Introduction: Navigating the Global Market for que es el motor de arranque

The global market for automotive components, particularly the motor de arranque (starter motor), presents a unique challenge for B2B buyers seeking reliable and efficient solutions. As international buyers from regions such as Africa, South America, the Middle East, and Europe—specifically countries like Nigeria and Germany—navigate this complex landscape, understanding the intricacies of starter motors is crucial. This guide delves into the various types of starter motors, their applications across different vehicle models, and the essential criteria for vetting suppliers.

By providing insights into the performance characteristics, maintenance requirements, and common issues associated with starter motors, this resource empowers decision-makers to make informed purchasing choices. Furthermore, we will explore cost considerations and the impact of regional supply chains on pricing and availability.

In a market where reliability and efficiency can significantly affect operational success, understanding the motor de arranque is not merely advantageous—it’s essential. This guide serves as a comprehensive tool, equipping B2B buyers with the knowledge necessary to optimize their procurement strategies, ensuring they secure the best products that meet their specific needs in a competitive environment.

Table Of Contents

- Top 4 Que Es El Motor De Arranque Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for que es el motor de arranque

- Understanding que es el motor de arranque Types and Variations

- Key Industrial Applications of que es el motor de arranque

- 3 Common User Pain Points for ‘que es el motor de arranque’ & Their Solutions

- Strategic Material Selection Guide for que es el motor de arranque

- In-depth Look: Manufacturing Processes and Quality Assurance for que es el motor de arranque

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘que es el motor de arranque’

- Comprehensive Cost and Pricing Analysis for que es el motor de arranque Sourcing

- Alternatives Analysis: Comparing que es el motor de arranque With Other Solutions

- Essential Technical Properties and Trade Terminology for que es el motor de arranque

- Navigating Market Dynamics and Sourcing Trends in the que es el motor de arranque Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of que es el motor de arranque

- Strategic Sourcing Conclusion and Outlook for que es el motor de arranque

- Important Disclaimer & Terms of Use

Understanding que es el motor de arranque Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Starter | Uses a direct electric motor to crank the engine | Automotive repair shops, dealerships | Pros: Reliable, widely available; Cons: Heavier, may require frequent maintenance. |

| Gear Reduction Starter | Features a gear reduction mechanism for increased torque | Heavy machinery, commercial vehicles | Pros: Higher torque, efficient; Cons: More complex, potentially higher costs. |

| Permanent Magnet Starter | Utilizes permanent magnets for compact design | Small engines, motorcycles | Pros: Lightweight, energy-efficient; Cons: Limited torque for larger engines. |

| High-Performance Starter | Designed for racing and high-demand applications | Motorsports, custom vehicles | Pros: High torque, fast engagement; Cons: Expensive, may not be suitable for everyday use. |

| Solenoid Starter | Incorporates a solenoid for engagement and disengagement | Standard automotive applications | Pros: Simple design, cost-effective; Cons: Slower engagement, potential for wear over time. |

What are the Characteristics of Conventional Starters?

Conventional starters are the most common type used in vehicles. They operate by using a direct electric motor to crank the engine, providing the necessary torque to initiate combustion. These starters are suitable for a wide range of automotive applications, making them a staple in repair shops and dealerships. When purchasing, B2B buyers should consider their reliability and the availability of replacement parts, as these can impact maintenance costs.

How Do Gear Reduction Starters Stand Out?

Gear reduction starters are engineered for heavy machinery and commercial vehicles, where higher torque is essential. By using a gear reduction mechanism, these starters can deliver more power while consuming less energy. B2B buyers in sectors requiring robust performance should evaluate the complexity and potential costs associated with these systems, as they may necessitate specialized knowledge for installation and maintenance.

Why Choose Permanent Magnet Starters?

Permanent magnet starters are compact and lightweight, making them ideal for small engines and motorcycles. They are known for their energy efficiency and quick engagement. B2B buyers should consider their applications carefully, as these starters might not provide sufficient torque for larger engines. Their lightweight design can be a significant advantage in sectors where weight savings are critical.

What Makes High-Performance Starters Unique?

High-performance starters are tailored for racing and high-demand applications, providing rapid engagement and high torque. These starters are typically more expensive and may not be suitable for regular vehicles. B2B buyers in the motorsports industry should weigh the benefits of enhanced performance against the higher costs and potential durability concerns in everyday use.

How Do Solenoid Starters Function?

Solenoid starters feature a solenoid that engages and disengages the starter motor, making them a cost-effective choice for standard automotive applications. While they are simple in design, they can be slower to engage compared to other types. B2B buyers should consider the balance between cost and performance, particularly in applications where quick starts are essential. Regular maintenance can mitigate wear and ensure longevity.

Key Industrial Applications of que es el motor de arranque

| Industry/Sector | Specific Application of que es el motor de arranque | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Assembly of vehicles requiring reliable starting systems | Ensures efficient production and reduces downtime during assembly | Quality of components, compatibility with various vehicle models |

| Transportation and Logistics | Fleet management for heavy-duty vehicles | Enhances reliability and reduces maintenance costs | Durability under heavy use, ease of installation and replacement |

| Agriculture | Starting systems for agricultural machinery | Improves operational efficiency and reduces equipment failure | Resistance to harsh environments, availability of spare parts |

| Construction | Construction machinery requiring dependable starting | Minimizes downtime, ensuring project timelines are met | Power requirements, compatibility with existing machinery |

| Mining | Heavy machinery used in mining operations | Increases productivity and reduces risk of operational delays | Robustness, ability to withstand extreme conditions |

How is ‘que es el motor de arranque’ Used in Automotive Manufacturing?

In automotive manufacturing, the starter motor is integral to the assembly line, where vehicles are constructed and tested. A reliable starting system ensures that each vehicle can be efficiently powered up during quality checks and final assembly. This minimizes downtime, which is crucial in a competitive market. Buyers in this sector need to consider the compatibility of starter motors with various vehicle models and the quality of components to prevent issues that could halt production.

What Role Does the Starter Motor Play in Transportation and Logistics?

In the transportation and logistics sector, the starter motor is essential for fleet management, particularly for heavy-duty vehicles such as trucks and buses. A dependable starter motor enhances vehicle reliability, which is vital for timely deliveries and operational efficiency. Businesses must focus on sourcing durable components that can withstand high usage rates and ensure ease of installation and maintenance, reducing the total cost of ownership.

How is ‘que es el motor de arranque’ Critical for Agriculture?

Agricultural machinery, including tractors and harvesters, relies heavily on starter motors to initiate operations. A robust starting system improves operational efficiency and reduces the likelihood of equipment failures during critical farming seasons. For international buyers, especially in regions with harsh climates, sourcing starter motors that are resistant to environmental stressors and have readily available spare parts is vital to maintaining productivity.

Why is a Reliable Starter Motor Important in Construction?

In the construction industry, machinery such as excavators and bulldozers must have dependable starting systems to meet project deadlines. A reliable starter motor minimizes the risk of downtime, which can lead to costly delays. Buyers should prioritize power requirements and ensure compatibility with existing machinery, as well as consider the availability of support and replacement parts to maintain operational efficiency.

How Does ‘que es el motor de arranque’ Benefit Mining Operations?

In mining, heavy machinery relies on starter motors to function effectively under extreme conditions. A reliable starter motor increases productivity by reducing the risk of operational delays caused by equipment failure. Buyers in this sector need to focus on sourcing robust starter motors designed for high-performance applications, ensuring they can withstand the rigors of mining environments while providing consistent performance.

3 Common User Pain Points for ‘que es el motor de arranque’ & Their Solutions

Scenario 1: Understanding Motor Start-Up System Components

The Problem: Many B2B buyers, especially those in the automotive and transportation sectors, struggle with understanding the complex components of the motor start-up system. This lack of knowledge can lead to difficulties in sourcing the right parts or services for maintenance and repair. For instance, a fleet manager in Nigeria may encounter issues when trying to replace or repair a starter motor without fully understanding its role and the implications of using substandard components. This can lead to unexpected breakdowns, increased downtime, and ultimately, higher operational costs.

The Solution: To address this challenge, B2B buyers should invest in comprehensive training and resources that explain the motor start-up system’s components, such as the ignition switch, starter motor, and solenoid. Engaging with suppliers who provide educational materials and workshops can greatly enhance understanding. Additionally, buyers should seek to establish relationships with reliable parts manufacturers who offer high-quality components that meet international standards. By ensuring that all team members are well-informed about the system’s workings, businesses can make more confident purchasing decisions, leading to improved fleet reliability and reduced maintenance costs.

Scenario 2: Managing Battery Health for Optimal Performance

The Problem: A common issue for B2B buyers is managing the health of the vehicle’s battery, which is crucial for the motor start-up system. In regions with extreme temperatures, such as the Middle East, batteries can fail prematurely due to overheating or excessive cold. This can result in significant disruptions in logistics and transportation operations, as vehicles may fail to start when needed. For businesses relying on timely deliveries, such battery failures can lead to lost contracts and damaged reputations.

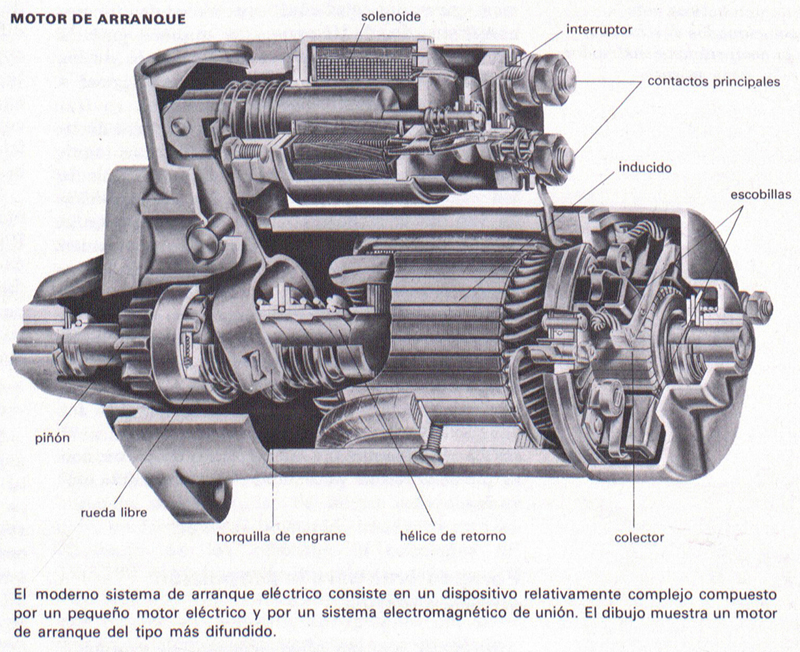

Illustrative image related to que es el motor de arranque

The Solution: To mitigate battery-related issues, B2B buyers should implement a proactive battery maintenance program. This includes regular inspections of battery terminals and connections to prevent corrosion, ensuring that batteries are adequately charged, and replacing them according to the manufacturer’s recommendations. Additionally, investing in battery management systems that provide real-time monitoring can help identify potential failures before they occur. Partnering with local automotive service providers for routine check-ups can further enhance battery longevity and reliability, ensuring that vehicles are always ready for operation.

Scenario 3: Preventing Overheating and System Failures

The Problem: Another prevalent pain point is the overheating of the starter motor, which can lead to system failures and costly repairs. This is particularly challenging for businesses with extensive vehicle fleets, such as logistics companies in South America, where the combination of heavy loads and hot climates can exacerbate the problem. When a starter motor overheats, it can lead to significant delays and increase the risk of complete engine failure, which is detrimental to operational efficiency.

The Solution: To prevent overheating, B2B buyers should prioritize routine maintenance checks that include inspecting the starter motor and its associated electrical connections. Implementing a scheduled maintenance program that focuses on cleaning debris and ensuring adequate airflow around the starter motor can significantly reduce the risk of overheating. Additionally, educating drivers about the importance of not engaging the starter for extended periods can prevent excessive heat buildup. Collaborating with automotive specialists for regular diagnostics can help identify underlying issues early, ensuring that the starter motor operates within its optimal temperature range and extends its lifespan.

Strategic Material Selection Guide for que es el motor de arranque

What Materials Are Commonly Used in Starter Motors?

When selecting materials for starter motors, several factors must be considered, including performance characteristics, cost, and compliance with international standards. Here, we analyze four common materials used in the construction of starter motors, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to que es el motor de arranque

Steel: The Backbone of Starter Motors

Key Properties: Steel is known for its high tensile strength, durability, and resistance to deformation under stress. It can withstand high temperatures and pressures, making it suitable for the demanding environment of a starter motor.

Pros & Cons: The primary advantage of steel is its robustness and longevity, which translates to a longer service life for starter motors. However, steel is susceptible to corrosion unless properly treated, which can lead to premature failure. Additionally, manufacturing complexity can increase due to the need for heat treatment and surface coatings.

Impact on Application: Steel components are compatible with high-temperature environments, making them ideal for automotive applications. However, they require careful handling to prevent corrosion, especially in humid or coastal regions.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that steel components meet local corrosion resistance standards. Compliance with ASTM or ISO standards is vital for ensuring product reliability.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight and offers excellent corrosion resistance, particularly when anodized. It has a lower melting point than steel, which can be advantageous in specific applications.

Pros & Cons: The key advantage of aluminum is its weight, which can contribute to overall vehicle efficiency. However, it is less durable than steel and may not withstand the same levels of stress, which could lead to failure under extreme conditions. Additionally, aluminum components can be more expensive to manufacture due to the need for specialized machining.

Impact on Application: Aluminum’s lightweight nature is beneficial for applications where weight savings are critical. However, its lower strength limits its use in high-stress components.

Illustrative image related to que es el motor de arranque

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prefer aluminum for its lightweight properties. Compliance with EU regulations regarding material safety and environmental impact is essential.

Copper: The Electrical Conductor

Key Properties: Copper is an excellent conductor of electricity, making it essential for electrical components in starter motors. It has good thermal conductivity and resistance to corrosion.

Pros & Cons: The primary advantage of copper is its superior electrical conductivity, which enhances the performance of starter motors. However, copper is relatively expensive compared to other materials and can be prone to oxidation, which can degrade its performance over time.

Impact on Application: Copper components are critical in ensuring efficient electrical flow, which is vital for the quick engagement of starter motors. However, oxidation can affect performance, necessitating regular maintenance.

Considerations for International Buyers: Buyers should be aware of the varying copper standards across regions, including compliance with ASTM and JIS standards. In regions like the Middle East, where high temperatures are common, ensuring that copper components are adequately treated to prevent oxidation is crucial.

Plastic Composites: Modern Solutions

Key Properties: Plastic composites are lightweight and can be engineered for specific thermal and electrical properties. They offer good resistance to corrosion and can be molded into complex shapes.

Pros & Cons: The main advantage of plastic composites is their versatility and lightweight nature. They can be less expensive to manufacture than metals. However, they may not withstand the same levels of mechanical stress and may degrade over time when exposed to high temperatures.

Impact on Application: Plastic composites can be used in non-load-bearing components of starter motors, such as housings and covers. Their lightweight nature can contribute to overall vehicle efficiency.

Considerations for International Buyers: Buyers should ensure that plastic composites meet relevant safety and performance standards. In Europe, compliance with REACH regulations is essential, while buyers in Africa may need to consider local environmental regulations.

Summary Table

| Material | Typical Use Case for que es el motor de arranque | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, gears | High strength and durability | Susceptible to corrosion, complex mfg | Medium |

| Aluminum | Housing, brackets | Lightweight, corrosion-resistant | Less durable under stress | High |

| Copper | Electrical connections | Excellent electrical conductivity | Expensive, prone to oxidation | High |

| Plastic Composites | Non-load-bearing components, housings | Lightweight, versatile | May not withstand high stress, thermal degradation | Low |

This strategic material selection guide provides valuable insights for B2B buyers in various regions, helping them make informed decisions when sourcing components for starter motors.

In-depth Look: Manufacturing Processes and Quality Assurance for que es el motor de arranque

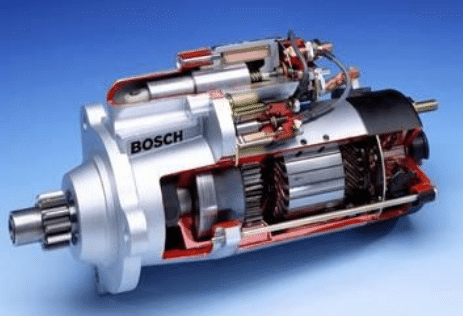

What Are the Key Stages in the Manufacturing Process of a Starter Motor?

The manufacturing process of a starter motor involves several critical stages to ensure quality and functionality. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Illustrative image related to que es el motor de arranque

1. Material Preparation

The first step in the manufacturing of starter motors is the selection and preparation of raw materials. Common materials include high-grade steel for the housing, copper for the windings, and various alloys for components like the solenoid. These materials are subjected to rigorous quality checks before processing to ensure they meet specifications. Suppliers often obtain certifications for their materials, ensuring compliance with international standards.

2. Forming Techniques

Forming is a crucial stage where raw materials are shaped into components. This can involve several techniques:

-

Stamping: This process is used to create the motor’s housing and other metal parts. High-precision stamping machines are employed to achieve the necessary tolerances.

-

Casting: Some components, such as the end bell, may be produced through casting processes, which allow for complex shapes and high durability.

-

Machining: Precision machining is used for parts that require exact dimensions, such as the rotor and stator. CNC (Computer Numerical Control) machines are typically utilized for this purpose to ensure high accuracy.

These forming techniques are designed to optimize the performance and longevity of the starter motor.

Illustrative image related to que es el motor de arranque

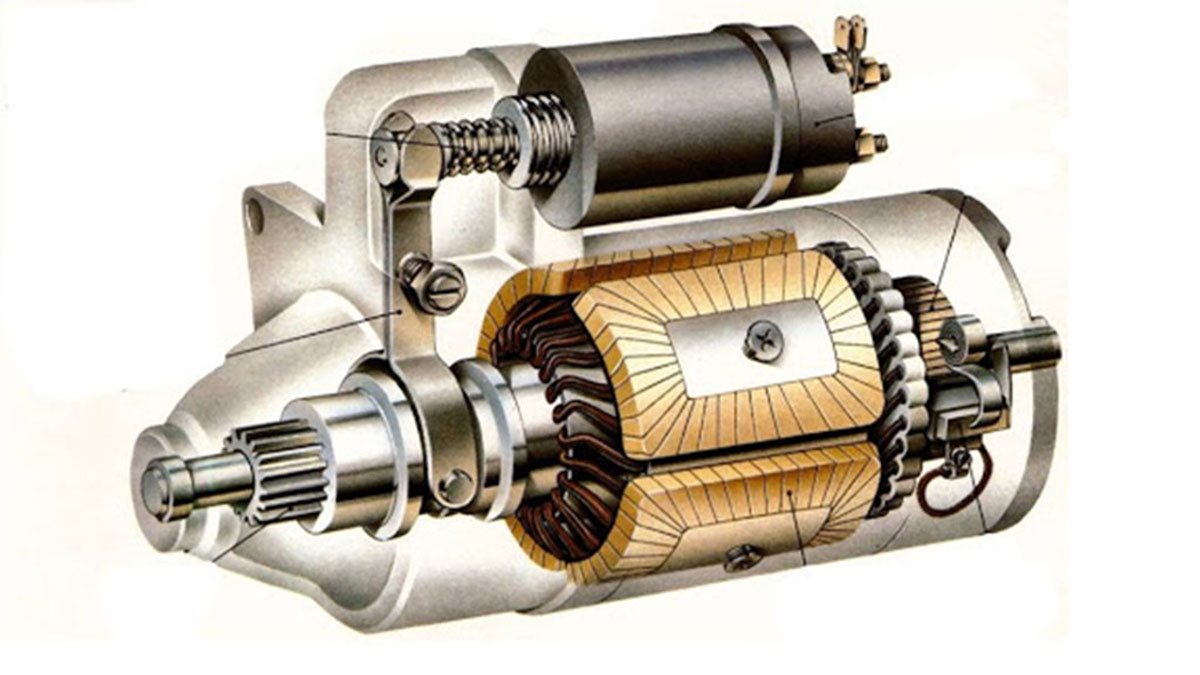

3. Assembly of Components

Once the individual parts are formed, they proceed to the assembly stage. This involves:

-

Winding the Coils: Copper wire is wound around the stator and rotor to create the electromagnetic fields necessary for motor operation.

-

Integrating Components: The various components, including the solenoid, brushes, and housing, are assembled in a clean environment to prevent contamination.

-

Electrical Connections: All electrical connections must be secure, and this often involves soldering and crimping techniques to ensure durability and reliability.

Assembly is typically done in a controlled environment to minimize defects and ensure quality.

4. Finishing Processes

After assembly, finishing processes are applied to enhance the motor’s durability and performance. These processes include:

-

Coating: Components may be coated with protective finishes to prevent corrosion and wear, particularly in harsh environments.

-

Testing: Each starter motor undergoes rigorous testing to ensure it meets performance standards. This includes electrical testing, functionality checks, and thermal testing to simulate operating conditions.

Finishing touches not only improve the aesthetic quality of the product but also its resilience against various operational challenges.

How Is Quality Assurance Implemented in Starter Motor Manufacturing?

Quality assurance (QA) in starter motor manufacturing is critical to ensuring reliability and performance. B2B buyers must understand the QA processes to assess potential suppliers effectively.

Illustrative image related to que es el motor de arranque

International Standards Relevant to Starter Motors

Manufacturers of starter motors are often required to comply with international standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with these standards indicates that a company adheres to best practices in quality control and management.

In addition, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for specific automotive applications may also be necessary. These certifications help ensure that products meet safety, health, and environmental protection standards.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints:

-

Incoming Quality Control (IQC): This stage involves checking raw materials and components upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted to catch defects early. This includes monitoring dimensions, tolerances, and assembly accuracy.

-

Final Quality Control (FQC): Once the starter motors are fully assembled, a final inspection is performed. This includes functionality tests, stress tests, and visual inspections for defects.

Common Testing Methods for Starter Motors

To ensure the reliability of starter motors, several testing methods are commonly employed:

-

Electrical Testing: Verifying the electrical resistance and functionality of the motor under different conditions.

-

Load Testing: Assessing the motor’s performance under actual load conditions to simulate real-world usage.

-

Vibration and Noise Testing: Evaluating the motor’s operational noise levels and vibrations to ensure it meets industry standards.

These tests are crucial for identifying potential failures and ensuring that the starter motor performs as expected in various conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is paramount to ensuring product reliability. Here are some methods to consider:

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. These audits help verify compliance with international standards and allow buyers to assess the effectiveness of the supplier’s QA measures.

Reviewing Quality Reports and Certifications

Buyers should request quality reports and certifications from suppliers. These documents should detail the manufacturing processes, testing methods, and results of quality checks. Reviewing this information can help buyers understand the supplier’s commitment to quality.

Utilizing Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct inspections at various stages of production, ensuring that the products meet specified standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances in quality control when sourcing starter motors from various regions. Factors to consider include:

-

Regional Compliance Standards: Different regions may have varying compliance requirements. For example, products sold in Europe must meet CE standards, while those in the U.S. may require adherence to ANSI (American National Standards Institute) regulations.

-

Cultural Differences in Quality Perception: Understanding the cultural context of suppliers can influence quality expectations. What is considered acceptable quality in one region may not meet standards in another.

-

Communication Barriers: Clear communication regarding quality expectations is crucial. Language differences can lead to misunderstandings, so it is important to establish clear guidelines and expectations.

By keeping these factors in mind, B2B buyers can enhance their procurement strategies and ensure they partner with reliable manufacturers of starter motors.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘que es el motor de arranque’

The following guide serves as a practical checklist for B2B buyers looking to procure components related to the starting system, specifically ‘que es el motor de arranque’. Understanding this component’s significance is essential for ensuring optimal vehicle performance and reliability.

Illustrative image related to que es el motor de arranque

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s vital to establish clear technical specifications for the starter motor. Consider factors such as voltage requirements, size dimensions, and compatibility with various vehicle models. Defining these specifications helps streamline the sourcing process and ensures that you acquire the correct component for your needs.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers who specialize in automotive components, particularly starter motors. Look for suppliers with a proven track record in the industry, particularly those who have experience serving your geographic region. This research can include online reviews, industry reports, and recommendations from other businesses in your network.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 or other quality management standards. Certifications indicate a commitment to quality and reliability in manufacturing processes. Additionally, check for compliance with international safety and environmental standards, which can be crucial depending on your market.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of their starter motors for testing purposes. This step allows you to assess the quality and performance of the product firsthand. Evaluate the sample’s durability, efficiency, and compatibility with your specifications before making a bulk order.

Step 5: Analyze Pricing and Payment Terms

Compare pricing structures among your shortlisted suppliers to ensure you are getting competitive rates. Pay attention to payment terms, including discounts for bulk orders, warranties, and after-sales support. Understanding the total cost of ownership, including maintenance and potential replacements, is essential for making an informed decision.

Step 6: Assess After-Sales Support and Warranty Policies

Inquire about the after-sales support offered by suppliers, including technical assistance and warranty policies. A reliable supplier should provide comprehensive support to address any issues that arise post-purchase. Evaluate the warranty duration and coverage to ensure you are protected against manufacturing defects.

Step 7: Finalize Contracts and Agreements

Once you have evaluated all aspects, finalize contracts with your chosen supplier. Ensure that all terms, including delivery timelines, payment schedules, and quality expectations, are clearly outlined in the agreement. Having a well-defined contract protects both parties and establishes accountability.

By following this practical sourcing checklist, B2B buyers can navigate the procurement of starter motors effectively, ensuring they select high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for que es el motor de arranque Sourcing

What Are the Key Cost Components in Sourcing a Starter Motor?

Understanding the cost structure associated with sourcing a starter motor is crucial for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The raw materials used in starter motor production, such as copper for windings and steel for housing, significantly affect costs. Fluctuations in global commodity prices can lead to variations in sourcing expenses. Buyers should consider suppliers that can offer competitive material prices without compromising quality.

-

Labor: Labor costs can vary widely by region. In countries with lower wage standards, labor-intensive processes may be more cost-effective. However, regions with higher labor costs often emphasize skill and efficiency, which can lead to better-quality products and faster turnaround times.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Tooling costs are significant in starter motor production, as specialized equipment is required for assembly and testing. Custom tooling for specific motor designs can increase initial costs but may reduce long-term expenses through improved production efficiency.

-

Quality Control: Ensuring the quality of starter motors through rigorous testing and inspections can add to costs. However, investing in quality control can reduce warranty claims and enhance customer satisfaction, making it a worthwhile expense.

-

Logistics: Shipping costs are a critical factor, especially for international buyers. Factors such as distance, shipping method, and Incoterms can influence the overall logistics cost. Buyers should explore various shipping options to identify the most cost-effective solutions.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the margin expectations of suppliers can aid in negotiations and help buyers make informed sourcing decisions.

What Influences the Pricing of Starter Motors for International Buyers?

Several factors influence the pricing of starter motors, particularly for international B2B buyers. These include volume or minimum order quantities (MOQs), specifications and customization options, material quality, supplier reliability, and Incoterms.

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their demand forecasts to negotiate better pricing terms based on volume.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Buyers should balance the need for customization with cost implications, ensuring that any modifications genuinely add value.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as ISO) can significantly impact pricing. Buyers should prioritize suppliers who provide transparency regarding material sourcing and quality assurance processes.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers may charge higher prices but often provide better service and product quality. Conducting thorough supplier evaluations can lead to more informed purchasing decisions.

-

Incoterms: Understanding Incoterms is essential for managing shipping costs and responsibilities. Different Incoterms can affect pricing by shifting the burden of freight and customs clearance to either the buyer or the seller.

What Tips Can Help Buyers Negotiate Better Prices for Starter Motors?

Negotiation is key in achieving cost-efficient sourcing for starter motors. Here are several tips to help international buyers enhance their purchasing strategies:

-

Total Cost of Ownership: Consider the total cost of ownership, which includes not only the purchase price but also maintenance, operational efficiency, and potential resale value. This holistic view can guide buyers toward better long-term investments.

-

Leverage Relationships: Building strong relationships with suppliers can facilitate better negotiations. Long-term partnerships often lead to more favorable pricing and terms.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends. Being informed about market conditions enables buyers to negotiate effectively and recognize fair pricing.

-

Flexibility in Orders: Be open to adjusting order quantities or delivery schedules. Flexibility can sometimes lead to better pricing or terms from suppliers.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide a clearer picture of the market and help identify the best deal. It also serves as leverage in negotiations.

By understanding the intricate cost structures and pricing dynamics of starter motors, B2B buyers can make informed decisions that maximize value while minimizing costs.

Alternatives Analysis: Comparing que es el motor de arranque With Other Solutions

Exploring Alternatives to “Que Es El Motor De Arranque”

When considering the “que es el motor de arranque,” it’s essential to evaluate other viable solutions or technologies that can perform similar functions in the automotive sector. The right choice often depends on performance, cost-effectiveness, ease of implementation, maintenance requirements, and specific use cases. Below, we compare the traditional starter motor with two alternative technologies: the Integrated Starter Generator (ISG) and Electric Vehicle (EV) Start-Up Systems.

Comparison Table

| Comparison Aspect | Que Es El Motor De Arranque | Integrated Starter Generator (ISG) | Electric Vehicle (EV) Start-Up Systems |

|---|---|---|---|

| Performance | High torque for combustion engines | Moderate torque; supports hybrid systems | Instant torque; designed for electric motors |

| Cost | Moderate initial cost; replacement can be expensive | Higher initial investment | Variable costs; depends on battery tech |

| Ease of Implementation | Standard installation in most vehicles | Requires compatible engine design | Complex integration in vehicle architecture |

| Maintenance | Regular checks needed; prone to wear | Minimal; less frequent maintenance | Low maintenance; battery health is key |

| Best Use Case | Conventional gasoline/diesel vehicles | Hybrid vehicles for improved efficiency | Fully electric vehicles with no combustion engine |

Detailed Breakdown of Alternatives

Integrated Starter Generator (ISG)

The Integrated Starter Generator (ISG) is an innovative solution that combines the functions of a starter motor and an alternator. It allows for a more efficient start-stop system, especially in hybrid vehicles. The ISG provides moderate torque and enhances fuel efficiency by enabling regenerative braking. However, its initial investment is generally higher than that of traditional starter motors. Additionally, ISG systems require a compatible engine design, which may limit their applicability in older vehicle models.

Illustrative image related to que es el motor de arranque

Electric Vehicle (EV) Start-Up Systems

Electric Vehicle (EV) start-up systems represent a significant shift in automotive technology, as they rely on electric motors instead of traditional combustion engines. These systems provide instant torque, making them highly efficient for starting and accelerating. Maintenance is relatively low, focusing primarily on battery health rather than mechanical wear and tear. However, the costs associated with EV technology can vary widely depending on the battery technology used, and the complexity of integration into existing automotive designs can be a barrier for some manufacturers.

Conclusion: Choosing the Right Solution for Your Needs

In determining the most suitable solution, B2B buyers should evaluate their specific requirements, including the type of vehicles they operate, budget constraints, and maintenance capabilities. For conventional vehicles, the traditional starter motor remains a reliable choice, while those looking to enhance efficiency in hybrid models may benefit from ISG technology. On the other hand, companies transitioning to electric vehicles will find that EV start-up systems offer unparalleled efficiency and lower maintenance in the long run. Each option has its pros and cons, and understanding these factors is crucial for making an informed decision that aligns with your operational goals.

Essential Technical Properties and Trade Terminology for que es el motor de arranque

What Are the Key Technical Properties of a Starter Motor?

Understanding the technical properties of a starter motor is crucial for international B2B buyers involved in automotive manufacturing or repair. Here are some essential specifications that can impact performance and durability:

-

Material Grade

The materials used in the construction of a starter motor, such as copper for windings and durable steel for the housing, significantly influence its efficiency and longevity. High-grade materials reduce wear and tear, ensuring reliable performance over time. For B2B buyers, sourcing starter motors made from superior materials can lead to lower replacement costs and enhanced vehicle reliability. -

Torque Rating

Torque rating is a critical specification that indicates the amount of rotational force the starter motor can generate. A higher torque rating typically results in better engine start-up capabilities, especially in cold weather or high-compression engines. For businesses, understanding torque requirements can help ensure compatibility with various vehicle models, thus preventing operational issues. -

Voltage Rating

Most starter motors operate at either 12V or 24V, depending on the vehicle type. The voltage rating determines the motor’s efficiency and compatibility with the vehicle’s electrical system. Buyers must ensure that the starter motor matches the vehicle’s specifications to avoid electrical failures and potential damage to other components. -

Current Draw

The current draw refers to the amount of electrical current the starter motor requires to operate. A lower current draw is beneficial as it minimizes strain on the vehicle’s battery and electrical system. Understanding current requirements is essential for B2B buyers when evaluating starter motors for fleet vehicles, as it impacts battery life and overall vehicle performance. -

Dimensions and Weight

The physical dimensions and weight of the starter motor are important for installation compatibility. A compact and lightweight starter motor can facilitate easier installation and may be preferable for certain vehicle designs. B2B buyers should consider these factors to avoid issues during the integration of starter motors into their vehicle assembly lines. -

Durability Rating

The durability rating, often measured in cycles or hours of operation, indicates how long a starter motor can function before failure. A higher durability rating translates to lower maintenance costs and improved reliability. For businesses, investing in starter motors with robust durability ratings can enhance customer satisfaction and reduce warranty claims.

What Trade Terms Are Commonly Used in the Starter Motor Industry?

Understanding industry jargon is vital for effective communication and negotiation in the B2B space. Here are some key terms associated with starter motors:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are used as components in another company’s product. In the starter motor industry, sourcing from OEMs ensures that the components meet the original specifications, which can be critical for maintaining vehicle performance and safety. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it can affect inventory costs and cash flow. Buyers should negotiate MOQs that align with their purchasing needs to avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a price quote for specific products or services. In the context of starter motors, issuing an RFQ helps buyers compare prices and terms from different suppliers, facilitating informed decision-making. -

Incoterms

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping contracts. Familiarity with these terms can help B2B buyers understand their obligations regarding shipping costs, risks, and insurance when importing starter motors from different regions. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is critical for B2B buyers to plan their inventory and production schedules effectively, ensuring that they can meet customer demands without delays. -

Warranty Period

The warranty period is the duration for which the manufacturer guarantees the starter motor against defects. A longer warranty period can indicate higher confidence in product quality. B2B buyers should assess warranty terms to mitigate risks and enhance customer satisfaction with their products.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they procure reliable and efficient starter motors for their operations.

Navigating Market Dynamics and Sourcing Trends in the que es el motor de arranque Sector

What Are the Key Market Drivers and Trends in the ‘Que es el motor de arranque’ Sector?

The global automotive sector is undergoing significant transformation, driven by technological advancements, regulatory changes, and shifting consumer preferences. Key trends influencing the ‘que es el motor de arranque’ sector include the rise of electric vehicles (EVs), which require innovative starting systems, and the demand for enhanced efficiency and reliability in traditional combustion engines. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing components that not only meet performance standards but also align with emerging sustainability mandates.

The integration of smart technologies, such as IoT-enabled diagnostics and predictive maintenance, is reshaping how starting systems are designed and manufactured. These innovations offer enhanced operational efficiency and enable proactive maintenance, reducing downtime for fleet operators and individual vehicle owners alike. Additionally, the competitive landscape is characterized by a growing emphasis on local sourcing and partnerships, allowing buyers to leverage regional expertise while minimizing lead times.

Emerging markets present unique opportunities, as increasing vehicle ownership and infrastructure development drive demand for reliable starting systems. For instance, in Nigeria, a rapidly growing automotive market, local manufacturers are beginning to prioritize quality and innovation to meet the expectations of discerning buyers. As such, international buyers must stay attuned to these market dynamics to secure strategic partnerships and ensure a steady supply of high-quality components.

How Can Sustainability and Ethical Sourcing Impact the ‘Que es el motor de arranque’ Sector?

Sustainability is becoming a pivotal consideration in the sourcing of automotive components, including starting systems. The environmental impact of production processes, resource extraction, and end-of-life disposal is under scrutiny, prompting buyers to seek suppliers that prioritize eco-friendly practices. Ethical sourcing not only addresses environmental concerns but also enhances brand reputation and customer loyalty.

Illustrative image related to que es el motor de arranque

B2B buyers should look for suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 for environmental management systems or adherence to the Global Reporting Initiative (GRI) standards. Furthermore, sourcing materials with lower environmental footprints, such as recycled metals or sustainable composites, can significantly reduce the overall impact of manufacturing starting systems.

The growing emphasis on transparency within supply chains means that buyers are increasingly interested in understanding the sourcing practices of their suppliers. Ensuring that components are manufactured under fair labor conditions and with minimal environmental impact is not just a regulatory requirement in many markets; it is also a business imperative that resonates with eco-conscious consumers.

What Is the Historical Context of the ‘Que es el motor de arranque’ Sector?

The history of starting systems dates back to the early 20th century when hand-crank engines were prevalent. The invention of the electric starter motor in 1912 revolutionized the automotive industry, providing a more efficient and user-friendly means of starting vehicles. This shift not only improved vehicle reliability but also paved the way for the development of advanced starting systems that incorporate electronic controls and smart technologies.

As the automotive landscape evolved, so did the design and functionality of starting systems. The transition from mechanical to electronic systems has allowed for greater precision and efficiency, catering to the needs of modern engines that demand higher performance. Today, the focus is on creating robust, lightweight, and energy-efficient starting systems that align with the demands of both traditional and electric vehicles, marking a significant evolution in the sector that continues to adapt to changing market dynamics and technological advancements.

Conclusion

The ‘que es el motor de arranque’ sector is poised for growth, driven by technological innovations and the increasing emphasis on sustainability. B2B buyers should be proactive in understanding market trends and the importance of ethical sourcing to navigate this dynamic landscape effectively. By partnering with forward-thinking suppliers, buyers can ensure they are well-positioned to meet the demands of the evolving automotive market.

Frequently Asked Questions (FAQs) for B2B Buyers of que es el motor de arranque

-

How do I solve issues with the starter motor in my vehicle?

To address problems with a starter motor, first check the battery voltage and connections, as a weak battery can hinder performance. Inspect the starter solenoid and motor for any signs of wear or damage. If the starter clicks but doesn’t engage, it may require replacement. Regular maintenance, including cleaning connections and ensuring the battery is charged, can prevent issues. For persistent problems, consult a professional mechanic to diagnose and resolve underlying issues effectively. -

What is the best starter motor for heavy-duty vehicles?

The best starter motor for heavy-duty vehicles typically features a higher torque output and robust construction to withstand demanding conditions. Look for models with sealed components to prevent dirt and moisture infiltration. Brands like Bosch and Delco Remy offer reliable options known for durability and performance. Assess your vehicle’s specifications, including voltage and mounting requirements, to ensure compatibility. Consulting with suppliers can help identify the best fit based on your operational needs. -

What factors should I consider when sourcing starter motors internationally?

When sourcing starter motors internationally, consider factors such as quality certifications, supplier reliability, and compliance with local regulations. Evaluate the manufacturer’s reputation and seek references or reviews from previous clients. Additionally, assess the logistics involved, including shipping times and costs, to ensure timely delivery. Understanding payment terms and warranty conditions is crucial for minimizing risks. Engaging in thorough supplier vetting will enhance your procurement process. -

What are the minimum order quantities (MOQs) for starter motors?

Minimum order quantities (MOQs) for starter motors can vary significantly based on the supplier and the type of motor. Typically, manufacturers may set MOQs ranging from 50 to 100 units for standard models, while custom or specialized motors may have higher MOQs. It’s advisable to discuss your specific requirements with potential suppliers to negotiate favorable terms. Smaller orders may be available through distributors, but pricing may be less competitive compared to bulk purchases. -

How can I ensure the quality of starter motors from my suppliers?

To ensure quality, request samples from potential suppliers before placing large orders. Verify that the motors comply with relevant quality standards, such as ISO certifications. Implement a quality assurance process that includes regular inspections and testing of the starter motors upon receipt. Establishing clear specifications and expectations with your supplier can also help maintain quality control. Engaging third-party inspection services can provide an additional layer of assurance. -

What payment terms are common when purchasing starter motors?

Common payment terms for purchasing starter motors include options like net 30 or net 60 days, requiring payment within 30 or 60 days after invoice receipt. Some suppliers may offer a discount for upfront payments or require a deposit before production. It’s essential to clarify payment methods accepted, such as bank transfers or letters of credit. Understanding the payment terms and negotiating favorable conditions can enhance cash flow management and reduce financial risk. -

What logistics considerations should I keep in mind when importing starter motors?

When importing starter motors, consider logistics factors such as shipping methods, customs duties, and import regulations in your country. Choose between air freight for speed or sea freight for cost-effectiveness based on your timeline and budget. Ensure that your supplier provides necessary documentation, including certificates of origin and compliance. Collaborating with a reliable freight forwarder can streamline the import process and help navigate any regulatory challenges. -

How can I customize starter motors to meet specific requirements?

Customization of starter motors can be achieved by discussing your specific needs with the manufacturer or supplier. Options may include altering voltage specifications, modifying physical dimensions, or incorporating unique features such as enhanced weatherproofing. Provide detailed specifications and performance criteria to the supplier to ensure that the customized motors meet your operational demands. Be aware that customization may affect lead times and pricing, so factor these into your project planning.

Top 4 Que Es El Motor De Arranque Manufacturers & Suppliers List

1. Driver Center – Motor de Arranque

Domain: drivercenter.eu

Introduction: El motor de arranque transforma la energía eléctrica de la batería en energía mecánica para arrancar el motor de combustión. Está compuesto por varias partes: solenoide, rotor, bobinas inductoras, escobillas, horquilla y piñón de ataque. Los problemas comunes incluyen ruidos al arrancar, el coche que no arranca o poca reacción del motor. El costo de un motor de arranque varía entre 120€ y 300€, pu…

2. Renauto – Motores de Arranque

Domain: renauto.es

Introduction: El motor de arranque es un componente esencial que permite la puesta en marcha del motor térmico del vehículo. Es un mecanismo eléctrico que se activa al girar la llave de contacto o presionar el botón de encendido. Sus partes incluyen: carcasa (hecha de hierro), bobinas inductoras (generan el campo magnético), escobillas (transmiten energía eléctrica al rotor), rotor (transforma energía eléctrica…

3. Autonocion – Motor de Arranque del Coche

Domain: autonocion.com

Registered: 2011 (14 years)

Introduction: Motor de arranque del coche: Es un motor eléctrico que proporciona el primer impulso al cigüeñal para iniciar el ciclo de combustión. Partes principales: 1. Interruptor de encendido: permite el paso de corriente eléctrica. 2. Batería: suministra corriente a todos los sistemas eléctricos. 3. Motor de arranque: convierte energía eléctrica en mecánica. Componentes del motor de arranque: – Carcasa: su…

4. HR Motor – Arranque Esencial

Domain: hrmotor.com

Registered: 2003 (22 years)

Introduction: El motor de arranque es un componente esencial en los vehículos de combustión interna, encargado de poner en marcha el motor principal. Funciona como un motor eléctrico que, al recibir energía de la batería, genera un par de fuerzas que impulsan el motor principal mediante un engranaje llamado piñón de bendix. Los motores de arranque han evolucionado desde manuales hasta eléctricos, mejorando en r…

Strategic Sourcing Conclusion and Outlook for que es el motor de arranque

In summary, understanding the motor de arranque is crucial for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This essential component, responsible for converting electrical energy into mechanical power, is pivotal for the efficient operation of vehicles. Strategic sourcing of high-quality starter motors can lead to improved vehicle reliability and reduced maintenance costs, thereby enhancing overall operational efficiency.

By prioritizing strategic sourcing practices, businesses can ensure they are acquiring components that not only meet performance standards but also align with sustainability goals and technological advancements. This approach not only mitigates risks associated with supply chain disruptions but also fosters long-term partnerships with reliable suppliers.

As the automotive industry continues to evolve with innovations such as electric vehicles and advanced starter technologies, it is imperative for B2B buyers to stay informed and proactive in their sourcing strategies. Embrace the opportunity to enhance your supply chain by investing in quality components that drive performance and reliability. Engage with trusted suppliers, explore new technologies, and position your business for future growth in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to que es el motor de arranque

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.