Введение: Навигация по глобальному рынку как проверить соленоид стартера

В динамичном ландшафте глобальных цепочек поставок обеспечение надежности оборудования часто зависит от работы таких критически важных компонентов, как соленоид стартера. Для международных покупателей B2B, стремящихся приобрести высококачественные соленоиды стартера, понимание того, как проверять эти компоненты, необходимо не только для поддержания эффективности работы, но и для минимизации дорогостоящих простоев. Данное руководство посвящено сложному процессу проверки соленоидов стартера и содержит практические рекомендации, предназначенные для различных отраслей промышленности.

В этом всеобъемлющем ресурсе мы рассмотрим различные типы соленоидов стартера, их конкретные области применения и лучшие практики для эффективной проверки поставщиков. Кроме того, мы рассмотрим финансовые последствия решений о поиске поставщиков, включая анализ затрат и оценку долгосрочной стоимости. Предоставляя возможность покупателям B2B из таких регионов, как Африка, Южная Америка, Ближний Восток и Европа, включая такие ключевые рынки, как Бразилия и Германия, данное руководство предоставляет им знания, необходимые для принятия обоснованных решений о покупке.

Ориентироваться в сложностях закупок соленоидов стартера может быть непросто, но, имея под рукой необходимую информацию, предприятия смогут выбрать наиболее подходящие компоненты для повышения производительности своего оборудования. От определения показателей качества до понимания процесса тестирования - это руководство является жизненно важным инструментом для тех, кто стремится оптимизировать свою цепочку поставок и добиться успеха в работе.

Содержание

- Топ 4 как проверить соленоид стартера список производителей и поставщиков

- Введение: Навигация по глобальному рынку как проверить соленоид стартера

- Как проверить соленоид стартера Типы и разновидности

- Ключевые промышленные применения того, как проверить соленоид стартера

- 3 распространенных болевых точки пользователей для ‘как проверить соленоид стартера’ и их решения

- Руководство по выбору стратегических материалов для проверки соленоида стартера

- Глубокий взгляд: Производственные процессы и обеспечение качества для как проверить соленоид стартера

- Практическое руководство по поиску: Пошаговый контрольный список для ‘как проверить соленоид стартера’

- Всесторонний анализ затрат и цен для как проверить соленоид стартера Sourcing

- Анализ альтернатив: Сравнение того, как проверить соленоид стартера, с другими решениями

- Основные технические свойства и торговая терминология для проверки соленоида стартера

- Навигация по динамике рынка и тенденциям поиска поставщиков в секторе "Как проверить соленоид стартера".

- Часто задаваемые вопросы (FAQ) для B2B покупателей о том, как проверить соленоид стартера

- Стратегический поиск Заключение и перспективы для как проверить соленоид стартера

- Важное предупреждение и условия использования

Как проверить соленоид стартера Типы и разновидности

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Испытание напряжением | Использует мультиметр для проверки напряжения на клеммах | Ремонт автомобилей, сельскохозяйственной техники | Плюсы: Простота и эффективность; Минусы: Требуется оборудование и знания. |

| Метод прямого замыкания | Временное отключение соленоида для проверки функциональности | Тяжелая техника, строительное оборудование | Плюсы: Быстрая диагностика; Минусы: риск короткого замыкания при неосторожном обращении. |

| Проверка замены соленоида | Сравнивает старые и новые соленоиды для выявления дефектов | Поставщики запчастей, услуги по техническому обслуживанию | Плюсы: Обеспечивает совместимость; Минусы: Требует много времени, если необходимо произвести несколько замен. |

| Оценка предохранительных выключателей | Проверяет предохранительные выключатели в сочетании с функцией соленоида | Промышленное оборудование, транспортные средства | Плюсы: Комплексный поиск и устранение неисправностей; Минусы: Более сложный и трудоемкий процесс. |

| Визуальный осмотр | Проверяет наличие физических дефектов или коррозии | Общее техническое обслуживание, управление автопарком | Плюсы: Не требует инструментов; Минусы: Ограниченные возможности диагностики. |

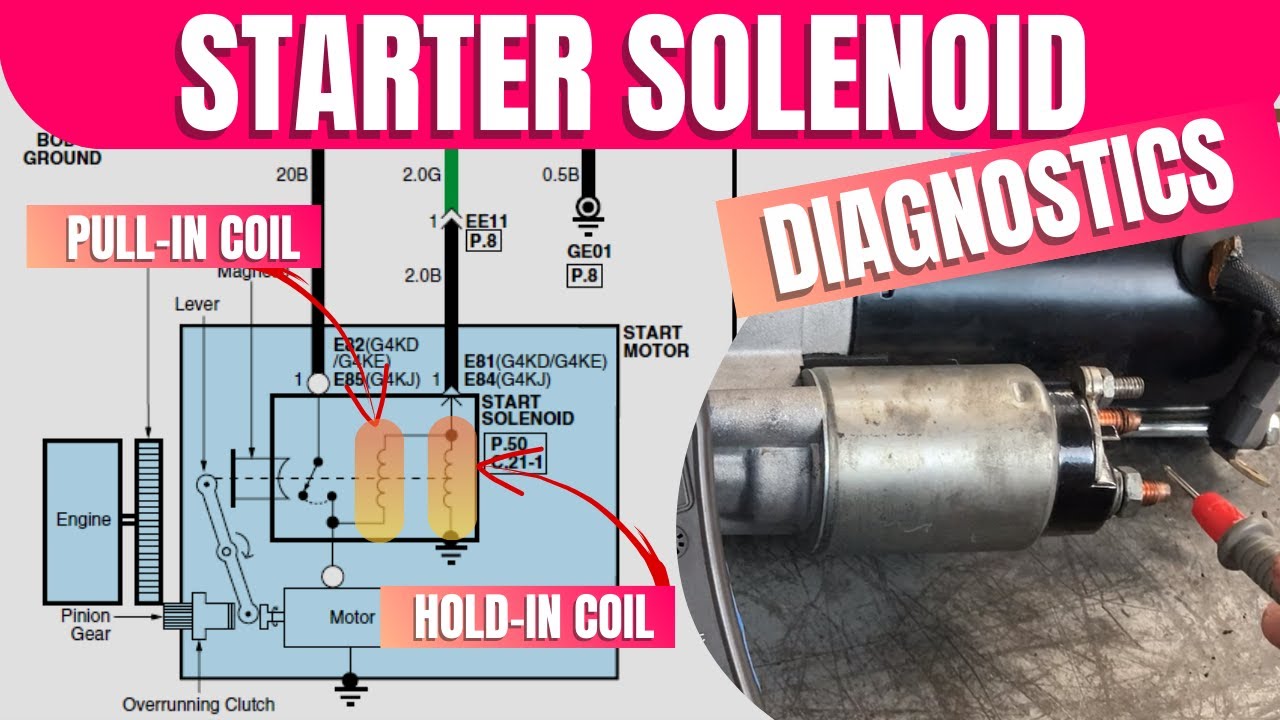

Каковы основные характеристики тестирования напряжения на соленоидах стартера?

Проверка напряжения - это основной метод диагностики проблем с соленоидом стартера. Используя мультиметр, специалисты могут измерить напряжение в различных точках соленоида. Этот метод особенно подходит для ремонта автомобилей и сельскохозяйственной техники, где надежность соленоида имеет решающее значение для эффективности работы. Покупателям следует обратить внимание на наличие обученного персонала, который может точно интерпретировать показания напряжения, поскольку неправильные показания могут привести к ошибочному диагнозу.

Как работает метод прямого замыкания для быстрой диагностики?

Метод прямого замыкания предполагает обход соленоида с помощью изолированного инструмента, чтобы определить, включился ли стартер. Этот метод обычно используется в тяжелой технике и строительном оборудовании, где простои могут быть дорогостоящими. Хотя он позволяет быстро оценить работоспособность соленоида, покупатели должны соблюдать осторожность, чтобы не повредить электрическую систему. Понимание рисков и наличие обученного персонала необходимы для такого подхода.

Что следует учитывать покупателям при проверке замены соленоида?

При замене соленоида важно сравнить старый и новый блоки, чтобы убедиться в их совместимости. Эта проверка крайне важна для поставщиков запчастей и служб технического обслуживания, поскольку несоответствие компонентов может привести к дальнейшим эксплуатационным проблемам. Покупатели должны отдавать предпочтение высококачественным соленоидам, чтобы свести к минимуму риск будущих поломок. Глубокое понимание требований конкретного транспортного средства или оборудования повысит эффективность этого метода.

Почему оценка предохранительных выключателей важна при поиске неисправностей?

Оценка предохранительных выключателей - это детальный процесс, в ходе которого проверяется взаимодействие между соленоидом и различными предохранительными выключателями. Такой подход особенно актуален для промышленного оборудования и транспортных средств, где безопасность имеет первостепенное значение. Несмотря на то, что такой подход позволяет получить полный обзор потенциальных проблем, он может быть более сложным и трудоемким. Покупателям следует убедиться, что их технические специалисты хорошо обучены системам безопасности, чтобы эффективно использовать этот метод диагностики.

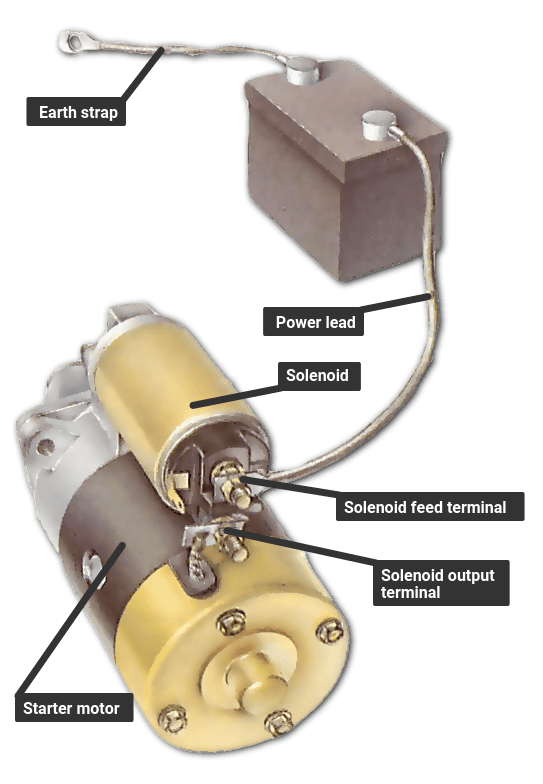

Как визуальный осмотр может помочь в диагностике соленоидов?

Визуальный осмотр - самый простой метод диагностики неисправностей соленоида стартера. Он предполагает проверку на наличие видимых признаков износа, коррозии или повреждений. Этот метод подходит для общего технического обслуживания и управления автопарком, поскольку не требует специализированных инструментов. Однако его диагностические возможности ограничены, что делает его скорее предварительным шагом, чем самостоятельным решением. Покупателям следует включить визуальный осмотр в график регулярного технического обслуживания, чтобы выявлять потенциальные проблемы на ранней стадии.

Ключевые промышленные применения того, как проверить соленоид стартера

| Отрасль/сектор | Конкретное применение того, как проверить соленоид стартера | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Сельское хозяйство | Регулярная проверка соленоидов стартера в тракторах и тяжелом оборудовании | Минимизирует время простоя и повышает производительность во время уборки урожая | Надежность компонентов соленоидов, наличие местных поставщиков |

| Строительство | Обеспечение надлежащего функционирования соленоидов стартера в строительной технике | Сокращает расходы на обслуживание и увеличивает время безотказной работы оборудования | Совместимость с различными марками и моделями машин |

| Ремонт автомобилей | Диагностические процедуры для проверки соленоидов стартера в автомобилях | Улучшает время выполнения ремонта и повышает удовлетворенность клиентов | Доступ к техническим спецификациям и запчастям для различных автомобилей |

| Горная промышленность | Тестирование соленоидов стартера в тяжелом горном оборудовании | Повышает безопасность и эффективность работы в суровых условиях | Долговечность и устойчивость компонентов к экстремальным условиям эксплуатации |

| Транспорт и логистика | Проверка технического обслуживания соленоидов стартера в автопарке | Обеспечивает надежность перевозок и сокращает задержки в работе | Экономичность и доступность запасных частей |

Как ‘Как проверить соленоид стартера’ используется в сельском хозяйстве?

В сельскохозяйственном секторе проверка соленоидов стартера в тракторах и тяжелом оборудовании имеет решающее значение для обеспечения бесперебойной работы в сезоны посадки и сбора урожая. Фермеры часто полагаются на эффективность работы этих машин, поскольку любой сбой может привести к значительным задержкам и финансовым потерям. Регулярные проверки помогают выявить потенциальные проблемы до их обострения и обеспечить своевременное техническое обслуживание. Покупатели в этом секторе должны уделять первоочередное внимание закупке надежных соленоидов, которые могут выдерживать жесткие условия сельскохозяйственной среды, обеспечивая минимальное время простоя в критические периоды.

Какую роль играет ‘как проверить соленоид стартера’ в строительстве?

В строительстве тяжелая техника, такая как экскаваторы и бульдозеры, зависит от исправных соленоидов стартера, обеспечивающих оптимальную работу. Регулярное тестирование этих компонентов помогает предотвратить неожиданные поломки, которые могут остановить проект и привести к увеличению расходов. Обеспечивая исправность соленоидов стартера, строительные компании могут повысить производительность и соблюсти сроки реализации проектов. При выборе поставщиков следует учитывать совместимость с различными марками техники, а также долговечность соленоидов, чтобы они могли выдерживать тяжелые условия работы.

Почему ‘как проверить соленоид стартера’ важно для автомобильного ремонта?

Автосервисы часто используют тестирование соленоида стартера для диагностики проблем с запуском автомобилей. Быстрая и точная оценка может привести к ускорению ремонта, повышению удовлетворенности клиентов и укреплению репутации автосервиса. Внедряя эффективные процедуры тестирования, автосервисы могут выделиться, предоставляя надежный сервис. Ключевыми моментами при поиске поставщиков являются доступ к подробным техническим спецификациям и широкий ассортимент деталей соленоидов для различных марок и моделей автомобилей.

Как ‘как проверить соленоид стартера’ влияет на горные работы?

В горнодобывающей промышленности надежность тяжелого оборудования имеет первостепенное значение, поскольку любая неисправность может иметь серьезные последствия для безопасности и эксплуатации. Регулярное тестирование соленоидов стартера обеспечивает бесперебойную работу оборудования даже в суровых условиях. Такой упреждающий подход минимизирует время простоя и повышает общую безопасность в горнодобывающей отрасли. Покупателям следует обратить внимание на соленоиды, которые отличаются долговечностью и устойчивостью к экстремальным температурам и пыли, чтобы соответствовать высоким требованиям этого сектора.

Какое значение имеет ‘как проверить соленоид стартера’ в сфере транспорта и логистики?

В секторе транспорта и логистики транспортные средства должны постоянно находиться в рабочем состоянии, чтобы обеспечивать своевременные поставки и эффективное обслуживание. Регулярные проверки соленоидов стартера жизненно важны для поддержания надежности автомобиля и предотвращения поломок, которые могут нарушить логистические операции. Предприятиям следует рассмотреть варианты экономически эффективного поиска запасных частей, что позволит им поддерживать свой автопарк без чрезмерных расходов. Кроме того, поставщики должны предоставлять компоненты, совместимые с широким спектром моделей автомобилей, чтобы упростить процессы технического обслуживания.

3 распространенных болевых точки пользователей для ‘как проверить соленоид стартера’ и их решения

Сценарий 1: Проблемы с прерывистым запуском при использовании новых соленоидов

Проблема: Частой проблемой, с которой сталкиваются покупатели B2B, является установка новых соленоидов стартера, которые не работают должным образом. После покупки запасного соленоида пользователи часто сталкиваются с проблемами периодического запуска, что приводит к разочарованию и простою в работе. Эта проблема особенно распространена при переходе от соленоида отечественного производства к более дешевой импортной альтернативе, которая может не соответствовать тем же стандартам качества. Покупателям остается только гадать, неисправен ли соленоид или проблема кроется где-то в электрической системе.

Решение: Чтобы решить эту проблему, покупателям следует сначала провести комплексную проверку напряжения с помощью мультиметра. Начните с подключения черного щупа к отрицательной клемме аккумулятора и красного щупа к положительной клемме, чтобы проверить напряжение аккумулятора. Затем проверьте напряжение на соленоиде со стороны аккумулятора; оно должно точно совпадать с напряжением аккумулятора. Затем проверьте соленоид со стороны стартера, держа ключ в положении OFF (ожидается 0 вольт), а затем в положении START (должно появиться напряжение аккумулятора). Если показания указывают на проблему, проверьте жгут проводов и убедитесь в надежности всех соединений. Если соленоид неисправен, обратитесь за заменой к авторитетным производителям, известным контролем качества. Кроме того, тщательная проверка совместимости перед установкой может предотвратить проблемы, вызванные несоответствием конструкции.

Сценарий 2: путаница в проводах соленоидов и расположении клемм

Проблема: Многие покупатели сталкиваются с путаницей в проводке и расположении клемм соленоидов стартера, особенно если речь идет о разных моделях или марках. Такая путаница может привести к неправильной установке, которая не только не позволит запустить двигатель, но и создаст риск повреждения электрической системы. Покупатели часто сомневаются, какие клеммы подключать, особенно если соленоид отличается по конфигурации от оригинального.

Решение: Чтобы решить эту проблему, необходимо обратиться к электрической схеме производителя, относящейся к конкретной модели соленоида. При покупке нового соленоида убедитесь, что к нему прилагается подробная инструкция по установке. Если документация отсутствует, воспользуйтесь интернет-ресурсами или форумами, где пользователи делятся опытом и решениями. Для тестирования используйте изолированные провода-перемычки для временного соединения клемм, что позволит вам проверить функциональность без внесения постоянных изменений. Этот метод поможет быстро определить, неисправен ли соленоид или другой компонент. Кроме того, стоит обратить внимание на универсальные соленоиды с регулируемой конфигурацией клемм, что снизит вероятность неправильного подключения.

Сценарий 3: предохранительные выключатели, усложняющие процесс тестирования

Проблема: Предохранительные выключатели предназначены для предотвращения случайного запуска оборудования, но они могут усложнить процесс поиска неисправностей при проверке соленоида стартера. Многие покупатели B2B сталкиваются с ситуациями, когда двигатель не запускается, что заставляет их подозревать соленоид, в то время как на самом деле проблема кроется в неисправном предохранительном выключателе. Это не только теряет время, но и может привести к ненужной замене деталей.

Решение: Чтобы эффективно устранять неисправности при рассмотрении защитных выключателей, покупателям следует применять систематический подход. Начните с определения всех предохранительных выключателей, которые могут влиять на пусковую цепь, например, предохранительных выключателей нейтрали или выключателей ВОМ. С помощью мультиметра проверьте целостность каждого выключателя, когда оборудование находится в соответствующем положении (например, в нейтральном). Если выключатель неисправен, его необходимо отремонтировать или заменить, чтобы обеспечить надлежащую работу. Для проверки соленоида временный обход предохранительного выключателя может помочь определить, правильно ли функционирует соленоид. Однако делать это следует только в диагностических целях и с осторожностью. Обучение персонала роли предохранительных выключателей также может упростить процесс поиска и устранения неисправностей, позволяя быстрее выявить основную причину проблем с запуском.

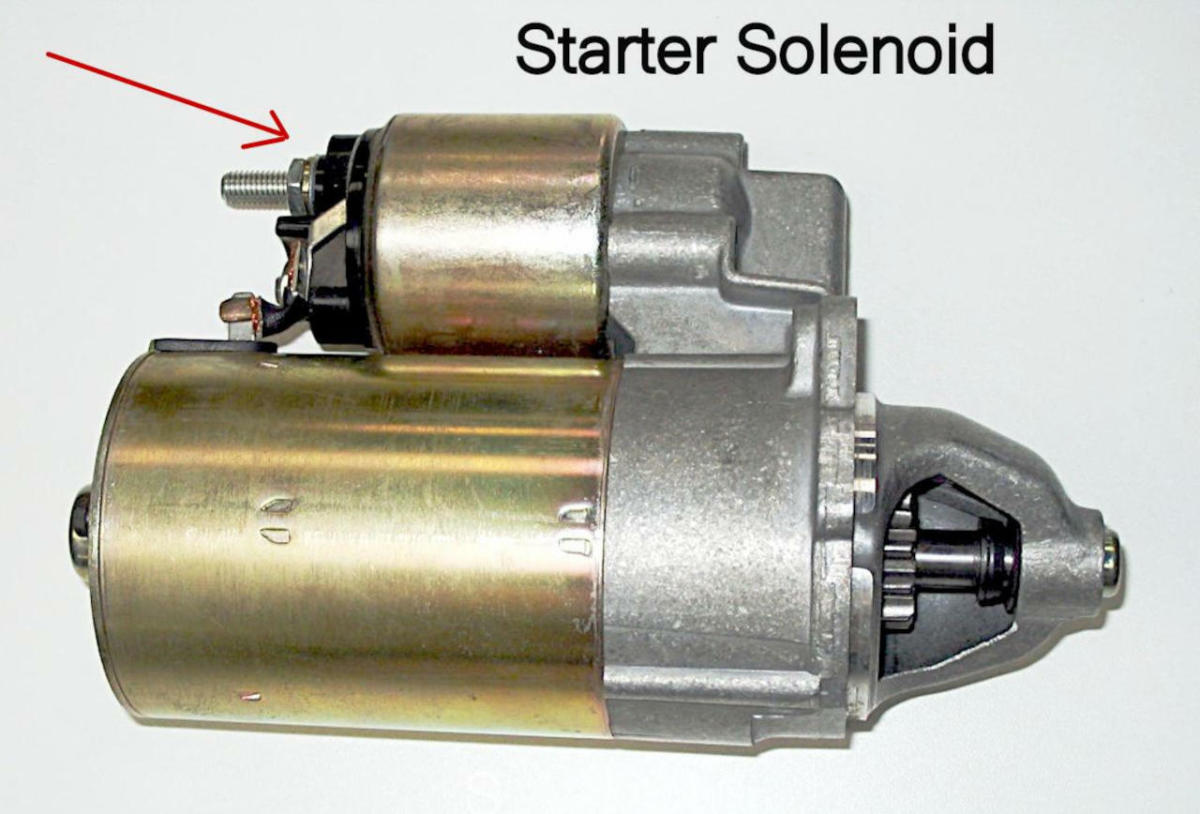

Иллюстративное изображение, связанное с как проверить соленоид стартера

Руководство по выбору стратегических материалов для проверки соленоида стартера

Какие материалы обычно используются при испытании соленоидов стартера?

При проверке соленоида стартера материалы, используемые в инструментах и оборудовании для тестирования, могут существенно повлиять на эффективность и надежность процесса. Ниже мы анализируем несколько распространенных материалов, которые являются неотъемлемой частью этой задачи, уделяя особое внимание их свойствам, преимуществам, недостаткам и соображениям для международных покупателей B2B.

Как медь влияет на тестирование соленоида стартера?

Ключевые свойства: Медь является отличным проводником электричества, обладает высокой теплопроводностью и устойчивостью к коррозии. Она выдерживает широкий диапазон температур, что делает ее пригодной для использования в различных средах.

Плюсы и минусы: Превосходная проводимость меди обеспечивает минимальное падение напряжения во время тестирования, что очень важно для получения точных показаний. Однако ее относительно высокая стоимость по сравнению с другими металлами может стать недостатком для покупателей с ограниченным бюджетом. Кроме того, медь может потускнеть со временем, что может повлиять на ее производительность, если не обеспечить надлежащий уход.

Влияние на применение: Медь обладает высокой совместимостью с электрическими приборами, что делает ее идеальным материалом для зондов и разъемов при тестировании соленоидов. Ее проводимость обеспечивает точность показаний напряжения, что очень важно для диагностики проблем с соленоидами.

Международные соображения: Покупателям в таких регионах, как Европа, возможно, придется обратить внимание на соответствие электрических компонентов стандартам, таким как DIN. В Африке и Южной Америке, где условия окружающей среды могут быть различными, обеспечение надлежащего покрытия медных компонентов для предотвращения коррозии является жизненно важным.

Иллюстративное изображение, связанное с как проверить соленоид стартера

Какую роль играет алюминий при проверке соленоида стартера?

Ключевые свойства: Алюминий легок, устойчив к коррозии и обладает достойной электропроводностью, хотя и не такой высокой, как медь.

Плюсы и минусы: Основным преимуществом алюминия является его низкая стоимость и малый вес, что позволяет сократить расходы на транспортировку. Однако его низкая электропроводность может привести к увеличению сопротивления и потенциальным неточностям в показаниях напряжения. Кроме того, алюминий может потребовать защитных покрытий для предотвращения окисления.

Влияние на применение: Алюминий часто используется в конструкции испытательных устройств, где вес имеет значение. Однако его низкая электропроводность может ограничить его применение в приложениях, требующих высокой точности.

Международные соображения: Соответствие местным стандартам, таким как ASTM в США или JIS в Японии, имеет решающее значение для алюминиевых компонентов. Покупатели также должны учитывать воздействие производства и переработки алюминия на окружающую среду, что может вызывать озабоченность в регионах со строгими нормами.

Чем отличается сталь при испытаниях соленоидов стартера?

Ключевые свойства: Сталь известна своей прочностью и долговечностью, хорошей устойчивостью к износу. Однако она не так хорошо проводит электричество, как медь или алюминий.

Плюсы и минусы: Прочность стали делает ее подходящей для использования в тяжелых условиях, и она обычно более доступна по цене, чем медь. Однако ее низкая проводимость может привести к менее точным показаниям напряжения, и она подвержена ржавчине, если на нее не нанесено надлежащее покрытие.

Влияние на применение: Сталь часто используется в конструктивных элементах испытательного оборудования, но менее пригодна для электрических соединений. Ее прочность может быть полезной в суровых условиях, но может потребовать дополнительного ухода для предотвращения коррозии.

Международные соображения: Покупатели должны знать о различных сортах стали и их соответствии международным стандартам. В таких регионах, как Ближний Восток, где влажность может быть высокой, рекомендуется выбирать нержавеющую сталь или варианты с покрытием для предотвращения ржавчины.

Что касается пластиковых материалов при испытании соленоида стартера?

Ключевые свойства: Пластмассы непроводящие, легкие, устойчивые к коррозии и химическим веществам. Их также можно формовать в различные формы для конкретных применений.

Плюсы и минусы: Главным преимуществом пластика является его универсальность и низкая стоимость. Однако его непроводящая природа ограничивает его использование в электрических приложениях, делая его более подходящим для изоляции компонентов или корпусов.

Влияние на применение: Из пластмассы можно создавать защитные оболочки для испытательного оборудования, обеспечивая безопасность во время работы. Однако их нельзя использовать для прямых электрических соединений.

Международные соображения: Соблюдение норм химической стойкости и воспламеняемости имеет большое значение, особенно в регионах с жесткими стандартами безопасности. Покупатели также должны учитывать воздействие производства и утилизации пластика на окружающую среду.

Иллюстративное изображение, связанное с как проверить соленоид стартера

Сводная таблица выбора материалов для испытания соленоида стартера

| Материал | Типичный пример использования для проверки соленоида стартера | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Медь | Щупы и разъемы для точных показаний напряжения | Отличная проводимость | Более высокая стоимость, возможность потускнения | Высокий |

| Алюминий | Легкие испытательные устройства | Экономичный и легкий | Низкая проводимость | Средний |

| Сталь | Конструктивные элементы испытательного оборудования | Прочный и крепкий | Низкая электропроводность, склонность к ржавчине | Низкий |

| Пластик | Изолирующие оболочки для испытательного оборудования | Универсальный и коррозионностойкий | Непроводящий | Низкий |

Этот анализ предоставляет практические рекомендации для покупателей B2B, которые хотят выбрать подходящие материалы для проверки соленоидов стартера, учитывая производительность, стоимость и международные стандарты.

Глубокий взгляд: Производственные процессы и обеспечение качества для как проверить соленоид стартера

Каковы основные этапы производственного процесса соленоидов стартера?

Производство соленоидов стартера включает в себя несколько критических этапов, которые обеспечивают соответствие конечного продукта стандартам производительности и качества. Эти этапы включают подготовку материала, формовку, сборку и отделку.

-

Подготовка материалов: На первом этапе необходимо найти высококачественное сырье, включая медь для электрических контактов, сталь для корпуса и изоляционные материалы. Поставщики часто проходят строгий процесс квалификации, чтобы гарантировать соответствие материалов определенным стандартам, таким как ASTM или ISO. Регулярные проверки и испытания поступающих материалов необходимы для подтверждения соответствия.

-

Формирование: На этом этапе сырье формируется в необходимые компоненты. Для создания таких деталей, как корпус соленоида, клеммы и внутренние компоненты, обычно используются такие методы, как штамповка и механическая обработка. Передовые технологии, такие как обработка с ЧПУ, используются для обеспечения точности и согласованности всех деталей.

-

Сборка: Процесс сборки включает в себя интеграцию всех сформированных компонентов в готовый соленоид. Это может включать пайку электрических соединений, установку катушек и обеспечение правильной подгонки всех деталей. Автоматизация играет важную роль на этом этапе для повышения эффективности и минимизации человеческих ошибок. Каждая сборочная линия обычно следует стандартизированному процессу для поддержания качества.

-

Отделка: На заключительном этапе производится обработка поверхности, например, покрытие или покраска для повышения коррозионной стойкости и улучшения эстетического вида. Кроме того, наносится необходимая маркировка или клеймо. На этом этапе проводятся проверки качества, чтобы убедиться, что соленоиды соответствуют как функциональным, так и эстетическим стандартам.

Как обеспечивается качество при производстве соленоидов стартера?

Обеспечение качества - важнейший аспект производства соленоидов стартера, включающий в себя различные международные стандарты и отраслевые нормы.

-

Международные стандарты: Многие производители придерживаются стандарта ISO 9001 - общепризнанного стандарта управления качеством, в котором изложены требования к системе управления качеством. Соответствие стандарту ISO 9001 гарантирует, что компании постоянно выпускают продукцию, отвечающую требованиям клиентов и нормативных документов.

-

Отраслевые сертификаты: В зависимости от рынка производители могут также получить такие сертификаты, как маркировка CE на соответствие европейским стандартам здравоохранения, безопасности и охраны окружающей среды или сертификат API для применения в нефтегазовой отрасли. Эти сертификаты часто требуют тщательного тестирования и документации.

-

Контрольные точки контроля качества: Контроль качества осуществляется на протяжении всего производственного процесса:

– Входящий контроль качества (IQC): Этот этап включает в себя проверку сырья и компонентов по мере их поступления на предприятие.

– Контроль качества в процессе производства (IPQC): В процессе производства регулярные проверки обеспечивают соответствие каждого компонента заданным размерам и допускам.

– Окончательный контроль качества (FQC): Перед отгрузкой каждый готовый соленоид проходит функциональное тестирование для проверки работоспособности. Они могут включать в себя электрические испытания, механические испытания и испытания на выносливость в различных условиях.

Какие методы тестирования используются для соленоидов стартера?

Методы испытаний играют решающую роль в проверке работоспособности и надежности соленоидов стартера. Вот некоторые распространенные методы испытаний, используемые производителями:

-

Электрические испытания: Это включает в себя проверку уровня напряжения на различных клеммах соленоида, обеспечение правильного включения и выключения соленоида под нагрузкой. Для этих измерений часто используются мультиметры и осциллографы.

-

Функциональное тестирование: Соленоиды подвергаются эксплуатационным испытаниям, чтобы убедиться, что они могут работать так, как задумано, в реальных условиях. Это может включать в себя имитацию процесса запуска в контролируемых условиях.

-

Испытания на долговечность: Производители часто проводят испытания на ресурс, чтобы оценить, насколько хорошо соленоид выдерживает многократное использование в течение долгого времени. При этом соленоид проходит множество циклов старт-стоп.

-

Экологические испытания: Это испытание позволяет оценить работу соленоидов в экстремальных условиях, таких как высокая температура, влажность и вибрация. Такие испытания крайне важны для применения в жестких условиях.

Как покупатели B2B могут проверить контроль качества поставщиков?

Для покупателей B2B, особенно в таких регионах, как Африка, Южная Америка, Ближний Восток и Европа, проверка процессов контроля качества поставщика имеет большое значение для обеспечения надежности продукции.

Иллюстративное изображение, связанное с как проверить соленоид стартера

-

Аудит поставщиков: Проведение регулярных аудитов поставщиков может помочь покупателям оценить их системы управления качеством и соответствие международным стандартам. Аудиты должны быть направлены на оценку производственных процессов, методов контроля качества и общих организационных возможностей.

-

Отчеты о качестве: Запрос отчетов и документации по качеству может дать представление о производственных и испытательных процессах поставщика. В этих отчетах должны быть подробно описаны результаты проверок, проблемы несоответствия и предпринятые корректирующие действия.

-

Проверки третьей стороной: Привлечение сторонних инспекционных служб может придать дополнительную уверенность. Эти независимые организации могут провести оценку и испытания на месте, чтобы убедиться, что продукция соответствует установленным стандартам перед отправкой.

-

Проверка сертификации: Покупатели также должны проверять подлинность любых сертификатов, заявленных поставщиком. Часто это можно сделать через официальные органы по сертификации или отраслевые ассоциации.

Каковы нюансы контроля качества для международных B2B-покупателей?

Международные покупатели B2B должны ориентироваться в различных нюансах контроля качества при закупке соленоидов стартера из разных регионов.

-

Соблюдение нормативных требований: В разных странах действуют уникальные нормативные требования. Понимание этих требований крайне важно, особенно при импорте продукции. Например, маркировка CE является обязательной для продукции, продаваемой в Европе, в то время как в Южной Америке или Африке могут применяться другие сертификаты.

-

Культурные и операционные различия: Покупатели должны знать о культурных различиях в деловой практике и общении. Это может повлиять на то, как поставщики воспринимают и решают вопросы качества.

-

Соображения по логистике и цепочке поставок: Международные перевозки могут создавать дополнительные риски, такие как повреждение товара во время транспортировки. Очень важно установить четкие требования к качеству и протоколы обработки поврежденных товаров.

-

Долгосрочные отношения: Установление долгосрочных отношений с надежными поставщиками поможет снизить риски, связанные с качеством. Регулярная связь и обратная связь могут улучшить сотрудничество и обеспечить постоянное улучшение стандартов качества.

Понимая производственные процессы и методы обеспечения качества для стартерных соленоидов, покупатели B2B могут принимать обоснованные решения, которые соответствуют их производственным потребностям и ожиданиям качества.

Практическое руководство по поиску: Пошаговый контрольный список для ‘как проверить соленоид стартера’

Введение

Это практическое руководство по поиску поставщиков призвано помочь покупателям B2B в оценке и приобретении необходимых инструментов и компонентов для эффективной проверки соленоида стартера. Обеспечение работоспособности соленоида стартера имеет решающее значение для эффективности работы оборудования и транспортных средств, особенно в регионах с различными климатическими условиями и стандартами электроснабжения. В этом контрольном списке описаны основные шаги, которые позволят вам обеспечить качество и надежность в процессе поиска поставщиков.

Шаг 1: Определите свои технические характеристики

Прежде чем приступить к процессу закупки, определите четкие технические характеристики необходимого вам соленоида стартера. Это включает в себя понимание требований к напряжению, конфигурации выводов и совместимости с существующим оборудованием. Четко сформулированные спецификации помогут избежать несоответствий и обеспечат надежную работу соленоида в конкретных условиях эксплуатации.

Шаг 2: Исследование потенциальных поставщиков

Проведите тщательное исследование, чтобы определить потенциальных поставщиков, специализирующихся на соленоидах стартера. Ориентируйтесь на поставщиков с проверенным послужным списком в вашей отрасли и регионе. Используйте такие платформы, как торговые выставки, отраслевые издания и онлайн-площадки, чтобы собрать список авторитетных поставщиков.

Шаг 3: Проверка сертификатов поставщиков

Важно убедиться, что выбранные вами поставщики имеют необходимые сертификаты и соответствуют международным стандартам качества. Такие сертификаты, как ISO 9001 или отраслевые аккредитации, свидетельствуют о приверженности качеству и надежности. Попросите предоставить документацию, подтверждающую соответствие требованиям, и изучите все соответствующие процессы контроля качества, которые они применяют.

Шаг 4: Запросить образцы продукции

Перед размещением оптового заказа запросите образцы соленоидов стартера, которые вы собираетесь приобрести. Испытания этих образцов позволят вам оценить их качество, долговечность и совместимость с вашим оборудованием. Этот шаг может избавить вас от дорогостоящих возвратов и сбоев в работе в дальнейшем.

Шаг 5: Оцените политику поддержки и гарантийного обслуживания поставщиков

Оцените уровень поддержки клиентов и гарантийные обязательства, предлагаемые потенциальными поставщиками. Надежный поставщик должен предоставлять техническую поддержку и четкую гарантийную политику, которая распространяется на дефекты и проблемы с производительностью. Предварительное ознакомление с этими правилами может повысить вашу уверенность в том, что поставщик стремится удовлетворить потребности клиентов.

Шаг 6: Проверьте отзывы и рекомендации

Изучите отзывы других предприятий, которые ранее уже приобретали соленоиды стартера у выбранных вами поставщиков. Поищите отзывы на таких платформах, как Trustpilot, или на отраслевых форумах. Положительные отзывы и тематические исследования могут дать представление о надежности поставщика и эффективности его продукции.

Шаг 7: Обсудите условия и завершите покупку

После того как вы выполнили предыдущие шаги, начните переговоры, чтобы окончательно согласовать условия покупки. Обсудите цены, сроки поставки и условия оплаты, чтобы убедиться, что они соответствуют вашему бюджету и операционным потребностям. Установление четких условий поможет избежать недоразумений и обеспечит более гладкий процесс сделки.

Следуя этому контрольному списку, вы сможете оптимизировать процесс поиска поставщиков и принимать обоснованные решения при закупке инструментов и компонентов для проверки соленоидов стартера, что в конечном итоге повысит надежность и производительность вашего оборудования.

Всесторонний анализ затрат и цен для как проверить соленоид стартера Sourcing

Понимание структуры затрат и ценообразования при поиске компонентов, таких как соленоиды стартера, имеет решающее значение для международных покупателей B2B. Данный анализ посвящен различным компонентам затрат, факторам, влияющим на цену, и советам по ведению переговоров, особенно для покупателей из таких регионов, как Африка, Южная Америка, Ближний Восток и Европа.

Каковы ключевые компоненты затрат при поиске поставщиков соленоидов стартера?

При оценке стоимости соленоидов стартера учитывайте следующие компоненты:

-

Материалы: Основные материалы, используемые в соленоидах стартера, включают медь для проводки, высококачественную сталь для корпуса и различные пластмассы для изоляции. Качество этих материалов существенно влияет на долговечность и производительность соленоида.

-

Трудовые ресурсы: Стоимость рабочей силы в разных регионах существенно различается. В странах с более низкой стоимостью рабочей силы, например, в Южной Америке или в некоторых частях Африки, производители могут предложить конкурентоспособные цены. Однако более высокая стоимость рабочей силы в Европе может привести к повышению цен на производимые там соленоиды.

-

Производственные накладные расходы: Сюда входят все косвенные затраты, связанные с производством, такие как коммунальные услуги, арендная плата и административные расходы. Эффективная производственная практика может помочь снизить эти расходы.

-

Инструменты: Первоначальные затраты на оснастку для производства соленоидов могут быть значительными, особенно для нестандартных конструкций. Покупатели должны рассмотреть вопрос о том, какая оснастка - стандартная или индивидуальная - будет лучше соответствовать их потребностям и бюджету.

-

Контроль качества (КК): Обеспечение соответствия соленоидов определенным стандартам производительности имеет решающее значение. Стоимость процессов контроля качества может быть различной, при этом более строгие требования к качеству обычно приводят к повышению цен.

-

Логистика: Стоимость доставки, таможенные пошлины и страхование являются жизненно важными факторами в общей стоимости владения. Выбор Инкотермс влияет на то, кто будет нести эти расходы, и может повлиять на общую цену.

-

Маржа: Поставщики добавляют маржу, чтобы покрыть свои расходы и обеспечить рентабельность. Понимание типичных наценок в вашей отрасли может помочь в переговорах о более выгодных ценах.

Как влияют цены на стоимость соленоида стартера?

На цену соленоидов стартера могут влиять несколько факторов:

-

Объем/MOQ (минимальный объем заказа): Большие заказы часто приводят к снижению стоимости единицы продукции. Покупатели должны оценить свои прогнозируемые потребности, чтобы договориться о выгодных условиях в зависимости от объема.

-

Технические характеристики/Индивидуальная настройка: Нестандартные соленоиды, разработанные для удовлетворения специфических требований, могут значительно увеличить стоимость. Покупатели должны взвесить необходимость изготовления на заказ и потенциальную экономию от использования стандартных изделий.

-

Материалы: Выбор материалов влияет как на производительность, так и на стоимость. Материалы более высокого класса могут повлечь за собой более высокие первоначальные затраты, но могут привести к снижению общей стоимости владения благодаря повышенной долговечности.

-

Качество и сертификаты: Поставщики с международно признанными сертификатами могут взимать дополнительную плату. Однако такие сертификаты могут гарантировать покупателям качество и надежность соленоида.

-

Факторы, связанные с поставщиками: Репутация, надежность и местоположение поставщиков могут влиять на ценообразование. Известные поставщики могут брать больше, но предлагать лучший сервис и гарантию качества.

-

Инкотермс: Понимание последствий различных терминов Инкотермс жизненно важно для расчета общих затрат. Такие термины, как FOB (Free On Board) или CIF (Cost, Insurance, and Freight), могут привести к значительной разнице в ценах.

Какие есть эффективные советы покупателям по ведению переговоров о ценах на соленоид стартера?

-

Стратегии ведения переговоров: Всегда подходите к переговорам с четким пониманием вашего бюджета и структуры затрат поставщика. Будьте готовы обсудить обязательства по объемам или долгосрочные партнерские отношения, чтобы обеспечить более выгодные цены.

-

Ориентация на экономическую эффективность: Оценивайте общую стоимость владения, а не только начальную цену. При оценке стоимости учитывайте такие факторы, как гарантия, надежность и стоимость обслуживания.

-

Международные нюансы ценообразования: Покупатели из разных регионов должны быть осведомлены об изменении рыночных условий. Например, импорт из Европы в Африку может быть сопряжен с дополнительными тарифами или расходами на доставку, что может повлиять на общую цену.

-

Исследования и бенчмаркинг: Проведите исследование рынка, чтобы понять типичные цены на соленоиды в вашей отрасли. Сравнение котировок от нескольких поставщиков может дать преимущество в переговорах.

-

Будьте в курсе тенденций рынка: Будьте в курсе изменений в стоимости материалов, расценках на рабочую силу и геополитических факторах, которые могут повлиять на ценообразование. Эти знания могут оказаться бесценными во время переговоров.

В заключение, понимание всеобъемлющей структуры затрат и динамики цен при закупке соленоидов стартера может помочь международным покупателям B2B принять обоснованные решения о покупке. Учитывая описанные компоненты затрат и факторы, влияющие на цену, покупатели могут эффективно вести переговоры и добиваться выгодной совокупной стоимости владения.

Иллюстративное изображение, связанное с как проверить соленоид стартера

Анализ альтернатив: Сравнение того, как проверить соленоид стартера, с другими решениями

Изучение альтернативных вариантов проверки соленоида стартера

В области диагностики автомобилей, в частности соленоидов стартера, предприятиям важно понимать различные методы, обеспечивающие оптимальную производительность и надежность. Традиционный метод проверки соленоида стартера можно сравнить с альтернативными решениями, которые могут предлагать различные преимущества в зависимости от условий эксплуатации и конкретных потребностей покупателей B2B.

Сравнительная таблица

| Аспект сравнения | Как проверить соленоид стартера | Тестирование цифровым мультиметром | Стендовые испытания с помощью проводов-перемычек |

|---|---|---|---|

| Производительность | Надежность при диагностике неисправностей соленоидов непосредственно в автомобиле | Точные показания для детальной диагностики | Быстрая оценка функциональности соленоида |

| Стоимость | Минимальный (требуются основные инструменты) | Низкий или средний уровень (стоимость мультиметра) | Низкий (недорогие провода-перемычки) |

| Простота внедрения | Умеренный (требует базовых знаний по электрике) | Умеренный (требуется знакомство с мультиметром) | Легкость (простая настройка проводки) |

| Техническое обслуживание | Низкая (периодический уход за инструментом) | Низкая (требуется минимальное обслуживание) | Очень низкий (только провода) |

| Лучший вариант использования | Диагностика в полевых условиях для решения периодических проблем | Детальное устранение неисправностей в сложных электрических системах | Быстрые тесты для немедленной обратной связи |

Подробная разбивка альтернатив

1. Тестирование цифровым мультиметром

Использование цифрового мультиметра для проверки соленоида стартера обеспечивает точный подход к диагностике электрических проблем. Этот метод включает в себя измерение напряжения, тока и сопротивления, что позволяет получить исчерпывающие данные о работе соленоида. Среди плюсов - детальная диагностика и возможность отследить проблемы с проводкой в электрической системе. Однако этот метод требует определенного уровня знакомства с мультиметром и электрическими системами, что может быть под силу не всем операторам.

2. Стендовые испытания с помощью проводов-перемычек

Стендовое тестирование соленоида с помощью проводов-перемычек - простой и эффективный метод. Для этого необходимо снять соленоид с автомобиля и подключить его непосредственно к источнику питания с помощью проводов-перемычек, чтобы проверить, активируется ли он. Этот метод удобен для быстрой оценки, особенно в условиях мастерской, где соленоиды можно проверить вне автомобиля. Простота этого метода является его главным преимуществом, хотя он и не дает представления о проблемах с проводкой или другими компонентами системы, которые могут повлиять на работу соленоида.

Заключение: выбор правильного решения для ваших нужд

Для покупателей B2B выбор метода проверки соленоида стартера должен определяться конкретными эксплуатационными требованиями и имеющимся опытом в организации. Если требуется немедленная диагностика на месте, то лучше всего использовать традиционный метод проверки соленоида. Напротив, для предприятий, которым требуется детальный поиск неисправностей, инвестиции в цифровой мультиметр могут принести значительную пользу в долгосрочной перспективе. Стендовые испытания являются отличным решением для быстрой проверки, особенно в ремонтных мастерских. Оценка компромиссов между этими методами позволит покупателям принимать обоснованные решения, соответствующие их производственным целям и техническим возможностям.

Иллюстративное изображение, связанное с как проверить соленоид стартера

Основные технические свойства и торговая терминология для проверки соленоида стартера

Каковы основные технические характеристики для проверки соленоида стартера?

При оценке производительности и надежности соленоида стартера необходимо понимать несколько важнейших характеристик. Эти характеристики не только обеспечивают надлежащую функциональность, но и влияют на принятие решений о закупках в контексте B2B.

-

Марка материала

Корпус соленоида и внутренние компоненты обычно изготавливаются из таких материалов, как сталь или высококачественная пластмасса. Выбор материала влияет на долговечность и устойчивость к коррозии, особенно в суровых условиях. Для предприятий, работающих в регионах с экстремальными погодными условиями, выбор соленоидов, изготовленных из атмосферостойких материалов, может привести к снижению частоты отказов и затрат на обслуживание. -

Номинальное напряжение

Большинство соленоидов стартера работают при напряжении 12 или 24 В, в зависимости от автомобиля или оборудования. Понимание номинального напряжения имеет решающее значение для совместимости с электрической системой. Несоответствие может привести к выходу из строя соленоида или повреждению других компонентов, что приведет к дорогостоящему ремонту или замене. -

Текущая мощность

Соленоид должен выдерживать пиковый ток, необходимый для включения двигателя стартера. Типичные номиналы тока составляют от 100 до 300 А. Знание силы тока помогает гарантировать, что соленоид сможет эффективно включить стартер без перегрева, что крайне важно для поддержания эффективности работы. -

Сопротивление катушки

Измеряемое в омах, сопротивление катушки влияет на время включения соленоида и его эффективность. Более низкое сопротивление обычно означает более быстрое срабатывание, но также может привести к более высокому потреблению тока. Предприятиям следует учитывать сопротивление катушки, чтобы гарантировать, что соленоид будет работать эффективно, не нагружая электрическую систему. -

Рейтинг долговечности

Показатели долговечности часто отражают ожидаемый срок службы соленоида при нормальных условиях эксплуатации. Сюда входят такие факторы, как циклы работы и устойчивость к воздействию окружающей среды. Понимание этих показателей позволяет покупателям B2B оценить долгосрочную ценность и надежность, снижая вероятность непредвиденных простоев. -

Диапазон температур

Диапазон рабочих температур определяет среду, в которой соленоид может эффективно работать. Компоненты, способные выдерживать более высокие температуры, необходимы для тяжелой техники, работающей в теплом климате. Эта спецификация обеспечивает надежность и производительность даже в условиях стресса.

Какие торговые термины имеют отношение к пониманию соленоидов стартера?

Понимание отраслевой терминологии имеет решающее значение для эффективного общения и принятия решений в сделках B2B, связанных с соленоидами стартера.

-

OEM (производитель оригинального оборудования)

OEM означает детали, произведенные оригинальным производителем транспортного средства или оборудования. Покупатели B2B часто предпочитают OEM-компоненты за их надежность и совместимость, что может привести к улучшению производительности и сокращению гарантийных обязательств. -

MOQ (минимальный объем заказа)

MOQ - это наименьшее количество товара, которое поставщик готов продать. Это важный момент для покупателей B2B, поскольку более высокие MOQ могут привести к увеличению расходов на инвентаризацию. Понимание MOQ помогает компаниям эффективно управлять цепочкой поставок. -

RFQ (запрос предложения)

RFQ - это документ, издаваемый покупателями для запроса ценовых котировок у поставщиков. Этот термин имеет решающее значение для процессов закупок, позволяя предприятиям сравнивать затраты и оценивать потенциальных поставщиков для удовлетворения своих потребностей в соленоиде стартера. -

Инкотермс (Международные торговые термины)

Это стандартизированные термины, определяющие обязанности покупателей и продавцов в международных сделках. Знакомство с Инкотермс помогает покупателям B2B понять обязанности по доставке, страхованию и транспортировке, что крайне важно для эффективного управления затратами и логистикой. -

Запасные части

Запчасти для вторичного рынка - это компоненты, произведенные производителями, отличными от производителя оригинального оборудования. Эти детали могут обеспечить экономию средств, но могут отличаться по качеству и совместимости. Предприятиям следует взвесить потенциальные риски и преимущества при рассмотрении вариантов вторичного рынка. -

Гарантийный срок

Этот термин означает срок, в течение которого изделие гарантированно защищено от дефектов. Понимание гарантийного срока на соленоиды стартера имеет решающее значение для предприятий, чтобы оценить риск инвестиций и возможность будущих расходов, связанных с отказом продукции.

Зная эти технические характеристики и торговые условия, покупатели B2B могут принимать обоснованные решения о закупке и управлении соленоидами стартера, что в конечном итоге приведет к повышению эффективности работы и снижению затрат.

Иллюстративное изображение, связанное с как проверить соленоид стартера

Навигация по динамике рынка и тенденциям поиска поставщиков в секторе "Как проверить соленоид стартера".

Каковы ключевые факторы, влияющие на рынок при поиске поставщиков соленоидов стартера?

На мировой рынок соленоидов стартера влияют несколько ключевых факторов, включая растущий спрос на автомобильное и промышленное оборудование, прогресс в области электрических систем и растущую тенденцию к использованию электромобилей (EV). В таких регионах, как Африка и Южная Америка, рост числа владельцев транспортных средств и развитие инфраструктуры стимулируют потребность в надежных компонентах стартеров. В то же время в Европе и на Ближнем Востоке нормативно-правовая база, способствующая развитию электромобилей, и жесткие стандарты выбросов изменяют ландшафт поиска поставщиков.

Большое значение приобретают также новые технологии в области диагностики и испытательного оборудования. Интеграция IoT и интеллектуальных технологий в автомобильные приложения позволяет в режиме реального времени контролировать компоненты, включая соленоиды стартера, повышая эффективность технического обслуживания и сокращая время простоя. В результате международные покупатели B2B должны быть в курсе этих технологических достижений, чтобы гарантировать, что они приобретают высококачественные и совместимые детали для своего оборудования.

Как устойчивое развитие и этический подход к закупкам влияют на индустрию соленоидов стартера?

Экологичность становится важнейшим фактором при выборе поставщиков соленоидов стартера. Влияние производственных процессов и сырья на окружающую среду нельзя упускать из виду, особенно в условиях, когда во всем мире растет требование снизить выбросы углекислого газа. Этические методы поиска поставщиков набирают обороты, и покупатели B2B все чаще отдают предпочтение поставщикам, которые демонстрируют приверженность принципам устойчивого развития. Это включает в себя использование переработанных материалов или сертифицированных ‘зеленых’ компонентов в производстве.

Например, сейчас организации ищут поставщиков, которые могут предоставить сертификаты на свою продукцию, такие как ISO 14001, подтверждающий соблюдение стандартов экологического менеджмента. Сосредоточившись на этих устойчивых практиках, компании могут не только соответствовать нормативным требованиям, но и повысить репутацию своего бренда среди экологически сознательных потребителей. Кроме того, внедрение практики устойчивой цепочки поставок может привести к экономии средств и повышению операционной эффективности, что является беспроигрышным вариантом для международных покупателей.

Каков исторический контекст соленоидов стартера в сделках B2B?

Эволюцию соленоидов стартера можно проследить с начала XX века, когда возникла необходимость в надежных пусковых механизмах для автомобилей. Изначально эти компоненты представляли собой простые механические устройства, но развитие электротехники за десятилетия превратило их в сложные электронные системы, повышающие производительность и надежность.

С развитием глобальных цепочек поставок поиск поставщиков соленоидов стартера стал более сложным, поскольку теперь производители имеют доступ к более широкому кругу поставщиков в разных регионах. Этот сдвиг привел к усилению конкуренции, стимулируя инновации и экономическую эффективность на рынке. Сегодня покупатели B2B должны ориентироваться в этом ландшафте, хорошо понимая как устаревшие продукты, так и современные достижения, чтобы принимать обоснованные решения о закупках, которые соответствуют их операционным потребностям и целям устойчивого развития.

Оставаясь в курсе тенденций рынка, практики устойчивого развития и исторической эволюции пусковых соленоидов, международные покупатели B2B могут стратегически позиционировать себя, чтобы воспользоваться возможностями в этом динамичном секторе.

Часто задаваемые вопросы (FAQ) для B2B покупателей о том, как проверить соленоид стартера

-

Как решить проблему периодического запуска с помощью соленоида стартера?

Чтобы решить проблему прерывистого запуска, сначала убедитесь, что аккумулятор полностью заряжен и все соединения надежны. С помощью мультиметра проверьте наличие напряжения на клеммах соленоида; при выключенном зажигании на одной стороне должно быть напряжение аккумулятора, а на другой - ноль. Когда зажигание повернуто в положение "Пуск", на клемме, подключенной к стартеру, должно появиться напряжение. Если этого не происходит, соленоид может быть неисправен, или могут быть проблемы с выключателем зажигания или предохранительными выключателями. -

Каков наилучший метод проверки соленоида стартера?

Самый эффективный метод проверки соленоида стартера - использование мультиметра. Начните с проверки напряжения на аккумуляторе и на соленоиде со стороны аккумулятора, чтобы убедиться, что они совпадают. Затем проверьте соленоид со стороны стартера; на нем должно быть ноль вольт при выключенном ключе и напряжение аккумулятора при повороте ключа для запуска. Если показания указывают на проблему, проверьте проводку или при необходимости замените соленоид. -

Каковы общие признаки неисправного соленоида стартера?

Общими признаками неисправного соленоида стартера являются щелкающие звуки при повороте ключа зажигания, отсутствие реакции двигателя стартера или периодические проблемы с запуском. Кроме того, если соленоид горячий на ощупь или на нем видна коррозия, возможно, он неисправен. Проверка с помощью мультиметра поможет подтвердить, что проблема заключается именно в соленоиде или в других элементах системы запуска. -

Как проверить поставщиков соленоидов стартера на международных рынках?

При выборе поставщиков соленоидов стартера проверьте их сертификаты, производственные возможности и отзывы прошлых клиентов. Прежде чем делать оптовые закупки, запросите образцы, чтобы оценить качество продукции. Кроме того, убедитесь, что они соответствуют международным стандартам для вашего конкретного рынка, например, сертификации ISO. Прямое общение по поводу процессов обеспечения качества и послепродажной поддержки также может дать представление об их надежности как поставщика. -

Какие варианты исполнения обычно предлагаются для соленоидов стартера?

Многие производители предлагают варианты настройки стартерных соленоидов, например, различные номиналы напряжения, конфигурации клемм и материалы корпуса. Вы также можете заказать специальную маркировку или брендинг для своей продукции. Обсуждение ваших конкретных требований с поставщиками может привести к созданию индивидуальных решений, отвечающих вашим производственным потребностям, особенно если вы работаете в рамках конкретных промышленных приложений или региональных стандартов соответствия. -

Какова минимальная партия заказа (MOQ) для соленоидов стартера при международных закупках?

Минимальные объемы заказа (MOQ) для стартерных соленоидов могут значительно отличаться в зависимости от поставщика, производственных возможностей и ваших конкретных требований. Как правило, MOQ варьируется от 50 до 500 единиц. Однако некоторые поставщики могут быть готовы договориться о более низком MOQ для новых клиентов или пилотных заказов. Важно сообщить о своих потребностях и узнать, смогут ли поставщики удовлетворить ваш запрос. -

На какие условия оплаты я должен рассчитывать при заказе соленоидов стартера на международном рынке?

Условия оплаты международных заказов на starter solenoids могут сильно различаться, но обычно включают такие варианты, как предоплата, аккредитив или оплата при получении. Обычно условия оплаты включают внесение предоплаты 30% при заказе и остаток средств перед отправкой. Всегда уточняйте условия заранее, чтобы избежать недоразумений, и используйте безопасные методы оплаты для защиты сделки. -

Как обеспечить качество заказов на соленоиды стартера?

Чтобы гарантировать качество заказов на соленоиды стартера, запросите подробную документацию о процессах контроля качества поставщика, включая протоколы испытаний и сертификаты. Проведение аудита на заводе, если это возможно, может дать представление об их производственной практике. Кроме того, рассмотрите возможность использования услуг сторонней инспекции перед отгрузкой для проверки спецификаций и качества продукции, чтобы гарантировать, что соленоиды соответствуют вашим стандартам и требованиям.

Топ 4 как проверить соленоид стартера список производителей и поставщиков

1. Reddit - Кабель электромагнитного пуска

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Эта компания, Reddit - Solenoid Jump Start Cable, является заметным субъектом на рынке. Для получения подробной информации о продукции рекомендуется посетить их сайт.

2. LinkedIn - Соленоид стартера

Домен: linkedin.com

Зарегистрирован: 2002 (23 года)

Введение: Соленоид стартера — это электромагнитный переключатель, который запускает стартер, когда ключ зажигания поворачивается в положение ‘старт’. Он контролирует высокий ток, необходимый для безопасной работы стартера, обеспечивая чистое включение и выключение для уменьшения износа. Симптомы неисправности соленоида стартера включают щелкающие звуки, невозможность запуска, затруднения при запуске двигателя, снижение ускорения...

3. WikiHow - Соленоид стартера

Домен: wikihow.com

Зарегистрирован: 2004 (21 год)

Введение: Соленоид стартера - это механизм, который передает электрический ток от аккумулятора к стартеру, приводя в действие двигатель стартера для запуска двигателя. Обычно он имеет цилиндрическую форму с прикрепленным цилиндром меньшего размера, расположенным рядом с двигателем и трансмиссией. Соленоид имеет две клеммы, одна из которых подключена к аккумулятору. Щелкающий звук при повороте ключа указывает на включение, в то время как отсутствие звука...

4. Del City - Руководство по подключению соленоидов

Домен: blog.delcity.net

Зарегистрирован: 1998 (27 лет)

Введение: Эта компания, Del City - Solenoid Wiring Guide, является заметным субъектом на рынке. Для получения подробной информации о продукции рекомендуется посетить их сайт.

Стратегический поиск Заключение и перспективы для как проверить соленоид стартера

В заключение следует отметить, что эффективная проверка соленоида стартера имеет решающее значение для обеспечения надежности машин и оборудования, особенно в отраслях, где используется тяжелая техника и автомобильная промышленность. Используя простые методы диагностики - например, вольтметр для оценки уровня напряжения в различных точках - покупатели B2B могут быстро определить, исправен ли соленоид, или проблемы кроются в проводке или системах безопасности.

Стратегический сорсинг играет важную роль в этом процессе, поскольку позволяет предприятиям закупать высококачественные и надежные соленоиды у авторитетных поставщиков. При оценке потенциальных поставщиков учитывайте их производственные стандарты, гарантии на продукцию и отзывы клиентов, которые могут существенно повлиять на производительность и долговечность.

Пока международные покупатели B2B из таких регионов, как Африка, Южная Америка, Ближний Восток и Европа, разбираются в сложностях технического обслуживания машин, приоритет качества при выборе поставщиков позволит повысить эффективность работы и снизить долгосрочные затраты. Мы рекомендуем вам воспользоваться информацией, представленной в этом руководстве, для внедрения надежных процедур тестирования и установления партнерских отношений с надежными поставщиками. Тем самым вы не только обеспечите оптимальную работу оборудования, но и будете способствовать устойчивому росту вашей деятельности.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.