Introduction: Navigating the Global Market for best alternator brands

In today’s global market, sourcing the best alternator brands presents a significant challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. As electrical demands in vehicles escalate, the need for reliable and efficient alternators has never been more critical. This comprehensive guide delves into the various types of alternators available, their applications across different industries, and essential factors to consider when selecting a supplier.

From high-output units required for performance vehicles to standard alternators suited for everyday applications, this guide provides a thorough analysis of the leading brands that meet diverse operational needs. It also addresses supplier vetting processes, helping buyers identify reputable manufacturers and distributors, while considering cost-effectiveness and warranty options.

By equipping B2B buyers with actionable insights, this guide empowers informed purchasing decisions that can enhance operational efficiency and reduce downtime. Whether you’re looking to upgrade existing systems or source replacements, understanding the landscape of alternator brands will enable you to navigate the complexities of the market with confidence, ensuring your investments yield the best possible returns.

Table Of Contents

- Top 2 Best Alternator Brands Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best alternator brands

- Understanding best alternator brands Types and Variations

- Key Industrial Applications of best alternator brands

- 3 Common User Pain Points for ‘best alternator brands’ & Their Solutions

- Strategic Material Selection Guide for best alternator brands

- In-depth Look: Manufacturing Processes and Quality Assurance for best alternator brands

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best alternator brands’

- Comprehensive Cost and Pricing Analysis for best alternator brands Sourcing

- Alternatives Analysis: Comparing best alternator brands With Other Solutions

- Essential Technical Properties and Trade Terminology for best alternator brands

- Navigating Market Dynamics and Sourcing Trends in the best alternator brands Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best alternator brands

- Strategic Sourcing Conclusion and Outlook for best alternator brands

- Important Disclaimer & Terms of Use

Understanding best alternator brands Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Output Alternators | Produce 130-220 amps; designed for demanding electrical loads | Performance vehicles, heavy-duty trucks | Pros: Supports high electrical demand; durable. Cons: Higher initial cost; may require additional modifications. |

| Regular Alternators | Standard output; use carbon brushes; lower voltage at high speeds | Standard vehicles, light-duty applications | Pros: Cost-effective; easy to find. Cons: Shorter lifespan; less efficient under high loads. |

| New Alternators | Made with all new components; match OE specifications | OEM replacements, fleet vehicles | Pros: Reliable performance; warranty coverage. Cons: Higher price point compared to remanufactured. |

| Remanufactured Alternators | Rebuilt from used parts; tested to meet OE standards | Cost-sensitive projects, older vehicles | Pros: Economical; good performance. Cons: Potentially shorter lifespan than new units; depends on the quality of remanufacturing. |

| Brushless Alternators | Utilize advanced technology; less maintenance required | Specialty vehicles, high-performance applications | Pros: Longer lifespan; efficient energy conversion. Cons: Higher cost; may not be compatible with all vehicles. |

What Are the Characteristics of High-Output Alternators?

High-output alternators are engineered to meet the power demands of vehicles with extensive electrical systems, such as performance cars and heavy-duty trucks. They typically produce between 130 to 220 amps, ensuring that all electrical components operate efficiently. For B2B buyers, these alternators are suitable for applications requiring additional power, such as advanced audio systems or heavy machinery. Considerations include the compatibility with existing vehicle systems and potential upgrades needed for wiring and mounting.

How Do Regular Alternators Differ from Other Types?

Regular alternators are the standard choice for most vehicles, featuring carbon brushes that wear out over time. While they are cost-effective and widely available, they typically produce lower voltage at high speeds, making them less suitable for high-demand applications. B2B buyers should weigh the initial savings against the potential need for more frequent replacements and maintenance, especially in commercial fleets where reliability is crucial.

Why Choose New Alternators for B2B Applications?

New alternators are manufactured to original equipment (OE) specifications, ensuring optimal performance and reliability. They are ideal for OEM replacements and are often used in fleet vehicles where downtime must be minimized. The primary consideration for B2B buyers is the investment required, as new units are generally more expensive than remanufactured options. However, they come with warranties and the peace of mind that comes from using brand-new components.

What Are the Advantages of Remanufactured Alternators?

Remanufactured alternators provide a cost-effective solution for businesses looking to replace faulty units without the expense of new parts. These alternators are rebuilt from used components that have been thoroughly inspected and tested to meet OE standards. Buyers should consider the quality of the remanufacturing process, as this can vary significantly between suppliers. They are particularly suitable for older vehicles or budget-conscious projects, balancing performance with affordability.

How Do Brushless Alternators Enhance Performance?

Brushless alternators leverage advanced technology to improve efficiency and reduce maintenance needs, making them an attractive option for specialty vehicles and high-performance applications. These units typically offer a longer lifespan and better energy conversion rates. B2B buyers should assess compatibility with their vehicle’s electrical systems and the higher initial investment required, as brushless alternators may not be universally applicable across all vehicle types.

Key Industrial Applications of best alternator brands

| Industry/Sector | Specific Application of best alternator brands | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production line vehicles and machinery for assembly | Ensures reliable operation and minimizes downtime during production | Compatibility with existing systems, quality certifications, and lead times. |

| Renewable Energy | Wind turbine generators and solar power systems | Provides consistent power generation, enhancing energy reliability | High output capacity, environmental compliance, and maintenance support. |

| Construction | Heavy machinery and construction equipment | Powers essential electrical systems, improving operational efficiency | Durability under extreme conditions, compatibility with various equipment models. |

| Marine | Commercial vessels and fishing boats | Supports navigation and onboard systems, critical for safety and efficiency | Saltwater resistance, high output for electronics, and compact design. |

| Agriculture | Tractors and agricultural machinery | Powers critical systems for irrigation and equipment operation | Adaptability to varying electrical loads, ruggedness, and serviceability. |

How Are Best Alternator Brands Used in Automotive Manufacturing?

In automotive manufacturing, best alternator brands are essential for powering production line vehicles and assembly machinery. These alternators ensure that the vehicles being produced can operate reliably, minimizing downtime during critical manufacturing processes. B2B buyers in this sector must consider compatibility with existing systems and look for quality certifications to ensure that the components meet industry standards. Additionally, lead times are crucial for maintaining production schedules, making timely sourcing a priority.

What Role Do Best Alternator Brands Play in Renewable Energy?

In the renewable energy sector, best alternator brands are employed in wind turbine generators and solar power systems to ensure consistent power generation. These alternators convert mechanical energy into electrical energy, enhancing energy reliability, which is vital for both grid stability and off-grid applications. International buyers should focus on high output capacity and environmental compliance, as these factors are critical for long-term performance and sustainability. Moreover, maintenance support is an important consideration to ensure ongoing operational efficiency.

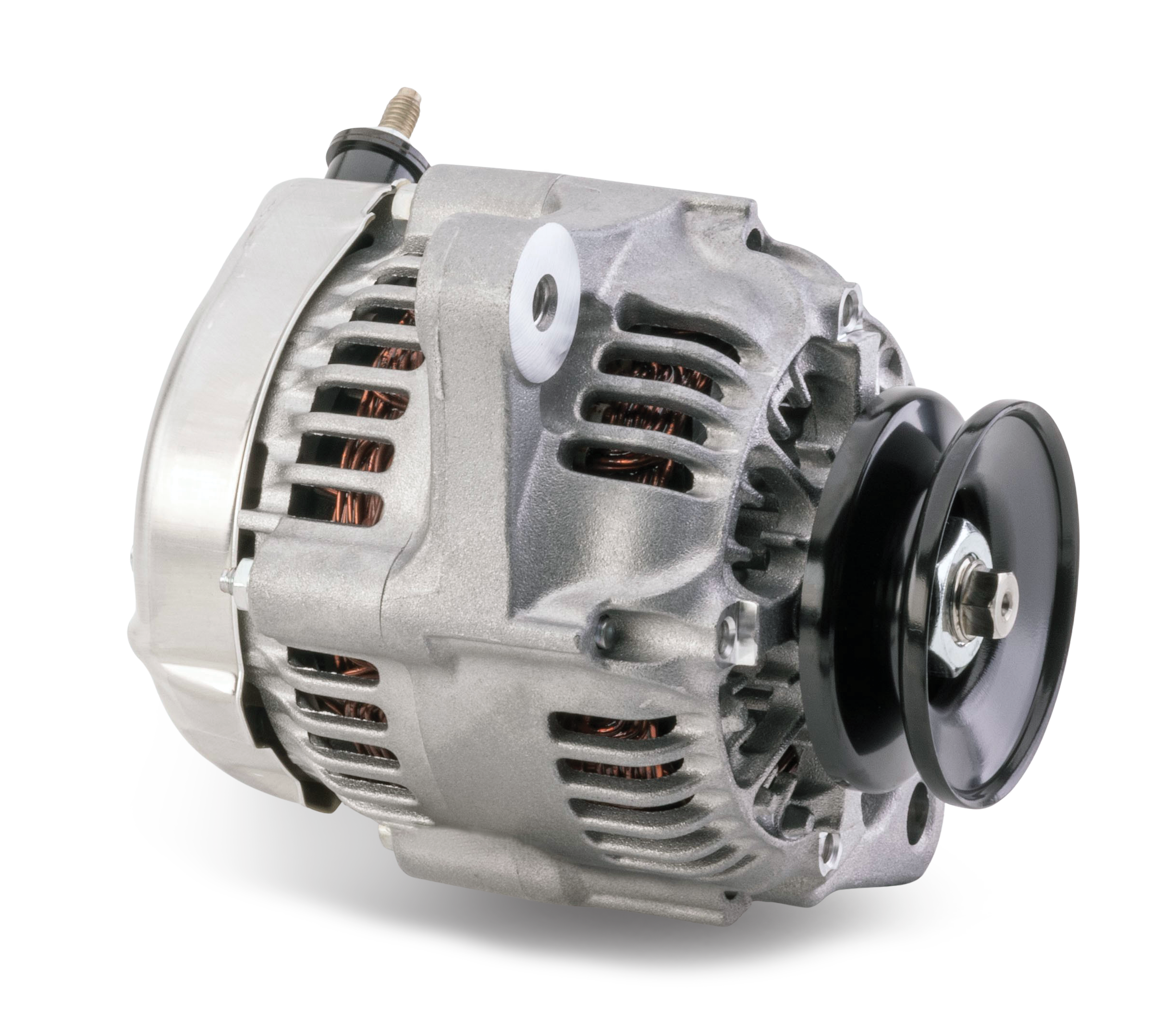

Illustrative image related to best alternator brands

How Do Best Alternator Brands Benefit Construction Industry Operations?

In the construction industry, best alternator brands are integral to heavy machinery and construction equipment, powering essential electrical systems that improve operational efficiency. These alternators help in running hydraulic systems and electrical components, which are vital for productivity on job sites. Buyers in this sector need to ensure that the alternators they source are durable enough to withstand extreme conditions and compatible with a variety of equipment models, as construction environments can be demanding.

Why Are Best Alternator Brands Important for Marine Applications?

For the marine industry, best alternator brands are critical in commercial vessels and fishing boats, where they support navigation and onboard systems. Reliable electrical power is crucial for safety and operational efficiency in marine environments. B2B buyers must consider factors such as saltwater resistance, high output for electronics, and compact design to fit within the limited space on vessels. These considerations ensure that the alternators perform optimally in harsh marine conditions.

How Do Best Alternator Brands Support Agricultural Machinery?

In agriculture, best alternator brands are used in tractors and other agricultural machinery to power critical systems for irrigation and equipment operation. These alternators must adapt to varying electrical loads and provide reliable performance to support the demands of modern farming practices. Buyers from agricultural sectors should prioritize ruggedness and serviceability, as machinery often operates in challenging environments, and quick repairs are essential to avoid operational delays.

3 Common User Pain Points for ‘best alternator brands’ & Their Solutions

Scenario 1: Sourcing Quality Alternators for Diverse Applications

The Problem: B2B buyers often face the challenge of sourcing high-quality alternators that meet specific requirements for various applications, especially in regions with fluctuating supply chains. This can lead to difficulties in ensuring compatibility with different vehicle models and electrical demands. The risk of purchasing subpar or incompatible products can result in increased operational costs, project delays, and customer dissatisfaction.

The Solution: To mitigate these challenges, B2B buyers should adopt a structured sourcing strategy. Start by identifying reputable suppliers known for their quality and reliability in the alternator market. Use comprehensive specifications that outline the required amperage, size, and compatibility with specific vehicle models. Engage with manufacturers who offer extensive product documentation and support to ensure that the alternators will meet the operational demands of the intended applications. Additionally, consider leveraging regional distributors who understand local market needs and can provide timely support and inventory management.

Scenario 2: Overcoming Performance Variability in High-Output Alternators

The Problem: Another common pain point is the performance variability in high-output alternators, which can significantly impact the efficiency of heavy-duty vehicles and specialized equipment. Buyers may experience inconsistent power delivery, leading to electrical system failures and increased downtime. This is particularly troublesome in sectors like mining or agriculture, where operational reliability is critical.

The Solution: To address this issue, B2B buyers should conduct thorough research on alternator brands that specialize in high-output solutions. Prioritize manufacturers that provide detailed performance data and real-world testing results. When selecting an alternator, ensure that it exceeds the vehicle’s electrical load requirements by at least 50% to maintain efficiency under various operating conditions. Implementing regular maintenance schedules and monitoring electrical loads can also help in identifying potential issues before they escalate, ensuring that the alternator operates at optimal performance levels.

Scenario 3: Navigating Warranty and Support Challenges

The Problem: Warranty and after-sales support can often become a source of frustration for B2B buyers, especially when dealing with defective alternators or those that fail prematurely. The lack of clear warranty terms can lead to unexpected costs, prolonged downtime, and strained relationships with clients who rely on timely repairs and replacements.

The Solution: To navigate these challenges effectively, buyers should prioritize partnerships with alternator brands that offer transparent warranty policies and robust customer support. Before making a purchase, carefully review the warranty terms and conditions, including coverage duration, service options, and the process for claims. Establish a direct line of communication with the manufacturer’s support team to address any concerns quickly. Additionally, consider implementing a warranty management system to track claims and service histories, which can aid in identifying trends and ensuring accountability from suppliers. By selecting brands with a strong reputation for service, buyers can enhance their operational resilience and maintain customer satisfaction.

Strategic Material Selection Guide for best alternator brands

What Materials Are Commonly Used in Best Alternator Brands?

When selecting alternators, the materials used in their construction significantly influence performance, durability, and overall value. Here, we analyze four common materials used in the best alternator brands, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Copper

Key Properties: Copper is known for its excellent electrical conductivity, which is crucial for efficient power generation. It also offers good thermal conductivity and resistance to corrosion.

Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances the alternator’s efficiency and performance. However, copper is relatively expensive compared to other materials, which can increase manufacturing costs. Additionally, its weight can be a concern in applications where reducing weight is critical.

Impact on Application: Copper is particularly suitable for electrical windings and connectors in alternators, as it ensures minimal energy loss. However, its susceptibility to oxidation necessitates protective coatings in certain environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards regarding electrical components, such as ASTM and IEC. In regions with high humidity, like parts of Africa and South America, additional corrosion protection may be necessary.

2. Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and excellent thermal conductivity. It is also less expensive than copper.

Pros & Cons: The lightweight nature of aluminum makes it an attractive option for automotive applications, where reducing weight can improve fuel efficiency. However, aluminum has lower electrical conductivity than copper, which may affect performance in high-demand applications.

Impact on Application: Aluminum is often used in the casing and brackets of alternators, providing structural integrity while minimizing weight. Its corrosion resistance is beneficial in harsh environments, but it may not perform as well in high-load electrical applications.

Illustrative image related to best alternator brands

Considerations for International Buyers: Buyers should be aware of the varying quality standards for aluminum in different regions. Compliance with local regulations regarding material sourcing and recycling can also impact purchasing decisions.

3. Steel

Key Properties: Steel is known for its high strength and durability, making it suitable for structural components. It has moderate corrosion resistance, depending on the alloy used.

Pros & Cons: The main advantage of steel is its robustness, which ensures longevity and reliability in demanding applications. However, it is heavier than aluminum and copper, which can negatively impact vehicle performance. Additionally, steel may require protective coatings to prevent rusting.

Illustrative image related to best alternator brands

Impact on Application: Steel is commonly used in the alternator’s frame and mounting brackets, providing the necessary support and protection for internal components. Its weight and potential for corrosion in humid environments are critical considerations.

Considerations for International Buyers: Buyers should ensure that steel components meet local and international standards for strength and corrosion resistance. In regions with high temperatures, such as the Middle East, thermal expansion properties should also be considered.

4. Plastic Composites

Key Properties: Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They have lower thermal and electrical conductivity compared to metals.

Pros & Cons: The primary advantage of plastic composites is their versatility and ability to reduce weight significantly. However, they may not withstand high temperatures or mechanical stresses as well as metals, limiting their use in critical components.

Impact on Application: Plastic composites are often used in non-structural components, such as covers and insulators, where weight savings are essential. Their corrosion resistance makes them suitable for various environments, but they may require careful selection based on thermal performance.

Considerations for International Buyers: Buyers should verify that plastic composites meet relevant safety and performance standards, particularly in regions with extreme environmental conditions. Understanding the lifecycle and recyclability of these materials is also essential for sustainability compliance.

Summary Table of Material Selection for Best Alternator Brands

| Material | Typical Use Case for best alternator brands | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical windings and connectors | Excellent conductivity | High cost; heavy | High |

| Aluminum | Casing and brackets | Lightweight; corrosion-resistant | Lower conductivity than copper | Medium |

| Steel | Frame and mounting brackets | High strength and durability | Heavy; requires corrosion protection | Medium |

| Plastic Composites | Covers and insulators | Lightweight; corrosion-resistant | Limited thermal/mechanical performance | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing alternators for their specific applications.

Illustrative image related to best alternator brands

In-depth Look: Manufacturing Processes and Quality Assurance for best alternator brands

What Are the Key Stages in the Manufacturing Process of High-Quality Alternators?

The manufacturing of alternators involves several critical stages that ensure the final product meets the rigorous standards required for performance and durability. Understanding these stages can help B2B buyers assess the quality of products they are sourcing.

1. Material Preparation: What Materials Are Used in Alternator Manufacturing?

The first step in the manufacturing process is material preparation, where high-quality raw materials are sourced. Common materials include:

- Copper: Used for windings and conductors due to its excellent electrical conductivity.

- Aluminum: Often used for the housing and rotor due to its lightweight and corrosion resistance.

- Steel: Utilized for components requiring strength, such as the stator frame and bearings.

- Insulation Materials: Essential for preventing electrical shorts and maintaining performance under various conditions.

Quality assurance begins at this stage, where suppliers must meet specific standards to ensure material integrity and reliability.

2. Forming: How Are Alternator Components Shaped and Prepared?

The forming stage involves shaping the raw materials into the various components of the alternator. Key techniques include:

- Die Casting: Used for creating the housing and end bells, providing a durable and precise fit.

- Stamping: Employed for producing the stator and rotor laminations, ensuring minimal energy loss.

- Winding: Copper wire is wound around the stator to create coils, a crucial step that affects the alternator’s efficiency.

Each technique is chosen based on the desired specifications and performance characteristics, with attention to detail crucial for the overall functionality of the alternator.

3. Assembly: How Are Alternator Parts Brought Together?

The assembly stage is where all the components are put together. This process typically includes:

- Component Inspection: Before assembly, each part is inspected for defects to ensure only high-quality components are used.

- Assembly Line Techniques: Utilizing automated systems for precision, workers assemble the rotor, stator, voltage regulator, and other components.

- Torque and Fit Checks: Ensuring that all components are fitted securely and that torque specifications are met to prevent mechanical failures.

Proper assembly is vital for ensuring the alternator’s performance and longevity.

4. Finishing: What Final Touches Are Applied to Alternators?

The finishing stage enhances the alternator’s appearance and protects it from environmental factors. This includes:

- Coating and Painting: Protective coatings are applied to resist corrosion and wear.

- Labeling: Clear and accurate labeling ensures compliance with international standards and provides essential information for buyers.

- Final Inspection: A thorough inspection checks for any cosmetic defects and ensures all functions operate correctly.

Finishing not only contributes to aesthetics but also enhances the durability of the alternator.

What Quality Assurance Measures Are Essential for Reliable Alternators?

Quality assurance is critical in the manufacturing process of alternators, ensuring that each unit meets strict performance standards. Here are the key aspects of quality control in alternator manufacturing.

Relevant International Standards: What Certifications Should You Look For?

B2B buyers should prioritize suppliers that comply with recognized international standards, such as:

Illustrative image related to best alternator brands

- ISO 9001: This standard outlines a quality management system that helps organizations ensure they meet customer and regulatory requirements consistently.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Certification: Relevant for products used in automotive applications, ensuring they meet specific performance and safety standards.

These certifications are indicators of a manufacturer’s commitment to quality and reliability.

Key Quality Control Checkpoints: How Are Quality Checks Implemented?

Quality control checkpoints throughout the manufacturing process help maintain high standards. Key checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors the manufacturing process to catch defects early. This includes checks during the forming and assembly stages.

- Final Quality Control (FQC): Conducts comprehensive testing and inspection of the finished alternator to ensure it meets all performance and safety standards.

These checkpoints are crucial for identifying issues before the product reaches the market.

Common Testing Methods: What Tests Are Conducted on Alternators?

Various testing methods are employed to validate the performance and reliability of alternators, including:

- Electrical Testing: Ensures the alternator produces the required voltage and current output.

- Thermal Testing: Assesses how well the alternator operates under high-temperature conditions, simulating real-world scenarios.

- Vibration Testing: Evaluates the alternator’s ability to withstand vibrations encountered during vehicle operation.

These tests help verify that the alternators meet or exceed industry performance standards.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can implement several verification strategies:

Conducting Audits: What Should You Look For?

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Key areas to focus on include:

Illustrative image related to best alternator brands

- Facility Conditions: Assess the cleanliness and organization of the manufacturing environment.

- Quality Control Documentation: Review their quality control plans, inspection reports, and compliance with international standards.

- Employee Training: Ensure that workers are adequately trained in quality assurance practices.

These audits can help identify reliable suppliers who prioritize quality.

Requesting Quality Reports: What Information Should Be Included?

B2B buyers should request detailed quality reports from suppliers, which should include:

- Inspection Results: Documentation of results from IQC, IPQC, and FQC processes.

- Testing Certifications: Proof of compliance with relevant international standards and testing results.

- Traceability Information: Details on the sourcing of materials and components used in the manufacturing process.

These reports provide assurance that the supplier adheres to stringent quality control measures.

Utilizing Third-Party Inspections: How Can You Ensure Objectivity?

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These services can conduct:

- Random Sampling Inspections: Evaluate a sample of products to ensure they meet specifications.

- Factory Audits: Conduct thorough examinations of the manufacturing facility and processes.

- Compliance Verification: Confirm that the supplier meets international standards and regulations.

Utilizing third-party inspections can mitigate risks associated with sourcing from international suppliers, particularly in regions where regulations may differ significantly.

Conclusion: Why Is Quality Assurance Critical for B2B Buyers of Alternators?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices of alternator suppliers is essential. By focusing on these aspects, buyers can make informed decisions that ensure they source reliable, high-quality products that meet their specific needs and standards. Prioritizing suppliers with robust quality control measures and relevant certifications will ultimately lead to better performance and reliability in the automotive applications where these alternators are utilized.

Illustrative image related to best alternator brands

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best alternator brands’

Introduction

Procuring high-quality alternators is vital for businesses looking to ensure the reliability and performance of their vehicles. This step-by-step checklist is designed to guide B2B buyers through the sourcing process, helping you identify the best alternator brands that meet your specific requirements. By following these steps, you can make informed purchasing decisions that enhance your operational efficiency.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of the alternators you need is the first step in the procurement process. Consider factors such as electrical output, compatibility with existing systems, and specific performance needs.

– Electrical Output: Ensure the alternator can handle the vehicle’s electrical load, especially if it has high-demand accessories.

– Compatibility: Check the dimensions and mounting configurations to avoid installation issues.

Step 2: Identify Reputable Brands

Research and compile a list of trusted alternator brands known for their reliability and performance. Look for brands that have a strong reputation in your target market regions, such as Africa, South America, the Middle East, and Europe.

– Brand Recognition: Established brands often provide better warranties and customer support.

– Customer Reviews: Analyze feedback from other B2B buyers to gauge product performance and service satisfaction.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and quality standards. This step ensures that the alternators meet international quality benchmarks and industry regulations.

– ISO Certifications: Look for suppliers with ISO 9001 or other relevant certifications that indicate quality management practices.

– Warranty Information: A solid warranty can be a reflection of the supplier’s confidence in their products.

Step 4: Request Product Samples

Obtaining samples is crucial for evaluating the quality and performance of the alternators before making a bulk purchase. This step allows you to assess the product firsthand.

– Testing: Conduct performance tests to confirm that the alternators meet your specifications.

– Fit and Finish: Inspect the physical quality, including materials used and craftsmanship.

Illustrative image related to best alternator brands

Step 5: Conduct Cost Analysis

Analyze the total cost of ownership, not just the initial purchase price. Consider factors such as shipping, duties, and potential maintenance costs.

– Long-Term Value: Invest in products that offer durability and low maintenance to reduce overall costs.

– Volume Discounts: Inquire about pricing structures for bulk purchases which can significantly reduce your costs.

Step 6: Establish Clear Communication

Effective communication with potential suppliers is essential throughout the sourcing process. Establish clear lines of communication to address any queries or concerns.

– Language and Time Zone Considerations: Be mindful of potential language barriers and time zone differences, especially when dealing with international suppliers.

– Response Time: Assess the responsiveness of suppliers during initial interactions as this can be indicative of their customer service.

Step 7: Finalize the Agreement

Once you have selected a supplier, ensure that all terms and conditions are clearly outlined in a formal agreement. This should include payment terms, delivery schedules, and warranty coverage.

– Legal Review: Consider having the agreement reviewed by a legal professional to ensure your interests are protected.

– Payment Terms: Negotiate favorable payment terms that align with your cash flow needs.

By following this checklist, B2B buyers can streamline their sourcing process and secure high-quality alternators that enhance their vehicle performance and reliability.

Comprehensive Cost and Pricing Analysis for best alternator brands Sourcing

What Are the Key Cost Components in Sourcing Alternators from Top Brands?

When engaging in B2B sourcing of alternators, understanding the comprehensive cost structure is crucial. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to best alternator brands

-

Materials: The quality and type of materials used in alternator production significantly affect pricing. Common materials include copper for wiring, aluminum for the casing, and various plastics for insulation. High-quality materials often lead to higher costs but result in improved performance and longevity.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but this must be balanced with the quality of workmanship. Skilled labor is essential for the assembly of complex alternator components.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance costs. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers as lower prices.

-

Tooling: The initial investment in tooling can be significant, particularly for custom or high-output alternators. These costs are typically amortized over the production run, influencing unit pricing.

-

Quality Control: Rigorous QC processes ensure that each alternator meets performance standards. Enhanced QC measures may increase costs, but they also reduce the risk of failures and returns, which is critical for maintaining customer satisfaction.

-

Logistics: Transportation and shipping costs can vary based on the distance from the manufacturer to the buyer’s location and the mode of transport. Incoterms play a significant role in determining who bears these costs.

-

Margin: Manufacturers and suppliers will include their profit margins in the pricing structure. These margins can fluctuate based on market demand and competition.

How Do Price Influencers Affect Alternator Sourcing Decisions?

Several factors influence the pricing of alternators, particularly for international buyers.

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their needs while ensuring they benefit from economies of scale.

-

Specifications and Customization: Custom alternators designed to meet specific requirements can incur additional costs. Buyers should clearly outline their needs to avoid unexpected charges.

-

Materials and Quality Certifications: The presence of quality certifications (like ISO) can affect pricing. Brands that invest in quality assurance may command higher prices but offer better reliability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a history of quality production may charge a premium but offer peace of mind.

-

Incoterms: These terms define the responsibilities of buyers and sellers concerning shipping costs and risks. Understanding Incoterms is vital for budgeting total costs effectively.

What Are the Best Practices for Negotiating Alternator Prices in International Markets?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation and cost-efficiency strategies can lead to significant savings.

-

Total Cost of Ownership: Consider the long-term implications of the purchase, including installation, maintenance, and potential downtime. A slightly higher upfront cost may be justified by a longer lifespan or better performance.

-

Flexibility in Payment Terms: Negotiating favorable payment terms can improve cash flow. Consider options like staggered payments based on delivery milestones.

-

Volume Commitments: Offering to commit to a larger volume over time can incentivize suppliers to offer better pricing. This approach can also foster stronger supplier relationships.

-

Understanding Pricing Nuances: Different regions may have varying pricing structures based on local demand, economic conditions, and competition. Conducting market research can provide insights that aid in negotiations.

-

Building Long-Term Relationships: Establishing a long-term partnership with suppliers can lead to better pricing, priority in production, and improved service over time.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of the cost structure and pricing influences in alternator sourcing, actual prices may vary based on specific requirements, market conditions, and supplier negotiations. It is advisable for buyers to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing best alternator brands With Other Solutions

Exploring Alternatives to Leading Alternator Brands

In the competitive landscape of automotive electrical systems, particularly for international B2B buyers, understanding the alternatives to the best alternator brands is crucial. While top brands offer reliability and performance, there are other viable solutions that can meet specific operational needs or budget constraints. This analysis will compare established alternator brands with two alternative approaches: high-output aftermarket alternators and battery management systems (BMS).

| Comparison Aspect | Best Alternator Brands | High-Output Aftermarket Alternators | Battery Management Systems (BMS) |

|---|---|---|---|

| Performance | High reliability and efficiency; meets OEM standards. | Designed for high-demand applications; superior power output. | Optimizes battery performance; prolongs battery life. |

| Cost | Generally higher due to brand reputation and warranty. | Moderate to high, depending on specifications and features. | Varies significantly; initial investment can be high but may save costs in the long run. |

| Ease of Implementation | Typically plug-and-play; fits most OEM specifications. | Requires compatibility checks and possible modifications. | Complex integration; needs specialized knowledge for installation. |

| Maintenance | Minimal maintenance; typically long-lasting with warranties. | Higher maintenance due to potential wear from increased output. | Requires regular monitoring and software updates for optimal performance. |

| Best Use Case | Standard vehicles and fleet operations needing reliable performance. | High-performance vehicles, off-road applications, or custom builds. | Electric vehicles (EVs), hybrid systems, and advanced battery setups. |

Understanding High-Output Aftermarket Alternators

High-output aftermarket alternators are designed for applications that demand greater electrical power, such as vehicles with advanced audio systems or those used in off-road scenarios. These alternators can produce significantly higher amperage, ensuring that all electrical components function optimally under heavy loads.

Pros: They offer superior performance, especially in high-demand environments, and can be customized to meet specific needs.

Cons: However, they may require modifications for installation and can lead to increased wear on the vehicle’s electrical system. Additionally, they might not be as reliable as established brands, which can affect long-term performance.

Exploring Battery Management Systems (BMS)

Battery management systems (BMS) represent a more technological approach to managing electrical power in vehicles, particularly in electric and hybrid models. A BMS oversees battery health, optimizing performance, and extending battery lifespan by regulating charging cycles and discharging rates.

Pros: A BMS can significantly enhance battery longevity and efficiency, making it a smart choice for businesses focused on sustainability and cost-effectiveness over time.

Cons: The complexity of installation and the need for specialized knowledge can deter some buyers. Moreover, the upfront costs may be higher, although they can lead to savings on battery replacements and maintenance in the long run.

Illustrative image related to best alternator brands

Conclusion: Choosing the Right Solution for Your Needs

When selecting between the best alternator brands and alternative solutions, B2B buyers should assess their specific requirements, including performance needs, budget constraints, and application environments. For standard operations, established alternator brands provide reliability and ease of installation. In contrast, high-output aftermarket options cater to specialized applications, while battery management systems offer advanced solutions for electric and hybrid vehicles. Understanding these alternatives allows buyers to make informed decisions that align with their operational goals and financial strategies.

Essential Technical Properties and Trade Terminology for best alternator brands

What Are the Essential Technical Properties of High-Quality Alternators?

When selecting alternators for various applications, understanding the technical properties is crucial for ensuring optimal performance and reliability. Here are some key specifications to consider:

-

Output Voltage and Amperage

The output voltage of an alternator typically ranges between 13 to 14.8 volts, while the amperage can vary significantly based on the application—ranging from 60 amps in standard vehicles to over 300 amps for high-performance models. B2B buyers must ensure that the alternator’s output matches the electrical demands of their vehicles or machinery, which is essential for maintaining battery health and powering all electrical systems effectively. -

Material Grade

The materials used in alternator construction—such as copper for windings and aluminum for housings—impact durability and efficiency. High-grade materials enhance conductivity and thermal management, thereby extending the lifespan of the alternator. For B2B buyers, investing in high-quality materials can reduce long-term operational costs associated with replacements and repairs. -

Cooling Mechanism

Many high-performance alternators are designed with advanced cooling features, such as built-in fans or heat sinks. Effective cooling prevents overheating, especially under heavy electrical loads. Buyers should assess the cooling capabilities of alternators, particularly in regions with extreme temperatures or in applications where high electrical demands are common. -

Size and Weight

The physical dimensions and weight of an alternator are crucial for compatibility with specific vehicle models. Larger, high-output alternators may require additional modifications to the vehicle’s electrical system. Understanding these specifications helps B2B buyers ensure that they choose an alternator that fits seamlessly into their applications without needing extensive alterations. -

Noise Level

The operational noise of an alternator can be a significant factor, especially in luxury vehicles or equipment where noise reduction is a priority. Evaluating the noise level can help buyers select alternators that meet specific industry standards or customer expectations for quiet operation.

What Common Trade Terms Should B2B Buyers Understand in the Alternator Market?

Navigating the alternator market requires familiarity with industry terminology. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

OEM alternators are produced by the same manufacturer that makes the original parts for a vehicle. B2B buyers often prefer OEM products for their reliability and compatibility, ensuring they meet the exact specifications required for optimal performance. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and purchasing decisions. It is essential to negotiate MOQ terms that align with business needs to avoid excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. This process allows B2B buyers to compare costs, specifications, and delivery options. Crafting a clear RFQ can streamline procurement and ensure that buyers receive competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and responsibilities associated with the delivery of alternators, ensuring clarity in trade agreements. -

Warranty Period

The warranty period indicates the duration a manufacturer guarantees the alternator’s performance. Understanding warranty terms is vital for B2B buyers as it reflects the manufacturer’s confidence in their product and provides assurance against defects or failures. -

Aftermarket

The aftermarket refers to the secondary market for parts and accessories, including alternators. B2B buyers should assess the quality and reliability of aftermarket options, as they can offer cost-effective solutions but may vary significantly in terms of performance and warranty coverage.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators, ensuring they select the right products that meet their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the best alternator brands Sector

What Are the Key Trends Shaping the Global Alternator Market for B2B Buyers?

The global alternator market is currently experiencing significant transformations driven by several factors. First, the increasing demand for advanced automotive technologies, including electric and hybrid vehicles, is reshaping the landscape. This shift necessitates high-performance alternators that can handle greater electrical loads. Consequently, manufacturers are focusing on producing high-output alternators designed to meet the needs of vehicles equipped with sophisticated electronic systems.

Illustrative image related to best alternator brands

Moreover, the rise in e-commerce and digital procurement platforms is revolutionizing how B2B buyers source alternators. International buyers from regions like Africa, South America, the Middle East, and Europe are leveraging these platforms for streamlined purchasing processes, making it easier to compare brands and access diverse suppliers. This trend is particularly relevant for countries such as Brazil and Vietnam, where local manufacturers are increasingly competing with established global brands.

Another key trend is the growing emphasis on remanufactured alternators, which offer a cost-effective and sustainable alternative to new units. As buyers become more budget-conscious, remanufactured options not only reduce expenses but also minimize environmental impact, aligning with the global push for sustainability.

How Is Sustainability and Ethical Sourcing Influencing Alternator Procurement?

Sustainability is becoming a pivotal concern for B2B buyers in the alternator sector. The environmental impact of production processes, including resource extraction and waste generation, has led to heightened scrutiny of supply chains. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing practices and environmental stewardship.

To align with sustainability goals, many top alternator brands are obtaining certifications that validate their commitment to green practices. Certifications such as ISO 14001 for environmental management systems and RoHS compliance for hazardous substances are becoming essential criteria for buyers. Furthermore, the use of recycled materials in the manufacturing of alternators is gaining traction, as it reduces reliance on virgin resources and minimizes waste.

For international buyers, particularly those in regions with stringent environmental regulations, partnering with brands that emphasize sustainability can enhance their corporate reputation and compliance. This trend not only meets regulatory requirements but also appeals to a growing consumer base that values eco-friendly products.

What Is the Historical Context of the Alternator Market Relevant to B2B Buyers?

The alternator market has evolved significantly since its inception in the early 20th century. Initially designed to replace generators, alternators became the standard power source for automotive electrical systems due to their efficiency and reliability. Over the decades, advancements in technology have led to the development of high-output and compact alternators, catering to the increasing electrical demands of modern vehicles.

The transition from traditional mechanical systems to electronic control units in vehicles has further propelled the alternator’s importance, making it a critical component for vehicle functionality. This evolution has prompted manufacturers to innovate continuously, ensuring that their products not only meet but exceed the performance expectations of B2B buyers.

Understanding this historical context enables international buyers to appreciate the advancements in alternator technology and the increasing importance of sourcing high-quality products. As the market continues to evolve, staying informed about these trends will be crucial for making strategic procurement decisions.

Illustrative image related to best alternator brands

Frequently Asked Questions (FAQs) for B2B Buyers of best alternator brands

-

How do I determine the right alternator brand for my business needs?

When selecting an alternator brand, consider several factors: compatibility with the vehicles in your market, the electrical load requirements, and the specific features you need, such as high output for performance vehicles. Research brands that are known for reliability and durability, like Denso or Remy. Additionally, assess the availability of local suppliers or distributors in your region to ensure prompt support and service. Reading customer reviews and industry reports can also provide insights into performance and customer satisfaction. -

What are the key factors in evaluating alternator suppliers?

When vetting alternator suppliers, consider their manufacturing capabilities, quality control processes, and compliance with international standards. Look for suppliers with proven track records and solid reputations in your target markets, such as Africa or South America. Request samples to evaluate product quality and ensure they offer warranties or guarantees. It’s also essential to assess their logistics capabilities, including shipping times and costs, to ensure they can meet your supply chain needs. -

What are the minimum order quantities (MOQs) for alternators?

Minimum order quantities for alternators can vary significantly based on the supplier and the type of alternator. Some manufacturers may have MOQs as low as 50 units, while others may require orders of several hundred. Discuss your specific needs with potential suppliers to negotiate favorable terms. Consider your inventory management strategy and market demand when determining how many units to order, as larger orders may lead to better pricing but also require more upfront investment. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms for international purchases of alternators can range from upfront payment to net 30, 60, or even 90 days, depending on the supplier’s policies and your negotiation. Common methods include wire transfers, letters of credit, and PayPal. It’s crucial to establish clear payment terms before placing an order to avoid any misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees when finalizing your payment method. -

How can I ensure the quality of alternators from my supplier?

To ensure quality, request certifications such as ISO 9001 from your alternator supplier, which indicates adherence to international quality management standards. Implement a quality assurance process that includes regular inspections and testing of received products. Establish clear specifications and standards that the alternators must meet. Building a strong relationship with your supplier can also facilitate better communication and adherence to quality expectations. -

What logistics considerations should I account for when importing alternators?

Logistics play a vital role in importing alternators. Consider shipping methods, transit times, and costs when selecting a supplier. Ensure that the supplier can provide the necessary documentation for customs clearance, such as bills of lading and certificates of origin. Additionally, factor in local regulations and duties that may apply to automotive parts in your target market. Establish a reliable shipping partner to mitigate risks related to delays or damages during transit. -

Are there customization options available for alternators?

Many suppliers offer customization options for alternators to meet specific electrical load requirements or vehicle specifications. Customizations may include changes in amperage output, physical dimensions, or connector types. When considering customization, discuss your needs with the supplier to understand feasibility, costs, and lead times. Customization can enhance compatibility and performance, but it may also affect MOQs and pricing. -

What are the symptoms of a failing alternator, and how can I convey this to my customers?

Common symptoms of a failing alternator include dimming lights, electrical failures, strange noises, and warning lights on the dashboard. Educate your customers about these signs to help them identify potential issues early. Providing informative materials or guides can enhance customer satisfaction and trust in your brand. Additionally, consider offering maintenance tips to prolong the life of the alternator, reinforcing your position as a knowledgeable supplier in the automotive industry.

Top 2 Best Alternator Brands Manufacturers & Suppliers List

1. AC Delco – Alternators

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Alternator brands: AC Delco, Duralast

2. Alternators – Key Recommendations

Domain: grassrootsmotorsports.com

Registered: 1999 (26 years)

Introduction: Alternators discussed include: 1. Nippodenso from Napa – noted as not bad, comes with a limited 3-year warranty. 2. OEM rebuilt alternators – recommended by multiple users for better quality. 3. Bosch rebuilt alternators from Auto Zone – mentioned as reliable. 4. Autozone reman alternators – one user reported 2 years and 100K+ miles without issues. 5. Local rebuilders – highly recommended for bett…

Strategic Sourcing Conclusion and Outlook for best alternator brands

As the automotive industry continues to evolve, the importance of selecting the right alternator brand cannot be overstated. By prioritizing strategic sourcing, international B2B buyers can ensure they are investing in high-quality, reliable products that meet the demands of their specific markets. Brands such as Wilson, Remy, Armature DNS, and Denso have established themselves as leaders in performance and durability, providing options that cater to a wide range of electrical needs.

When sourcing alternators, consider factors such as compatibility, electrical load, and potential upgrades to ensure optimal performance. The right alternator not only enhances vehicle reliability but also supports the growing trend of advanced automotive technologies, particularly in regions like Africa, South America, the Middle East, and Europe, where demand for efficient and high-performance vehicles is on the rise.

Looking ahead, now is the time for B2B buyers to align their purchasing strategies with reputable alternator brands that can deliver both quality and value. By making informed choices, businesses can secure a competitive advantage and contribute to the sustainable growth of their operations. Engage with trusted suppliers and explore partnerships that will empower your business to thrive in a rapidly changing automotive landscape.

Illustrative image related to best alternator brands

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.