Introduction: Navigating the Global Market for what does the alternator do in a vehicle

The alternator plays a pivotal role in vehicle functionality, transforming mechanical energy from the engine into electrical energy to power a vehicle’s electrical systems. For international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe (including regions like Saudi Arabia and Vietnam), understanding the intricacies of alternators is crucial. This guide delves into the core functions of alternators, the various types available, their applications across different vehicle models, and essential considerations for supplier vetting.

Navigating the global market for alternators involves not just identifying the right specifications but also evaluating suppliers based on reliability, cost-effectiveness, and service quality. Buyers will gain insights into how to assess the longevity and performance of alternators, ensuring they make informed purchasing decisions that align with their operational needs. Additionally, this guide will highlight common challenges faced in sourcing and maintaining alternators, along with practical solutions to mitigate these issues.

By equipping B2B buyers with comprehensive knowledge, this resource empowers them to enhance their procurement strategies, ensuring they secure high-quality alternators that meet the demands of their diverse clientele. Understanding the role and significance of the alternator is more than just a technical necessity; it’s a strategic advantage in optimizing vehicle performance and reliability in competitive markets.

Содержание

- Top 3 What Does The Alternator Do In A Vehicle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what does the alternator do in a vehicle

- Understanding what does the alternator do in a vehicle Types and Variations

- Key Industrial Applications of what does the alternator do in a vehicle

- 3 Common User Pain Points for ‘what does the alternator do in a vehicle’ & Their Solutions

- Strategic Material Selection Guide for what does the alternator do in a vehicle

- In-depth Look: Manufacturing Processes and Quality Assurance for what does the alternator do in a vehicle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what does the alternator do in a vehicle’

- Comprehensive Cost and Pricing Analysis for what does the alternator do in a vehicle Sourcing

- Alternatives Analysis: Comparing what does the alternator do in a vehicle With Other Solutions

- Essential Technical Properties and Trade Terminology for what does the alternator do in a vehicle

- Navigating Market Dynamics and Sourcing Trends in the what does the alternator do in a vehicle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what does the alternator do in a vehicle

- Strategic Sourcing Conclusion and Outlook for what does the alternator do in a vehicle

- Важное предупреждение и условия использования

Understanding what does the alternator do in a vehicle Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Обычный генератор | Uses mechanical energy to produce AC, then converts to DC | Standard vehicles, light-duty trucks | Плюсы: Надежный, широко доступный. Минусы: Limited efficiency in extreme conditions. |

| Высокопроизводительный генератор | Provides increased output for high-demand electrical systems | Автомобили с высокими эксплуатационными характеристиками, индивидуальные сборки | Плюсы: Поддерживает передовую электронику. Минусы: Более высокая стоимость, может потребовать модификации. |

| Умный генератор | Features advanced voltage regulation and energy management | Гибридные и электрические автомобили | Плюсы: Повышает топливную экономичность, снижает выбросы. Минусы: More complex, higher maintenance needs. |

| Морской генератор | Designed for harsh marine environments, resistant to corrosion | Катера, яхты, морское оборудование | Плюсы: Durable, reliable in saltwater. Минусы: More expensive, specific to marine use. |

| Heavy-Duty Alternator | Built for heavy-duty applications with robust construction | Commercial trucks, construction vehicles | Плюсы: High durability, long lifespan. Минусы: Bulkier, higher weight can affect efficiency. |

Каковы характеристики обычных генераторов?

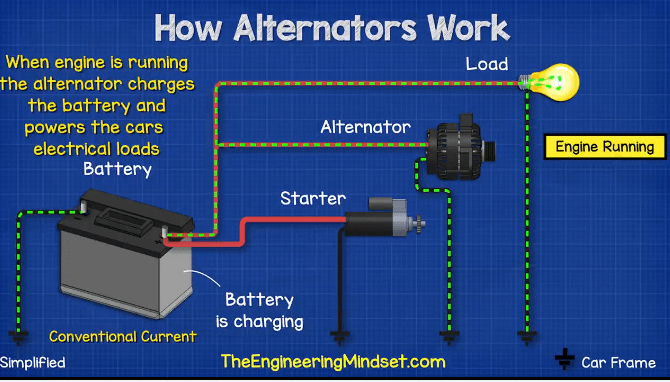

Conventional alternators are the most common type found in standard vehicles. They convert mechanical energy from the engine into electrical energy, supplying power to the battery and vehicle electronics. These alternators typically offer a balanced performance suitable for everyday driving needs. When considering a purchase, B2B buyers should evaluate the vehicle’s power requirements and ensure compatibility with existing electrical systems.

Как генераторы с высокой мощностью улучшают характеристики автомобилей?

High-output alternators are tailored for vehicles with increased electrical demands, such as those equipped with advanced audio systems, lighting, or other accessories. These alternators provide a greater electrical output, ensuring that all components function optimally. Buyers in performance automotive sectors should assess the specific power requirements of their installations and consider the trade-offs in terms of cost and installation complexity.

What Makes Smart Alternators Suitable for Hybrid and Electric Vehicles?

Smart alternators incorporate advanced technology that optimizes energy generation and management. They are particularly beneficial for hybrid and electric vehicles, where efficiency and reduced emissions are critical. B2B buyers should consider the integration of smart alternators into their fleet, as these systems can enhance overall vehicle performance and reduce operational costs over time.

Why Are Marine Alternators Designed for Harsh Environments?

Marine alternators are specifically designed to withstand the corrosive effects of saltwater and other harsh marine conditions. Their robust construction ensures reliable performance in boats and yachts. Buyers in the marine industry must prioritize durability and reliability when selecting alternators, as equipment failure can lead to significant operational downtime and safety risks.

How Do Heavy-Duty Alternators Support Commercial Applications?

Heavy-duty alternators are engineered for demanding applications, such as commercial trucks and construction vehicles. They are built to endure extreme conditions and provide a high output to support extensive electrical systems. B2B purchasers should focus on the longevity and reliability of these alternators, as the cost of downtime in commercial operations can be substantial.

Key Industrial Applications of what does the alternator do in a vehicle

| Отрасль/сектор | Specific Application of what does the alternator do in a vehicle | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Powering electrical components in vehicles | Ensures reliability and performance of vehicles, enhancing customer satisfaction. | Quality certifications, compatibility with various vehicle models, and sourcing from reputable manufacturers. |

| Транспорт и логистика | Charging systems in commercial vehicles | Reduces downtime by ensuring vehicles remain operational and efficient. | Availability of spare parts, warranty terms, and service support for maintenance. |

| Горнодобывающая промышленность и тяжелое оборудование | Power supply for machinery in remote locations | Guarantees functionality of equipment in harsh environments, improving productivity. | Durability under extreme conditions, ease of installation, and local support services. |

| Agriculture and Farming | Electrical systems in agricultural vehicles | Enhances operational efficiency and reliability of farming equipment. | Compatibility with various agricultural machinery and local climate considerations. |

| Транспортные средства с возобновляемой энергией | Supporting hybrid and electric vehicle systems | Contributes to sustainability goals while providing reliable power management. | Innovations in energy efficiency, compliance with international standards, and potential for integration with renewable sources. |

How Does the Alternator Benefit the Automotive Manufacturing Industry?

In the automotive manufacturing sector, the alternator plays a crucial role by powering various electrical components such as lights, infotainment systems, and power steering. A reliable alternator ensures that vehicles perform optimally, leading to higher customer satisfaction and brand loyalty. Manufacturers must consider sourcing alternators that are compatible with a range of vehicle models and come with quality certifications to ensure durability and performance.

What Role Does the Alternator Play in Transportation and Logistics?

For the transportation and logistics industry, alternators are essential for the efficient operation of commercial vehicles. They charge the battery and power electrical systems during long hauls, reducing the risk of vehicle breakdowns. This reliability minimizes downtime and enhances operational efficiency. When sourcing alternators, businesses should prioritize suppliers that offer robust warranties and readily available spare parts to ensure quick replacements.

How is the Alternator Used in Mining and Heavy Equipment?

In mining and heavy equipment applications, alternators are vital for providing electrical power to machinery operating in remote and harsh environments. These robust systems ensure that equipment functions correctly, thereby enhancing productivity. Buyers in this sector should focus on sourcing alternators that are designed for durability, withstanding extreme conditions, and providing local service support for maintenance and repairs.

What is the Importance of the Alternator in Agriculture and Farming?

In agriculture, the alternator is critical for the operation of various farming vehicles, powering essential systems like GPS and automated controls. A reliable alternator enhances the efficiency and reliability of agricultural machinery, which is crucial during peak seasons. Buyers should look for alternators that are compatible with different types of agricultural equipment and consider local climate conditions that may affect performance.

How Does the Alternator Support Renewable Energy Vehicles?

The rise of hybrid and electric vehicles highlights the importance of alternators in managing power supply effectively. They help charge batteries while ensuring that all vehicle systems operate smoothly. Businesses focused on renewable energy vehicles should seek alternators that are energy-efficient and compliant with international standards to align with sustainability goals while ensuring operational reliability.

3 Common User Pain Points for ‘what does the alternator do in a vehicle’ & Their Solutions

Scenario 1: Understanding Alternator Functionality for Fleet Maintenance

Проблема: B2B buyers managing vehicle fleets often struggle with understanding how alternators function within their vehicles. Misconceptions can lead to incorrect maintenance practices, resulting in unexpected breakdowns and increased operational costs. For instance, a fleet manager might assume that the battery alone powers all vehicle electronics, neglecting the critical role of the alternator. This lack of understanding can cause delays in repairs and affect the overall efficiency of the fleet.

Illustrative image related to what does the alternator do in a vehicle

Решение: To overcome this challenge, fleet managers should invest in training sessions focused on vehicle electrical systems, specifically highlighting the alternator’s role. Additionally, creating a comprehensive maintenance guide that details how the alternator interacts with the battery and other electrical components will empower your team. Regular inspections should include checking the alternator’s health to ensure it’s functioning correctly. Consider using telematics solutions that provide real-time data on vehicle performance, allowing for proactive maintenance before issues arise. Such measures not only reduce downtime but also enhance fleet reliability.

Scenario 2: Identifying Signs of Alternator Failure in Commercial Vehicles

Проблема: Commercial vehicle operators often face the challenge of identifying early warning signs of alternator failure. Symptoms like dimming headlights or dashboard warning lights can be easily overlooked, leading to sudden vehicle failures that disrupt service and incur additional costs. For example, a delivery truck experiencing intermittent electrical issues may not be immediately recognized as an alternator problem, risking timely deliveries and customer satisfaction.

Решение: B2B buyers should implement a standardized checklist for vehicle inspections that includes specific signs of alternator failure. This checklist could cover visual cues, such as checking for dashboard warning lights and listening for unusual sounds under the hood. Establishing a routine maintenance schedule that includes diagnostic checks of the alternator can help catch issues before they escalate. Furthermore, investing in diagnostic tools that can read the vehicle’s electrical system data will aid mechanics in pinpointing alternator-related problems swiftly. By prioritizing early detection, businesses can maintain service continuity and protect their operational bottom line.

Scenario 3: Selecting the Right Alternator for Different Vehicle Types

Проблема: Businesses that operate a diverse fleet of vehicles may encounter difficulties when selecting the appropriate alternator for different vehicle types. Each vehicle model may have specific electrical requirements, and using an incompatible alternator can lead to performance issues or even damage to the vehicle’s electrical system. This lack of clarity can create confusion among procurement teams, potentially resulting in costly errors.

Решение: To address this issue, B2B buyers should develop a systematic approach for sourcing alternators tailored to each vehicle type in their fleet. This includes maintaining a detailed database of each vehicle’s specifications, including alternator requirements, power ratings, and compatibility with electrical systems. Collaborating with reputable suppliers who can provide accurate product information and support will also streamline the procurement process. Additionally, consider engaging with manufacturers who offer warranty programs and customer support for their alternators, ensuring you have reliable replacements when needed. By establishing clear guidelines and sourcing practices, businesses can minimize risks and ensure optimal vehicle performance.

Strategic Material Selection Guide for what does the alternator do in a vehicle

Какие материалы обычно используются в генераторах и каковы их эксплуатационные характеристики?

When considering the materials used in alternators, it is crucial to analyze their properties, advantages, disadvantages, and implications for international B2B buyers. This understanding helps ensure that the selected materials meet performance requirements while adhering to regional standards.

1. Алюминий

Ключевые свойства:

Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It typically withstands temperatures up to 150°C and has a density of about 2.7 g/cm³.

Плюсы и минусы:

Aluminum’s lightweight nature contributes to overall vehicle efficiency, making it a preferred choice for automotive applications. However, its lower strength compared to steel can be a limitation in high-stress applications. Manufacturing complexity is moderate, as aluminum can be cast or machined easily.

Влияние на применение:

In alternators, aluminum is often used for housings and components that require efficient heat dissipation. Its compatibility with various automotive fluids is generally good, but care must be taken to avoid galvanic corrosion when in contact with other metals.

Соображения для международных покупателей:

Aluminum is widely accepted across global markets, including Africa and Europe, where standards such as ASTM and DIN are prevalent. Buyers should ensure compliance with local regulations regarding recyclability and material sourcing.

2. Медь

Ключевые свойства:

Copper has excellent electrical conductivity, thermal conductivity, and corrosion resistance. It can operate effectively at temperatures up to 200°C.

Illustrative image related to what does the alternator do in a vehicle

Плюсы и минусы:

Copper’s high conductivity makes it ideal for windings and electrical connections in alternators, ensuring efficient energy transfer. However, it is more expensive than aluminum and heavier, which can affect vehicle weight. Manufacturing processes for copper can be complex due to its malleability.

Влияние на применение:

In alternators, copper is primarily used for windings and connectors. Its compatibility with electrical systems is exceptional, but it may require insulation to prevent short circuits.

Соображения для международных покупателей:

Copper is subject to fluctuating prices due to market demand, which can impact overall costs. Buyers in regions like South America and the Middle East should consider sourcing strategies that mitigate price volatility and ensure compliance with international standards.

3. Сталь

Ключевые свойства:

Steel offers high tensile strength, durability, and resistance to deformation. It can withstand high temperatures (up to 300°C) and has a density of approximately 7.85 g/cm³.

Плюсы и минусы:

Steel’s robustness makes it suitable for structural components in alternators, providing longevity and reliability. However, it is heavier than aluminum and can be prone to rust if not properly coated. Manufacturing processes can be complex due to the need for precise machining.

Влияние на применение:

Steel is often used for the alternator’s frame and rotor components, where strength is critical. Its compatibility with various automotive environments is generally good, but additional coatings may be necessary to prevent corrosion.

Соображения для международных покупателей:

Steel must comply with various international standards (e.g., ASTM, JIS) regarding strength and corrosion resistance. Buyers should also consider local availability and the cost implications of importing steel components.

4. Пластиковые композиты

Ключевые свойства:

Plastic composites are lightweight, corrosion-resistant, and can be engineered for specific thermal and electrical properties. They typically withstand temperatures up to 120°C.

Плюсы и минусы:

These materials are highly versatile and can be molded into complex shapes, making them suitable for various components in alternators. However, they may not offer the same strength as metals and can degrade under UV exposure. Manufacturing is generally less complex and more cost-effective.

Влияние на применение:

Plastic composites are often used for non-structural parts, such as housings and insulators. Their compatibility with electrical systems is good, but they may require careful selection to ensure they can withstand automotive environments.

Соображения для международных покупателей:

Plastic composites must meet specific industry standards for automotive applications. Buyers should ensure compliance with local regulations regarding material safety and environmental impact.

Сводная таблица

| Материал | Typical Use Case for what does the alternator do in a vehicle | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Housings and heat sinks | Легкий и коррозионно-стойкий | Более низкая прочность по сравнению со сталью | Средний |

| Медь | Обмотки и электрические соединения | Отличная электропроводность | Более высокая стоимость и вес | Высокий |

| Сталь | Structural components (frame, rotor) | Высокая прочность и долговечность | Более тяжелый и подверженный ржавчине | Средний |

| Пластиковые композиты | Non-structural parts (housings, insulators) | Легкий и универсальный | Снижение прочности и деградация под воздействием ультрафиолета | Низкий |

This analysis provides a comprehensive overview of the materials commonly used in alternators, enabling B2B buyers to make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for what does the alternator do in a vehicle

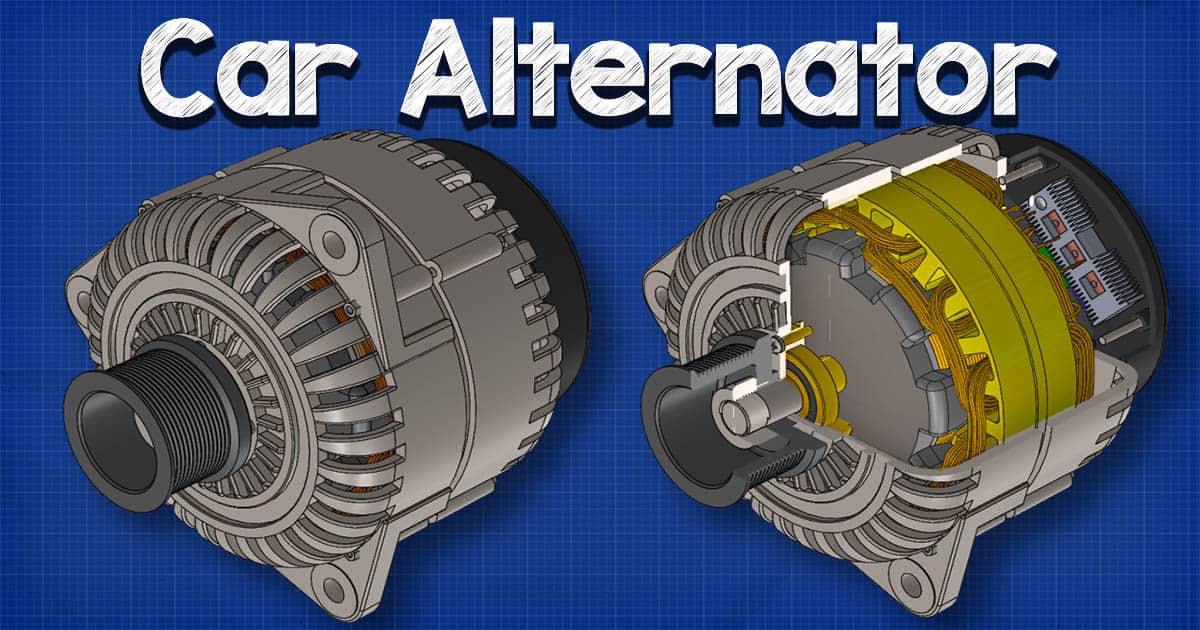

What Are the Key Manufacturing Processes for Vehicle Alternators?

Manufacturing an alternator involves several stages that ensure the component meets the required performance specifications and quality standards. Understanding these processes is vital for B2B buyers looking to procure reliable automotive components.

Illustrative image related to what does the alternator do in a vehicle

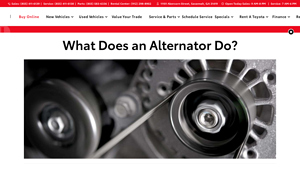

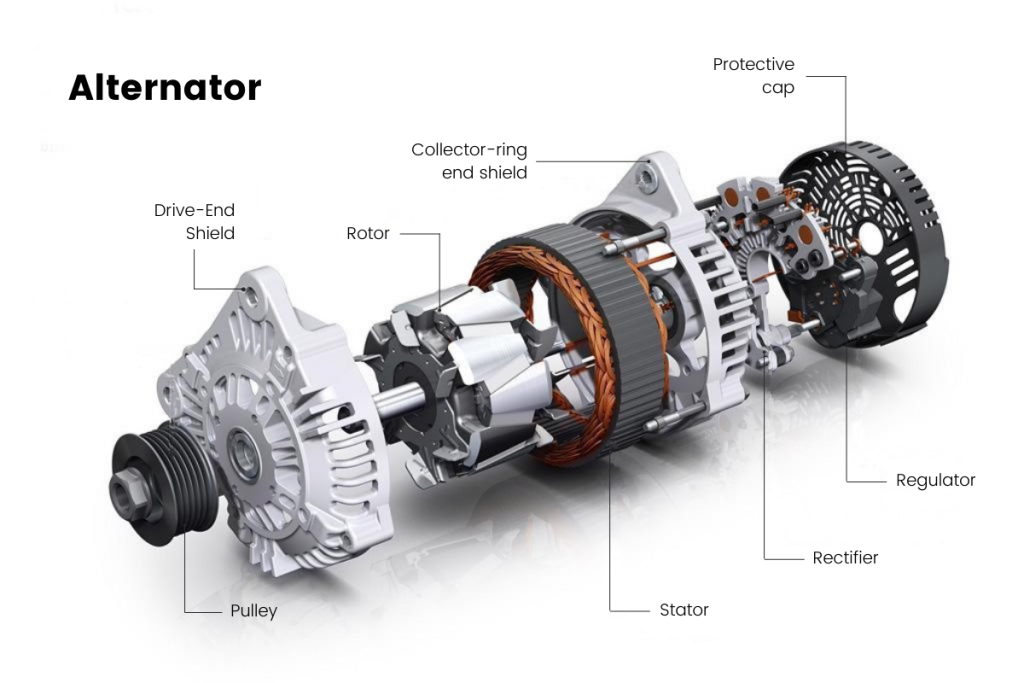

What Materials Are Used in Alternator Manufacturing?

The primary materials used in alternator manufacturing include high-grade steel for the rotor and stator, aluminum for the housing, and copper for the windings. These materials are selected for their durability, conductivity, and ability to withstand high temperatures. The preparation of these materials involves precision cutting and shaping to ensure they fit together correctly during assembly.

How Is the Alternator Formed?

The forming stage typically involves several key techniques:

-

Stator and Rotor Manufacturing: The stator is made by stacking thin laminations of electrical steel to reduce energy loss due to eddy currents. The rotor is created using a combination of casting and machining processes to achieve the required magnetic properties.

-

Намотка: Copper wires are wound around the stator’s core to create the necessary electromagnetic field. This process requires precision to ensure that the coils are evenly distributed and securely attached.

-

Housing Fabrication: The alternator housing is formed through die casting or stamping. This stage is crucial as it protects internal components and contributes to the overall structural integrity of the alternator.

What Assembly Techniques Are Commonly Used?

Once the individual components are prepared, the assembly process begins. This typically involves:

-

Интеграция компонентов: The rotor is placed within the stator, and the two are aligned precisely. This alignment is essential for efficient energy conversion.

-

Электрические соединения: The windings are connected to the rectifier, which converts AC to DC. This step requires careful attention to ensure that connections are secure and that there are no short circuits.

-

Заключительная сборка: After integrating all components, the alternator is assembled into its housing, and the voltage regulator is added to manage output levels.

Какие меры контроля качества применяются при производстве генераторов?

Quality assurance is critical in the manufacturing of alternators, as failures can lead to significant vehicle malfunctions. Various international and industry-specific standards guide these practices.

Which International Standards Are Relevant for Alternator Quality Assurance?

ISO 9001 is a widely recognized standard that outlines criteria for a quality management system. Manufacturers of alternators often adhere to this standard to ensure consistent quality in their processes. Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the market and application.

Каковы ключевые точки контроля качества в производственном процессе?

Quality control checkpoints are integral to ensuring that alternators meet required specifications. These checkpoints typically include:

-

Входящий контроль качества (IQC): Raw materials are inspected upon arrival to verify they meet specified standards.

-

Контроль качества в процессе производства (IPQC): During the manufacturing stages, inspections are conducted to ensure that each process is performed correctly, including measurements of dimensions and weights.

-

Окончательный контроль качества (FQC): Once the alternator is fully assembled, it undergoes rigorous testing to assess its electrical performance, mechanical integrity, and safety features.

What Common Testing Methods Are Used to Verify Alternator Quality?

Testing methods for alternators include:

-

Электрические испытания: This involves measuring output voltage and current to ensure the alternator functions correctly under various load conditions.

-

Термические испытания: Alternators are subjected to high temperatures to evaluate their performance and durability under extreme conditions.

-

Вибрационные испытания: This assesses the alternator’s ability to withstand vibrations that occur during vehicle operation, ensuring long-term reliability.

Как покупатели B2B могут проверить методы контроля качества поставщиков?

For B2B buyers, verifying the quality control practices of alternator suppliers is essential for ensuring product reliability. Here are several methods to achieve this:

What Steps Can Buyers Take to Conduct Supplier Audits?

-

Аудит поставщиков: Regular audits can be conducted to review the manufacturing processes, quality control measures, and compliance with international standards. This is an effective way to assess the supplier’s commitment to quality.

-

Запрос отчетов о качестве: Suppliers should provide documentation of their quality control processes, including test results and compliance certifications. This transparency is crucial for buyers.

-

Проверки третьей стороной: Engaging third-party inspection agencies can provide unbiased assessments of the supplier’s manufacturing and quality assurance processes. This can be particularly valuable when entering new markets or establishing relationships with unfamiliar suppliers.

Каковы нюансы контроля качества для иностранных покупателей?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe need to consider specific quality control nuances:

-

Соблюдение нормативных требований: Different countries have varying regulations regarding automotive components. Buyers should ensure that their suppliers comply with local laws, which may include additional certifications beyond ISO and CE.

-

Культурные аспекты: Understanding the local manufacturing culture can aid in building effective partnerships. This includes awareness of communication styles, negotiation practices, and expectations regarding quality.

-

Логистические проблемы: Quality assurance may also extend to logistics, including the conditions under which alternators are transported. Buyers should ensure that suppliers maintain quality during shipping and handling to avoid damage.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with alternators is critical for B2B buyers. By focusing on these areas, buyers can make informed decisions that ensure the reliability and performance of the components they procure.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what does the alternator do in a vehicle’

To assist B2B buyers in understanding the critical role of alternators in vehicles, this guide provides a comprehensive checklist for sourcing and evaluating alternators. By following these steps, buyers can ensure they are making informed decisions that meet their operational needs.

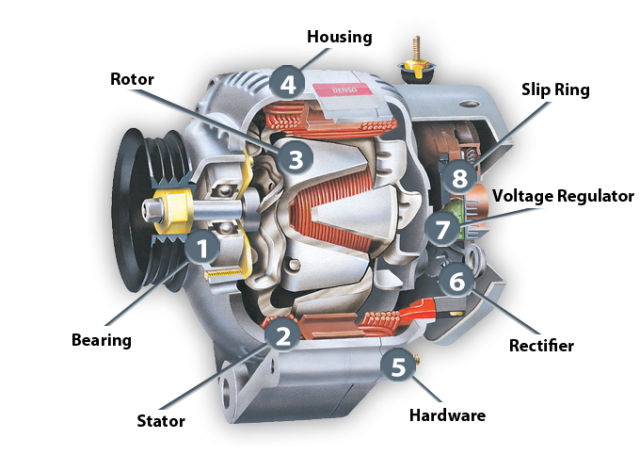

Шаг 1: Understand the Functionality of Alternators

Before procuring alternators, it’s essential to grasp their role in vehicle performance. Alternators convert mechanical energy from the engine into electrical energy, powering the vehicle’s battery and electrical systems. This knowledge helps in selecting products that meet the specific energy requirements of different vehicle models.

Шаг 2: Определите свои технические характеристики

Identify the technical requirements for the alternators you need. This includes voltage output, amperage rating, and compatibility with specific vehicle models. Knowing these specifications ensures you procure alternators that will function effectively within the intended vehicles, minimizing the risk of operational failures.

Illustrative image related to what does the alternator do in a vehicle

Шаг 3: Оцените потенциальных поставщиков

Conduct thorough research on potential suppliers to ensure they meet your quality and reliability standards. Request company profiles, certifications, and references from other clients in your industry. Look for suppliers that have experience with the specific types of vehicles you work with, especially in your target regions like Africa, South America, and the Middle East.

- Сертификаты поставщиков: Verify that suppliers hold relevant industry certifications, which indicate adherence to quality standards.

- Customer Feedback: Seek reviews or testimonials from previous buyers to gauge supplier reliability and product performance.

Шаг 4: Оцените качество продукции и гарантию

Evaluate the quality of the alternators offered by different suppliers. Look for products that come with warranties, as this can be a sign of the manufacturer’s confidence in their product. A robust warranty can also protect your investment in case of premature failure.

- Material Quality: Check for alternators made from durable materials that can withstand harsh conditions, especially in regions with extreme climates.

- Стандарты тестирования: Ensure that the alternators have undergone rigorous testing to meet international standards.

Шаг 5: Рассмотрим послепродажную поддержку и обслуживание

Assess the after-sales support offered by the suppliers. This includes installation assistance, technical support, and availability of spare parts. Good after-sales service can significantly enhance your operational efficiency and reduce downtime.

- Availability of Technical Resources: Ensure that suppliers provide manuals, installation guides, and troubleshooting resources.

- Response Time for Support: Evaluate the supplier’s response time for inquiries or support requests, as timely assistance is critical in maintaining vehicle performance.

Шаг 6: Переговоры об условиях и ценах

Once you have shortlisted potential suppliers, engage in negotiations to secure favorable pricing and terms. Consider the total cost of ownership, including shipping, installation, and potential maintenance costs. Make sure the terms align with your budget while ensuring product quality is not compromised.

Шаг 7: Make Informed Purchases

After completing the evaluation and negotiation process, finalize your purchase decision. Ensure that all agreements are documented and review the purchase order carefully before signing. This step is crucial to avoid misunderstandings regarding product specifications, delivery timelines, and payment terms.

By following this checklist, B2B buyers can effectively navigate the procurement process for alternators, ensuring they select the right products that align with their operational needs and contribute to the overall performance of their vehicle fleet.

Comprehensive Cost and Pricing Analysis for what does the alternator do in a vehicle Sourcing

What Are the Cost Components for Sourcing an Alternator in a Vehicle?

When analyzing the cost structure associated with sourcing alternators, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control, logistics, and the desired profit margin.

Материалы: The primary materials used in alternator production include copper for wiring, aluminum for the casing, and various plastics and metals for internal components. The cost of these raw materials can fluctuate based on global market trends and availability, which can significantly impact overall pricing.

Illustrative image related to what does the alternator do in a vehicle

Труд: Labor costs vary significantly depending on the region of manufacturing. In regions with lower labor costs, such as parts of Asia and South America, buyers may find more competitive pricing. However, regions with higher labor standards may reflect these costs in the final product pricing.

Производственные накладные расходы: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can be a point of negotiation for buyers.

Инструментарий: The initial setup costs for manufacturing tooling can be substantial. Custom tooling for specific alternator designs or specifications will increase initial costs but may lead to lower per-unit costs for higher volume orders.

Контроль качества (КК): Ensuring quality is paramount, particularly for automotive components. Investing in rigorous QC processes can prevent costly recalls and warranty claims. Buyers should consider suppliers that prioritize quality certifications, as these can assure product reliability.

Логистика: Transportation costs must also be factored in, especially for international shipments. Incoterms play a crucial role in determining who bears these costs. Buyers should be aware of the logistics chain and any potential tariffs or duties that could affect total costs.

Маржа: Suppliers typically apply a markup based on their operational costs and market conditions. Understanding the margin expectations of suppliers can provide leverage during negotiations.

What Influences the Pricing of Alternators for International B2B Buyers?

Several factors can influence the pricing of alternators, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe.

Illustrative image related to what does the alternator do in a vehicle

Объем и минимальное количество заказа (MOQ): Bulk orders often lead to reduced unit prices. Buyers should negotiate MOQs that align with their needs while ensuring they benefit from economies of scale.

Технические характеристики и персонализация: Alternators can vary widely in specifications. Custom features or designs may incur additional costs. Buyers should clearly communicate their needs to avoid unexpected charges.

Сертификация материалов и качества: The choice of materials significantly affects pricing. Alternators made from high-quality materials or those that meet specific international standards may command higher prices but offer better longevity and performance.

Факторы поставщика: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers with a track record of quality may charge more, but they can also reduce the risk of issues down the line.

Инкотермс: Understanding and negotiating Incoterms is critical for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact overall costs.

What Tips Can Help Buyers Optimize Costs When Sourcing Alternators?

Buyers should adopt a strategic approach when sourcing alternators to optimize costs. Here are several actionable tips:

-

Обсудите условия: Always seek to negotiate pricing, payment terms, and delivery schedules. Having multiple suppliers can enhance bargaining power.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but the entire lifecycle cost, including installation, maintenance, and potential downtime.

-

Разберитесь в нюансах ценообразования: Be aware of currency fluctuations, trade tariffs, and import regulations that could affect pricing, especially in international transactions.

-

Build Relationships with Suppliers: Long-term relationships can lead to better pricing and service. Suppliers may offer discounts to repeat customers or those who commit to larger orders.

-

Evaluate Multiple Suppliers: Diversifying suppliers can mitigate risks and provide leverage in negotiations. It can also help in sourcing more competitive pricing.

Заключение

Sourcing alternators involves understanding a complex interplay of costs and pricing factors. By leveraging insights on cost components, price influencers, and strategic negotiation tactics, international B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing what does the alternator do in a vehicle With Other Solutions

Understanding Alternative Solutions to Vehicle Power Generation

When it comes to powering a vehicle’s electrical systems, the alternator plays a critical role by converting mechanical energy from the engine into electrical energy. However, other technologies and methods can also fulfill similar functions. This section explores viable alternatives to the traditional alternator, allowing B2B buyers to evaluate various options based on their specific operational needs and constraints.

Сравнительная таблица

| Аспект сравнения | What Does The Alternator Do In A Vehicle | Alternative 1 Name: DC Generator | Alternative 2 Name: Battery-Only System |

|---|---|---|---|

| Производительность | Efficiently charges the battery and powers electrical components while the engine runs. | Provides a steady supply of DC power but is less efficient for varying loads. | Relies solely on stored energy; performance degrades as the battery discharges. |

| Стоимость | Moderate initial cost with long-term reliability. | Lower initial cost but may require frequent replacements. | High initial cost for quality batteries; ongoing replacement costs. |

| Простота внедрения | Standard installation in most combustion engine vehicles. | Simple installation but may require additional components for regulation. | Installation can be complex, especially for larger systems needing multiple batteries. |

| Техническое обслуживание | Requires minimal maintenance; typically lasts 7-10 years. | Regular maintenance needed for efficiency and longevity. | Requires frequent monitoring and potential replacement of batteries. |

| Лучший вариант использования | Ideal for conventional vehicles with combustion engines. | Suitable for specific applications requiring constant DC power. | Best for electric vehicles or hybrid models where charging infrastructure is available. |

Подробная разбивка альтернатив

Alternative 1: DC Generator

A DC generator serves as an alternative power source, converting mechanical energy into direct current (DC) electricity. While it can provide a steady power supply, its efficiency diminishes under varying loads, making it less suitable for the fluctuating demands of a vehicle’s electrical system. The installation of a DC generator is relatively straightforward, but it may necessitate additional components to manage voltage regulation effectively. Additionally, while the initial costs are lower than those of an alternator, the maintenance requirements can add to the overall expense over time.

Alternative 2: Battery-Only System

The battery-only system relies on stored electrical energy to power the vehicle’s electrical components. This method eliminates the need for an alternator entirely, making it attractive for electric and hybrid vehicles. However, as the battery discharges, the performance of the system deteriorates, leading to potential operational challenges. While the initial investment in high-quality batteries can be substantial, ongoing costs for replacements and maintenance can also be significant. This system is best suited for environments with robust charging infrastructure, where regular recharging is feasible.

Заключение: выбор правильного решения для ваших нужд

For B2B buyers evaluating power generation solutions for vehicles, understanding the role of the alternator and its alternatives is essential. The traditional alternator is a reliable choice for combustion engine vehicles, offering efficient performance and low maintenance requirements. In contrast, a DC generator may suit niche applications requiring consistent power, while battery-only systems cater to the growing electric vehicle market. Ultimately, the decision should align with the specific operational context, budgetary constraints, and long-term maintenance capabilities of the fleet in question. By carefully weighing these factors, buyers can select the most effective solution to meet their unique power generation needs.

Essential Technical Properties and Trade Terminology for what does the alternator do in a vehicle

What Are the Key Technical Properties of an Alternator in a Vehicle?

Understanding the essential technical properties of an alternator is crucial for B2B buyers involved in automotive manufacturing, repair, or parts distribution. Here are some critical specifications:

-

Выходное напряжение

– Определение: The standard voltage output for most vehicle alternators is typically 12 volts for passenger vehicles and can be higher for commercial or heavy-duty vehicles.

– Важность: Ensuring the correct voltage output is vital for compatibility with the vehicle’s electrical system. An alternator that does not provide adequate voltage can lead to insufficient charging of the battery and electrical malfunctions. -

Номинальный ток

– Определение: This measures the maximum current the alternator can supply, usually expressed in amps (A). Common ratings range from 40A to over 200A depending on the vehicle type and electrical load.

– Важность: Knowing the amperage rating helps buyers ensure that the alternator can handle the electrical demands of modern vehicles, especially those with numerous electronic components. -

Диапазон оборотов

– Определение: The revolutions per minute (RPM) at which the alternator operates efficiently, typically between 1,000 and 6,000 RPM.

– Важность: Understanding the RPM range is essential for ensuring optimal performance. An alternator functioning outside this range may not generate adequate power, leading to battery drain or failure. -

Cooling System

– Определение: Alternators can feature either passive or active cooling systems. Passive systems rely on airflow, while active systems may include built-in fans.

– Важность: A robust cooling system extends the lifespan of the alternator by preventing overheating, which can lead to component failure. B2B buyers should assess cooling options based on the expected operating environment. -

Состав материала

– Определение: The materials used in the alternator’s construction, including aluminum for the housing and copper for the windings.

– Важность: High-quality materials ensure durability and efficient energy transfer, which are critical for long-term reliability in various operating conditions.

Каковы распространенные торговые термины, связанные с генераторами?

Familiarity with industry-specific terminology can enhance communication and streamline transactions in the B2B marketplace. Here are several key terms:

-

OEM (производитель оригинального оборудования)

– Определение: Refers to parts produced by the vehicle manufacturer or their authorized suppliers.

– Важность: OEM parts typically guarantee compatibility and reliability, making them a preferred choice for maintenance and repairs. -

MOQ (минимальный объем заказа)

– Определение: The smallest number of units that a supplier is willing to sell in a single order.

– Важность: Understanding MOQ is crucial for inventory management and pricing strategies. Buyers must assess whether they can meet these minimums based on their sales forecasts. -

RFQ (запрос предложения)

– Определение: A document sent by a buyer to potential suppliers requesting pricing and terms for a specific product.

– Важность: An RFQ helps buyers obtain competitive pricing and terms from multiple suppliers, facilitating better purchasing decisions. -

Инкотермс (Международные торговые термины)

– Определение: A set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions.

– Важность: Familiarity with Incoterms helps buyers understand shipping costs, risks, and obligations, which is essential for international trade involving alternators. -

Гарантийный срок

– Определение: The time frame during which a manufacturer guarantees the performance of the alternator against defects.

– Важность: A longer warranty period can indicate higher product quality and reliability, providing peace of mind for B2B buyers regarding their investment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding alternators, ensuring they meet their operational needs while maintaining quality and reliability.

Navigating Market Dynamics and Sourcing Trends in the what does the alternator do in a vehicle Sector

Какие глобальные факторы влияют на рынок генераторов?

The global automotive industry is experiencing a significant transformation, primarily driven by technological advancements and a shift towards electrification. As vehicles increasingly integrate advanced electronic systems, the role of the alternator has become even more critical in ensuring efficient energy management. This is particularly pertinent for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where the demand for reliable automotive components is steadily rising.

Emerging trends in the automotive sector include the adoption of smart technologies and automation, which necessitate high-performance alternators capable of supporting a growing array of electrical systems. Additionally, as hybrid and electric vehicles gain traction, manufacturers are exploring innovative alternator designs that enhance energy efficiency and reduce overall vehicle weight. This evolution is prompting B2B buyers to seek suppliers who offer cutting-edge alternators that align with these market dynamics.

Moreover, the increasing regulatory pressure for fuel efficiency and lower emissions is pushing manufacturers to invest in high-quality, durable alternators. As a result, international buyers are urged to prioritize sourcing from reputable suppliers that can provide robust warranties and reliable performance metrics, ensuring that they remain competitive in the global market.

How Is Sustainability Impacting the Sourcing of Alternators in the Automotive Sector?

Sustainability is becoming a pivotal factor in the automotive supply chain, influencing how alternators are manufactured and sourced. Buyers are increasingly focusing on the environmental impact of their procurement choices, leading to a demand for ethically sourced materials and production processes. This shift is particularly relevant for regions like Europe and the Middle East, where stringent environmental regulations are in place.

Ethical sourcing practices not only enhance brand reputation but also contribute to the reduction of carbon footprints. B2B buyers are encouraged to seek out suppliers who prioritize the use of recycled materials and environmentally friendly manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and adherence to REACH regulations (Registration, Evaluation, Authorisation, and Restriction of Chemicals) can serve as indicators of a supplier’s commitment to sustainability.

Additionally, the trend towards ‘green’ technologies, including the development of eco-friendly alternators, is gaining momentum. These alternators are designed to minimize energy loss and improve efficiency, thereby supporting the overall sustainability goals of the automotive industry. As consumers increasingly demand greener vehicles, the sourcing of sustainable alternators will become a critical consideration for B2B buyers aiming to meet market expectations.

Каков исторический контекст развития альтернаторов в автомобильной промышленности?

The alternator’s evolution has been instrumental in shaping modern automotive technology. Initially introduced in the early 1960s, the alternator replaced the less efficient dynamo, providing a more reliable source of electrical power for vehicles. This transition allowed for the development of more advanced electrical systems, paving the way for the integration of features like power steering, electronic ignition, and enhanced lighting systems.

As the automotive industry evolved, so did the design and functionality of alternators. Advances in materials and manufacturing processes have led to lighter, more efficient alternators that can handle the increasing electrical demands of contemporary vehicles. Today, alternators are equipped with sophisticated voltage regulators and smart technology that optimizes performance, ensuring that all vehicle systems operate smoothly.

Understanding the historical context of alternators not only provides insight into their significance but also highlights the ongoing innovations that continue to shape the automotive landscape. For B2B buyers, this knowledge is essential for making informed sourcing decisions that align with current and future market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of what does the alternator do in a vehicle

-

How do I identify signs of a failing alternator?

Identifying a failing alternator is crucial for vehicle maintenance. Common signs include dimming headlights, dashboard warning lights, and difficulty starting the engine. If you notice unusual sounds like whining or screeching, or if electrical components like power windows and radios malfunction, these may indicate alternator issues. Regular inspections can help catch these problems early, ensuring the vehicle operates smoothly and preventing potential disruptions in logistics. -

Какой тип генератора лучше всего подходит для коммерческих автомобилей?

For commercial vehicles, high-output alternators are often the best choice. They are designed to handle the greater electrical demands of vehicles that power multiple accessories or equipment. Look for alternators with robust build quality and warranties. Consider suppliers that offer customization options for specific vehicle models, ensuring compatibility and efficiency, which is critical for business operations. -

Как проверить поставщиков генераторов переменного тока?

When vetting suppliers for alternators, consider their reputation, certifications, and experience in the industry. Request references from previous clients and inquire about their quality assurance processes. Ensure they comply with international standards, particularly if sourcing from different regions. A good supplier should also provide transparent communication and support throughout the purchasing process, enhancing trust and reliability. -

Каковы типичные минимальные объемы заказа (MOQ) для генераторов переменного тока?

Minimum order quantities for alternators can vary significantly between suppliers. Some may offer MOQs as low as 10 units, while others might require orders of 100 or more. It’s essential to discuss your specific needs with potential suppliers and negotiate MOQs based on your purchasing capabilities. This flexibility can be vital for managing inventory and cash flow, especially for businesses in emerging markets. -

На какие условия оплаты следует рассчитывать при поставке генераторов?

Payment terms can differ widely among suppliers, typically ranging from upfront payments to net 30 or net 60 terms. Some suppliers may offer discounts for early payments or larger orders. It’s advisable to establish clear payment terms upfront and consider using secure payment methods to mitigate risks. Understanding these terms is crucial for managing cash flow and ensuring timely delivery of products. -

What quality assurance measures should be in place for alternators?

Quality assurance for alternators should include rigorous testing and inspection processes. Look for suppliers that perform electrical and mechanical tests to verify functionality and durability. Certifications from recognized standards organizations can also indicate quality. Regular audits and feedback loops with suppliers will help maintain high standards and reduce the risk of defective products impacting your operations. -

How do logistics impact the sourcing of alternators internationally?

Logistics play a critical role in the international sourcing of alternators. Factors such as shipping costs, lead times, and customs regulations can significantly affect overall expenses and delivery timelines. It’s essential to work with logistics partners who understand the complexities of international trade and can ensure efficient transportation and compliance with local regulations. Planning for potential delays can help maintain supply chain continuity. -

What are the benefits of customizing alternators for specific applications?

Customizing alternators can provide significant advantages, especially for specialized vehicles or equipment. Tailored alternators can meet unique power requirements, enhance performance, and improve overall vehicle efficiency. Additionally, customization can lead to better integration with existing systems, reducing installation time and costs. Engaging with manufacturers that offer customization options allows businesses to optimize their operations and ensure reliability in their fleet.

Top 3 What Does The Alternator Do In A Vehicle Manufacturers & Suppliers List

1. Reddit – Automotive Basics

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: This company, Reddit – Automotive Basics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Facebook – Alternator

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: This company, Facebook – Alternator, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Тойота Саванна - Альтернаторы

Домен: savannahtoyota.com

Зарегистрирован: 1996 (29 лет)

Введение: The alternator powers all electronics in a vehicle while the engine is running, functioning as a generator using the gas engine as its energy source. It typically lasts between 80,000 and 150,000 miles (about seven years). The average cost for a new alternator ranges from $500 to $1,000, depending on the vehicle type. Signs of a failing alternator include a battery warning light, dim headlights, b…

Strategic Sourcing Conclusion and Outlook for what does the alternator do in a vehicle

In conclusion, understanding the pivotal role of the alternator in vehicle performance is essential for B2B buyers in the automotive sector. As a critical component, the alternator not only recharges the battery but also powers essential electrical systems, ensuring the vehicle operates efficiently. Recognizing the importance of sourcing high-quality alternators can lead to improved vehicle reliability and customer satisfaction, particularly in markets across Africa, South America, the Middle East, and Europe.

Strategic sourcing of alternators involves evaluating suppliers based on quality, reliability, and responsiveness to market demands. This approach minimizes the risk of component failure, which can lead to costly downtime and diminished brand reputation. Buyers should seek partnerships with manufacturers that offer comprehensive support, including warranty options and service assistance.

As the automotive landscape evolves with advancements in technology, now is the time for international buyers to invest in superior alternator solutions that align with their operational needs. By prioritizing quality and efficiency in sourcing, businesses can enhance their competitive edge and ensure long-term success in a dynamic market. Engage with trusted suppliers today to secure the best alternator solutions for your fleet and elevate your business operations.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.