant long-term savings. -

Tolerance Levels

Tolerance levels in alternator manufacturing refer to the allowable deviation in dimensions and performance specifications. Precise tolerances are essential for ensuring proper fitment and operation within the assembly. Buyers must consider tolerance specifications to avoid issues related to alignment and functionality, which can lead to increased maintenance costs.

What Are the Common Trade Terms Associated with Alternators?

Familiarity with industry jargon can facilitate smoother transactions and negotiations in the B2B marketplace. Here are some essential terms to understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the original manufacturing of vehicles or equipment. When purchasing alternators, opting for OEM parts often ensures compatibility and adherence to industry standards, which is critical for maintaining warranty and performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for buyers to understand inventory management and budgeting. Knowing the MOQ helps companies plan their purchases effectively, ensuring they meet supply needs without excessive overstock. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. For B2B buyers, submitting an RFQ allows for competitive pricing and helps in making informed purchasing decisions. It’s an essential tool for negotiating terms and ensuring cost-effectiveness. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms is vital for B2B transactions, as they dictate who bears the risk and cost at various stages of the shipping process, ultimately influencing total landed costs. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is essential for inventory planning and ensuring that production schedules are met. Longer lead times can impact operational efficiency, making it important to factor this into procurement strategies.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the alternator market more effectively, ensuring they select products that meet their operational needs while optimizing procurement processes.

Navigating Market Dynamics and Sourcing Trends in the how does alternator work Sector

What Are the Key Market Dynamics Influencing the Alternator Sector?

The global alternator market is currently experiencing significant growth, driven by various factors, including the rising demand for efficient automotive power systems and the expansion of the electric vehicle (EV) market. As countries like Nigeria and Brazil focus on improving their transportation infrastructure, the demand for reliable and high-performance alternators is set to increase. Additionally, the integration of advanced technologies such as smart alternators—which incorporate features for better energy management—presents an emerging trend that B2B buyers should watch closely.

International B2B buyers must navigate a landscape characterized by competitive pricing, technological advancements, and a shift towards sourcing from suppliers who can demonstrate innovation and reliability. In regions like the Middle East and Africa, local manufacturing initiatives are gaining traction, allowing buyers to source products more efficiently while supporting regional economies. Moreover, the importance of after-sales service and warranty offerings is becoming a differentiating factor for suppliers, influencing buyer decisions.

Illustrative image related to how does alternator work

How Is Sustainability and Ethical Sourcing Shaping the Alternator Industry?

As environmental concerns grow, sustainability has become a focal point in the alternator sector. B2B buyers are increasingly prioritizing suppliers that adopt eco-friendly practices in their manufacturing processes. This includes the use of recyclable materials, reduction of waste, and minimizing the carbon footprint associated with production.

Ethical sourcing is equally vital, as it ensures that materials used in alternator manufacturing are procured responsibly. Certifications like ISO 14001 for environmental management and adherence to the Conflict Minerals Act are becoming essential for suppliers aiming to appeal to conscientious buyers. By choosing suppliers committed to sustainability, B2B buyers not only enhance their corporate social responsibility (CSR) profiles but also meet the growing consumer demand for greener products.

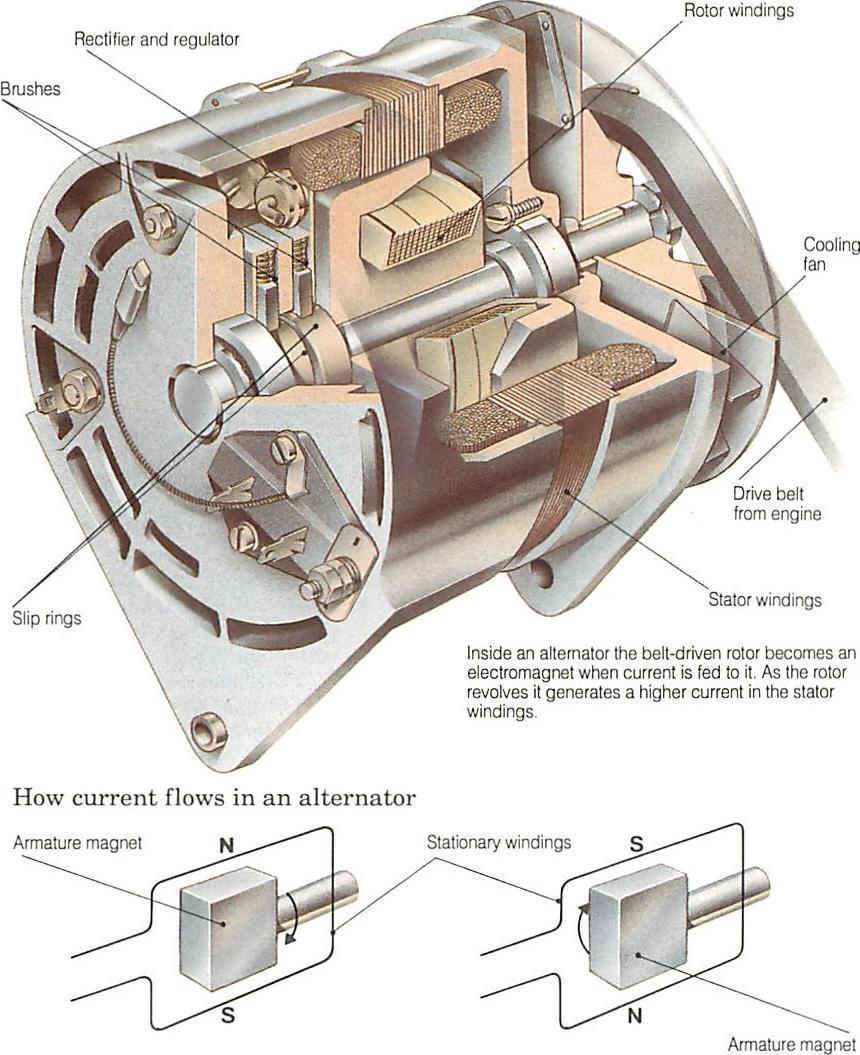

What Is the Brief Evolution of the Alternator?

The alternator has evolved significantly since its inception in the early 20th century. Initially designed for automotive applications, its role has expanded with advancements in technology. The shift from traditional generators to alternators in vehicles marked a significant milestone, as alternators are more efficient at generating electricity, especially at lower engine speeds.

Over the decades, the introduction of electronic voltage regulators and advancements in materials have further optimized alternator performance and reliability. Today, the focus is on integrating smart technologies that allow alternators to communicate with vehicle systems for improved energy management, reflecting the ongoing evolution of this critical component in modern vehicles. This historical context is crucial for B2B buyers to understand the trajectory of product development and the implications for sourcing decisions.

Illustrative image related to how does alternator work

Frequently Asked Questions (FAQs) for B2B Buyers of how does alternator work

-

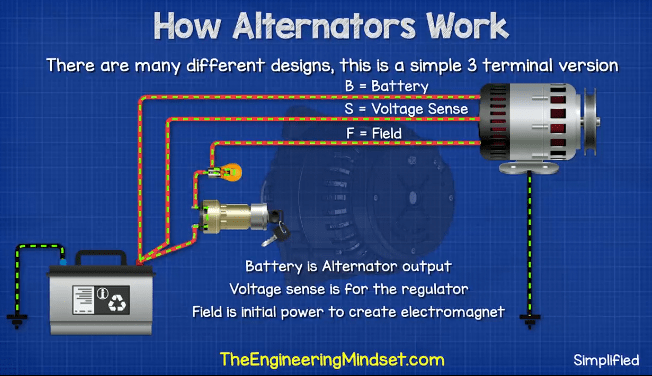

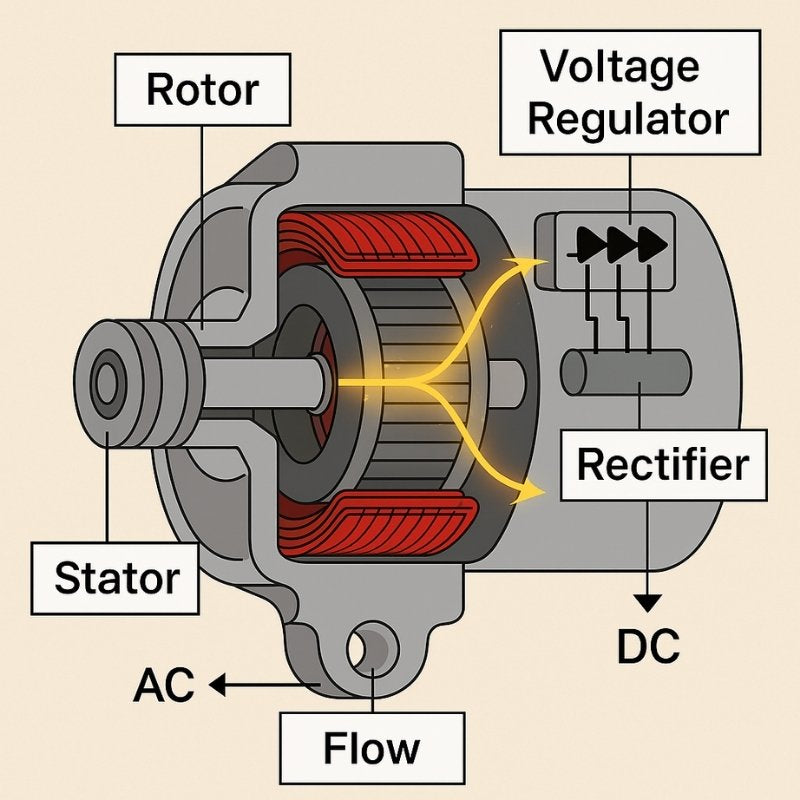

How does an alternator convert mechanical energy into electrical energy?

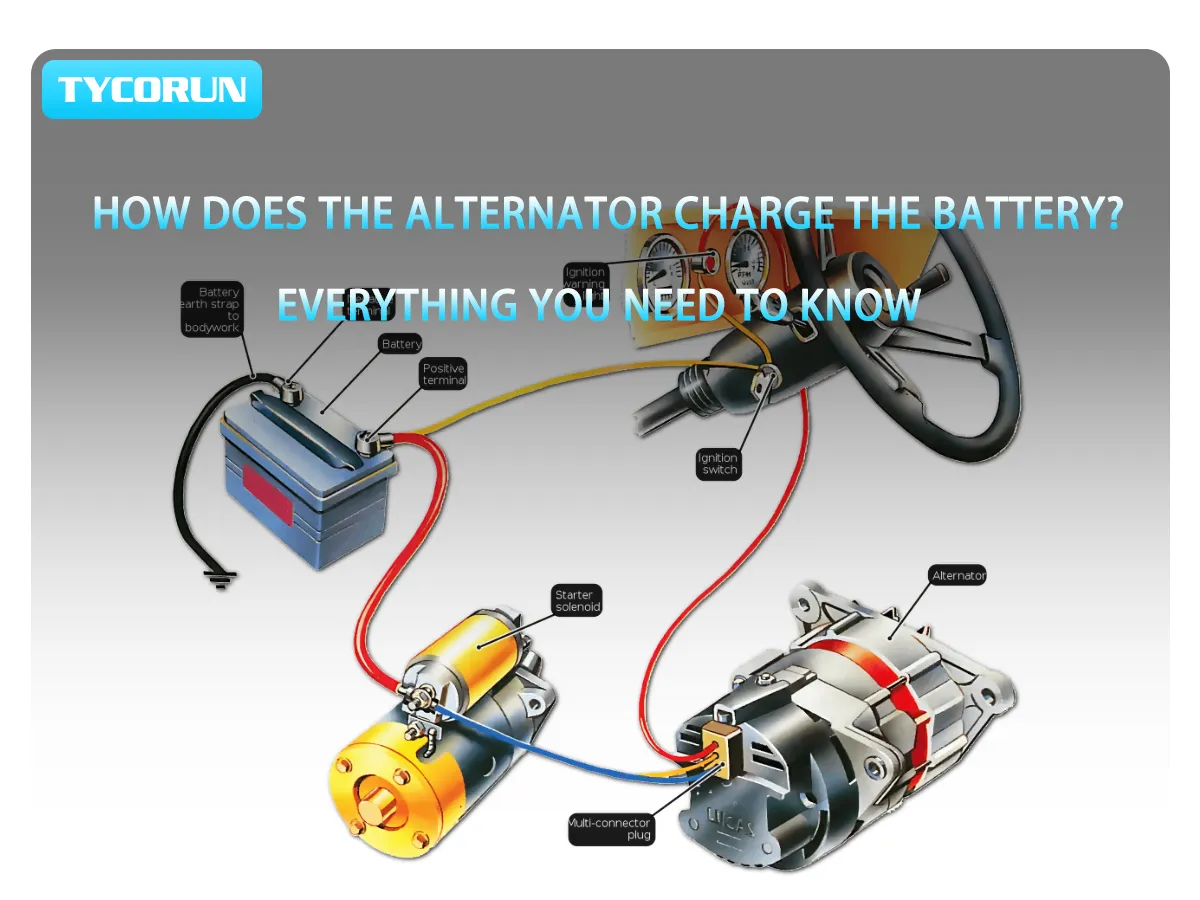

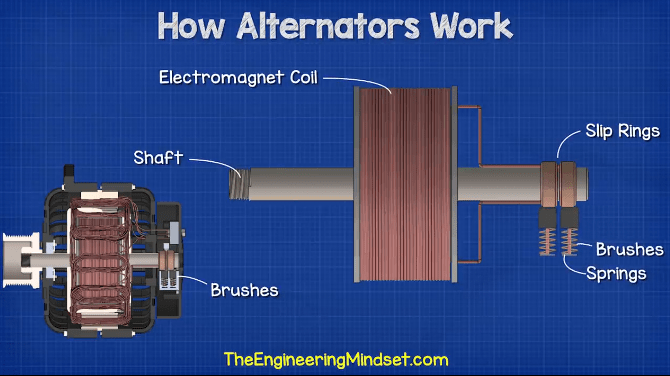

An alternator converts mechanical energy into electrical energy through electromagnetic induction. As the vehicle’s engine runs, it turns a drive belt connected to the alternator’s rotor. This rotor, which is an electromagnet, spins within the stator—a stationary set of coils. This movement generates alternating current (AC) in the stator windings, which is then converted to direct current (DC) using a rectifier, allowing the alternator to charge the battery and power the vehicle’s electrical systems. -

What are the main components of an alternator?

The primary components of an alternator include the rotor, stator, rectifier, voltage regulator, and brushes. The rotor creates a magnetic field that spins inside the stator, which contains coils of wire. This motion induces AC voltage, which the rectifier converts to DC. The voltage regulator ensures that the output voltage remains stable, protecting the battery and electrical components from damage due to voltage fluctuations. -

What should I consider when sourcing alternators internationally?

When sourcing alternators, consider the manufacturer’s reputation, product quality, and compliance with international standards. Verify certifications and quality assurance processes to ensure reliability. Additionally, assess the supplier’s ability to provide after-sales support and warranty services. Understanding local regulations and import duties in your region will also help in making informed purchasing decisions. -

What are the typical minimum order quantities (MOQs) for alternators?

Minimum order quantities for alternators can vary significantly based on the supplier and the type of alternator being procured. Generally, MOQs can range from a few units for small suppliers to hundreds or thousands for larger manufacturers. It’s crucial to communicate your specific needs with potential suppliers to negotiate favorable terms that align with your business requirements. -

How can I vet suppliers when purchasing alternators?

To effectively vet suppliers, conduct thorough research on their business history, customer reviews, and product quality. Request references from previous clients and check their compliance with international quality standards. Utilizing platforms that offer supplier ratings and certifications can also provide insight into their reliability. Consider visiting the manufacturing site if feasible, to inspect the production processes and quality control measures firsthand. -

What payment terms are commonly offered by alternator suppliers?

Payment terms can vary widely among alternator suppliers. Common options include upfront payments, net 30 or net 60 terms, and letter of credit arrangements for larger orders. It’s essential to clarify these terms before finalizing a deal, as they can impact cash flow and overall project financing. Look for suppliers who offer flexible terms that align with your financial capabilities and purchasing cycle. -

What quality assurance measures should I expect from alternator manufacturers?

Reputable alternator manufacturers should implement strict quality assurance measures, including regular testing of their products to meet industry standards. Look for suppliers that offer certifications such as ISO 9001 or similar. Additionally, inquire about their testing protocols, warranty policies, and how they handle defective products. A robust QA process ensures the alternators you receive are reliable and meet your performance expectations. -

How does logistics play a role in sourcing alternators from abroad?

Logistics is crucial when sourcing alternators internationally, as it affects delivery times and costs. Evaluate the supplier’s shipping options, including freight forwarders and shipping methods (air vs. sea). Understand customs regulations and any tariffs that may apply to your order. Establish clear communication with your supplier regarding shipping timelines and tracking to ensure a smooth procurement process and timely delivery of your alternators.

Top 2 How Does Alternator Work Manufacturers & Suppliers List

1. Electude – Alternator Essentials

Domain: electude.com

Registered: 2005 (20 years)

Introduction: An alternator is a crucial component in automotive systems that converts mechanical energy into electrical energy to generate power for the vehicle’s electrical consumer units and the battery. Key components include:

– Pulley: Transfers mechanical energy from the engine to the alternator.

– Rotor: Creates the magnetic field for generating alternating current.

– Stator: The static part where vol…

2. The Engineering Mindset – Car Alternator

Domain: theengineeringmindset.com

Registered: 2015 (10 years)

Introduction: The car alternator is an essential component of combustion engine vehicles’ electrical systems. It generates electricity by converting mechanical energy from the engine into electrical energy. The alternator produces alternating current (AC) electricity, which is then converted into direct current (DC) by a rectifier for use in the vehicle’s electrical components. Key parts of the alternator inclu…

Strategic Sourcing Conclusion and Outlook for how does alternator work

In summary, understanding how an alternator functions is crucial for international B2B buyers, especially those in sectors reliant on automotive and electrical components. An alternator efficiently converts mechanical energy into DC electrical energy, ensuring the continuous operation of vehicle electrical systems and battery charging. Key components such as the rotor, stator, rectifier, and voltage regulator work in concert to achieve this, highlighting the importance of quality and reliability in sourcing these parts.

Strategic sourcing can significantly enhance supply chain efficiency and reduce costs, enabling businesses in Africa, South America, the Middle East, and Europe to secure high-performance alternators that meet their specific needs. By investing in robust supplier relationships and prioritizing quality, companies can ensure they have access to the latest advancements in alternator technology, ultimately leading to improved operational performance.

As we look to the future, international buyers are encouraged to leverage market insights and prioritize partnerships with suppliers that demonstrate innovation and reliability. Embrace the opportunity to enhance your sourcing strategy today, ensuring that your business remains competitive in an evolving global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.