Introduction: Navigating the Global Market for el alternador de un carro

In the competitive landscape of the automotive industry, sourcing reliable alternators for vehicles poses a significant challenge for international B2B buyers. The alternator, a crucial component responsible for charging the battery and powering essential electrical systems, requires careful consideration regarding quality, cost, and supplier reliability. This comprehensive guide delves into the multifaceted world of ‘el alternador de un carro’, covering various types, applications, and the intricacies of supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam, will find actionable insights tailored to their specific market needs. With a focus on understanding the technical specifications and performance standards of alternators, this guide equips decision-makers with the knowledge necessary to make informed purchasing decisions. From evaluating supplier credentials to assessing cost-effectiveness, we aim to empower businesses in optimizing their procurement strategies.

By addressing the complexities of sourcing alternators, this resource not only highlights the importance of quality assurance but also emphasizes the potential impact on vehicle performance and customer satisfaction. As the demand for reliable automotive parts continues to rise globally, having a strategic approach to sourcing alternators will be essential for maintaining a competitive edge in the marketplace.

Table Of Contents

- Top 1 El Alternador De Un Carro Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for el alternador de un carro

- Understanding el alternador de un carro Types and Variations

- Key Industrial Applications of el alternador de un carro

- 3 Common User Pain Points for ‘el alternador de un carro’ & Their Solutions

- Strategic Material Selection Guide for el alternador de un carro

- In-depth Look: Manufacturing Processes and Quality Assurance for el alternador de un carro

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘el alternador de un carro’

- Comprehensive Cost and Pricing Analysis for el alternador de un carro Sourcing

- Alternatives Analysis: Comparing el alternador de un carro With Other Solutions

- Essential Technical Properties and Trade Terminology for el alternador de un carro

- Navigating Market Dynamics and Sourcing Trends in the el alternador de un carro Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of el alternador de un carro

- Strategic Sourcing Conclusion and Outlook for el alternador de un carro

- Important Disclaimer & Terms of Use

Understanding el alternador de un carro Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Alternator | Uses electromagnetic induction; typically found in older models. | General automotive maintenance and repair. | Pros: Cost-effective, widely available. Cons: Less efficient, heavier. |

| Smart Alternator | Features advanced electronics for improved efficiency and control. | Electric vehicles, hybrids, and modern fleets. | Pros: Better fuel economy, lightweight. Cons: Higher initial cost, complex repairs. |

| High-Output Alternator | Designed for vehicles with high electrical demands (e.g., audio systems). | Performance vehicles, commercial trucks. | Pros: Supports high power needs, enhances performance. Cons: More expensive, may require modifications. |

| Mini Alternator | Compact size for space-restricted applications; lower power output. | Small vehicles, motorcycles, and ATVs. | Pros: Space-saving, lightweight. Cons: Limited output, not suitable for larger vehicles. |

| Rebuilt Alternator | Refurbished units that offer a cost-effective alternative to new. | Budget-conscious repairs and fleet services. | Pros: Affordable, environmentally friendly. Cons: Potential for shorter lifespan, variable quality. |

What Are the Characteristics of Conventional Alternators?

Conventional alternators are the standard type used in many vehicles, relying on electromagnetic induction to generate electricity. They are typically heavier and less efficient than newer models but are readily available and cost-effective. B2B buyers should consider these units for general automotive maintenance or repair services, especially in older vehicles. Their simplicity makes them easy to replace, although they may not meet the demands of modern electrical systems.

How Do Smart Alternators Enhance Vehicle Efficiency?

Smart alternators incorporate advanced electronics that optimize energy production based on real-time vehicle needs. This technology is particularly beneficial in electric and hybrid vehicles, where energy efficiency is paramount. B2B buyers in the automotive sector should consider smart alternators for fleets or vehicles that prioritize fuel economy and reduced emissions. While they come at a higher initial cost, the long-term savings in fuel and maintenance can be significant.

When to Choose High-Output Alternators for Commercial Applications?

High-output alternators are designed for vehicles with substantial electrical requirements, such as those equipped with advanced audio systems or numerous electronic accessories. They are essential for performance vehicles and heavy-duty commercial trucks. B2B buyers should assess the power needs of their vehicles before investing in high-output alternators, as they can enhance performance but may also require vehicle modifications. The upfront investment can lead to improved functionality and driver satisfaction.

What Are the Benefits of Mini Alternators in Compact Vehicles?

Mini alternators are compact and lightweight, making them ideal for small vehicles, motorcycles, and ATVs. Their reduced size allows for installation in space-restricted areas without compromising vehicle performance. B2B buyers should consider mini alternators for applications where weight and space are critical. However, their limited output means they are unsuitable for larger vehicles or those with high electrical demands.

Why Consider Rebuilt Alternators for Budget-Conscious Repairs?

Rebuilt alternators offer a cost-effective solution for businesses looking to minimize expenses. These refurbished units can provide reliable performance at a fraction of the cost of new alternators, making them an attractive option for budget-conscious repairs and fleet services. However, buyers should be cautious about the variable quality and potential for a shorter lifespan compared to new units. Proper sourcing and warranty considerations are essential for ensuring a satisfactory purchase.

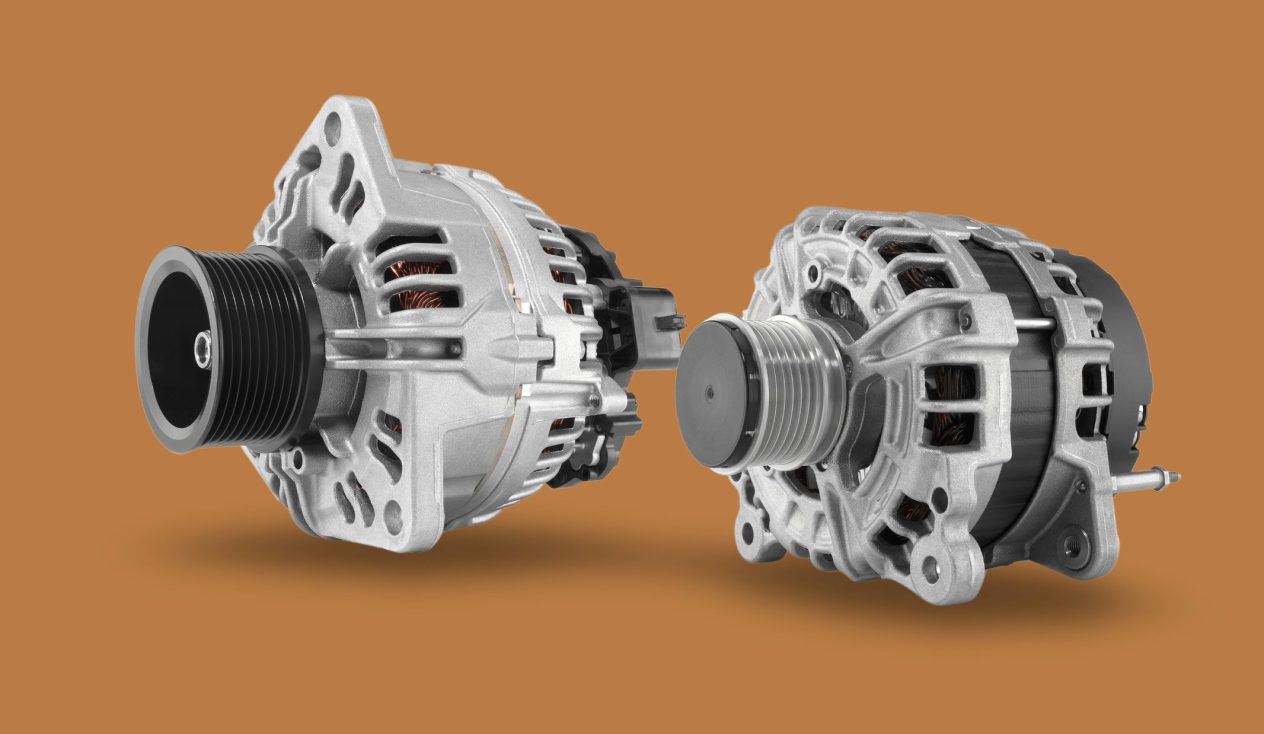

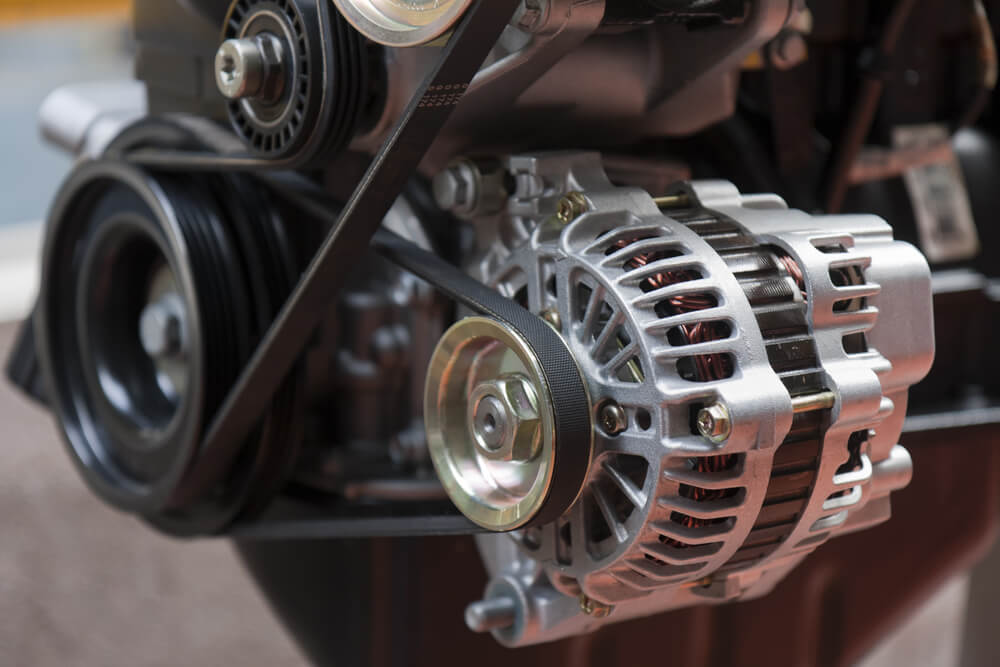

Illustrative image related to el alternador de un carro

Key Industrial Applications of el alternador de un carro

| Industry/Sector | Specific Application of el alternador de un carro | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of electric vehicles (EVs) | Enhances vehicle performance and energy efficiency | Reliability, compatibility with EV technology, and cost-effectiveness |

| Transportation Services | Fleet management for logistics and delivery | Ensures continuous operation and reduces downtime | Durability, ease of maintenance, and warranty support |

| Agricultural Equipment | Powering machinery and vehicles in farming | Increases productivity by ensuring reliable electrical systems | Resistance to harsh environments and energy efficiency |

| Construction Industry | Use in heavy machinery and construction vehicles | Guarantees operational reliability and safety | Compliance with international standards and sourcing quality parts |

| Mining Operations | Electrical systems in mining vehicles | Enhances operational efficiency and reduces energy costs | High durability, temperature resistance, and sourcing from trusted manufacturers |

How is ‘el alternador de un carro’ utilized in automotive manufacturing for electric vehicles (EVs)?

In the automotive manufacturing sector, particularly in the production of electric vehicles (EVs), the alternator plays a crucial role in managing the vehicle’s electrical systems. While traditional vehicles rely on alternators primarily for battery charging, EVs utilize advanced alternators for energy efficiency and optimization of electrical performance. This application not only enhances the vehicle’s performance but also contributes to overall energy efficiency, a vital consideration for businesses aiming to meet sustainability goals. Buyers in this sector should prioritize sourcing alternators that are reliable and compatible with EV technology while also being cost-effective.

What role does ‘el alternador de un carro’ play in transportation services for fleet management?

In the transportation services industry, particularly for logistics and delivery fleets, the alternator ensures that vehicles remain operational without unexpected downtime. A well-functioning alternator provides the necessary electrical power to vital systems, including GPS and communication devices, which are essential for fleet management. This reliability translates into improved service delivery and customer satisfaction. Businesses should focus on sourcing alternators that are durable and easy to maintain, as these factors significantly reduce operational costs and enhance fleet efficiency.

How does ‘el alternador de un carro’ benefit agricultural equipment?

In the agricultural sector, alternators are integral to powering various machinery and vehicles used in farming operations. They ensure that electrical systems function optimally, which is critical for equipment such as tractors and harvesters that rely on consistent power supply for operations. The use of efficient alternators can lead to increased productivity, as farmers can rely on their machines to perform under demanding conditions. Buyers should consider sourcing alternators that offer resistance to harsh environments and high energy efficiency to maximize operational effectiveness.

In what ways does ‘el alternador de un carro’ enhance construction operations?

The construction industry relies heavily on heavy machinery and vehicles, where the alternator is essential for maintaining electrical systems. A reliable alternator ensures that machinery operates safely and efficiently, reducing the risk of accidents caused by electrical failures. This operational reliability is crucial for meeting project deadlines and ensuring worker safety. When sourcing alternators for construction vehicles, businesses should ensure compliance with international standards and prioritize quality parts to minimize maintenance issues.

What is the significance of ‘el alternador de un carro’ in mining operations?

In mining operations, alternators are used in vehicles designed for harsh environments, where reliable electrical systems are paramount. They provide power to critical functions, ensuring that machinery operates efficiently and safely under extreme conditions. By enhancing operational efficiency and reducing energy costs, the right alternator can significantly impact a mining operation’s bottom line. Buyers should prioritize sourcing alternators that demonstrate high durability and temperature resistance, ensuring they can withstand the rigorous demands of mining environments.

3 Common User Pain Points for ‘el alternador de un carro’ & Their Solutions

Scenario 1: Difficulty in Identifying Alternator Failures

The Problem: Many B2B buyers, particularly those managing fleets or automotive repair shops, face significant challenges in diagnosing alternator failures. Common symptoms, such as dimming lights or difficulty starting vehicles, can be misattributed to other electrical issues. This uncertainty can lead to unnecessary repairs, increased downtime, and ultimately higher operational costs. The inability to accurately pinpoint alternator issues can compromise vehicle reliability and negatively impact customer satisfaction.

The Solution: To effectively address this problem, B2B buyers should invest in diagnostic tools that provide real-time data on alternator performance. Equip your team with multimeters or advanced automotive diagnostic scanners capable of measuring voltage output, current draw, and overall system health. Training technicians to recognize specific failure signs, such as unusual noises or warning lights, will enhance their diagnostic skills. Additionally, establishing a preventive maintenance schedule that includes regular checks of the alternator can help in early detection of potential issues, ensuring that vehicles remain operational and reliable.

Scenario 2: Sourcing High-Quality Alternators for Fleet Vehicles

The Problem: Sourcing reliable and high-quality alternators can be a daunting task for B2B buyers, especially those managing large fleets. With numerous suppliers and brands available, the risk of procuring subpar products that lead to frequent replacements or performance issues increases. This not only escalates maintenance costs but also risks fleet downtime, affecting service delivery and profitability.

The Solution: To mitigate these risks, B2B buyers should develop a comprehensive sourcing strategy. Begin by establishing relationships with reputable manufacturers known for producing durable and high-performance alternators. Conduct thorough market research to compare specifications, warranties, and customer reviews. It is also beneficial to attend industry trade shows or forums to connect directly with suppliers and gather insights on the latest technologies and trends. Implementing a quality assurance process, including testing alternators before installation, can further ensure reliability and performance, ultimately leading to cost savings in the long run.

Scenario 3: Managing the Lifecycle of Alternators in Commercial Vehicles

The Problem: Many organizations struggle with managing the lifecycle of alternators within their commercial vehicles, leading to inefficient use of resources and increased operational costs. Without a clear understanding of when alternators need servicing or replacement, businesses may either replace them too early—incurring unnecessary costs—or too late, risking vehicle reliability and safety.

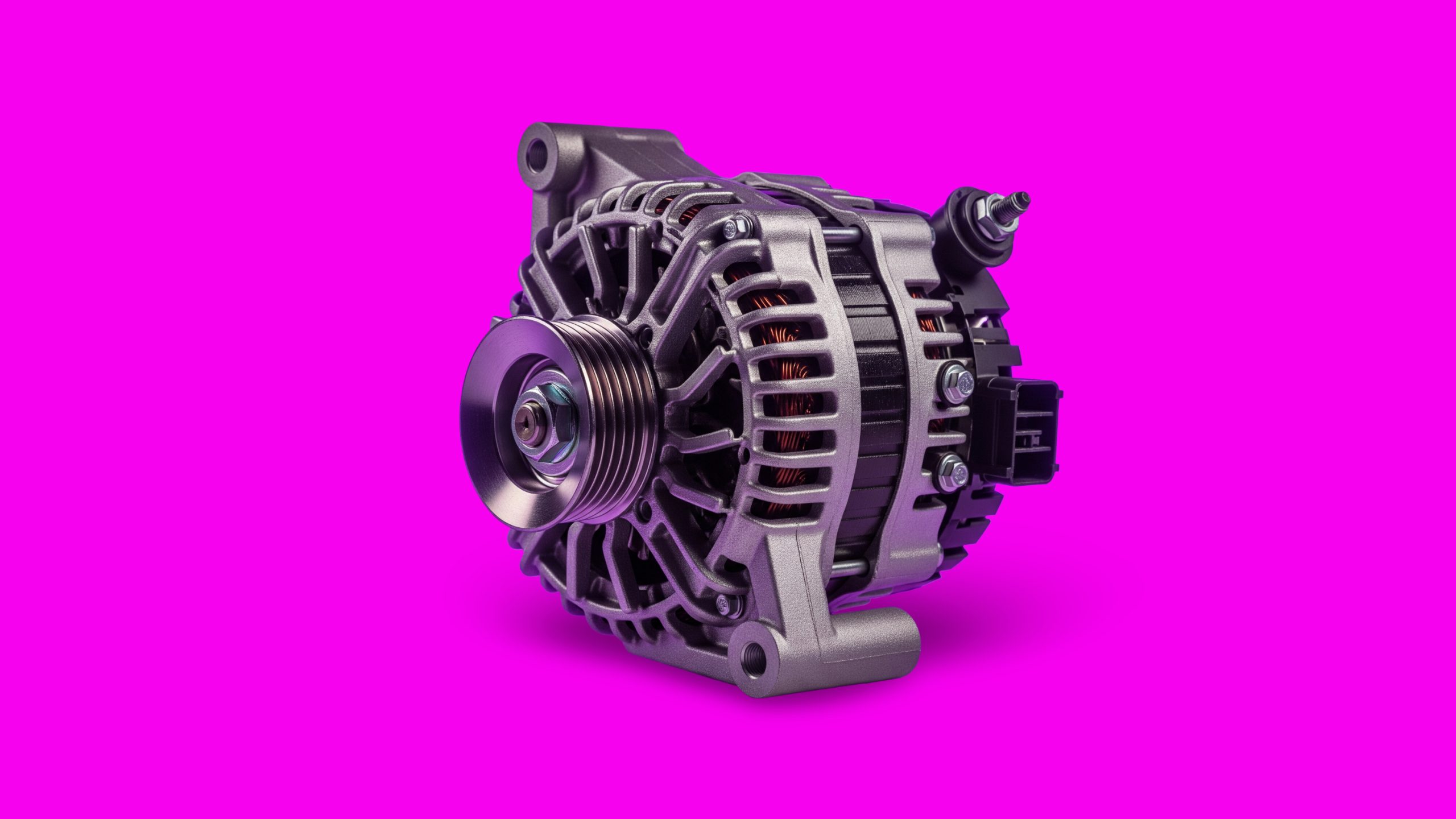

Illustrative image related to el alternador de un carro

The Solution: To effectively manage the lifecycle of alternators, B2B buyers should implement a robust inventory and maintenance management system. This system should track the age and performance of each alternator, schedule regular inspections, and set reminders for replacement based on usage and wear patterns. Utilizing software solutions that integrate with fleet management systems can provide valuable data analytics, helping to predict when an alternator is likely to fail based on historical performance trends. Additionally, conducting regular training sessions for maintenance personnel on the latest alternator technologies and maintenance practices will enhance their ability to manage alternator lifecycles effectively, ensuring optimal vehicle performance and reducing costs.

By addressing these common pain points with actionable solutions, B2B buyers can improve operational efficiency, reduce costs, and enhance vehicle reliability in their fleets.

Strategic Material Selection Guide for el alternador de un carro

What Are the Key Materials Used in the Construction of Car Alternators?

When selecting materials for the construction of car alternators, several factors come into play, including performance characteristics, manufacturing complexity, and cost. Below, we analyze four common materials used in alternator components, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Impact the Performance of Car Alternators?

Aluminum is widely used in the casing and some internal components of car alternators due to its lightweight and excellent thermal conductivity.

- Key Properties: Aluminum has a high strength-to-weight ratio and is resistant to corrosion, which is essential for longevity in various environmental conditions. It can withstand temperatures up to 200°C (392°F) without significant degradation.

- Pros & Cons: The lightweight nature of aluminum improves fuel efficiency in vehicles. However, it can be more expensive than steel and may require specialized manufacturing techniques, increasing production complexity.

- Impact on Application: Aluminum’s corrosion resistance makes it suitable for vehicles operating in humid or coastal environments, where saltwater exposure is a concern.

- Considerations for International Buyers: Compliance with international standards such as ASTM B221 for aluminum extrusions is crucial. Buyers in regions like Africa and South America should also consider local sourcing to reduce costs and ensure compliance with regional regulations.

What Role Does Copper Play in Electrical Conductivity in Alternators?

Copper is predominantly used for windings and electrical connections within the alternator due to its excellent electrical conductivity.

- Key Properties: Copper has a conductivity rating of 59.6 x 10^6 S/m, making it one of the best materials for electrical applications. It also has good thermal conductivity and can withstand high temperatures.

- Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances the efficiency of the alternator. However, it is relatively expensive and can corrode if not properly insulated, leading to potential performance issues.

- Impact on Application: Copper’s high conductivity is vital for applications requiring quick energy transfer, such as in high-performance vehicles.

- Considerations for International Buyers: Compliance with standards such as ASTM B170 for copper wire is essential. Buyers should also be aware of fluctuating copper prices, which can impact overall costs.

How Does Steel Contribute to the Structural Integrity of Alternators?

Steel is often utilized in the structural components of alternators, such as the frame and rotor.

- Key Properties: Steel offers high tensile strength and durability, making it suitable for heavy-duty applications. It can withstand significant mechanical stress and has a temperature rating of around 300°C (572°F).

- Pros & Cons: The durability of steel enhances the overall robustness of the alternator. However, its weight can negatively affect vehicle performance and fuel efficiency. Additionally, it is prone to corrosion unless treated.

- Impact on Application: Steel is particularly beneficial in commercial vehicles that require robust components capable of withstanding harsh operating conditions.

- Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM A36 for structural steel. In regions with high humidity, additional coatings may be necessary to prevent corrosion.

What Advantages Does Plastic Offer in Alternator Manufacturing?

Plastic is increasingly being used for non-structural components, such as housings and insulators, in car alternators.

- Key Properties: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes, providing design flexibility. They can operate effectively at temperatures up to 120°C (248°F).

- Pros & Cons: The main advantage of plastic is its low weight and cost-effectiveness, which can significantly reduce manufacturing expenses. However, plastics may not withstand high temperatures as effectively as metals, limiting their use in certain components.

- Impact on Application: Plastic components are ideal for applications where weight reduction is critical, such as in electric vehicles.

- Considerations for International Buyers: Compliance with standards such as ISO 9001 for quality management systems is important. Buyers should also consider the recyclability of plastics, which is increasingly becoming a preference in global markets.

Summary Table of Material Selection for Car Alternators

| Material | Typical Use Case for el alternador de un carro | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Casing and internal components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Copper | Windings and electrical connections | Superior electrical conductivity | Expensive and prone to corrosion | High |

| Steel | Structural components like frame and rotor | High durability and strength | Heavy and prone to corrosion | Medium |

| Plastic | Non-structural components like housings | Lightweight and cost-effective | Limited high-temperature performance | Low |

This analysis serves as a guide for B2B buyers in selecting the appropriate materials for alternators, taking into account performance, cost, and regulatory compliance in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for el alternador de un carro

What Are the Main Stages of Manufacturing an Automotive Alternator?

The manufacturing process of an automotive alternator is intricate, involving several key stages that ensure both efficiency and quality. Understanding these stages is crucial for B2B buyers looking to procure high-quality alternators.

1. Material Preparation

The first step involves the selection and preparation of raw materials. Common materials used in alternator production include aluminum for the housing, copper for the windings, and various types of steel for the internal components. Suppliers typically conduct thorough inspections of these materials to ensure they meet specified standards. This includes checking for impurities and ensuring that the materials can withstand the operational demands of an automotive alternator.

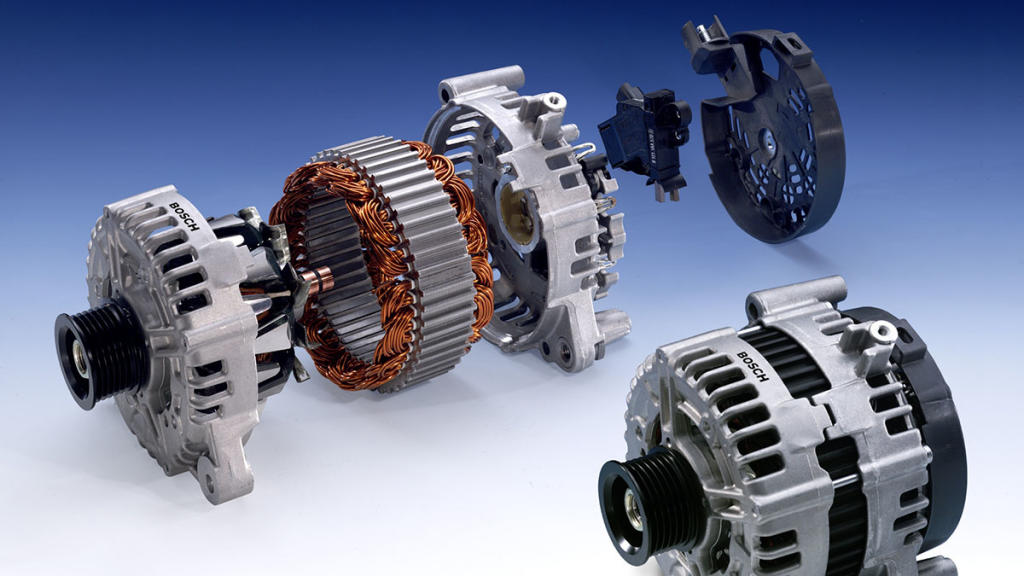

Illustrative image related to el alternador de un carro

2. Forming

Once materials are prepared, the next stage is forming. This typically involves:

- Casting: Aluminum is often cast into the required shapes for the alternator housing. This process can include die-casting or sand-casting techniques, depending on the design specifications.

- Machining: After casting, components undergo machining to achieve precise dimensions. CNC (Computer Numerical Control) machines are commonly used for this purpose, ensuring high accuracy and consistency.

These processes are vital as they set the foundation for the alternator’s performance and durability.

3. Assembly

Following the forming stage, components are assembled. This process usually includes:

- Winding: Copper wire is wound around the stator to create electromagnetic fields. This step is critical, as the number of turns and the wire’s gauge directly impact the alternator’s efficiency.

- Installation: Other components, such as the rotor, rectifier, and bearings, are installed. The assembly line is often designed to minimize errors, with workers trained to follow strict protocols.

Quality checks during assembly, such as torque specifications and alignment checks, are essential to ensure that components fit correctly and operate efficiently.

4. Finishing

The final stage is finishing, which may involve:

- Coating: Protective coatings are applied to prevent corrosion and enhance durability. This is particularly important for alternators used in harsh environments.

- Testing: Each alternator undergoes rigorous testing to ensure it meets performance standards. This includes load testing, electrical testing, and thermal cycling tests to simulate real-world conditions.

How Is Quality Assurance Implemented in Alternator Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of alternators, ensuring that each unit meets international standards and customer expectations. B2B buyers should be familiar with the QA processes and standards that govern alternator production.

Relevant International Standards for Quality Control

Manufacturers typically adhere to international quality standards, such as:

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries, including automotive manufacturing. It emphasizes a process approach to quality, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking indicates that products meet EU safety, health, and environmental protection standards. This is crucial for B2B buyers in Europe, as it signifies compliance with EU regulations.

Industry-Specific Certifications

In addition to general standards, specific certifications may apply, such as:

- API (American Petroleum Institute): For alternators used in heavy machinery and specific automotive applications, API certification ensures that products meet high-performance standards.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints established to catch defects early. These checkpoints typically include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival. This includes checking for specifications, dimensions, and material properties to ensure they are suitable for production.

- In-Process Quality Control (IPQC): During manufacturing, various tests are conducted at different stages. For example, the winding process may involve checking the resistance of the coils to ensure they meet electrical specifications.

- Final Quality Control (FQC): Before shipment, each alternator undergoes comprehensive testing. This includes performance tests under simulated conditions to confirm that they meet operational requirements.

What Testing Methods Are Commonly Used in Alternator Quality Assurance?

A variety of testing methods are employed to ensure the reliability and performance of alternators:

- Electrical Testing: This involves verifying the alternator’s output voltage and current under load conditions. It ensures that the unit can perform effectively in real-world situations.

- Thermal Testing: Alternators are subjected to temperature extremes to assess their performance and durability. This is particularly important for alternators in regions with high ambient temperatures.

- Vibration Testing: This simulates the vibrations experienced during vehicle operation, ensuring that components can withstand operational stresses without failure.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers:

- Audits: Conduct regular audits of suppliers to assess their adherence to quality standards and manufacturing processes. This can provide insights into their operational efficiency and quality practices.

- Quality Reports: Request detailed quality reports that outline testing results, defect rates, and compliance with international standards. These documents can help buyers evaluate the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly valuable for international buyers who may not have direct access to supplier facilities.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, there are several nuances to consider:

- Regulatory Compliance: Ensure that products meet the regulatory requirements of the destination country. This may involve understanding local certifications and standards.

- Cultural Considerations: Be aware of cultural differences that may impact communication and negotiations. Building strong relationships with suppliers can facilitate better quality assurance practices.

- Logistics and Shipping: Consider the impact of logistics on product quality. Proper handling during shipping and storage is crucial to prevent damage that could compromise quality.

By understanding the manufacturing processes and quality assurance measures in the production of automotive alternators, B2B buyers can make informed decisions and select suppliers that align with their quality expectations and operational needs.

Illustrative image related to el alternador de un carro

Practical Sourcing Guide: A Step-by-Step Checklist for ‘el alternador de un carro’

To effectively procure ‘el alternador de un carro,’ it is essential for B2B buyers to follow a systematic approach. This checklist serves as a practical guide, ensuring that you make informed decisions while sourcing alternators for vehicles.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of the alternators you need is the first step in the sourcing process. Consider factors such as voltage output, amperage, and compatibility with specific vehicle models. Clearly defining these specifications helps in narrowing down potential suppliers who can meet your precise needs.

Step 2: Conduct Market Research

Researching the market is vital to identify the range of products available and the various suppliers in the industry. Look for trends, pricing variations, and new technologies in alternator manufacturing. This information will empower you to negotiate better deals and identify high-quality products that align with your budget.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request company profiles, product catalogs, and references from other businesses in similar markets. Pay attention to their experience, market reputation, and ability to meet your specific technical requirements.

- Check for certifications: Ensure that the supplier has relevant industry certifications that guarantee product quality and compliance with international standards.

- Review customer feedback: Look for testimonials or case studies that highlight the supplier’s reliability and service quality.

Step 4: Assess Quality Control Processes

Quality control is a critical aspect of manufacturing alternators. Inquire about the supplier’s quality assurance measures and production processes. Understanding how they maintain quality can help mitigate risks of defects and ensure the longevity of the products you purchase.

- Request documentation: Ask for reports or certifications that indicate compliance with quality standards.

- Evaluate testing procedures: Learn about the tests performed on alternators before they are shipped to ensure they meet required specifications.

Step 5: Consider Logistics and Supply Chain Reliability

Logistics plays a significant role in your procurement strategy. Assess the supplier’s ability to deliver products on time and in good condition. A reliable supply chain reduces delays and potential losses in your operations.

- Evaluate shipping options: Understand the shipping methods available and their associated costs.

- Discuss lead times: Clarify lead times for production and delivery to avoid disruptions in your supply chain.

Step 6: Negotiate Terms and Pricing

Once you’ve identified potential suppliers, it’s time to negotiate terms and pricing. Be transparent about your budget and expectations while being open to discussions about volume discounts or long-term contracts. Effective negotiation can lead to cost savings and favorable terms that benefit both parties.

Step 7: Finalize Contracts and Agreements

Before proceeding with the order, ensure that all contractual details are clear and agreed upon. Review terms regarding warranties, return policies, and after-sales support. This step is crucial to protect your interests and ensure a smooth business relationship moving forward.

Illustrative image related to el alternador de un carro

By following this checklist, B2B buyers can confidently navigate the procurement of alternators, ensuring they select the best products and suppliers for their business needs.

Comprehensive Cost and Pricing Analysis for el alternador de un carro Sourcing

What Are the Key Cost Components in Sourcing Car Alternators?

Understanding the cost structure of sourcing car alternators is crucial for B2B buyers aiming to optimize their procurement strategies. The primary cost components include:

-

Materials: The bulk of the cost is derived from raw materials, including copper for windings, steel for the casing, and various electronic components. Prices for these materials can fluctuate based on global market trends, impacting overall sourcing costs.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, assembly, and quality control. In regions with higher labor costs, such as parts of Europe, manufacturers may have to adjust their pricing to maintain margins.

-

Manufacturing Overhead: This includes expenses related to utilities, maintenance of machinery, and factory space. Overhead costs can vary significantly based on the geographical location of the manufacturing facility.

-

Tooling: Initial tooling costs for custom or specialized alternators can be substantial. These costs are particularly relevant when working with suppliers to create tailored solutions for specific vehicle types.

-

Quality Control (QC): Ensuring that alternators meet industry standards involves rigorous testing and inspection processes, which add to the overall cost. Certifications like ISO can influence pricing, as suppliers may pass on the costs associated with maintaining these standards.

-

Logistics: Transportation and warehousing costs are crucial for international sourcing. Factors like shipping distance, customs duties, and local regulations can significantly affect the final price.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on competition and the perceived value of the alternator.

How Do Price Influencers Impact Car Alternator Sourcing?

Several factors can influence the pricing of car alternators, which B2B buyers should consider:

-

Volume/MOQ: Bulk purchasing often leads to reduced per-unit costs. Understanding the minimum order quantity (MOQ) set by suppliers can aid in negotiating better prices.

-

Specifications and Customization: Custom alternators designed for specific applications or vehicle models may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials: The choice of materials impacts not only the performance but also the price. High-quality materials may lead to higher upfront costs but can result in lower Total Cost of Ownership (TCO) due to increased durability.

-

Quality and Certifications: Suppliers offering certified products may charge higher prices. However, these certifications often assure better performance and reliability, which can be advantageous in the long run.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may have higher prices due to their brand equity and service level, while newer entrants may offer competitive rates to gain market share.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Incoterms can dictate who bears costs and risks at different stages, influencing the overall cost structure.

What Buyer Tips Can Help Optimize Costs in Sourcing Car Alternators?

B2B buyers should adopt strategic approaches to optimize their sourcing of car alternators:

-

Negotiation: Engage suppliers in discussions about pricing, especially when purchasing in bulk. Establishing long-term relationships may also lead to better pricing and terms.

-

Focus on Cost-Efficiency: Evaluate not just the purchase price but also the TCO, which includes maintenance and operational costs. A lower-priced alternator may not be cost-effective if it requires frequent replacements.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying price structures due to local economic conditions, tariffs, and trade agreements. Buyers from Africa, South America, the Middle East, and Europe should be aware of these differences when sourcing.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, their production capabilities, and their pricing strategies. Leverage industry reports and peer reviews to assess supplier reliability.

-

Request Samples: Before finalizing large orders, request samples to evaluate quality and performance. This step helps ensure that the alternators meet your specific requirements.

Disclaimer

Prices and cost structures mentioned are indicative and can vary based on market conditions and specific supplier negotiations. Always conduct a thorough market analysis and supplier evaluation before making purchasing decisions.

Alternatives Analysis: Comparing el alternador de un carro With Other Solutions

Exploring Alternatives to El Alternador de un Carro

In the automotive industry, ensuring optimal vehicle performance requires a reliable electrical system, traditionally fulfilled by the alternator. However, as technology advances, several alternative solutions have emerged that can serve similar functions. This section compares the conventional alternator with alternative technologies, aiding B2B buyers in making informed decisions.

| Comparison Aspect | El Alternador De Un Carro | Batería de Ion de Litio | Generador Eólico |

|---|---|---|---|

| Performance | High efficiency in recharging and powering electrical systems while the engine runs. | Excellent for storing energy but requires external charging. | Can provide continuous power in windy conditions but is highly variable. |

| Cost | Moderate initial cost, with potential for high maintenance if not managed properly. | Higher initial investment but lower long-term costs due to durability. | High initial setup cost, especially for installation and infrastructure. |

| Ease of Implementation | Simple integration into existing vehicle systems. | Requires specialized installation, especially in retrofitting vehicles. | Complex setup and requires significant space and proper location for installation. |

| Maintenance | Regular checks needed to ensure optimal performance and prevent failures. | Minimal maintenance needed, with occasional checks on battery health. | Low maintenance after installation, but requires monitoring for performance. |

| Best Use Case | Ideal for standard vehicles with conventional engines. | Best for electric vehicles or hybrid models needing high energy density. | Suitable for vehicles operating in remote, windy areas or as supplementary power sources. |

What Are the Advantages and Disadvantages of a Batería de Ion de Litio?

The lithium-ion battery is a strong alternative to the traditional alternator, particularly in electric and hybrid vehicles. Its primary advantage lies in its ability to store large amounts of energy and provide it on demand, making it suitable for high-performance applications. However, its higher initial cost and the need for specialized charging systems can be a drawback for some users. Additionally, retrofitting traditional vehicles with lithium-ion batteries can be complex and costly.

How Does a Generador Eólico Compare to El Alternador?

Wind generators are an innovative alternative that harnesses wind energy to generate electricity. This technology can be particularly beneficial in areas with consistent wind patterns, providing a renewable energy source. However, the variability of wind means that power generation is not guaranteed, making it less reliable than an alternator for immediate vehicle power needs. Moreover, the installation of wind generators can be expensive and requires significant space, which may not be feasible for all vehicle types.

Making an Informed Decision as a B2B Buyer

When selecting the right solution for vehicle power management, B2B buyers should consider the specific needs of their operations. Factors such as vehicle type, operating environment, budget constraints, and long-term energy goals play a crucial role in the decision-making process. While the traditional alternator remains a reliable choice for many vehicles, alternatives like lithium-ion batteries and wind generators offer innovative solutions that may align better with certain operational strategies, particularly in sectors focused on sustainability and energy efficiency. Ultimately, evaluating the pros and cons of each option in relation to specific use cases will lead to a more informed and strategic investment.

Essential Technical Properties and Trade Terminology for el alternador de un carro

What Are the Key Technical Properties of an Alternator?

Understanding the technical properties of an alternator is crucial for B2B buyers in the automotive sector. Here are some essential specifications that should be considered:

Illustrative image related to el alternador de un carro

-

Output Voltage

The output voltage of an alternator typically ranges from 12V to 14.5V. This specification is vital because it determines the compatibility of the alternator with various vehicle electrical systems. Buyers must ensure that the alternator they select matches the voltage requirements of the vehicles in their fleet to avoid electrical failures. -

Amperage Rating

Amperage rating indicates the amount of current an alternator can produce, usually ranging from 60A to over 200A. This property is significant for businesses that manage vehicles with high electrical demands, such as those equipped with advanced infotainment systems or additional lighting. A higher amperage rating ensures that all electrical components receive adequate power. -

Material Grade

The materials used in an alternator, such as high-grade copper for windings and durable aluminum or steel for the housing, affect its performance and longevity. Understanding material grades helps B2B buyers assess the durability and reliability of the alternator, especially in harsh operating conditions commonly found in regions like Africa and the Middle East. -

Efficiency Rating

Efficiency ratings indicate how well an alternator converts mechanical energy into electrical energy, typically expressed as a percentage. Higher efficiency means better fuel economy and reduced strain on the engine, which is crucial for fleet management. Buyers should prioritize alternators with high efficiency to minimize operational costs. -

Noise Level

Noise level measurements, often expressed in decibels (dB), are important for vehicle comfort. An alternator that operates quietly contributes to a more pleasant driving experience. This specification may be particularly relevant for commercial vehicles where customer experience is paramount.

What Are Common Trade Terminologies Related to Alternators?

Familiarity with industry jargon is essential for effective communication and decision-making in the B2B automotive sector. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of vehicles. In the context of alternators, buyers often seek OEM parts for their reliability and compatibility with specific vehicle models. Understanding OEM standards can ensure that the parts meet quality expectations. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to manage inventory levels effectively and negotiate better pricing. This term is particularly important when sourcing alternators in bulk for fleet operations. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing for specific products. It is a crucial step in procurement that allows buyers to compare offers and negotiate terms. Being skilled in crafting RFQs can lead to better pricing and service agreements for alternators. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers dealing with global suppliers of alternators, as they dictate shipping costs, risk management, and delivery responsibilities. -

Aftermarket Parts

Aftermarket parts refer to components made by companies other than the OEM. These can include alternators that might be less expensive but vary in quality and compatibility. Buyers must weigh the benefits and risks of using aftermarket parts versus OEM to ensure vehicle reliability. -

Warranty Period

The warranty period indicates the duration for which a product is guaranteed against defects. This term is critical for B2B buyers as it reflects the manufacturer’s confidence in their product and provides a safety net for potential failures. Understanding warranty terms can influence purchasing decisions significantly.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing alternators, ultimately enhancing operational efficiency and vehicle reliability.

Navigating Market Dynamics and Sourcing Trends in the el alternador de un carro Sector

What Are the Current Market Dynamics in the Alternator Sector?

The global alternator market is experiencing significant growth, driven by the increasing demand for electric vehicles (EVs) and advancements in automotive technology. As countries ramp up efforts to reduce carbon emissions, the shift towards EVs is reshaping sourcing strategies for alternators. In regions like Africa and South America, where automotive markets are expanding, there is a growing emphasis on high-efficiency alternators that can support modern electrical systems in vehicles, including enhanced infotainment and safety features.

Emerging trends include the integration of smart technologies within alternators, allowing for better energy management and performance monitoring. B2B buyers are increasingly looking for suppliers who can provide not only traditional alternators but also those equipped with smart functionalities that align with the latest industry standards. Additionally, the adoption of modular designs is gaining traction, enabling manufacturers to customize alternators for specific vehicle models, thus reducing lead times and costs.

International buyers, particularly from the Middle East and Europe, are also paying close attention to supply chain resilience. With disruptions caused by geopolitical tensions and the pandemic, there is a shift towards local sourcing and partnerships with regional manufacturers. This trend is crucial for ensuring a steady supply of components while minimizing logistics costs.

How Are Sustainability and Ethical Sourcing Influencing the Alternator Market?

Sustainability has become a critical consideration in the alternator market, with B2B buyers increasingly prioritizing ethical sourcing practices. The environmental impact of manufacturing processes is under scrutiny, prompting suppliers to adopt more sustainable methods. This includes the use of recycled materials and energy-efficient manufacturing processes that reduce waste and emissions.

Buyers are also seeking suppliers who hold green certifications, which can serve as a benchmark for environmental responsibility. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are becoming essential in supplier selection. Furthermore, the use of eco-friendly materials, such as biodegradable components and non-toxic coatings, is gaining traction among manufacturers looking to enhance their product offerings.

Illustrative image related to el alternador de un carro

Ethical sourcing is not just about environmental considerations; it also encompasses fair labor practices and transparency in the supply chain. B2B buyers are more likely to engage with suppliers who can demonstrate a commitment to social responsibility, including fair wages and safe working conditions. This growing focus on sustainability and ethics is reshaping the competitive landscape, with companies that prioritize these values gaining a distinct advantage in the market.

What Is the Evolution of Alternator Technology Relevant to Today’s B2B Buyers?

The evolution of alternator technology has been marked by significant advancements aimed at improving efficiency and reliability. Initially, alternators were simple mechanical devices designed to convert mechanical energy from the engine into electrical energy. Over the decades, innovations such as the introduction of electronic voltage regulation and the use of lightweight materials have transformed alternator design.

Today, modern alternators are equipped with advanced features, including integrated sensors for real-time monitoring and diagnostics. This evolution is particularly relevant for B2B buyers who require products that not only meet performance standards but also provide data that can be utilized for predictive maintenance. Such capabilities enhance the overall lifecycle management of vehicles, making them more appealing to fleet operators and automotive manufacturers alike.

As the market continues to evolve, buyers must stay informed about these technological advancements to make educated sourcing decisions that align with their operational goals and the growing demand for sustainable and efficient automotive solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of el alternador de un carro

-

How do I solve issues with a malfunctioning alternator in vehicles?

To address a malfunctioning alternator, first, check for common symptoms such as dimming lights, unusual noises, or the battery warning light illuminating on the dashboard. If these signs are present, conduct a thorough inspection of the alternator, including checking the belt for wear and ensuring all electrical connections are secure. If the alternator is confirmed to be faulty, sourcing a replacement from a reliable supplier is essential. Ensure that the new alternator meets the specifications required for your vehicle’s make and model. -

What is the best type of alternator for commercial vehicles?

The best alternator for commercial vehicles typically offers high output and durability, as these vehicles often have higher electrical demands. Look for alternators with a robust construction, high amperage output (usually above 150 amps), and features like thermal protection and voltage regulation. Brands like Bosch, Delco Remy, and Valeo are known for their reliability in commercial applications. It’s advisable to consult with your supplier to ensure the alternator is compatible with the specific requirements of your vehicle fleet. -

How do I vet suppliers for automotive alternators?

When vetting suppliers for automotive alternators, start by assessing their reputation in the market through customer reviews and case studies. Verify their certifications and adherence to international quality standards, such as ISO 9001. Request samples to evaluate the quality of their products and inquire about their manufacturing processes. Additionally, ensure they have a reliable supply chain and logistics capabilities to meet your delivery timelines, especially if you are sourcing from different regions. -

What are the common payment terms when sourcing alternators internationally?

Common payment terms for international sourcing of alternators include options like Letters of Credit (LC), advance payments, or open account terms. The choice of payment method often depends on the supplier’s policies and your relationship with them. Negotiating favorable terms can help mitigate risks, so consider discussing partial payments upon order confirmation and the balance upon delivery. Always ensure that payment terms align with your cash flow management strategies and include provisions for quality checks upon receipt. -

What is the minimum order quantity (MOQ) for automotive alternators?

The minimum order quantity (MOQ) for automotive alternators can vary widely among suppliers, ranging from as low as 10 units to several hundred. Factors influencing MOQ include the supplier’s production capabilities, the type of alternator, and the materials used. For small to medium-sized businesses, it’s essential to discuss MOQs with potential suppliers to find a balance between cost-effectiveness and inventory management. Some suppliers may offer flexibility on MOQs for first-time orders or long-term partnerships. -

How can I ensure quality assurance (QA) for sourced alternators?

To ensure quality assurance (QA) for sourced alternators, establish clear quality standards and specifications with your supplier before placing an order. Request certifications and test reports that confirm compliance with relevant industry standards. Implementing a quality control process, including pre-shipment inspections and random sampling, can help identify defects before products reach your warehouse. Additionally, fostering an open line of communication with your supplier allows for prompt resolution of any quality concerns. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider logistics aspects such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with automotive parts to navigate international shipping complexities. Ensure that all necessary documentation, including commercial invoices and packing lists, is prepared to facilitate smooth customs clearance. Additionally, account for potential tariffs and taxes that may apply, and plan for storage solutions upon arrival to manage your inventory effectively. -

How do I customize alternators for specific vehicle requirements?

Customizing alternators for specific vehicle requirements involves collaborating closely with your supplier to define the necessary specifications, such as output voltage, size, and mounting configurations. Discuss any unique electrical demands your vehicles may have, such as additional features for high-performance applications. Ensure that the supplier has the capabilities to produce custom units and inquire about the lead times associated with such orders. It’s also beneficial to request prototypes or test samples before finalizing the order to confirm compatibility and performance.

Top 1 El Alternador De Un Carro Manufacturers & Suppliers List

1. Facebook – Alternador de Auto

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: El alternador de un auto sirve para generar electricidad y cargar la batería del vehículo. Funciona convirtiendo la energía mecánica del motor en energía eléctrica mediante un proceso de inducción electromagnética.

Strategic Sourcing Conclusion and Outlook for el alternador de un carro

In the evolving landscape of automotive components, strategic sourcing of alternators represents a significant opportunity for international B2B buyers. Understanding the critical role alternators play in vehicle functionality—converting mechanical energy into electrical energy to power essential systems—highlights the need for reliable suppliers. As the demand for electric vehicles grows, the importance of sourcing high-quality alternators from reputable manufacturers becomes even more pronounced.

For buyers in regions such as Africa, South America, the Middle East, and Europe, establishing strong relationships with suppliers can facilitate access to the latest technologies and innovations in alternator design. This can lead to enhanced vehicle performance and customer satisfaction. Additionally, prioritizing suppliers who adhere to quality standards and sustainability practices can provide a competitive edge in the market.

Looking ahead, the automotive industry is set for transformation, with advancements in technology paving the way for smarter, more efficient alternators. B2B buyers should engage proactively with suppliers, leveraging market insights to make informed sourcing decisions. By embracing strategic sourcing, businesses can not only enhance their product offerings but also contribute to a more sustainable automotive future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.