Introduction: Navigating the Global Market for car alternator function

In the complex landscape of automotive components, understanding the function of car alternators is crucial for international B2B buyers looking to optimize their supply chains. With the rising demand for reliable automotive electrical systems, sourcing high-quality alternators that meet specific market needs can be a daunting challenge. This guide offers a comprehensive overview of car alternator functions, exploring various types, applications across different vehicle categories, and essential factors for supplier vetting.

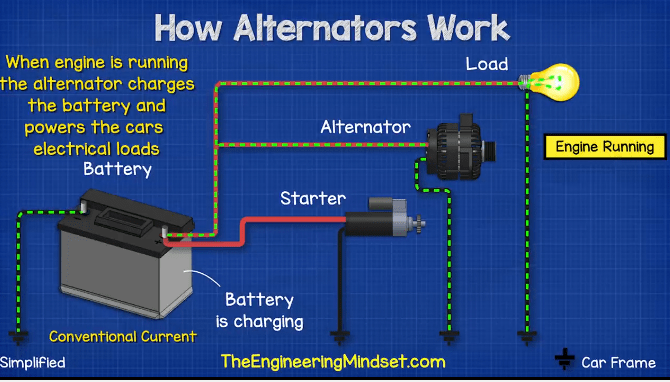

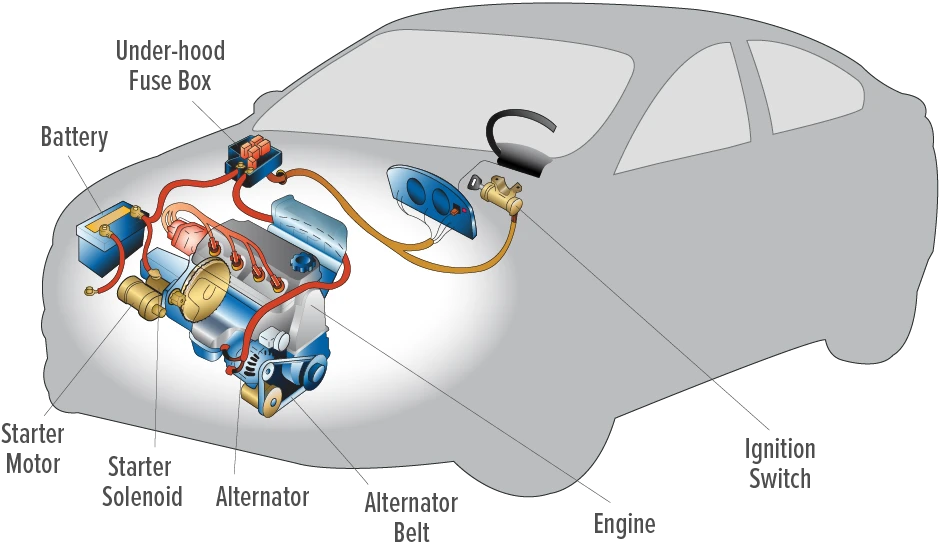

From the vital role alternators play in converting mechanical energy into electrical energy to their integration within the vehicle’s charging system, this resource equips buyers with the insights necessary to make informed purchasing decisions. Additionally, it addresses cost considerations, durability, and the latest advancements in alternator technology, ensuring that businesses can source products that align with both performance and budgetary requirements.

Targeting B2B buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Saudi Arabia—this guide aims to empower stakeholders in the automotive sector. By providing actionable insights and practical recommendations, it ensures that decision-makers can navigate the global market effectively, enhancing their procurement strategies while fostering partnerships that drive business growth.

Table Of Contents

- Top 3 Car Alternator Function Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car alternator function

- Understanding car alternator function Types and Variations

- Key Industrial Applications of car alternator function

- 3 Common User Pain Points for ‘car alternator function’ & Their Solutions

- Strategic Material Selection Guide for car alternator function

- In-depth Look: Manufacturing Processes and Quality Assurance for car alternator function

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator function’

- Comprehensive Cost and Pricing Analysis for car alternator function Sourcing

- Alternatives Analysis: Comparing car alternator function With Other Solutions

- Essential Technical Properties and Trade Terminology for car alternator function

- Navigating Market Dynamics and Sourcing Trends in the car alternator function Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car alternator function

- Strategic Sourcing Conclusion and Outlook for car alternator function

- Important Disclaimer & Terms of Use

Understanding car alternator function Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Alternator | Uses mechanical energy conversion; includes a voltage regulator | Automotive manufacturing, repair services | Pros: Reliable, widely available. Cons: Less efficient at low speeds. |

| High-Output Alternator | Designed for high-demand electrical systems; provides more amperage | Performance vehicles, off-road applications | Pros: Supports advanced electrical accessories. Cons: Higher cost, may require modifications. |

| Smart Alternator | Integrates with vehicle systems for optimal energy management | Electric vehicle production, hybrid systems | Pros: Increases fuel efficiency, reduces emissions. Cons: More complex, potentially higher repair costs. |

| Mini Alternator | Smaller size, lighter weight; ideal for compact vehicles | Small vehicle manufacturing, urban mobility | Pros: Space-saving, lightweight. Cons: Limited power output, not suitable for larger vehicles. |

| Dual-Voltage Alternator | Capable of producing both 12V and 24V; versatile usage | Commercial vehicles, fleet management | Pros: Flexibility for varied applications. Cons: More complex installation, may require additional components. |

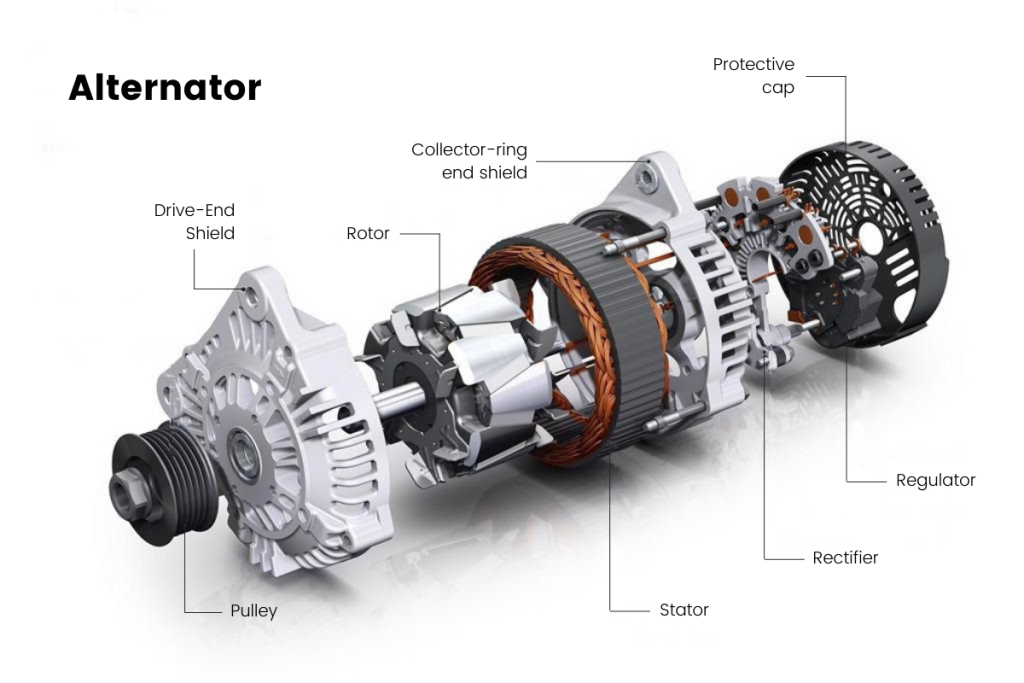

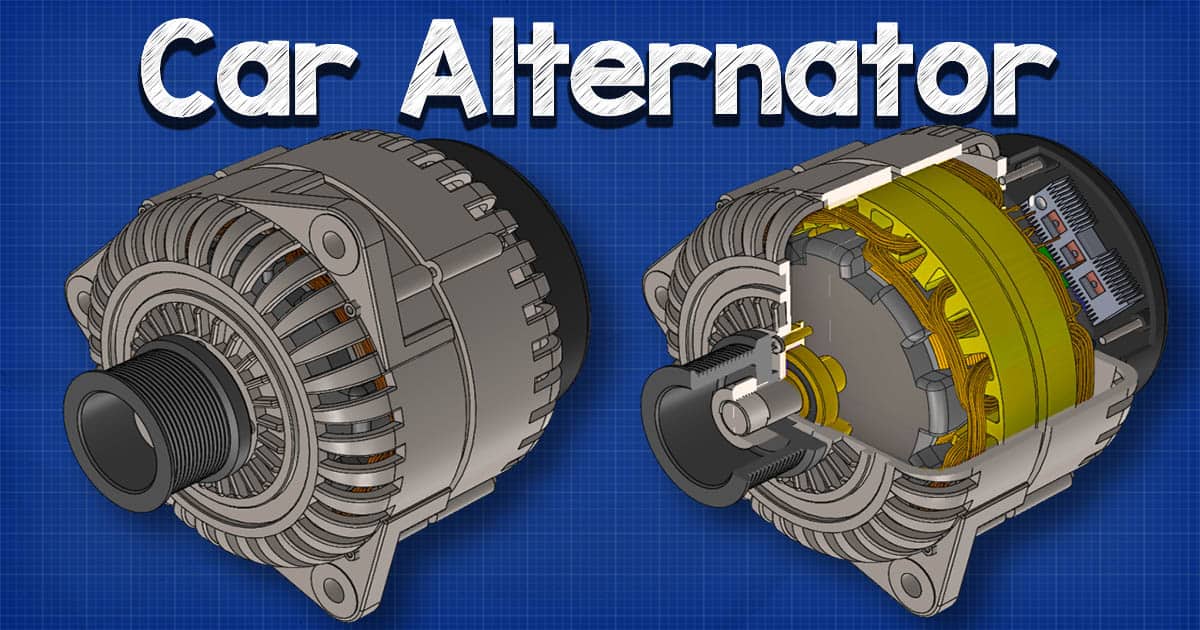

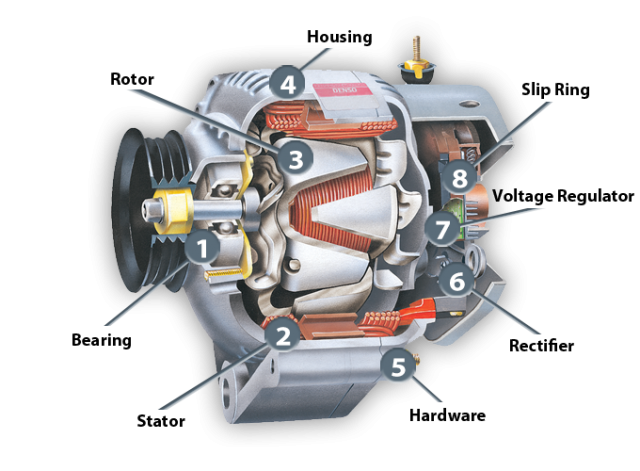

What Are the Key Characteristics of Conventional Alternators?

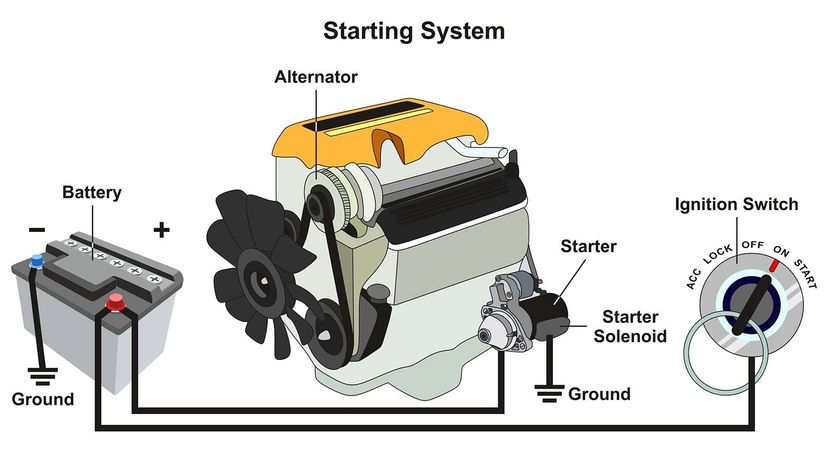

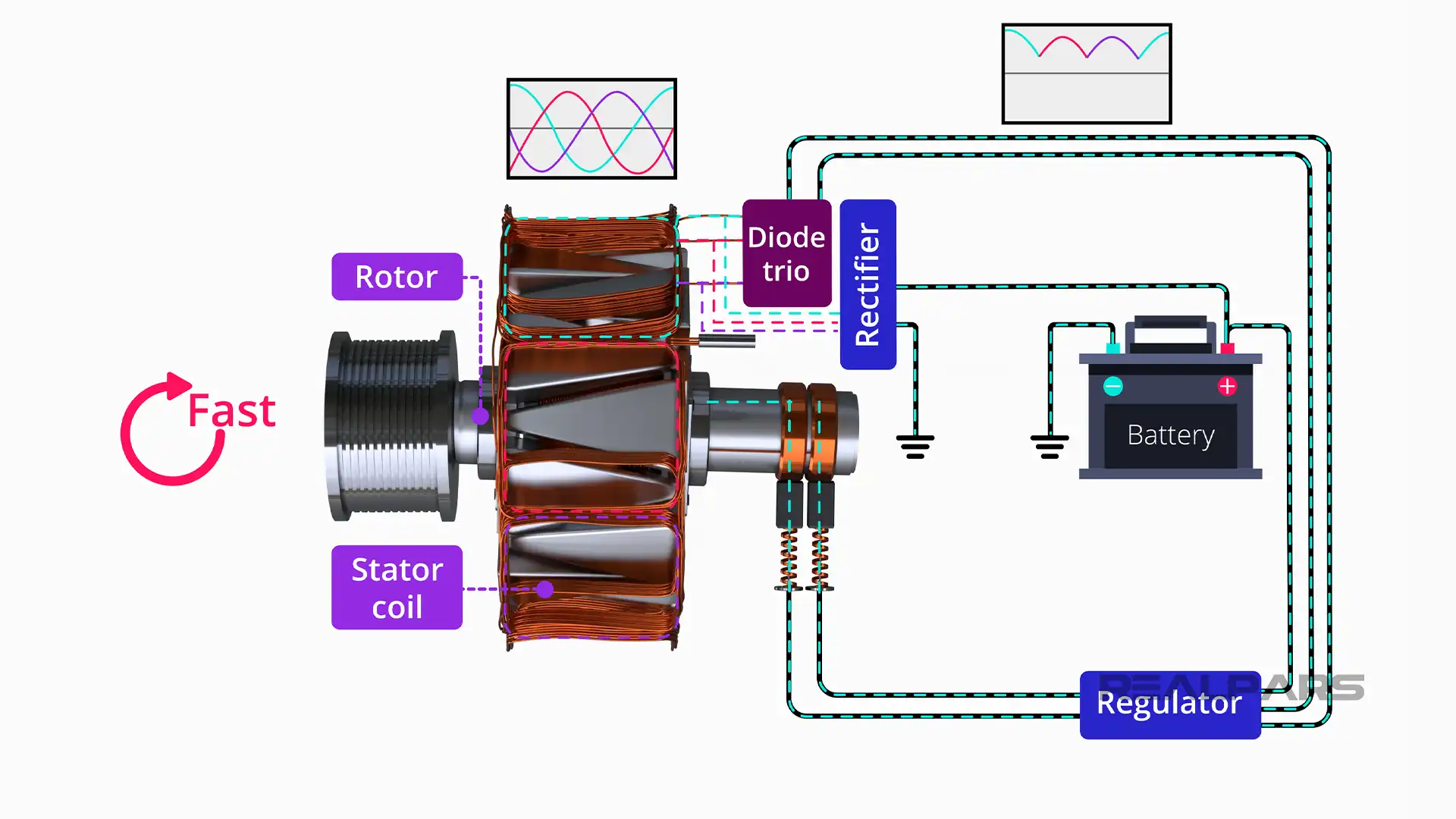

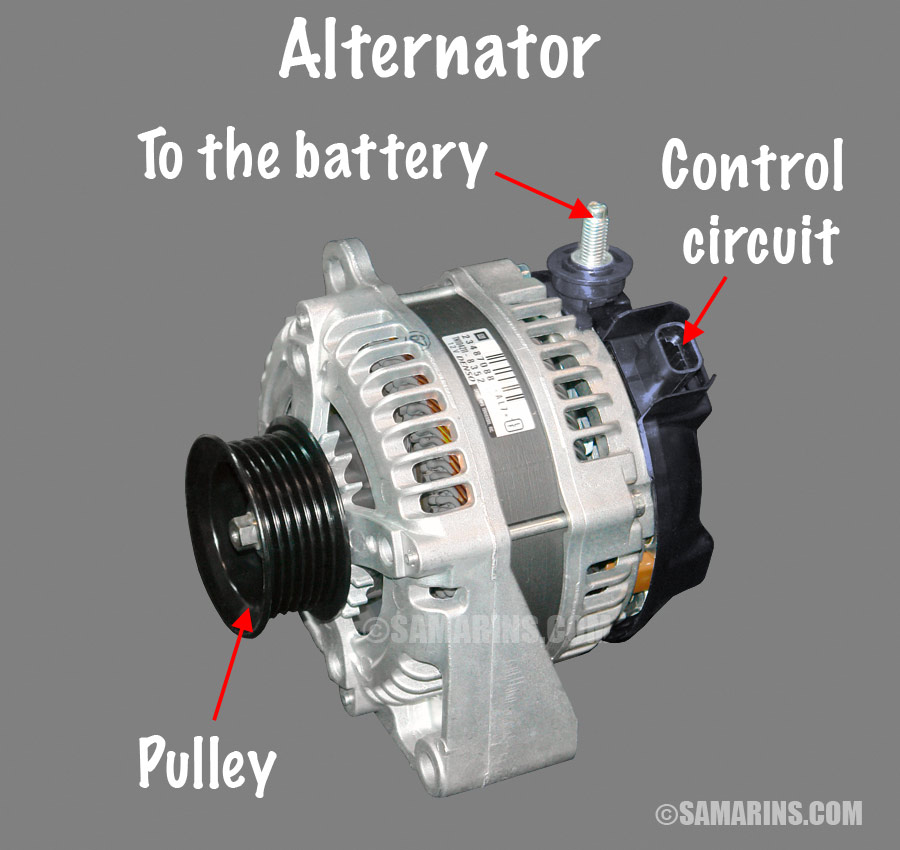

Conventional alternators are the most widely used type in vehicles, converting mechanical energy from the engine into electrical energy. They feature a pulley system, rotor, and stator, along with a voltage regulator to maintain consistent output. Suitable for standard automotive applications, these alternators are reliable and easily sourced. B2B buyers should consider their compatibility with existing vehicle models and their ability to meet standard electrical demands.

How Do High-Output Alternators Enhance Performance?

High-output alternators are engineered for vehicles with increased electrical requirements, such as those equipped with powerful audio systems or additional lighting. These alternators generate a higher amperage, making them ideal for performance and off-road applications. B2B buyers in sectors like automotive tuning or off-road vehicle manufacturing should evaluate the specific electrical needs of their vehicles, as well as potential installation challenges and costs associated with high-output units.

What Advantages Do Smart Alternators Offer?

Smart alternators represent the latest advancement in automotive electrical systems, capable of communicating with the vehicle’s onboard computer for optimized energy management. This technology enhances fuel efficiency and reduces emissions, making it especially suitable for electric and hybrid vehicles. B2B buyers involved in the production of eco-friendly vehicles should prioritize smart alternators, considering their integration complexity and potential for long-term cost savings through efficiency gains.

Why Choose Mini Alternators for Compact Vehicles?

Mini alternators provide a lightweight and space-efficient solution for compact vehicles. Their smaller size does not compromise essential functionality, but they do have limitations in power output. Ideal for urban mobility solutions and small vehicle manufacturing, B2B buyers should assess the specific power needs of their vehicles to ensure compatibility with mini alternators, balancing the benefits of reduced weight against the limitations of power generation.

What Are the Benefits of Dual-Voltage Alternators?

Dual-voltage alternators are designed to produce both 12V and 24V outputs, making them versatile for a range of applications, particularly in commercial vehicles and fleet management. This flexibility allows for the use of varied electrical systems without the need for multiple alternators. B2B buyers should consider the installation complexities and the potential need for additional components when opting for dual-voltage systems, weighing the benefits of versatility against the associated costs.

Key Industrial Applications of car alternator function

| Industry/Sector | Specific Application of car alternator function | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicles and automotive components | Ensures reliable electrical supply for vehicle operation | Quality standards, compatibility with vehicle models, supply chain reliability |

| Transportation & Logistics | Fleet management and maintenance of commercial vehicles | Enhances operational efficiency and reduces downtime | Durability, maintenance support, availability of spare parts |

| Renewable Energy | Integration in hybrid and electric vehicles | Supports energy management and battery charging in sustainable transport | Compliance with environmental regulations, efficiency ratings |

| Agriculture | Powering agricultural vehicles and machinery | Ensures reliable operation of equipment in remote locations | Robustness in harsh conditions, service network availability |

| Construction | Use in heavy machinery and construction vehicles | Provides consistent power for tools and machinery | Performance in extreme conditions, sourcing of OEM parts |

How is the Car Alternator Function Applied in Automotive Manufacturing?

In the automotive manufacturing sector, the car alternator function is pivotal in ensuring that vehicles operate efficiently. It converts mechanical energy from the engine into electrical energy, powering essential systems such as lighting, infotainment, and safety features. This reliability is critical for manufacturers who must adhere to stringent quality standards and ensure that their vehicles meet consumer expectations. Buyers must consider compatibility with various vehicle models, as well as the quality of the alternator to minimize warranty claims and enhance customer satisfaction.

What Role Does the Car Alternator Play in Transportation & Logistics?

In the transportation and logistics industry, car alternators are vital for fleet management and maintenance of commercial vehicles. They ensure that vehicles have a consistent power supply for navigation systems, communication devices, and other electrical accessories. The reliability of the alternator directly impacts operational efficiency, reducing downtime and maintenance costs. B2B buyers should prioritize sourcing durable alternators that can withstand the rigors of long-haul transportation, as well as ensure the availability of spare parts for quick replacements.

How is the Car Alternator Function Leveraged in Renewable Energy?

The renewable energy sector increasingly integrates car alternators in hybrid and electric vehicles, where they play a crucial role in energy management. By converting mechanical energy into electrical energy, alternators facilitate battery charging and support the vehicle’s overall energy efficiency. This application is particularly relevant for manufacturers focused on sustainability and reducing carbon footprints. Buyers must ensure that the alternators comply with environmental regulations and possess high efficiency ratings to meet performance benchmarks in this competitive market.

In What Ways Does the Car Alternator Function Support Agriculture?

In agriculture, the car alternator function is essential for powering vehicles and machinery used in farming operations. These vehicles often operate in remote locations where reliable electrical supply is paramount for equipment such as tractors and harvesters. The alternator provides a consistent power source, enabling farmers to maximize productivity. Buyers in this sector should look for alternators that demonstrate robustness in harsh conditions and have a reliable service network to support maintenance needs.

How is the Car Alternator Function Utilized in Construction?

In the construction industry, car alternators are integral to the operation of heavy machinery and construction vehicles. They provide the necessary electrical power for tools, machinery, and safety systems, ensuring that projects run smoothly and efficiently. Reliability is key in construction, where delays can lead to significant cost overruns. Buyers should consider the performance of alternators in extreme conditions, as well as the availability of OEM parts for maintenance and repairs, to ensure uninterrupted operations on job sites.

3 Common User Pain Points for ‘car alternator function’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Alternators for Diverse Vehicle Models

The Problem: B2B buyers often struggle to find reliable suppliers who can provide high-quality alternators compatible with a wide range of vehicle models. This challenge is particularly pronounced for businesses operating in regions with varied automotive makes and models, such as in Africa or South America, where local markets may demand both new and remanufactured parts. Buyers may also face difficulties in verifying the authenticity of the products, leading to concerns about performance and warranty issues.

The Solution: To effectively address this sourcing challenge, businesses should establish partnerships with reputable manufacturers or distributors known for their quality assurance practices. Conducting thorough market research to identify suppliers with a proven track record in alternator production is crucial. Buyers should also consider sourcing from suppliers that offer comprehensive product catalogs, including specifications, compatibility lists, and detailed warranties. Engaging with industry trade shows and networking events can help in building relationships with trusted suppliers. Additionally, implementing a quality control process that includes testing incoming alternators can further mitigate risks associated with product reliability.

Scenario 2: Underperformance of Alternators Leading to Frequent Vehicle Downtime

The Problem: Frequent vehicle downtime due to alternator failure can significantly impact a business’s operational efficiency, especially for companies reliant on transportation for logistics or service delivery. Alternators that underperform may not adequately charge the battery, leading to starting issues, dim lights, and eventually complete vehicle failure. This problem can be exacerbated in harsh environments where temperature fluctuations and dust can affect alternator performance.

The Solution: To combat this issue, businesses should prioritize the selection of high-performance alternators designed for specific environmental conditions. It is essential to consult with technical experts or automotive engineers who can recommend alternators with suitable specifications, such as higher amperage ratings and enhanced cooling features. Additionally, implementing a preventive maintenance schedule that includes regular inspections of the alternator and associated components—like the battery and voltage regulator—can help identify potential issues before they lead to failure. Investing in training for mechanics to recognize early signs of alternator malfunction can also reduce vehicle downtime.

Scenario 3: Complexity in Understanding Alternator Specifications for Custom Applications

The Problem: B2B buyers often find themselves overwhelmed by the technical specifications of alternators, especially when dealing with custom or high-performance vehicle applications. Misunderstanding these specifications can lead to purchasing alternators that do not meet the specific power requirements of the vehicle or its accessories, resulting in inadequate performance or premature failure.

The Solution: To navigate the complexities of alternator specifications, businesses should invest in training for their purchasing teams, focusing on key aspects such as amperage output, voltage regulation, and compatibility with various electrical systems. Utilizing resources such as detailed product datasheets and manufacturer guidelines can also provide clarity. Furthermore, collaborating closely with engineers during the selection process can ensure that the chosen alternator meets the unique demands of custom applications. Creating a standardized checklist based on common specifications needed for different vehicle types can streamline the decision-making process and enhance overall procurement efficiency.

Strategic Material Selection Guide for car alternator function

What Materials Are Commonly Used in Car Alternators and Their Key Properties?

When selecting materials for car alternators, it is crucial to consider their properties, performance, and suitability for specific applications. The choice of materials can significantly impact the durability, efficiency, and overall functionality of the alternator. Below, we analyze four common materials used in alternators: aluminum, copper, steel, and plastic.

How Does Aluminum Contribute to Car Alternator Functionality?

Aluminum is frequently used in the casing and some internal components of car alternators due to its lightweight and excellent corrosion resistance. With a temperature rating of up to 150°C, aluminum can withstand the heat generated during alternator operation.

Pros: Aluminum is lightweight, which contributes to overall vehicle efficiency. It also offers good thermal conductivity, aiding in heat dissipation, and is relatively cost-effective.

Cons: While aluminum is resistant to corrosion, it can be less durable compared to other metals, particularly under high-stress conditions. It may also require additional coatings for enhanced corrosion resistance.

Impact on Application: Aluminum’s compatibility with various media makes it suitable for alternators operating in diverse environments, including humid and coastal areas.

Illustrative image related to car alternator function

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards regarding aluminum quality, such as ASTM or ISO certifications, to guarantee performance and safety.

What Role Does Copper Play in Alternator Efficiency?

Copper is often used for windings and electrical connections in alternators due to its excellent electrical conductivity. It typically operates effectively at temperatures up to 200°C, making it ideal for high-performance applications.

Pros: Copper’s superior conductivity ensures efficient energy transfer, reducing energy losses. It is also highly durable and resistant to corrosion, which extends the lifespan of the alternator.

Cons: The primary drawback of copper is its relatively high cost compared to other metals. Additionally, its weight can contribute to an increase in the overall weight of the alternator.

Impact on Application: The high conductivity of copper makes it suitable for applications requiring efficient power generation, particularly in regions with high electrical demands.

Considerations for International Buyers: Compliance with international standards such as JIS and ASTM is essential, particularly for buyers in Europe, to ensure that the copper used meets specific quality and performance criteria.

How Does Steel Enhance the Durability of Alternators?

Steel is commonly used for the structural components of alternators, such as the housing and rotor. It offers excellent strength and durability, with a temperature tolerance that can exceed 300°C.

Illustrative image related to car alternator function

Pros: Steel’s high tensile strength ensures that alternators can withstand mechanical stress and vibrations, making them suitable for rugged environments. It is also relatively cost-effective.

Cons: Steel is heavier than aluminum and can be prone to corrosion if not properly treated. This may necessitate additional coatings or treatments to enhance its longevity.

Impact on Application: Steel’s robustness makes it ideal for heavy-duty applications, especially in regions with harsh climates or rough terrain, such as parts of Africa and South America.

Considerations for International Buyers: Buyers should consider local regulations regarding steel quality and corrosion resistance, ensuring that products meet standards like DIN or ASTM.

Illustrative image related to car alternator function

What Advantages Does Plastic Offer for Alternator Components?

Plastic is increasingly used in non-structural components of alternators, such as housings and insulators, due to its lightweight and insulating properties. It can typically handle temperatures up to 120°C.

Pros: Plastic is lightweight and cost-effective, which can help reduce the overall weight of the alternator. It also provides excellent electrical insulation, enhancing safety.

Cons: Plastic may not be as durable as metals and can degrade under high temperatures or UV exposure. It is also less suitable for load-bearing applications.

Illustrative image related to car alternator function

Impact on Application: The use of plastic is beneficial in environments where weight reduction is critical, but it may not be suitable for high-stress applications.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with safety and environmental regulations, particularly in Europe, where standards for material safety can be stringent.

Summary of Material Selection for Car Alternators

| Material | Typical Use Case for car alternator function | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Casing and internal components | Lightweight and corrosion-resistant | Less durable under stress | Medium |

| Copper | Windings and electrical connections | Superior electrical conductivity | Higher cost and weight | High |

| Steel | Structural components like housing | High strength and durability | Heavier and prone to corrosion | Medium |

| Plastic | Non-structural components like housings | Lightweight and cost-effective | Less durable and temperature-sensitive | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions that optimize the performance and longevity of car alternators in various global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for car alternator function

What Are the Key Stages in the Manufacturing Process of Car Alternators?

The manufacturing of car alternators involves a series of well-defined stages, each critical to ensuring the final product meets performance and durability standards. Understanding these stages helps B2B buyers evaluate potential suppliers effectively.

1. Material Preparation: What Materials Are Essential for Car Alternators?

The manufacturing process begins with the selection and preparation of raw materials. Key materials typically include:

Illustrative image related to car alternator function

- Copper Wire: Used for winding the stator and rotor coils, copper is essential for its excellent conductivity.

- Silicon Steel: This material is used for the stator and rotor cores, providing the necessary magnetic properties.

- Aluminum or Plastic Housings: These materials are selected for their lightweight and corrosion-resistant properties, which are crucial for automotive applications.

Before production, these materials undergo quality checks to ensure they meet specifications. For instance, copper wire must have a specific diameter and conductivity, while silicon steel should have the right magnetic permeability.

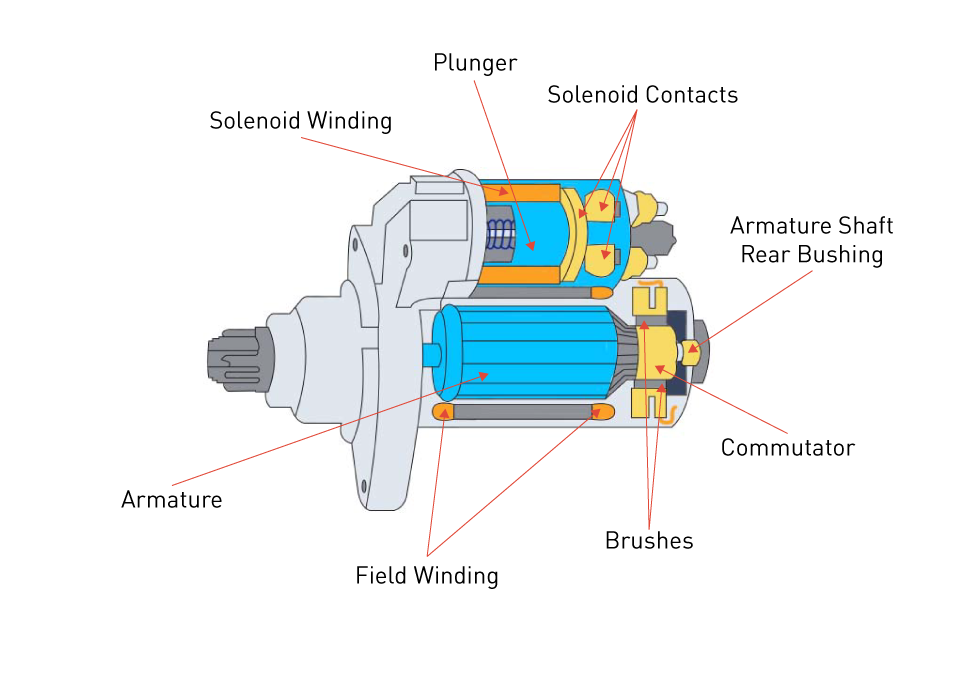

2. Forming: How Are Components Shaped for Alternators?

The forming process involves shaping the raw materials into the required components through techniques such as:

- Stamping: Used for creating the stator and rotor cores, stamping involves pressing metal sheets into desired shapes using high-pressure machines.

- Winding: Copper wire is wound around the stator and rotor to create coils. Precision in this stage is vital to ensure optimal electrical performance.

- Casting: Aluminum or plastic housings are often cast to create the outer shell of the alternator, providing protection and support for internal components.

Each of these forming techniques requires specialized machinery and skilled operators to achieve the desired tolerances and finishes.

3. Assembly: What Steps Are Involved in Assembling Car Alternators?

The assembly stage is where all the formed components come together. This stage typically includes:

- Coil Installation: The wound stator and rotor are installed into the housing, ensuring proper alignment to maximize efficiency.

- Electrical Connections: This includes connecting the rectifier and voltage regulator, which are crucial for converting and controlling the electrical output.

- Final Assembly: The alternator is sealed, with all components securely fastened to withstand vibrations and temperature changes during operation.

Quality control measures during assembly are critical to prevent errors that could lead to product failure.

4. Finishing: How Is the Final Product Prepared for Distribution?

Once assembled, alternators undergo finishing processes, including:

- Surface Treatment: Components may be treated to improve corrosion resistance, such as anodizing aluminum housings or applying protective coatings.

- Testing: Each alternator is subjected to rigorous performance tests, including output voltage, current load tests, and thermal cycling tests to ensure reliability and efficiency.

The finishing stage not only enhances the product’s longevity but also its marketability.

What Quality Assurance Standards Are Applicable to Car Alternators?

Quality assurance is paramount in the manufacturing of car alternators, particularly for B2B buyers. Various international standards and industry-specific certifications ensure that products meet safety and performance benchmarks.

1. What Are the Key International Standards for Quality Assurance?

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality. Suppliers certified under ISO 9001 demonstrate a commitment to continual improvement and customer satisfaction.

- CE Marking: For products marketed in Europe, CE marking indicates compliance with safety, health, and environmental protection standards.

B2B buyers should prioritize suppliers with these certifications to mitigate risks associated with product quality.

2. What Are the Common Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify defects in real time.

- Final Quality Control (FQC): This is the last line of defense, where finished products are tested for functionality and compliance with specifications before shipping.

Implementing these checkpoints ensures that any deviations from quality standards are caught early, reducing waste and improving overall efficiency.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

For international B2B buyers, particularly from diverse markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality assurance processes is crucial.

1. What Methods Can Be Used for Supplier Verification?

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This includes reviewing their certifications, processes, and past performance.

- Quality Reports: Requesting detailed quality reports, including metrics on defect rates and testing results, can help assess a supplier’s reliability.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s operations and adherence to quality standards.

2. What Nuances Should Buyers Consider for International Transactions?

When sourcing from international suppliers, B2B buyers should be aware of:

- Regulatory Compliance: Ensure that products meet local regulations and standards in the buyer’s country, which may differ from those in the supplier’s country.

- Cultural Differences: Understanding cultural nuances can facilitate better communication and negotiation, leading to more effective partnerships.

- Logistics and Supply Chain Considerations: Assessing the supplier’s ability to deliver on time and manage logistics efficiently is vital to avoid disruptions.

By focusing on these aspects, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who prioritize quality in their manufacturing processes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator function’

Introduction

This guide serves as a practical checklist for B2B buyers aiming to procure car alternators. Understanding the function and specifications of alternators is crucial for making informed purchasing decisions. This checklist will help you navigate through the essential steps to ensure that you select the right alternators for your automotive needs, optimizing performance and reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing car alternators. Consider factors such as voltage output, amperage, and compatibility with various vehicle models. Knowing these details will help you communicate effectively with suppliers and ensure that the products meet your operational requirements.

- Voltage Requirements: Determine the necessary voltage levels that align with your vehicle’s electrical system.

- Amperage Needs: Assess how much current is required for the electrical components in your vehicles.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and technological advancements in alternator designs. New technologies may offer improved efficiency, durability, or lightweight materials that could benefit your fleet. Understanding market dynamics will help you make competitive purchasing decisions.

- Eco-friendly Options: Look for suppliers offering sustainable or more efficient alternators to align with global environmental standards.

- Smart Technologies: Consider alternators equipped with intelligent voltage regulators that optimize performance based on real-time needs.

Step 3: Evaluate Potential Suppliers

Before making a purchase, it is essential to vet potential suppliers thoroughly. Request company profiles, product catalogs, and references from other businesses in your industry. Evaluating a supplier’s reliability and reputation can prevent future issues.

- Supplier Certifications: Check for industry-standard certifications that indicate compliance with quality and safety standards.

- Client Testimonials: Seek feedback from other buyers to gauge the supplier’s track record and service quality.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the alternators for testing. This allows you to assess the quality and performance of the products in real-world conditions. Testing samples can prevent costly mistakes and ensure that the alternators meet your specifications.

Illustrative image related to car alternator function

- Performance Testing: Verify that the samples function properly under various load conditions.

- Durability Assessment: Evaluate the materials used to ensure they meet your longevity expectations.

Step 5: Understand Warranty and Support Terms

Review the warranty and support terms offered by the supplier. A robust warranty can provide peace of mind and protect your investment in case of defects or performance issues. Additionally, understanding the support services available can help you resolve any problems quickly.

- Warranty Duration: Look for warranties that cover a reasonable period, typically 1-2 years.

- Technical Support: Ensure that the supplier provides adequate technical support and resources for installation and troubleshooting.

Step 6: Negotiate Pricing and Payment Terms

Once you have selected a supplier, engage in negotiations regarding pricing and payment terms. Establishing favorable terms can enhance your budget management and overall cost-effectiveness. Be transparent about your purchasing volume, as this may influence your negotiation leverage.

- Bulk Purchase Discounts: Inquire about discounts for larger orders to maximize cost savings.

- Flexible Payment Options: Discuss payment terms that align with your cash flow requirements.

Step 7: Finalize Your Order and Logistics

After completing the previous steps, it’s time to finalize your order. Confirm all specifications, pricing, and delivery timelines. Effective logistics planning is essential to ensure timely receipt and distribution of the alternators to meet your operational needs.

Illustrative image related to car alternator function

- Delivery Schedule: Confirm the expected delivery date to ensure alignment with your inventory needs.

- Shipping Costs: Factor in shipping costs to your overall budget to avoid unexpected expenses.

By following these steps, B2B buyers can efficiently source car alternators that meet their technical and operational requirements, ensuring reliability and performance in their vehicle fleets.

Comprehensive Cost and Pricing Analysis for car alternator function Sourcing

What Are the Key Cost Components in Sourcing Car Alternators?

Understanding the cost structure involved in sourcing car alternators is crucial for international B2B buyers. The primary components contributing to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly influences the cost of car alternators. High-quality copper for windings, durable alloys for casings, and reliable insulation materials are essential. Suppliers often provide different grades of materials, impacting both the performance and price.

-

Labor: Labor costs vary by region, influenced by local wage standards and the complexity of manufacturing processes. Countries with lower labor costs may offer competitive pricing, but it’s crucial to consider skill levels and training.

-

Manufacturing Overhead: This includes expenses related to production facilities, equipment depreciation, and utilities. Overhead costs can fluctuate based on the efficiency of the manufacturing process and the location of the factory.

-

Tooling: Initial tooling costs for new designs can be significant. Buyers should inquire about the tooling lifespan and whether these costs are amortized over production runs, which can affect pricing for larger orders.

-

Quality Control: Rigorous QC processes ensure that alternators meet required specifications. Costs associated with testing, certifications, and compliance with international standards can add to the overall price.

-

Logistics: Shipping costs, customs duties, and insurance are critical factors. Incoterms play a vital role in defining who is responsible for these costs, affecting the final pricing for international buyers.

-

Margin: Suppliers typically include a margin that reflects the risk and investment involved in the manufacturing process. This margin can vary based on market demand and competition.

How Do Price Influencers Affect Sourcing Decisions for Car Alternators?

Several factors influence the pricing of car alternators, which international buyers should carefully consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their procurement strategies while ensuring they do not overstock.

-

Specifications and Customization: Customized alternators tailored to specific vehicle requirements may incur additional costs. Buyers should assess whether customization is necessary, as standard models often provide better pricing.

-

Material Quality and Certifications: The quality of materials and any relevant certifications (like ISO or IATF) can significantly influence price. Buyers should balance the need for high-quality components with budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their proven quality and service, while new entrants might offer competitive rates to gain market share.

-

Incoterms: Understanding the implications of Incoterms is essential for cost management. Buyers should clarify terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) to assess total landed costs accurately.

What Buyer Tips Should Be Considered for Cost-Efficient Sourcing of Car Alternators?

To optimize sourcing strategies, international B2B buyers can employ several tactics:

-

Negotiation: Engage in thorough negotiations to secure favorable terms. Leverage volume commitments or long-term contracts to achieve better pricing.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not just the purchase price but also installation, maintenance, and potential failures. A slightly higher upfront cost for a more reliable alternator can lead to savings in the long run.

-

Research Local Markets: Familiarize yourself with local market conditions, including currency fluctuations, tariffs, and import regulations that may affect overall costs.

-

Supplier Relationships: Build strong relationships with suppliers to foster collaboration. Reliable suppliers may offer better pricing or terms based on trust and ongoing partnerships.

Disclaimer on Indicative Prices

Pricing for car alternators can vary widely based on the factors outlined above. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing car alternator function With Other Solutions

Introduction: Exploring Alternatives to Car Alternator Function

In the automotive industry, the car alternator plays a crucial role in converting mechanical energy into electrical energy, powering the vehicle’s electrical systems and charging the battery. However, as technology advances, alternative solutions have emerged that can perform similar functions. This analysis aims to compare the traditional car alternator with two alternative solutions: the Integrated Starter Generator (ISG) and the Electric Vehicle (EV) battery system. Understanding these alternatives can assist B2B buyers in making informed decisions based on performance, cost, and application.

Comparison Table

| Comparison Aspect | Car Alternator Function | Integrated Starter Generator (ISG) | Electric Vehicle (EV) Battery System |

|---|---|---|---|

| Performance | High efficiency, but limited to combustion engines. | High efficiency, supports start-stop functionality. | Very high, designed for electric propulsion. |

| Cost | Moderate initial cost, with additional maintenance. | Higher upfront cost, but reduces fuel consumption. | High initial cost, but lower operating costs. |

| Ease of Implementation | Standard installation in combustion vehicles. | Requires integration with engine systems, more complex. | Requires specialized design and infrastructure. |

| Maintenance | Low maintenance, but replacement needed every 7-10 years. | Low maintenance, integrated with engine management. | Minimal maintenance, but battery replacement can be costly. |

| Best Use Case | Ideal for traditional vehicles with combustion engines. | Best for modern vehicles with stop-start technology. | Optimal for electric vehicles and hybrid systems. |

Detailed Breakdown of Alternatives

Integrated Starter Generator (ISG)

The ISG combines the functions of a starter motor and an alternator into one unit. It allows for regenerative braking and provides additional power during acceleration, which can enhance vehicle performance and fuel efficiency. The main advantage of the ISG is its ability to support start-stop technology, which can significantly reduce fuel consumption in urban driving conditions. However, its implementation can be more complex and costly compared to traditional alternators, making it less ideal for all vehicle types.

Electric Vehicle (EV) Battery System

The EV battery system represents a significant shift in automotive technology, as it replaces the need for an alternator entirely. By storing energy in high-capacity batteries, these systems can power the vehicle’s electrical components and drive the vehicle itself. The primary advantages include zero emissions and lower operating costs due to fewer moving parts. However, the initial investment is considerably higher, and the need for charging infrastructure may pose challenges in certain markets.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate energy solution for vehicles, B2B buyers should consider their specific operational requirements and market conditions. While the traditional car alternator remains a reliable option for combustion engine vehicles, alternatives like the ISG and EV battery systems offer innovative advantages that could align better with future mobility trends. Ultimately, buyers must weigh factors such as performance, cost, ease of implementation, and maintenance to determine the most suitable solution for their fleet or manufacturing needs.

Essential Technical Properties and Trade Terminology for car alternator function

What Are the Key Technical Properties of Car Alternators?

When evaluating car alternators for procurement or manufacturing, understanding their technical specifications is essential for ensuring optimal performance and compatibility with various vehicle systems. Here are critical specifications to consider:

1. Output Voltage

The standard output voltage for most car alternators is typically 12 volts, but some systems may require 14 volts to adequately charge the battery. This specification is crucial for compatibility with the vehicle’s electrical system, ensuring all components receive the necessary power without risk of overcharging or undercharging.

2. Current Rating (Amperage)

The amperage rating indicates the maximum amount of current the alternator can produce. Common ratings range from 40A to over 200A. This property is vital for B2B buyers to consider, as vehicles with more electrical accessories—such as heated seats, advanced audio systems, or additional lighting—will require higher amperage ratings to function effectively.

3. Efficiency Rating

Efficiency ratings indicate how well the alternator converts mechanical energy from the engine into electrical energy. An efficient alternator minimizes energy loss, which can lead to better fuel economy and reduced strain on the engine. For B2B buyers, selecting high-efficiency alternators can result in lower operational costs and improved vehicle performance.

4. Temperature Range

Alternators must operate effectively within a specific temperature range, typically from -40°C to +125°C. Understanding this specification is critical for international buyers, especially in regions with extreme climates, as it ensures the alternator’s reliability and longevity under various environmental conditions.

Illustrative image related to car alternator function

5. Weight and Size

The physical dimensions and weight of an alternator can impact its installation and overall vehicle design. Lighter and more compact units may be preferable for certain applications, especially in performance or electric vehicles. B2B buyers should assess these specifications to ensure compatibility with vehicle design and performance requirements.

6. Material Composition

The materials used in alternator construction, such as aluminum or high-grade steel, affect durability and weight. Choosing alternators made from corrosion-resistant materials can enhance longevity, particularly in regions with harsh weather conditions. For international buyers, understanding material properties can influence procurement decisions based on regional needs.

What Are Common Trade Terms Used in the Car Alternator Industry?

Navigating the procurement process in the automotive sector requires familiarity with industry jargon. Here are several key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are sold to vehicle manufacturers for assembly into new cars. For buyers, purchasing OEM alternators ensures compatibility and reliability, as these components are designed to meet specific manufacturer standards.

Illustrative image related to car alternator function

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs effectively and ensure that procurement aligns with business needs.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers for specific products or services. It is a critical step in the purchasing process, allowing buyers to compare costs and terms from different suppliers to secure the best deal.

4. Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers navigate international transactions more effectively, ensuring clarity in logistics and cost allocation.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. Understanding lead times is crucial for B2B buyers in managing supply chain efficiency and meeting production schedules.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the alternator and the terms of repair or replacement. Knowledge of warranty terms can protect buyers from unexpected costs and ensure long-term product support.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions regarding car alternators, enhancing their procurement strategy and aligning with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the car alternator function Sector

What Are the Current Market Dynamics and Key Trends in the Car Alternator Function Sector?

The global car alternator market is witnessing significant growth driven by the increasing demand for automotive vehicles, particularly in emerging markets like Africa and South America. As consumers become more reliant on vehicles for mobility, the need for reliable electrical systems has surged. Additionally, the rise of electric and hybrid vehicles is reshaping the alternator landscape, with manufacturers focusing on advanced alternator designs that can handle higher electrical loads.

A notable trend is the integration of smart technology within alternators. Advanced voltage regulators and control units are being developed to optimize power generation and improve fuel efficiency. These innovations cater to the growing demand for energy-efficient solutions among B2B buyers, especially in regions with fluctuating energy prices. For international buyers from regions like Nigeria and Saudi Arabia, sourcing alternators equipped with these technologies can lead to significant cost savings and enhanced vehicle performance.

Moreover, the shift towards sustainability is influencing sourcing trends. Buyers are increasingly prioritizing suppliers who offer eco-friendly components and practices. This is particularly relevant in Europe, where regulations around emissions and energy consumption are stringent. The ability to provide traceable, high-quality components can be a differentiator for suppliers in a competitive global market.

How Is Sustainability and Ethical Sourcing Impacting the Car Alternator Function Sector?

Sustainability in the automotive sector is no longer optional; it has become a critical consideration for B2B buyers. The production and disposal of car alternators can have significant environmental impacts, including resource depletion and pollution. As such, international buyers are increasingly seeking suppliers who adhere to sustainable practices. This includes the use of recycled materials, reduced energy consumption during manufacturing, and environmentally friendly packaging.

Ethical sourcing is equally important, with a growing emphasis on supply chain transparency. Buyers want assurances that their suppliers are not only compliant with local labor laws but also committed to fair labor practices. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can enhance a supplier’s credibility and appeal to conscientious buyers.

Incorporating “green” certifications and materials into the supply chain not only meets regulatory requirements but also positions companies favorably in the eyes of environmentally conscious consumers. For instance, alternators that utilize biodegradable components or are manufactured using renewable energy sources can be marketed as sustainable options, attracting a wider customer base.

What Is the Brief Evolution of the Car Alternator Function?

The alternator has evolved significantly since its inception in the early 20th century. Initially, vehicles relied on generators that were less efficient and more maintenance-intensive. The transition to alternators in the 1960s marked a pivotal shift, as they offered higher efficiency, longer lifespan, and greater electrical output.

Over the decades, advancements in technology have continued to enhance the functionality of alternators. The introduction of digital voltage regulators and the shift towards compact designs have allowed for better performance in modern vehicles. As electric and hybrid vehicles become more prevalent, the alternator’s role is evolving to meet new demands, paving the way for future innovations in the automotive sector.

This evolution reflects not only technological advancements but also changing consumer expectations, which emphasize efficiency, sustainability, and reliability. For B2B buyers, understanding this evolution is crucial for making informed sourcing decisions that align with market trends and consumer preferences.

Illustrative image related to car alternator function

Frequently Asked Questions (FAQs) for B2B Buyers of car alternator function

-

How do I identify a faulty alternator in a vehicle?

To identify a faulty alternator, monitor key symptoms such as dimming dashboard lights, difficulty starting the engine, and frequent battery boosts. Additionally, pay attention to slower electrical accessories, which may indicate insufficient power supply from the alternator. If these issues arise, it’s advisable to conduct a diagnostic check or consult a professional mechanic to confirm the alternator’s condition. Regular maintenance and inspections can also help preemptively identify potential problems, ensuring your vehicles remain operational and efficient. -

What factors should I consider when sourcing alternators for my fleet?

When sourcing alternators, consider factors such as compatibility with various vehicle models, quality standards, and manufacturer reputation. Assess the alternator’s efficiency, output voltage, and durability to meet the demands of your fleet. Additionally, evaluate the supplier’s capacity for customization to accommodate specific vehicle requirements. Request samples or technical specifications to ensure the alternators meet your operational needs, and look for suppliers who offer comprehensive warranties and reliable after-sales support. -

What is the best type of alternator for heavy-duty vehicles?

For heavy-duty vehicles, such as trucks and buses, high-output alternators that can handle substantial electrical loads are recommended. Look for alternators with a higher amperage rating, typically between 150-300 amps, to ensure they can power auxiliary equipment and maintain battery charge effectively. Brands known for durability and performance in harsh conditions are ideal. Always consult with manufacturers or suppliers for specifications tailored to your specific heavy-duty vehicle needs. -

What are the typical minimum order quantities (MOQ) for alternators from suppliers?

Minimum order quantities (MOQ) for alternators can vary widely depending on the supplier and the type of alternator. Generally, MOQs can range from 50 to 500 units. When negotiating with suppliers, inquire about pricing tiers that might apply based on order volume. Larger orders may also provide leverage for negotiating better pricing and terms. Always clarify the MOQ before placing an order to ensure it aligns with your inventory and operational requirements. -

What payment terms should I expect when importing alternators internationally?

Payment terms for international purchases of alternators typically range from advance payment, letter of credit, to 30-60 days after shipment, depending on the supplier’s policies. It’s essential to establish clear terms before finalizing a deal. Consider using secure payment methods to protect your transaction. Additionally, discuss potential discounts for early payments or bulk orders to optimize your procurement costs. Always ensure that payment terms are documented in the contract to avoid misunderstandings. -

How can I ensure the quality of alternators sourced from international suppliers?

To ensure quality, conduct thorough research on potential suppliers, including their manufacturing processes and quality control measures. Request certifications, such as ISO standards, and inquire about their testing procedures for alternators. Establish a quality assurance protocol that includes pre-shipment inspections and testing of samples. Building strong relationships with suppliers who are transparent about their quality practices can also enhance trust and ensure consistent product quality. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider factors such as shipping methods, transit times, and customs regulations. Choose a reliable logistics partner familiar with automotive parts to ensure timely delivery and compliance with import regulations. Factor in potential duties and taxes to your total landed cost. Additionally, track shipments to manage inventory effectively and plan for contingencies in case of delays. Clear communication with your logistics provider can streamline the import process. -

Can alternators be customized to fit specific vehicle models?

Yes, many manufacturers offer customization options for alternators to fit specific vehicle models and requirements. Customization can include alterations to output voltage, amperage, and mounting configurations. When discussing customization with suppliers, provide detailed specifications and any unique requirements your vehicles may have. This ensures the alternators will function optimally within your fleet, enhancing performance and reliability. Always confirm the lead times for custom orders to align with your operational timelines.

Top 3 Car Alternator Function Manufacturers & Suppliers List

1. Kia – Alternator

Domain: kia.com

Registered: 1996 (29 years)

Introduction: An alternator is an integral part of every combustion engine vehicle, responsible for converting chemical energy to electrical energy to charge and replenish the battery and power other electrical components. It works as part of the vehicle’s charging system, which includes the car battery, voltage regulator, and alternator itself. The alternator converts mechanical energy to electrical energy in …

2. Electude – Alternator

Domain: electude.com

Registered: 2005 (20 years)

Introduction: An alternator is a crucial automotive component that converts mechanical energy into electrical energy, generating power for the vehicle’s electrical consumer units and battery. Key components include:

– Pulley: Transfers mechanical energy from the engine.

– Rotor: Creates the magnetic field for generating alternating current.

– Stator: The static part where voltage is generated.

– Rectifier: …

3. Matthews Tire – Complete Electrical System Check

Domain: matthewstire.com

Registered: 2001 (24 years)

Introduction: Matthews Tire offers a complete electrical system check for just $39.95. They provide services related to battery and alternator maintenance, including wiring a battery tender to ensure the vehicle stays charged. The average life of a battery is 4-5 years, and they advise customers to keep track of when they last changed their battery and ensure it stays charged.

Strategic Sourcing Conclusion and Outlook for car alternator function

In conclusion, understanding the function and significance of car alternators is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The alternator plays a vital role in converting mechanical energy into electrical energy, ensuring the reliability of vehicle electrical systems and battery performance. For businesses sourcing automotive parts, selecting high-quality alternators that meet rigorous performance standards can significantly enhance vehicle longevity and customer satisfaction.

Strategic sourcing of automotive components like alternators not only reduces operational costs but also strengthens supply chain resilience. By establishing partnerships with reputable manufacturers and suppliers, businesses can ensure access to advanced technologies and reliable products that meet global standards.

As the automotive industry evolves with the integration of electric and hybrid technologies, staying ahead of market trends is essential. International buyers should actively seek innovative solutions and sustainable practices in sourcing to remain competitive. Embrace this opportunity to enhance your product offerings and drive business growth. Engage with trusted suppliers today to secure a brighter, more efficient automotive future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to car alternator function

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.