Introduction: Navigating the Global Market for picture of alternator

In today’s global marketplace, sourcing high-quality pictures of alternators can pose a significant challenge for B2B buyers seeking to make informed purchasing decisions. With the automotive industry’s rapid evolution and the increasing demand for visual content in marketing and educational materials, understanding the nuances of alternator images is crucial. This comprehensive guide aims to equip international buyers, particularly from regions like Africa, South America, the Middle East, and Europe (including Saudi Arabia and Vietnam), with actionable insights into the various types of alternator pictures available, their applications, and the critical factors to consider when selecting suppliers.

Throughout this guide, we will explore the diverse categories of alternator images—from high-resolution stock photos to technical diagrams—tailored to meet the specific needs of your business. We will also delve into the importance of vetting suppliers to ensure the authenticity and quality of the images you acquire. Additionally, we’ll discuss the cost implications of sourcing these images and provide practical tips for maximizing your budget while achieving high standards of visual representation.

By the end of this guide, you will be empowered to make strategic decisions that not only enhance your marketing efforts but also foster stronger relationships with your customers and partners. With the right knowledge at your fingertips, navigating the complexities of the global market for alternator pictures will become a streamlined and efficient process.

Table Of Contents

- Top 4 Picture Of Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for picture of alternator

- Understanding picture of alternator Types and Variations

- Key Industrial Applications of picture of alternator

- 3 Common User Pain Points for ‘picture of alternator’ & Their Solutions

- Strategic Material Selection Guide for picture of alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for picture of alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘picture of alternator’

- Comprehensive Cost and Pricing Analysis for picture of alternator Sourcing

- Alternatives Analysis: Comparing picture of alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for picture of alternator

- Navigating Market Dynamics and Sourcing Trends in the picture of alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of picture of alternator

- Strategic Sourcing Conclusion and Outlook for picture of alternator

- Important Disclaimer & Terms of Use

Understanding picture of alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Automotive | Compact size, typically 12V output, belt-driven | Cars, light trucks, and SUVs | Pros: Widely available, cost-effective. Cons: Limited power for heavy-duty applications. |

| Heavy-Duty Alternator | Larger size, higher voltage (24V), robust construction | Trucks, buses, and industrial machinery | Pros: High output, durable for extreme conditions. Cons: More expensive and heavier. |

| Marine Alternator | Corrosion-resistant materials, designed for wet conditions | Boats and marine vehicles | Pros: Resilient against saltwater, specialized for marine use. Cons: Higher maintenance costs. |

| High-Performance Alternator | Enhanced cooling systems, upgraded components | Racing cars, performance vehicles | Pros: Increased efficiency and power output. Cons: Higher price point, may require specific installation. |

| Alternator with Integrated Voltage Regulator | Built-in voltage regulation technology | Modern vehicles with advanced electrical systems | Pros: Simplifies installation and improves efficiency. Cons: Potentially higher cost, less flexibility for upgrades. |

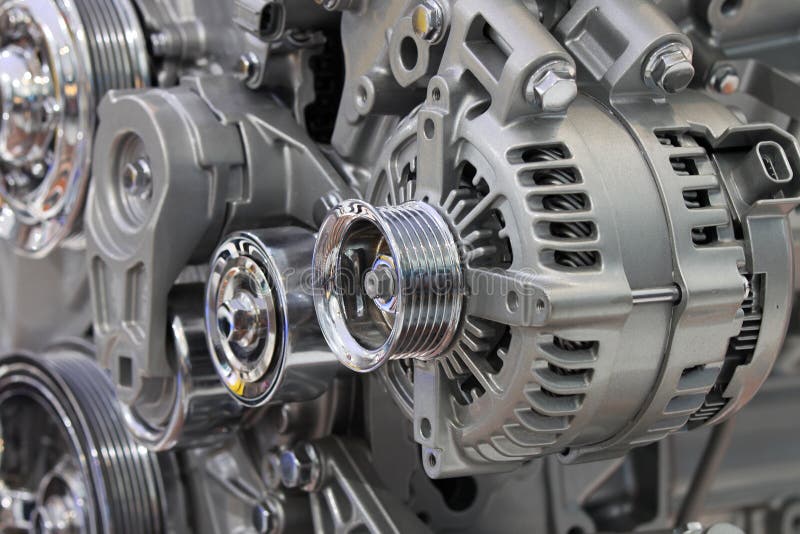

What Are the Key Characteristics of Standard Automotive Alternators?

Standard automotive alternators are the most common type used in passenger vehicles. They are designed to generate 12 volts of electrical power and are typically belt-driven, making them compact and lightweight. Ideal for everyday cars, light trucks, and SUVs, these alternators are favored for their cost-effectiveness and availability. Buyers should consider their vehicle’s electrical demands, as standard alternators may not suffice for those requiring higher power outputs.

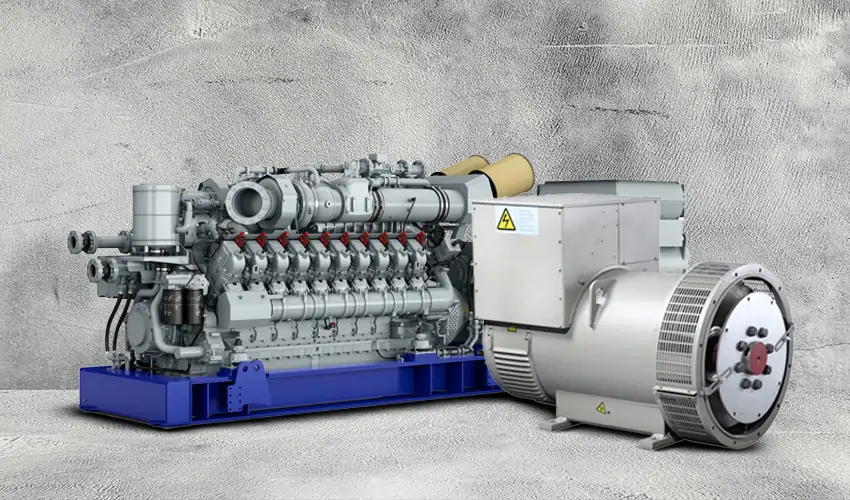

How Do Heavy-Duty Alternators Differ from Standard Ones?

Heavy-duty alternators are specifically engineered for larger vehicles such as trucks and buses, featuring a robust design that can handle 24 volts and higher outputs. These alternators are built to endure extreme conditions, making them suitable for industrial machinery as well. While they offer the advantage of high output and durability, buyers should be prepared for a higher upfront cost and increased weight, which can affect vehicle performance.

What Makes Marine Alternators Unique?

Marine alternators are built with corrosion-resistant materials to withstand harsh marine environments, including exposure to saltwater. Their design focuses on reliability and performance in wet conditions, making them ideal for boats and other marine vehicles. While they provide excellent resilience, buyers must consider the potential for higher maintenance costs due to the specialized components required for marine applications.

What Are the Advantages of High-Performance Alternators?

High-performance alternators are designed for racing cars and performance vehicles, incorporating enhanced cooling systems and upgraded components to increase efficiency and power output. These alternators are essential for high-demand electrical systems often found in competitive racing environments. However, their higher price point and specific installation requirements may deter some buyers, making it crucial to evaluate the vehicle’s performance needs before purchase.

Why Choose Alternators with Integrated Voltage Regulators?

Alternators with integrated voltage regulators offer a streamlined solution for modern vehicles equipped with advanced electrical systems. By simplifying installation and improving overall efficiency, these alternators are increasingly popular among manufacturers. However, buyers should be aware of the potentially higher costs and reduced flexibility for future upgrades, which may influence their purchasing decision based on long-term vehicle maintenance plans.

Key Industrial Applications of picture of alternator

| Industry/Sector | Specific Application of picture of alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Product catalogs and training materials for alternator components | Enhanced understanding of product specifications and assembly processes | Quality of images, clarity for technical manuals, and licensing options |

| Renewable Energy | Marketing materials for hybrid and electric vehicle alternators | Improved visibility and differentiation in a competitive market | High-resolution images, adaptability for various media formats |

| Construction Equipment | Maintenance guides for heavy machinery alternators | Increased uptime and reduced repair costs | Durability of images in outdoor settings, compatibility with manuals |

| Marine Industry | Technical documentation for marine alternators | Compliance with safety standards and operational efficiency | Licensing for commercial use, clarity in complex diagrams |

| Industrial Machinery | Training resources for alternator installation and repair | Enhanced workforce competency and reduced errors | Image quality, relevance to specific machinery types, and accessibility |

How is the ‘picture of alternator’ utilized in automotive manufacturing?

In the automotive manufacturing sector, pictures of alternators are essential for creating comprehensive product catalogs and training materials. These images help technicians and assembly line workers understand the specifications and assembly processes of various alternator models. By providing clear visuals, manufacturers can ensure that their staff is well-informed about the components, which helps reduce errors during installation and maintenance. For international buyers, especially those in regions like Africa and South America, sourcing high-quality images can also assist in aligning with local regulations and standards.

What role does the ‘picture of alternator’ play in renewable energy marketing?

In the renewable energy sector, particularly for hybrid and electric vehicles, pictures of alternators are pivotal in marketing efforts. These images are used in promotional materials to showcase advanced alternator technology and efficiency. By highlighting these features, companies can enhance their visibility and differentiate their products in a competitive market. For B2B buyers in Europe and the Middle East, it’s crucial to ensure that the images are high-resolution and adaptable for various media formats, as this can significantly impact the effectiveness of marketing campaigns.

How does the ‘picture of alternator’ support maintenance in construction equipment?

In the construction equipment industry, pictures of alternators serve as vital components of maintenance guides. These visuals aid operators and technicians in identifying alternator locations and understanding their functionality within heavy machinery. By improving the clarity of maintenance documentation, companies can increase equipment uptime and reduce repair costs. For buyers in regions like Africa and South America, sourcing images that are durable and clear enough for outdoor settings is essential to ensure that the information remains accessible in various working conditions.

Why are ‘pictures of alternator’ important in marine industry documentation?

In the marine industry, pictures of alternators are crucial for technical documentation and compliance with safety standards. These images help illustrate the installation and operational procedures for marine alternators, ensuring that crews are well-trained and aware of safety protocols. For businesses operating in international waters, having clear and compliant visuals can significantly enhance operational efficiency. Key considerations for sourcing these images include licensing for commercial use and ensuring clarity in complex diagrams that may be required for regulatory compliance.

What is the significance of ‘pictures of alternator’ in industrial machinery training?

In the realm of industrial machinery, pictures of alternators are invaluable for training resources aimed at installation and repair. These visuals enhance workforce competency by providing clear examples of how to handle various alternator models, thereby reducing errors and improving safety. For B2B buyers, especially in regions with diverse industrial practices, sourcing relevant images that reflect specific machinery types is essential. Additionally, ensuring the images are accessible and of high quality can facilitate better learning outcomes and operational efficiency.

3 Common User Pain Points for ‘picture of alternator’ & Their Solutions

Scenario 1: Sourcing High-Quality Images for Marketing Materials

The Problem: B2B buyers often struggle to find high-quality images of alternators that effectively convey the product’s features and benefits for marketing purposes. This challenge is compounded by the need for images that not only meet resolution and quality standards but also align with the branding and messaging of the company. Low-quality or poorly curated images can lead to ineffective marketing campaigns, undermining the perceived value of the product.

The Solution: To overcome this challenge, buyers should utilize reputable stock photo platforms that specialize in automotive images, such as Adobe Stock or Shutterstock. When sourcing images, buyers should filter results based on resolution and licensing options to ensure they receive high-quality images suitable for print and digital use. Additionally, buyers can engage professional photographers who understand automotive components to create custom images that highlight unique features of their alternators. This personalized approach not only enhances brand identity but also builds trust with potential customers by showcasing the product in a professional light.

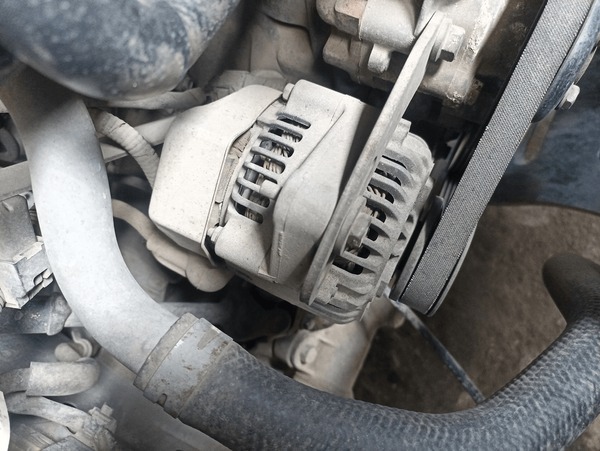

Illustrative image related to picture of alternator

Scenario 2: Ensuring Accurate Representation in Technical Documentation

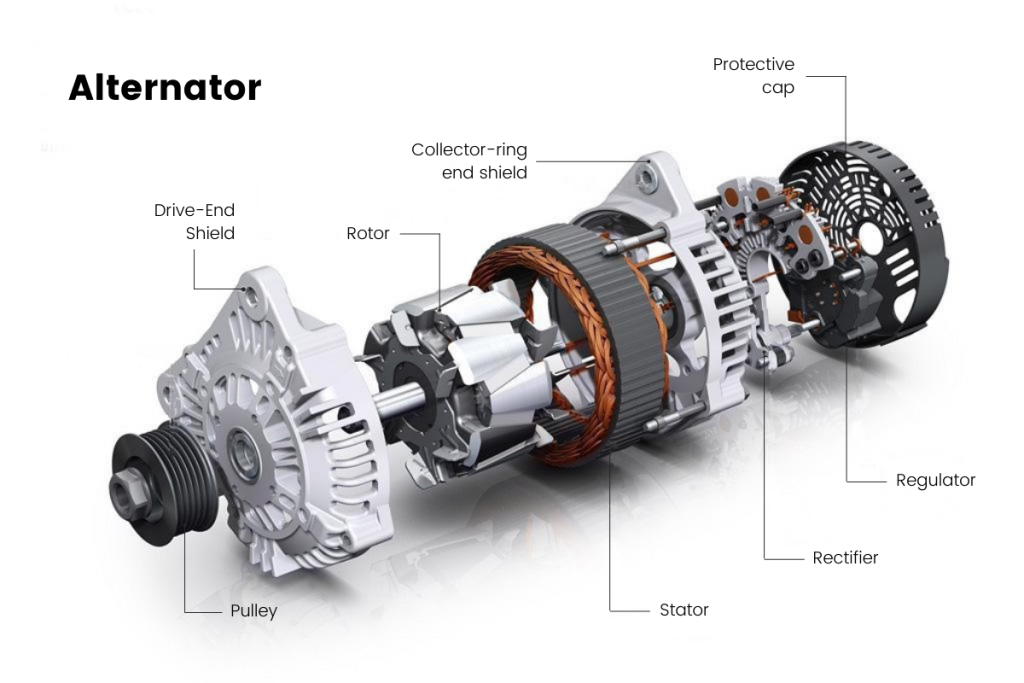

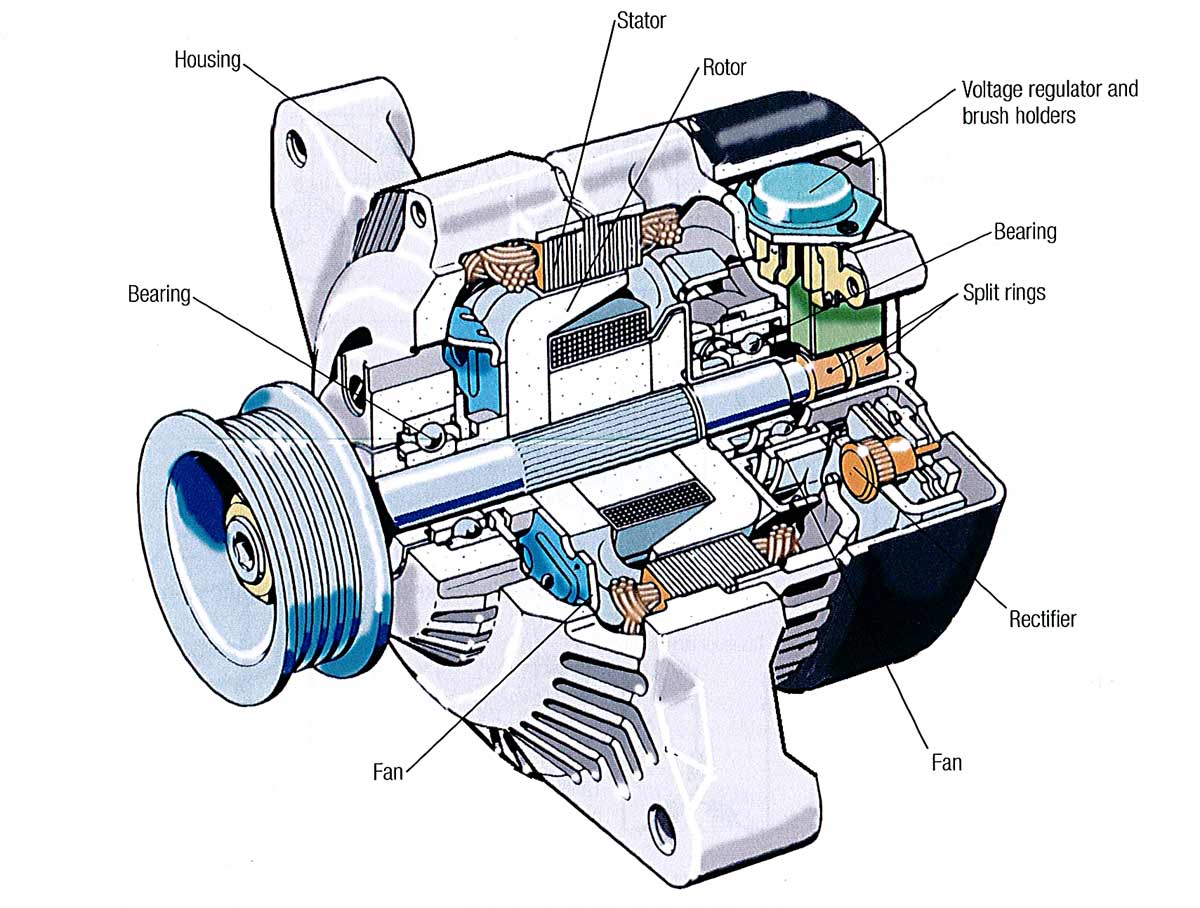

The Problem: Another common pain point for B2B buyers is the difficulty in finding accurate images of alternators for technical documentation. Misrepresentation of product details through inaccurate images can lead to misunderstandings about the product’s specifications and performance, which could ultimately affect customer satisfaction and product returns. Technical teams often require precise images that detail specific components, such as the rotor, stator, and rectifier, which are essential for installation and maintenance guides.

The Solution: To address this issue, buyers should focus on sourcing images from manufacturers or technical guides that provide detailed diagrams and descriptions. Collaborating with engineers to create custom illustrations or photographs can also ensure that all components are accurately represented. Furthermore, investing in 3D modeling technology can offer interactive visualizations that allow potential customers to explore the alternator’s inner workings, thereby enhancing understanding and reducing the risk of miscommunication.

Scenario 3: Navigating Licensing and Usage Rights for Images

The Problem: B2B buyers frequently encounter challenges regarding the licensing and usage rights of images they wish to use. Misunderstanding these legal aspects can lead to unintended copyright violations, resulting in costly fines and damage to the company’s reputation. Buyers may find themselves overwhelmed by the variety of licensing agreements available, which can create uncertainty about how and where they can use the images they acquire.

The Solution: To mitigate this risk, buyers should familiarize themselves with different types of licensing agreements, such as royalty-free, rights-managed, and extended licenses. A detailed assessment of how the images will be used—whether for online marketing, print materials, or internal documentation—will help in selecting the appropriate licensing type. It is advisable to consult with legal professionals or industry experts who specialize in intellectual property rights to ensure compliance. Additionally, opting for platforms that offer clear licensing terms and customer support can simplify the process and provide peace of mind regarding the legality of image usage.

Strategic Material Selection Guide for picture of alternator

What Are the Key Materials Used in Alternator Manufacturing?

When selecting materials for alternators, several options are commonly used, each with distinct properties and implications for performance, cost, and suitability for various applications. Below, we analyze four prevalent materials: aluminum, steel, copper, and plastic.

How Does Aluminum Benefit Alternator Design?

Aluminum is frequently utilized in the housing and components of alternators due to its lightweight nature and excellent thermal conductivity. This material can withstand temperatures up to 150°C, making it suitable for automotive applications where heat dissipation is crucial.

Pros and Cons: Aluminum’s lightweight characteristic enhances fuel efficiency in vehicles, while its corrosion resistance prolongs the lifespan of the alternator. However, the manufacturing complexity can be higher due to the need for specialized welding techniques. Additionally, aluminum can be less durable under extreme mechanical stress compared to steel.

Impact on Application: Aluminum is compatible with various automotive fluids, making it a versatile choice for alternators. However, international buyers should consider the specific alloy grades used, as they can affect performance under different environmental conditions.

What Role Does Steel Play in Alternator Durability?

Steel is often used in the structural components of alternators, particularly in the rotor and stator. Its high tensile strength allows it to endure significant mechanical stress, with a temperature rating up to 300°C.

Pros and Cons: The durability of steel makes it ideal for heavy-duty applications, ensuring a long service life. However, it is heavier than aluminum, which may negatively impact vehicle efficiency. Additionally, steel is prone to corrosion unless treated, which can lead to increased maintenance costs.

Impact on Application: Steel’s robustness makes it suitable for applications in rugged environments, including construction and mining vehicles. Buyers in regions with high humidity or saline conditions, such as coastal areas in Africa and South America, should prioritize corrosion-resistant coatings.

Why Is Copper Essential for Electrical Conductivity in Alternators?

Copper is a key material in the windings of alternators due to its superior electrical conductivity. It operates effectively at temperatures up to 200°C and is crucial for efficient energy transfer.

Pros and Cons: The excellent conductivity of copper enhances the performance of alternators, leading to better energy efficiency and reduced heat generation. However, copper is more expensive than aluminum, which can increase overall production costs. Additionally, its weight can be a disadvantage in applications where reducing mass is critical.

Illustrative image related to picture of alternator

Impact on Application: Copper’s compatibility with various electrical systems makes it a standard choice for alternators globally. Buyers should be aware of fluctuations in copper prices, which can affect procurement budgets, especially in emerging markets.

How Does Plastic Contribute to Alternator Design?

Plastic is increasingly being used in non-structural components of alternators, such as housings and insulators. It can withstand temperatures up to 100°C and is often used for its lightweight and insulating properties.

Pros and Cons: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for rapid production and design flexibility. However, plastic is less durable than metals and can degrade under high temperatures or exposure to certain chemicals.

Impact on Application: In regions with lower mechanical stress requirements, plastic can be a cost-effective choice. However, international buyers should ensure compliance with local standards for materials used in automotive applications, as regulations can vary significantly.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for picture of alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and lightweight components | Lightweight and corrosion-resistant | Higher manufacturing complexity | Medium |

| Steel | Rotor and stator components | High tensile strength and durability | Heavier and prone to corrosion | Medium |

| Copper | Electrical windings | Excellent electrical conductivity | Expensive and heavier | High |

| Plastic | Non-structural components | Low cost and design flexibility | Less durable and temperature-sensitive | Low |

This analysis provides a comprehensive overview of the materials used in alternators, offering valuable insights for B2B buyers looking to make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for picture of alternator

What Are the Main Stages in the Manufacturing Process of Alternators?

The manufacturing process of alternators is complex and involves several critical stages, each essential for ensuring the quality and functionality of the final product.

Material Preparation: What Materials Are Used in Alternator Manufacturing?

The manufacturing of alternators begins with careful material selection. High-quality materials such as aluminum, copper, and steel are commonly used. Aluminum is typically employed for the casing due to its lightweight and corrosion-resistant properties. Copper is preferred for windings due to its excellent conductivity, while steel is used for components like the rotor and stator.

Before production begins, these materials undergo rigorous inspections to ensure they meet industry standards. Suppliers are often required to provide certificates of compliance, detailing material properties and testing results.

Illustrative image related to picture of alternator

Forming: How Are Alternator Components Shaped?

Once the materials are prepared, the next stage is forming. This involves various techniques such as casting, forging, and machining.

- Casting: Aluminum casings are often produced through die casting, allowing for precise shapes and reduced waste.

- Forging: Steel components are typically forged to enhance their strength and durability. This process involves shaping the metal using compressive forces.

- Machining: Precision machining is used to create intricate parts, such as the rotor and stator, ensuring they fit together seamlessly.

Each forming technique is chosen based on the component requirements, balancing factors like cost, weight, and strength.

How Are Alternators Assembled for Optimal Performance?

The assembly process is where individual components come together to form the complete alternator. This stage involves several key steps:

- Sub-Assembly: Components like the rotor, stator, and rectifier are assembled separately. This allows for easier handling and inspection.

- Main Assembly: The sub-assemblies are combined into the main alternator unit. Careful alignment is critical to ensure that components function correctly.

- Connection: Electrical connections are made, ensuring that the alternator can effectively convert mechanical energy into electrical energy.

During assembly, manufacturers often use automated systems to enhance accuracy and efficiency. However, skilled technicians are essential for quality checks and adjustments.

Illustrative image related to picture of alternator

What Finishing Techniques Are Employed to Enhance Durability?

Finishing processes are crucial for enhancing the durability and aesthetic appeal of alternators. Common finishing techniques include:

- Coating: Protective coatings are applied to prevent corrosion and wear. This may include anodizing aluminum casings or applying a paint finish.

- Polishing: Certain components may be polished to reduce friction and improve performance.

- Quality Control Inspections: After finishing, components undergo inspections to ensure that they meet the required specifications.

These finishing processes not only contribute to the alternator’s lifespan but also its appearance, which can be vital for B2B buyers who value product presentation.

What Quality Assurance Standards Are Relevant for Alternators?

Quality assurance is a critical aspect of alternator manufacturing, ensuring that the final product meets international standards and customer expectations.

What Are the Key International Standards for Alternator Quality Assurance?

Manufacturers typically adhere to several international standards to guarantee quality:

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries, including automotive. Compliance indicates a commitment to quality and continuous improvement.

- CE Marking: For products sold in the European Economic Area, CE marking demonstrates conformity with health, safety, and environmental protection standards.

- API Standards: For alternators used in specific applications, such as marine or industrial, adherence to American Petroleum Institute (API) standards may be required.

These certifications not only ensure compliance but also enhance the credibility of the manufacturer in the eyes of B2B buyers.

How Are Quality Control Checkpoints Structured During Manufacturing?

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process to catch defects early and maintain product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): Before production starts, raw materials are inspected for quality and specifications. This initial checkpoint is crucial for preventing defects from entering the production line.

- In-Process Quality Control (IPQC): During manufacturing, various inspections are conducted to ensure that components are being produced according to specifications. This includes measuring dimensions and checking for proper assembly.

- Final Quality Control (FQC): Once the alternators are fully assembled, they undergo final inspections. This includes functional testing to ensure they meet performance standards.

Each checkpoint is documented, providing a traceable quality history that B2B buyers can review.

What Testing Methods Are Commonly Used to Ensure Alternator Quality?

Testing methods employed during and after manufacturing are essential for verifying performance and reliability. Common testing methods include:

Illustrative image related to picture of alternator

- Electrical Testing: This involves measuring output voltage and current under different load conditions to ensure the alternator functions correctly.

- Thermal Testing: Alternators are subjected to high temperatures to assess their operational limits and durability.

- Vibration Testing: This simulates real-world conditions to ensure that the alternator can withstand the stresses of operation without failure.

These tests help manufacturers identify any potential issues before the product reaches the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial. Here are some strategies:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. This can be done through in-person visits or third-party audit services.

- Requesting QC Reports: Suppliers should be able to provide detailed quality control reports, including results from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Engaging third-party inspection agencies to conduct independent quality checks can add an extra layer of assurance.

These measures help ensure that the products received meet the expected quality standards, thus reducing the risk of defects and enhancing buyer satisfaction.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

B2B buyers from different regions must be aware of specific nuances in quality control and certification that may affect their purchasing decisions. For example:

- Regional Compliance: Different countries may have varying regulations regarding automotive components. Understanding local standards is essential for compliance.

- Cultural Expectations: Buyers from different regions may have distinct expectations regarding product quality and supplier reliability. This can influence the selection of suppliers and negotiation processes.

- Logistics and Supply Chain: The ability to verify quality control practices may be affected by logistical challenges, such as distance and communication barriers.

By being aware of these nuances, international B2B buyers can make more informed decisions and build stronger relationships with their suppliers.

In conclusion, the manufacturing processes and quality assurance practices for alternators are vital for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions and select suppliers that align with their quality standards and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘picture of alternator’

To successfully procure images of alternators for your B2B needs, follow this comprehensive sourcing checklist. This guide will help you navigate the complexities of selecting the right images that align with your business requirements.

Step 1: Identify Your Image Requirements

Clearly define what types of alternator images you need. Consider the purpose—are they for marketing, educational materials, or technical documentation? Knowing whether you require close-up shots, technical diagrams, or images of alternators in various applications can guide your sourcing strategy effectively.

- Types of Images: Determine if you need stock images, custom photography, or technical illustrations.

- Resolution Requirements: Specify the image resolution based on where the images will be used (e.g., web, print).

Step 2: Research Reputable Image Sources

Explore various platforms that offer high-quality images of alternators. Sites like iStock, Shutterstock, and Adobe Stock are popular for stock photography. Ensure the platforms you consider are reputable and provide a wide range of images.

- Licensing Options: Check for different licensing agreements to ensure you can use the images as intended.

- Image Quality: Look for platforms that provide high-resolution images suitable for your specific needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, assess the suppliers from whom you plan to purchase images. Review their portfolios and check for variety and quality in their offerings.

- Supplier Reputation: Research the supplier’s reputation through reviews and testimonials.

- Sample Requests: If possible, request samples or a trial period to evaluate the image quality and relevance.

Step 4: Verify Licensing and Usage Rights

Understanding licensing agreements is critical to avoid future legal issues. Ensure that you are clear on the usage rights associated with each image you intend to purchase.

Illustrative image related to picture of alternator

- Commercial vs. Editorial Use: Confirm whether the images can be used for commercial purposes or are restricted to editorial use.

- Exclusivity Options: Inquire if exclusive rights are available, particularly if the images will be central to your branding.

Step 5: Assess Image Relevance and Quality

Once you have shortlisted potential images, evaluate their relevance to your business context. High-quality images should not only be visually appealing but also accurately represent the alternator’s features and functions.

- Technical Accuracy: Ensure that the images depict the alternator correctly, especially if they will be used in technical documentation.

- Visual Appeal: Consider the composition and color balance of the images to ensure they align with your brand identity.

Step 6: Negotiate Pricing and Terms

When you have identified the right images and suppliers, it’s time to discuss pricing and terms. Don’t hesitate to negotiate for bulk purchasing discounts or better terms.

- Volume Discounts: If you need multiple images, inquire about bulk purchase discounts.

- Payment Terms: Clarify payment methods and any additional fees that may apply.

Step 7: Finalize Your Purchase and Keep Records

Once you have agreed on terms, finalize your purchase. Ensure that you keep records of your transactions, including invoices and licensing agreements, for future reference.

- Documentation: Maintain a file with all relevant agreements to safeguard your rights to use the images.

- Follow-Up: After the purchase, follow up with the supplier for any additional support or questions regarding the images.

By adhering to this checklist, B2B buyers can effectively source high-quality images of alternators that meet their specific needs while ensuring compliance with licensing and usage rights.

Comprehensive Cost and Pricing Analysis for picture of alternator Sourcing

What Are the Key Cost Components for Sourcing Pictures of Alternators?

When sourcing images of alternators, understanding the cost structure is vital for effective budgeting and price negotiation. The primary cost components include:

Illustrative image related to picture of alternator

-

Materials: This encompasses the digital resources used, such as high-resolution cameras and editing software. For stock images, the costs might be less significant, as they are usually bundled into a licensing fee.

-

Labor: The cost of professional photographers, graphic designers, or agencies who create or curate the images can vary. Labor costs might be higher for custom shoots compared to purchasing stock images.

-

Manufacturing Overhead: This includes expenses related to the production of images, such as studio rental, equipment maintenance, and utilities. For stock images, this is less of a concern, as these costs are typically absorbed by the provider.

-

Tooling: While not directly applicable to digital images, tooling can refer to software tools used in image production and editing.

-

Quality Control (QC): Ensuring that images meet specific quality standards can incur additional costs. This may involve post-production editing or hiring third-party reviewers to assess image quality.

-

Logistics: For physical images, logistics can involve shipping and handling costs. However, for digital images, this is generally minimal, focusing on the delivery method (e.g., online download).

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand, exclusivity of images, and the supplier’s brand reputation.

How Do Price Influencers Affect the Cost of Alternator Images?

Various factors can influence the pricing of alternator images:

-

Volume/MOQ (Minimum Order Quantity): Purchasing images in bulk can often lead to discounts. Agencies may offer tiered pricing based on the number of images purchased.

-

Specifications/Customization: Customized images tailored to specific requirements may incur higher costs compared to generic stock images. Custom shoots can involve additional planning and resources.

-

Materials Used: The quality of the images, such as resolution and the type of camera used, can significantly affect price. High-definition or specialized images command higher fees.

-

Quality and Certifications: Images that come with certain certifications (like ISO for quality) may be priced higher due to the assurance of quality and compliance.

-

Supplier Factors: The reputation and experience of the supplier can greatly impact pricing. Established suppliers may charge more due to their brand value.

-

Incoterms: Understanding the delivery terms is crucial, especially for international buyers. Different Incoterms can influence the final cost based on shipping responsibilities.

What Are Effective Buyer Tips for Negotiating Prices on Alternator Images?

When negotiating prices for alternator images, consider the following strategies:

-

Leverage Volume Discounts: If you plan to purchase multiple images, negotiate for a bulk discount. Suppliers may be more willing to reduce prices for larger orders.

-

Assess Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the potential long-term value of high-quality images, including their impact on marketing and branding efforts.

-

Understand Pricing Nuances for International Transactions: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and other fees that may affect the total cost.

-

Negotiate Terms: Don’t hesitate to discuss the terms of usage and licensing. A flexible agreement can often lead to lower costs, especially if you’re willing to accept non-exclusive rights.

-

Research Market Rates: Familiarize yourself with the standard pricing for similar images in your region. This knowledge can empower you in negotiations.

Disclaimer on Indicative Prices

While the costs outlined above provide a framework for budgeting and negotiation, actual prices may vary significantly based on specific requirements, supplier relationships, and market conditions. Always conduct thorough research and engage directly with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing picture of alternator With Other Solutions

Introduction to Alternative Solutions for Alternators

When considering the purchase or implementation of an alternator, it’s essential to explore various alternatives that can fulfill similar roles in automotive and industrial applications. This analysis aims to provide B2B buyers with a comparative overview of the traditional “picture of alternator” against alternative technologies, enabling informed decision-making tailored to specific operational needs.

Comparison Table

| Comparison Aspect | Picture Of Alternator | Alternative 1: Generator | Alternative 2: Battery Management System (BMS) |

|---|---|---|---|

| Performance | High efficiency in converting mechanical to electrical energy | Reliable power source for continuous operation | Manages energy flow and optimizes battery usage |

| Cost | Moderate initial investment with long-term savings | Higher upfront cost but lower maintenance | Varies based on technology and features, often cost-effective in long run |

| Ease of Implementation | Generally straightforward installation in vehicles | Requires proper setup and integration | Complexity varies; requires technical expertise for installation |

| Maintenance | Regular checks needed, typically low-cost | Maintenance can be higher due to mechanical parts | Minimal if properly configured, mainly software updates |

| Best Use Case | Ideal for automotive applications requiring stable electrical output | Best for off-grid power generation or backup power | Suitable for electric vehicles and systems needing energy efficiency |

Detailed Breakdown of Alternatives

Alternative 1: Generator

Generators serve as a robust alternative to alternators, particularly in scenarios requiring a steady power supply, such as in construction sites or remote locations. They can operate independently of the vehicle’s engine, making them versatile for various applications. However, generators typically come with a higher initial investment and require regular maintenance, including oil changes and fuel supply management. Their performance is reliable, but they may not be as efficient as alternators in converting energy for automotive use.

Alternative 2: Battery Management System (BMS)

A Battery Management System offers a sophisticated method of managing battery energy flow and optimizing performance, particularly in electric vehicles. BMS technology ensures that batteries operate within safe limits, enhancing their lifespan and efficiency. While the initial setup can be complex and may require technical expertise, the long-term benefits include reduced maintenance costs and improved energy utilization. BMS is particularly advantageous for companies focusing on sustainability and energy efficiency, making it a strong contender for modern automotive and industrial applications.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate power generation solution, B2B buyers must consider their specific operational requirements, including performance needs, budget constraints, and maintenance capabilities. The traditional alternator remains a staple for automotive applications due to its reliability and efficiency. However, options like generators and Battery Management Systems may better serve specific use cases, particularly in off-grid or electric vehicle contexts. By evaluating the detailed comparisons and understanding the strengths and weaknesses of each alternative, businesses can make informed choices that align with their strategic goals and operational demands.

Essential Technical Properties and Trade Terminology for picture of alternator

What Are the Key Technical Properties of an Alternator?

Understanding the technical specifications of an alternator is crucial for B2B buyers in various industries, especially in automotive manufacturing and maintenance. Here are some essential properties that should be considered:

Illustrative image related to picture of alternator

-

Material Grade

The material used in alternators, such as aluminum or steel, significantly affects their durability and performance. Aluminum is lightweight and resistant to corrosion, making it ideal for automotive applications where efficiency and weight savings are critical. Steel, on the other hand, provides increased strength and resilience. Selecting the appropriate material grade is vital for ensuring longevity and reliability in demanding environments. -

Voltage Output

Alternators typically generate a voltage output ranging from 12V to 24V for automotive applications. Understanding the required voltage is essential for compatibility with the vehicle’s electrical system. A mismatch can lead to insufficient power supply or damage to electrical components. Buyers should specify their voltage requirements when sourcing alternators to ensure optimal functionality. -

Current Rating (Amperage)

The current rating, measured in amperes (A), indicates the maximum amount of electrical current an alternator can provide. This specification is critical for ensuring that the alternator can support all electrical devices within the vehicle, such as lights, infotainment systems, and charging ports. A higher amperage rating is often necessary for vehicles with extensive electrical systems, making it a key consideration for B2B buyers. -

Efficiency Rating

The efficiency of an alternator determines how effectively it converts mechanical energy into electrical energy. Higher efficiency ratings translate to better fuel economy and reduced emissions, which are essential for meeting regulatory standards and improving operational costs. B2B buyers should evaluate efficiency ratings to select alternators that align with sustainability goals. -

Cooling Mechanism

Alternators often incorporate built-in cooling mechanisms, such as fans, to prevent overheating during operation. An effective cooling system enhances performance and extends the alternator’s lifespan. Buyers should consider the cooling requirements based on the intended application to avoid premature failures.

What Are Common Trade Terms Related to Alternators?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B space. Here are some commonly used terms in the alternator trade:

-

OEM (Original Equipment Manufacturer)

OEM refers to manufacturers that produce parts that are used as components in the products of another manufacturer. In the context of alternators, OEM parts are those made by the vehicle’s manufacturer, ensuring compatibility and reliability. Buyers often prefer OEM parts for their quality and assurance of fit. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. For alternators, this term is vital for businesses looking to manage inventory and cost. Understanding MOQ helps buyers negotiate better terms and plan their purchases effectively to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. B2B buyers should prepare detailed RFQs for alternators to receive accurate pricing and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms is essential for understanding shipping costs, risk management, and delivery timelines related to alternator procurement. -

Aftermarket

The aftermarket refers to the market for parts and accessories that are not sourced from the original manufacturer. Aftermarket alternators can offer cost-effective alternatives for repairs and replacements. Buyers should weigh the benefits and potential risks of aftermarket options, such as compatibility and warranty coverage.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators, ensuring they meet their operational needs while maintaining quality and efficiency.

Navigating Market Dynamics and Sourcing Trends in the picture of alternator Sector

What Are the Key Market Trends Affecting the Alternator Sector?

The global alternator market is witnessing a robust growth trajectory, driven by the increasing demand for efficient power generation in automotive and industrial applications. Key trends influencing this sector include the rising adoption of electric vehicles (EVs), which necessitate advanced alternator technologies to manage battery efficiency and power distribution. Furthermore, the shift towards hybrid systems, particularly in regions like Europe and the Middle East, emphasizes the need for versatile alternator designs that can accommodate both traditional combustion engines and electric drivetrains.

Emerging technologies such as IoT (Internet of Things) are also transforming how alternators are designed and integrated. Smart alternators equipped with sensors can optimize performance by monitoring electrical loads in real-time, providing actionable data for maintenance and efficiency improvements. This technological integration is particularly appealing to international B2B buyers looking to enhance operational efficiency in their fleets, especially in markets like Africa and South America, where infrastructure improvements are ongoing.

Illustrative image related to picture of alternator

Additionally, the sourcing landscape is evolving, with an increasing emphasis on local suppliers to mitigate risks associated with long supply chains. Countries like Vietnam are emerging as manufacturing hubs, offering competitive pricing and shorter lead times, which are crucial for B2B buyers aiming for agile supply chains.

How Is Sustainability Shaping Ethical Sourcing in the Alternator Market?

Sustainability is becoming a cornerstone of the alternator sector, prompting B2B buyers to prioritize ethical sourcing practices. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. As such, companies are increasingly seeking suppliers that employ sustainable manufacturing practices, such as the use of recycled materials and energy-efficient production methods.

Moreover, certifications such as ISO 14001 for environmental management systems are gaining importance among international buyers. These certifications not only enhance credibility but also align with the growing consumer demand for environmentally responsible products. Buyers from regions like Europe and the Middle East are particularly attuned to these trends, as regulatory frameworks increasingly mandate sustainable practices.

Illustrative image related to picture of alternator

In the context of the alternator sector, utilizing green materials—such as eco-friendly lubricants and recyclable components—can significantly reduce the carbon footprint of the final product. This not only satisfies regulatory requirements but also enhances brand reputation, making it a key consideration for B2B buyers looking to differentiate themselves in competitive markets.

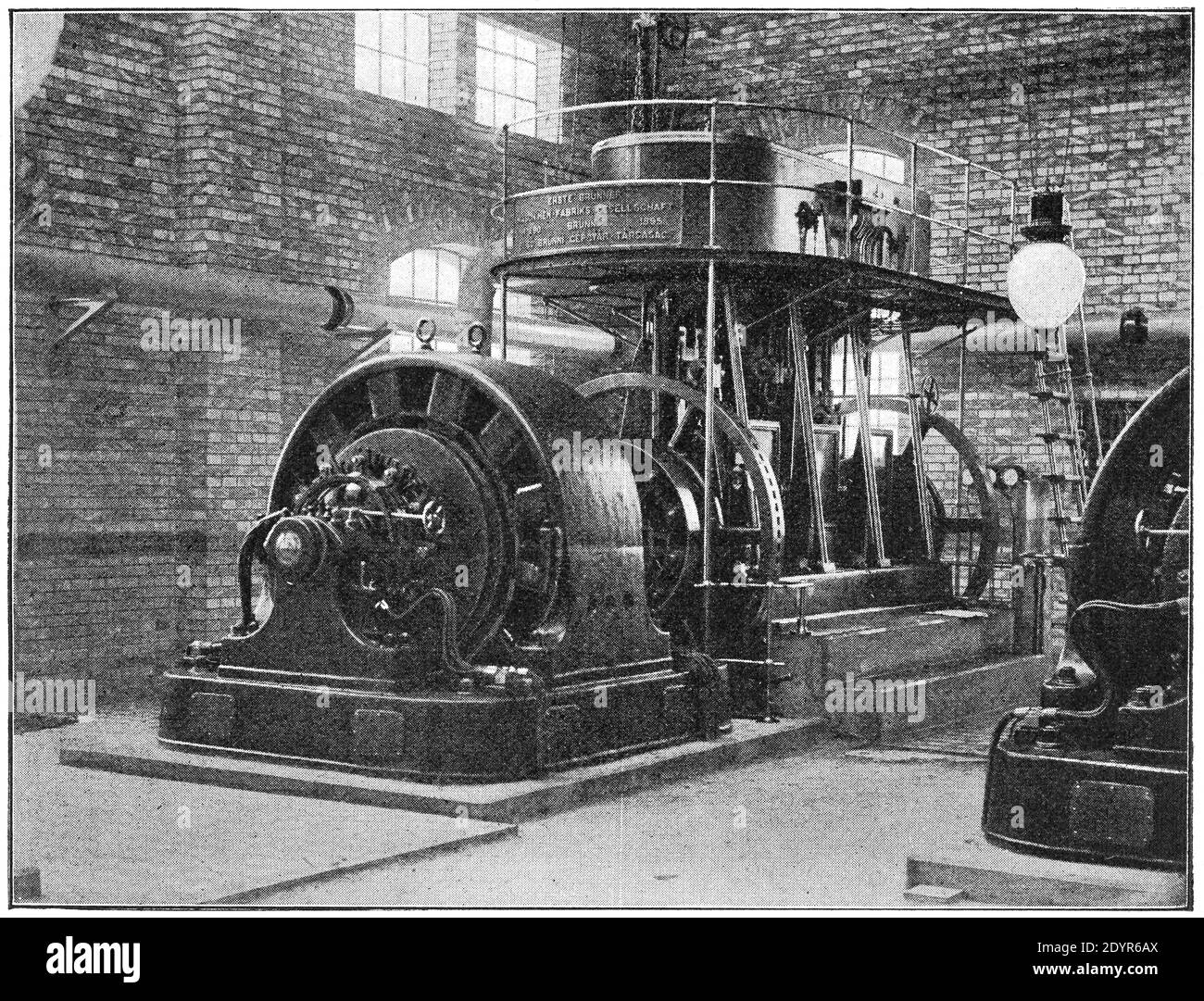

What Are the Historical Developments Influencing Today’s Alternator Technologies?

The evolution of alternator technology has been marked by significant milestones that have shaped its current form. Initially, the development of the alternator in the early 20th century was primarily focused on mechanical efficiency and reliability. Early models struggled with maintenance issues and were often replaced by less efficient generators.

However, advancements in materials science and electronics have led to the modern alternator’s design, which emphasizes compactness and enhanced efficiency. The introduction of digital voltage regulators in the 1980s revolutionized how alternators manage electrical output, resulting in greater reliability and performance.

Today, the focus is on integrating smart technologies that allow for real-time monitoring and optimization of electrical systems. This historical context is crucial for B2B buyers, as it highlights the ongoing innovation in the sector and the importance of sourcing from manufacturers that are at the forefront of these technological advancements. Understanding this evolution can guide buyers in making informed decisions about which products align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of picture of alternator

-

How do I find high-quality pictures of alternators for my business needs?

To source high-quality pictures of alternators, consider reputable stock photo platforms such as Shutterstock, Adobe Stock, and Getty Images. These platforms offer extensive libraries with professional images suitable for various applications, from marketing materials to technical documentation. Additionally, you can contact specialized automotive photography services for custom images that meet your specific requirements. Always check the licensing agreements to ensure the images can be used for your intended purpose. -

What types of images of alternators are most useful for B2B marketing?

For B2B marketing, images that showcase alternators in various contexts are most effective. This includes close-up shots highlighting key components, images of alternators installed in vehicles, and pictures demonstrating their functionality. Infographics or diagrams illustrating how alternators work can also be beneficial, as they provide educational value. Ensure that the images are high-resolution and align with your brand’s visual identity to enhance your marketing materials. -

What should I consider when vetting suppliers for alternator images?

When vetting suppliers for alternator images, evaluate their portfolio for quality and relevance to your industry. Check for customer reviews and testimonials to assess their reliability and service quality. Additionally, inquire about licensing terms to avoid legal complications later. If you’re looking for custom photography, discuss your specific needs and request samples to gauge their capability in delivering tailored images. -

Can I customize the images of alternators to fit my branding?

Yes, many stock photo providers offer customization options, allowing you to modify images to suit your branding. This could include adding your logo, adjusting colors, or incorporating text overlays. If you require extensive modifications, consider hiring a graphic designer or an agency that specializes in image editing. Ensure that any alterations comply with the licensing agreement of the original image. -

What are the typical minimum order quantities (MOQ) for purchasing stock images of alternators?

Most stock photo websites do not have a strict minimum order quantity, as images can often be purchased individually or in packages. However, for bulk purchases, some suppliers may offer discounts or subscription plans that allow access to multiple images at a lower overall cost. Always review the pricing structure of the platform you choose to maximize your budget. -

What payment terms should I expect when purchasing images for my business?

Payment terms for purchasing images can vary by supplier. Most stock photo platforms require upfront payment via credit card, PayPal, or other online payment methods. Some may offer subscription models that allow for monthly payments, granting access to a specified number of images per month. Always confirm the payment options and any potential fees associated with international transactions, especially when dealing with suppliers from different regions. -

How can I ensure the quality of images I purchase for my projects?

To ensure the quality of images, look for high-resolution files (preferably 300 DPI) that meet industry standards for print and digital use. Request samples or previews before making a purchase to evaluate the image quality. Additionally, read the specifications provided by the supplier regarding file formats and sizes. If you opt for custom photography, establish clear quality expectations in your agreement with the photographer. -

What logistics considerations should I keep in mind when sourcing images internationally?

When sourcing images internationally, consider the time zones and communication methods to ensure smooth transactions. Factor in potential import duties or tariffs if you require physical copies of images, such as printed materials. Additionally, review the supplier’s delivery timelines and ensure they can meet your project deadlines. It’s beneficial to establish clear communication channels to address any issues promptly and maintain a professional relationship.

Top 4 Picture Of Alternator Manufacturers & Suppliers List

1. iStock – Alternator Stock Photos

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: This company, iStock – Alternator Stock Photos, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Adobe Stock – Car Alternator Assets

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Car Alternator Images – Browse 7,399 Stock Photos, Vectors, and Video | Adobe Stock. Available formats include images, videos, audio, templates, and 3D assets. Users can start a free 30-day trial to access 10 images or 3 4K videos. The collection includes 519 videos related to car alternators.

3. Getty Images – Car Alternator Photos

Domain: gettyimages.com

Registered: 1999 (26 years)

Introduction: This company, Getty Images – Car Alternator Photos, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Electude – Alternator Overview

Domain: electude.com

Registered: 2005 (20 years)

Introduction: An alternator is a crucial automotive component that converts mechanical energy into electrical energy, generating power for the vehicle’s electrical consumer units and battery. Key components include:

– Pulley: Transfers mechanical energy from the engine to the alternator.

– Rotor: Creates the magnetic field for generating alternating current.

– Stator: The static part where voltage is generat…

Strategic Sourcing Conclusion and Outlook for picture of alternator

In the evolving landscape of automotive components, particularly alternators, strategic sourcing plays a pivotal role in ensuring quality, cost-effectiveness, and timely delivery. As outlined in this guide, understanding the intricacies of alternator imagery can significantly enhance the decision-making process for international B2B buyers. Leveraging high-quality images not only aids in the selection of the right product but also strengthens marketing efforts, allowing businesses to present their offerings compellingly.

For buyers in Africa, South America, the Middle East, and Europe, it is imperative to partner with reliable suppliers who can provide authentic, high-resolution images of alternators. This approach facilitates informed choices and fosters trust with end-users. As markets grow increasingly competitive, the ability to showcase products visually can differentiate your brand and enhance customer engagement.

Looking ahead, the demand for efficient and innovative alternator solutions will continue to rise. By adopting a strategic sourcing mindset, you can position your business to capitalize on emerging opportunities. We encourage you to explore partnerships that not only meet your immediate needs but also align with your long-term growth strategies. Invest in quality imagery and supplier relationships today to pave the way for a successful tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.