Introduction: Navigating the Global Market for how much to get a headlight replaced

In an ever-evolving automotive landscape, understanding how much to get a headlight replaced is crucial for international B2B buyers. The diverse range of headlight technologies—from cost-effective halogen bulbs to premium LED assemblies—presents a significant challenge in sourcing reliable and affordable replacement options. This guide is designed to navigate the complexities of headlight replacement, covering essential aspects such as types of headlights, associated costs, and best practices for supplier vetting.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—including markets like Saudi Arabia and Nigeria—will find actionable insights tailored to their specific needs. We delve into the nuances of headlight technology, helping you evaluate the pros and cons of various options while considering the implications of labor costs and installation complexities.

Moreover, this comprehensive resource emphasizes the importance of quality and safety in headlight replacements, ensuring that your purchasing decisions are informed and strategic. By equipping you with the knowledge to make sound investments, this guide empowers B2B buyers to enhance their vehicle fleets’ safety and performance, ultimately leading to improved customer satisfaction and operational efficiency.

Table Of Contents

- Top 2 How Much To Get A Headlight Replaced Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much to get a headlight replaced

- Understanding how much to get a headlight replaced Types and Variations

- Key Industrial Applications of how much to get a headlight replaced

- 3 Common User Pain Points for ‘how much to get a headlight replaced’ & Their Solutions

- Strategic Material Selection Guide for how much to get a headlight replaced

- In-depth Look: Manufacturing Processes and Quality Assurance for how much to get a headlight replaced

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much to get a headlight replaced’

- Comprehensive Cost and Pricing Analysis for how much to get a headlight replaced Sourcing

- Alternatives Analysis: Comparing how much to get a headlight replaced With Other Solutions

- Essential Technical Properties and Trade Terminology for how much to get a headlight replaced

- Navigating Market Dynamics and Sourcing Trends in the how much to get a headlight replaced Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much to get a headlight replaced

- Strategic Sourcing Conclusion and Outlook for how much to get a headlight replaced

- Important Disclaimer & Terms of Use

Understanding how much to get a headlight replaced Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Halogen Bulbs | Cost-effective, easy to replace, shorter lifespan | Fleet maintenance, budget-conscious repairs | Pros: Low cost, easy installation. Cons: Short lifespan, less brightness. |

| High-Intensity Discharge (HID) | Bright, long-lasting, requires ballast | Luxury vehicle repairs, high-performance markets | Pros: Excellent visibility, longer life. Cons: Higher cost, complex installation. |

| Light Emitting Diode (LED) | Energy-efficient, long lifespan, higher upfront cost | Modern vehicle repairs, energy-efficient fleets | Pros: Longevity, low energy consumption. Cons: Expensive replacements, potential module costs. |

| Complete Headlight Assembly | All-in-one unit, includes advanced features | High-end vehicle servicing, insurance claims | Pros: Comprehensive solution, includes all necessary components. Cons: High cost, often requires professional installation. |

| Headlight Restoration Kits | DIY solution for cloudy lenses | Cost-saving for older vehicles | Pros: Affordable, restores visibility. Cons: Time-consuming, may not last as long as new parts. |

What Are the Characteristics of Halogen Bulbs for Headlight Replacement?

Halogen bulbs are the most common type of headlight replacement, favored for their affordability and ease of installation. They typically cost between $10 and $40 per bulb, making them a popular choice for fleet maintenance and budget-conscious repairs. However, they have a shorter lifespan compared to other options, averaging 500 to 1,000 hours. B2B buyers should consider the trade-off between initial cost and longevity, particularly for vehicles that require frequent maintenance.

Illustrative image related to how much to get a headlight replaced

Why Choose High-Intensity Discharge (HID) Bulbs?

High-Intensity Discharge (HID) bulbs are known for their brightness and longevity, making them ideal for luxury vehicles and high-performance markets. These bulbs can cost around $150 each but provide three to five times the brightness of halogen bulbs and last 2,000 to 3,000 hours. While their installation can be complex and typically requires a professional, their superior visibility can enhance safety, which is a vital consideration for B2B buyers in the automotive sector.

What Makes Light Emitting Diode (LED) Bulbs a Smart Choice?

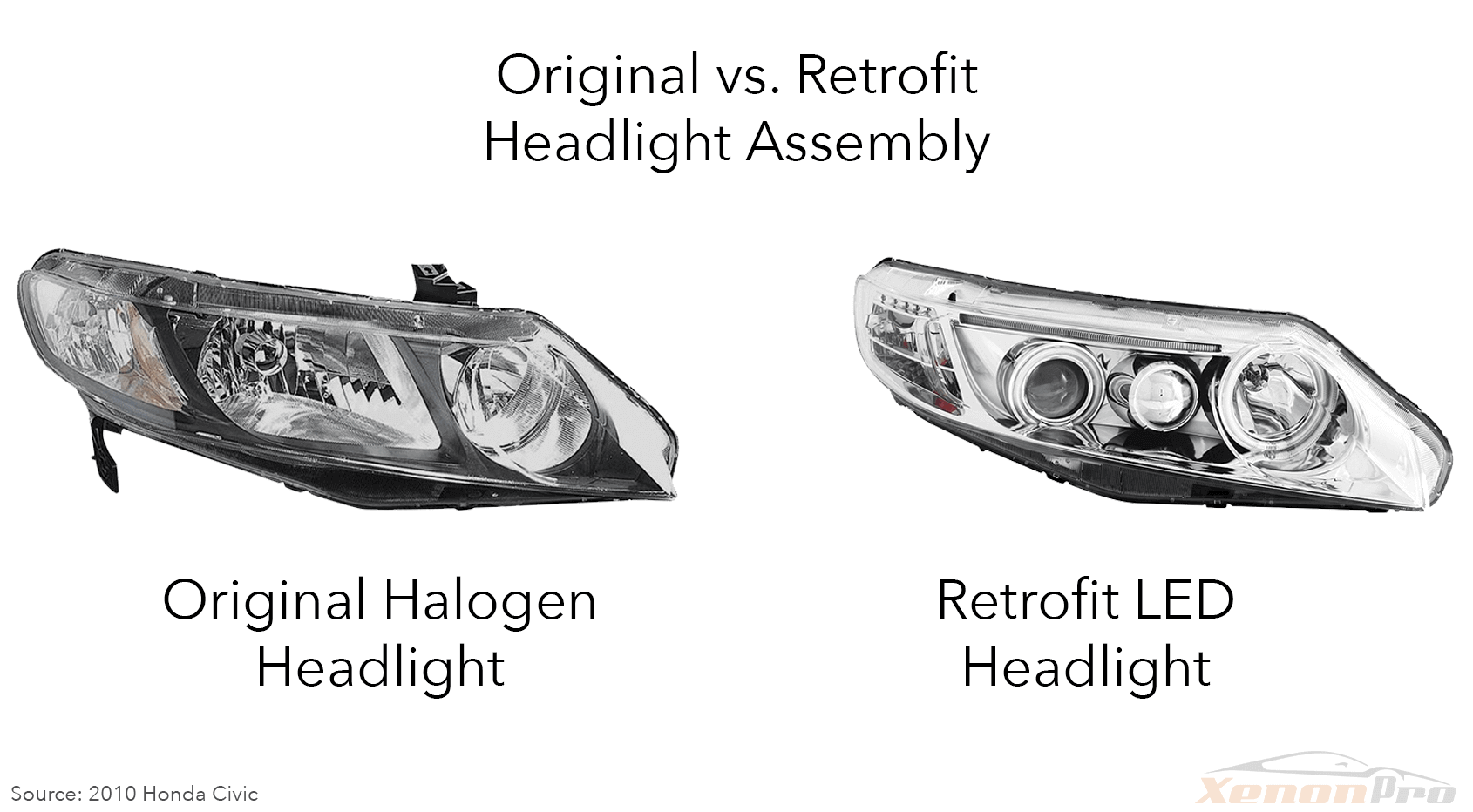

LED bulbs are the latest innovation in headlight technology, offering energy efficiency and a lifespan of approximately 30,000 hours. The cost for a pair ranges from $50 to $200, making them suitable for modern vehicle repairs and energy-efficient fleets. Although the initial investment is higher, their long-term savings in energy consumption and reduced replacement frequency can be appealing for B2B buyers. However, it’s crucial to account for potential additional costs associated with complete headlight assemblies.

When to Opt for a Complete Headlight Assembly?

Complete headlight assemblies are essential for vehicles with advanced lighting features, such as adaptive lighting systems. These all-in-one units can be costly, ranging from hundreds to thousands of dollars, depending on the vehicle’s make and model. B2B buyers, especially those involved in high-end vehicle servicing or insurance claims, should weigh the benefits of a comprehensive solution against the higher upfront costs and ensure proper installation to maintain vehicle safety and performance.

How Can Headlight Restoration Kits Benefit B2B Buyers?

Headlight restoration kits offer a cost-effective solution for addressing cloudy or dim headlight lenses, which can be a safety hazard. These kits are typically priced around $25 and can save buyers from spending hundreds on new assemblies. While restoration can be time-consuming, it is an excellent option for older vehicles where budget constraints are a concern. B2B buyers should consider the balance between immediate cost savings and the potential need for future replacements.

Illustrative image related to how much to get a headlight replaced

Key Industrial Applications of how much to get a headlight replaced

| Industry/Sector | Specific Application of how much to get a headlight replaced | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Providing headlight replacement services for various vehicles | Enhances customer satisfaction and safety, increasing repeat business | Availability of diverse headlight types and brands |

| Fleet Management | Regular headlight maintenance and replacement for company vehicles | Ensures compliance with safety regulations, reducing accident risks | Bulk purchasing options for cost savings |

| Vehicle Manufacturing | Sourcing headlight components for assembly lines | Reduces production costs and ensures quality control | Supplier reliability and adherence to safety standards |

| Car Rental Services | Offering headlight replacement as part of vehicle maintenance | Improves customer experience and vehicle safety | Quick turnaround times and availability of parts |

| Export/Import Businesses | Importing headlight replacement parts for local markets | Expands product offerings and meets local demand | Understanding local regulations and sourcing quality parts |

How Do Automotive Repair Shops Benefit from Headlight Replacement Services?

Automotive repair shops can leverage headlight replacement services as a core offering, addressing a common vehicle maintenance need. By providing timely and reliable replacements, these businesses enhance customer satisfaction and safety, which fosters loyalty and increases repeat business. Shops should ensure they stock a variety of headlight types, including halogen, HID, and LED, to cater to different vehicle models and customer preferences.

What Advantages Do Fleet Management Companies Gain from Regular Headlight Maintenance?

Fleet management companies benefit significantly from regular headlight maintenance and replacement. By ensuring that all vehicles are equipped with functioning headlights, these companies not only comply with safety regulations but also mitigate the risk of accidents caused by poor visibility. Cost-effective bulk purchasing options for headlight components can further enhance profitability, making it essential for fleet managers to establish reliable supplier relationships.

How Can Vehicle Manufacturers Optimize Their Headlight Component Sourcing?

Vehicle manufacturers can optimize their operations by sourcing high-quality headlight components for their assembly lines. This practice helps in reducing production costs while ensuring that the headlights meet safety and performance standards. Manufacturers should prioritize supplier reliability and the ability to provide components that adhere to international safety regulations, especially when exporting vehicles to markets in Africa, South America, the Middle East, and Europe.

Why is Headlight Replacement Important for Car Rental Services?

Car rental services can significantly enhance their customer experience by including headlight replacement in their vehicle maintenance routines. Ensuring that all rental vehicles have fully functional headlights is crucial for safety, particularly in regions with varying driving conditions. Quick turnaround times for parts procurement and availability of replacement services can be a competitive advantage for rental companies in maintaining their fleet.

Illustrative image related to how much to get a headlight replaced

What Should Export/Import Businesses Consider When Sourcing Headlight Parts?

Export/import businesses can capitalize on the demand for headlight replacement parts in local markets by understanding regional preferences and regulations. Offering a diverse range of headlight components can meet local demand and expand product offerings. It is crucial for these businesses to ensure that the parts sourced meet quality standards, as subpar products could lead to safety issues and potential liability.

3 Common User Pain Points for ‘how much to get a headlight replaced’ & Their Solutions

Scenario 1: Confusion Over Headlight Types and Costs

The Problem: B2B buyers often encounter confusion regarding the various types of headlights available, each with different costs and lifespans. This challenge is particularly pronounced when managing fleets or purchasing for multiple vehicle types. For instance, a buyer might be unsure whether to opt for halogen, HID, or LED lights, especially given the significant price differences—ranging from $10 for halogen bulbs to thousands for advanced LED or laser assemblies. This lack of clarity can lead to overspending or inadequate lighting solutions that compromise vehicle safety.

The Solution: To navigate this confusion effectively, B2B buyers should conduct thorough research before making purchasing decisions. Start by compiling a detailed inventory of your vehicles, noting the make, model, and year, as well as any specific headlight requirements. Utilize this information to consult with reputable suppliers or auto parts stores, ensuring they provide compatibility checks based on your vehicle specifications. Furthermore, consider creating a cost-benefit analysis comparing the lifespan and brightness of different bulb types. For instance, while LED bulbs may have a higher upfront cost, their longevity and energy efficiency could lead to savings over time. By being well-informed and strategic, buyers can make decisions that enhance fleet safety while optimizing costs.

Scenario 2: Unexpected High Labor Costs During Replacement

The Problem: Another common issue arises when B2B buyers are blindsided by high labor costs associated with headlight replacements. Many newer vehicles have complex headlight assemblies that may require specialized tools or significant disassembly to access, such as removing the front bumper. This can lead to labor charges that escalate from a few hundred to over a thousand dollars, depending on the vehicle and the service provider. This unpredictability can strain budgets and disrupt operational timelines.

The Solution: To mitigate unexpected labor costs, B2B buyers should establish relationships with trustworthy local mechanics or dealerships known for their transparency in pricing. Before scheduling any replacement, request a detailed estimate that outlines both parts and labor costs. It is also wise to inquire about the possibility of bulk servicing agreements for fleet vehicles, which can often secure better rates. Additionally, consider training in-house staff on basic headlight replacement procedures for simpler vehicles, which can save on labor costs while empowering your team with valuable skills. This proactive approach not only helps manage expenses but also enhances overall operational efficiency.

Scenario 3: Managing Headlight Maintenance and Safety Compliance

The Problem: Ensuring that all vehicles in a fleet have functioning headlights is not only a safety concern but also a compliance issue. For businesses operating in regions with stringent safety regulations, failing to maintain headlights can lead to penalties or increased insurance costs. Buyers may struggle with maintaining a consistent schedule for inspections and replacements, particularly when dealing with multiple vehicles across various locations.

The Solution: To streamline headlight maintenance and ensure compliance, B2B buyers should implement a systematic maintenance schedule that includes regular inspections of all vehicle headlights. Utilize fleet management software to automate reminders for checks based on mileage or time intervals. Additionally, consider investing in headlight restoration kits that can extend the life of existing headlights, providing a cost-effective solution to cloudy or dim lights. Training your team to recognize when headlights are dimming or showing signs of wear can also be beneficial. By adopting a proactive maintenance strategy, businesses can enhance safety, reduce compliance risks, and ultimately lower overall replacement costs, creating a more reliable fleet.

Strategic Material Selection Guide for how much to get a headlight replaced

What Are the Common Materials Used in Headlight Replacement?

When considering headlight replacements, various materials are utilized in manufacturing the bulbs and assemblies. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe.

1. Halogen Bulbs: A Traditional Choice

Key Properties: Halogen bulbs are made with a tungsten filament and filled with halogen gas, which allows them to operate at higher temperatures without burning out quickly. They typically have a temperature rating of around 300°C.

Pros & Cons: Halogen bulbs are relatively inexpensive, with replacement costs ranging from $10 to $40. They provide good light output and are easy to replace. However, they have a shorter lifespan of approximately 500-1,000 hours and are less energy-efficient compared to newer technologies.

Impact on Application: Halogen bulbs are suitable for standard automotive lighting applications but may not meet the brightness needs for high-performance vehicles.

Considerations for International Buyers: Buyers should ensure compliance with local automotive lighting regulations and standards, such as those set by the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN).

2. High-Intensity Discharge (HID) Bulbs: Bright and Efficient

Key Properties: HID bulbs utilize xenon gas and require a ballast to ignite. They operate at temperatures around 200°C and offer a significantly brighter output compared to halogen bulbs.

Illustrative image related to how much to get a headlight replaced

Pros & Cons: HID bulbs last longer (2,000-3,000 hours) and provide superior visibility, making them ideal for nighttime driving. However, they are more expensive, typically costing around $150 per bulb, and can be complex to install, often requiring professional assistance.

Impact on Application: These bulbs are commonly used in luxury vehicles and high-performance applications, where visibility is paramount.

Considerations for International Buyers: Buyers must be aware of the specific regulations regarding HID usage in their regions, as some countries may have restrictions on brightness levels.

3. Light Emitting Diode (LED) Bulbs: The Future of Automotive Lighting

Key Properties: LED bulbs are composed of semiconductor materials that emit light when an electric current passes through. They have a lifespan of approximately 30,000 hours and operate at lower temperatures, around 80°C.

Pros & Cons: LEDs are highly energy-efficient and provide excellent illumination. However, they come with a higher upfront cost, ranging from $50 to $200 per pair, and may require complete headlight assemblies if the electronics fail.

Illustrative image related to how much to get a headlight replaced

Impact on Application: Ideal for modern vehicles, LEDs are increasingly becoming the standard due to their longevity and performance.

Considerations for International Buyers: Buyers should ensure that LED products meet local standards, such as the American National Standards Institute (ANSI) and European Norm (EN) standards, to avoid compliance issues.

4. Polycarbonate and Glass: Lens Materials

Key Properties: Headlight lenses can be made from polycarbonate or glass. Polycarbonate is lightweight and impact-resistant, while glass offers superior clarity and scratch resistance.

Pros & Cons: Polycarbonate is cheaper and more durable against impacts, but it can yellow over time due to UV exposure. Glass provides better optical clarity but is heavier and more prone to shattering.

Impact on Application: The choice of lens material affects the overall performance of the headlight assembly, influencing light output and durability.

Considerations for International Buyers: Buyers should consider the environmental conditions in their regions, such as UV exposure and temperature extremes, when selecting lens materials.

Summary Table of Material Selection for Headlight Replacement

| Material | Typical Use Case for how much to get a headlight replaced | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Halogen Bulbs | Standard automotive lighting | Inexpensive and easy to replace | Short lifespan and less energy-efficient | Low |

| High-Intensity Discharge (HID) Bulbs | Luxury and high-performance vehicles | Superior brightness and visibility | High cost and complex installation | High |

| Light Emitting Diode (LED) Bulbs | Modern vehicles | Long lifespan and energy-efficient | High upfront cost and potential assembly replacement | Medium |

| Polycarbonate and Glass Lenses | Headlight assemblies | Lightweight (polycarbonate) and clarity (glass) | UV degradation (polycarbonate) and fragility (glass) | Medium |

This comprehensive analysis of materials used in headlight replacements provides B2B buyers with essential insights into product performance, cost considerations, and compliance needs across various international markets.

Illustrative image related to how much to get a headlight replaced

In-depth Look: Manufacturing Processes and Quality Assurance for how much to get a headlight replaced

What Are the Main Stages of Headlight Manufacturing and How Do They Ensure Quality?

The manufacturing process for headlights involves several intricate stages, each designed to enhance functionality, longevity, and safety. Understanding these stages is vital for B2B buyers, especially those engaged in automotive supply chains across diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Stages in Headlight Manufacturing?

-

Material Preparation

The first step in headlight manufacturing involves sourcing high-quality materials. Typically, manufacturers use polycarbonate or acrylic for the lens due to their durability and resistance to UV rays. Metal components, such as aluminum for housing, are also sourced with attention to corrosion resistance. Advanced materials like LED modules and optics are prepared separately, often requiring specialized suppliers. -

Forming

This stage involves shaping the prepared materials into their required forms. For lenses, techniques such as injection molding or vacuum forming are commonly used. Injection molding allows for precise shaping and is crucial for ensuring that the headlight lens fits snugly in the housing. Metal components are often stamped or extruded to achieve the desired shapes, ensuring strength and structural integrity. -

Assembly

In the assembly stage, all components are brought together. This includes the lens, housing, bulb sockets, and electrical connections. Automated assembly lines are frequently employed, allowing for precision and speed. Skilled technicians also perform checks during assembly to ensure that all parts fit correctly and function as intended. -

Finishing

The final stage focuses on quality and aesthetic appeal. This includes applying coatings for UV protection, polishing lenses to eliminate imperfections, and conducting final assembly inspections. The headlight units are then packaged for distribution, ensuring they are protected during transit.

How Is Quality Assurance Integrated into the Headlight Manufacturing Process?

Quality assurance (QA) is critical in ensuring that headlights meet safety standards and perform reliably over time. Manufacturers adhere to various international standards, including ISO 9001, which outlines the requirements for a quality management system.

What International Standards Should B2B Buyers Be Aware Of?

-

ISO 9001

This standard is vital for ensuring that manufacturers maintain a consistent quality management system. Compliance indicates that the manufacturer has systematic processes for monitoring and improving product quality. -

CE Marking

In Europe, CE marking signifies that a product meets safety, health, and environmental protection standards. It is essential for B2B buyers in Europe to ensure that their suppliers have products that are CE certified. -

API Standards

While API (American Petroleum Institute) standards are more relevant to oil and gas, they can also indirectly affect automotive components through lubrication and material standards.

What Are the Key Quality Control Checkpoints in Headlight Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to ensure compliance with standards.

-

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting raw materials as they arrive at the manufacturing facility. Materials are tested for specifications like tensile strength, UV resistance, and dimensions before being approved for production. -

In-Process Quality Control (IPQC)

During the manufacturing process, periodic inspections are conducted to monitor production techniques and ensure that the assembly processes align with quality standards. This includes checks for dimensional accuracy and functional tests of electrical components. -

Final Quality Control (FQC)

Once the headlights are assembled, FQC involves rigorous testing of the final product. This includes functional tests for light output, durability testing under extreme conditions, and checks for any defects in the lens and housing.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in international markets, verifying a supplier’s quality control processes is critical to ensuring product reliability and safety.

-

Supplier Audits

Conducting on-site audits allows buyers to assess a manufacturer’s quality control systems firsthand. This includes reviewing documentation, observing production processes, and checking compliance with international standards. -

Quality Reports

Requesting detailed quality assurance reports can provide insights into a manufacturer’s QC processes. These reports should outline the results of various tests, including failure rates, defect tracking, and improvements implemented over time. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of a manufacturer’s quality practices. These services often conduct their own testing and can offer certifications that assure buyers of product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the complexities of QC and certification can be particularly challenging for international buyers. Here are some nuances to consider:

Illustrative image related to how much to get a headlight replaced

-

Regional Standards Variability

Different regions may have varying standards. For example, while CE marking is crucial in Europe, it may not be recognized in African or South American markets. Understanding local regulations is essential for compliance. -

Cultural Differences in Quality Expectations

Quality perceptions can differ significantly across cultures. Buyers must communicate clearly with suppliers about their quality expectations and ensure that these are documented in contracts. -

Logistical Challenges

International shipping can introduce risks, such as damage during transit. B2B buyers should ensure that their suppliers have adequate packaging and handling processes to mitigate these risks.

In summary, understanding the manufacturing processes and quality assurance protocols for headlight replacements is crucial for B2B buyers. By focusing on the main stages of production, relevant international standards, and effective verification methods, buyers can make informed decisions that ensure product reliability and safety in diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much to get a headlight replaced’

Introduction

This guide serves as a practical checklist for B2B buyers looking to navigate the complexities of headlight replacement costs and sourcing options. Understanding the various factors influencing headlight replacement—from bulb types to labor costs—is essential for making informed purchasing decisions that align with your business needs.

Step 1: Identify Vehicle Specifications

Start by determining the specific make, model, and year of the vehicles in your fleet. Each vehicle may require different types of headlight bulbs, such as halogen, HID, or LED. Accurate specifications will help you avoid costly mistakes and ensure compatibility.

Illustrative image related to how much to get a headlight replaced

Step 2: Research Headlight Options

Explore the various headlight types available on the market. Each type has its advantages and drawbacks:

– Halogen bulbs: Typically the most affordable but shorter-lived.

– HID bulbs: Brighter and longer-lasting but can be expensive.

– LED bulbs: The most durable but may require an entire assembly replacement.

Understanding these options will enable you to select the best fit for your operational needs.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with industry standards. Look for indicators such as:

– DOT certification: Ensures the bulbs meet federal safety standards.

– ISO certifications: Reflects the quality management systems in place.

This step is crucial for ensuring that you procure reliable and safe products.

Step 4: Request Quotations

Gather quotations from multiple suppliers to compare prices and services. Ensure each quotation includes:

– Cost breakdown: Itemize prices for bulbs, assemblies, and labor.

– Lead times: Understand how quickly suppliers can deliver.

A well-structured quotation helps in budgeting and allows for better negotiation.

Step 5: Assess Warranty and Return Policies

Review the warranty and return policies offered by your suppliers. Key points to consider include:

– Duration of warranty: Longer warranties can indicate higher quality.

– Return conditions: Understanding what qualifies for a return can protect your investment.

This step is vital to safeguard against potential defects and ensure customer satisfaction.

Step 6: Consider Bulk Purchase Discounts

Inquire about bulk purchasing options, as many suppliers offer discounts for larger orders. Benefits of bulk purchases include:

– Cost savings: Reducing the per-unit price can significantly lower overall expenses.

– Consistent supply: Ensures that you have enough stock for maintenance without frequent reordering.

This approach can enhance your procurement strategy, especially for fleet management.

Illustrative image related to how much to get a headlight replaced

Step 7: Plan for Installation and Maintenance

Finally, assess whether you will handle installations in-house or require professional services. Consider:

– Labor costs: Hiring professionals may be more expensive but ensures proper installation.

– Training: If you choose to do it yourself, invest in training for your team to avoid costly errors.

Proper planning in this area can minimize downtime and enhance safety across your fleet.

Comprehensive Cost and Pricing Analysis for how much to get a headlight replaced Sourcing

What Are the Key Cost Components for Headlight Replacement?

When considering the costs associated with headlight replacement, it’s essential to break down the various components involved in the process. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The type of headlight significantly influences material costs. Halogen bulbs range from $10 to $40, while HID and LED options can exceed $150 and $200, respectively. The choice of materials affects not only the price but also the longevity and performance of the headlights.

-

Labor: Labor costs vary depending on the complexity of the installation. Simple bulb replacements may incur minimal labor charges, while replacing an entire headlight assembly, especially in modern vehicles with advanced features, can add hundreds of dollars to the total cost.

-

Manufacturing Overhead and Tooling: Suppliers often incur costs related to manufacturing overhead, which includes expenses for machinery, factory space, and utilities. Tooling costs can also be significant, particularly for specialized headlight assemblies that require unique molds or production processes.

-

Quality Control (QC): Ensuring that headlights meet safety and performance standards incurs additional costs. Quality control processes are essential, especially for products that must comply with local regulations in different regions.

-

Logistics: Shipping and handling costs can vary based on the distance from the supplier to the buyer, especially when considering international shipping. Buyers should factor in potential tariffs and customs duties when sourcing headlights across borders.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary widely based on the supplier’s market position, brand reputation, and the specific characteristics of the headlights being sold.

What Price Influencers Should B2B Buyers Consider?

Several factors can influence the pricing of headlight replacements, which B2B buyers should consider when sourcing:

Illustrative image related to how much to get a headlight replaced

-

Volume/MOQ: Bulk purchasing can lead to significant discounts. Suppliers often provide better pricing for higher volumes, making it advantageous for businesses that require multiple replacements.

-

Specifications and Customization: Custom headlights tailored to specific vehicle models may incur higher costs. Buyers should assess whether standard options suffice or if customized solutions are necessary.

-

Materials and Quality Certifications: The quality of materials used in headlight manufacturing directly impacts pricing. Opting for bulbs that meet international safety standards can prevent future liabilities and should be prioritized in supplier selection.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a proven track record may charge more but offer better quality assurance and service.

-

Incoterms: Understanding the terms of shipping (Incoterms) is crucial for international buyers. These terms define the responsibilities of buyers and sellers in the shipping process, impacting total costs.

How Can Buyers Optimize Costs and Enhance Value?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, there are several strategies to optimize costs:

-

Negotiation: Engage in negotiations with suppliers to secure better pricing, especially for large orders. Establishing long-term relationships can also lead to favorable terms.

-

Cost-Efficiency: Consider the total cost of ownership rather than just the initial purchase price. Investing in higher-quality headlights may yield better longevity and performance, reducing replacement frequency.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, shipping costs, and local regulations that may affect pricing. Conducting thorough market research can lead to better sourcing decisions.

-

Warranty and After-Sales Support: Evaluate the warranty and support offered by suppliers. A comprehensive warranty can provide peace of mind and reduce long-term costs associated with faulty products.

Disclaimer

The prices and cost estimates provided in this analysis are indicative and may vary based on specific circumstances, including geographic location, supplier agreements, and market conditions. Buyers should conduct their due diligence to obtain accurate and relevant pricing information tailored to their unique needs.

Alternatives Analysis: Comparing how much to get a headlight replaced With Other Solutions

Exploring Alternatives to Headlight Replacement Costs

When it comes to vehicle maintenance, headlight replacement is a common concern for businesses managing fleets or individual vehicles. However, understanding the full spectrum of options available can lead to more informed decisions. Below, we explore the costs and benefits of traditional headlight replacement compared to alternatives such as headlight restoration and upgrading to advanced lighting technologies.

Illustrative image related to how much to get a headlight replaced

| Comparison Aspect | How Much To Get A Headlight Replaced | Headlight Restoration | Upgrading to LED Headlights |

|---|---|---|---|

| Performance | Good visibility, depends on bulb type | Restores clarity and brightness | Superior brightness and longevity |

| Cost | $20 – $1,300+ (depending on vehicle and assembly) | $25 – $150 (DIY or professional) | $50 – $200 per bulb, $600 – $2,800 for assembly |

| Ease of Implementation | Moderate (may require professional help) | Easy (DIY kits available) | Moderate (professional installation recommended) |

| Maintenance | Regular checks needed; bulbs have limited lifespan | Requires periodic reapplication | Low; LEDs last up to 30,000 hours |

| Best Use Case | Immediate replacement for safety | Cost-effective for older vehicles | Long-term investment for newer models |

What Are the Pros and Cons of Headlight Restoration?

Headlight restoration is a viable option for vehicles with cloudy or dull lenses. This process involves cleaning and polishing the headlight lens to restore clarity, enhancing visibility significantly. The primary advantage is cost-effectiveness; restoration kits can be purchased for as little as $25. Additionally, this solution is typically easy to implement, especially with DIY kits available. However, the restoration is not a permanent fix and may need to be repeated every couple of years, depending on environmental exposure.

How Does Upgrading to LED Headlights Compare?

Upgrading to LED headlights is increasingly popular among businesses looking for long-term solutions. LEDs provide excellent brightness, improved visibility, and consume less energy, making them an eco-friendly choice. The initial investment can be higher, ranging from $50 to over $2,800 for complete assemblies, but their lifespan—up to 30,000 hours—often justifies the cost. While installation may require professional assistance, the reduced maintenance needs and superior performance can lead to significant savings over time. However, for older vehicles, this investment may not be practical.

Conclusion: Which Solution is Right for Your Needs?

When deciding on the best solution for headlight issues, B2B buyers should consider various factors, including the age and model of their vehicles, budget constraints, and long-term maintenance capabilities. For immediate needs, traditional headlight replacement is essential for safety, while restoration can serve as a cost-effective short-term fix. On the other hand, upgrading to LED headlights may be ideal for businesses looking to future-proof their fleet with enhanced performance and lower long-term costs. Each option has its unique advantages and disadvantages, and selecting the right one will depend on the specific operational needs and financial considerations of the buyer.

Essential Technical Properties and Trade Terminology for how much to get a headlight replaced

What Are the Key Technical Properties Relevant to Headlight Replacement Costs?

Understanding the technical properties associated with headlight replacements is crucial for B2B buyers in automotive parts and services. Here are several critical specifications to consider:

-

Material Grade: Headlights are typically made from polycarbonate or glass. Polycarbonate offers higher impact resistance and is lighter, while glass provides superior clarity. Selecting the right material affects both durability and performance, which can influence cost and safety. B2B buyers must assess the material used in headlight assemblies to ensure they meet safety and regulatory standards.

-

Bulb Type: The market offers various bulb types, including halogen, HID, and LED. Each type has unique characteristics regarding brightness, lifespan, and cost. Halogen bulbs are cost-effective but short-lived; HIDs are brighter but more expensive; LEDs offer longevity but often require entire assemblies for replacement. Understanding these differences is essential for making informed purchasing decisions.

-

Wattage and Lumens: Wattage indicates the energy consumption of the bulb, while lumens measure brightness. Higher wattage typically means brighter light but can also lead to higher energy costs and potential heat issues. This specification is crucial for ensuring that headlights meet both performance and safety requirements.

-

Compatibility and Fitment: The fitment of headlights is vehicle-specific, meaning that B2B buyers must ensure compatibility with various makes and models. This involves understanding the part numbers and specifications outlined in vehicle manuals. Proper fitment is critical for effective performance and compliance with safety regulations.

What Are Common Trade Terms in Headlight Replacement?

Familiarizing yourself with industry jargon can streamline the procurement process and improve communication with suppliers. Here are some essential terms:

Illustrative image related to how much to get a headlight replaced

-

OEM (Original Equipment Manufacturer): This term refers to parts made by the vehicle’s original manufacturer. OEM headlights typically guarantee compatibility and quality but may come at a premium price. Understanding whether to source OEM or aftermarket options can significantly impact costs and reliability.

-

MOQ (Minimum Order Quantity): MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budget planning, especially for international buyers who may need to consider shipping costs and inventory levels.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for specific products. It is an essential tool for B2B buyers to compare costs and negotiate terms effectively. A well-structured RFQ can yield competitive pricing and better service agreements.

-

Incoterms (International Commercial Terms): These are predefined commercial terms used in international trade. They clarify responsibilities regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and manage risks when sourcing headlight components from different countries.

Why Is It Important for B2B Buyers to Understand These Properties and Terms?

By grasping the essential technical properties and trade terminology, B2B buyers can make informed decisions that enhance operational efficiency and cost-effectiveness. Knowledge of material grades, bulb types, and fitment ensures that the right products are selected for safety and performance. Furthermore, understanding trade terms aids in negotiations, sourcing strategies, and compliance with international regulations. This insight ultimately contributes to better pricing, improved supplier relationships, and enhanced product quality in the competitive automotive market.

Navigating Market Dynamics and Sourcing Trends in the how much to get a headlight replaced Sector

What Are the Current Market Dynamics Affecting Headlight Replacement Costs?

The global market for headlight replacements is influenced by several factors that international B2B buyers must navigate. Increasing vehicle complexity, particularly in luxury and newer models, has driven up replacement costs. Advanced lighting technologies like LED and HID have become more prevalent, offering better efficiency and longevity but at a higher price point. The average cost for headlight replacement can range significantly—from $20 for basic halogen bulb replacements to over $2,800 for high-end LED assemblies. This variance is largely due to the vehicle’s make and model, as well as the specific type of headlight technology employed.

In addition, the rise of e-commerce platforms has transformed sourcing strategies, allowing buyers from regions like Africa, South America, the Middle East, and Europe to access a broader range of products and suppliers. However, the challenge remains in ensuring product quality, especially with numerous aftermarket options flooding the market. B2B buyers are increasingly leaning towards suppliers who offer warranties and certifications to mitigate risks associated with poor-quality replacements.

Emerging trends also include the integration of smart technologies in headlight systems, such as adaptive lighting features. This evolution necessitates a deeper understanding of the technical specifications required for proper replacements, making it essential for buyers to stay updated on industry standards and innovations.

Illustrative image related to how much to get a headlight replaced

How Can Sustainability and Ethical Sourcing Impact the Headlight Replacement Sector?

Sustainability is becoming a crucial consideration in the automotive industry, and the headlight replacement sector is no exception. Environmental impacts associated with the production and disposal of headlight components necessitate a focus on sustainable sourcing practices. B2B buyers are increasingly looking for suppliers who prioritize eco-friendly manufacturing processes and materials. This includes the use of recyclable components and adherence to regulations regarding hazardous materials.

Moreover, ethical sourcing is gaining traction, with businesses keen on ensuring that their supply chains are transparent and socially responsible. Suppliers who can demonstrate commitment to ethical practices—such as fair labor conditions and minimal environmental impact—are likely to gain preference among international buyers. Certifications such as ISO 14001 for environmental management and other ‘green’ labels can enhance supplier credibility and foster trust.

As the global market shifts towards sustainability, B2B buyers should consider not only the immediate cost of headlight replacements but also the long-term implications of their sourcing decisions on the environment and society. This holistic approach can lead to better brand reputation and customer loyalty.

What Is the Evolution of Headlight Replacement Technologies?

Historically, headlight replacement was straightforward, with incandescent bulbs being the standard. However, over the past two decades, technological advancements have dramatically transformed this sector. The introduction of halogen bulbs improved brightness and longevity, but the real game-changer came with high-intensity discharge (HID) and light-emitting diode (LED) technologies.

These innovations have not only enhanced visibility and safety on the roads but have also increased complexity in replacement processes. Many modern vehicles now feature sealed headlight assemblies, which necessitate complete module replacements when a light fails, thereby escalating costs. As buyers navigate this evolving landscape, understanding the historical context of these technologies can provide valuable insights into current market offerings and pricing structures.

Illustrative image related to how much to get a headlight replaced

In conclusion, the headlight replacement market is a complex interplay of technology, cost, and sustainability. B2B buyers must stay informed about the latest trends, ethical sourcing practices, and technological advancements to make sound purchasing decisions that align with their business goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of how much to get a headlight replaced

-

How do I determine the cost of headlight replacement for my fleet vehicles?

To estimate the cost of headlight replacement for your fleet, start by identifying the type of headlights used in each vehicle. Costs can range from $10 for basic halogen bulbs to over $1,000 for complete LED or HID assemblies. Consult your vehicle’s manual or a reliable auto parts supplier for specific part numbers. Additionally, consider labor costs if you’re outsourcing the replacement. Regularly assessing the condition of your headlights can prevent more costly replacements in the future. -

What is the best type of headlight for commercial vehicles?

For commercial vehicles, LED headlights are often the best choice due to their longevity and energy efficiency. While they may have a higher initial cost, their lifespan of around 30,000 hours reduces the frequency of replacements, ultimately saving costs. HID headlights offer excellent brightness but can be more expensive and complicated to replace. Assess your vehicle’s usage and local regulations to select the most suitable option. -

How can I source quality headlight replacements internationally?

To source quality headlight replacements, start by identifying reputable suppliers through industry trade shows, online directories, and trade associations. Look for suppliers with positive reviews and certifications that meet international standards, such as ISO or DOT. Request samples to evaluate product quality and ensure they can accommodate your specific vehicle types. Building relationships with reliable suppliers can also lead to better pricing and terms. -

What should I consider when vetting suppliers for headlight replacements?

When vetting suppliers, focus on their experience in the automotive parts industry, product quality, and compliance with international safety standards. Request references from other businesses that have sourced headlight replacements from them. Evaluate their capacity for customization and flexibility regarding minimum order quantities (MOQ). Additionally, consider their logistics capabilities to ensure timely delivery, especially if you operate in regions with complex trade regulations. -

What are the typical payment terms for international headlight suppliers?

Payment terms can vary widely among international suppliers. Common arrangements include upfront payments, letters of credit, or net 30 to 60 days after delivery. Always clarify payment expectations before finalizing agreements to avoid misunderstandings. Assess the financial stability of the supplier to mitigate risks associated with payment defaults. Negotiating favorable terms can enhance your cash flow management. -

How do I handle quality assurance for headlight replacements?

Quality assurance is critical when sourcing headlight replacements. Implement a comprehensive inspection process upon receipt of goods, checking for compliance with specifications and standards. Work closely with your supplier to establish quality control measures, including pre-shipment inspections. Consider using third-party quality assurance services to ensure that products meet your standards, especially when dealing with new or unverified suppliers. -

What logistics challenges should I be aware of when importing headlights?

Logistics challenges can include customs clearance delays, shipping costs, and compliance with local regulations. Ensure that your supplier provides all necessary documentation, such as certificates of origin and compliance. Familiarize yourself with import duties and taxes that may apply in your region. Partnering with a reliable freight forwarder can help navigate these complexities and ensure timely delivery of your headlight shipments. -

Can I customize headlight specifications for my vehicles?

Yes, many suppliers offer customization options for headlight specifications to meet your specific needs. This may include variations in brightness, color temperature, or design features. Discuss your requirements with potential suppliers early in the sourcing process. Be prepared to provide detailed specifications and volume forecasts to facilitate the customization process and ensure that it aligns with your operational needs.

Top 2 How Much To Get A Headlight Replaced Manufacturers & Suppliers List

1. Ford Fusion – Headlight Bulb Replacement Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2014 Ford Fusion; front left headlight bulb needs replacement; quoted labor cost of $300; oil change place refused to do the replacement; extensive labor required involving lifting the car and removing several body panels; inquiry about options for replacing just the bulb.

2. Honda Clarity – Headlight Replacement Cost

Domain: insideevsforum.com

Registered: 2017 (8 years)

Introduction: The cost to replace a headlight unit for a Honda Clarity is $1500 per headlight, totaling $3000 for both front headlights. The Clarity uses a sealed headlight assembly, meaning individual bulbs cannot be replaced. The headlights may contain a string of LEDs mounted on a board, and if the plastic cover is scratched, it may affect light output. Some users have suggested alternatives like polishing t…

Strategic Sourcing Conclusion and Outlook for how much to get a headlight replaced

In navigating the costs associated with headlight replacement, international B2B buyers must recognize the significant variations influenced by vehicle type, bulb technology, and labor. The strategic sourcing of quality components not only ensures compliance with safety standards but also promotes long-term cost efficiency. Understanding the nuances of halogen, HID, and LED options allows businesses to make informed purchasing decisions that align with their operational needs and budget constraints.

Investing in reliable, high-quality headlights can mitigate future expenses related to frequent replacements and potential safety hazards. By prioritizing partnerships with reputable suppliers, companies can secure competitive pricing and access to advanced lighting solutions that enhance vehicle performance.

Illustrative image related to how much to get a headlight replaced

As the automotive industry continues to evolve, it is imperative for buyers in Africa, South America, the Middle East, and Europe to stay ahead of trends and innovations in headlight technology. Embrace strategic sourcing as a vital part of your procurement strategy, ensuring you not only meet regulatory demands but also enhance the safety and efficiency of your fleet. Now is the time to leverage insights into headlight replacement to optimize your supply chain and drive sustainable growth in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.