Introduction: Navigating the Global Market for altimator

As international B2B buyers navigate the complexities of sourcing high-quality alternators, understanding the intricacies of this essential automotive component is paramount. The alternator plays a crucial role in powering various vehicle systems, making its procurement a vital concern for businesses in sectors such as transportation, logistics, and automotive manufacturing. This comprehensive guide addresses the critical challenges faced by buyers, including identifying different types of alternators, understanding their applications, and assessing supplier credibility.

In this guide, we delve into various aspects of the alternator market, from the technical specifications and performance metrics to cost considerations and maintenance implications. We provide insights into how to effectively vet suppliers, ensuring that you partner with reputable manufacturers who deliver reliability and durability. Furthermore, we will explore regional market trends, particularly focusing on Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia.

By equipping you with in-depth knowledge and actionable strategies, this guide empowers you to make informed purchasing decisions. Whether you are looking to enhance your fleet’s performance or streamline your supply chain, understanding the global market for alternators will help you achieve operational excellence and drive business success.

Table Of Contents

- Top 3 Altimator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for altimator

- Understanding altimator Types and Variations

- Key Industrial Applications of altimator

- 3 Common User Pain Points for ‘altimator’ & Their Solutions

- Strategic Material Selection Guide for altimator

- In-depth Look: Manufacturing Processes and Quality Assurance for altimator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘altimator’

- Comprehensive Cost and Pricing Analysis for altimator Sourcing

- Alternatives Analysis: Comparing altimator With Other Solutions

- Essential Technical Properties and Trade Terminology for altimator

- Navigating Market Dynamics and Sourcing Trends in the altimator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of altimator

- Strategic Sourcing Conclusion and Outlook for altimator

- Important Disclaimer & Terms of Use

Understanding altimator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternator | Conventional design, typically 12V or 24V output | Automotive, commercial vehicles | Pros: Widely available, cost-effective. Cons: May not handle high electrical loads. |

| High-Output Alternator | Increased amperage for demanding electrical systems | Performance vehicles, fleet operations | Pros: Supports additional accessories. Cons: Higher cost, may require modifications. |

| Brushless Alternator | No brushes, reduced wear, and maintenance | Heavy machinery, industrial applications | Pros: Longer lifespan, lower maintenance. Cons: Higher initial investment. |

| Smart Alternator | Regulates output based on battery charge level | Hybrid vehicles, advanced automotive systems | Pros: Improved fuel efficiency. Cons: Complexity may lead to higher repair costs. |

| Marine Alternator | Designed for high humidity and vibration resistance | Boats, marine equipment | Pros: Durable, corrosion-resistant. Cons: Can be more expensive than standard models. |

What Are the Characteristics of Standard Alternators?

Standard alternators are the most common type found in vehicles, typically providing 12V or 24V output. They are designed to handle the basic electrical needs of automobiles and light trucks, making them suitable for a wide range of B2B applications, especially in the automotive sector. Buyers should consider the alternator’s output capacity to ensure it meets the electrical demands of the vehicle. While they are cost-effective, they may struggle with high electrical loads, which can be a limitation for businesses operating vehicles with numerous electronic accessories.

Why Choose High-Output Alternators for Specific Applications?

High-output alternators are engineered to deliver increased amperage, making them ideal for performance vehicles and fleet operations that require additional electrical power for accessories like sound systems and lighting. These alternators are particularly beneficial for businesses that rely on vehicles with enhanced electrical demands. When purchasing, buyers should assess their vehicle’s electrical requirements and consider the potential need for modifications. While they provide significant benefits, the higher cost can be a drawback for budget-conscious buyers.

What Are the Advantages of Brushless Alternators?

Brushless alternators eliminate the traditional brushes found in standard models, resulting in reduced wear and maintenance needs. They are particularly suitable for heavy machinery and industrial applications where reliability is critical. B2B buyers should evaluate their operational environment, as brushless alternators can offer a longer lifespan and lower maintenance costs, although they typically come with a higher upfront investment. This makes them a strong choice for businesses looking to minimize downtime and maintenance expenses.

How Do Smart Alternators Enhance Vehicle Efficiency?

Smart alternators feature advanced technology that adjusts output based on the battery’s charge level, optimizing energy use. These alternators are increasingly used in hybrid vehicles and advanced automotive systems, appealing to businesses focused on sustainability and efficiency. When considering a smart alternator, buyers should weigh the complexity of the system against potential fuel savings and improved battery life. However, the added complexity can lead to higher repair costs, which is an important factor for budget-sensitive organizations.

What Makes Marine Alternators Unique for Maritime Applications?

Marine alternators are specifically designed to withstand harsh environments, including high humidity and vibration, making them essential for boats and marine equipment. Their durability and corrosion resistance are crucial for businesses operating in maritime industries. When purchasing a marine alternator, buyers should ensure compatibility with their vessel’s electrical system and consider the potential for higher costs compared to standard models. However, the investment is often justified by the enhanced longevity and reliability of marine alternators in challenging conditions.

Key Industrial Applications of altimator

| Industry/Sector | Specific Application of altimator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Powering electrical systems in vehicles | Ensures reliable operation of all vehicle electrical components | OEM quality standards, compatibility with vehicle models |

| Renewable Energy | Energy generation in hybrid and electric vehicles | Enhances efficiency and sustainability of transportation | Sourcing from certified manufacturers, durability under varying conditions |

| Construction Equipment | Electrical power for machinery and tools | Increases productivity and reduces downtime | Robustness in harsh environments, maintenance support |

| Marine | Power supply for onboard electrical systems | Ensures reliability of navigation and safety systems | Compliance with maritime regulations, corrosion resistance |

| Agricultural Machinery | Powering irrigation systems and farm equipment | Optimizes operational efficiency and crop yield | Adaptability to different power requirements, service availability |

How is the alternator used in the automotive industry, and what problems does it solve?

In the automotive sector, the alternator is critical for powering the vehicle’s electrical systems, including lighting, infotainment, and safety features. By converting mechanical energy into electrical energy, it ensures that the battery remains charged while the engine runs, preventing battery drain and electrical failures. For international buyers, especially in regions with varying climates such as Africa and Europe, sourcing alternators that meet OEM standards is essential for reliability and performance. Compatibility with specific vehicle models and the availability of local service support are also key considerations.

What role does the alternator play in renewable energy applications?

In hybrid and electric vehicles, the alternator serves as a generator that recharges the battery while the vehicle is in motion. This application is vital in enhancing the efficiency of electric drivetrains, allowing for longer travel distances and reduced reliance on external charging infrastructure. For B2B buyers in South America and the Middle East, sourcing high-quality alternators designed for energy-efficient performance can significantly impact the sustainability of transportation solutions. Buyers should prioritize manufacturers with proven track records in the renewable energy sector and those offering robust warranty and support services.

How does the alternator contribute to construction equipment efficiency?

Construction machinery relies heavily on alternators to power essential electrical systems, from hydraulic lifts to lighting. A reliable alternator ensures that machinery operates smoothly, minimizing downtime due to electrical failures. For buyers in regions such as Europe and Africa, where construction projects are often subject to harsh environmental conditions, sourcing durable alternators that can withstand extreme temperatures and dust is crucial. Additionally, buyers should consider suppliers that offer comprehensive maintenance support to ensure long-term operational efficiency.

Why is the alternator important for marine applications?

In marine environments, alternators provide crucial electrical power for navigation systems, communication devices, and safety equipment. This ensures that vessels operate safely and efficiently on the water. For international buyers, particularly in regions with stringent maritime regulations, sourcing alternators that comply with these standards is vital. Corrosion resistance and durability are also critical factors, given the harsh marine conditions. Buyers should seek manufacturers with expertise in marine applications to ensure reliability and compliance.

How does the alternator optimize agricultural machinery operations?

In agriculture, alternators are used to power irrigation systems and various farm equipment, enhancing operational efficiency and productivity. A reliable alternator allows farmers to maintain consistent power supply for essential operations, directly impacting crop yield. For B2B buyers in sectors like agriculture in Africa and South America, it is essential to consider the adaptability of alternators to different power requirements and environmental conditions. Additionally, sourcing from suppliers who provide robust after-sales support can help mitigate risks associated with equipment failure during critical farming periods.

3 Common User Pain Points for ‘altimator’ & Their Solutions

Scenario 1: Unexpected Equipment Failure During Operations

The Problem: A logistics company based in South America relies heavily on its fleet of delivery vehicles to meet tight schedules. One day, a critical vehicle experiences an unexpected alternator failure, leading to delays in shipments and loss of customer trust. This scenario highlights the vulnerability of businesses to equipment breakdowns, particularly when they rely on the seamless operation of machinery that is vital for service delivery.

The Solution: To mitigate the risk of alternator failure, businesses should prioritize preventive maintenance and establish a robust inventory management system for critical spare parts, including alternators. This involves conducting regular diagnostic checks on vehicles to identify early warning signs such as dimming lights or sluggish electrical responses. Furthermore, partnering with reputable suppliers for high-quality alternators can ensure that replacements are reliable and durable. Implementing a regular training program for maintenance staff on how to recognize alternator issues can also enhance the longevity of the equipment and improve operational efficiency.

Scenario 2: High Replacement Costs Due to Poor Quality Parts

The Problem: A manufacturing firm in Europe faces escalating costs due to frequent alternator failures in its machinery. The firm had been sourcing alternators from low-cost suppliers, which led to a cycle of replacements that not only disrupted production but also increased operational expenses. The company’s bottom line is affected, and the management is frustrated by the lack of reliable performance from these components.

The Solution: To address this issue, businesses should shift their focus towards sourcing premium-quality alternators from established manufacturers that offer warranties and support. Performing thorough research on suppliers, including checking certifications and customer reviews, can help ensure that the selected parts meet industry standards. Additionally, investing in training for procurement teams on the importance of quality over cost can prevent future missteps. Implementing a centralized procurement strategy can also enable bulk purchasing, leading to negotiated discounts with reliable suppliers, ultimately reducing long-term costs.

Scenario 3: Complications in Technical Specifications for Customized Equipment

The Problem: An engineering firm in the Middle East is tasked with designing custom machinery for a client. The alternator specifications required for the project are complex, and the team struggles to find an appropriate component that meets the unique demands of the machinery. This situation not only risks project delays but also the possibility of failing to meet client expectations, which can harm the firm’s reputation.

The Solution: To overcome this challenge, the engineering firm should engage in detailed consultations with alternator manufacturers to understand the specifications and capabilities of various models. Collaborating with technical experts can provide insights into alternative solutions that might not be immediately obvious. Creating a checklist of performance criteria—such as voltage output, size, and integration capabilities—can help streamline the selection process. Additionally, developing a prototype using a test alternator can provide valuable data before finalizing the design, ensuring that the final product meets both functionality and client satisfaction. By taking these proactive steps, the firm can enhance its project delivery and strengthen client relationships.

Strategic Material Selection Guide for altimator

What Are the Common Materials Used in Alternators?

When selecting materials for alternators, it is crucial to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials used in alternators: aluminum, copper, steel, and plastic. Each material has unique characteristics that can significantly affect the performance and longevity of the alternator.

How Does Aluminum Perform in Alternator Applications?

Aluminum is widely used in alternator housings and components due to its lightweight and excellent thermal conductivity. Key properties include a temperature rating of up to 150°C and good corrosion resistance, making it suitable for various environmental conditions.

Pros: Aluminum is durable and lightweight, which helps in reducing the overall weight of the vehicle, enhancing fuel efficiency. It is also relatively cost-effective and easy to manufacture, allowing for complex shapes and designs.

Cons: While aluminum is resistant to corrosion, it can be less durable than other metals under high-stress conditions. Additionally, it may require surface treatments to enhance its longevity in harsh environments.

Impact on Application: Aluminum’s lightweight nature and thermal properties make it ideal for applications where weight savings are critical, such as in automotive and aerospace industries.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as DIN and ASTM for aluminum alloys, which may influence material selection based on local regulations.

What Role Does Copper Play in Alternator Functionality?

Copper is predominantly used in the windings of alternators due to its excellent electrical conductivity, with a conductivity rating of 59.6% IACS (International Annealed Copper Standard).

Pros: The high conductivity of copper ensures efficient energy transfer, reducing energy losses and improving overall performance. It also has good thermal properties, which help in heat dissipation.

Cons: Copper is more expensive than aluminum, which can increase the overall cost of the alternator. It is also prone to corrosion if not properly insulated or treated.

Impact on Application: Copper’s superior conductivity makes it essential for applications requiring high efficiency and reliability, particularly in high-performance vehicles.

Considerations for International Buyers: Buyers should be aware of the copper supply chain and pricing fluctuations, especially in regions like South America where mining operations are prevalent. Compliance with international standards for electrical components is also crucial.

Why Is Steel Used in Alternator Construction?

Steel is often used for the structural components of alternators, including the rotor and stator cores. Its properties include high tensile strength and the ability to withstand high temperatures, generally rated up to 300°C.

Pros: Steel provides excellent durability and strength, making it suitable for high-stress applications. It is also cost-effective and widely available.

Cons: Steel is heavier than aluminum, which can negatively impact vehicle weight and fuel efficiency. Additionally, it is susceptible to corrosion if not adequately treated.

Impact on Application: Steel’s strength makes it ideal for applications where mechanical stability is paramount, such as in heavy-duty vehicles.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should consider local availability and treatment options to prevent corrosion, especially in humid or coastal environments.

How Does Plastic Contribute to Alternator Design?

Plastic is commonly used for non-structural components in alternators, such as housings and insulators. Key properties include a wide range of temperature ratings depending on the type of plastic, with some high-performance plastics rated up to 200°C.

Pros: Plastic is lightweight, corrosion-resistant, and can be molded into complex shapes, allowing for innovative designs. It is also cost-effective compared to metals.

Cons: While plastics are resistant to corrosion, they may not withstand high temperatures as effectively as metals. Additionally, they can be less durable under mechanical stress.

Impact on Application: Plastic’s versatility makes it suitable for various applications, particularly where weight reduction and design flexibility are essential.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with local environmental regulations, especially in Europe, where there are strict guidelines regarding materials used in automotive applications.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings and structural components | Lightweight and good thermal conductivity | Less durable under high stress | Medium |

| Copper | Windings | Excellent electrical conductivity | Higher cost and corrosion risk | High |

| Steel | Rotor and stator cores | High strength and durability | Heavier and corrosion-prone | Low |

| Plastic | Non-structural components | Lightweight and versatile | Limited high-temperature performance | Medium |

This analysis provides insights into the strategic selection of materials for alternators, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for altimator

What Are the Key Stages of the Manufacturing Process for Alternators?

The manufacturing of alternators involves several critical stages that ensure the final product meets stringent performance and quality standards. Understanding these stages helps B2B buyers evaluate potential suppliers effectively.

1. Material Preparation: What Raw Materials Are Used?

The first stage involves sourcing high-quality raw materials essential for the alternator’s components. Key materials include:

- Copper Wire: Used for the stator windings, copper is crucial for conductivity.

- Silicon Steel: This is used for the rotor and stator laminations, enhancing magnetic efficiency.

- Aluminum: Often utilized in the casing for its lightweight properties and resistance to corrosion.

- Insulation Materials: Critical for preventing electrical shorts and ensuring safety.

Sourcing these materials from reputable suppliers is vital, as the quality directly impacts the alternator’s performance and lifespan.

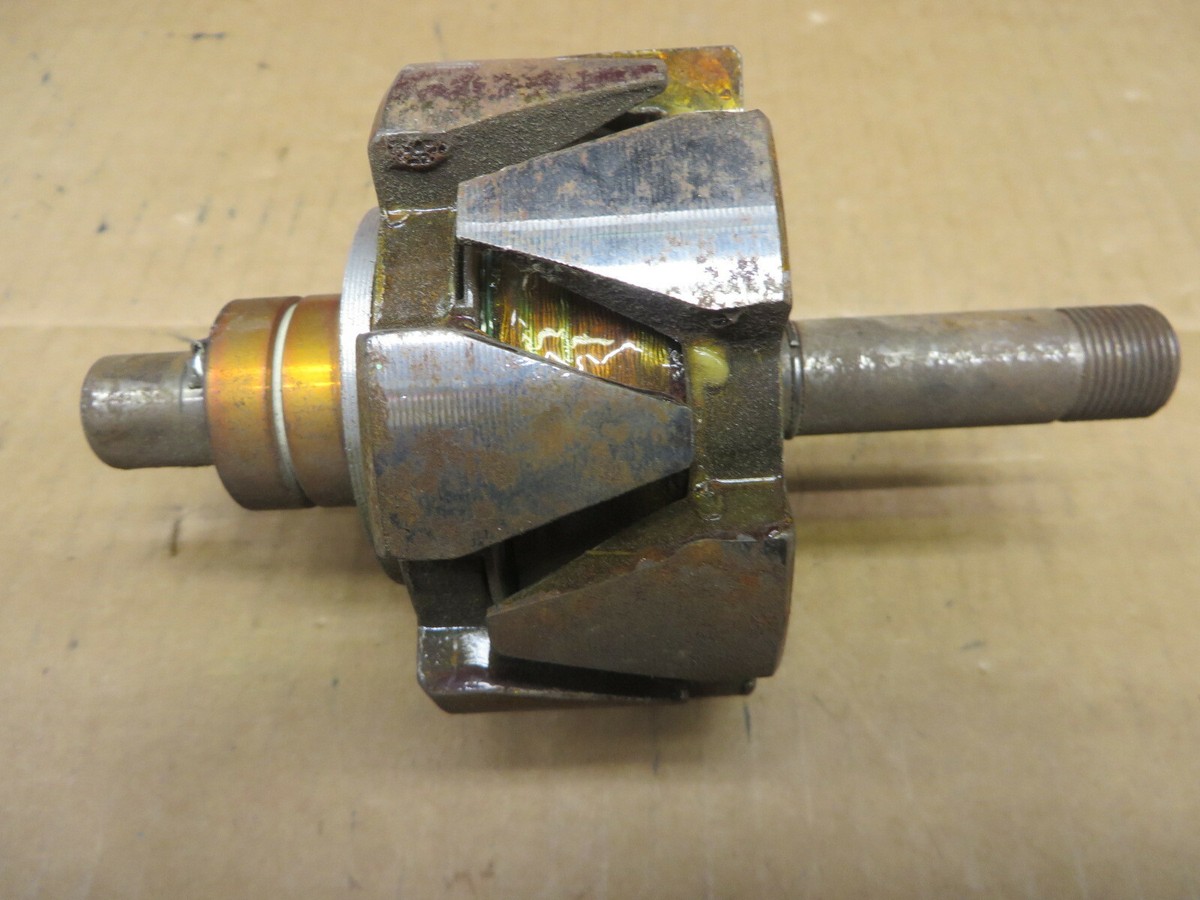

2. Forming: How Are Components Shaped?

The forming stage includes techniques such as stamping, machining, and casting. Each component undergoes specific processes:

- Stator and Rotor Manufacturing: Stamping processes create the stator and rotor laminations, which are then stacked and assembled.

- Winding the Stator: Copper wire is precisely wound around the stator to create the electromagnetic field.

- Casting the Housing: The alternator’s casing is often produced through die-casting techniques, ensuring durability and precise dimensions.

Advanced forming technologies, including computer numerical control (CNC) machines, enhance precision and reduce material waste.

3. Assembly: What Is the Process for Bringing Components Together?

During the assembly phase, precision is critical. The assembly process typically involves:

- Component Integration: The rotor is placed inside the stator, followed by the installation of the voltage regulator, diode rectifier, and cooling fan.

- Electrical Connections: All electrical components are connected, ensuring robust and secure connections to handle varying loads.

- Quality Checks: Initial quality control checks are performed to identify any assembly issues before moving to the next stage.

Efficient assembly techniques not only improve productivity but also ensure that the alternators meet performance specifications.

Illustrative image related to altimator

4. Finishing: What Final Touches Are Applied?

The finishing stage involves surface treatments and protective coatings. This can include:

- Painting and Coating: To prevent corrosion and improve aesthetics, alternators are often coated with specialized paints or finishes.

- Final Assembly Checks: Comprehensive inspections ensure that all components are functioning correctly and that the alternator meets design specifications.

This stage is essential for enhancing the product’s longevity and reliability, particularly in harsh environments.

What Quality Control Measures Are Essential in Alternator Manufacturing?

Quality assurance is a critical aspect of alternator manufacturing, ensuring that each unit performs reliably under various conditions. Adhering to international standards is vital for B2B buyers seeking trustworthy suppliers.

1. What International Standards Should Suppliers Meet?

- ISO 9001: This standard outlines requirements for a quality management system (QMS), ensuring consistent quality in manufacturing processes.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Specific to automotive parts, these standards ensure quality and performance in alternator production.

B2B buyers should prioritize suppliers with certifications that reflect adherence to these international standards.

2. What Are the Key Quality Control Checkpoints?

Quality control in alternator manufacturing typically includes several checkpoints:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to confirm it meets performance and safety standards.

These checkpoints are essential for maintaining high-quality production and minimizing defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must implement strategies to verify the quality control measures of potential suppliers. Here are some effective approaches:

1. What Role Do Audits Play in Supplier Evaluation?

Conducting regular audits of suppliers is an effective way to assess their adherence to quality standards. These audits can include:

- On-Site Inspections: Assessing manufacturing processes and quality control measures in real-time.

- Documentation Review: Evaluating quality control records, test results, and compliance with international standards.

Regular audits help build confidence in a supplier’s ability to deliver consistent quality.

2. How Important Are Third-Party Inspections?

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services can include:

- Random Sampling: Testing a random selection of alternators from a batch to ensure they meet specified standards.

- Certification Services: Verifying that suppliers have the necessary certifications and compliance with international standards.

Third-party inspections add an additional layer of assurance, particularly for international buyers.

What Unique Challenges Do International Buyers Face in Quality Assurance?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, navigating quality assurance can present unique challenges:

1. How Do Regulatory Differences Impact Quality Control?

Different regions have varying regulations regarding manufacturing and product quality. Buyers must be aware of:

Illustrative image related to altimator

- Import Regulations: Understanding specific import requirements and standards in their respective countries.

- Local Compliance: Ensuring that suppliers can meet both international and local quality standards.

This knowledge is crucial for avoiding compliance issues and ensuring product reliability.

2. What Are the Best Practices for Managing Supplier Relationships?

Building strong relationships with suppliers can enhance quality assurance. Best practices include:

- Regular Communication: Establishing open lines of communication to discuss quality concerns and expectations.

- Collaborative Problem Solving: Working with suppliers to address quality issues proactively.

By fostering strong partnerships, B2B buyers can ensure that their suppliers remain committed to quality and performance standards.

Conclusion: Ensuring Quality in Alternator Procurement

Understanding the manufacturing processes and quality assurance practices for alternators is essential for B2B buyers. By focusing on supplier qualifications, international standards, and robust quality control measures, buyers can make informed decisions that ensure the reliability and performance of their electrical components in various applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘altimator’

In the competitive landscape of automotive parts procurement, sourcing alternators requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This guide outlines a practical checklist for international B2B buyers, particularly targeting markets in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Begin by establishing clear technical specifications for the alternators you need. This includes understanding the voltage, amperage, and compatibility with various vehicle models. Precise specifications help avoid compatibility issues and ensure you procure the right product for your needs.

Illustrative image related to altimator

- Consider application requirements: Different vehicles have varying electrical demands; ensure your alternators can meet these.

- Note environmental factors: If operating in extreme conditions, choose alternators designed for durability and resilience.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in automotive parts, particularly alternators. Use industry networks, trade shows, and online platforms to gather a list of reputable manufacturers and distributors.

- Look for established brands: Suppliers with a proven track record often offer higher quality and reliability.

- Check for local suppliers: This can reduce shipping costs and lead times, particularly important for urgent needs.

Step 3: Evaluate Supplier Certifications

Verify the certifications and standards that suppliers adhere to, such as ISO 9001 or specific automotive industry standards. Certifications are indicators of quality management and product reliability.

- Request documentation: Ensure that suppliers can provide proof of their certifications.

- Assess compliance with local regulations: This is especially crucial when sourcing from international suppliers.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the alternators for testing. This step allows you to evaluate the quality and performance of the product firsthand.

- Conduct performance tests: Check for compatibility with your vehicle models and assess the alternator’s output under load.

- Inspect for quality: Look for any manufacturing defects or inconsistencies.

Step 5: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to establish favorable terms and conditions. This includes pricing, payment terms, delivery schedules, and return policies.

- Discuss bulk order discounts: Many suppliers are open to negotiating prices for larger orders.

- Clarify warranty and service agreements: Ensure you understand the terms of warranty and what support is available post-purchase.

Step 6: Plan for Logistics and Delivery

Consider the logistics of transporting the alternators from the supplier to your location. Factor in shipping methods, customs regulations, and potential tariffs that may apply.

- Choose reliable shipping partners: Work with logistics companies experienced in handling automotive parts.

- Understand import regulations: Ensure compliance with the importing country’s regulations to avoid delays.

Step 7: Establish a Long-term Relationship

After a successful transaction, focus on building a long-term relationship with your chosen supplier. This can lead to better pricing, priority service, and improved communication for future orders.

- Provide feedback: Share your experience with the supplier to help them improve their offerings.

- Stay engaged: Regular communication can lead to better collaboration and understanding of your future needs.

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for alternators, ensuring they acquire high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for altimator Sourcing

What Are the Key Cost Components in Alternator Manufacturing?

The cost structure of alternators encompasses several critical components. Understanding these elements is essential for B2B buyers to make informed sourcing decisions.

-

Materials: The primary materials used in alternator production include copper for wiring, aluminum for the housing, and various plastics for insulation. The fluctuating prices of these raw materials can significantly impact the overall cost. Buyers should consider sourcing from regions with stable material costs or long-term contracts to mitigate volatility.

-

Labor: Labor costs vary by region and can be influenced by local wage standards, skill levels, and labor laws. For manufacturers in countries with lower labor costs, the savings can be substantial, but it is essential to ensure that quality is not compromised.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment depreciation, and maintenance. Efficient manufacturing processes can lower these overhead costs, making it crucial for buyers to evaluate suppliers’ operational efficiencies.

-

Tooling: The initial investment in tooling and machinery for production can be significant. Custom tooling for specific alternator designs can increase costs, but it may also enhance production efficiency and product quality.

-

Quality Control (QC): Rigorous quality control processes are essential to ensure reliability and performance. The costs associated with testing and certification can vary based on the level of quality assurance required, impacting the final price.

-

Logistics: Transportation costs, including shipping, customs, and handling, can add to the overall expense. Buyers should consider the proximity of suppliers to reduce logistics costs and timeframes.

-

Margin: Manufacturers typically apply a margin to cover their costs and generate profit. This margin can vary based on competition, market demand, and the perceived value of the alternator.

How Do Pricing Influencers Affect Alternator Costs?

Several factors influence the pricing of alternators, which buyers should consider during negotiations:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to discounts, as suppliers are more willing to negotiate on price for larger orders. Understanding the MOQ is crucial for buyers looking to maximize cost efficiency.

-

Specifications and Customization: Customized alternators tailored to specific applications may incur higher costs due to additional engineering and production requirements. Buyers should weigh the need for customization against potential cost increases.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO standards) can influence price. High-quality materials and certifications may lead to higher upfront costs but can result in lower Total Cost of Ownership (TCO) due to improved durability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may command higher prices but offer better assurance regarding product quality and delivery times.

-

Incoterms: Understanding Incoterms is essential for determining responsibility for shipping costs and risks. Buyers should negotiate terms that minimize their exposure to unexpected costs.

What Tips Can Help Buyers Optimize Alternator Sourcing Costs?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, the following tips can enhance cost efficiency in sourcing alternators:

-

Negotiate Wisely: Engage in discussions with multiple suppliers to compare quotes and terms. Leverage volume commitments to negotiate better pricing and payment terms.

-

Focus on Total Cost of Ownership (TCO): Instead of solely considering the purchase price, evaluate the TCO, which includes maintenance, durability, and potential downtime costs. A slightly higher initial investment in quality may yield long-term savings.

-

Research Market Conditions: Stay informed about global material prices and economic conditions that can affect alternator costs. This knowledge will equip buyers to make timely purchasing decisions.

-

Consider Regional Suppliers: Sourcing from local or regional manufacturers can reduce shipping costs and lead times, enhancing overall supply chain efficiency.

-

Be Aware of Pricing Nuances: Recognize that prices can vary significantly based on region, supplier reputation, and market demand. Buyers should be prepared to adapt their sourcing strategies accordingly.

Disclaimer for Indicative Prices

Prices for alternators can vary widely based on the aforementioned factors. It is advisable for buyers to obtain multiple quotes and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing altimator With Other Solutions

Understanding Alternatives for B2B Buyers: A Comparative Analysis

When evaluating solutions like ‘altimator’, it’s essential to consider various alternatives that may offer similar benefits or functionalities. This analysis will help B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, make informed decisions based on their specific operational needs.

Comparison Table

| Comparison Aspect | ‘Altimator’ | Alternative 1: Traditional Alternator | Alternative 2: Lithium-ion Battery System |

|---|---|---|---|

| Performance | High efficiency in power generation, can handle variable loads | Reliable, but may struggle under heavy loads | Excellent energy density, quick recharge |

| Cost | Moderate initial investment, long-term savings on maintenance | Lower upfront cost, potential for higher long-term maintenance | Higher initial investment, but reduced operational costs over time |

| Ease of Implementation | Requires specific installation and calibration | Widely understood technology, easier to integrate | Complex installation, needs specialized knowledge |

| Maintenance | Low maintenance with proper use | Moderate maintenance needs, can wear out over time | Minimal maintenance, but battery replacement can be costly |

| Best Use Case | Ideal for applications requiring consistent power output | Suitable for traditional vehicles and equipment | Best for applications needing high energy capacity with fast discharge |

Detailed Breakdown of Alternatives

Traditional Alternator

The traditional alternator has been the go-to solution for generating electrical power in vehicles and machinery. It is relatively cost-effective, with a lower upfront investment compared to ‘altimator’. However, it may not handle high electrical loads as efficiently and can require more frequent maintenance, especially in heavy-duty applications. This makes it a suitable choice for standard automotive uses, but less ideal for operations requiring high efficiency and reliability.

Lithium-ion Battery System

Lithium-ion battery systems are increasingly popular due to their excellent energy density and ability to discharge energy quickly. This technology is particularly beneficial in applications where space is limited, and rapid power delivery is crucial, such as in electric vehicles or portable devices. However, the initial investment can be significantly higher than that of ‘altimator’ and traditional alternators. Additionally, while maintenance requirements are lower, the cost of replacing a lithium-ion battery can be substantial, making it less appealing for businesses looking for long-term cost efficiency.

Illustrative image related to altimator

Conclusion: Choosing the Right Solution for Your Business

Selecting the right power generation solution requires a careful assessment of your specific operational requirements, budget constraints, and long-term goals. While ‘altimator’ offers high efficiency and lower maintenance, alternatives like traditional alternators and lithium-ion systems may provide advantages in cost or specific use cases. B2B buyers should weigh these factors, considering their unique environments and needs, to ensure they choose a solution that aligns with their operational demands and financial strategies.

Essential Technical Properties and Trade Terminology for altimator

What Are the Key Technical Properties of an Alternator?

Understanding the technical specifications of an alternator is crucial for international B2B buyers. Here are several key properties that should be considered:

1. Material Grade

The materials used in an alternator, such as aluminum for the housing and copper for the windings, are vital for performance and durability. High-grade materials resist corrosion, improve thermal conductivity, and enhance overall efficiency. For buyers, ensuring the alternator meets specific material standards can prevent premature failure and reduce maintenance costs.

2. Voltage Output

Alternators typically produce between 12 to 14.5 volts of direct current (DC) to recharge the battery and power electrical systems. Understanding the voltage output is essential for ensuring compatibility with various vehicle systems. An alternator with a consistent voltage output reduces the risk of electrical system failures, which can lead to costly repairs and downtime.

3. Current Rating (Amperage)

The current rating, often expressed in amperes (A), indicates the maximum electrical output the alternator can deliver. Higher amperage ratings are necessary for vehicles with extensive electrical systems or aftermarket accessories. For B2B buyers, selecting the right amperage ensures that the alternator can handle the vehicle’s electrical demands without overloading.

4. Efficiency Rating

The efficiency of an alternator is a measure of how effectively it converts mechanical energy into electrical energy. High-efficiency alternators minimize energy loss, which translates to better fuel economy and lower operational costs. For businesses, investing in high-efficiency models can lead to significant long-term savings and improved performance.

5. Bearing Type

Alternators may use either ball bearings or bushings. Ball bearings typically provide better performance and longevity, which is crucial in high-load applications. Understanding the type of bearings used can help buyers assess the reliability and lifespan of the alternator, which is essential for minimizing downtime in commercial operations.

6. Cooling Mechanism

Many alternators incorporate a built-in cooling fan or utilize the vehicle’s airflow for cooling. Effective cooling is essential to prevent overheating, especially in high-demand situations. Buyers should consider the cooling design when selecting alternators for applications that require sustained performance under load.

What Are Common Trade Terms Related to Alternators?

Navigating the procurement process for alternators involves familiarity with industry jargon. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These components are typically designed to fit and perform exactly like the original parts. B2B buyers often prefer OEM alternators for their reliability and compatibility, ensuring optimal vehicle performance.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. Understanding the MOQ is vital for international buyers to manage inventory effectively and ensure they are not overcommitting financially. It can also affect negotiation strategies when sourcing alternators.

Illustrative image related to altimator

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price offers from suppliers for specific products or services. B2B buyers utilize RFQs to compare costs and terms from various manufacturers before making purchasing decisions. This process helps ensure competitive pricing and favorable terms.

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery obligations, which is crucial for successful international procurement.

5. Aftermarket

The aftermarket refers to parts and accessories that are not sourced from the original manufacturer. Aftermarket alternators can offer cost-effective alternatives but may vary in quality. B2B buyers must evaluate the trade-offs between cost and reliability when considering aftermarket options.

6. Warranty Period

The warranty period is the timeframe during which the manufacturer guarantees the alternator against defects. Understanding warranty terms is essential for buyers to assess the risk involved in their purchase and plan for potential repairs or replacements.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and financial goals.

Navigating Market Dynamics and Sourcing Trends in the altimator Sector

What Are the Current Market Dynamics and Key Trends in the Alternator Sector?

The global alternator market is experiencing significant growth, driven by the increasing demand for advanced automotive technology and the proliferation of electric vehicles (EVs). As international B2B buyers, especially from Africa, South America, the Middle East, and Europe, it is essential to recognize the implications of these trends. Key drivers include the rising focus on fuel efficiency, stringent emission regulations, and the push for renewable energy solutions. Countries like Germany and Saudi Arabia are leading the way in adopting innovative automotive technologies, which has led to a surge in demand for high-performance alternators that can support complex electrical systems.

Emerging technologies such as smart alternators equipped with integrated voltage regulation and energy recovery systems are gaining traction. These innovations not only enhance vehicle performance but also contribute to sustainability efforts by reducing energy wastage. Additionally, the trend towards digitalization in supply chains is reshaping sourcing strategies. B2B buyers are increasingly leveraging data analytics and IoT technologies to optimize procurement processes, enabling more informed decisions regarding alternator sourcing.

The competitive landscape is also evolving, with manufacturers focusing on quality and customization to meet the diverse needs of international buyers. As a result, understanding regional market nuances becomes crucial for B2B buyers looking to establish strong partnerships with suppliers who can deliver tailored solutions.

How Does Sustainability and Ethical Sourcing Impact the Alternator Sector?

Sustainability and ethical sourcing are becoming paramount considerations in the alternator sector, as environmental concerns gain prominence among consumers and businesses alike. The production of alternators involves materials and processes that can have significant environmental impacts, particularly concerning resource extraction and waste generation. Thus, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices.

Companies are adopting ‘green’ certifications and utilizing eco-friendly materials in the manufacturing of alternators. For instance, the use of recycled metals and environmentally safe coatings not only reduces the carbon footprint but also enhances the overall sustainability profile of the product. Ethical supply chains are essential for ensuring that all materials are sourced responsibly, minimizing human rights abuses and environmental degradation.

International buyers are also exploring partnerships with manufacturers who emphasize transparency in their supply chains. By selecting suppliers that adhere to ethical standards, businesses can strengthen their brand reputation and align with the values of environmentally conscious consumers. Engaging in sustainable sourcing not only fulfills corporate social responsibility goals but also positions companies favorably in an increasingly eco-aware market.

What Is the Brief Evolution and History of Alternators in the Automotive Industry?

The alternator has undergone significant evolution since its introduction in the early 20th century. Initially designed as a simple generator, the alternator has transformed into a complex electrical device capable of powering modern vehicles’ extensive electronic systems. The shift from direct current (DC) generators to alternating current (AC) alternators marked a pivotal moment in automotive engineering, enhancing efficiency and reliability.

In the 1960s, the widespread adoption of alternators began as vehicles became equipped with more electrical accessories, such as air conditioning and advanced lighting systems. This evolution continued into the 21st century with the rise of hybrid and electric vehicles, where alternators play a critical role in energy management and battery recharging. Today, the focus is not only on performance but also on sustainability and the integration of smart technologies, reflecting the changing needs of the automotive industry and the expectations of B2B buyers worldwide.

Understanding this evolution is vital for international buyers, as it informs procurement strategies and highlights the importance of sourcing from manufacturers that are at the forefront of technological advancements in the alternator sector.

Frequently Asked Questions (FAQs) for B2B Buyers of altimator

-

How do I solve alternator performance issues in my fleet?

To address alternator performance issues, first, conduct a thorough inspection of the electrical system in each vehicle. Look for common symptoms such as dimming lights, stalling engines, or dashboard warning lights. Engage a qualified technician to perform diagnostics to determine if the alternator or battery is at fault. Regular maintenance, including checking connections and ensuring the alternator is free from corrosion, can prevent future problems. Additionally, consider implementing a proactive replacement schedule based on mileage or performance metrics to minimize downtime. -

What is the best alternator for commercial vehicles?

When sourcing alternators for commercial vehicles, prioritize quality and reliability. Look for brands known for durability, such as Bosch or Delco Remy, which provide robust performance in high-demand environments. It’s also crucial to ensure that the alternator meets the specific power requirements of your vehicles, considering factors like load capacity and electrical demands. Consulting with suppliers who specialize in commercial vehicle parts can help you find the most suitable options tailored to your fleet’s needs. -

What factors should I consider when selecting an alternator supplier?

When selecting an alternator supplier, evaluate their reputation and experience in the industry. Look for suppliers with certifications and a history of quality assurance. Assess their product range to ensure they can meet your specific requirements, including customization options if needed. Additionally, consider their logistics capabilities and ability to deliver on time, especially for international shipments. Lastly, check for customer reviews and testimonials to gauge their reliability and support services. -

What are the typical minimum order quantities (MOQ) for alternators?

Minimum order quantities for alternators can vary significantly depending on the supplier and the type of alternator. Generally, MOQs can range from 10 to 100 units for standard models. However, for customized or specialized alternators, the MOQ might be higher due to the additional manufacturing processes involved. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you’re looking to stock inventory or make bulk purchases. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms for international alternator purchases typically range from advance payment to net 30 or net 60 days after invoice. Some suppliers may offer payment via letters of credit for larger orders, which provides security for both parties. It’s essential to clarify the payment terms before finalizing the deal, including any potential deposits required. Additionally, consider transaction fees associated with international payments and exchange rates that may affect the overall cost. -

How can I ensure quality assurance for alternators purchased overseas?

To ensure quality assurance for alternators sourced from overseas, establish clear specifications and standards before engaging with suppliers. Request samples or certifications that demonstrate compliance with international quality standards such as ISO or TS16949. Implement a robust inspection process upon receipt, including testing the alternators under load conditions. Collaborating with third-party quality assurance firms can also provide additional oversight and verification of the products before they reach your operations. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider the logistics of shipping, including the mode of transportation (air vs. sea) based on urgency and cost. Understand customs regulations and duties that may apply to your shipments, as these can affect overall pricing. Work closely with your supplier to ensure proper documentation is provided to facilitate smooth customs clearance. Additionally, consider the supplier’s logistics capabilities, including their experience with international shipping and their ability to provide tracking throughout the shipping process. -

How do I handle warranty claims for alternators sourced internationally?

Handling warranty claims for internationally sourced alternators requires clear communication with your supplier. Ensure that warranty terms are explicitly stated in your purchase agreement, including the duration and coverage details. Document any issues with the alternators, including photographs and operational data, to support your claim. Contact the supplier promptly to initiate the warranty process, following their procedures for returns or replacements. Understanding the supplier’s policy on international returns will help streamline the resolution process.

Top 3 Altimator Manufacturers & Suppliers List

1. HowStuffWorks – Alternator

Domain: auto.howstuffworks.com

Registered: 1998 (27 years)

Introduction: The alternator is a crucial component in a vehicle that generates electricity to power the car’s electrical systems and recharge the battery. It works in conjunction with the battery, and issues with the alternator can lead to symptoms such as dimming lights, malfunctioning radio, and ultimately engine failure. A failing alternator can leave a driver stranded due to a lack of power for essential f…

2. Savannah Toyota – Alternator Insights

Domain: savannahtoyota.com

Registered: 1996 (29 years)

Introduction: The alternator powers all electronics in a vehicle while the engine is running, functioning as a generator using the gas engine as its energy source. It typically lasts between 80,000 and 150,000 miles (about seven years). Signs of a failing alternator include a battery warning light, dim headlights, burning rubber smell, devices not charging, whining sounds, and inability to start the vehicle. Th…

3. Advance Auto Parts – Alternator

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: Alternator – Advance Auto Parts

– Discounts: 15% OFF orders $35+, 20% OFF $100+ (online only, use code BLACKFRIDAY, exclusions apply)

– Function: Part of the vehicle’s electrical charging system, converts mechanical energy into electricity, powers electrical system, maintains battery charge.

– Importance: A failing alternator leads to reliance on battery power, which depletes quickly.

– Brands: OE…

Strategic Sourcing Conclusion and Outlook for altimator

How Can Strategic Sourcing Enhance Your Business’s Access to Quality Alternators?

In today’s competitive automotive landscape, strategic sourcing of alternators is crucial for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. A well-informed procurement strategy not only ensures access to high-quality alternators but also fosters long-term relationships with reputable suppliers. By prioritizing quality, buyers can mitigate the risks associated with alternator failures, which can lead to operational downtimes and increased maintenance costs.

Understanding the technical specifications and performance metrics of alternators is essential for making informed purchasing decisions. Establishing a proactive sourcing strategy that includes evaluating suppliers based on their production capabilities, quality assurance processes, and after-sales support can greatly enhance supply chain resilience. Additionally, considering local market trends and regional regulations can provide a competitive edge in procurement.

As we look to the future, the demand for reliable automotive components will only grow. Now is the time for B2B buyers to engage in strategic sourcing initiatives that will not only meet their immediate needs but also secure their position in the evolving market landscape. Invest in partnerships that align with your business goals, and empower your operations with superior alternator solutions that drive efficiency and performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.