Introduction: Navigating the Global Market for starter motor

In today’s global marketplace, sourcing reliable starter motors can present significant challenges for international B2B buyers. With varying standards, quality concerns, and a plethora of suppliers, identifying the right starter motor that meets both operational requirements and budget constraints is crucial for businesses across Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. This guide aims to streamline the sourcing process, offering insights into different types of starter motors, their applications, and the essential factors to consider when evaluating suppliers.

Navigating through the complexities of the starter motor market requires an informed approach. From understanding the technical specifications and performance metrics to evaluating cost implications and supplier reliability, this comprehensive guide covers all the bases. You’ll find detailed discussions on the various types of starter motors, including high-torque options and remanufactured units, alongside practical tips for vetting suppliers to ensure you partner with reputable manufacturers.

By leveraging the information presented in this guide, B2B buyers will be empowered to make informed purchasing decisions that enhance operational efficiency and reduce downtime. Equip your business with the knowledge needed to navigate the global market for starter motors effectively, and ensure you secure the best value for your investment.

Table Of Contents

- Top 4 Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter motor

- Understanding starter motor Types and Variations

- Key Industrial Applications of starter motor

- 3 Common User Pain Points for ‘starter motor’ & Their Solutions

- Strategic Material Selection Guide for starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor’

- Comprehensive Cost and Pricing Analysis for starter motor Sourcing

- Alternatives Analysis: Comparing starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for starter motor

- Navigating Market Dynamics and Sourcing Trends in the starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter motor

- Strategic Sourcing Conclusion and Outlook for starter motor

- Important Disclaimer & Terms of Use

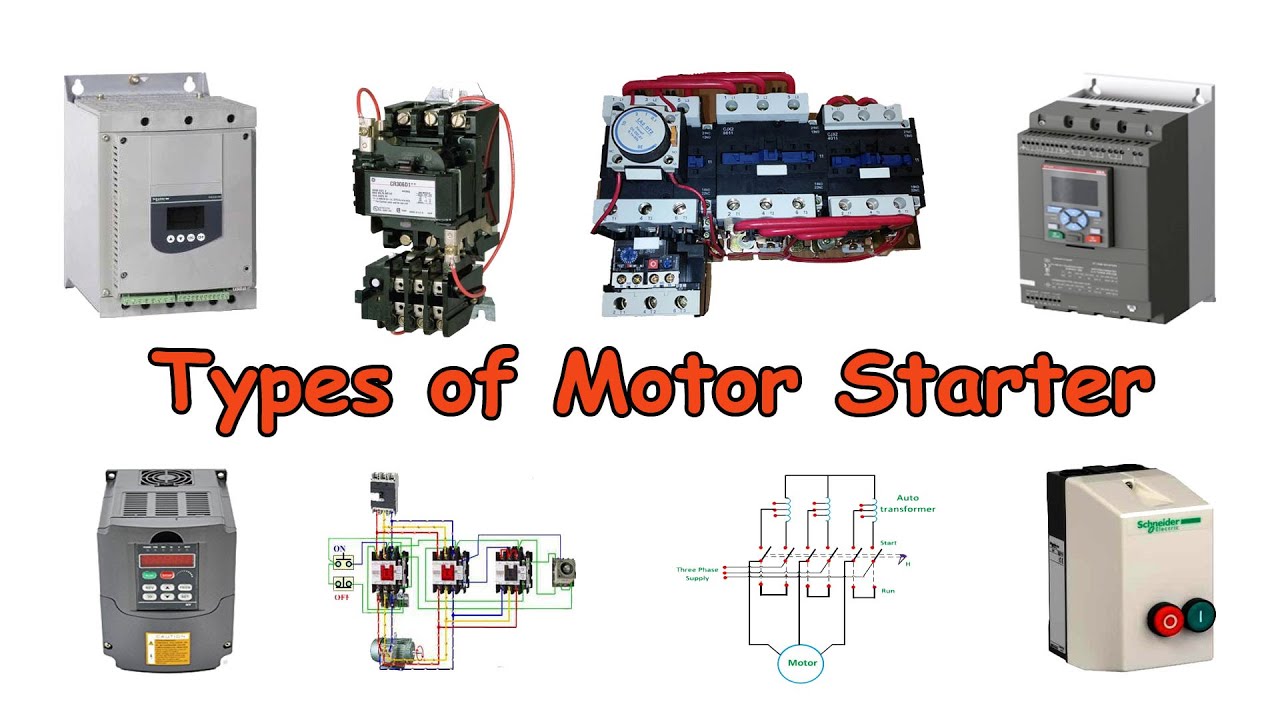

Understanding starter motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gear Reduction | Uses gears to increase torque, compact design | Heavy machinery, commercial vehicles | Pros: Higher torque output; Cons: More complex installation. |

| Permanent Magnet | Utilizes permanent magnets for efficiency | Automotive, motorcycles | Pros: Lightweight; Cons: Limited torque compared to other types. |

| DC Series Wound | Combines field and armature windings for high starting torque | Industrial equipment, agricultural machinery | Pros: Strong starting power; Cons: Higher power consumption. |

| Solenoid-activated | Engages starter motor via a solenoid switch | Automotive, heavy-duty trucks | Pros: Reliable engagement; Cons: Can be prone to solenoid failure. |

| High Torque | Designed for high-performance applications | Racing, off-road vehicles | Pros: Exceptional starting power; Cons: Higher cost and weight. |

What are the characteristics of Gear Reduction starter motors and their suitability for B2B buyers?

Gear reduction starter motors are known for their compact design and ability to deliver high torque output. This is achieved through a gear system that amplifies the motor’s torque, making it particularly effective for heavy machinery and commercial vehicles that require reliable starting power under demanding conditions. For B2B buyers, the complexity of installation may be a consideration, but the benefits of enhanced performance and durability make them a preferred choice for industries that rely on heavy equipment.

How do Permanent Magnet starter motors stand out in the market?

Permanent magnet starter motors are characterized by their lightweight construction and efficiency, making them an ideal option for automotive applications and motorcycles. These motors utilize permanent magnets instead of electromagnetic coils, resulting in a more compact design. For B2B buyers, the trade-off is a limitation in torque compared to other starter types. However, their ease of installation and lower weight often outweigh the downsides, particularly in sectors where weight savings are critical.

Why are DC Series Wound starter motors commonly used in industrial applications?

DC series wound starter motors are designed with both field and armature windings, which provide exceptional starting torque. This feature makes them well-suited for industrial equipment and agricultural machinery that need reliable starting power. While they consume more power, their strong starting capabilities are often essential for B2B buyers in sectors where performance is paramount. Buyers should consider the operational costs against the benefits of using these motors in demanding environments.

What advantages do solenoid-activated starter motors offer to B2B buyers?

Solenoid-activated starter motors engage through a solenoid switch, providing a reliable method for starting engines in automotive and heavy-duty truck applications. This type of motor is favored for its straightforward engagement mechanism, ensuring consistent performance. However, B2B buyers should be aware of the potential for solenoid failure, which could lead to operational downtime. The balance of reliability and simplicity often makes these motors a go-to choice for many businesses.

What makes High Torque starter motors a preferred choice in performance-driven sectors?

High torque starter motors are specifically designed for high-performance applications, such as racing and off-road vehicles. Their ability to deliver exceptional starting power is crucial in environments where quick and reliable engine starts are necessary. While they may come at a higher cost and added weight, B2B buyers in the automotive and motorsports industries often prioritize performance over these factors. Understanding the specific requirements of their applications will help buyers make informed decisions regarding their starter motor investments.

Key Industrial Applications of starter motor

| Industry/Sector | Specific Application of Starter Motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Vehicle Assembly Lines | Ensures reliable vehicle starts, enhancing production efficiency | Need for high-torque starters that meet OEM specifications, bulk purchasing options, and quick delivery times. |

| Agriculture | Tractors and Farm Equipment | Reliable starting in various weather conditions increases operational uptime | Durability and resistance to environmental factors are crucial, along with service availability in remote areas. |

| Construction | Heavy Machinery (e.g., Excavators, Cranes) | Minimizes downtime, ensuring continuous operation on job sites | Must comply with rigorous safety standards and be able to withstand heavy use; sourcing from reputable suppliers is vital. |

| Marine | Boats and Yachts | Reliable starting systems are critical for safety and performance | Need for marine-grade starters that resist corrosion and provide high performance under variable conditions. |

| Mining | Mining Equipment (e.g., Drills, Haulers) | Maximizes productivity and reduces maintenance costs | Sourcing should focus on components designed for extreme conditions, with considerations for after-sales support. |

How are Starter Motors Used in Automotive Manufacturing?

In the automotive manufacturing sector, starter motors are integral to vehicle assembly lines. They facilitate the initial engine start-up, which is essential for testing and quality assurance processes. Reliable starters ensure that vehicles can be tested efficiently, minimizing production delays. For international buyers, especially in regions like Europe and South America, sourcing high-torque starters that meet original equipment manufacturer (OEM) specifications is critical. Additionally, the ability to purchase in bulk and receive timely deliveries can significantly enhance production schedules.

What Role do Starter Motors Play in Agriculture?

Starter motors are vital in agricultural applications, particularly for tractors and other farm machinery. These motors provide reliable starting capabilities regardless of weather conditions, which is essential for maintaining operational uptime during planting and harvesting seasons. Buyers from Africa and the Middle East should prioritize sourcing durable starters that can withstand harsh environments and high usage rates. Availability of local service and support is also a key consideration, ensuring that agricultural operations can continue with minimal interruptions.

How are Starter Motors Essential in Construction?

In the construction industry, starter motors are used in heavy machinery such as excavators and cranes. A dependable starting system is crucial for minimizing downtime on job sites, directly impacting productivity and project timelines. Buyers in Europe, particularly in countries with stringent safety regulations like Germany, must ensure that the starter motors they procure comply with safety standards and can endure rigorous operational demands. Sourcing from reputable suppliers who offer robust warranties and after-sales support can mitigate risks associated with machinery failures.

Why are Starter Motors Important for Marine Applications?

In the marine industry, starter motors are essential for the operation of boats and yachts. A reliable starting system is critical for both safety and performance, especially in emergency situations. Marine-grade starter motors must resist corrosion and function effectively in varying environmental conditions. International buyers in regions with significant marine activity should focus on sourcing high-quality, specialized starter motors that meet maritime standards. Ensuring that suppliers provide adequate support and service is crucial for maintaining fleet readiness.

How Do Starter Motors Benefit the Mining Sector?

In mining operations, starter motors are integral to the functionality of equipment such as drills and haulers. These motors ensure that machinery starts reliably, maximizing productivity and minimizing maintenance costs. Buyers from South America and Africa should look for starter motors designed to withstand extreme conditions and heavy usage. It is important to consider suppliers that offer robust components along with after-sales support to address any operational challenges that may arise in remote mining locations.

3 Common User Pain Points for ‘starter motor’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Starter Motors for Diverse Vehicle Models

The Problem: B2B buyers, particularly those in regions with varied vehicle populations like Africa and South America, often struggle to find high-quality starter motors that are compatible with a wide range of vehicle makes and models. This issue is exacerbated by the lack of reliable suppliers who can guarantee the availability of parts that meet OEM specifications. As a result, businesses face extended downtimes and increased costs due to improper sourcing and the risk of using subpar components.

The Solution: To effectively address this challenge, B2B buyers should establish relationships with reputable suppliers who specialize in a diverse inventory of starter motors. When sourcing, it’s crucial to verify that suppliers provide detailed product specifications and compatibility information for each starter motor. Utilizing advanced search tools on supplier platforms can streamline the process by filtering options based on vehicle make, model, and year. Additionally, implementing a vendor management system can help track supplier performance and quality, ensuring that only the best components are procured.

Scenario 2: High Failure Rates of Starter Motors in Harsh Operating Conditions

The Problem: In many regions, particularly in the Middle East and Africa, vehicles are often subjected to extreme temperatures and challenging terrain, leading to high failure rates of starter motors. B2B buyers frequently face the dilemma of replacing failed units regularly, resulting in increased operational costs and downtime for fleets. This situation can undermine trust among clients and affect business reputation.

The Solution: To mitigate the impact of environmental factors on starter motor performance, B2B buyers should prioritize sourcing motors specifically designed for high durability and heat resistance. Look for products that feature robust construction, such as those with advanced insulation and weatherproofing. Additionally, consider collaborating with manufacturers that offer custom solutions tailored to the unique demands of your operating conditions. Regular maintenance and checks can also prolong the life of starter motors; implementing a preventive maintenance schedule will help identify potential issues before they lead to failures.

Scenario 3: Complexity in Installation and Maintenance of Starter Motors

The Problem: Many B2B buyers, especially those managing workshops or fleets, encounter challenges related to the installation and maintenance of starter motors. Inadequate training and lack of technical knowledge among staff can lead to improper installation, resulting in further operational issues and increased costs for repairs and replacements. This is particularly troublesome when dealing with advanced vehicle technologies that require specialized handling.

The Solution: To overcome installation and maintenance challenges, investing in training programs for technical staff is essential. Providing them with access to manufacturer-specific installation guides, video tutorials, and troubleshooting resources can enhance their skills significantly. Additionally, consider partnering with suppliers who offer technical support and after-sales service. Utilizing diagnostic tools to evaluate starter motor performance can also assist in identifying issues early, ensuring that any installation or operational problems are addressed promptly. Regular workshops and refresher courses can ensure that your team stays updated on best practices and new technologies in starter motor maintenance.

Strategic Material Selection Guide for starter motor

What Are the Key Materials Used in Starter Motors?

When selecting materials for starter motors, several factors influence performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in the manufacturing of starter motors, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Influence Starter Motor Performance?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for components that experience significant mechanical stress. It can withstand high temperatures and pressures, essential for the demanding environment of an automotive starter motor.

Pros & Cons: The primary advantage of steel is its strength and durability, which translates to a longer lifespan for starter motors. However, steel is prone to corrosion if not properly treated, which can lead to premature failure. Additionally, manufacturing processes for steel components can be complex and costly, impacting overall production costs.

Impact on Application: Steel is compatible with various automotive applications, particularly in regions with extreme weather conditions. However, its weight can be a disadvantage in applications where reducing weight is a priority.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN for steel quality. Corrosion resistance treatments may be necessary in humid climates, making it crucial to understand local environmental conditions.

What Role Does Aluminum Play in Starter Motors?

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it an attractive option for automotive applications. It also has good thermal conductivity, which can help dissipate heat generated during operation.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which can enhance vehicle efficiency and performance. However, it may not withstand high mechanical stresses as effectively as steel, potentially leading to reduced durability in high-performance applications.

Impact on Application: Aluminum is particularly beneficial in applications where weight reduction is critical, such as in electric vehicles. Its corrosion resistance makes it suitable for humid or coastal environments.

Illustrative image related to starter motor

Considerations for International Buyers: Buyers should verify that aluminum components meet international standards such as JIS or ASTM. In markets like Africa and South America, where cost considerations are paramount, the higher initial cost of aluminum may be a concern.

How Does Copper Enhance Electrical Performance in Starter Motors?

Key Properties: Copper is an excellent conductor of electricity, with high thermal and electrical conductivity. It is also resistant to corrosion, especially when alloyed with other metals.

Pros & Cons: The primary advantage of copper is its ability to efficiently transmit electrical current, which is critical for starter motor performance. However, copper is relatively expensive compared to other materials, which can increase overall production costs.

Impact on Application: Copper is vital for electrical connections within the starter motor, ensuring reliable performance. Its thermal properties help manage heat, reducing the risk of electrical failures.

Illustrative image related to starter motor

Considerations for International Buyers: Compliance with electrical standards is crucial, especially in regions like Germany, where regulations are stringent. Buyers should also consider the fluctuating prices of copper in the global market, which can affect procurement strategies.

What Benefits Does Plastic Offer in Starter Motor Components?

Key Properties: Plastic materials, particularly high-performance polymers, are lightweight and resistant to corrosion and chemical degradation. They can be molded into complex shapes, allowing for innovative designs.

Pros & Cons: The main advantage of plastic is its versatility and weight reduction potential. However, plastics may not offer the same level of mechanical strength as metals, which can limit their use in high-stress applications.

Impact on Application: Plastics are often used in non-load-bearing components of starter motors, such as housings and insulators. Their resistance to chemicals and moisture makes them suitable for various environments.

Considerations for International Buyers: Buyers should ensure that plastic materials meet relevant safety and performance standards, particularly in regions with strict regulations. Understanding the local market’s acceptance of plastic components is also essential.

Illustrative image related to starter motor

Summary Table of Material Selection for Starter Motors

| Material | Typical Use Case for starter motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, gears | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Housing, lightweight components | Lightweight, corrosion-resistant | Lower mechanical strength | High |

| Copper | Electrical connections | Excellent conductivity | Higher cost | High |

| Plastic | Non-load-bearing parts, insulators | Versatile, lightweight | Limited mechanical strength | Low |

This strategic material selection guide provides insights for international B2B buyers, helping them make informed decisions based on performance requirements, cost considerations, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for starter motor

What Are the Key Stages in the Manufacturing Process of Starter Motors?

The manufacturing process of starter motors involves several critical stages that ensure the end product meets stringent performance and durability standards. Understanding these stages can help B2B buyers assess the quality and reliability of the components they are sourcing.

Material Preparation: How Are Components Sourced and Processed?

The manufacturing process begins with the careful selection of raw materials, typically comprising high-grade metals and polymers. Steel is commonly used for the housing, while copper is favored for windings due to its excellent electrical conductivity.

Illustrative image related to starter motor

After material selection, the components undergo various preparation processes, including cutting, forging, and machining. These processes shape the raw materials into precise components that will later be assembled. For instance, the stator and rotor are machined to exact dimensions to ensure optimal performance and fit.

What Techniques Are Used in the Forming Stage of Starter Motors?

Once the materials are prepared, they move to the forming stage, where they are shaped into their final forms. This involves techniques such as die-casting for the motor housing and stamping for other metal components.

Advanced forming techniques, such as CNC machining, are employed to ensure accuracy. This precision is crucial, as even minor deviations can lead to performance issues in the final product. In high-quality starter motors, components are often designed for easy assembly, which can significantly reduce manufacturing costs and time.

Illustrative image related to starter motor

How Is the Assembly Process Conducted for Starter Motors?

The assembly of starter motors is a meticulous process that involves integrating various components, including the armature, solenoid, and housing. Each component must be correctly aligned and secured to ensure the motor functions as intended.

Automated assembly lines often assist in this stage, enhancing efficiency and consistency. Each starter motor is assembled in a clean environment to minimize contamination and defects. Workers are trained in best practices to guarantee that every assembly step adheres to quality standards.

What Finishing Techniques Are Applied to Ensure Quality?

The finishing stage involves several treatments aimed at enhancing the durability and aesthetic appeal of the starter motor. This may include painting, coating, and polishing. These processes not only improve the appearance but also provide corrosion resistance, which is particularly important in automotive applications.

Illustrative image related to starter motor

Additionally, final inspections are conducted to identify any defects or inconsistencies. This step ensures that only products meeting quality specifications move forward to packaging and distribution.

How Is Quality Assurance Implemented in Starter Motor Manufacturing?

Quality assurance (QA) is a critical aspect of the starter motor manufacturing process. It encompasses various checks and standards to ensure that each motor meets international and industry-specific benchmarks.

What International Standards Govern Starter Motor Quality?

International standards such as ISO 9001 play a pivotal role in defining the quality management systems of manufacturers. Adhering to these standards ensures that companies maintain consistent quality throughout their processes, from material selection to final assembly.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for certain automotive applications are crucial. These certifications provide assurance to B2B buyers that the products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. The primary checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): During manufacturing, random samples are tested at various stages to detect any deviations from quality standards.

- Final Quality Control (FQC): Before packaging, finished starter motors undergo comprehensive testing, including performance and durability tests.

These checkpoints create a robust QC framework that helps manufacturers maintain high standards.

What Testing Methods Are Commonly Used for Starter Motors?

Various testing methods are employed to ensure that starter motors function reliably under different conditions. Common tests include:

- Electrical Testing: Measures the motor’s electrical performance, including current draw and resistance.

- Mechanical Testing: Assesses the physical integrity of components, such as torque and vibration resistance.

- Thermal Testing: Evaluates how the motor performs under extreme temperatures, ensuring it can withstand real-world conditions.

These tests are critical for identifying potential failures before the motors reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is paramount.

What Steps Can Buyers Take to Ensure Supplier Compliance?

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Audits can reveal whether they adhere to international standards and best practices.

-

Requesting Quality Reports: Buyers should request documentation that outlines the supplier’s quality assurance processes, including results from IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s production facilities and quality control procedures.

-

Certifications and Compliance: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 and CE. This adds an additional layer of confidence in the supplier’s commitment to quality.

What Are the Nuances of QC and Certification for International Buyers?

International buyers should be aware of the nuances in quality control and certification requirements across different regions. For instance, European buyers may prioritize CE certification, while buyers from other regions may focus on compliance with local standards.

Understanding these regional differences can help buyers make informed decisions when selecting suppliers. Additionally, maintaining clear communication with suppliers regarding quality expectations is crucial for successful international transactions.

In conclusion, the manufacturing processes and quality assurance measures for starter motors are complex and highly regulated. By understanding these processes and actively verifying supplier compliance, B2B buyers can ensure they are sourcing high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor’

The following guide is designed to assist B2B buyers in effectively sourcing starter motors. This checklist will help ensure that your procurement process is thorough, efficient, and aligned with your operational needs.

Illustrative image related to starter motor

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to establish clear technical specifications for the starter motors you require. Consider factors such as the vehicle make and model, engine size, and power requirements. This clarity will streamline your search and help suppliers provide the most suitable options for your needs.

- Power Output: Determine the torque and power output required to match your engine specifications.

- Compatibility: Ensure the starter motor is compatible with the vehicle or machinery it will be used in.

Step 2: Research and Identify Potential Suppliers

Conduct comprehensive research to identify potential suppliers that specialize in starter motors. Utilize industry directories, trade shows, and online marketplaces to compile a list of reputable manufacturers and distributors.

- Supplier Reputation: Look for suppliers with a strong reputation in the industry, evidenced by reviews and testimonials.

- Regional Considerations: Pay attention to suppliers with experience in your target regions, such as Africa, South America, the Middle East, and Europe, as they will understand local market dynamics.

Step 3: Evaluate Supplier Certifications and Quality Standards

Once you’ve identified potential suppliers, it’s vital to assess their certifications and quality standards. This step helps ensure that the starter motors meet industry regulations and performance benchmarks.

Illustrative image related to starter motor

- ISO Certification: Verify if the supplier holds relevant ISO certifications, indicating adherence to quality management standards.

- Testing Protocols: Inquire about the testing protocols used for their starter motors, such as durability and performance testing.

Step 4: Request Samples and Conduct Performance Tests

Before making a bulk purchase, request samples of the starter motors for evaluation. Testing these samples will provide insights into their performance and reliability.

- Installation Testing: Assess how easily the starter motor can be installed and whether it integrates smoothly with existing systems.

- Performance Metrics: Monitor key performance metrics such as start-up time and torque generation during testing.

Step 5: Negotiate Terms and Pricing

Once you have selected your preferred suppliers, initiate negotiations to finalize terms and pricing. This step is crucial to ensure that you receive the best value for your investment.

- Bulk Discounts: Inquire about discounts for bulk purchases, as this can significantly reduce costs.

- Payment Terms: Discuss flexible payment options and terms that align with your budget and cash flow.

Step 6: Establish Logistics and Delivery Timelines

Effective logistics management is essential to ensure timely delivery of starter motors. Discuss logistics with your suppliers and establish clear delivery timelines.

- Shipping Options: Evaluate different shipping options, considering both cost and delivery speed.

- Inventory Management: Plan for inventory levels to avoid stock shortages or excess, which can impact your operations.

Step 7: Review Post-Purchase Support and Warranty Policies

Finally, ensure that your supplier offers robust post-purchase support and warranty policies. This will safeguard your investment and provide peace of mind regarding the performance of the starter motors.

- Warranty Duration: Understand the warranty duration and what it covers, including potential defects or performance issues.

- Support Channels: Identify available support channels for troubleshooting and assistance post-purchase.

By following this step-by-step checklist, B2B buyers can navigate the sourcing process for starter motors effectively, ensuring they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for starter motor Sourcing

What Are the Key Cost Components in Starter Motor Manufacturing?

When sourcing starter motors, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The raw materials for starter motors, such as copper for wiring, steel for casing, and specialized alloys for internal components, significantly influence cost. The price of these materials can fluctuate based on market demand and availability, particularly for international buyers who may face additional tariffs or import duties.

-

Labor: Labor costs vary depending on the region. Manufacturing in countries with higher labor costs, such as Germany, can lead to elevated prices. Conversely, sourcing from regions with lower labor costs may reduce overall expenses, but it’s essential to consider the trade-offs in quality and reliability.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative costs associated with production facilities. Efficient manufacturing processes can help mitigate these costs, making it vital to assess potential suppliers’ operational efficiencies.

-

Tooling: Initial tooling costs can be significant, especially for custom or high-spec starter motors. These costs are amortized over production runs, so larger orders can help distribute these expenses, making them more manageable.

-

Quality Control (QC): Rigorous QC processes ensure that starter motors meet industry standards. Investing in quality checks can lead to higher upfront costs but can save money in the long run by reducing returns and warranty claims.

-

Logistics: Transportation costs are crucial, particularly for international shipments. Factors such as shipping method, distance, and customs duties can all affect the final landed cost of starter motors.

-

Margin: Suppliers typically mark up their prices to ensure profitability. The margin varies based on market competition, supplier reputation, and the complexity of the product.

What Influences Pricing for Starter Motors in International Markets?

Several factors can influence the pricing of starter motors, particularly for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Higher volumes can lead to discounts, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Material Quality and Certifications: Motors built with higher-quality materials or certified to specific industry standards (such as ISO or SAE) typically command higher prices. Buyers should weigh the importance of certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their assurance of quality and service, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for calculating total landed costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect pricing and the risk associated with shipping.

How Can Buyers Negotiate Better Prices for Starter Motors?

Effective negotiation strategies can help buyers secure favorable terms:

-

Research: Understand the market landscape and average pricing to establish a baseline for negotiations. This knowledge empowers buyers to negotiate confidently.

-

Explore Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, consider the TCO, which includes maintenance, durability, and potential downtime. Highlighting TCO can justify higher initial investments for quality products.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Suppliers may offer discounts for repeat business or larger orders.

-

Request Multiple Quotes: Obtaining quotes from various suppliers allows buyers to compare prices and negotiate better deals. This competitive approach can reveal significant pricing discrepancies.

-

Be Aware of International Pricing Nuances: For buyers from regions like Africa, South America, and the Middle East, understanding local tariffs, import duties, and currency fluctuations can provide insight into total costs and help in negotiations.

In summary, a comprehensive understanding of the cost structure, pricing influencers, and effective negotiation strategies is essential for B2B buyers sourcing starter motors globally. By leveraging these insights, businesses can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing starter motor With Other Solutions

Introduction to Alternative Solutions for Starter Motors

In the automotive sector, the starter motor plays a crucial role in initiating the engine’s operation. However, various alternative solutions and technologies can also facilitate this process, each with unique advantages and disadvantages. This analysis will compare the traditional starter motor with alternatives such as the Integrated Starter Generator (ISG) and Manual Starting Systems, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Starter Motor | Integrated Starter Generator (ISG) | Manual Starting Systems |

|---|---|---|---|

| Performance | High torque output for reliable starts | Provides both starting and regenerative braking | Basic mechanical engagement, less torque |

| Cost | Moderate ($100-$250) | Higher upfront cost ($300-$800) | Low (under $100) |

| Ease of Implementation | Standard installation in vehicles | Requires additional modifications to the electrical system | Simple, but requires physical effort |

| Maintenance | Regular checks needed | Low, but dependent on electrical system | Minimal, but manual effort can be tiring |

| Best Use Case | Conventional vehicles | Hybrid and electric vehicles | Older models or specific applications (e.g., lawnmowers) |

Detailed Breakdown of Alternatives

Integrated Starter Generator (ISG)

The Integrated Starter Generator combines the functions of a starter motor and an alternator into a single unit, primarily used in hybrid and electric vehicles. One of its main advantages is the ability to regenerate energy during braking, enhancing overall vehicle efficiency. However, the ISG is typically more expensive than traditional starter motors and may require complex installation, making it less suitable for retrofitting in older vehicles. This solution is best for businesses focused on modern, eco-friendly automotive solutions.

Manual Starting Systems

Manual starting systems, often seen in older vehicles and certain machinery, use a crank or pull mechanism to start the engine. While this method is significantly cheaper and simpler to implement, it lacks the torque and reliability of electric starters. Maintenance is minimal, but the physical effort required can be a drawback for some users. This option is ideal for niche markets where cost is a primary concern, such as agricultural equipment or older vehicle restorations.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate starting solution for a vehicle or equipment, B2B buyers should consider the specific application, budget constraints, and maintenance capabilities. For modern vehicles, the Integrated Starter Generator offers efficiency and advanced features, albeit at a higher cost. In contrast, traditional starter motors are well-suited for most vehicles, providing reliability and performance without the complexity of integration. For older models or simpler machinery, manual systems may suffice if cost-effectiveness is paramount. Ultimately, understanding the operational requirements and financial implications will guide buyers in making the most informed decision tailored to their unique circumstances.

Essential Technical Properties and Trade Terminology for starter motor

What Are the Key Technical Properties of Starter Motors?

When selecting starter motors for various applications, understanding the technical properties is crucial for B2B buyers. Here are some critical specifications to consider:

1. Material Grade

The materials used in manufacturing starter motors, such as high-grade steel or aluminum, impact durability and performance. High-quality materials ensure resistance to corrosion and wear, which is essential for longevity, especially in harsh environments. For B2B buyers, choosing the right material grade can minimize maintenance costs and improve the reliability of vehicles in their fleets.

2. Torque Rating

Torque rating indicates the rotational force a starter motor can generate to crank the engine. Measured in Newton-meters (Nm), this specification is vital, as it ensures the motor can handle the engine’s size and requirements. B2B purchasers need to match the torque rating with the engine specifications to avoid starting failures, which can result in operational downtime.

Illustrative image related to starter motor

3. Voltage Rating

Most starter motors operate at 12V or 24V systems. The voltage rating is a critical factor because it must align with the vehicle’s electrical system. A mismatch can lead to performance issues or complete failure. B2B buyers should ensure that the starter motor’s voltage rating matches the requirements of their specific applications to guarantee optimal performance.

4. Current Draw

Current draw refers to the amount of electrical current the starter motor consumes during operation, usually measured in amperes (A). High current draw can indicate a powerful starter but may also lead to battery drain if not managed properly. Understanding current draw helps B2B buyers assess the compatibility of the starter with their vehicle’s electrical system and battery capacity.

5. Cooling Mechanism

Many starter motors incorporate built-in cooling mechanisms, such as venting or heat-resistant materials, to dissipate heat generated during operation. This feature is particularly important for heavy-duty applications where starters are subjected to frequent and prolonged use. B2B buyers should prioritize motors with effective cooling systems to extend service life and maintain performance.

Illustrative image related to starter motor

What Are Common Trade Terms Associated with Starter Motors?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms related to starter motors:

1. OEM (Original Equipment Manufacturer)

OEM refers to products made by the original manufacturer of a vehicle. Purchasing OEM starter motors ensures compatibility and quality, as they meet the manufacturer’s specifications. B2B buyers often prefer OEM parts for their reliability and performance in specific vehicle models.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory and costs effectively. It can also impact procurement strategies, particularly for companies looking to optimize their supply chain.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers requesting pricing and terms for specific products. This process is crucial in B2B transactions, as it helps buyers compare offers from different suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers engaged in international trade, as they clarify cost responsibilities and delivery obligations.

5. Remanufactured

Remanufactured starter motors are refurbished units that have been restored to meet or exceed original performance specifications. For cost-conscious B2B buyers, remanufactured options provide a balance of affordability and reliability, making them an attractive choice for fleet management.

By grasping these essential technical properties and industry terms, B2B buyers can make more informed decisions when sourcing starter motors, ultimately leading to improved operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the starter motor Sector

What Are the Current Market Dynamics and Key Trends in the Starter Motor Sector?

The global starter motor market is experiencing significant growth, driven by the increasing demand for vehicles and advancements in automotive technologies. Key trends include the rise of electric vehicles (EVs), which require specialized starter motors, and the growing preference for remanufactured components due to their cost-effectiveness and reduced environmental impact. Additionally, the integration of advanced technologies, such as smart systems and IoT capabilities, is reshaping sourcing strategies for international B2B buyers.

In regions like Africa and South America, the demand for affordable and durable starter motors is on the rise, influenced by the expanding automotive sectors and increasing vehicle ownership. In contrast, European markets, particularly Germany, are witnessing a shift towards high-performance and technologically advanced starters that support eco-friendly vehicles. Meanwhile, Middle Eastern markets are focusing on sourcing robust starter motors that can withstand extreme temperatures and harsh operating conditions.

B2B buyers should also consider the importance of flexible sourcing strategies to adapt to fluctuating market demands and supply chain disruptions. Collaborating with reliable suppliers who offer customizable solutions can enhance competitiveness and ensure timely delivery. Understanding regional market dynamics and customer preferences is essential for international buyers looking to navigate the complexities of the starter motor sector effectively.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in the Starter Motor Sector?

As sustainability becomes increasingly vital in global supply chains, B2B buyers in the starter motor sector must prioritize ethical sourcing and environmentally friendly practices. The environmental impact of starter motor production, including resource extraction and waste generation, necessitates a shift towards sustainable materials and manufacturing processes. Buyers should seek suppliers that utilize recycled materials and have certifications such as ISO 14001, which demonstrates commitment to environmental management.

Ethical supply chains are also crucial, particularly in regions where labor practices may be scrutinized. B2B buyers should ensure that their suppliers adhere to fair labor practices and maintain transparency throughout the sourcing process. This not only protects brand reputation but also aligns with the growing consumer demand for ethically sourced products.

Additionally, the adoption of green certifications and materials in the production of starter motors can enhance product appeal and marketability. By prioritizing sustainability, B2B buyers not only contribute to environmental conservation but also align with global trends that favor responsible business practices.

What Is the Brief Evolution of the Starter Motor Industry?

The starter motor industry has evolved significantly since its inception in the early 20th century. Initially, starter motors were mechanical devices powered by hand cranks, which posed safety and convenience challenges. The introduction of the electric starter motor in the 1910s revolutionized vehicle operation, providing a safer and more reliable method of starting internal combustion engines.

Illustrative image related to starter motor

Over the decades, advancements in materials and technology have led to the development of high-torque starter motors capable of delivering better performance and efficiency. The rise of electronic control systems in vehicles has further transformed starter motor design, enabling features such as remote starting and improved energy management. As the automotive industry continues to embrace electric and hybrid vehicles, the starter motor sector is poised for continued innovation, presenting new opportunities and challenges for B2B buyers navigating this dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of starter motor

-

1. How do I solve starting issues with my vehicle?

To address starting issues, first check the battery for voltage and connections, as these are common culprits. If the battery is in good condition, inspect the starter motor and its components, including the solenoid and wiring. Look for signs of wear or corrosion. If the starter is suspected to be faulty, consider replacing it with a new or remanufactured unit that meets OEM specifications. Always consult a professional mechanic if you are unsure about the diagnosis or repair process. -

2. What is the best starter motor for commercial vehicles?

When sourcing starter motors for commercial vehicles, prioritize high-torque starters designed for heavy-duty applications. Look for products from reputable manufacturers that offer warranties and meet OEM specifications. Consider factors such as the specific engine type and model of the vehicle, as well as compatibility with your operational requirements. Brands like Duralast and ACDelco are often recommended for their reliability and performance in demanding conditions. -

3. How do I vet suppliers for starter motors in international markets?

To effectively vet suppliers, begin by researching their reputation through reviews and testimonials from previous customers. Verify their certifications and compliance with international quality standards, such as ISO. It’s also beneficial to request samples of their products to assess quality firsthand. Engaging in direct communication about your needs and expectations can provide insight into their customer service and reliability. -

4. What are the typical minimum order quantities (MOQ) for starter motors?

Minimum order quantities for starter motors can vary widely depending on the supplier and product type. Typically, MOQs can range from 10 to 100 units for bulk purchases, with manufacturers offering lower MOQs for custom or specialized products. Always discuss MOQs upfront to align with your purchasing strategy, especially if you are entering new markets or trying to manage inventory efficiently. -

5. What payment terms should I expect when buying starter motors internationally?

Payment terms can differ significantly across suppliers and regions. Common options include advance payment, letters of credit, and payment upon delivery. It’s crucial to establish clear payment terms before finalizing the purchase. Consider discussing payment plans that offer some flexibility, especially for larger orders, to mitigate financial risks. Always ensure that payment methods are secure to protect against fraud. -

6. How can I ensure quality assurance for starter motors sourced internationally?

To ensure quality assurance, request detailed quality control processes from your supplier. This can include pre-shipment inspections and compliance with international standards. It’s advisable to establish a clear quality assurance agreement that outlines the criteria for acceptable quality. Consider hiring third-party inspection services to evaluate the products before they are shipped, ensuring that they meet your specifications. -

7. What logistics considerations should I be aware of when importing starter motors?

When importing starter motors, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics provider familiar with international shipping processes to minimize delays. Be sure to understand the documentation required for customs clearance, including bills of lading and invoices. Additionally, plan for lead times in production and shipping to avoid disruptions in your supply chain. -

8. Can I customize starter motors for specific applications?

Yes, many manufacturers offer customization options for starter motors to suit specific applications, such as higher torque requirements or unique mounting configurations. When discussing customization, provide detailed specifications about your needs, including voltage, size, and performance criteria. Custom orders may have longer lead times and higher costs, so it’s important to factor these into your procurement planning.

Top 4 Starter Motor Manufacturers & Suppliers List

1. RAC – Starter Motor

Domain: rac.co.uk

Registered: 1996 (29 years)

Introduction: Starter Motor: An essential electric component in internal combustion vehicles that initiates engine rotation when the ignition is engaged. It operates by receiving an electrical signal from the ignition system, activating the starter solenoid, which sends a charge to the battery and engages the starter motor. Common causes of failure include broken solenoid, mechanical issues, electrical faults, …

2. Haynes – Starter Motor

Domain: us.haynes.com

Registered: 1996 (29 years)

Introduction: This company, Haynes – Starter Motor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Auto Electro – Starter Motors

Domain: autoelectro.co.uk

Registered: 1999 (26 years)

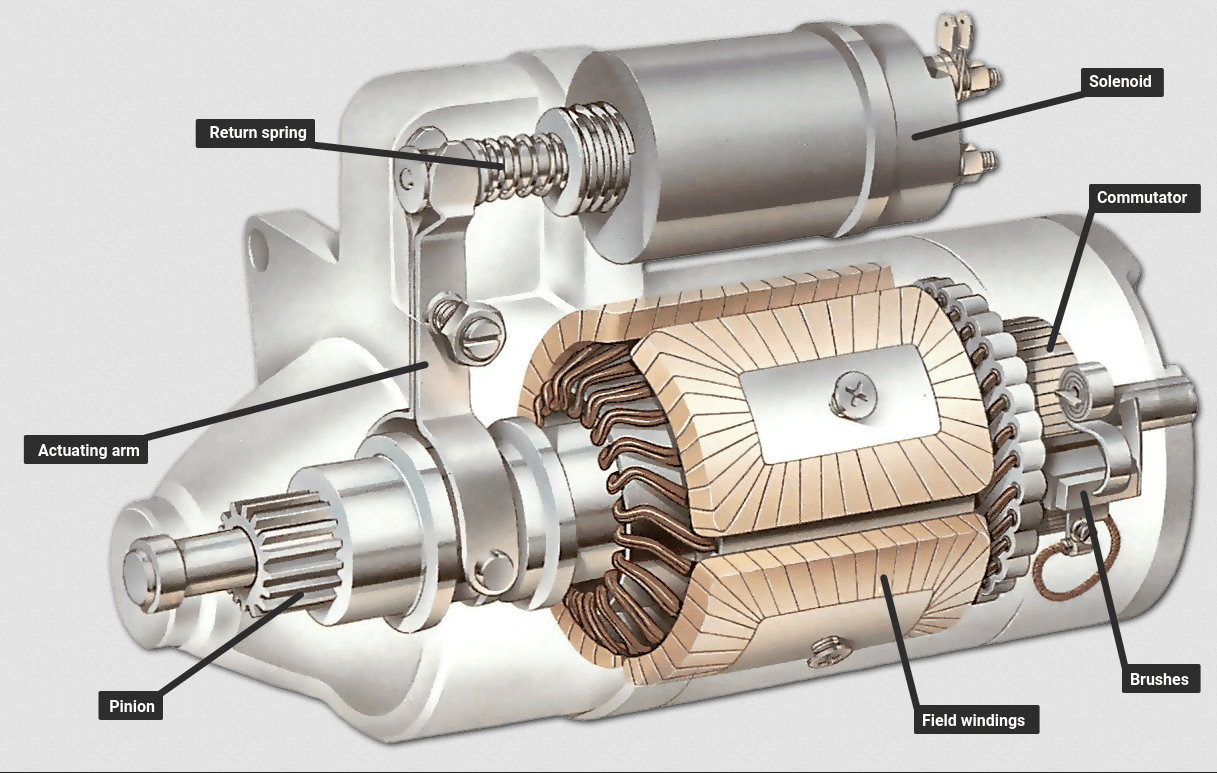

Introduction: Starter motors are essential components that engage the engine during ignition, allowing it to turn over and suck in air for combustion. Key components include:

– Armature: An electromagnet mounted on the drive shaft, made of laminated soft iron core with conductor loops.

– Commutator: A section of the shaft that conducts electricity, made of two plates attached to the armature axle.

– Brushes:…

4. ScienceDirect – Starter Motor

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: A starter motor is a device essential for running an internal combustion engine up to a speed sufficient for satisfactory carburation. Key features include:

– Engagement with the flywheel through a pinion, utilizing inertia-engaged or pre-engaged methods to transmit torque.

– Mounted on the engine casing with a pinion that engages with the flywheel teeth, typically with a gear ratio of about 10:…

Strategic Sourcing Conclusion and Outlook for starter motor

What Are the Key Takeaways for Strategic Sourcing of Starter Motors?

In the rapidly evolving automotive sector, strategic sourcing of starter motors is essential for optimizing supply chains and ensuring operational efficiency. Key takeaways include the importance of selecting high-quality components that meet or exceed OEM specifications, as well as the value of building relationships with reliable suppliers. Buyers should prioritize suppliers that offer comprehensive support, including rapid delivery options and robust warranties, which can significantly reduce downtime and maintenance costs.

How Can International Buyers Prepare for Future Market Trends?

As the global automotive market continues to expand, particularly in regions such as Africa, South America, the Middle East, and Europe, international buyers must stay ahead of emerging trends. This includes adapting to technological advancements like electric and hybrid vehicles, which may alter starter motor requirements. By leveraging strategic sourcing practices, businesses can enhance their competitive edge, ensuring they are well-positioned to meet the evolving demands of the market.

What Steps Should Buyers Take to Enhance Their Sourcing Strategy?

To maximize the benefits of strategic sourcing, buyers should conduct thorough market research and align their sourcing strategies with long-term business goals. Establishing partnerships with manufacturers who prioritize innovation and sustainability will be crucial. As we look ahead, now is the time for international B2B buyers to take proactive steps in refining their sourcing strategies to ensure resilience and adaptability in a dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.