Introduction: Navigating the Global Market for starter motor components

In the dynamic landscape of the global market for starter motor components, sourcing reliable and high-quality parts is a critical challenge for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. Starter motors are essential for the ignition of internal combustion engines, making the performance and reliability of these components crucial for various applications in automotive, industrial machinery, and commercial vehicles. This comprehensive guide delves into the different types of starter motor components, their applications, and the intricacies of supplier vetting.

From understanding the core elements, such as armatures and solenoids, to exploring cost factors and market trends, this guide equips international buyers with the insights necessary for making informed purchasing decisions. It also highlights the importance of evaluating suppliers based on quality assurance, compliance with industry standards, and post-purchase support. By leveraging this guide, B2B buyers can navigate the complexities of sourcing starter motor components effectively, ensuring they partner with trustworthy suppliers who meet their operational needs while optimizing their supply chain efficiency. With a focus on actionable insights, this resource empowers businesses to enhance their procurement strategies in a competitive marketplace.

Table Of Contents

- Top 4 Starter Motor Components Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter motor components

- Understanding starter motor components Types and Variations

- Key Industrial Applications of starter motor components

- 3 Common User Pain Points for ‘starter motor components’ & Their Solutions

- Strategic Material Selection Guide for starter motor components

- In-depth Look: Manufacturing Processes and Quality Assurance for starter motor components

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor components’

- Comprehensive Cost and Pricing Analysis for starter motor components Sourcing

- Alternatives Analysis: Comparing starter motor components With Other Solutions

- Essential Technical Properties and Trade Terminology for starter motor components

- Navigating Market Dynamics and Sourcing Trends in the starter motor components Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter motor components

- Strategic Sourcing Conclusion and Outlook for starter motor components

- Important Disclaimer & Terms of Use

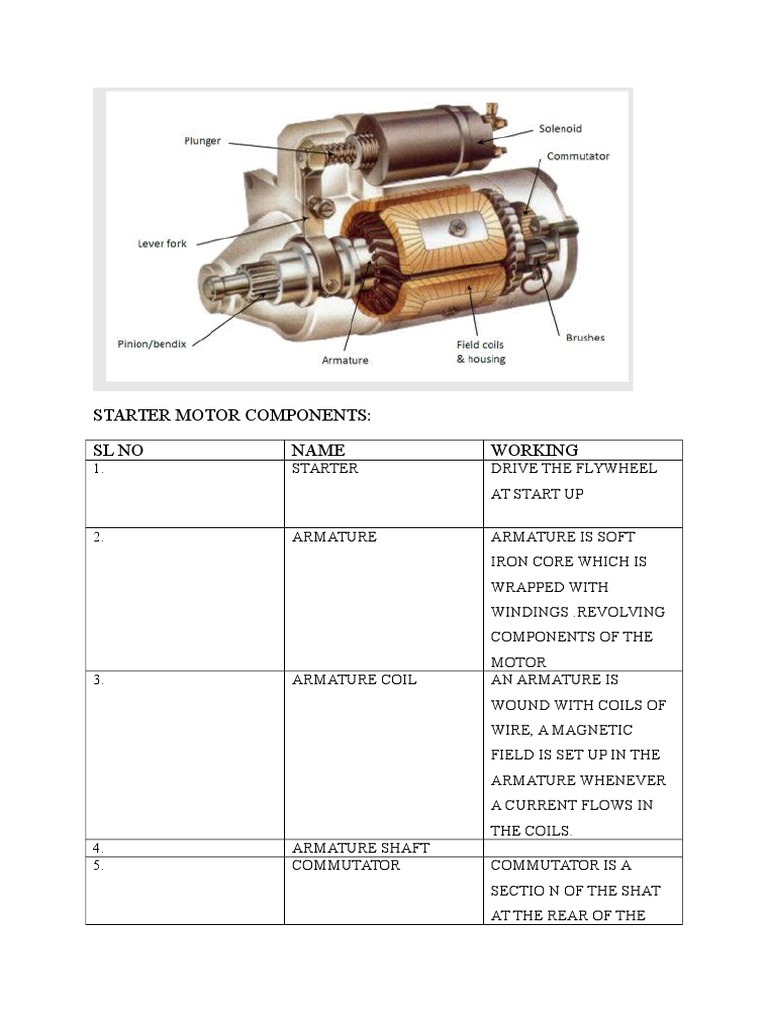

Understanding starter motor components Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Armature | Electromagnet core wrapped with conductors; mounted on a shaft. | Automotive, Industrial Machinery | Pros: Essential for operation; Cons: Requires precise manufacturing. |

| Commutator | Composed of two plates for electrical connection; part of the armature. | Automotive, Power Tools | Pros: Enables efficient current distribution; Cons: Can wear out over time. |

| Solenoid | Contains coils wrapped around a movable core; acts as a switch. | Automotive, Heavy Equipment | Pros: Reliable engagement mechanism; Cons: Can fail due to wear. |

| Pinion | Gear mechanism that engages with the flywheel; critical for starting. | Automotive, Marine Applications | Pros: Directly initiates engine operation; Cons: Vulnerable to wear and tear. |

| Field Coils | Create magnetic fields when energized; vital for armature rotation. | Automotive, Generators | Pros: Efficient operation; Cons: Complexity in installation and maintenance. |

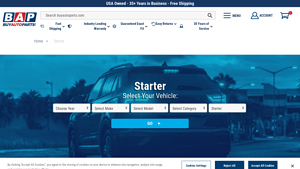

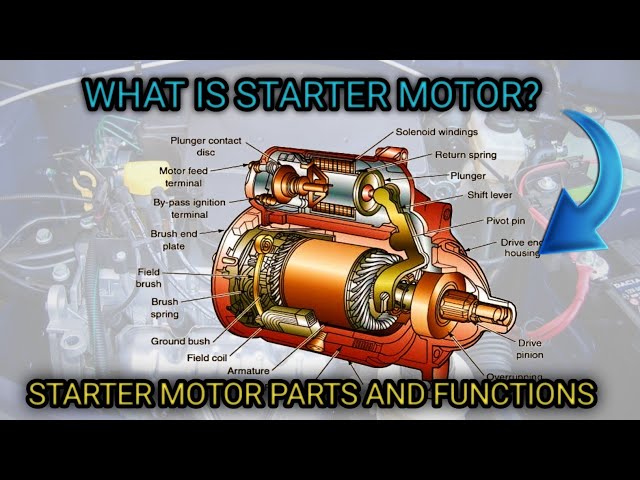

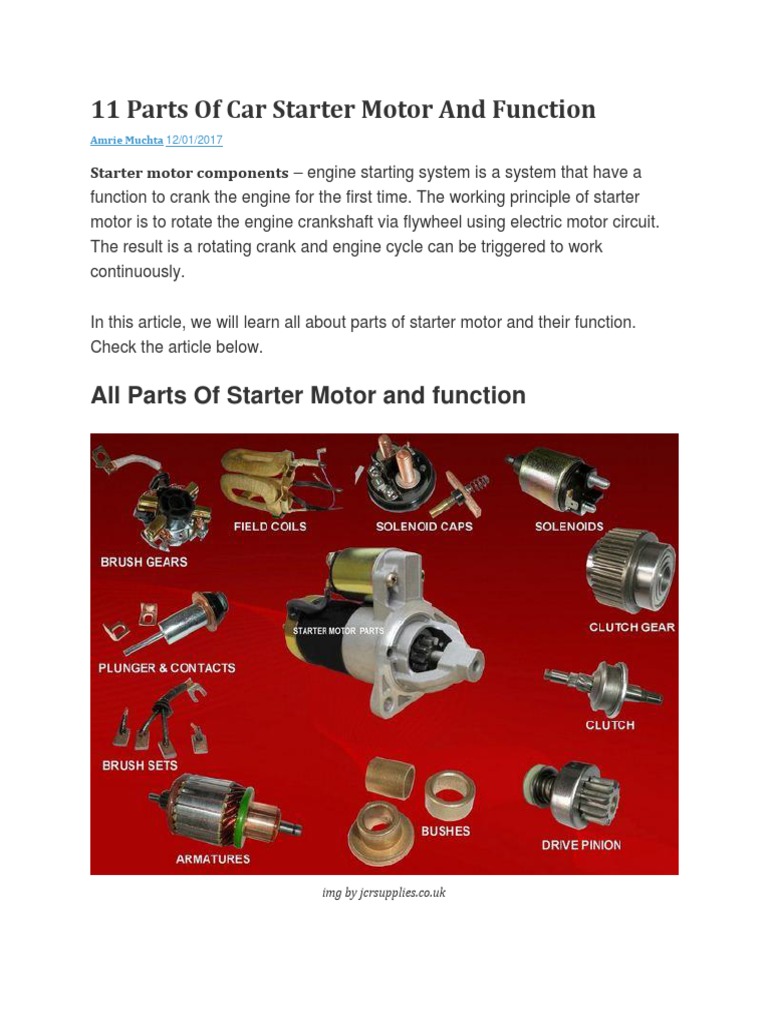

What Are the Key Characteristics of Armatures in Starter Motors?

The armature serves as the core of the starter motor, functioning as an electromagnet that is crucial for initiating engine cranking. Comprised of a laminated soft iron core and multiple conductor windings, it is designed to efficiently convert electrical energy into mechanical energy. B2B buyers should prioritize sourcing high-quality armatures, as their performance directly impacts the reliability of the starter motor. Considerations include the durability of materials used and the precision of the manufacturing process.

How Does the Commutator Function in Starter Motors?

The commutator is integral to the operation of the starter motor, facilitating the transfer of electrical current to the armature. It consists of two plates that provide connections to the armature coil, allowing for efficient electromagnetic function. Buyers must consider the quality and durability of commutators as they can wear out over time, potentially leading to starter failure. Selecting a reliable supplier who can provide commutators with high wear resistance is essential for long-term operations.

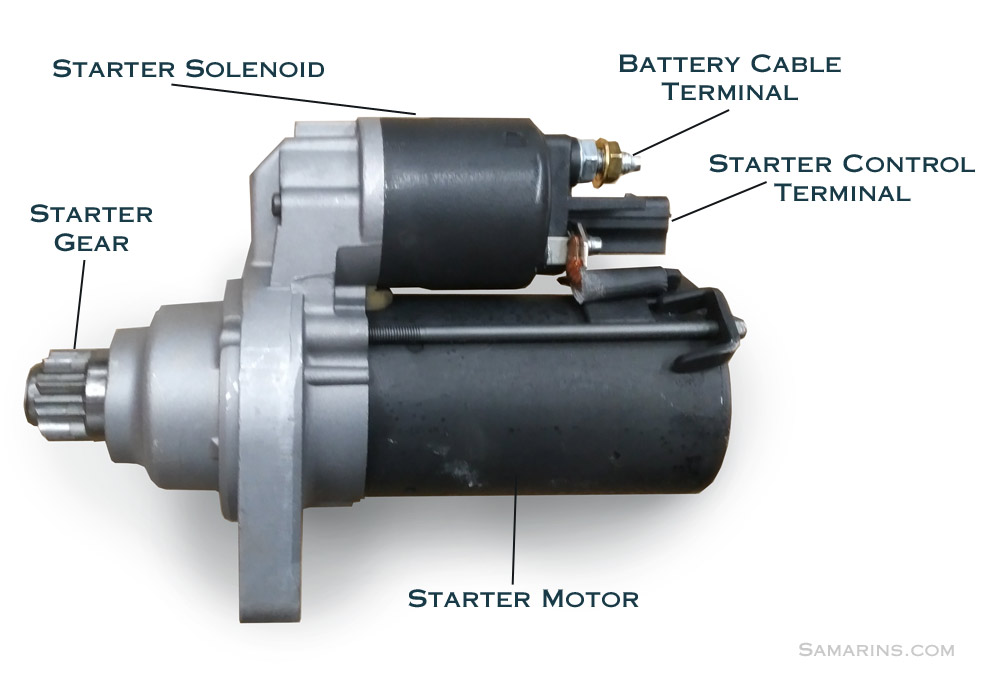

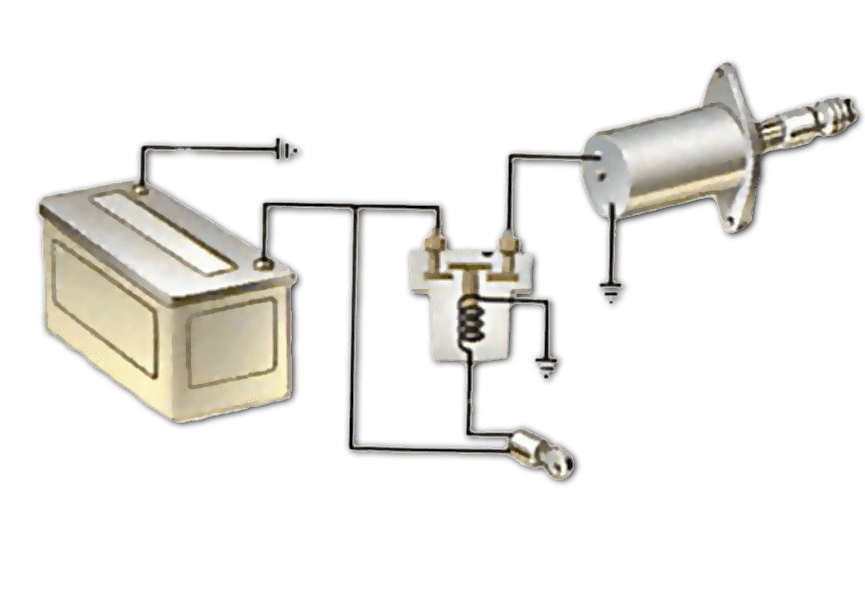

Why Is the Solenoid Important in Starter Motors?

The solenoid acts as a critical switch that engages the starter motor when the ignition is turned on. It consists of coils wrapped around a movable core that, when energized, creates a magnetic field to push the plunger, engaging the pinion with the flywheel. For B2B buyers, understanding the solenoid’s reliability is crucial, as its failure can lead to engine starting issues. Buyers should assess suppliers based on their solenoid designs and the quality of materials used.

What Role Does the Pinion Play in Engine Starting?

The pinion is a specialized gear that engages with the engine’s flywheel to initiate the cranking process. It is designed to extend into the gearbox housing, ensuring a secure connection with the flywheel. Buyers must be aware that while the pinion is essential for starting, it is also subject to significant wear and tear. Sourcing high-quality pinions that can withstand repeated use is critical for maintaining operational efficiency, especially in demanding environments.

How Do Field Coils Contribute to Starter Motor Functionality?

Field coils are essential components that generate the magnetic field required for the armature to rotate. When energized by the vehicle’s battery, these coils transform electrical energy into magnetic energy, enabling the starter motor to function effectively. For B2B buyers, it is important to consider the complexity of field coil installation and maintenance. Ensuring that the supplier offers reliable and efficient field coils can lead to improved performance and longevity of the starter motor system.

Key Industrial Applications of starter motor components

| Industry/Sector | Specific Application of starter motor components | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Starter motors in assembly lines | Ensures reliable engine ignition for quality control | Quality certifications and compliance with standards |

| Agriculture | Starter motors in tractors and harvesters | Enhances operational efficiency in the field | Durability and resistance to harsh environmental conditions |

| Construction Equipment | Starter motors in excavators and cranes | Reduces downtime, ensuring project timelines are met | Availability of replacement parts and support services |

| Marine Industry | Starter motors in boats and ships | Critical for reliable propulsion and safety | Corrosion resistance and compliance with marine standards |

| Heavy Equipment | Starter motors in mining machinery | Vital for operational reliability in rugged conditions | Proven performance under extreme loads and conditions |

How Are Starter Motor Components Used in Automotive Manufacturing?

In automotive manufacturing, starter motors are integral to the assembly line, ensuring that each vehicle can be reliably ignited during testing and quality assurance processes. A malfunctioning starter can cause delays, impacting production schedules and overall efficiency. Buyers in this sector should prioritize sourcing components that meet stringent quality certifications and industry standards to mitigate these risks and ensure seamless integration into production workflows.

What Role Do Starter Motor Components Play in Agriculture?

Starter motors are essential in agricultural machinery, particularly in tractors and harvesters. They facilitate the ignition process, allowing for quick and efficient operation in the field. Given the demanding environments of agricultural operations, buyers must focus on sourcing durable components that can withstand extreme conditions, such as dust, moisture, and temperature fluctuations, ensuring minimal downtime during critical harvesting periods.

How Are Starter Motor Components Critical in Construction Equipment?

In the construction industry, starter motors are crucial for heavy machinery such as excavators and cranes. These components ensure that equipment can start reliably, which is vital for maintaining project timelines and reducing downtime. When sourcing starter motor components, companies should consider the availability of replacement parts and robust after-sales support, as any delay in machinery operation can lead to significant financial losses.

Why Are Starter Motor Components Important for the Marine Industry?

In the marine industry, starter motors are vital for boats and ships, directly affecting propulsion and safety. Reliable ignition systems are crucial for navigation and operational efficiency. Buyers in this sector should prioritize sourcing starter motor components that are corrosion-resistant and compliant with marine standards to ensure longevity and reliability in harsh marine environments, where equipment failure can have serious consequences.

What Are the Key Considerations for Heavy Equipment Applications?

In heavy equipment applications, such as mining machinery, starter motors are essential for ensuring operational reliability in rugged and demanding conditions. These components must perform under extreme loads and environmental stressors. Buyers should seek out starter motor components that have a proven track record of performance in similar conditions, as well as those that offer comprehensive warranties and support, to ensure long-term operational success.

3 Common User Pain Points for ‘starter motor components’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Starter Motor Components

The Problem: B2B buyers often face challenges in sourcing high-quality starter motor components, especially in regions like Africa and South America, where access to reliable suppliers may be limited. They may encounter issues such as counterfeit parts, inconsistent quality, and inadequate technical support. This not only affects the operational efficiency of their machinery but can also lead to increased maintenance costs and potential downtime.

The Solution: To overcome this problem, buyers should prioritize establishing relationships with reputable manufacturers and distributors known for their quality assurance processes. Conduct thorough due diligence by requesting certifications, customer reviews, and samples before committing to larger orders. Utilizing platforms that specialize in B2B transactions can help identify verified suppliers. Additionally, buyers should consider joining industry associations or networks that can provide insights into trustworthy vendors. Collaborating with suppliers who offer comprehensive warranties and technical support can further mitigate risks associated with quality discrepancies.

Scenario 2: Incompatibility Issues with Starter Motor Components

The Problem: Another common pain point for B2B buyers is the incompatibility of starter motor components with existing machinery. This is particularly prevalent in industries where equipment is frequently updated or modified, leading to mismatches between components. Incompatibility can result in poor performance, increased wear and tear, and additional costs for modifications or replacements.

The Solution: To address compatibility concerns, buyers should ensure they conduct a thorough compatibility assessment before purchasing starter motor components. This includes cross-referencing the specifications of the new parts with the existing machinery’s requirements. Buyers should leverage technical documentation and consult with the component manufacturer to confirm compatibility. Additionally, investing in customizable starter motor components that can be tailored to fit specific machinery can provide a long-term solution. Engaging with suppliers who offer design consultations can also help identify the best-fit solutions for unique applications.

Scenario 3: Lack of Technical Support and Expertise

The Problem: Many B2B buyers in emerging markets struggle with a lack of technical support and expertise when it comes to selecting and maintaining starter motor components. This can lead to improper installation, inadequate troubleshooting, and challenges in optimizing performance, ultimately resulting in operational inefficiencies.

The Solution: To enhance technical support, buyers should seek suppliers who provide comprehensive technical resources, such as installation guides, troubleshooting tips, and access to expert consultations. Participating in training programs or workshops offered by manufacturers can also equip the purchasing team with the necessary knowledge to make informed decisions. Additionally, forming partnerships with local technicians or engineers who specialize in starter motors can be invaluable. These partnerships can facilitate better understanding and application of the components, ensuring optimal performance and reliability. Investing in ongoing education and resources will empower teams to address issues proactively and enhance overall operational efficiency.

Strategic Material Selection Guide for starter motor components

What Are the Key Materials Used in Starter Motor Components?

When selecting materials for starter motor components, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. Below is an analysis of four common materials used in starter motors: steel, copper, aluminum, and plastic composites.

How Does Steel Perform in Starter Motor Components?

Steel is a widely used material in starter motor components due to its strength and durability. It has high tensile strength and can withstand significant mechanical stress, making it suitable for components like the housing and pinion gears. Steel also offers good temperature resistance, typically up to 300°C, which is essential for components that undergo thermal cycling during operation.

Pros: Steel is relatively cost-effective and readily available, making it a popular choice for manufacturers. Its durability ensures a long lifespan for components, reducing the need for frequent replacements.

Cons: Steel is prone to corrosion if not adequately treated, which can lead to failure in harsh environments. Additionally, its weight can be a disadvantage in applications where reducing overall mass is critical.

Impact on Application: Steel components are highly compatible with various media, including oils and fuels, but require protective coatings in corrosive environments.

Considerations for International Buyers: Buyers should ensure that the steel grades comply with international standards such as ASTM or DIN. Corrosion resistance treatments may be necessary for specific markets, particularly in humid or saline environments.

What Role Does Copper Play in Starter Motor Components?

Copper is primarily used in starter motors for electrical components, such as brushes and windings, due to its excellent electrical conductivity. It can efficiently handle high currents, which is vital for the performance of the starter motor.

Pros: Copper’s high conductivity allows for efficient energy transfer, which enhances the starter motor’s performance. It is also relatively easy to work with, facilitating complex manufacturing processes.

Cons: The primary drawback of copper is its susceptibility to corrosion, especially in moist environments. Additionally, copper is more expensive than other conductive materials, which can increase overall production costs.

Illustrative image related to starter motor components

Impact on Application: Copper components are highly effective in electrical applications but may require protective coatings or alloys to improve corrosion resistance.

Considerations for International Buyers: Buyers should be aware of the copper quality standards in their region, such as JIS in Japan or IEC standards in Europe, to ensure compatibility and reliability.

How Does Aluminum Benefit Starter Motor Components?

Aluminum is increasingly used in starter motor components due to its lightweight and corrosion-resistant properties. It is often used for housings and brackets, where reducing weight is essential for overall vehicle performance.

Pros: Aluminum’s lightweight nature contributes to improved fuel efficiency in vehicles. It also has good corrosion resistance, especially when anodized, making it suitable for harsh environments.

Cons: While aluminum is durable, it has lower tensile strength compared to steel, which may limit its use in high-stress applications. It is also more expensive than steel, which can impact cost-effectiveness.

Impact on Application: Aluminum is compatible with various media, including oils and fuels, but care must be taken in applications involving high temperatures.

Considerations for International Buyers: Buyers should consider the specific aluminum grades and treatments that comply with local standards, such as ASTM or EN, to ensure performance and longevity.

What Are the Advantages of Plastic Composites in Starter Motor Components?

Plastic composites are increasingly used in starter motor components, particularly in non-structural applications like insulation and protective covers. These materials offer flexibility in design and can be engineered for specific performance characteristics.

Pros: Plastic composites are lightweight, cost-effective, and resistant to corrosion and chemicals. They can be molded into complex shapes, allowing for innovative designs.

Illustrative image related to starter motor components

Cons: The main limitation is their lower mechanical strength compared to metals, which may restrict their use in high-stress applications. Additionally, they may have lower thermal resistance, which could lead to performance issues in high-temperature environments.

Impact on Application: Plastic composites are suitable for components that do not bear significant loads but require protection from environmental factors.

Considerations for International Buyers: Buyers should verify that the plastic materials meet relevant standards, such as ISO or ASTM, and ensure they are suitable for the specific operating conditions in their region.

Illustrative image related to starter motor components

Summary Table of Material Selection for Starter Motor Components

| Material | Typical Use Case for starter motor components | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Housing, pinion gears | High strength and durability | Prone to corrosion | Medium |

| Copper | Brushes, windings | Excellent electrical conductivity | Susceptible to corrosion | High |

| Aluminum | Housings, brackets | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Plastic Composites | Insulation, protective covers | Lightweight and cost-effective | Lower mechanical strength | Low |

This strategic material selection guide provides B2B buyers with critical insights into the properties and considerations for choosing materials for starter motor components, ensuring informed purchasing decisions tailored to their specific regional needs.

In-depth Look: Manufacturing Processes and Quality Assurance for starter motor components

What Are the Key Stages of Manufacturing Starter Motor Components?

The manufacturing of starter motor components involves a series of precise and methodical stages. Understanding these stages helps B2B buyers assess the quality and reliability of the products they intend to procure.

How Is Material Prepared for Starter Motor Components?

The initial stage involves sourcing high-quality raw materials, which typically include various grades of steel, copper, and insulating materials. These materials are subjected to rigorous testing to ensure they meet industry specifications. The preparation process may involve cutting, cleaning, and treating materials to enhance their durability. For instance, steel components often undergo heat treatment processes to improve their strength and resistance to wear.

What Forming Techniques Are Commonly Used in Starter Motor Manufacturing?

Forming techniques vary based on the specific component being produced. Common methods include:

-

Stamping: Used for flat components like the armature and housing. This process involves pressing sheets of metal into desired shapes using dies.

-

Machining: Critical for parts requiring tight tolerances, such as the commutator and shaft. CNC (Computer Numerical Control) machining is often employed to ensure precision.

-

Casting: Utilized for complex shapes that cannot be easily formed through stamping or machining. Die casting is a common method for producing lightweight yet robust components.

These forming techniques ensure that each part meets the necessary specifications for functionality and performance.

How Are Starter Motor Components Assembled?

Once the individual components are manufactured, the assembly process begins. This stage is crucial as it directly impacts the final product’s performance. Key assembly steps include:

-

Component Integration: Parts like the armature, solenoid, and brushes are assembled into the starter motor housing. Precision is critical to ensure proper alignment and functionality.

-

Electrical Connections: The electrical components, including the solenoid and wiring, must be securely connected. This is often done using automated systems to enhance consistency.

-

Final Assembly Checks: After assembly, each unit undergoes a visual inspection to identify any obvious defects. This step is essential for ensuring the initial quality of the assembled product.

What Are the Quality Assurance Practices for Starter Motor Components?

Quality assurance (QA) is integral to the manufacturing process, ensuring that starter motor components meet the required standards for safety and performance.

Which International Standards Should B2B Buyers Be Aware Of?

International standards play a vital role in ensuring quality across borders. Key certifications include:

-

ISO 9001: This standard focuses on quality management systems and is widely recognized across various industries. Companies that achieve ISO 9001 certification demonstrate their commitment to quality and continuous improvement.

-

CE Marking: For components sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

-

API Certification: For automotive components, the American Petroleum Institute (API) provides standards that ensure quality in materials and manufacturing processes.

Understanding these certifications helps buyers gauge the credibility and reliability of potential suppliers.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) checkpoints are established throughout the manufacturing process to catch defects early. Common checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers must provide documentation to verify that materials meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken at various stages to ensure adherence to specifications. This includes checking dimensions, electrical properties, and surface finishes.

-

Final Quality Control (FQC): The final products undergo comprehensive testing and inspection before shipping. This may involve functionality tests, performance evaluations, and durability assessments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control measures of potential suppliers:

-

Supplier Audits: Conducting on-site audits provides valuable insights into a supplier’s manufacturing processes, quality control systems, and overall operational efficiency. This firsthand assessment helps in making informed decisions.

-

Quality Assurance Reports: Requesting detailed QA reports, including testing results and compliance documentation, can help buyers evaluate a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and final products. This is particularly useful for international transactions where buyers cannot be present.

What Are the Unique QC Considerations for International B2B Buyers?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

-

Regulatory Compliance: Different regions have varying regulations and standards. Buyers should ensure that their suppliers comply with both local and international standards relevant to their market.

-

Cultural Differences: Understanding the cultural context of suppliers can help in building trust and ensuring that quality expectations are met. This includes recognizing different approaches to quality management.

-

Logistics and Supply Chain Challenges: Quality assurance extends beyond manufacturing to include shipping and handling. Buyers should consider how logistics may affect product quality during transit.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices is essential for B2B buyers of starter motor components. By focusing on material preparation, forming techniques, assembly processes, and quality control measures, buyers can make informed decisions and ensure they receive reliable, high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor components’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure starter motor components effectively. With the global market expanding, particularly in regions like Africa, South America, the Middle East, and Europe, it’s crucial to follow a structured approach that ensures both quality and reliability. Each step outlined here aims to streamline your sourcing process, minimize risks, and enhance supplier relationships.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of effective sourcing. Consider factors such as the specific type of starter motor components needed—be it armatures, solenoids, or brushes. Detailed specifications will help you communicate effectively with suppliers and ensure compatibility with your existing systems.

- Key Considerations:

- Voltage ratings and current requirements.

- Material specifications (e.g., copper vs. aluminum).

- Compliance with local standards and certifications.

Step 2: Conduct Market Research

Understanding the market landscape is essential to identify potential suppliers. Research current trends, pricing benchmarks, and available technologies that can enhance performance. This knowledge will empower you to make informed decisions and negotiate effectively.

- Action Items:

- Review industry reports and white papers.

- Analyze competitor sourcing strategies.

- Utilize online platforms and trade shows for insights.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Assess their track record, financial stability, and reputation in the market. Request company profiles, product catalogs, and case studies relevant to your industry.

- What to Look For:

- Customer reviews and testimonials.

- Evidence of successful partnerships or projects.

- Quality assurance processes and certifications.

Step 4: Verify Supplier Certifications

Supplier certifications are a testament to their compliance with industry standards. Ensure that your potential suppliers hold relevant certifications such as ISO 9001 for quality management or other local certifications pertinent to your region.

- Importance of Certification:

- Demonstrates commitment to quality and safety.

- Reduces the risk of non-compliance with regulations.

- Builds trust in the supplier’s operational integrity.

Step 5: Request Samples and Prototypes

Before finalizing your order, it’s prudent to request samples or prototypes of the starter motor components. This step allows you to assess the quality and compatibility of the products with your specifications.

- Testing Parameters:

- Evaluate performance under operational conditions.

- Inspect for defects or inconsistencies.

- Confirm adherence to your technical requirements.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, focus on negotiating favorable terms and conditions. This includes pricing, delivery schedules, payment terms, and warranties. A clear agreement minimizes misunderstandings and establishes a strong working relationship.

- Negotiation Tips:

- Be transparent about your budget and requirements.

- Explore bulk purchase discounts or long-term agreements.

- Ensure clarity on after-sales support and service.

Step 7: Establish a Communication Plan

Effective communication is vital for ongoing supplier relationships. Establish a plan that outlines how often you will communicate, the preferred channels, and who will be the main point of contact on both sides.

Illustrative image related to starter motor components

- Benefits of a Communication Plan:

- Facilitates timely updates on orders and shipments.

- Addresses issues promptly, reducing downtime.

- Strengthens the partnership through regular engagement.

By following this step-by-step checklist, you can enhance your sourcing strategy for starter motor components, ensuring that you partner with the right suppliers while meeting your operational needs effectively.

Comprehensive Cost and Pricing Analysis for starter motor components Sourcing

What Are the Key Cost Components for Sourcing Starter Motor Components?

When sourcing starter motor components, it is essential to understand the various cost components that contribute to the overall pricing. The primary cost elements include:

-

Materials: The choice of materials significantly influences the cost. High-quality materials, such as copper for windings and durable alloys for housing, drive up expenses but enhance performance and longevity.

-

Labor: Labor costs can vary widely depending on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tooling can be a significant initial investment, especially for specialized components. However, the cost can be amortized over large production runs.

-

Quality Control (QC): Implementing rigorous QC measures ensures that components meet required specifications, which can increase costs but is essential for reliability and compliance with industry standards.

-

Logistics: Transportation and warehousing costs can add to the total expenditure, especially for international shipments. Factors like distance, shipping method, and customs duties must be considered.

-

Margin: Supplier margins can vary based on their market positioning and service offerings. Understanding the supplier’s business model can help in negotiations.

How Do Price Influencers Affect Starter Motor Component Sourcing?

Several factors influence the pricing of starter motor components:

-

Volume/MOQ: Higher order volumes often lead to reduced per-unit costs. Negotiating minimum order quantities (MOQs) can be beneficial, especially for larger enterprises.

-

Specifications and Customization: Custom components tailored to specific applications typically come at a premium. Clearly defining specifications can help manage costs effectively.

-

Materials: The choice between standard and high-performance materials can impact pricing. Buyers should weigh the long-term benefits of investing in superior materials against immediate cost savings.

-

Quality and Certifications: Components that meet stringent quality standards or possess certifications (such as ISO or TS) may command higher prices but offer assurance of reliability and performance.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but provide better support and assurance of quality.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is crucial. They dictate who is responsible for shipping costs, insurance, and tariffs, influencing the overall landed cost.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

-

Leverage Volume Discounts: Buyers should consolidate orders to increase volume and negotiate better pricing with suppliers. This not only reduces costs but also strengthens supplier relationships.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on upfront costs, consider the TCO, including maintenance and lifespan. Investing in higher-quality components may yield lower TCO over time.

-

Understand Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should be aware of currency fluctuations, import tariffs, and local regulations that can impact costs.

-

Request Multiple Quotes: Engaging multiple suppliers allows for better comparison and negotiation leverage. It’s essential to ensure that quotes are based on the same specifications for accurate comparison.

-

Build Long-Term Relationships: Establishing a good rapport with suppliers can lead to better terms and pricing in the long run. Consider negotiating for loyalty discounts or long-term contracts.

Disclaimer

Prices for starter motor components can fluctuate based on market conditions, supplier pricing strategies, and geopolitical factors. It is advisable for buyers to conduct thorough market research and obtain updated quotes before making purchasing decisions.

Illustrative image related to starter motor components

Alternatives Analysis: Comparing starter motor components With Other Solutions

Understanding the Alternatives to Starter Motor Components

In the automotive and machinery sectors, the choice of starting mechanisms is crucial for operational efficiency. While starter motor components are widely used for initiating engine function, several alternative technologies and methods can achieve similar objectives. This analysis aims to compare starter motor components with other viable solutions, providing international B2B buyers with critical insights to guide their decision-making process.

| Comparison Aspect | Starter Motor Components | Alternative 1: Inertia Starter | Alternative 2: Electric Motor Starter |

|---|---|---|---|

| Performance | Reliable but limited to specific applications; provides adequate power for cranking. | High torque output; effective for larger engines but requires more space. | Consistent performance across various applications; can handle varying loads. |

| Cost | Moderate initial investment; long-term durability can lower overall costs. | Generally higher upfront costs; potential for higher repair costs due to wear. | Varies widely; can be economical for smaller applications but expensive for larger setups. |

| Ease of Implementation | Straightforward installation; requires specific alignment with the flywheel. | More complex installation; requires additional space and structural considerations. | Installation can be complex, depending on the system design and load requirements. |

| Maintenance | Low maintenance; periodic checks of components like brushes and solenoids are needed. | Higher maintenance needs; components can wear out faster due to mechanical stress. | Maintenance requirements vary; generally low for smaller motors but can increase with size. |

| Best Use Case | Ideal for standard combustion engines and smaller machinery. | Best suited for high-performance engines where high torque is necessary. | Versatile; applicable in various industrial settings, including HVAC and automation. |

What are the Advantages and Disadvantages of Inertia Starters?

Inertia starters operate on a different principle, utilizing a flywheel to store energy and release it for starting engines. The primary advantage of inertia starters is their ability to produce high torque, making them suitable for larger engines or heavy machinery. However, they require more space and can be more complex to install. Their mechanical nature also leads to higher wear and tear, necessitating more frequent maintenance and repairs, which can increase operational costs over time.

How Do Electric Motor Starters Compare?

Electric motor starters offer a modern alternative, often providing consistent performance and efficiency across various applications. They can manage different load conditions, making them highly adaptable. However, the complexity of installation can vary significantly based on the specific system design. While they can be economical for smaller applications, costs can escalate with larger setups due to the need for robust components and systems. Maintenance requirements may also increase with size, making them less appealing for some buyers focused on cost-efficiency.

Choosing the Right Solution: What Should B2B Buyers Consider?

When evaluating starter motor components against alternatives like inertia and electric motor starters, B2B buyers should consider several factors. These include the specific application requirements, the cost of implementation and maintenance, and the expected performance under various operating conditions. Understanding the unique needs of their operations will guide buyers in selecting the most effective starting solution. By carefully weighing these aspects, businesses can optimize their investments and enhance their operational efficiency.

Essential Technical Properties and Trade Terminology for starter motor components

What Are the Essential Technical Properties of Starter Motor Components?

When sourcing starter motor components, understanding their technical specifications is crucial for ensuring quality, performance, and compatibility with various vehicle models. Here are some key specifications that buyers should prioritize:

Illustrative image related to starter motor components

1. Material Grade

The material used in starter motor components significantly impacts durability and performance. Common materials include high-grade steel for the housing, copper for the windings, and various grades of iron for the armature. For B2B buyers, selecting components made from high-quality materials ensures longevity and reduces the likelihood of failure, which can lead to costly downtimes.

2. Tolerance Levels

Tolerance refers to the permissible limits of variation in a physical dimension. For instance, the pinion’s fit with the flywheel must be precise to avoid excessive wear. Tight tolerances ensure that components function correctly within the starter motor assembly, minimizing issues such as misalignment and mechanical failure. Understanding tolerance levels is essential for manufacturers to maintain quality control.

3. Electrical Resistance

This property measures how much a component resists the flow of electric current. Lower electrical resistance in components like brushes and windings is desirable as it leads to improved efficiency and lower energy consumption. For B2B buyers, components with optimal electrical resistance ensure better performance of the starter motor, which is vital for vehicle reliability.

4. Thermal Conductivity

Thermal conductivity is crucial for components that experience high temperatures, such as the armature and solenoid. Materials with high thermal conductivity can dissipate heat effectively, preventing overheating and prolonging component life. B2B purchasers should consider thermal properties to ensure that the starter motor can operate under various climatic conditions without performance degradation.

5. Magnetic Properties

The magnetic properties of components such as the field coils and armature directly influence the starter motor’s efficiency. High-quality magnetic materials enhance the motor’s performance by improving torque and reducing energy consumption. Buyers should look for specifications indicating strong magnetic properties to ensure optimal functionality.

What Are Common Trade Terms in the Starter Motor Component Industry?

Navigating the B2B landscape requires familiarity with specific industry jargon. Here are some essential terms that decision-makers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand name. For buyers, sourcing OEM starter motor components ensures compatibility and reliability, as these parts meet the original specifications of the vehicle manufacturer.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is vital for buyers to manage inventory and costs effectively. A lower MOQ can provide flexibility for smaller businesses, while larger companies may negotiate for higher quantities at reduced prices.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ is crucial for comparing costs and negotiating favorable terms with multiple suppliers, ensuring they get the best deal on starter motor components.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, ensuring smoother transactions across borders.

5. Aftermarket

The aftermarket refers to the secondary market for parts and accessories after the original sale of the vehicle. Understanding the aftermarket landscape helps buyers identify additional sourcing opportunities for starter motor components that may not be available through OEM channels.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing starter motor components, ensuring they meet their operational needs while optimizing costs and performance.

Navigating Market Dynamics and Sourcing Trends in the starter motor components Sector

What Are the Key Trends Shaping the Starter Motor Components Market?

The global starter motor components market is witnessing a transformative phase driven by several factors. First, the increasing demand for electric vehicles (EVs) is reshaping the landscape. As manufacturers pivot toward electric propulsion, traditional starter motor components are evolving to accommodate hybrid systems and integrated starter-generator units. This shift is particularly evident in regions like Europe, where stringent emissions regulations are pushing for cleaner technologies.

Another significant trend is the rise of Industry 4.0 technologies, such as IoT and AI, enhancing manufacturing processes and supply chain efficiency. B2B buyers in Africa and South America can leverage these technologies for real-time data analytics, predictive maintenance, and inventory management, ultimately reducing costs and improving operational efficiency. Furthermore, with the ongoing global semiconductor shortage, sourcing strategies are adapting to prioritize suppliers with robust capabilities in electronics integration, essential for modern starter motors.

Illustrative image related to starter motor components

Additionally, there is a heightened focus on quality and reliability, as end-users demand products that ensure longevity and performance. Buyers are advised to engage with suppliers who offer traceability in their sourcing processes and can demonstrate adherence to international quality standards. This is particularly crucial for markets in the Middle East and Africa, where harsh operating conditions necessitate durable components.

How Is Sustainability Influencing Sourcing Decisions in the Starter Motor Components Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the starter motor components sector. The environmental impact of manufacturing processes and materials used in starter motors is under scrutiny, prompting buyers to seek suppliers committed to ethical practices and sustainable sourcing. The importance of reducing carbon footprints is not just a regulatory requirement; it has become a competitive differentiator in the global marketplace.

Ethical supply chains are essential for maintaining brand integrity and customer trust. B2B buyers are increasingly looking for suppliers who can provide ‘green’ certifications and demonstrate responsible sourcing of materials, such as recycled metals and eco-friendly coatings. This trend is particularly relevant for companies in Europe, where consumers are more inclined to support brands that prioritize sustainability.

Moreover, the use of sustainable materials, such as bioplastics or lightweight composites, is gaining traction. These materials not only reduce environmental impact but also enhance the efficiency and performance of starter motors. Buyers should prioritize partnerships with suppliers who invest in R&D for sustainable innovations, as this can lead to long-term cost savings and improved market positioning.

What Is the Historical Context of Starter Motor Components in B2B Markets?

The evolution of starter motor components dates back to the early 20th century, when the advent of the electric starter revolutionized vehicle ignition systems. Prior to this innovation, hand-cranking engines was the norm, posing significant safety risks and inconvenience. The introduction of the electric starter motor significantly improved vehicle usability and reliability, leading to widespread adoption.

Over the decades, advancements in materials and technology have refined starter motor designs, enhancing efficiency and performance. The shift toward automated manufacturing processes has also enabled the production of more complex components with tighter tolerances, catering to the evolving demands of the automotive industry. As the market continues to innovate, understanding this historical context provides valuable insights into current trends and future directions for international B2B buyers in the starter motor components sector.

Frequently Asked Questions (FAQs) for B2B Buyers of starter motor components

-

How do I solve issues with starter motor components failing prematurely?

To address premature failures of starter motor components, it’s crucial to identify the root cause of the problem. Factors such as poor electrical connections, inadequate voltage supply, and substandard components can contribute to failures. Ensure that all connections are clean and secure, and consider sourcing components from reputable suppliers who adhere to quality standards. Regular maintenance and testing of the electrical system can also help prevent issues. If failures persist, consult with a technical expert to perform a thorough analysis of the starter system and its components. -

What is the best type of starter motor component for high-temperature environments?

For applications in high-temperature environments, it is advisable to choose starter motor components made from materials that can withstand elevated temperatures without degrading. Look for components with heat-resistant insulation on windings and high-temperature-rated bearings. Additionally, components such as solenoids and brushes should be rated for high thermal performance. Collaborate with suppliers who specialize in high-temperature applications to ensure that the components are tailored to your specific operational conditions. -

How can I verify the quality of starter motor components from a supplier?

To verify the quality of starter motor components, request certifications and quality assurance documentation from potential suppliers. Look for ISO certifications or industry-specific standards that demonstrate adherence to quality control processes. Additionally, ask for samples to conduct in-house testing or seek third-party testing services. Engaging in a site visit or audit can also provide insights into the supplier’s manufacturing processes and quality management systems. Customer reviews and references can further guide your decision. -

What are common payment terms when sourcing starter motor components internationally?

Common payment terms for international sourcing of starter motor components typically include options like upfront payment, partial payment upon order confirmation, and the balance upon delivery. Letters of credit (LC) and payment through escrow services are also popular for large transactions to mitigate risk. It’s essential to negotiate clear terms that protect both parties and consider using trade finance options if available. Ensure that payment terms are documented in the purchase agreement to avoid disputes later on. -

What minimum order quantities (MOQ) should I expect from suppliers of starter motor components?

Minimum order quantities (MOQ) for starter motor components can vary significantly among suppliers based on their manufacturing capabilities and inventory policies. Typically, MOQs can range from 50 to several hundred units. It’s advisable to discuss your needs with suppliers to determine their flexibility on MOQ, especially if you’re looking to test a new component. Some suppliers may offer lower MOQs for first-time orders or allow for mixed orders of different components to meet MOQ requirements. -

How can I ensure timely logistics for shipping starter motor components internationally?

To ensure timely logistics for shipping starter motor components, work closely with suppliers who have established relationships with reliable logistics partners. Discuss shipping options such as air freight for urgent deliveries or sea freight for cost-effective bulk shipments. Implement tracking systems to monitor shipments and establish clear timelines for delivery. Additionally, consider customs regulations and documentation requirements in both the exporting and importing countries to avoid delays at borders. -

What customization options are available for starter motor components?

Customization options for starter motor components can include alterations in size, voltage ratings, and material specifications to meet specific application requirements. Many suppliers offer tailored solutions based on your operational needs, such as changes in the pinion gear design or insulation materials for enhanced durability. Engage with suppliers early in the design process to discuss your specific requirements and obtain prototypes before final production to ensure that the components meet your expectations. -

What are the key factors to consider when vetting suppliers of starter motor components?

When vetting suppliers of starter motor components, consider their industry experience, manufacturing capabilities, and quality certifications. Evaluate their track record for timely deliveries and customer service responsiveness. Request references from other clients and analyze their product range to ensure they can meet your specific requirements. Additionally, assess their financial stability to ensure they can sustain operations and provide support over the long term. Engaging in a trial order can also help assess their reliability before committing to larger purchases.

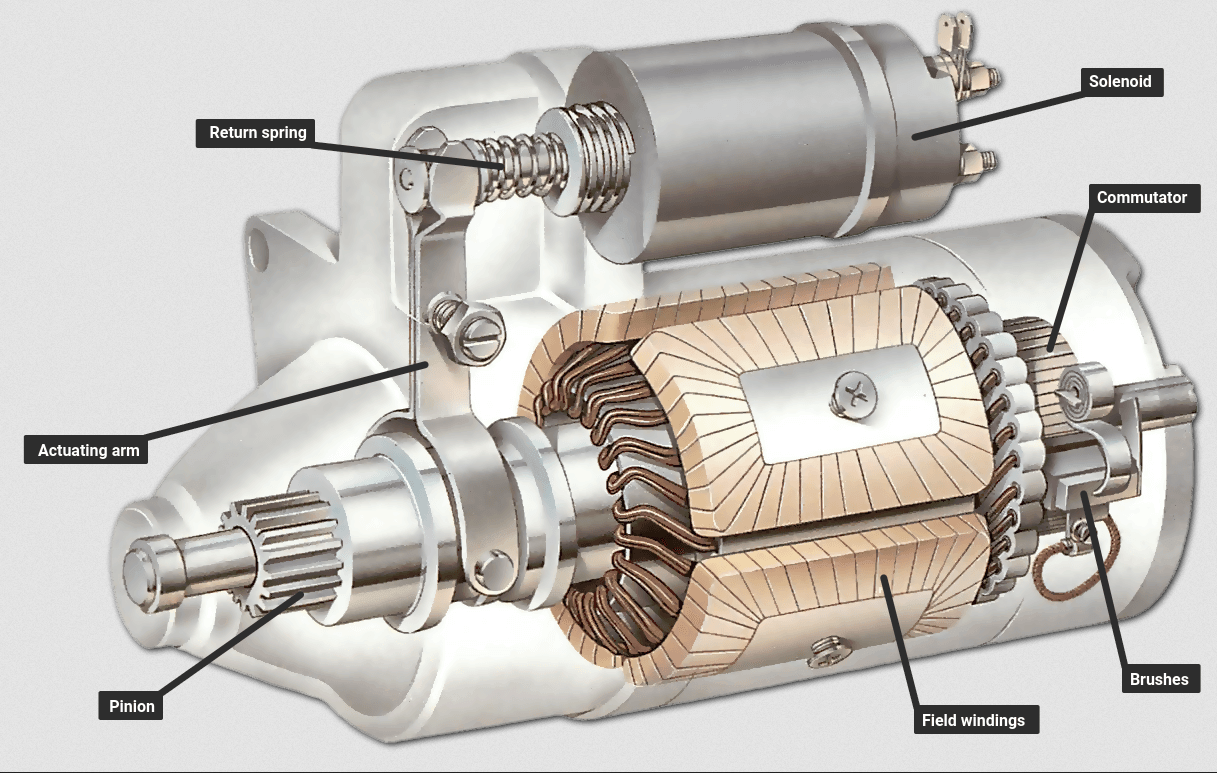

Top 4 Starter Motor Components Manufacturers & Suppliers List

1. AutoElectro – Starter Motors

Domain: autoelectro.co.uk

Registered: 1999 (26 years)

Introduction: Starter motors are responsible for turning the engine over during ignition, allowing it to suck in air and fuel for combustion. Key components include:

– Armature: An electromagnet mounted on the drive shaft, made of laminated soft iron core with conductor loops.

– Commutator: A section of the shaft where brushes run to conduct electricity, made of two plates attached to the armature axle.

– Br…

2. Facebook – Starter Motor Parts

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Starter Motor Parts: 1. Housing – Outer casing made of metal for durability, protects internal components. 2. Bendix Drive (Overrunning Clutch) – Engages starter motor with engine’s flywheel, disengages pinion gear after engine starts. 3. Armature – Rotating component with windings and laminated iron cores, generates torque when electric current flows. 4. Lever Fork (Shift Fork) – Pushes pinion ge…

3. Scribd – Starter Motor Components

Domain: scribd.com

Registered: 2006 (19 years)

Introduction: The starter motor consists of several main components that work together to start the engine. Key components include: 1. Solenoid Starter: Uses electrical current to engage the drive pinion gear. 2. Field Coils: Generate a magnetic field. 3. Armature Coils: React to induce movement. 4. Brushes: Transfer current between static and rotating parts. 5. Drive Pinion Clutch: Connects and disconnects the…

4. BuyAutoParts – Quality Auto Parts

Domain: buyautoparts.com

Registered: 2001 (24 years)

Introduction: {“Fast Shipping”:”Free Shipping on orders over $99. Ships from multiple warehouses across the country.”,”Warranty”:”1 Year Unlimited Mileage Warranty covering parts and shipping costs.”,”Returns”:”Return for any reason within 60 days for a full refund.”,”Expertise”:”30 years of service in auto parts since 1989, rated 4.9/5 by over 400,000 customers.”,”Top Sellers”:[{“Price”:”$335.41″,”Condition”:”…

Strategic Sourcing Conclusion and Outlook for starter motor components

In today’s competitive landscape, effective strategic sourcing of starter motor components is paramount for businesses seeking to optimize their supply chains and enhance operational efficiency. By focusing on sourcing high-quality components—such as armatures, solenoids, and pinions—companies can ensure the reliability of their products, ultimately driving customer satisfaction and loyalty.

Understanding the intricacies of starter motor functionality not only aids in selecting the right components but also enables buyers to negotiate better terms with suppliers. This includes assessing supplier capabilities, quality standards, and delivery reliability, which are critical in maintaining a smooth production flow.

As we look to the future, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with suppliers who demonstrate innovation and responsiveness to market demands. Embracing technological advancements and sustainable practices within the sourcing process will be essential in navigating the complexities of the global market.

Investing in strategic sourcing today will pave the way for enhanced competitiveness and growth tomorrow. Take action now by reevaluating your supply chain strategies to secure a robust and resilient sourcing framework for starter motor components.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.