Introduction: Navigating the Global Market for car alternator issues

Navigating the complexities of sourcing reliable car alternator components presents a significant challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As the alternator plays a crucial role in a vehicle’s electrical system, understanding the common issues associated with this component is essential for maintaining optimal vehicle performance and minimizing downtime. This comprehensive guide will delve into various types of alternator problems, their applications in different vehicle models, and strategies for vetting suppliers effectively.

In addition to identifying signs of alternator failure—such as dimming headlights or dashboard warning lights—this guide will also address cost considerations, repair versus replacement decisions, and the implications of sourcing quality parts from reputable suppliers. By equipping B2B buyers with actionable insights and best practices, we aim to empower informed purchasing decisions that enhance operational efficiency and drive business success.

With a focus on practical solutions tailored to diverse market needs, this guide will serve as a valuable resource for businesses seeking to navigate the global market for car alternator issues. Whether you are looking to establish long-term supplier relationships or simply seeking to understand the intricacies of alternator maintenance, you will find the information necessary to optimize your procurement strategies and bolster your bottom line.

Table Of Contents

- Top 3 Car Alternator Issues Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car alternator issues

- Understanding car alternator issues Types and Variations

- Key Industrial Applications of car alternator issues

- 3 Common User Pain Points for ‘car alternator issues’ & Their Solutions

- Strategic Material Selection Guide for car alternator issues

- In-depth Look: Manufacturing Processes and Quality Assurance for car alternator issues

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator issues’

- Comprehensive Cost and Pricing Analysis for car alternator issues Sourcing

- Alternatives Analysis: Comparing car alternator issues With Other Solutions

- Essential Technical Properties and Trade Terminology for car alternator issues

- Navigating Market Dynamics and Sourcing Trends in the car alternator issues Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car alternator issues

- Strategic Sourcing Conclusion and Outlook for car alternator issues

- Important Disclaimer & Terms of Use

Understanding car alternator issues Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dimming or Flickering Lights | Noticeable reduction in brightness of headlights or interior lights; often intermittent. | Automotive repair shops, fleet maintenance. | Pros: Quick diagnostics; Cons: May indicate deeper electrical issues. |

| Battery Charging Issues | Inability to maintain battery charge; frequent dead batteries. | Battery suppliers, automotive service centers. | Pros: Identifies need for alternator replacement; Cons: May require simultaneous battery replacement. |

| Unusual Noises | High-pitched whining or grinding sounds from the engine. | Vehicle repair workshops, parts distributors. | Pros: Early warning of mechanical failure; Cons: Requires skilled diagnosis to pinpoint exact issue. |

| Electrical Component Malfunctions | Failure of electrical systems such as HVAC or infotainment. | Automotive electronics manufacturers, service providers. | Pros: Indicates potential alternator failure; Cons: Can lead to multiple repairs if other components are affected. |

| Stalling or Poor Acceleration | Engine performance issues linked to electrical supply inconsistencies. | Automotive service chains, fleet operators. | Pros: Critical for vehicle safety; Cons: May involve extensive diagnostics and repairs. |

What are the Key Characteristics of Dimming or Flickering Lights?

Dimming or flickering lights are often the first noticeable symptoms of alternator issues. This problem arises when the alternator fails to deliver sufficient voltage to the vehicle’s lighting system. For B2B buyers in the automotive repair sector, recognizing these signs can lead to timely interventions, preventing further complications. Repair shops can quickly address this issue, ensuring that vehicles remain safe and operational. However, this symptom may also indicate deeper electrical problems, necessitating thorough diagnostics.

How Do Battery Charging Issues Affect Vehicle Reliability?

Battery charging issues manifest when the alternator fails to replenish the battery effectively, leading to frequent dead batteries. For businesses involved in battery supply or automotive services, understanding this issue is crucial. It often requires both the alternator and battery to be tested for optimal performance. While addressing these issues can enhance vehicle reliability, it may lead to additional costs if both components need replacement, impacting budget considerations for fleet operators.

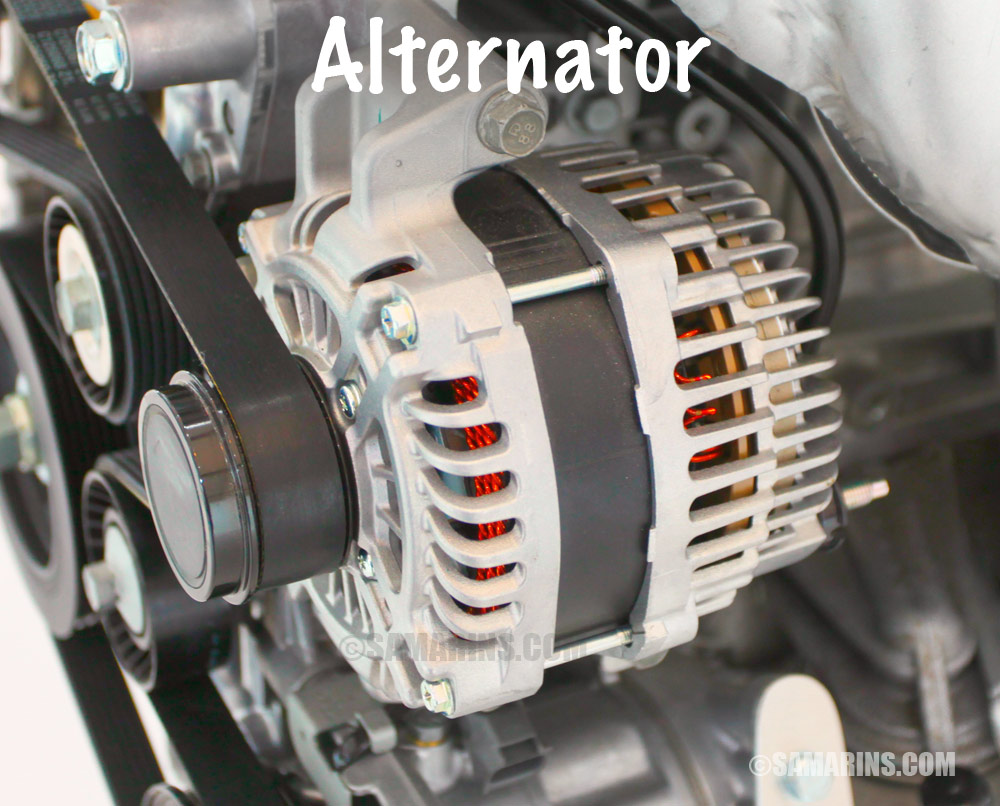

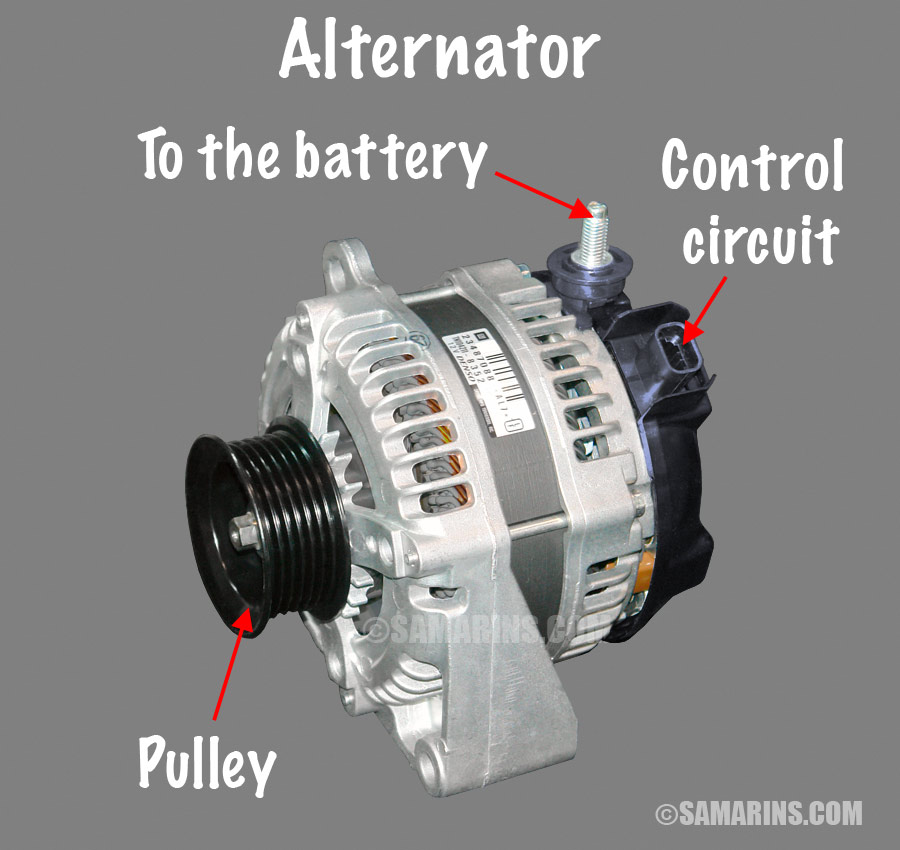

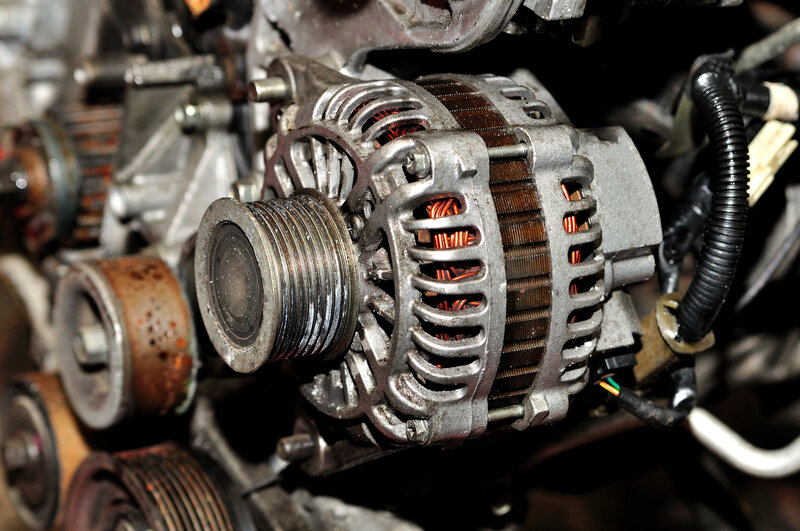

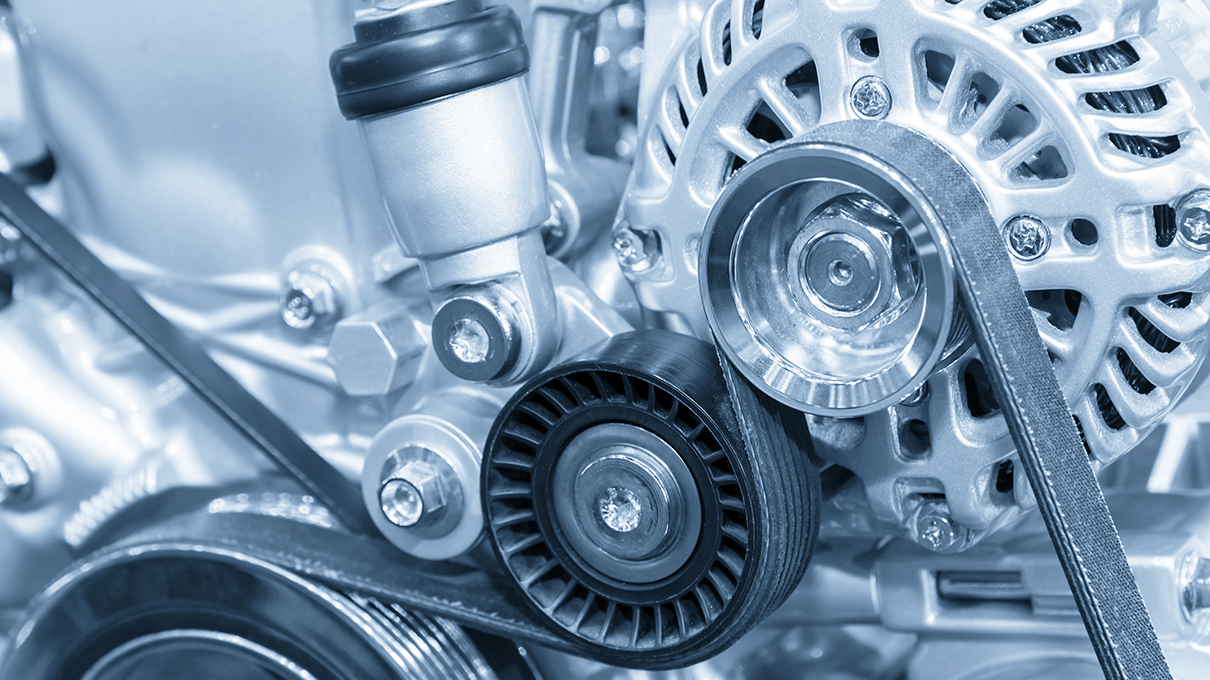

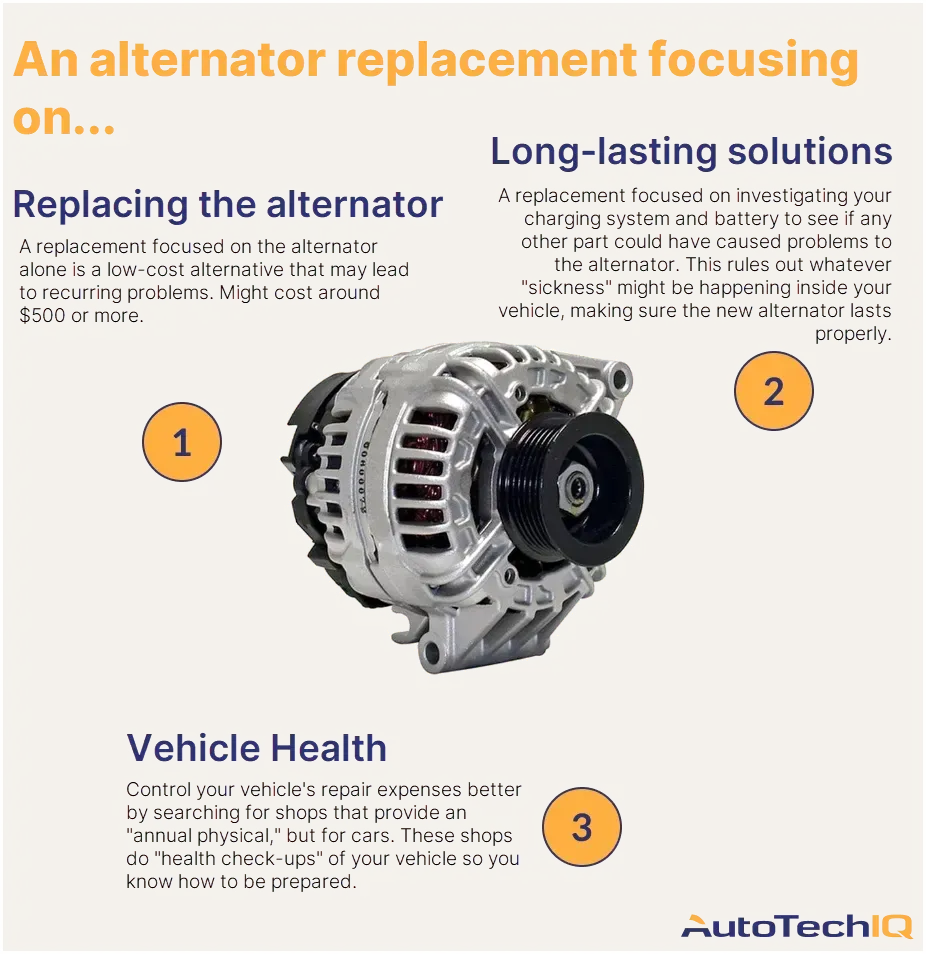

Illustrative image related to car alternator issues

What Do Unusual Noises Indicate About Alternator Health?

Unusual noises, such as whining or grinding, often indicate mechanical problems within the alternator. These sounds can signal worn bearings or loose belts, making it essential for automotive workshops to conduct immediate inspections. B2B buyers in the repair industry should prioritize skilled technicians who can accurately diagnose these issues. While early detection can prevent severe damage, misdiagnosis may lead to unnecessary repairs, impacting customer satisfaction and operational costs.

How Do Electrical Component Malfunctions Signal Alternator Problems?

Electrical component malfunctions, such as failures in infotainment systems or HVAC, can signal alternator issues. For automotive electronics manufacturers and service providers, recognizing these signs can lead to better customer service and repair efficiency. Addressing these problems promptly can mitigate risks of further electrical failures. However, the interdependence of vehicle systems means that fixing the alternator may not resolve all issues, increasing the complexity of repairs.

Why is Stalling or Poor Acceleration a Critical Concern?

Stalling or poor acceleration linked to alternator issues can severely impact vehicle safety and performance. For fleet operators and automotive service chains, these symptoms are critical indicators that require immediate attention. Understanding the relationship between electrical supply and engine performance is essential for effective vehicle maintenance. While addressing these issues can enhance overall vehicle reliability, the diagnostic process can be time-consuming and may involve multiple repairs, influencing repair timelines and costs.

Key Industrial Applications of car alternator issues

| Industry/Sector | Specific Application of car alternator issues | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Diagnosing and repairing alternator issues in vehicles | Enhanced customer satisfaction and repeat business | Access to high-quality alternators and diagnostic tools |

| Fleet Management | Regular maintenance and replacement of alternators in fleet | Reduced downtime and improved vehicle reliability | Bulk purchasing options and reliable supply chains |

| Transportation Logistics | Ensuring operational efficiency of delivery vehicles | Increased on-time delivery rates and reduced operational costs | Compatibility with various vehicle models and fast delivery times |

| Agricultural Machinery | Maintaining alternators in farm equipment | Minimizing equipment failure and maximizing productivity | Knowledge of specific machinery requirements and local suppliers |

| Construction Equipment | Addressing alternator issues in heavy machinery | Enhancing machine uptime and operational efficiency | Sourcing durable alternators that withstand harsh conditions |

How Are Automotive Repair Shops Addressing Car Alternator Issues?

Automotive repair shops play a crucial role in diagnosing and resolving car alternator issues. These shops often encounter customers experiencing symptoms like dimming lights or warning dashboard signals. By effectively addressing these issues, repair shops can enhance customer satisfaction, leading to repeat business. For international buyers, sourcing high-quality alternators and diagnostic equipment is vital to ensure reliable repairs and maintain competitive service standards.

Illustrative image related to car alternator issues

What Are the Benefits of Regular Maintenance in Fleet Management?

Fleet management companies must regularly maintain and replace alternators to prevent unexpected vehicle breakdowns. Issues with the alternator can lead to significant downtime, impacting delivery schedules. By ensuring vehicles are equipped with reliable alternators, businesses can enhance operational efficiency and reduce costs associated with delays. Sourcing alternators in bulk can also provide cost savings, making it a strategic procurement decision for fleet managers.

How Can Transportation Logistics Improve Efficiency with Alternator Maintenance?

In the transportation logistics sector, maintaining the functionality of delivery vehicles is critical. Alternator issues can lead to delays and increased operational costs, making timely diagnosis and repair essential. By ensuring that vehicles are equipped with reliable alternators, logistics companies can improve their on-time delivery rates. It is important for buyers to consider the compatibility of alternators with various vehicle models and to establish fast delivery times with suppliers to minimize disruptions.

Why Is Alternator Maintenance Important for Agricultural Machinery?

In agricultural settings, equipment reliability is paramount. Alternator issues can lead to machinery failure, which directly impacts productivity. By addressing these problems proactively, agricultural businesses can minimize downtime and maintain operational efficiency. Buyers in this sector should focus on sourcing alternators that meet the specific requirements of their machinery and work with local suppliers who understand the unique challenges of agricultural operations.

How Does Construction Equipment Benefit from Addressing Alternator Issues?

Construction companies rely heavily on heavy machinery, where alternator failures can halt operations and lead to costly delays. By ensuring that alternators are regularly inspected and replaced when necessary, companies can enhance machine uptime and operational efficiency. For sourcing, it is crucial to find durable alternators that can withstand the harsh conditions of construction sites, along with suppliers that can provide timely support and replacements to keep projects on track.

3 Common User Pain Points for ‘car alternator issues’ & Their Solutions

Scenario 1: Inconsistent Power Supply Leading to Operational Delays

The Problem: B2B buyers in the automotive sector, particularly fleet managers or vehicle rental companies, often face issues with unreliable alternators leading to inconsistent power supply. This can cause operational delays, as vehicles may stall or fail to start due to insufficient battery charge. Such interruptions not only inconvenience drivers but also impact overall productivity, leading to potential revenue loss. Furthermore, the unpredictability of alternator failures can complicate fleet management and maintenance scheduling, making it challenging to ensure that all vehicles remain operational.

The Solution: To mitigate these challenges, it is essential for B2B buyers to implement a robust preventive maintenance strategy. Regularly scheduled inspections of the alternator and electrical systems can help identify issues before they escalate. Buyers should invest in diagnostic tools that can monitor the alternator’s performance and health in real-time. Additionally, developing a relationship with a reliable parts supplier can ensure quick access to high-quality alternators and components, minimizing downtime. Training staff on the signs of alternator failure, such as flickering lights or unusual noises, can empower them to address potential issues proactively, thereby maintaining operational efficiency.

Scenario 2: Increased Repair Costs Due to Delayed Maintenance

The Problem: Many B2B buyers, especially those managing automotive repair shops or parts distribution, often encounter escalating repair costs due to neglecting alternator maintenance. When alternators fail without warning, it can lead to a cascade of issues, including battery damage and electrical system failures. This not only increases the cost of repairs but can also lead to extended downtime for vehicles, negatively impacting customer satisfaction and loyalty.

The Solution: To counteract this issue, B2B buyers should prioritize establishing a comprehensive maintenance schedule that includes routine alternator checks. Implementing a systematic approach that incorporates the use of diagnostic equipment can help assess the condition of the alternator and associated components regularly. Additionally, offering maintenance packages that include alternator inspections can attract more clients and increase revenue streams. Educating customers about the importance of timely alternator maintenance can also foster long-term relationships and drive repeat business. This proactive strategy ultimately reduces the likelihood of costly repairs and enhances operational efficiency.

Scenario 3: Difficulty Sourcing Reliable Replacement Parts

The Problem: International B2B buyers, particularly in regions like Africa and South America, often struggle to source reliable replacement alternators and parts. The lack of access to quality components can lead to prolonged vehicle downtimes and subpar repair outcomes, which adversely affect business operations. This issue is compounded by counterfeit products flooding the market, posing additional risks to vehicle performance and safety.

Illustrative image related to car alternator issues

The Solution: To overcome these sourcing challenges, B2B buyers should establish partnerships with reputable manufacturers and suppliers known for their quality and reliability. Conducting thorough market research to identify certified suppliers can help mitigate the risks associated with counterfeit parts. Additionally, buyers should consider leveraging technology to streamline the sourcing process; using platforms that connect them with verified suppliers can enhance transparency and reduce procurement risks. Implementing a strict quality assurance process for incoming parts will also ensure that only reliable components are used, leading to improved vehicle performance and reduced maintenance issues. By prioritizing quality in sourcing, businesses can enhance their service offerings and build trust with their customers.

Strategic Material Selection Guide for car alternator issues

What Are the Key Materials Used in Car Alternators?

When selecting materials for car alternators, several factors come into play, including performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in alternator manufacturing and their implications for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

How Does Aluminum Benefit Alternator Manufacturing?

Aluminum is a widely used material in car alternators due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 150°C, making it suitable for the high temperatures generated during alternator operation.

Pros: Aluminum is corrosion-resistant, which is essential for vehicles operating in humid or coastal environments. Its low density contributes to overall vehicle weight reduction, improving fuel efficiency.

Illustrative image related to car alternator issues

Cons: While aluminum is durable, it is not as strong as some alternatives, which may lead to issues in high-stress applications. Additionally, the manufacturing process can be more complex due to the need for specialized welding techniques.

Impact on Application: Aluminum’s compatibility with electrical components makes it ideal for use in alternators, where efficient conductivity is essential.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B221 for aluminum extrusions. In regions with high humidity, selecting treated aluminum can enhance longevity.

What Role Does Copper Play in Alternator Components?

Copper is another critical material, primarily used in windings and connectors within alternators. It boasts excellent electrical conductivity, with a conductivity rating of 59% IACS (International Annealed Copper Standard), making it ideal for efficient power transfer.

Pros: Copper’s high conductivity translates to lower energy losses, enhancing the alternator’s overall efficiency. It is also highly ductile, allowing for intricate designs in windings.

Illustrative image related to car alternator issues

Cons: Copper is prone to corrosion, particularly in saline environments, which can affect performance over time. Additionally, it is more expensive than aluminum, impacting overall manufacturing costs.

Impact on Application: The use of copper in windings ensures optimal electrical performance, crucial for maintaining battery charge and powering electrical systems.

Considerations for International Buyers: Compliance with standards such as ASTM B170 for copper wire is essential. Buyers in humid regions may need to consider additional coatings or treatments to prevent corrosion.

How Does Steel Contribute to Alternator Durability?

Steel, particularly carbon steel, is often used for the structural components of alternators, such as the housing and mounting brackets. It offers a high tensile strength, with a yield strength of around 250 MPa, making it suitable for demanding applications.

Pros: Steel’s durability and resistance to mechanical stress make it ideal for protecting sensitive internal components. It is also cost-effective compared to other materials.

Cons: Steel is heavier than aluminum, which can negatively impact vehicle performance. It is also susceptible to rust if not properly coated or treated.

Impact on Application: Steel’s strength ensures that the alternator can withstand vibrations and shocks, which is critical for long-term reliability.

Considerations for International Buyers: Buyers should ensure that steel components meet relevant standards, such as DIN EN 10025 for structural steel. In regions with high humidity, a rust-resistant coating is advisable.

What Advantages Does Plastic Offer in Alternator Design?

Plastics, particularly thermoplastics, are increasingly used in alternator housings and insulators. They can withstand temperatures up to 120°C and provide excellent electrical insulation.

Pros: Plastics are lightweight and can be molded into complex shapes, allowing for innovative designs. They are also resistant to corrosion and chemicals, enhancing longevity.

Cons: Plastics may not offer the same mechanical strength as metals, potentially leading to issues under high-stress conditions. They can also degrade under prolonged exposure to UV light.

Impact on Application: The use of plastic in non-load-bearing components can reduce weight without compromising performance, making them suitable for modern vehicles.

Considerations for International Buyers: Compliance with standards such as ISO 9001 for quality management is essential. Buyers should consider the specific environmental conditions in their region, such as UV exposure, when selecting plastic materials.

Summary Table of Material Selection for Car Alternators

| Material | Typical Use Case for car alternator issues | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Copper | Windings and connectors | Excellent electrical conductivity | Prone to corrosion and higher cost | High |

| Steel | Structural components and brackets | High tensile strength and durability | Heavier and susceptible to rust | Low |

| Plastic | Housings and insulators | Lightweight and corrosion-resistant | Lower mechanical strength | Medium |

This analysis provides a comprehensive overview of the materials used in car alternators, enabling B2B buyers to make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for car alternator issues

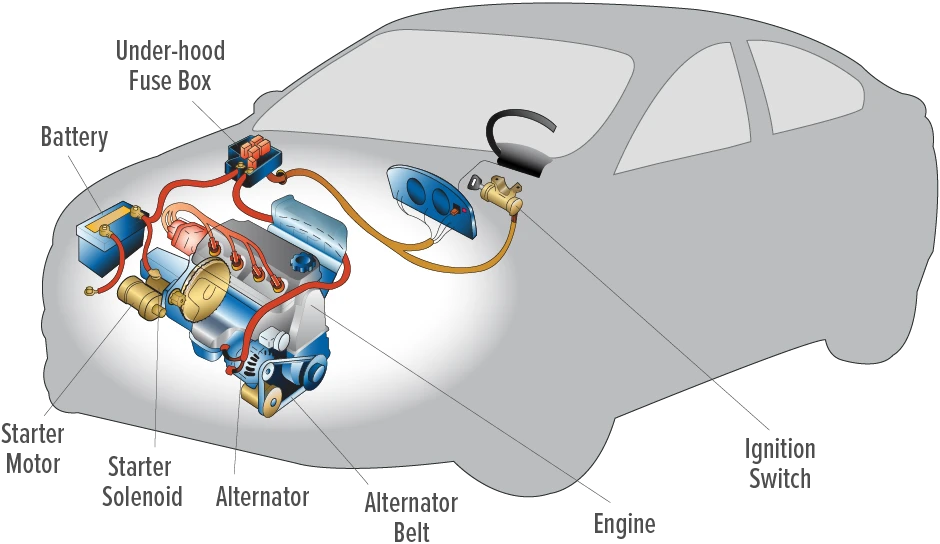

What Are the Key Stages in the Manufacturing Process of Car Alternators?

The manufacturing process of car alternators involves several critical stages that ensure the final product meets the necessary specifications and quality standards. Understanding these stages can help B2B buyers identify reliable suppliers and assess the quality of alternators.

Illustrative image related to car alternator issues

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing alternators is material preparation. The primary materials include:

- Aluminum: Used for the housing due to its lightweight and excellent conductivity.

- Copper: Essential for windings, providing efficient electrical conduction.

- Steel: Commonly used for the rotor and other structural components.

Suppliers often source materials from certified vendors to ensure quality. Material selection is crucial as the performance of the alternator largely depends on the quality of these raw materials.

How Are Alternators Formed and Assembled?

Once the materials are prepared, the next phase is forming and assembly. This includes:

-

Casting and Machining: The aluminum housing is cast and then machined to precise dimensions. This process ensures that all components fit together seamlessly.

-

Winding the Coils: Copper wire is wound around the stator to create electromagnetic fields. Precision in this step is vital, as any inconsistency can lead to inefficiencies.

-

Rotor Assembly: The rotor, typically containing permanent magnets or windings, is assembled with bearings. This component is essential for generating electrical current.

-

Final Assembly: All components, including the voltage regulator and rectifier, are assembled into the housing. This stage also involves installing the serpentine or V-belt that connects the alternator to the engine.

What Finishing Techniques Are Commonly Used?

The finishing stage focuses on enhancing the alternator’s durability and performance. Techniques may include:

- Surface Treatment: Processes such as anodizing or powder coating protect the alternator from corrosion and wear.

- Quality Inspections: Post-assembly, each unit undergoes rigorous inspections to ensure compliance with specifications.

What Quality Control Measures Are Essential for Alternators?

Quality assurance is paramount in the manufacturing of car alternators. Adhering to international standards and implementing robust QC processes helps maintain product integrity and reliability.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers must familiarize themselves with relevant international standards such as:

- ISO 9001: Focuses on quality management systems, ensuring that manufacturers maintain consistent quality throughout the production process.

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards, essential for suppliers targeting the European market.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control is typically structured around several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are tested to monitor quality at various stages of production.

-

Final Quality Control (FQC): Before shipment, finished alternators undergo comprehensive testing to verify functionality, performance, and compliance with standards.

How Are Alternators Tested for Quality Assurance?

Testing methods are crucial for verifying the performance and reliability of alternators. Common testing techniques include:

Illustrative image related to car alternator issues

- Electrical Testing: Measures output voltage and current to ensure the alternator meets performance specifications.

- Load Testing: Assesses how the alternator performs under various loads, simulating real-world conditions.

- Thermal Testing: Evaluates how the alternator handles heat, which is critical for long-term durability.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure they are sourcing high-quality alternators, B2B buyers should consider the following verification methods:

What Audits and Reports Should Be Requested?

Buyers should request:

- Supplier Audits: Regular audits by third-party organizations can provide insights into the supplier’s quality management practices.

- Quality Reports: Manufacturers should provide detailed QC reports that outline the results of various testing methods performed on the alternators.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can further assure buyers of product quality. These independent inspections can cover:

- Material Verification: Confirming that raw materials meet specified standards.

- Final Product Inspection: Ensuring that the finished alternators comply with both quality and safety standards.

What Are the Unique QC Considerations for International Buyers?

B2B buyers from different regions must navigate various regulatory landscapes. Here are some considerations:

-

Regional Certifications: Buyers in Africa and the Middle East may require additional certifications specific to their markets. Understanding local regulations can help avoid compliance issues.

-

Supply Chain Transparency: International buyers should seek suppliers who provide full visibility into their supply chain practices. This transparency can help mitigate risks associated with sourcing materials and components.

Conclusion

Understanding the manufacturing processes and quality assurance protocols associated with car alternators is essential for B2B buyers. By focusing on the key stages of manufacturing, international standards, and effective QC measures, buyers can make informed decisions when sourcing alternators. Ensuring robust quality assurance practices not only enhances product reliability but also fosters long-term partnerships with suppliers, ultimately benefiting both parties in the competitive automotive market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator issues’

In the automotive industry, understanding and addressing car alternator issues is crucial for ensuring vehicle reliability and safety. This guide serves as a practical checklist for B2B buyers involved in sourcing components or services related to alternator problems. By following these steps, you can make informed decisions that enhance your procurement process and overall operational efficiency.

Step 1: Identify Common Alternator Issues

Understanding the most prevalent alternator problems is essential for effective sourcing. Common issues include dimming headlights, dashboard warning lights, and electrical component malfunctions. Being aware of these problems helps you specify what to look for in both products and supplier capabilities.

Step 2: Define Your Technical Specifications

Clearly outline the technical requirements for the alternators you need. This includes factors such as voltage ratings, amperage output, and compatibility with specific vehicle models. Precise specifications will streamline the procurement process and ensure that you receive products that meet your operational needs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request documentation such as company profiles, case studies, and references from other businesses in your region or industry. Assess their track record for reliability and quality, as well as their ability to support your specific needs regarding alternator issues.

Step 4: Verify Supplier Certifications

Confirm that your potential suppliers hold relevant certifications and comply with international quality standards. Certifications such as ISO 9001 or specific automotive industry standards indicate a commitment to quality and reliability. This step is vital for ensuring that the alternators you procure will meet safety and performance requirements.

Illustrative image related to car alternator issues

Step 5: Request Sample Products

Whenever possible, request samples of the alternators or components you are considering. Testing these samples will allow you to evaluate their performance and compatibility with your vehicles. This proactive approach can prevent costly mistakes and ensure that you are sourcing high-quality products.

Step 6: Negotiate Terms and Pricing

Once you have shortlisted suppliers, engage in negotiations regarding pricing and terms. Consider factors such as bulk discounts, payment terms, and warranty provisions. A well-negotiated agreement not only improves your bottom line but also establishes a strong relationship with your supplier.

Step 7: Plan for Ongoing Support and Maintenance

After procurement, ensure that your suppliers offer ongoing support and maintenance services. This is particularly important for alternators, which may require periodic checks and servicing to maintain optimal performance. A supplier that provides reliable post-sale support can be an invaluable partner in your business operations.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing solutions for car alternator issues. Implementing these practices will not only enhance procurement efficiency but also contribute to the overall reliability and safety of the vehicles in your fleet.

Illustrative image related to car alternator issues

Comprehensive Cost and Pricing Analysis for car alternator issues Sourcing

What Are the Key Cost Components for Sourcing Car Alternator Issues?

When sourcing solutions for car alternator issues, understanding the cost structure is essential. The primary cost components include:

-

Materials: The quality of materials used in alternator manufacturing significantly affects pricing. High-grade metals, magnets, and electronic components can lead to higher upfront costs but may offer better performance and longevity.

-

Labor: Labor costs vary by region and depend on the complexity of the assembly process. Skilled labor is essential for quality assurance and ensuring that the alternators meet safety and performance standards.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, leading to more competitive pricing.

-

Tooling: The initial investment in tooling for manufacturing alternators can be substantial. However, once the tooling is in place, it can produce alternators at a lower cost per unit, particularly for larger production runs.

-

Quality Control (QC): Implementing rigorous QC processes is crucial to maintain product reliability. While it adds to the cost, it can prevent costly returns and warranty claims later, enhancing customer satisfaction and brand reputation.

-

Logistics: Transportation costs are a significant factor, especially for international shipments. Variability in shipping methods and distances can impact overall pricing, necessitating careful planning to optimize logistics.

-

Margin: Supplier margins can vary widely based on market demand, competition, and perceived value. Understanding these margins can aid in negotiation and ensure you are paying a fair price.

What Influences the Pricing of Car Alternator Solutions?

Several price influencers affect sourcing decisions:

-

Volume/MOQ: Bulk purchasing often leads to discounts. Suppliers may have Minimum Order Quantities (MOQ) that can impact pricing, especially if you are looking for customized solutions.

-

Specifications and Customization: Custom alternators tailored to specific vehicle models or performance requirements can incur additional costs. Be clear about your needs to ensure accurate pricing.

-

Materials: The choice between standard and premium materials influences cost. Buyers should balance between initial cost and the long-term benefits of durability and efficiency.

-

Quality Certifications: Alternators with certifications (like ISO or TS) may come at a premium but can provide assurance of quality and compliance with international standards.

-

Supplier Factors: The reliability and reputation of suppliers can influence costs. Established suppliers may charge more due to perceived quality, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is vital. These terms dictate who is responsible for shipping costs and risks, which can impact the total cost.

What Tips Can Help Buyers Negotiate Better Prices?

To achieve cost-efficiency in sourcing alternators, consider the following tips:

-

Negotiation: Always engage in negotiations. Suppliers may have room to adjust pricing based on your volume or long-term partnership potential. Establishing a rapport can also lead to better terms.

-

Focus on Total Cost of Ownership: Rather than solely looking at upfront costs, evaluate the total cost of ownership, which includes maintenance, durability, and performance. Investing in higher-quality alternators may yield savings over time.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, be aware of potential tariffs, import duties, and currency fluctuations that could affect total costs.

-

Local Suppliers: Consider sourcing from local suppliers to reduce logistics costs and lead times. This can also improve communication and support.

-

Research Market Trends: Stay informed about market trends and pricing fluctuations. Understanding the broader economic context can empower you during negotiations.

Disclaimer for Indicative Prices

Pricing for car alternator sourcing can vary significantly based on the factors discussed. The figures provided in this analysis are indicative and should be verified with suppliers for accurate quotes tailored to specific needs and conditions.

Alternatives Analysis: Comparing car alternator issues With Other Solutions

Understanding Alternatives to Car Alternator Issues

In the automotive industry, addressing car alternator issues is crucial for maintaining vehicle reliability. However, there are alternative technologies and methods that can achieve similar outcomes in terms of electrical power generation and management. This comparison focuses on evaluating traditional car alternator problems against alternative solutions, including battery management systems and hybrid vehicle technologies.

Comparison Table of Car Alternator Issues and Alternatives

| Comparison Aspect | Car Alternator Issues | Battery Management Systems | Hybrid Vehicle Technologies |

|---|---|---|---|

| Performance | Essential for vehicle power; can lead to failures if not addressed | Enhances battery lifespan and efficiency; manages energy use | Provides dual power sources, improving fuel efficiency and reducing emissions |

| Cost | Replacement costs range from $250 to $800; repair may be cheaper | Initial investment can be high; long-term savings on battery costs | Higher upfront costs; potential savings on fuel and tax incentives |

| Ease of Implementation | Generally straightforward to replace or repair | Requires integration with existing systems; may need professional installation | Complex integration with existing powertrains; requires specialized knowledge |

| Maintenance | Regular checks needed; prone to wear and tear | Minimal maintenance; periodic software updates may be necessary | Regular maintenance of both engine and electric systems required |

| Best Use Case | Conventional vehicles relying on internal combustion engines | Electric or hybrid vehicles seeking improved battery performance | Environmentally conscious consumers or fleets aiming for fuel efficiency |

In-Depth Analysis of Alternatives

Battery Management Systems (BMS)

Battery management systems are designed to optimize the performance and longevity of batteries in electric and hybrid vehicles. A BMS monitors battery health, regulates charging and discharging cycles, and prevents overcharging. The primary advantage of this system is its ability to extend battery life, resulting in lower replacement costs over time. However, the initial investment can be significant, and integrating a BMS into existing systems may require professional expertise. BMSs are best suited for electric and hybrid vehicles, where battery efficiency is paramount.

Hybrid Vehicle Technologies

Hybrid vehicles combine traditional internal combustion engines with electric propulsion, offering a sustainable alternative to conventional vehicles. These technologies not only enhance fuel efficiency but also reduce emissions, making them an attractive option for environmentally conscious buyers. Although the upfront costs for hybrid vehicles can be higher due to complex engineering, they can lead to significant savings in fuel costs and may qualify for government incentives. The maintenance of hybrid systems can be more involved, requiring specialized knowledge to ensure both the engine and electric components function optimally.

Illustrative image related to car alternator issues

Conclusion: Making the Right Choice for Your Business

When considering alternatives to traditional car alternator issues, B2B buyers should evaluate their specific needs, budget, and long-term goals. While conventional alternators are essential for standard vehicles, battery management systems and hybrid technologies offer innovative solutions for enhancing energy efficiency and vehicle performance. Buyers should weigh the upfront costs against potential savings and consider the complexity of implementation and maintenance. By aligning their choice with operational requirements and sustainability objectives, businesses can ensure they invest in the most suitable automotive solutions for their fleets.

Essential Technical Properties and Trade Terminology for car alternator issues

What Are the Key Technical Properties of Car Alternators?

Understanding the technical properties of car alternators is crucial for B2B buyers involved in automotive parts sourcing. Here are some of the most critical specifications to consider:

-

Output Voltage

– Definition: This is the voltage the alternator produces, typically between 12 to 14.5 volts for most vehicles.

– B2B Importance: Ensuring the right output voltage is essential for compatibility with a vehicle’s electrical system. An alternator that produces insufficient voltage can lead to battery undercharging, while excessive voltage can damage electronic components. -

Current Rating (Amperage)

– Definition: Measured in amperes (A), this indicates the maximum electrical current the alternator can supply.

– B2B Importance: The current rating must match the vehicle’s requirements to power electrical systems effectively. Inadequate amperage can cause electrical failures, making it vital for suppliers to ensure their products meet the specifications of the vehicles they service. -

Material Grade

– Definition: This refers to the quality of materials used in the alternator’s construction, such as aluminum for the casing and copper for the windings.

– B2B Importance: High-quality materials enhance durability and performance. Buyers should prioritize alternators made from corrosion-resistant materials, especially in regions with harsh climates, to reduce the frequency of replacements and maintenance. -

Temperature Range

– Definition: This specifies the operational temperature limits of the alternator, generally ranging from -40°C to +125°C.

– B2B Importance: Understanding the temperature range is crucial, especially for buyers in regions with extreme weather conditions. An alternator that operates efficiently within a specified range will ensure reliability and longevity. -

Mounting Type

– Definition: This refers to how the alternator is mounted within the engine bay, which can vary by vehicle make and model.

– B2B Importance: Compatibility with vehicle mounts is essential for installation. Providing precise mounting specifications can streamline the procurement process and reduce installation errors.

What Common Trade Terms Should B2B Buyers Know in the Alternator Market?

Familiarity with industry terminology can greatly enhance communication and negotiation between buyers and suppliers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to parts produced by the manufacturer of the original vehicle components.

– Importance: OEM alternators are typically seen as higher quality and reliability, making them a preferred choice for buyers seeking to maintain vehicle performance and resale value. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers negotiate better deals and manage inventory levels. It’s essential for planning procurement strategies, especially in bulk purchasing scenarios. -

RFQ (Request for Quotation)

– Definition: A formal process where buyers request price quotes from suppliers for specific quantities of products.

– Importance: RFQs are vital for obtaining competitive pricing and ensuring that suppliers can meet the technical specifications required for alternators. -

Incoterms (International Commercial Terms)

– Definition: These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, which is crucial for effective supply chain management. -

Warranty Period

– Definition: The duration during which the manufacturer guarantees the alternator’s performance and will replace or repair defects.

– Importance: A strong warranty reflects product confidence and can significantly influence purchasing decisions. Buyers should evaluate warranty terms to mitigate risks associated with alternator failures. -

Aftermarket Parts

– Definition: Parts made by companies other than the original manufacturer, often at a lower cost.

– Importance: Understanding the distinction between OEM and aftermarket parts is crucial for buyers looking to balance cost and quality. Aftermarket options may offer significant savings but can vary in reliability.

By understanding these properties and terms, B2B buyers can make informed decisions when sourcing alternators, ensuring they meet the specific needs of their markets and customers.

Navigating Market Dynamics and Sourcing Trends in the car alternator issues Sector

What Are the Key Market Trends Influencing the Car Alternator Sector?

The car alternator sector is currently experiencing significant shifts driven by technological advancements and changing consumer preferences. Global drivers such as the rise of electric vehicles (EVs) and the increasing demand for energy-efficient automotive components are reshaping market dynamics. As manufacturers pivot towards electric and hybrid models, there is a growing need for alternators that are optimized for these technologies. This transition opens up new opportunities for B2B buyers to source innovative alternator designs that can efficiently handle the unique power requirements of EVs and hybrids.

In terms of sourcing trends, digitalization is gaining momentum. E-commerce platforms are becoming vital channels for B2B transactions, allowing buyers from regions like Africa, South America, the Middle East, and Europe to access a wider range of suppliers and compare prices more effectively. Additionally, the integration of IoT (Internet of Things) technology into automotive components is on the rise, enabling predictive maintenance solutions that can enhance the lifecycle of alternators. This trend not only lowers operational costs but also improves customer satisfaction by reducing downtime.

Illustrative image related to car alternator issues

Another key dynamic involves the increasing focus on supply chain resilience. The recent global disruptions have highlighted the importance of having diversified sourcing strategies. B2B buyers are urged to establish relationships with multiple suppliers across different geographies to mitigate risks associated with reliance on a single source. As a result, buyers are encouraged to conduct thorough due diligence when selecting partners, focusing on quality, reliability, and technological compatibility.

How Is Sustainability Shaping the Sourcing Landscape in the Car Alternator Market?

Sustainability is becoming a cornerstone of B2B sourcing strategies in the car alternator sector. The environmental impact of automotive manufacturing is under scrutiny, prompting buyers to prioritize suppliers who adhere to sustainable practices. This includes the use of recycled materials in alternator production, which not only reduces waste but also minimizes the carbon footprint associated with raw material extraction and processing.

Ethical supply chains are equally important. B2B buyers are increasingly looking for suppliers who demonstrate corporate social responsibility (CSR) by ensuring fair labor practices and transparent sourcing. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria for supplier evaluation. These certifications provide assurance that suppliers are committed to minimizing their environmental impact and maintaining ethical labor standards.

Moreover, the push for ‘green’ certifications is influencing product development. Suppliers who can demonstrate compliance with environmental regulations and offer eco-friendly alternators are gaining a competitive edge in the market. Buyers should seek out partners who utilize sustainable practices in their manufacturing processes, such as energy-efficient production techniques and low-impact packaging. This not only aligns with global sustainability goals but also resonates with the values of environmentally conscious consumers.

What Is the Historical Context of Car Alternators in B2B Sourcing?

The evolution of car alternators has been marked by technological advancements and changing automotive needs. Initially, vehicles relied on generators, which were less efficient and often unable to meet the growing electrical demands of modern cars. The introduction of the alternator in the 1960s revolutionized vehicle electrical systems, providing a more reliable source of power and enabling the use of advanced electronic features.

Over the years, alternators have evolved from basic designs to sophisticated units equipped with smart technologies. Today, they are integral to the overall performance of vehicles, especially as the automotive industry shifts towards electrification. This historical context is crucial for B2B buyers as it underscores the importance of sourcing high-quality, technologically advanced alternators that align with current market demands and future trends.

In conclusion, navigating the car alternator sector requires an understanding of market dynamics, sustainability imperatives, and historical context. By leveraging this knowledge, B2B buyers can make informed sourcing decisions that enhance their competitive advantage in a rapidly changing automotive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of car alternator issues

-

How do I solve common alternator problems in vehicles?

To address common alternator issues, start by diagnosing symptoms such as dimming headlights, warning lights on the dashboard, or unusual noises. Inspect the alternator belt for wear or looseness and check electrical connections for corrosion. If the alternator is faulty, it may need repairs or replacement. In some cases, cleaning or replacing worn components like bearings can restore functionality. Always consult a qualified mechanic for a thorough inspection to ensure accurate diagnosis and effective solutions. -

What is the best way to identify a reliable alternator supplier?

When sourcing alternators, prioritize suppliers with a strong reputation and proven track record in the automotive industry. Look for certifications and compliance with international quality standards. Request references from other clients and evaluate their experience with the supplier. Additionally, assess their product range, pricing, and ability to meet your specific requirements. Conducting factory audits and visiting trade shows can also provide insight into their operations and product quality. -

What customization options should I consider for alternators?

Customization options for alternators can include variations in voltage output, size, and connector types based on vehicle specifications. Discuss your specific needs with suppliers to explore options for modified designs that suit your clientele. Additionally, inquire about branding opportunities, such as private labeling, to enhance your market presence. Ensure that any customizations meet relevant industry standards to maintain quality and reliability. -

What are typical minimum order quantities (MOQs) for alternators?

Minimum order quantities for alternators can vary significantly by supplier and region. Typically, MOQs may range from 50 to several hundred units, depending on the supplier’s production capabilities and your specific requirements. When negotiating, consider your storage capacity and market demand to avoid excess inventory. Discuss potential flexibility with the supplier, especially for initial orders, to establish a mutually beneficial relationship. -

What payment terms are commonly accepted for international alternator purchases?

Payment terms for international purchases often include options such as letters of credit, wire transfers, or PayPal for smaller transactions. Standard practices may require a 30% deposit upon order confirmation, with the remaining balance due before shipment. Discuss and negotiate terms that provide security for both parties while considering factors like currency fluctuations and transaction fees. Ensure clear documentation to avoid misunderstandings during the payment process. -

How can I ensure quality assurance (QA) for alternators sourced internationally?

To ensure quality assurance for sourced alternators, implement a robust QA process that includes pre-shipment inspections and compliance with international quality standards such as ISO or TS16949. Establish clear specifications and performance criteria with your supplier. Consider third-party inspection services to verify product quality before shipment. Regular communication with the supplier during production can also help address potential issues early in the process. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider logistics aspects such as shipping methods, customs regulations, and lead times. Choose between air freight for speed or sea freight for cost-effectiveness based on your urgency and budget. Familiarize yourself with import tariffs and taxes applicable in your country to avoid unexpected costs. Collaborating with a reputable freight forwarder can streamline the logistics process and ensure timely delivery. -

How do I handle warranty and returns for faulty alternators?

Establish clear warranty policies with your suppliers that outline coverage periods and conditions for faulty alternators. Communicate these terms to your customers to manage expectations. In the case of returns, ensure that you have a streamlined process in place for handling defective units, including documentation requirements and shipping instructions. Timely resolution of warranty claims can help maintain customer satisfaction and strengthen your business reputation.

Top 3 Car Alternator Issues Manufacturers & Suppliers List

1. Alternator Replacement – Cost in the UK

Domain: rac.co.uk

Registered: 1996 (29 years)

Introduction: Alternator replacement cost in the UK ranges from £250 to £800, with an average price for parts and labour around £535.05. Average replacement costs by manufacturer include: Audi £628.59, BMW £603.37, Citroen £629.99, Ford £494.90, Mercedes £614.57, MINI £549.36, Nissan £482.06, Peugeot £663.06, Renault £587.78, Toyota £477.93, Vauxhall £477.93, Volkswagen £507.07, Volvo £539.62.

2. MGEXP – Bad Alternator Symptoms

Domain: mgexp.com

Registered: 2011 (14 years)

Introduction: Symptoms of a bad alternator include: 1. Pulsating headlights and dash lights, especially noticeable at night. 2. Whining or strange noises from the alternator. 3. An alternator warning light that stays on. 4. Voltage drops below 13 volts at idle with all electrical components on. Common issues may include a bad regulator or burned out diodes. Recommended solutions include testing with a voltmeter…

3. Facebook – Battery Warning Light Insights

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Battery Warning Light Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for car alternator issues

In navigating the complexities of car alternator issues, strategic sourcing emerges as a pivotal approach for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the critical functions of alternators—charging batteries, powering electrical systems, and maintaining voltage—can help businesses make informed procurement decisions.

Key takeaways include recognizing the early signs of alternator failure, such as dimming headlights and dashboard warning lights, and understanding the potential for both repair and replacement. By prioritizing quality sourcing from reputable suppliers, buyers can ensure the reliability of their automotive components, minimize downtime, and reduce overall maintenance costs.

As we look to the future, the demand for high-quality alternators is expected to grow, driven by increasing vehicle usage and the expansion of automotive markets. B2B buyers are encouraged to engage with suppliers who demonstrate a commitment to quality and innovation. By forging strong partnerships and adopting proactive maintenance strategies, businesses can enhance their operational efficiency and ultimately drive profitability. Now is the time to reassess your sourcing strategies and invest in quality alternators to secure your competitive edge in the automotive industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to car alternator issues