Introduction: Navigating the Global Market for symptoms of a faulty starter

In today’s dynamic automotive landscape, understanding the symptoms of a faulty starter is crucial for B2B buyers looking to maintain their fleets efficiently. A malfunctioning starter not only delays operations but can also lead to significant repair costs and downtime. As businesses across Africa, South America, the Middle East, and Europe seek reliable transportation solutions, recognizing these early warning signs becomes essential. This guide delves into the multifaceted world of starter failures, offering insights into common symptoms, underlying causes, and effective troubleshooting techniques.

From identifying the subtle sounds of a failing starter to understanding the implications of oil leaks on performance, our comprehensive resource equips you with the knowledge needed to make informed purchasing decisions. We explore various types of starters, their applications in different vehicle models, and criteria for selecting reputable suppliers. Additionally, we provide valuable information on cost considerations, ensuring that you can weigh your options effectively.

By empowering international B2B buyers, particularly those in regions such as Nigeria and Vietnam, this guide serves as a practical tool for mitigating risks associated with starter malfunctions. With actionable insights and a clear understanding of the starter’s role in vehicle performance, you can navigate the complexities of the global market with confidence.

Table Of Contents

- Top 1 Symptoms Of A Faulty Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for symptoms of a faulty starter

- Understanding symptoms of a faulty starter Types and Variations

- Key Industrial Applications of symptoms of a faulty starter

- 3 Common User Pain Points for ‘symptoms of a faulty starter’ & Their Solutions

- Strategic Material Selection Guide for symptoms of a faulty starter

- In-depth Look: Manufacturing Processes and Quality Assurance for symptoms of a faulty starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘symptoms of a faulty starter’

- Comprehensive Cost and Pricing Analysis for symptoms of a faulty starter Sourcing

- Alternatives Analysis: Comparing symptoms of a faulty starter With Other Solutions

- Essential Technical Properties and Trade Terminology for symptoms of a faulty starter

- Navigating Market Dynamics and Sourcing Trends in the symptoms of a faulty starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of symptoms of a faulty starter

- Strategic Sourcing Conclusion and Outlook for symptoms of a faulty starter

- Important Disclaimer & Terms of Use

Understanding symptoms of a faulty starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Unresponsive Engine | Engine fails to crank despite battery and dashboard lights working | Automotive repair shops, fleet services | Pros: Clear indicator of starter failure. Cons: May require professional diagnosis. |

| Clicking or Grinding Noises | Distinct sounds during ignition attempts, indicating starter issues | Vehicle maintenance providers | Pros: Easy to identify; immediate attention needed. Cons: May indicate broader electrical issues. |

| Dashboard Indicators | Warning lights illuminate without engine response | Fleet management and logistics companies | Pros: Early warning of potential failure. Cons: May confuse with battery or alternator issues. |

| Smoke or Burning Smell | Visible smoke or odor from starter area during attempts to start | Automotive service centers, parts suppliers | Pros: Serious indication of overheating; needs immediate action. Cons: Risk of further damage if ignored. |

| Oil-Drenched Starter | Starter soaked in engine oil, affecting functionality | Automotive repair and parts distribution | Pros: Identifies potential oil leak issues. Cons: Requires additional repairs beyond starter replacement. |

What Are the Key Characteristics of an Unresponsive Engine?

An unresponsive engine is a primary symptom indicating a potential starter failure. When the engine does not crank despite the dashboard lights functioning, it typically signifies that the starter motor is not receiving power or is malfunctioning. This symptom is particularly relevant for automotive repair shops and fleet services, as it allows for rapid diagnosis and repair. Buyers should consider the implications of a faulty starter on operational efficiency and potential vehicle downtime.

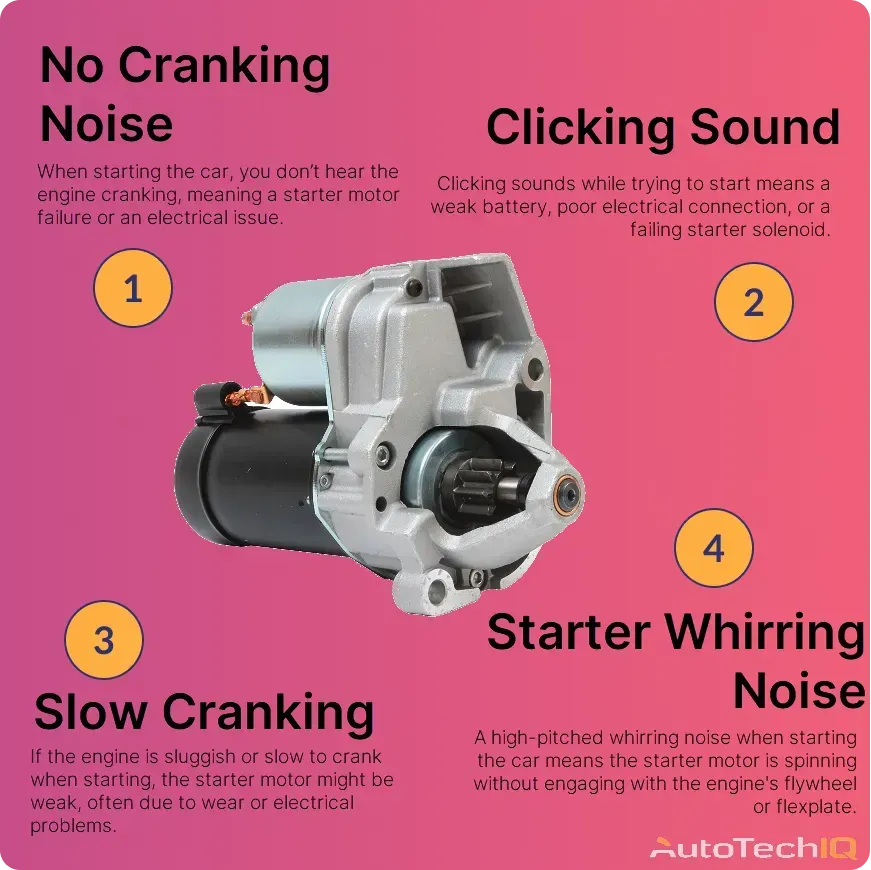

How Can Clicking or Grinding Noises Indicate Starter Issues?

Clicking or grinding noises during ignition attempts are unmistakable indicators of starter problems. A clicking sound often suggests that the starter gear is not engaging properly, while grinding can indicate physical damage within the starter system. Vehicle maintenance providers can use this information to swiftly address starter issues. Buyers should weigh the urgency of repairs against potential costs, as these noises can lead to more severe mechanical failures if neglected.

Why Are Dashboard Indicators Important for Diagnosing Starters?

Dashboard indicators, such as warning lights, can illuminate without any engine response, suggesting a starter malfunction. This symptom is crucial for fleet management and logistics companies, as it can prevent unexpected breakdowns. Buyers should prioritize vehicles equipped with advanced diagnostic systems that can provide early warnings, allowing for timely maintenance and minimizing operational disruptions.

What Does Smoke or a Burning Smell from the Starter Mean?

The presence of smoke or a burning smell during ignition attempts is a serious sign of overheating within the starter system. This symptom requires immediate attention to prevent further damage to electrical components. Automotive service centers and parts suppliers need to be aware of this issue, as it can lead to significant repair costs. Buyers must act quickly to address this symptom, as ignoring it can result in more extensive damage and higher repair expenses.

How Can an Oil-Drenched Starter Affect Vehicle Performance?

An oil-drenched starter indicates a potential oil leak that can hinder the starter’s performance. This symptom is particularly relevant for automotive repair businesses, as it may require additional repairs beyond just replacing the starter. Buyers should consider the implications of oil leaks on overall vehicle health and the associated costs of repairs. Addressing this issue promptly can prevent more significant mechanical failures and ensure reliable vehicle operation.

Key Industrial Applications of symptoms of a faulty starter

| Industry/Sector | Specific Application of Symptoms of a Faulty Starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnostics for Vehicle Start Issues | Reduces downtime by quickly identifying starter failures | Quality of diagnostic tools and technician expertise |

| Transportation & Logistics | Fleet Maintenance and Management | Ensures reliability of vehicles, minimizing service interruptions | Availability of replacement parts and service support |

| Construction Equipment | Maintenance of Heavy Machinery | Prevents costly delays in project timelines due to equipment failure | Access to specialized parts for various machinery types |

| Agriculture | Troubleshooting Agricultural Machinery | Enhances operational efficiency by maintaining equipment functionality | Knowledge of specific agricultural equipment needs |

| Mining | Diagnostics for Mining Equipment | Increases productivity by reducing unexpected equipment failures | Sourcing durable components suited for harsh environments |

How Are Symptoms of a Faulty Starter Applied in Automotive Repair?

In the automotive repair industry, recognizing symptoms of a faulty starter is crucial for diagnostics. Mechanics can quickly identify issues such as clicking sounds or unresponsive engines, allowing for efficient repairs. This not only reduces vehicle downtime but also enhances customer satisfaction. For international buyers, sourcing high-quality diagnostic tools and ensuring technicians are well-trained in troubleshooting starter issues can significantly impact service quality.

What Role Do Symptoms of a Faulty Starter Play in Transportation & Logistics?

In the transportation and logistics sector, fleet managers rely on understanding starter symptoms to maintain vehicle reliability. Early detection of starter problems can prevent breakdowns, ensuring that deliveries are made on time. For businesses operating in regions like Africa and South America, sourcing reliable replacement parts and establishing robust maintenance schedules are critical for minimizing operational disruptions.

How Are Symptoms of a Faulty Starter Utilized in Construction Equipment Maintenance?

Construction companies depend on heavy machinery that requires constant operation. Identifying symptoms of a faulty starter helps in early maintenance, thus preventing costly project delays. Buyers in this sector must consider the availability of specialized parts that can withstand the demanding conditions of construction sites, ensuring that machinery remains functional and projects stay on track.

Why Are Symptoms of a Faulty Starter Important in Agriculture?

In agriculture, machinery such as tractors and harvesters must be operational to meet seasonal demands. Diagnosing starter issues quickly can enhance operational efficiency, allowing farmers to maximize productivity. International buyers should focus on sourcing parts that cater specifically to agricultural machinery, which may have unique requirements compared to standard vehicles.

How Do Symptoms of a Faulty Starter Impact Mining Operations?

Mining operations heavily rely on machinery that must perform under extreme conditions. Recognizing starter symptoms can lead to timely repairs, which is essential for maintaining productivity. For businesses in the mining sector, sourcing durable components that can endure harsh environments is vital to minimize unexpected equipment failures and maintain continuous operation.

3 Common User Pain Points for ‘symptoms of a faulty starter’ & Their Solutions

Scenario 1: Difficulty Diagnosing the Problem with Vehicle Starters

The Problem: B2B buyers, particularly fleet managers or vehicle maintenance providers, often face challenges when diagnosing starter issues. The interconnected nature of the battery, alternator, and starter can lead to confusion; symptoms of a faulty starter might mimic battery or alternator failures. For example, a vehicle that fails to start may show signs like dim lights or clicking sounds, which could indicate issues elsewhere in the electrical system. This ambiguity not only causes frustration but also leads to unnecessary downtime and increased operational costs.

The Solution: To mitigate this issue, implement a systematic troubleshooting protocol that begins with a comprehensive diagnostic checklist. Start by checking the battery’s voltage and connections, as a weak battery can often mimic starter failure. Utilize specialized diagnostic tools to read any fault codes from the vehicle’s onboard computer, which can provide clues about the specific component at fault. Training your team on the fundamentals of the starter system—understanding the roles of the battery, starter, and alternator—can empower them to make informed decisions. Additionally, consider investing in high-quality multimeters and battery testers that can accurately assess the health of these components, ensuring that your team can efficiently pinpoint the root cause of the problem.

Scenario 2: High Repair Costs Due to Frequent Starter Failures

The Problem: In regions with extreme weather conditions, such as high heat in the Middle East or cold in parts of Europe, starters can fail prematurely, resulting in high repair and replacement costs. This is especially true for companies operating a fleet of vehicles, where frequent starter failures can lead to significant downtime and increased maintenance expenses. Without a solid understanding of starter symptoms, businesses may spend unnecessarily on repairs that could be avoided with better preventative measures.

The Solution: To address this issue, implement a proactive maintenance schedule that includes regular inspections of the starter system. Educate your team about the specific symptoms of starter failure, such as unusual sounds, dashboard alerts, or unresponsive engines. Create a checklist that includes checks for loose or corroded connections, oil leaks, and the condition of the starter itself. Additionally, consider sourcing starters that are specifically designed for extreme conditions. Brands that provide enhanced durability or weather-resistant features can help extend the lifespan of the starters in your fleet, ultimately reducing repair costs. Training technicians to recognize early signs of starter issues can also facilitate timely interventions, preventing costly breakdowns.

Scenario 3: Unreliable Supplier Relationships Impacting Starter Replacement

The Problem: B2B buyers may encounter challenges with unreliable suppliers when sourcing replacement starters, leading to delays and frustration. Inconsistent supply chains can hinder timely repairs, especially for businesses that rely on their vehicles for daily operations. If a supplier does not provide quality products or fails to deliver on time, it can disrupt business continuity and erode customer trust.

The Solution: Establishing strong relationships with reputable suppliers is crucial. Conduct thorough research to identify suppliers who specialize in automotive components and have a proven track record for quality and reliability. Create a vendor assessment framework that includes criteria such as delivery times, product warranties, and customer service responsiveness. Consider diversifying your supplier base to include both local and international vendors, which can help mitigate risks associated with supply chain disruptions. Additionally, negotiate long-term contracts with suppliers for critical components like starters to secure better pricing and ensure availability. Regularly evaluate supplier performance and maintain open lines of communication to address any issues proactively, ensuring your business remains operational and your vehicle fleet stays in top condition.

Strategic Material Selection Guide for symptoms of a faulty starter

What Materials Are Commonly Used in Starters and Their Performance?

When evaluating materials for components related to the symptoms of a faulty starter, it’s essential to consider those that can withstand the rigors of automotive environments. Here, we analyze four common materials: steel, aluminum, copper, and plastic composites. Each material has unique properties that impact performance, durability, and suitability for various applications.

How Does Steel Perform in Starter Applications?

Steel is a widely used material in automotive components due to its strength and durability. It typically boasts high tensile strength and excellent resistance to wear and tear, making it suitable for starter housings and gears. Steel components can withstand high temperatures and pressures, which is critical in starter applications where they are exposed to engine vibrations and thermal cycling.

Pros: Steel’s durability ensures a longer lifespan for starter components, reducing the frequency of replacements. It is also relatively cost-effective compared to other metals.

Cons: The main drawback of steel is its susceptibility to corrosion if not properly treated or coated. Additionally, steel components can be heavier, which may affect the overall weight of the vehicle.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local automotive standards, such as ASTM or ISO specifications, particularly regarding corrosion resistance treatments.

Illustrative image related to symptoms of a faulty starter

What Role Does Aluminum Play in Starter Systems?

Aluminum is another popular choice for starter components, particularly in applications where weight reduction is a priority. Aluminum is lightweight yet strong, providing good thermal conductivity, which helps dissipate heat generated during starter operation.

Pros: The lightweight nature of aluminum can improve vehicle fuel efficiency and performance. It is also resistant to corrosion, especially when anodized.

Cons: While aluminum is strong, it is generally not as durable as steel under extreme stress conditions. The manufacturing process can also be more complex, leading to higher production costs.

Illustrative image related to symptoms of a faulty starter

International Considerations: Buyers in Europe and the Middle East often prefer aluminum for its lightweight properties, but they should verify compliance with EU regulations regarding material safety and environmental impact.

How Does Copper Enhance Starter Functionality?

Copper is primarily used in electrical connections and wiring within starter systems due to its excellent electrical conductivity. This property ensures efficient power transfer from the battery to the starter motor, which is crucial for reliable engine starts.

Pros: Copper’s high conductivity leads to better performance and quicker engine starts. It is also relatively easy to work with in terms of manufacturing and forming.

Cons: Copper is prone to corrosion and oxidation, which can impair conductivity over time. Additionally, it is more expensive than other metals, which can increase overall component costs.

International Considerations: B2B buyers should consider the availability of copper and its compliance with international standards, particularly in regions with stringent electrical safety regulations.

What Are the Advantages of Plastic Composites in Starter Components?

Plastic composites are increasingly used in automotive applications, including starters, due to their lightweight nature and versatility. These materials can be molded into complex shapes, allowing for innovative designs that can enhance performance.

Pros: Plastic composites are resistant to corrosion and can withstand a range of temperatures, making them suitable for various environments. They also contribute to weight savings, which can improve overall vehicle efficiency.

Cons: While durable, plastic composites may not withstand the same levels of stress as metals, particularly in high-temperature applications. They can also be more expensive to produce due to the specialized manufacturing processes required.

International Considerations: Buyers from developing regions should ensure that plastic composites meet local automotive standards for safety and performance, as well as environmental regulations regarding material disposal.

Summary Table of Material Selection for Starters

| Material | Typical Use Case for symptoms of a faulty starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Starter housings, gears | High durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight starter components | Lightweight and corrosion-resistant | Less durable under extreme stress | High |

| Copper | Electrical wiring and connections | Excellent electrical conductivity | Prone to corrosion | High |

| Plastic Composites | Non-structural components, housings | Corrosion-resistant and lightweight | May not withstand high stress | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in starter systems, helping them make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for symptoms of a faulty starter

What Are the Key Stages in the Manufacturing Process of Starters?

The manufacturing process of starters involves several critical stages that ensure the final product meets performance and durability standards. Each stage is designed to optimize the quality and reliability of the starter, which is essential for vehicle operation.

Illustrative image related to symptoms of a faulty starter

How Is Material Prepared for Starter Manufacturing?

Material preparation is the first step in the starter manufacturing process. High-quality materials, typically including steel, copper, and various plastics, are sourced from certified suppliers. The selection of materials is crucial, as they directly impact the starter’s performance and longevity.

Once sourced, materials undergo rigorous inspection to ensure they meet specific mechanical and chemical properties. This includes checking for impurities, tensile strength, and corrosion resistance. Only materials that pass these inspections move forward to the next stage.

What Techniques Are Used for Forming Starters?

The forming stage involves shaping the prepared materials into components that will make up the starter. Techniques such as stamping, forging, and machining are commonly employed.

- Stamping is used for creating metal parts, where sheets of metal are cut and shaped into the desired forms using high-pressure machines.

- Forging involves shaping metal through compressive forces, which enhances its strength by aligning the grain structure.

- Machining is utilized for precision parts, where components are cut to exact specifications using CNC (Computer Numerical Control) machines.

Each technique is chosen based on the specific requirements of the starter components, ensuring that they meet design and performance specifications.

How Are Starters Assembled?

Assembly is a critical phase in the starter manufacturing process. It involves bringing together all the individual components, such as the motor, gears, and electrical connections, to form the complete starter unit.

This stage is often conducted in a clean environment to prevent contamination and ensure that all parts fit together correctly. Skilled technicians use assembly jigs and fixtures to maintain precision during the process. Automated systems may also be employed to enhance efficiency and consistency.

What Finishing Processes Are Applied to Starters?

The finishing stage includes several processes aimed at enhancing the durability and aesthetic appeal of the starter. This may involve surface treatments such as painting, plating, or coating to protect against corrosion and wear.

Additionally, finishing processes may include quality checks to ensure that all components are correctly aligned and that the starter operates smoothly. These checks help to identify any potential issues before the product reaches the market.

Illustrative image related to symptoms of a faulty starter

How Is Quality Assurance Implemented in Starter Manufacturing?

Quality assurance (QA) is vital in ensuring that starters are reliable and perform as expected. Various international standards and industry-specific certifications guide the QA process, providing a framework for manufacturers.

Which International Standards Are Relevant for Starter Quality Control?

ISO 9001 is a widely recognized international standard for quality management systems. It outlines criteria for consistent quality and customer satisfaction, ensuring manufacturers adhere to best practices throughout the production process.

In addition to ISO standards, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the market and application. These certifications indicate that products meet specific safety and performance requirements, which can be crucial for buyers in different regions.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are essential throughout the manufacturing process to maintain high standards. Common checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint assesses raw materials before they enter the production line. It ensures that only materials meeting quality standards are used.

- In-Process Quality Control (IPQC): During manufacturing, IPQC involves monitoring processes and components to catch defects early. This proactive approach helps to minimize waste and rework.

- Final Quality Control (FQC): At this stage, the completed starters undergo thorough testing to ensure they function correctly. This may include performance tests, electrical checks, and safety assessments.

Each checkpoint plays a critical role in maintaining the integrity of the manufacturing process and the quality of the final product.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insights into their quality control processes. This includes evaluating their adherence to international standards and industry certifications.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including testing results and compliance with standards. Reviewing these reports can help assess their commitment to quality.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s manufacturing processes and quality assurance practices. This adds an extra layer of verification and confidence.

What Are the Common Testing Methods for Starters?

Testing methods are crucial for validating the performance and reliability of starters. Common testing techniques include:

Illustrative image related to symptoms of a faulty starter

- Electrical Testing: This involves checking the starter’s electrical connections and performance under load to ensure it meets specifications.

- Mechanical Testing: Assessing the starter’s physical components for structural integrity and wear helps to identify potential failure points.

- Environmental Testing: Simulating extreme conditions, such as high or low temperatures and humidity, can help predict how the starter will perform in real-world scenarios.

These tests are essential for ensuring that starters will function reliably in various environments, particularly in regions with extreme weather conditions, such as Africa and the Middle East.

Conclusion: Why Quality Assurance Matters for Starters in Global Markets

For B2B buyers, particularly those in diverse markets like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance of starters is vital. Ensuring that suppliers adhere to international standards and implement robust quality control measures is critical for securing reliable and high-performing products. By taking proactive steps to verify quality practices, buyers can mitigate risks and enhance their operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘symptoms of a faulty starter’

Introduction

In the automotive industry, understanding the symptoms of a faulty starter is crucial for ensuring smooth operations and minimizing downtime. This guide provides B2B buyers with a practical checklist to effectively identify and source components related to starter issues, enabling informed purchasing decisions and enhancing overall vehicle performance.

Step 1: Identify Common Symptoms of Starter Failure

Before sourcing components, familiarize yourself with the typical signs of a faulty starter. Symptoms include unusual sounds like clicking or grinding when attempting to start the vehicle, as well as dashboard lights illuminating without the engine turning over. Recognizing these signs early can prevent further complications and costly repairs.

Step 2: Define Your Technical Specifications

Clearly outline the specifications required for your starter components. This includes voltage ratings, compatibility with specific vehicle models, and size constraints. By defining these parameters, you can ensure that the components you procure meet the exact needs of your fleet or inventory.

Step 3: Evaluate Supplier Certifications

When selecting suppliers, verify their certifications to ensure they comply with industry standards. Look for ISO certifications or automotive industry-specific credentials that guarantee quality and reliability. This step is essential to mitigate risks associated with subpar components that could lead to operational failures.

Step 4: Request Samples for Testing

Before finalizing your purchase, request samples of the starter components. Testing samples in real-world conditions allows you to evaluate their performance and compatibility with your vehicles. Ensure that the samples are representative of the entire batch to avoid discrepancies in quality.

Step 5: Assess Warranty and Return Policies

Review the warranty terms and return policies offered by potential suppliers. A robust warranty indicates confidence in their product quality, while flexible return policies provide assurance in case of defects or incompatibility. This step is vital for protecting your investment and ensuring long-term satisfaction.

Illustrative image related to symptoms of a faulty starter

Step 6: Check for After-Sales Support

Inquire about the after-sales support provided by suppliers. This includes technical assistance, installation guidance, and troubleshooting resources. A supplier that offers comprehensive support can be invaluable, especially when dealing with complex starter systems, ensuring you can quickly resolve any issues that arise.

Step 7: Gather Feedback from Existing Customers

Finally, seek feedback from other businesses that have purchased from your shortlisted suppliers. Customer testimonials and case studies can provide insights into the reliability and performance of the components, as well as the supplier’s responsiveness to issues. This information can guide you toward making a more informed decision.

By following this checklist, B2B buyers can systematically approach the procurement of starter components, ensuring they secure high-quality products that contribute to the efficient operation of their vehicles.

Illustrative image related to symptoms of a faulty starter

Comprehensive Cost and Pricing Analysis for symptoms of a faulty starter Sourcing

What Are the Key Cost Components in Sourcing Starter Symptoms?

When analyzing the cost structure associated with sourcing components related to symptoms of a faulty starter, several crucial elements come into play. The primary cost components include:

-

Materials: The quality and type of materials significantly impact the overall cost. For starters, components such as copper windings, steel gears, and high-grade plastics are essential. Sourcing from suppliers that offer high-quality materials can reduce long-term failure rates and improve customer satisfaction.

-

Labor: Labor costs encompass not only the assembly of starter components but also the skilled labor required for testing and quality assurance. In regions like Africa and South America, labor rates can vary widely, affecting overall production costs.

-

Manufacturing Overhead: This includes the costs associated with running a manufacturing facility, such as utilities, rent, and equipment maintenance. Efficient production processes can help minimize overhead costs.

-

Tooling: Tooling costs are incurred for the equipment necessary to manufacture starter components. Investment in advanced tooling can improve precision and reduce waste, ultimately lowering costs.

-

Quality Control (QC): Implementing rigorous QC measures ensures that each component meets safety and performance standards. While this incurs additional upfront costs, it can significantly reduce warranty claims and enhance brand reputation.

-

Logistics: The cost of shipping and handling materials and finished products can vary based on location and volume. Understanding international shipping regulations and choosing the right Incoterms is crucial for cost management.

-

Margin: Suppliers typically apply a markup to cover their expenses and generate profit. Understanding the margins of different suppliers can help buyers negotiate better deals.

How Do Price Influencers Impact Sourcing Decisions?

Several factors influence the pricing of starter components, which can vary significantly between suppliers and regions:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to discounts, making it crucial for B2B buyers to assess their purchasing capacity. Negotiating lower MOQs can lead to cost savings.

-

Specifications and Customization: Custom specifications can increase costs. Buyers should weigh the benefits of customization against standard options that may be more economical.

-

Quality and Certifications: Components that meet international quality standards often come at a premium. However, investing in certified products can reduce the risk of failures and associated costs.

-

Supplier Factors: Supplier reliability, reputation, and location can impact pricing. Established suppliers may charge higher prices due to their track record, but they may also offer better service and support.

-

Incoterms: Understanding shipping terms is essential for calculating total costs. Different Incoterms can influence who bears the costs and risks associated with shipping, impacting overall pricing.

What Are Effective Buyer Tips for Cost Efficiency?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiation: Always negotiate pricing and terms with suppliers. Building long-term relationships can lead to better rates and more favorable terms over time.

-

Total Cost of Ownership (TCO): Evaluate the total cost, not just the purchase price. Consider maintenance, warranty, and replacement costs when selecting a supplier.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates and local tariffs that may affect pricing. A solid understanding of the local market can aid in negotiating better deals.

-

Supplier Diversification: Having multiple suppliers can mitigate risks associated with supply chain disruptions. It also provides leverage in negotiations.

-

Monitoring Trends: Stay informed about market trends and shifts in demand that may affect pricing. This knowledge can help buyers make timely purchasing decisions.

Conclusion

Understanding the comprehensive cost and pricing analysis for symptoms of a faulty starter is essential for making informed sourcing decisions. By considering the various cost components, price influencers, and effective buyer strategies, B2B buyers can enhance their procurement processes, ensuring both quality and cost efficiency in their operations. While prices may fluctuate, maintaining a strategic approach will yield long-term benefits.

Alternatives Analysis: Comparing symptoms of a faulty starter With Other Solutions

Understanding Alternatives to Faulty Starter Symptoms

When diagnosing vehicle issues, particularly with starting problems, it’s crucial to differentiate between symptoms of a faulty starter and other potential electrical failures. This analysis will compare the symptoms of a faulty starter with alternative diagnostic methods and technologies that can help identify or resolve similar issues. By understanding these alternatives, B2B buyers can make informed decisions about maintenance and repair solutions for their fleets or vehicle assets.

Comparison Table

| Comparison Aspect | Symptoms Of A Faulty Starter | Jump-Start Method | Diagnostic Scan Tool |

|---|---|---|---|

| Performance | Directly indicates starter issues | Quick test, but not definitive | Comprehensive vehicle diagnostics |

| Cost | Low cost for observation and troubleshooting | Low cost for cables/jump box | Moderate to high cost for tools |

| Ease of Implementation | Requires basic knowledge of car systems | Simple, requires minimal tools | Requires training to interpret data |

| Maintenance | Minimal; monitor starter conditions | None, but depends on battery health | Regular updates and calibration needed |

| Best Use Case | Identifying starter failure | Quick diagnostics in emergencies | Comprehensive vehicle health checks |

Detailed Breakdown of Alternatives

Jump-Start Method

The jump-start method is a quick way to determine if a vehicle’s starting issues stem from a dead battery rather than the starter itself. By connecting another battery, it allows a technician to see if the vehicle starts. This method is advantageous due to its low cost and simplicity; however, it only provides a temporary solution and does not diagnose underlying issues if the vehicle fails to start even after a jump. It is best used in emergencies but should not replace thorough diagnostics when persistent issues arise.

Diagnostic Scan Tool

A diagnostic scan tool offers a comprehensive approach to vehicle diagnostics, allowing users to assess various systems, including the starter, battery, and alternator. This tool connects to the vehicle’s onboard computer, providing detailed error codes and performance data. While the initial investment can be moderate to high, it proves invaluable for fleet maintenance and can save costs by identifying issues early. The downside is that it requires training to interpret the data effectively, which might not be feasible for all businesses.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate solution for diagnosing starting issues, B2B buyers must consider the specific context of their operations. For immediate troubleshooting, the jump-start method may suffice, but for ongoing fleet management and maintenance, investing in a diagnostic scan tool offers a more thorough and sustainable approach. Ultimately, understanding the nuances of each option empowers businesses to make strategic choices that enhance vehicle reliability and minimize downtime.

Essential Technical Properties and Trade Terminology for symptoms of a faulty starter

What Are the Key Technical Properties of a Starter System?

When diagnosing symptoms of a faulty starter, understanding its technical properties is crucial for B2B buyers involved in automotive parts procurement. Here are several critical specifications that can impact the performance and reliability of starter systems:

1. Material Grade

The materials used in a starter, such as the housing, gears, and electrical components, are fundamental to its durability. High-quality metals like aluminum or steel are commonly used to resist wear and corrosion. For B2B buyers, selecting parts made from superior material grades ensures longevity and reliability, reducing the frequency of replacements and downtime.

2. Torque Rating

Torque rating refers to the amount of rotational force the starter can generate to turn the engine over. This specification is vital for compatibility with various engine sizes and types. Understanding torque ratings helps buyers ensure that the starter can handle specific engine demands, particularly in regions where larger engines are prevalent, such as in agricultural or heavy-duty vehicles.

3. Voltage Rating

Most starters operate at 12V or 24V, depending on the vehicle’s electrical system. The voltage rating affects the starter’s performance and compatibility with the vehicle’s electrical components. For B2B transactions, confirming the voltage rating is essential to avoid issues related to electrical failures or subpar performance.

4. Current Draw

Current draw is the amount of electrical current the starter consumes when engaged. This metric is important for assessing the starter’s efficiency and the impact on the vehicle’s battery. Buyers should consider current draw to ensure it aligns with the vehicle’s battery capacity, which is particularly crucial in markets with varying battery technologies.

5. Temperature Tolerance

Starters must function effectively across a range of temperatures. High or low temperatures can affect performance and lifespan. B2B buyers should inquire about temperature tolerance specifications, especially in regions with extreme climates, to prevent premature failures.

6. Lifetime Rating (Cycles)

The lifetime rating indicates how many start cycles a starter can endure before failure. This specification is particularly relevant for fleet operators or businesses that rely heavily on vehicle performance. A higher cycle rating can translate to lower operational costs and less frequent replacements.

What Common Trade Terminology Should B2B Buyers Know?

In the automotive parts industry, specific jargon is frequently used that can affect procurement processes. Familiarity with these terms can enhance communication and decision-making for B2B buyers.

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle or its components. These parts are often preferred for their guaranteed compatibility and quality. B2B buyers should understand the benefits of OEM parts versus aftermarket alternatives to make informed purchasing decisions.

Illustrative image related to symptoms of a faulty starter

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget management and inventory planning, particularly for businesses that require large quantities of starters for fleet maintenance.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process is vital for negotiating favorable terms and ensuring competitive pricing. B2B buyers should utilize RFQs to gather multiple offers and make informed purchasing decisions.

4. Incoterms

Incoterms are international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms helps B2B buyers clarify the costs and logistics involved in acquiring starter systems, particularly in cross-border transactions.

5. Warranty Period

The warranty period is the duration for which a product is guaranteed against defects. For B2B buyers, understanding warranty terms can provide insights into the product’s reliability and the manufacturer’s confidence in their offerings.

6. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Knowing the lead time is crucial for inventory management and ensuring that operations remain uninterrupted, especially in regions where supply chain delays are common.

By grasping these technical properties and industry terms, B2B buyers can enhance their procurement strategies, ensuring they select the right starter systems for their specific needs.

Illustrative image related to symptoms of a faulty starter

Navigating Market Dynamics and Sourcing Trends in the symptoms of a faulty starter Sector

What Are the Global Market Dynamics Impacting the Symptoms of a Faulty Starter Sector?

The symptoms of a faulty starter sector are influenced by various global drivers, including increasing vehicle ownership in emerging markets and the growing complexity of automotive technologies. In regions such as Africa, South America, the Middle East, and Europe, the demand for reliable starter systems is rising as more consumers and businesses depend on vehicles for transportation and logistics. The advancement of electric vehicles (EVs) and hybrid technologies is also reshaping the market, as these vehicles often require different starter systems compared to traditional internal combustion engines.

Current trends in B2B sourcing reflect a shift towards digital platforms that facilitate the procurement of automotive components. Many international buyers are leveraging online marketplaces to access a broader range of suppliers, ensuring competitive pricing and quality assurance. Moreover, the integration of AI and data analytics in supply chain management is helping companies forecast demand and manage inventory more effectively, reducing downtime related to faulty starter issues.

Emerging markets are particularly keen on sourcing durable and cost-effective starter systems. As urbanization accelerates in countries like Nigeria and Vietnam, the need for robust vehicle performance and maintenance becomes critical. Buyers are increasingly focused on sourcing from manufacturers who can provide not just components but also comprehensive support and service solutions to address potential starter failures proactively.

How Does Sustainability and Ethical Sourcing Impact the Symptoms of a Faulty Starter Sector?

Sustainability and ethical sourcing are becoming paramount in the automotive components sector, particularly concerning the symptoms of a faulty starter. The environmental impact of automotive manufacturing, including waste generation and carbon emissions, has prompted international buyers to seek suppliers committed to sustainable practices. This includes adopting processes that minimize waste and utilize renewable resources in starter production.

Moreover, an ethical supply chain is essential for building brand reputation and ensuring compliance with international regulations. Buyers are increasingly looking for suppliers that possess ‘green’ certifications, which indicate adherence to environmental standards. These certifications often involve the use of recyclable materials in starter components, reducing the ecological footprint of automotive production.

For B2B buyers, prioritizing sustainability can lead to long-term cost savings and a competitive advantage. Implementing sustainable practices in sourcing can also mitigate risks associated with supply chain disruptions caused by environmental regulations or resource scarcity. As consumer awareness about sustainability grows, companies that emphasize ethical sourcing in their operations may find themselves more favorably positioned in the market.

What Is the Historical Context of the Symptoms of a Faulty Starter Sector?

The evolution of starter systems can be traced back to the early 20th century, when electric starters replaced manual cranking methods in vehicles. This innovation significantly improved the reliability and convenience of starting engines. Over the decades, advancements in technology have led to the development of more sophisticated starter systems that integrate with vehicle electronics, enhancing performance and efficiency.

Historically, the symptoms of a faulty starter were often misdiagnosed due to the interconnected nature of automotive electrical systems. However, advancements in diagnostic tools and increased awareness among technicians have improved the ability to identify starter issues accurately. This evolution has paved the way for a more informed market, where B2B buyers can make better decisions based on reliable data and insights into starter performance and maintenance.

In summary, understanding the market dynamics, sustainability considerations, and historical context surrounding the symptoms of a faulty starter sector is crucial for international B2B buyers. By leveraging this knowledge, companies can make informed sourcing decisions that enhance operational efficiency and align with broader environmental goals.

Frequently Asked Questions (FAQs) for B2B Buyers of symptoms of a faulty starter

-

How do I identify the symptoms of a faulty starter in my fleet vehicles?

To identify a faulty starter, look for common symptoms such as unusual noises (clicking, grinding, or whirring) when attempting to start the vehicle, or a complete lack of response despite dashboard lights illuminating. If the engine fails to crank even after multiple jump-start attempts, this indicates starter issues. Regular inspections and diagnostics can help identify these symptoms early, reducing downtime and maintenance costs. -

What is the best diagnostic method for determining starter problems?

The most effective method to diagnose starter problems is the jump-start test. Connect jumper cables from a functional vehicle’s battery to the suspected faulty one. If the vehicle starts, the battery may be the issue; if it doesn’t, the starter is likely faulty. Additionally, listen for sounds from the starter when attempting to start the engine; this can provide further clues about the starter’s condition. -

How can I source reliable starters for vehicles in international markets?

When sourcing starters, focus on suppliers with a proven track record and positive reviews in your target market. Verify certifications and compliance with international standards, ensuring quality and compatibility with your vehicles. Attending industry trade shows and utilizing online marketplaces can help establish connections with reputable manufacturers. Always request samples to assess quality before making bulk purchases. -

What are the common causes of starter failure to consider in procurement?

Common causes of starter failure include improper installation, exposure to extreme temperatures, and corrosion from moisture. When procuring starters, consider the environmental conditions in your operational areas. Ensure that your suppliers provide starters designed to withstand these challenges, enhancing longevity and reliability. Discuss warranty options and return policies for defective products to mitigate risks. -

What customization options should I look for in starters from suppliers?

Many suppliers offer customization options such as voltage specifications, size variations, and specific connector types tailored to your fleet’s needs. Discuss your requirements with potential suppliers and inquire about their ability to provide bespoke solutions. Customization can enhance compatibility and performance, ensuring that the starters meet the specific demands of your vehicles. -

What are the minimum order quantities (MOQs) for starters in international trade?

MOQs can vary significantly depending on the supplier and the type of starter. Generally, larger manufacturers may have higher MOQs, while smaller or more flexible suppliers may accommodate lower quantities. It’s essential to negotiate terms that align with your purchasing strategy, ensuring you can maintain inventory without overcommitting financially. Always clarify MOQs before finalizing contracts. -

What payment terms are standard when sourcing starters internationally?

Payment terms can differ based on supplier policies and the nature of the transaction. Common terms include a deposit upfront with the balance due upon delivery, or full payment in advance. For larger orders, consider negotiating terms such as letters of credit or payment upon inspection to mitigate risk. Always ensure that payment methods are secure and compliant with international trade regulations. -

How can I ensure quality assurance (QA) for starters sourced from overseas?

To ensure quality assurance, request detailed product specifications and certifications from suppliers. Conducting pre-shipment inspections can help verify that the products meet your quality standards. Additionally, establish clear communication channels with suppliers for addressing defects or performance issues. Building long-term relationships with trusted suppliers can enhance quality control and reliability in your sourcing efforts.

Top 1 Symptoms Of A Faulty Starter Manufacturers & Suppliers List

1. Subaru – Starter Motor Issues

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: 2004 Subaru WRX, original equipment starter motor, symptoms include grinding screech during cold starts, low amplitude grinding squeal on warm days, concerns about starter motor failure, battery not new but not original, no current starting problems.

Strategic Sourcing Conclusion and Outlook for symptoms of a faulty starter

How Can Strategic Sourcing Enhance Your Understanding of Starter Symptoms?

In conclusion, identifying the symptoms of a faulty starter is essential for maintaining optimal vehicle performance, particularly in regions where reliable transportation is crucial for business operations. Key signs such as unusual sounds, dashboard alerts, and non-responsiveness can help businesses diagnose issues before they escalate, potentially saving costs and downtime. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, strategic sourcing of high-quality starter components is vital.

By partnering with reputable suppliers who understand the local climates and conditions affecting starter longevity—such as extreme temperatures and humidity—you can ensure that your fleet remains operational. Moreover, sourcing components that meet international quality standards can enhance reliability and reduce maintenance needs.

As we look to the future, the importance of proactive maintenance and strategic sourcing will only grow. Investing in quality parts and leveraging local expertise will empower your organization to navigate challenges effectively. Engage with trusted suppliers today to fortify your fleet’s performance and safeguard against the risks associated with faulty starters.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.