Introduction: Navigating the Global Market for starter installation cost

In today’s competitive landscape, effectively navigating the global market for starter installation cost is paramount for international B2B buyers. Sourcing reliable and cost-effective starter installation services can pose significant challenges, particularly when considering the diverse automotive standards and pricing structures across regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Brazil. This guide is designed to provide an in-depth exploration of various factors influencing starter installation costs, including the types of starters available, their applications, and crucial elements for supplier vetting.

With this comprehensive resource, buyers will gain insights into the nuances of starter installation, from understanding the price variations based on vehicle make and model to the hidden costs associated with labor and parts. Additionally, the guide will cover practical strategies for evaluating suppliers, ensuring quality and reliability in every transaction. By addressing key challenges and outlining actionable solutions, this guide empowers international B2B buyers to make informed purchasing decisions that align with their operational needs and budgetary constraints. Ultimately, understanding the intricacies of starter installation costs will enhance procurement strategies, leading to more efficient and cost-effective outcomes in the automotive sector.

Table Of Contents

- Top 6 Starter Installation Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter installation cost

- Understanding starter installation cost Types and Variations

- Key Industrial Applications of starter installation cost

- 3 Common User Pain Points for ‘starter installation cost’ & Their Solutions

- Strategic Material Selection Guide for starter installation cost

- In-depth Look: Manufacturing Processes and Quality Assurance for starter installation cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter installation cost’

- Comprehensive Cost and Pricing Analysis for starter installation cost Sourcing

- Alternatives Analysis: Comparing starter installation cost With Other Solutions

- Essential Technical Properties and Trade Terminology for starter installation cost

- Navigating Market Dynamics and Sourcing Trends in the starter installation cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter installation cost

- Strategic Sourcing Conclusion and Outlook for starter installation cost

- Important Disclaimer & Terms of Use

Understanding starter installation cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Replacement | Basic installation of a new starter. | General automotive repair shops. | Pros: Cost-effective, quick installation. Cons: May lack warranty on parts. |

| OEM (Original Equipment Manufacturer) Installation | Installation of manufacturer-approved parts. | Dealerships and authorized service centers. | Pros: Guaranteed compatibility and quality. Cons: Higher costs than aftermarket options. |

| Aftermarket Replacement | Use of third-party parts for installation. | Independent repair shops, fleet services. | Pros: Often cheaper, wider selection. Cons: Quality can vary significantly. |

| Rebuilt Starter Installation | Refurbished starters installed instead of new. | Cost-sensitive operations, used vehicle dealerships. | Pros: Lower cost than new starters. Cons: Potentially shorter lifespan and less reliability. |

| DIY Installation | Self-installation by the vehicle owner. | Individual vehicle owners, small businesses. | Pros: Saves on labor costs, flexibility. Cons: Requires expertise and tools, risk of improper installation. |

What Are the Characteristics of Standard Replacement Installations?

Standard replacement installations involve the straightforward process of swapping out a faulty starter with a new one. This type is highly suited for general automotive repair shops that prioritize efficiency and cost-effectiveness. B2B buyers should consider the speed of installation and the potential for lower costs, although warranties on parts may be limited. This option is ideal for businesses looking to maintain a steady turnover of vehicle repairs without the need for specialized components.

Why Choose OEM Installations for Starter Replacement?

OEM installations utilize parts that are approved by the original vehicle manufacturer, ensuring compatibility and reliability. This type is primarily found in dealerships and authorized service centers, making it suitable for businesses that prioritize quality and brand loyalty. While OEM parts come at a higher price, they often offer superior performance and warranty coverage. B2B buyers should weigh the benefits of long-term reliability against the initial investment, especially for high-value vehicles.

What Are the Benefits of Aftermarket Replacement Installations?

Aftermarket replacement installations involve the use of third-party parts, which can vary widely in quality and price. This option is popular among independent repair shops and fleet services due to its cost-saving potential. B2B buyers should assess the reputation of aftermarket suppliers and consider the trade-off between price and quality. While aftermarket parts can be significantly cheaper, the variability in performance may affect customer satisfaction and warranty claims.

When Should You Consider Rebuilt Starter Installations?

Rebuilt starter installations involve using refurbished starters, making them a cost-effective choice for budget-conscious operations, such as used vehicle dealerships or cost-sensitive businesses. This option allows for lower upfront costs compared to new starters, but buyers should be aware of potential longevity issues. B2B purchasers must evaluate the reliability of the rebuilder and consider the trade-offs between immediate savings and the risk of future failures.

What Makes DIY Installation an Attractive Option for Some Buyers?

DIY installations empower vehicle owners and small businesses to perform starter replacements themselves, eliminating labor costs. This method is suited for those with mechanical expertise and the necessary tools. While it offers flexibility and potential savings, B2B buyers must recognize the risks associated with improper installations, which could lead to further complications. This approach is best for businesses that have skilled personnel willing to invest time in learning and executing the installation process correctly.

Key Industrial Applications of starter installation cost

| Industry/Sector | Specific Application of Starter Installation Cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Replacement of vehicle starters | Reduces downtime, enhances customer satisfaction | Availability of parts, labor cost, warranty terms |

| Transportation & Logistics | Fleet vehicle maintenance | Ensures operational efficiency, minimizes delays | Bulk purchasing options, service agreements |

| Mining & Construction | Heavy machinery starter replacements | Increases equipment reliability, reduces breakdowns | Compatibility with machinery, lead times |

| Agriculture | Agricultural equipment starter costs | Enhances productivity, ensures timely operations | Seasonal demand, part availability |

| Renewable Energy | Wind turbine starter systems | Optimizes energy production, reduces maintenance costs | Technical specifications, supplier reliability |

How Do Automotive Repair Shops Benefit from Understanding Starter Installation Costs?

Automotive repair shops frequently encounter starter replacements as a common service. Understanding the installation costs allows these businesses to provide accurate estimates to customers, ensuring transparency and trust. By sourcing affordable and reliable starter components, repair shops can enhance customer satisfaction and loyalty. Additionally, they can better manage labor costs by training technicians on efficient installation practices, thus minimizing vehicle downtime for customers.

What Are the Key Considerations for Transportation & Logistics Companies?

In the transportation and logistics sector, fleet maintenance is critical for operational efficiency. The costs associated with starter installation directly impact the overall maintenance budget. By investing in quality starters and understanding installation costs, companies can prevent unexpected breakdowns that lead to delays and increased operational costs. When sourcing starters, businesses should consider bulk purchasing options, service agreements, and the reliability of suppliers to ensure quick turnaround times.

How Do Mining & Construction Industries Address Starter Installation Costs?

In the mining and construction industries, heavy machinery is essential for operations. The cost of starter installation can significantly affect project timelines and budgets. A reliable starter ensures that machinery functions optimally, reducing the likelihood of breakdowns that can halt productivity. Buyers in this sector must consider the compatibility of starters with their specific machinery models and the lead times for sourcing these parts, as delays can have substantial financial implications.

Why Is Understanding Starter Costs Important for Agriculture?

Agricultural operations rely heavily on machinery for planting and harvesting. The cost of starter installation can directly impact productivity, especially during peak seasons. Understanding these costs allows farmers to budget effectively and ensure that their equipment is always ready for use. Seasonal demand can affect the availability of parts, so buyers must plan ahead and establish relationships with reliable suppliers to avoid delays during critical farming periods.

How Does the Renewable Energy Sector Utilize Starter Installation Costs?

In the renewable energy sector, particularly with wind turbines, the cost of starter installation is crucial for optimizing energy production. A malfunctioning starter can lead to significant downtime, affecting energy output and revenue. By understanding the installation costs, operators can budget for maintenance and ensure that they have the right components on hand. Buyers should focus on technical specifications and the reliability of suppliers, as the unique requirements of renewable energy systems can complicate sourcing efforts.

Illustrative image related to starter installation cost

3 Common User Pain Points for ‘starter installation cost’ & Their Solutions

Scenario 1: Unexpected Labor Costs Emerge During Installation

The Problem: Many B2B buyers encounter unanticipated labor costs when installing starters, especially in complex vehicles or machinery. For instance, when a company operates a fleet of vehicles, mechanics may discover that the starter is lodged in a hard-to-reach location, requiring more time and expertise to replace than initially expected. This not only inflates the installation cost but can also lead to downtime, impacting operational efficiency and profitability.

The Solution: To mitigate unexpected labor costs, B2B buyers should conduct thorough pre-installation assessments. This involves having a qualified technician examine the vehicle or machinery beforehand to determine the accessibility of the starter and any potential complications. Additionally, engaging with reputable suppliers who provide transparent pricing models can help in forecasting installation expenses more accurately. Consider investing in maintenance training for in-house staff to handle minor starter issues, which can reduce reliance on external mechanics and lower labor costs over time.

Scenario 2: Difficulty in Sourcing Quality Starters at Competitive Prices

The Problem: B2B buyers often struggle to find quality starters at competitive prices, particularly in emerging markets where local suppliers may not offer reliable parts. This scarcity can lead to inflated costs and the risk of purchasing subpar components that fail prematurely, resulting in further expenses and logistical challenges associated with replacements.

The Solution: Establishing long-term relationships with trusted suppliers who specialize in automotive parts can significantly alleviate sourcing challenges. B2B buyers should prioritize suppliers who offer a warranty on their products and have a proven track record of quality. Additionally, leveraging online platforms and marketplaces that aggregate multiple suppliers can provide better price comparisons and access to a wider range of products. It’s also advisable to conduct market research to identify regional distributors who may offer more favorable terms and conditions than larger, international suppliers.

Scenario 3: Unclear Warranty and Support Policies

The Problem: After investing in starter installation, B2B buyers often find themselves in a bind due to unclear warranty and support policies. For example, if a starter fails shortly after installation, the buyer may face challenges in claiming warranty service due to vague terms or inadequate support from the supplier. This can lead to additional costs and operational disruptions, as the buyer is left to either source a replacement quickly or face vehicle downtime.

The Solution: To avoid issues with warranties and support, B2B buyers should meticulously review warranty terms before making a purchase. It’s essential to ask suppliers specific questions about what is covered under warranty, the process for claims, and the availability of customer support. Buyers should also consider drafting contracts that include detailed service level agreements (SLAs) outlining the responsibilities of the supplier in case of product failure. Additionally, documenting the installation process and keeping all related invoices can streamline any warranty claims, ensuring that buyers are prepared should issues arise.

Strategic Material Selection Guide for starter installation cost

What Are the Common Materials Used in Starter Installation Cost?

When considering the installation costs associated with automotive starters, the selection of materials plays a crucial role in determining the overall performance, durability, and cost-effectiveness of the components involved. Below, we analyze four common materials used in starter manufacturing and installation, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Influence Starter Installation Costs?

Key Properties: Steel is known for its high tensile strength and durability, making it a common choice for structural components in automotive starters. It offers good resistance to wear and can withstand high temperatures, which is essential for components subjected to engine heat.

Pros & Cons: The primary advantage of steel is its strength and longevity, which can lead to lower replacement costs over time. However, steel is susceptible to corrosion if not properly treated or coated, which can affect its performance in humid or corrosive environments. Additionally, the manufacturing complexity can increase costs, particularly for precision-engineered components.

Impact on Application: Steel components are generally compatible with a wide range of automotive applications, including those in high-performance vehicles. However, in regions with high humidity or salt exposure, such as coastal areas in Brazil or the Middle East, corrosion resistance becomes a critical consideration.

International Considerations: Buyers in Africa, South America, the Middle East, and Europe should ensure that steel components meet relevant standards, such as ASTM or DIN, to guarantee quality and performance. Additionally, local regulations regarding corrosion resistance and environmental impact should be taken into account.

Illustrative image related to starter installation cost

What Role Does Aluminum Play in Starter Manufacturing?

Key Properties: Aluminum is lightweight and offers excellent corrosion resistance, making it a popular choice for components that require reduced weight without sacrificing strength.

Pros & Cons: The lightweight nature of aluminum can lead to improved fuel efficiency in vehicles, which is a significant advantage. However, aluminum is generally less durable than steel and may not withstand as much wear and tear, particularly in high-stress applications. The manufacturing process for aluminum can also be more expensive due to the need for specialized techniques.

Impact on Application: Aluminum is suitable for components that require a balance between weight and strength, such as starter housings. It is particularly beneficial in electric vehicles or hybrids where weight reduction is crucial.

International Considerations: When sourcing aluminum components, international buyers should verify compliance with standards like JIS or ASTM, particularly regarding alloy specifications. Additionally, regional preferences for lightweight materials may influence purchasing decisions.

How Does Copper Affect Starter Performance and Cost?

Key Properties: Copper is an excellent conductor of electricity, making it ideal for electrical components in starters, such as wiring and contacts. It also has good thermal conductivity, which is vital for dissipating heat.

Pros & Cons: The main advantage of copper is its superior conductivity, which enhances starter performance and reliability. However, copper is more expensive than other materials, and it can be prone to corrosion if not properly insulated or coated.

Illustrative image related to starter installation cost

Impact on Application: Copper components are essential for ensuring efficient electrical connections in starters, which is critical for reliable engine starting. In areas with high electrical demands, such as heavy-duty vehicles, the use of copper can significantly enhance performance.

International Considerations: Buyers should be aware of the global copper market’s fluctuations, which can impact costs. Additionally, compliance with electrical safety standards is crucial, particularly in regions like Europe, where regulations are stringent.

What Advantages Does Plastic Offer in Starter Components?

Key Properties: Plastic materials, particularly engineered plastics, offer excellent resistance to corrosion and chemicals, along with lightweight properties.

Pros & Cons: The primary advantage of plastic is its resistance to environmental factors, which can prolong the life of components. However, plastics may not offer the same level of strength as metals, potentially leading to issues in high-stress applications. Manufacturing processes for plastics can also be less expensive, making them a cost-effective choice.

Illustrative image related to starter installation cost

Impact on Application: Plastic components are often used in non-structural parts of starters, such as housing or insulation, where weight savings and corrosion resistance are prioritized.

International Considerations: International buyers should ensure that plastic components meet relevant safety and environmental regulations, particularly regarding chemical resistance and flame retardance.

Summary Table of Material Selection for Starter Installation Cost

| Material | Typical Use Case for starter installation cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components in starters | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight starter housings | Excellent corrosion resistance | Less durable than steel | High |

| Copper | Electrical wiring and contacts | Superior electrical conductivity | Higher cost and corrosion risk | High |

| Plastic | Non-structural components like housings | Corrosion resistance and lightweight | Lower strength compared to metals | Low |

This detailed analysis provides valuable insights for B2B buyers considering starter installation costs, emphasizing the importance of material selection based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for starter installation cost

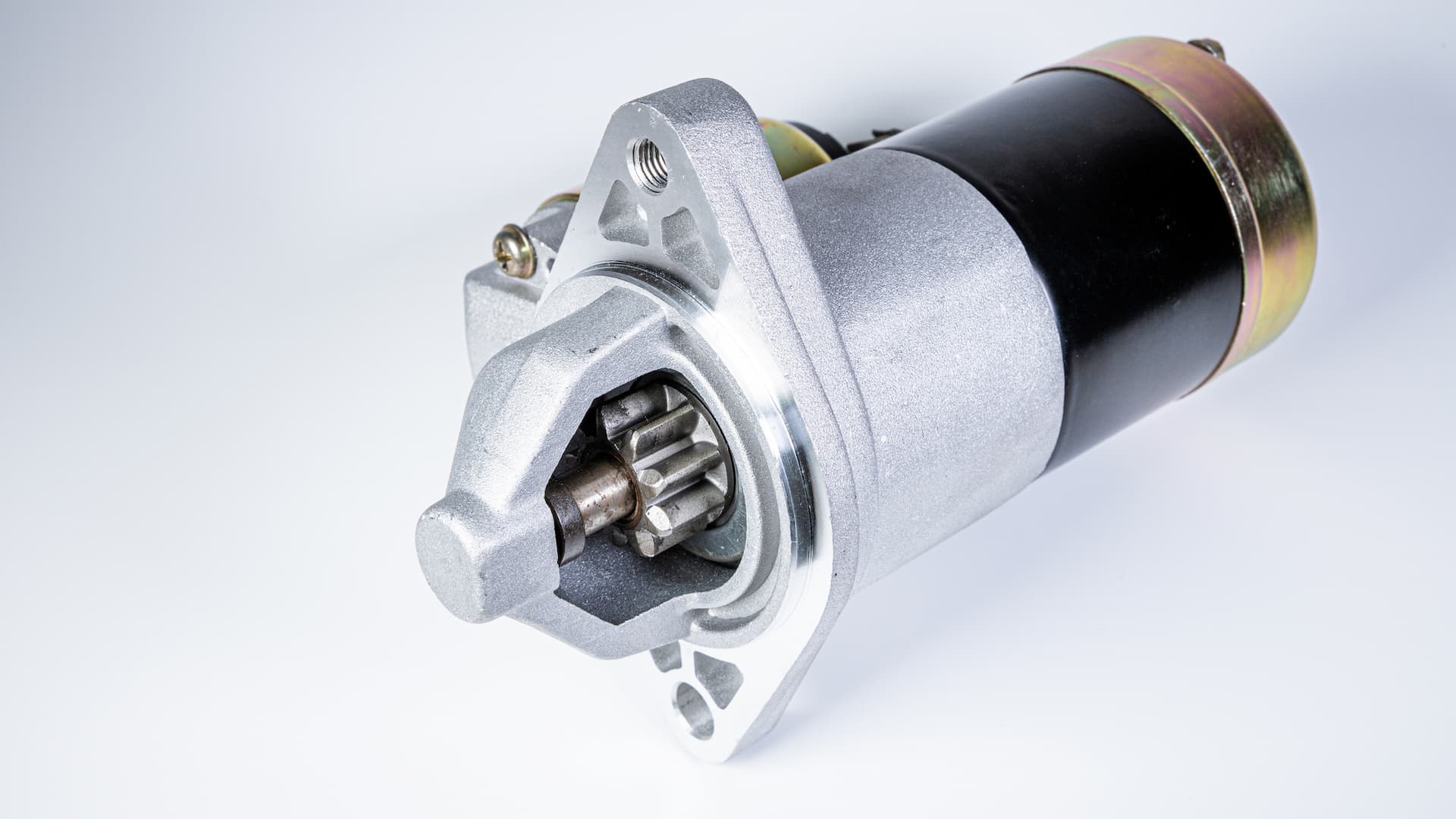

What Are the Key Manufacturing Processes for Starter Motors?

Understanding the manufacturing processes involved in producing starter motors is essential for B2B buyers looking to assess installation costs accurately. The production of starter motors typically involves several main stages: material preparation, forming, assembly, and finishing.

How is Material Prepared for Starter Production?

The manufacturing journey begins with material selection, where high-quality metals, such as steel and aluminum, are chosen for their durability and conductivity. The materials undergo treatment processes to enhance their properties, including heat treatment and surface coatings that improve resistance to wear and corrosion.

Once the materials are selected, they are cut to size, which may involve processes like laser cutting or stamping. This precision ensures that components fit together correctly during assembly, reducing potential issues later in the manufacturing process.

What Forming Techniques Are Used in Starter Manufacturing?

The forming stage involves shaping the prepared materials into the necessary components. Techniques such as forging and casting are common. For instance, the starter housing may be cast from aluminum for lightweight durability, while components like the armature and solenoid may be forged for strength.

Additionally, advanced techniques such as CNC machining may be utilized to achieve precise tolerances. This precision is critical, as any misalignment can lead to starter failure or inefficiencies, ultimately affecting the installation cost and reliability of the product.

Illustrative image related to starter installation cost

How Are Starter Motors Assembled?

Assembly is a crucial phase where all components come together. During this stage, each part, including the electromagnetic field coils, solenoids, and brushes, is systematically integrated. Skilled technicians often perform assembly, ensuring that each unit meets specific standards.

Automated assembly lines may also be employed, especially in high-volume production settings. Automated systems help maintain consistency and reduce human error, which is vital for quality assurance.

What Finishing Processes Are Involved in Starter Production?

The finishing stage includes various processes designed to enhance the starter motor’s performance and longevity. These processes may involve surface treatments like anodizing or powder coating to provide additional protection against environmental factors.

Final testing and inspection are also part of the finishing process, ensuring that each starter motor meets the required specifications before it reaches the market. This is where quality assurance begins to play a significant role.

How Is Quality Assurance Implemented in Starter Motor Manufacturing?

Quality assurance (QA) is a fundamental aspect of manufacturing starter motors. It ensures that products not only meet customer expectations but also comply with international standards.

Which International Standards Should B2B Buyers Consider?

International standards, such as ISO 9001, provide a framework for quality management systems across various industries, including automotive manufacturing. Adherence to these standards helps ensure consistency in production processes and product quality.

In addition to ISO standards, other certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for certain automotive applications can also be crucial. These certifications signify compliance with safety and quality requirements, providing peace of mind for B2B buyers.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically structured around several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is where raw materials and components are inspected upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During manufacturing, various inspections occur to monitor production processes and detect any deviations early. This could involve measuring tolerances and checking assembly integrity.

-

Final Quality Control (FQC): Once the starter motors are fully assembled, they undergo comprehensive testing, including performance and durability tests, to ensure they function correctly under expected conditions.

What Common Testing Methods Are Used for Quality Assurance?

Various testing methods are employed to assess the quality of starter motors:

-

Electrical Testing: This includes checking the resistance and continuity of electrical components to ensure they function correctly.

-

Functional Testing: Starter motors are often tested under load conditions to verify their performance before they are shipped.

-

Durability Testing: This may involve simulating extreme conditions to assess how the starter motor performs over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control measures is crucial to ensuring that the products meet their standards. Here are several ways to conduct this verification:

Illustrative image related to starter installation cost

What Should Buyers Look for in Supplier Audits?

Conducting supplier audits can provide valuable insights into their manufacturing processes and quality control systems. Audits should evaluate compliance with international standards, adherence to specified processes, and the effectiveness of their QC checkpoints.

How Can Buyers Access Quality Control Reports?

Requesting quality control reports from suppliers can help buyers assess past performance and identify potential risks. These reports typically include data on defect rates, testing outcomes, and corrective actions taken.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections and audits, providing unbiased evaluations of the supplier’s manufacturing and quality control processes.

Illustrative image related to starter installation cost

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, may encounter unique challenges regarding quality control. Variations in regulatory requirements, standards, and expectations can complicate the procurement process.

How Do Regional Standards Impact Quality Assurance?

Different regions may have specific regulations that affect product quality. For example, automotive components sold in Europe must comply with CE standards, while products intended for markets in the Middle East may need to meet local regulations.

What Should Buyers Know About Cultural Differences in Quality Expectations?

Cultural perceptions of quality can vary significantly across regions. Buyers should be aware of these differences when negotiating contracts and setting expectations with suppliers. Establishing clear communication and understanding the local market can help mitigate misunderstandings.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices in starter motor production is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions that will ultimately impact installation costs and product reliability.

Illustrative image related to starter installation cost

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter installation cost’

Introduction

Navigating the complexities of starter installation costs can be challenging for international B2B buyers. This guide provides a step-by-step checklist to ensure you make informed decisions when sourcing starters and installation services. By following these steps, you can streamline your procurement process and avoid common pitfalls.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly define the technical specifications of the starter you require. Consider factors such as the type of vehicle, engine size, and specific performance needs. This clarity will help you communicate effectively with potential suppliers and ensure they understand your requirements.

Step 2: Research Market Prices

Conduct thorough research to understand the current market prices for starters and installation services. Utilize online platforms, industry reports, and local suppliers to gather price ranges. This knowledge will empower you to negotiate better terms and avoid overpaying for components or services.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who demonstrate reliability and quality in their products and services, as this will reduce risks associated with sourcing.

- Check Reviews and Ratings: Look for feedback from previous customers to assess the supplier’s reputation.

- Assess Experience: Suppliers with a proven track record in your specific market or vehicle type are more likely to meet your needs effectively.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications and adhere to industry standards. Certifications can indicate the quality of their products and services, and compliance with international standards can be particularly crucial for buyers from diverse regions.

Illustrative image related to starter installation cost

- ISO Certifications: Look for ISO 9001 or other relevant certifications that demonstrate quality management systems.

- Local Compliance: Ensure suppliers comply with local regulations and standards pertinent to your region.

Step 5: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that include all associated costs. Look for transparency in pricing, which should cover the cost of the starter, installation, and any additional fees such as shipping or handling.

- Breakdown of Costs: Ensure the quote provides a clear breakdown of each cost component.

- Validity Period: Ask for the duration for which the quote is valid to avoid surprises later.

Step 6: Assess Warranty and Support

Evaluate the warranty offered by suppliers on starters and installation services. A robust warranty can protect your investment and provide peace of mind. Additionally, inquire about after-sales support and maintenance services.

- Warranty Duration: Longer warranty periods often indicate supplier confidence in their products.

- Support Services: Ensure that the supplier offers responsive customer support for any issues that may arise post-installation.

Step 7: Finalize Your Order

After thorough evaluation and negotiation, finalize your order with the selected supplier. Ensure all terms, including payment schedules and delivery timelines, are clearly defined in the purchase agreement. This step is critical to ensuring that both parties are aligned and that the procurement process runs smoothly.

Illustrative image related to starter installation cost

By following this practical sourcing guide, B2B buyers can effectively navigate the complexities of starter installation costs, ensuring a successful procurement process that meets their operational needs.

Comprehensive Cost and Pricing Analysis for starter installation cost Sourcing

What Are the Key Cost Components Involved in Starter Installation?

When assessing the cost of starter installation, several components contribute to the overall expenditure. The primary cost components include:

-

Materials: The cost of the starter itself can vary significantly based on the brand, type (new, rebuilt, or remanufactured), and compatibility with specific vehicle models. Prices typically range from $50 to $350 for parts alone.

-

Labor: Labor costs depend on the complexity of the installation, which can vary by vehicle make and model. For simple installations, labor may cost between $150 and $300, while more intricate replacements in luxury vehicles could exceed $1,100.

-

Manufacturing Overhead: This encompasses the indirect costs associated with the production of starters, including facility costs, utilities, and salaries of non-direct labor.

-

Tooling: Specialized tools may be required for certain models, impacting initial setup costs for mechanics and repair shops.

-

Quality Control (QC): Ensuring that each starter meets safety and performance standards incurs additional costs. This is particularly important for B2B buyers who require certification for compliance in their markets.

-

Logistics: The transportation of starters from manufacturers to suppliers and ultimately to repair shops or dealerships also adds to the overall cost. This includes shipping fees, customs duties, and handling charges.

-

Margin: Suppliers typically add a profit margin to cover operational costs and ensure profitability, which can vary based on market demand and competition.

How Do Price Influencers Affect Starter Installation Costs?

Several factors can influence the pricing of starter installations, especially in international markets:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can lead to significant discounts, making it advantageous for businesses that require multiple starters for fleet maintenance.

-

Specifications and Customization: Custom starters designed for specific applications may come at a premium. Buyers should consider the necessity of customization against potential cost increases.

-

Material Quality and Certifications: Higher-quality starters often come with certifications that assure reliability and performance, but these certifications can increase costs. Buyers should assess their needs to balance quality and price.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: The chosen Incoterms can affect costs related to shipping, insurance, and delivery. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) when negotiating prices.

What Tips Can Help Buyers Achieve Cost-Efficiency in Starter Installation?

To maximize cost-efficiency in starter installation, international B2B buyers should consider the following strategies:

-

Negotiate Pricing: Leverage volume purchases and establish long-term relationships with suppliers to negotiate better pricing. Highlighting consistent orders can also strengthen your bargaining position.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with maintenance, warranty, and potential downtime due to starter failures.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to labor costs, material availability, and local market conditions. Buyers should conduct market research to align their expectations with local pricing trends.

-

Be Aware of Currency Fluctuations: For international transactions, currency exchange rates can impact final costs. Buyers should monitor exchange rates and consider locking in prices when favorable.

-

Plan for Logistics Costs: Factor in logistics when budgeting for starter installations, especially for international shipments. Understanding the complete supply chain will help avoid unexpected expenses.

Conclusion

Understanding the comprehensive cost structure and pricing influencers for starter installation is crucial for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. By focusing on the key cost components, recognizing price influencers, and employing strategic buying tips, organizations can make informed decisions that optimize their investment in starter installations. Always remember that the prices mentioned are indicative and may vary based on specific circumstances and market conditions.

Alternatives Analysis: Comparing starter installation cost With Other Solutions

Exploring Alternatives to Starter Installation Costs

In the realm of automotive maintenance, particularly regarding starter systems, understanding alternative solutions can significantly enhance decision-making for B2B buyers. By comparing starter installation costs with other viable options, businesses can make informed choices that align with their operational needs and budget constraints. This analysis will present two alternative solutions: battery replacement and the use of advanced ignition systems.

Comparison Table

| Comparison Aspect | Starter Installation Cost | Battery Replacement | Advanced Ignition Systems |

|---|---|---|---|

| Performance | High reliability when functioning correctly | Moderate; depends on battery health | High; can enhance engine performance |

| Cost | $150 – $1,100 (installation) | $50 – $300 (DIY or professional) | $200 – $600 (installation) |

| Ease of Implementation | Moderate; requires skilled labor | Easy to moderate; DIY possible | Moderate; requires technical knowledge |

| Maintenance | Minimal once installed; potential for failure | Regular checks needed; lifespan varies | Low; once installed, minimal upkeep |

| Best Use Case | Vehicles with failed starters requiring replacement | Vehicles with weak or dead batteries | Performance vehicles or modern engines needing reliable ignition |

Detailed Breakdown of Alternatives

1. Battery Replacement

Battery replacement is often a more straightforward and cost-effective solution for starting issues. The average cost ranges from $50 to $300, depending on the type of battery and whether installation is DIY or performed by a professional. This solution is advantageous for businesses operating vehicles that experience frequent battery drain or wear, as a new battery can restore functionality without the complexities involved in starter replacement. However, this method does have limitations; if the starter motor is indeed the issue, merely replacing the battery will not resolve the problem. Regular maintenance is required to ensure optimal battery life.

2. Advanced Ignition Systems

Investing in advanced ignition systems can be a strategic move for companies looking to improve overall vehicle performance and reliability. The costs for these systems range from $200 to $600, including installation. These systems can enhance engine start-up efficiency, improve fuel combustion, and reduce emissions, making them suitable for businesses focused on sustainability and performance. However, they require a certain level of technical expertise for installation and may necessitate occasional adjustments or calibrations. While the initial investment is higher, the long-term benefits could outweigh the costs, especially for fleets operating in demanding environments.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between starter installation costs and alternative solutions, it’s crucial for B2B buyers to assess their specific needs, vehicle usage, and budget. If the primary issue lies with the starter, a direct replacement may be necessary despite the higher costs involved. Conversely, if the issue is related to battery performance or ignition efficiency, exploring battery replacements or advanced ignition systems could yield better long-term value. Ultimately, understanding the operational context and vehicle requirements will guide buyers in selecting the most effective solution that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for starter installation cost

What Are the Critical Technical Specifications for Starter Installation Costs?

When assessing starter installation costs, several technical specifications play a crucial role in determining both the price and the reliability of the components used. Understanding these specifications is essential for B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe.

1. Material Grade

The material grade of a starter can significantly impact its performance and longevity. Common materials include high-strength steel for the casing and copper for the electrical components. Higher-grade materials generally offer better resistance to wear and thermal stress, which is vital for starters operating in extreme conditions. For international buyers, sourcing starters made from premium materials can reduce long-term operational costs and maintenance needs.

2. Torque Specifications

Torque specifications refer to the tightness with which bolts and connections are fastened. Proper torque is crucial for ensuring optimal performance and preventing failures. B2B buyers should consider the torque specifications outlined by the manufacturer, as incorrect torque can lead to premature wear or catastrophic failure, resulting in additional costs and downtime.

Illustrative image related to starter installation cost

3. Electrical Ratings

The electrical rating of a starter, including voltage and current specifications, is critical for compatibility with various vehicle systems. Most starters operate at 12 volts; however, some heavy-duty or luxury vehicles may require starters rated for higher voltages. Ensuring that the starter meets the electrical requirements of the vehicle is vital to avoid potential failures and additional installation costs.

4. Size and Design Configurations

Starters come in various sizes and designs, which can influence installation complexity and costs. Compact designs may be more accessible for installation, while larger, more complex models might require specialized tools and more labor time. Understanding the specific size and design needed for a particular vehicle model can help in accurately estimating installation costs.

5. Warranty and Service Life

A starter’s warranty and expected service life are essential considerations for B2B buyers. A longer warranty often indicates a manufacturer’s confidence in their product, which can translate to fewer replacements and lower costs over time. Buyers should look for starters with robust warranties, as these can mitigate long-term costs associated with replacements and repairs.

6. Compliance and Certification Standards

Compliance with industry standards and certifications (like ISO or SAE) is critical for ensuring quality and reliability. Starters that meet these standards are more likely to perform reliably under various operating conditions. For international buyers, confirming that products meet local and international compliance standards can prevent legal and operational issues.

What Are the Key Trade Terms Relevant to Starter Installation Costs?

Familiarity with industry-specific terminology can enhance communication and negotiation for B2B buyers dealing with starter installation costs.

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. OEM starters are often preferred for their compatibility and reliability. Understanding the difference between OEM and aftermarket parts can help buyers make informed decisions regarding cost and quality.

Illustrative image related to starter installation cost

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is essential for B2B buyers who need to balance inventory levels with procurement costs. Understanding MOQ can help in negotiating better pricing and managing cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document soliciting quotes from suppliers for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process for starter installations, ensuring competitive pricing and clear specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is crucial for international buyers to understand shipping costs, risk management, and delivery terms related to starter components.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. Understanding lead times is critical for inventory management and project planning, especially in industries where timely installation is essential.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding starter installation costs, ultimately leading to better procurement outcomes and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the starter installation cost Sector

What Are the Key Drivers Influencing the Starter Installation Cost Market?

The global automotive sector is undergoing significant transformations, driven by technological advancements, evolving consumer preferences, and regulatory changes. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for optimizing sourcing strategies related to starter installation costs.

One of the primary drivers is the shift towards electric vehicles (EVs). As countries push for greener alternatives, the demand for traditional starter motors may decline, but the market for EV components, including electronic starters, is expected to rise. Moreover, the increasing complexity of vehicle systems, especially in luxury and high-performance cars, necessitates specialized knowledge and components, influencing installation costs significantly.

Illustrative image related to starter installation cost

Another trend is the rise of digital tools in the procurement process. B2B buyers are increasingly leveraging e-commerce platforms and automated sourcing solutions to streamline their purchasing processes, compare prices, and identify reliable suppliers. This trend is particularly notable in emerging markets, where access to technology can enhance transparency and efficiency in the sourcing of automotive parts.

Additionally, fluctuating raw material prices and supply chain disruptions, exacerbated by geopolitical tensions and the COVID-19 pandemic, have led to increased costs and uncertainty in sourcing starter components. Buyers must remain agile, adapting their strategies to manage these market fluctuations while ensuring they secure high-quality products at competitive prices.

How Does Sustainability Impact the Sourcing of Starter Installation Costs?

Sustainability has become a cornerstone of B2B procurement strategies, particularly in the automotive sector. The environmental impact of sourcing decisions has prompted companies to prioritize ethical supply chains and sustainable materials. For starters, this means considering the lifecycle of components, from raw material extraction to end-of-life disposal.

B2B buyers are increasingly looking for suppliers who adhere to ‘green’ certifications and utilize eco-friendly materials. This shift not only helps mitigate environmental impact but also aligns with consumer preferences, as end-users are becoming more conscious of sustainability issues. Companies that adopt sustainable practices may also benefit from cost savings over time, as energy-efficient production processes and reduced waste lead to lower operational costs.

Furthermore, regulatory pressures are on the rise globally, with governments implementing stricter environmental regulations. This trend necessitates that businesses remain compliant to avoid penalties, making it imperative for international buyers to engage with suppliers who prioritize sustainability in their operations. Ethical sourcing not only enhances brand reputation but also fosters long-term relationships with environmentally conscious partners.

What Is the Historical Context of the Starter Installation Cost Market?

The starter installation cost market has evolved significantly over the decades, reflecting broader trends in the automotive industry. In the early 20th century, starter motors were a luxury, primarily found in high-end vehicles. However, as mass production techniques advanced, starters became standard in almost all vehicles by the 1950s. This widespread adoption led to a surge in manufacturing and sourcing, significantly lowering costs.

Throughout the late 20th century, the introduction of electronic ignition systems and advancements in automotive technology further transformed starter designs, making them more efficient and reliable. As vehicles became increasingly sophisticated, the complexity of starter installation also grew, requiring specialized skills and tools, which in turn affected labor costs.

Today, the focus on electric vehicles and the integration of smart technologies are shaping the future of starter systems. This historical context highlights the necessity for B2B buyers to stay informed about technological innovations and market shifts to make strategic sourcing decisions that align with current and future industry trends.

Frequently Asked Questions (FAQs) for B2B Buyers of starter installation cost

1. How do I determine the total cost of starter installation for my fleet?

To calculate the total cost of starter installation for your fleet, consider several factors, including the price of the starter units, labor costs, and any additional parts needed for installation. Research local mechanic rates and compare quotes from multiple service providers to get a comprehensive estimate. Additionally, evaluate the accessibility of the starter in your vehicle models, as this can impact labor time and cost. Finally, factor in any potential downtime for your vehicles, which can also affect overall expenses.

2. What is the best way to choose a supplier for starter parts?

When selecting a supplier for starter parts, prioritize those with a solid reputation and proven track record in your region. Investigate their product quality, warranty terms, and customer service. Request samples or specifications to assess the compatibility with your vehicles. Additionally, consider their logistics capabilities, especially if you’re importing from abroad. It’s beneficial to choose suppliers who can provide customization options to meet specific needs and have clear communication regarding minimum order quantities (MOQs) and pricing structures.

3. How can I verify the quality of starter components before purchasing?

To ensure the quality of starter components, request certifications and compliance documents from your supplier, such as ISO or other relevant quality assurance standards. Conduct a thorough inspection of product samples, focusing on materials, construction, and compatibility with your vehicles. Additionally, seek reviews or testimonials from other B2B buyers who have previously sourced from the supplier. Establishing a relationship with suppliers who offer return policies or guarantees can also mitigate risks associated with defective parts.

4. What are typical payment terms when sourcing starters internationally?

Payment terms for international sourcing of starters can vary significantly. Common arrangements include upfront payments, letters of credit, or payment upon delivery. Negotiate terms that align with your cash flow and risk tolerance. Ensure that you clearly understand the currency exchange rates involved and any additional fees that may apply. It’s advisable to work with suppliers who offer flexible payment options and consider using escrow services for larger transactions to ensure both parties’ security.

5. How do logistics impact the cost of starter installations?

Logistics play a crucial role in the overall cost of starter installations, particularly for international sourcing. Shipping methods, import duties, and delivery times can significantly affect your budget. Choose suppliers who have efficient logistics networks to minimize shipping costs and delays. Additionally, consider warehousing options to reduce lead times, especially if you frequently require replacements. Collaborating with logistics experts can help optimize your supply chain and ensure timely availability of starter parts.

6. What factors influence the installation cost of starters in different regions?

Installation costs of starters can vary by region due to labor rates, availability of skilled mechanics, and the complexity of vehicle designs. Regions with higher labor costs, such as Western Europe, may see elevated installation fees compared to other areas. Additionally, import tariffs and local market conditions can affect part prices. Understanding these regional differences will help you budget more accurately and potentially identify areas where you can negotiate better rates.

7. How can I customize starter components for specific vehicles?

To customize starter components, communicate your specific requirements to your supplier, including vehicle make, model, and any special modifications. Suppliers with engineering capabilities can often create tailored solutions, but be prepared to discuss minimum order quantities and lead times. Providing detailed specifications and collaborating closely during the design phase will ensure that the final product meets your operational needs. Always request prototypes or samples before finalizing large orders to confirm compatibility and performance.

8. What are the common signs that a starter needs replacement?

Common indicators of a failing starter include irregular cranking, unusual noises when starting, or complete failure to engage. If your vehicles exhibit these symptoms, it’s advisable to conduct a thorough diagnostic to confirm the starter’s condition. In some cases, the issue may be linked to other electrical components, so a comprehensive check is essential. Establishing a routine maintenance schedule can help identify and address starter issues before they lead to costly downtime.

Top 6 Starter Installation Cost Manufacturers & Suppliers List

1. Reddit – Automotive Parts Pricing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Starter replacement, labor charges, part price, dealership pricing, diagnostic fees, OEM parts, markup on parts.

2. Last Chance Auto Repairs – Starter Replacement Costs

Domain: lastchanceautorepairs.com

Registered: 2009 (16 years)

Introduction: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Factors affecting cost: Vehicle type & model, New vs Re-Manufactured starters, Additional repairs. DIY costs: Parts only: $100 – $400, Time investment: 2-6 hours. Professional b…

3. Facebook – Starter Replacement Cost

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: cost to get car to the shop and replace starter

4. Compustar – Remote Starters

Domain: compustar.com

Registered: 1995 (30 years)

Introduction: Remote starters are an upgrade for vehicles, with costs ranging from $349.99 to $449.99 for basic, short-range systems installed on non-luxury vehicles. Prices vary based on the vehicle’s year, make, and model. Compustar remote start installers typically charge between $319.99 and $449.99 for systems plus installation. Additional costs may arise for features like extended-range remotes, bypass int…

5. Car Talk – Starter Replacement Costs

Domain: cartalk.com

Registered: 1995 (30 years)

Introduction: Cost to replace a starter: $600 to $900 for common vehicles; $900 to $1,400 for luxury models. Symptoms of a bad starter include a click when trying to start, screeching noise, or intermittent functionality. Starters can be new, remanufactured, or rebuilt. Modern vehicles with stop-start systems have starters designed to last despite frequent use.

6. CarBuzz – Starter Motor Replacement Costs

Domain: carbuzz.com

Registered: 2003 (22 years)

Introduction: Starter motor replacement cost ranges from $450 to $600 on average. For specific models, the Toyota Tundra (2000-2005) V8 starter replacement costs between $650 and $900, while the Honda Civic costs between $490 and $760. Factors affecting costs include labor time (1.5 to 2.5 hours for most starters, up to 4 hours for valley-mounted starters), starter motor costs ($120 to $200 for aftermarket, aro…

Strategic Sourcing Conclusion and Outlook for starter installation cost

As we conclude our exploration of starter installation costs, it is essential to emphasize the significance of strategic sourcing in optimizing your procurement processes. By understanding the nuances of starter replacement—from parts costs to labor—international B2B buyers can make informed decisions that directly impact their operational efficiency and budget management.

Engaging with reliable suppliers, especially those who understand the unique challenges faced in regions such as Africa, South America, the Middle East, and Europe, can yield substantial savings. Buyers should prioritize sourcing high-quality starters and components that align with their specific vehicle requirements, ensuring that they select options that are both cost-effective and dependable.

Looking ahead, the automotive parts market is poised for growth, with advancements in technology and supply chain management enhancing accessibility and affordability. We encourage B2B buyers to actively seek out partnerships with manufacturers and distributors who can provide tailored solutions and support. By doing so, you can secure a competitive edge in your operations while ensuring that your fleet remains reliable and efficient. Now is the time to act—evaluate your sourcing strategies and capitalize on the opportunities available in the evolving automotive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.