Introduction: Navigating the Global Market for how much does it cost to install an alternator

In the dynamic landscape of automotive maintenance, one of the most pressing concerns for B2B buyers is understanding the costs associated with installing an alternator. Whether you are operating a fleet of vehicles in Nigeria, managing a transport company in Vietnam, or overseeing automotive repairs in Europe, accurately assessing how much it costs to install an alternator is crucial for effective budgeting and supplier negotiations. This comprehensive guide delves into various factors influencing alternator installation costs, including the type and model of the vehicle, labor expenses, and the availability of parts across different regions.

Our guide aims to empower international B2B buyers by providing actionable insights into the complexities of sourcing and installing alternators. We will explore the nuances of different alternator types, their applications in various vehicle makes and models, and the importance of vetting suppliers to ensure quality and reliability. Additionally, we will address key considerations such as warranty implications and potential related repairs that may impact overall costs.

By equipping buyers with essential knowledge and strategies, this guide facilitates informed purchasing decisions, ultimately leading to enhanced operational efficiency and cost savings. As you navigate the global market for alternator installation, let this resource serve as your trusted companion in making sound investment choices tailored to your unique business needs.

Содержание

- Top 2 How Much Does It Cost To Install An Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much does it cost to install an alternator

- Understanding how much does it cost to install an alternator Types and Variations

- Key Industrial Applications of how much does it cost to install an alternator

- 3 Common User Pain Points for ‘how much does it cost to install an alternator’ & Their Solutions

- Strategic Material Selection Guide for how much does it cost to install an alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how much does it cost to install an alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does it cost to install an alternator’

- Comprehensive Cost and Pricing Analysis for how much does it cost to install an alternator Sourcing

- Alternatives Analysis: Comparing how much does it cost to install an alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how much does it cost to install an alternator

- Navigating Market Dynamics and Sourcing Trends in the how much does it cost to install an alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much does it cost to install an alternator

- Strategic Sourcing Conclusion and Outlook for how much does it cost to install an alternator

- Важное предупреждение и условия использования

Understanding how much does it cost to install an alternator Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Стандартный генератор переменного тока | Basic design, typically used in older vehicles | Fleet management, used car sales | Pros: Lower cost; Cons: Limited power for modern electronics |

| Высокопроизводительный генератор | Increased amperage for high-demand vehicles | Performance vehicles, heavy-duty fleets | Pros: Enhanced electrical capacity; Cons: Higher initial cost |

| Восстановленный генератор переменного тока | Rebuilt from used parts, cost-effective option | Автосервисы, экономные покупатели | Pros: Cost savings; Cons: Potential variability in quality |

| OEM Alternator | Original equipment manufacturer parts, exact specifications | Dealerships, high-end vehicle maintenance | Pros: Guaranteed fit and performance; Cons: Premium pricing |

| Performance Alternator | Designed for racing or heavy-duty applications, often lightweight | Автоспорт, индивидуальные сборки | Pros: Superior performance; Cons: Expensive and specialized |

Каковы характеристики стандартных генераторов переменного тока?

Standard alternators are the most common type found in older vehicles and basic models. They are designed to meet the minimal electrical demands of essential systems such as lighting and ignition. For B2B buyers, particularly in fleet management or used car sales, these alternators offer a cost-effective solution for maintaining older vehicles. However, they may not suffice for modern cars equipped with advanced electronics, which may lead to higher failure rates and additional costs in the long run.

How Do High-Output Alternators Benefit Specific Applications?

High-output alternators are engineered to provide greater amperage, catering to vehicles with significant electrical demands, such as performance cars and heavy-duty trucks. These alternators are essential for businesses that operate fleets with high-tech features or aftermarket accessories. While they deliver the necessary power to keep all systems functioning optimally, the initial investment is higher compared to standard options, making it crucial for buyers to assess their specific power requirements before purchasing.

What Should Buyers Consider About Remanufactured Alternators?

Remanufactured alternators are a popular choice for auto repair shops and budget-conscious buyers seeking quality at a lower price point. These alternators are built from used parts that have been refurbished to meet industry standards. While they provide significant cost savings, buyers should consider the potential variability in quality and warranty coverage. Ensuring a reputable supplier can mitigate risks associated with remanufactured parts.

Why Choose OEM Alternators for Vehicle Maintenance?

OEM alternators are manufactured by the original vehicle maker, ensuring precise compatibility and performance. They are commonly used by dealerships and for high-end vehicle maintenance where reliability is paramount. B2B buyers should weigh the benefits of guaranteed fit and performance against the higher costs associated with OEM parts. This investment often pays off in terms of longevity and reduced maintenance needs over time.

What Are the Advantages of Performance Alternators?

Performance alternators are tailored for racing and heavy-duty applications, designed to be lightweight while delivering superior electrical output. These alternators are ideal for businesses involved in motorsports or custom vehicle builds where high performance is essential. However, their specialized nature comes with a higher price tag, making them less suitable for standard applications. B2B buyers should evaluate the specific performance needs of their vehicles to justify the investment in these high-end components.

Key Industrial Applications of how much does it cost to install an alternator

| Отрасль/сектор | Specific Application of how much does it cost to install an alternator | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Авторемонтные мастерские | Estimating costs for alternator replacement in customer vehicles | Accurate pricing improves customer trust and satisfaction | Understanding of regional pricing variations and labor costs |

| Управление автопарком | Budgeting for alternator replacements across multiple vehicles | Streamlined maintenance schedules reduce downtime | Volume purchasing agreements for parts and services |

| Транспорт и логистика | Ensuring reliability of delivery vehicles through alternator upkeep | Minimizing breakdowns enhances operational efficiency | Availability of quality parts and reliable service providers |

| Сельскохозяйственное оборудование | Maintaining farm machinery with reliable alternator installations | Prevents operational delays during critical farming seasons | Compatibility with various equipment models and local sourcing |

| Строительная и тяжелая техника | Ensuring uptime of construction equipment reliant on alternators | Reduces project delays and improves productivity | Sourcing durable alternators that can withstand harsh environments |

How is the Cost of Installing an Alternator Relevant to Automotive Repair Shops?

In automotive repair shops, understanding the cost of installing an alternator is crucial for effective customer service. These shops often face varying labor costs and parts prices depending on the vehicle’s make and model. Accurate pricing not only fosters customer trust but also helps in maintaining a competitive edge. Shops must consider local market rates and the availability of parts, ensuring they can provide timely and cost-effective solutions to their clients.

Why is Alternator Cost Estimation Important for Fleet Management?

For fleet management, budgeting for alternator replacements is essential to maintain operational efficiency. Fleet managers need to ensure that all vehicles are in optimal condition to prevent unexpected breakdowns. By estimating installation costs, managers can develop streamlined maintenance schedules that minimize vehicle downtime. Additionally, establishing volume purchasing agreements can lead to cost savings, making it crucial to understand local market conditions and supplier reliability.

How Does Alternator Maintenance Impact Transportation & Logistics?

In the transportation and logistics industry, the reliability of delivery vehicles is paramount. Regular maintenance, including alternator installations, directly affects the operational efficiency of logistics companies. Accurate cost estimation for alternator replacements allows businesses to allocate resources effectively and minimize disruptions. Companies must prioritize sourcing quality parts and reliable service providers to ensure their vehicles remain operational, particularly in regions where supply chains may be less stable.

What Role Does Alternator Cost Play in Agricultural Equipment Maintenance?

For the agricultural sector, maintaining farm machinery is vital to prevent delays during critical planting and harvesting seasons. The cost of installing alternators becomes a significant factor in ensuring that equipment is always operational. Farmers and agricultural businesses need to be aware of the compatibility of alternators with various machinery models and the availability of local sourcing options. This knowledge helps them make informed decisions that can significantly impact productivity.

Why is Understanding Alternator Costs Critical for Construction & Heavy Machinery?

In the construction industry, the uptime of heavy machinery is essential for keeping projects on schedule. Understanding the costs associated with alternator installations can help construction companies budget effectively for maintenance and repairs. By sourcing durable alternators that can withstand harsh operating conditions, businesses can avoid costly project delays. Companies should focus on finding reliable suppliers that offer quality parts tailored to their specific machinery needs.

3 Common User Pain Points for ‘how much does it cost to install an alternator’ & Their Solutions

Scenario 1: The Unforeseen Repair Cost Dilemma

Проблема: B2B buyers often face unexpected repair costs when their fleet vehicles require alternator replacement. The lack of upfront transparency regarding pricing can lead to budget overruns, especially for companies managing multiple vehicles. An alternator replacement can range from $100 to $1,000, depending on the make and model of the vehicle, and without a clear estimate, businesses may find themselves scrambling to accommodate these expenses. Additionally, the hidden costs of labor and associated parts can further complicate budgeting and financial forecasting.

Решение: To mitigate the risk of unexpected costs, B2B buyers should establish a thorough understanding of their vehicle specifications and average repair costs before any issues arise. Utilizing tools like repair cost estimators can provide a clearer picture of expected expenses based on their specific vehicles. Moreover, maintaining a relationship with trusted local repair shops can facilitate better price negotiations and transparency. Regular vehicle maintenance checks can also preemptively identify potential alternator issues, allowing companies to budget for repairs during scheduled downtimes, thereby minimizing disruption to operations.

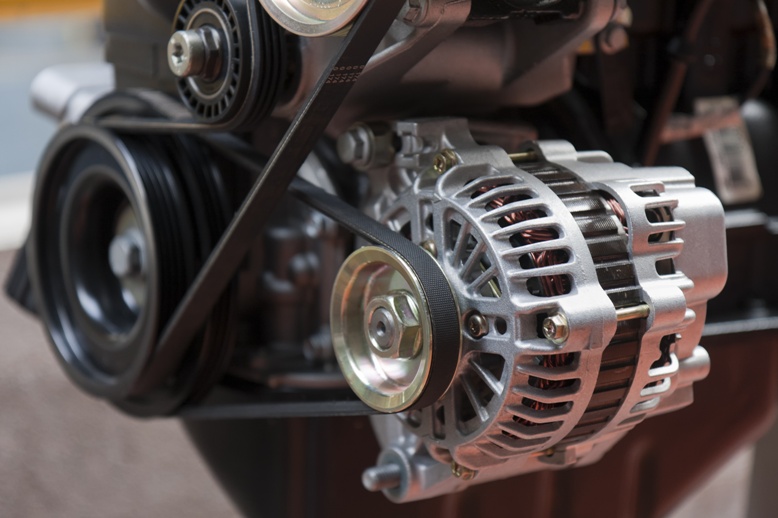

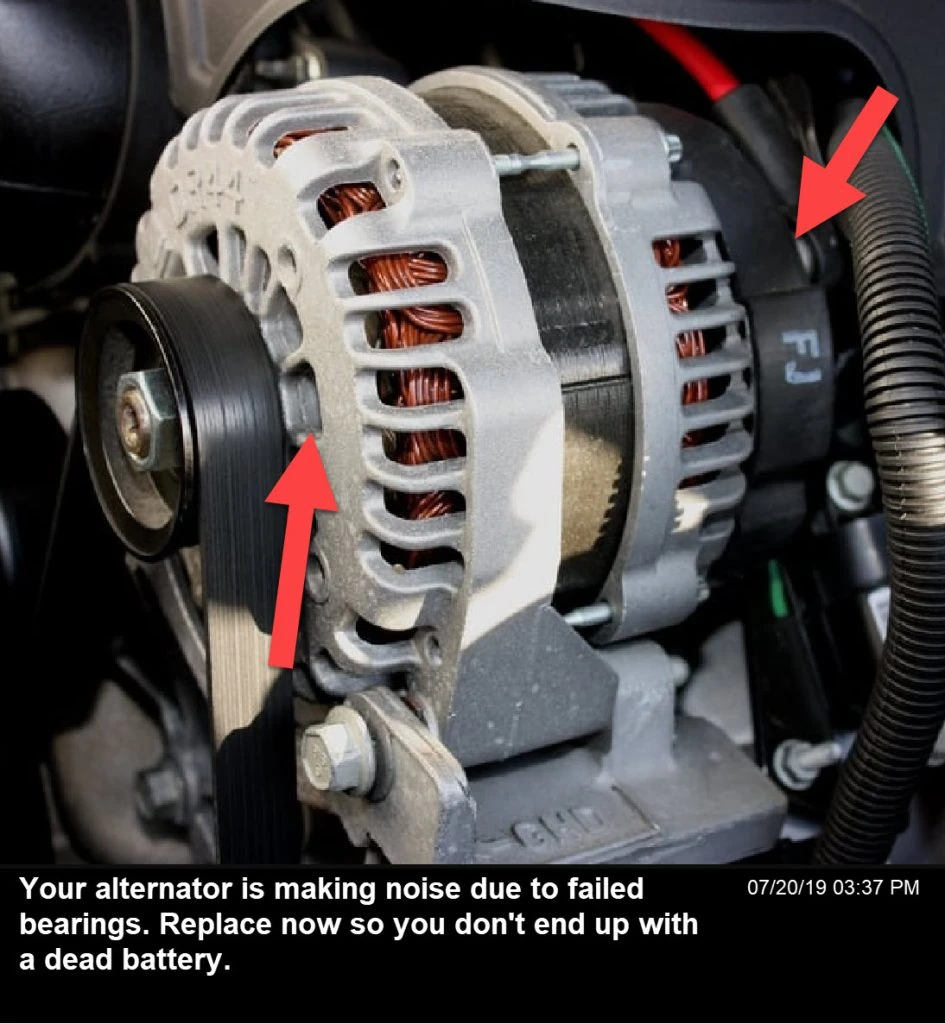

Illustrative image related to how much does it cost to install an alternator

Scenario 2: Sourcing Quality Parts Amidst Global Supply Chain Challenges

Проблема: In the wake of global supply chain disruptions, sourcing quality alternators for fleet vehicles has become a significant pain point for B2B buyers. Many businesses, especially in emerging markets, struggle with the availability of reliable parts that meet their vehicle’s specifications. This scarcity can lead to delays in repairs, impacting the overall efficiency of the fleet and resulting in lost revenue.

Решение: B2B buyers should consider establishing strategic partnerships with multiple suppliers to diversify their sourcing options. This can include local manufacturers, remanufactured parts suppliers, and reputable online retailers. Conducting thorough due diligence on suppliers to assess their reliability and quality standards is essential. Moreover, buyers can benefit from investing in inventory management systems that provide real-time data on part availability, which allows for proactive ordering and reduces lead times for critical repairs. Engaging with industry forums and networks can also provide insights into emerging suppliers and alternatives that may be more resilient to supply chain disruptions.

Scenario 3: Navigating Warranty Confusion for Cost-Efficient Repairs

Проблема: Many B2B buyers are often confused about warranties associated with alternator replacements, leading to misinformed decisions that can result in higher long-term costs. With various parts available—some with limited warranties and others offering lifetime coverage—buyers may inadvertently opt for cheaper parts that lack adequate protection, ultimately leading to repeated repairs and increased expenses.

Решение: To navigate warranty confusion, it is crucial for B2B buyers to educate themselves on the different types of warranties available for alternators. A detailed comparison of warranties should be conducted, focusing not only on price but also on the terms and conditions associated with each part. When sourcing parts, buyers should prioritize those that offer robust warranty options, even if they come at a slightly higher initial cost. This approach not only provides peace of mind but also contributes to long-term savings by minimizing the risk of premature failures. Establishing a clear policy within the organization regarding warranty claims can streamline the process of repairs and replacements, ensuring that all stakeholders understand the importance of choosing quality over cost in the long run.

Strategic Material Selection Guide for how much does it cost to install an alternator

What Are the Common Materials Used in Alternator Installation and Their Costs?

When considering the cost of installing an alternator, the choice of materials used in the alternator itself can significantly affect both the performance and overall installation costs. Here, we analyze four common materials: aluminum, copper, steel, and plastic.

How Does Aluminum Impact Alternator Performance and Cost?

Aluminum is widely used in the housing of alternators due to its lightweight nature and excellent thermal conductivity. This metal can withstand high temperatures, making it suitable for automotive applications where heat dissipation is crucial.

Плюсы: Aluminum is resistant to corrosion, which enhances the longevity of the alternator. It is also relatively inexpensive compared to other metals, reducing overall manufacturing costs.

Минусы: While aluminum is lightweight, it may not offer the same structural strength as steel, which can be a concern in high-stress environments. Additionally, the manufacturing process can be complex, leading to increased labor costs if not managed efficiently.

Влияние на применение: Aluminum’s thermal properties allow it to effectively manage the heat generated during alternator operation, ensuring consistent performance.

Illustrative image related to how much does it cost to install an alternator

Соображения для международных покупателей: Buyers from regions like Africa and South America should ensure compliance with local standards for aluminum quality, such as ASTM or EN standards, to guarantee the durability of the alternator in varying climates.

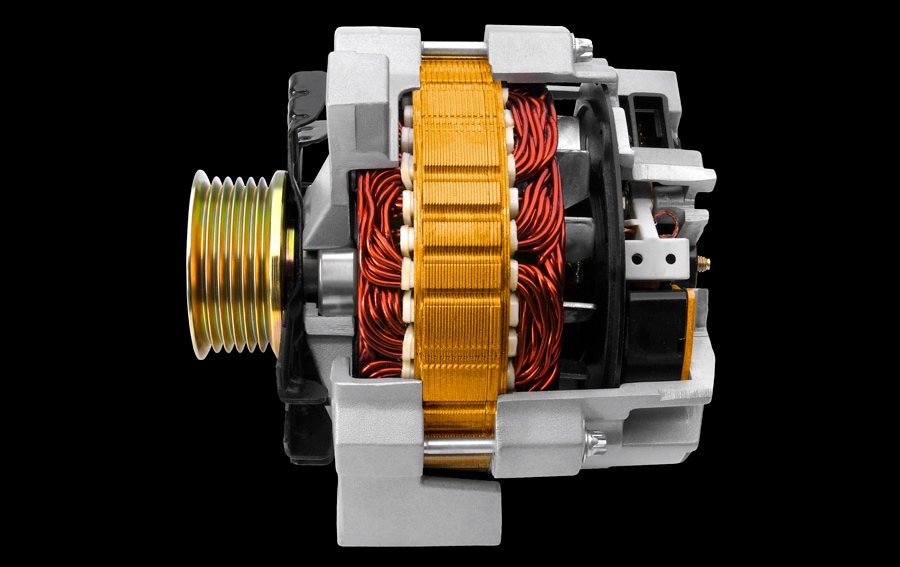

Какую роль играет медь в эффективности генератора?

Copper is a critical material in the windings of an alternator due to its excellent electrical conductivity. This property is essential for efficient energy transfer from the alternator to the vehicle’s electrical system.

Плюсы: Copper’s high conductivity allows for smaller wire gauges, reducing weight and space in the alternator design. It also has a long lifespan, contributing to the overall reliability of the alternator.

Минусы: The primary drawback of copper is its relatively high cost compared to aluminum and other materials. Additionally, copper is susceptible to corrosion if not properly insulated, which can affect performance over time.

Illustrative image related to how much does it cost to install an alternator

Влияние на применение: In terms of specific media compatibility, copper is ideal for automotive electrical systems, where efficient power delivery is paramount.

Соображения для международных покупателей: Buyers should be aware of fluctuations in copper prices, which can impact the total cost of alternator installation. Compliance with international standards regarding copper purity is also essential to ensure quality.

How Does Steel Influence the Structural Integrity of Alternators?

Steel is often used in the internal components and mounting brackets of alternators due to its strength and durability.

Illustrative image related to how much does it cost to install an alternator

Плюсы: Steel provides excellent structural integrity, making it suitable for high-stress applications. It is also cost-effective and widely available, which can lower manufacturing costs.

Минусы: The primary disadvantage of steel is its weight, which can impact the overall weight of the vehicle. Additionally, steel is prone to rust if not adequately coated or treated.

Влияние на применение: Steel’s strength ensures that the alternator can withstand vibrations and impacts, which is critical in automotive applications.

Соображения для международных покупателей: Buyers should ensure that the steel used meets international standards for automotive applications, such as JIS or DIN, to guarantee quality and performance.

Illustrative image related to how much does it cost to install an alternator

What Is the Role of Plastic in Alternator Design?

Plastic is commonly used in non-structural components of alternators, such as covers and insulators.

Плюсы: Plastic is lightweight and resistant to corrosion, making it an excellent choice for components that do not require high strength. It can also be molded into complex shapes, allowing for innovative designs.

Минусы: The main limitation of plastic is its lower thermal resistance compared to metals, which can lead to deformation under high temperatures. Additionally, certain plastics may not be as durable over time.

Влияние на применение: Plastic components can help reduce the overall weight of the alternator, contributing to better fuel efficiency in vehicles.

Соображения для международных покупателей: Buyers should verify that the plastics used comply with safety and environmental regulations in their respective countries, particularly in the automotive sector.

Сводная таблица выбора материалов для расчета стоимости установки генератора

| Материал | Typical Use Case for how much does it cost to install an alternator | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Корпус и структурные компоненты | Легкий и коррозионно-стойкий | Less structural strength than steel | Средний |

| Медь | Обмотки для обеспечения электропроводности | Высокая электропроводность | Более высокая стоимость и подверженность коррозии | Высокий |

| Сталь | Internal components and mounting brackets | Отличная прочность и долговечность | Более тяжелый и подверженный ржавчине | Низкий |

| Пластик | Неструктурные компоненты, такие как крышки | Легкий и формуемый | Lower thermal resistance and durability | Низкий |

This analysis provides B2B buyers with a comprehensive understanding of the materials used in alternator installations, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how much does it cost to install an alternator

The manufacturing process of alternators involves several critical stages, each designed to ensure that the final product meets the highest quality standards. For B2B buyers, understanding these processes can aid in making informed purchasing decisions, particularly when considering the cost of installation and overall value. Here’s an in-depth look at the manufacturing processes and quality assurance measures associated with alternators.

Каковы основные этапы производства генератора?

How is Material Preparation Conducted in Alternator Manufacturing?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials, including copper for windings, steel for the casing, and various plastics for insulating components. Suppliers should be vetted for material quality, as subpar materials can lead to premature failure of the alternator. B2B buyers should inquire about the sourcing of these materials and the suppliers’ adherence to international standards, such as ISO 9001, which ensures a consistent quality management system.

Какие методы формовки используются при производстве генераторов?

After materials are prepared, the next stage is forming. This includes processes such as stamping, machining, and casting. For example, the rotor and stator are typically stamped from high-grade steel, which is then machined to achieve precise dimensions. The use of advanced forming techniques, such as CNC machining, allows for high precision and repeatability in manufacturing. Buyers should be aware of the technologies used by suppliers, as modern techniques can improve the performance and longevity of the alternator.

How is the Assembly of Alternators Performed?

The assembly process involves bringing together all the individual components, including the rotor, stator, diodes, and voltage regulator. This stage often requires skilled labor and advanced automation to ensure accuracy and efficiency. Key assembly techniques include the use of automated robotic arms for precise placement of components and soldering methods that ensure strong electrical connections. B2B buyers should assess whether suppliers use automated processes, as these can enhance consistency and reduce human error during assembly.

What Finishing Processes Are Common in Alternator Manufacturing?

Finishing processes are crucial for enhancing the durability and performance of alternators. This may include surface treatments to prevent corrosion, painting, and applying protective coatings. Ensuring that these processes are executed correctly is vital for the long-term reliability of the alternator. Buyers should inquire about the types of finishing processes used and their adherence to industry standards, which can indicate the expected lifespan and performance of the product.

Какие меры контроля качества применяются при производстве генераторов?

Which International Standards Should B2B Buyers Look for in Alternator QC?

Quality control is a fundamental aspect of alternator manufacturing. International standards such as ISO 9001 provide guidelines for quality management systems, ensuring that manufacturers adhere to strict quality protocols. Additionally, certifications like CE mark (for European compliance) and API standards (for performance specifications) are crucial indicators of quality. B2B buyers should verify that their suppliers have these certifications, as they reflect a commitment to maintaining high-quality production standards.

Каковы основные пункты контроля качества при производстве генераторов?

Quality control checkpoints are integrated throughout the manufacturing process. Incoming Quality Control (IQC) checks the quality of raw materials before they are used in production. In-Process Quality Control (IPQC) involves monitoring the manufacturing process at various stages to identify defects early. Finally, Final Quality Control (FQC) ensures that each completed alternator meets performance specifications before it is shipped. B2B buyers should ask suppliers about their QC processes and any documentation or reports that detail these checkpoints.

Какие общие методы тестирования используются для проверки качества генератора?

Common testing methods for alternators include electrical testing, thermal testing, and mechanical stress tests. Electrical testing verifies the output voltage and current, ensuring the alternator meets specified electrical performance criteria. Thermal testing assesses how the alternator performs under extreme conditions, while mechanical stress tests evaluate its durability against vibrations and impacts. Buyers can request test reports from suppliers to understand the quality and reliability of the alternators they intend to purchase.

Как покупатели B2B могут проверить методы контроля качества поставщиков?

What Steps Can Buyers Take to Audit Supplier Quality Control?

To ensure that suppliers adhere to high-quality standards, B2B buyers should conduct regular audits. This may involve on-site visits to the manufacturing facility to review production processes, quality control measures, and compliance with international standards. During these audits, buyers can assess the supplier’s ability to maintain quality throughout the production cycle and verify the effectiveness of their QC checkpoints.

Illustrative image related to how much does it cost to install an alternator

How Can Third-Party Inspections Enhance Quality Assurance for B2B Buyers?

Third-party inspections can provide an additional layer of assurance for B2B buyers. Engaging independent inspection agencies to evaluate the manufacturing process and product quality can help mitigate risks associated with purchasing. These agencies can perform detailed assessments, including material verification, process audits, and final product inspections, ensuring that the alternators meet all specified requirements before shipment.

Каковы нюансы контроля качества для международных B2B-покупателей?

How Do Regional Standards Impact Alternator Quality Assurance?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of regional standards that may impact alternator quality. For instance, the European Union has stringent regulations regarding electronic components, which can affect the design and manufacturing processes. Buyers must ensure that their suppliers are compliant with these regional standards to avoid legal and operational issues.

What Should Buyers Consider Regarding Warranty and Support for Alternators?

Finally, warranty and support are critical aspects of purchasing alternators. Buyers should inquire about the warranty period and the conditions that apply. A longer warranty often indicates a manufacturer’s confidence in their product quality. Additionally, understanding the support structure for warranty claims, including the process for handling defective units, can significantly impact the overall purchasing experience.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for alternators is vital for B2B buyers. By focusing on material quality, manufacturing techniques, and rigorous quality control practices, buyers can make informed decisions that enhance their supply chain and ensure the reliability of their vehicle’s electrical systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does it cost to install an alternator’

To assist international B2B buyers in understanding the costs associated with installing an alternator, this guide provides a practical checklist to facilitate informed decision-making. By following these steps, buyers can ensure they procure the right parts and services while managing costs effectively.

Шаг 1: Определите свои технические характеристики

Understanding the technical requirements of the alternator is crucial. The specifications include the year, make, model, and engine size of the vehicle, which determine the type of alternator needed. Additionally, consider the amperage and mounting style to ensure compatibility and optimal performance.

Шаг 2: Исследование рыночных цен

Conduct thorough research to gather data on the average costs of alternator installations across various regions. Prices can vary significantly based on geographical location and market demand. Utilize online resources, local automotive shops, and industry reports to compile a comprehensive cost range, typically between $100 and $1,000.

Illustrative image related to how much does it cost to install an alternator

Шаг 3: Оцените потенциальных поставщиков

Before committing to a supplier, it’s essential to perform due diligence. Request detailed company profiles and inquire about their experience with your specific vehicle type. Look for case studies or references from other businesses in your region to gauge their reliability and service quality.

- Проверьте сертификаты поставщиков: Ensure that the suppliers have the necessary certifications, such as ISO or local automotive standards, which indicate adherence to quality and safety protocols.

Шаг 4: Analyze Labor Costs

Labor costs can significantly impact the total installation price. Obtain estimates from multiple service providers to compare labor charges, which can range from $182 to $267. Inquire about the average time required for installation, as this will affect the overall labor expense.

Шаг 5: Consider Warranty and Quality of Parts

Evaluate the warranty offered on the alternators, as this can reflect the quality of the parts. A longer warranty period often indicates a higher quality product, which can save costs in the long run through reduced replacements. Ensure that the alternators you consider are from reputable manufacturers known for reliability.

Illustrative image related to how much does it cost to install an alternator

Шаг 6: Plan for Related Repairs

Be prepared for the possibility of related repairs that may arise during the alternator installation process. Issues such as a failing battery or wiring problems can add to the total cost. Discuss with your mechanic any potential additional repairs that could be needed and factor these into your budget.

Шаг 7: Review Installation Options

Decide whether to opt for professional installation or consider a DIY approach. Professional services may provide a warranty on the installation work, while DIY can save costs if you have the necessary skills and tools. Evaluate the pros and cons of each option based on your expertise and available resources.

By following this checklist, B2B buyers can make informed choices regarding the procurement and installation of alternators, ensuring both quality and cost-effectiveness in their vehicle maintenance strategies.

Comprehensive Cost and Pricing Analysis for how much does it cost to install an alternator Sourcing

What Are the Key Cost Components for Installing an Alternator?

When evaluating the costs associated with installing an alternator, several components contribute to the overall price. Understanding these elements can help international B2B buyers make informed purchasing decisions.

-

Материалы: The primary cost driver is the alternator itself, which can range from $50 to $700 depending on the make and model. The materials used, such as copper windings and durable housings, also impact the price. High-quality materials increase longevity and performance, which is crucial for vehicles operating in diverse environments.

-

Трудовые ресурсы: Labor costs for installation typically range from $100 to $300. This can vary significantly based on the complexity of the installation, regional labor rates, and the specific vehicle type. In markets like Africa or South America, labor may be less expensive, but it’s essential to ensure that technicians are trained and knowledgeable about the specific vehicle systems.

-

Производственные накладные расходы: Overhead costs include expenses related to production facilities, utilities, and administrative functions. These costs are generally factored into the price of the alternator and can vary by region and supplier efficiency.

-

Tooling and Quality Control: Specialized tools may be required for the installation, particularly for certain vehicle models. Additionally, quality control processes ensure that the alternators meet performance standards, which can add to the overall cost.

-

Логистика: The cost of transporting the alternators from the manufacturer to the point of sale can be significant, particularly for international shipments. Factors such as shipping methods, distance, and customs duties must be considered, especially for buyers in regions like the Middle East and Europe.

-

Маржа: Suppliers typically include a margin in their pricing to cover risks and profit. This margin can vary widely based on market competition, supplier reputation, and the overall demand for alternators.

What Factors Influence Pricing for Alternator Installations?

Several factors play a critical role in determining the price of alternator installations:

-

Объем и минимальный объем заказа (MOQ): Bulk purchases often lead to significant discounts. Buyers should negotiate MOQs with suppliers to lower costs.

-

Технические характеристики и индивидуальная настройка: Custom alternators or those with specific specifications may incur additional costs. Buyers should assess their needs carefully to avoid over-specifying.

-

Качество материалов и сертификаты: Higher quality materials and certifications (e.g., ISO standards) justify higher prices but can lead to better performance and durability, reducing long-term costs.

-

Факторы, связанные с поставщиками: The choice of supplier can significantly influence pricing. Established suppliers with a reputation for quality may command higher prices but provide better reliability and support.

-

Инкотермс: Understanding the terms of trade can affect costs. Incoterms dictate who is responsible for shipping, insurance, and tariffs, influencing the total cost of ownership.

What Are the Best Practices for B2B Buyers Negotiating Alternator Costs?

For international buyers, particularly in regions like Africa and South America, effective negotiation and strategic purchasing can lead to cost savings:

-

Understand Total Cost of Ownership: Buyers should evaluate the long-term costs associated with alternators, including installation, maintenance, and potential downtime due to failures.

-

Используйте связи: Building strong relationships with suppliers can result in better pricing, priority service, and access to new products.

-

Будьте в курсе рыночных цен: Researching market prices and trends enables buyers to negotiate more effectively and avoid overpaying.

-

Рассмотрите местных поставщиков: Sourcing from local manufacturers can reduce shipping costs and lead times, but ensure they meet quality standards.

-

Запросить несколько предложений: Obtaining quotes from several suppliers allows for comparisons and can provide leverage in negotiations.

Отказ от ответственности за ориентировочные цены

The prices mentioned in this analysis are indicative and can vary based on geographic location, market conditions, and individual supplier pricing strategies. It is advisable for buyers to conduct thorough research and obtain specific quotes tailored to their unique needs and circumstances.

Alternatives Analysis: Comparing how much does it cost to install an alternator With Other Solutions

Понимание альтернатив стоимости установки генератора

When considering vehicle electrical systems, the cost of installing an alternator is a critical factor. However, there are alternatives that can either complement or replace traditional alternators, depending on specific needs and circumstances. This section provides a comparative analysis of the costs and implications of installing an alternator against alternative solutions such as battery maintenance systems and solar panel installations.

Illustrative image related to how much does it cost to install an alternator

Сравнительная таблица

| Аспект сравнения | How Much Does It Cost To Install An Alternator | Battery Maintenance System | Solar Panel Installation |

|---|---|---|---|

| Производительность | Provides consistent power to electrical systems | Extends battery life, but not a power generator | Generates power for various uses, including battery charging |

| Стоимость | $100 – $1,000 (average $744 – $1,034) | $50 – $200 (initial cost) | $1,000 – $3,000 (plus installation) |

| Простота внедрения | Moderate; requires mechanical expertise | Easy; often DIY-friendly | Complex; requires professional installation |

| Техническое обслуживание | Periodic checks; lifespan of 7-10 years | Low; minimal upkeep needed | Moderate; battery and system checks needed |

| Лучший вариант использования | Standard vehicles requiring reliable power | Fleets needing battery longevity | Off-grid applications or renewable energy initiatives |

Подробная разбивка альтернатив

Battery Maintenance Systems

Battery maintenance systems are designed to optimize the performance and lifespan of car batteries. These systems monitor battery health and can include devices that maintain charge levels, preventing sulfation and extending battery life. The cost of implementing a battery maintenance system ranges from $50 to $200, making it a low-cost alternative compared to installing a new alternator. The primary advantage is that these systems can enhance battery longevity without replacing the alternator. However, they do not generate power; thus, they are best suited for use alongside an existing alternator rather than as a replacement.

Solar Panel Installation

Solar panel installations provide a renewable energy source for vehicles, particularly in off-grid scenarios or for electric vehicles. The costs for solar panel systems range from $1,000 to $3,000, depending on the size and complexity of the installation. While solar panels can offer significant savings on energy costs and contribute to sustainability goals, their installation is complex and typically requires professional expertise. Moreover, solar panels function best in sunny environments and may not be suitable for all geographical areas. They can be an excellent long-term investment, especially for businesses looking to reduce their carbon footprint or energy dependency.

Заключение: правильный выбор для ваших нужд

When evaluating how much it costs to install an alternator versus alternative solutions, B2B buyers should consider their specific operational requirements, budget constraints, and long-term goals. For standard vehicles that require reliable power delivery, investing in a new alternator remains the most practical solution. However, for businesses seeking to enhance battery longevity or explore renewable energy sources, battery maintenance systems or solar panel installations could provide valuable alternatives. Ultimately, the choice will depend on the unique needs of the organization, the existing vehicle infrastructure, and the desired balance between upfront costs and long-term benefits.

Essential Technical Properties and Trade Terminology for how much does it cost to install an alternator

What Are the Key Technical Properties to Consider When Installing an Alternator?

When evaluating the cost of installing an alternator, understanding the technical specifications is vital for B2B buyers. Here are some critical properties to consider:

-

Марка материала

– The materials used in the alternator, such as copper for windings and aluminum for the casing, significantly affect performance and durability. High-grade materials enhance efficiency and longevity, which can reduce long-term replacement costs. Buyers should prioritize suppliers that offer alternators made with premium materials. -

Номинальный ток

– This specification indicates the alternator’s power output capacity, measured in amps. Higher amperage ratings are necessary for vehicles with extensive electrical systems, such as those equipped with advanced infotainment or safety features. Understanding the required amperage helps in sourcing an alternator that meets the vehicle’s demands without risking electrical failures. -

Тип крепления

– The mounting style of an alternator must match the vehicle’s design for proper installation and function. Different vehicles may require unique mounting configurations, which can impact installation costs. Ensuring compatibility prevents additional expenses related to modifications or incorrect installations. -

Electrical Connections Type

– Alternators can have various connection types, including 1-wire and 3-wire configurations. The type of connections can influence the complexity of the installation and the associated labor costs. Buyers should consult with technicians to determine which type is best suited for their specific vehicle. -

Гарантийный срок

– The warranty offered on an alternator can indicate its quality and reliability. Alternators with longer warranty periods may carry a higher upfront cost but can provide peace of mind and potential savings on future repairs. This aspect is crucial for B2B buyers looking for long-term value. -

Rebuild Availability

– The ability to source remanufactured alternators can impact both cost and availability. Some vehicles may have limited options for new alternators, making remanufactured units a viable alternative. Buyers should assess the availability of cores for rebuilding, as this can influence pricing and service timelines.

What Are the Common Trade Terms Related to Alternator Installation Costs?

Understanding industry jargon is essential for effective communication and negotiation in the automotive parts market. Here are some common terms related to alternator installation costs:

-

OEM (производитель оригинального оборудования)

– OEM parts are made by the same manufacturer that produced the original components for the vehicle. These parts typically guarantee compatibility and quality but may come at a higher price. B2B buyers often weigh the benefits of OEM against aftermarket alternatives based on cost and performance. -

MOQ (минимальный объем заказа)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand, as purchasing below the MOQ can lead to higher costs per unit. Negotiating favorable MOQs can significantly affect budgeting for alternator inventory. -

RFQ (запрос предложения)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products, such as alternators. This process allows buyers to compare offers and make informed purchasing decisions. Crafting a detailed RFQ can lead to better pricing and service agreements. -

Инкотермс (Международные торговые термины)

– Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs in international trade. Understanding these terms helps B2B buyers clarify costs and liabilities associated with the importation of alternators, ensuring smoother transactions. -

Рынок послепродажного обслуживания

– Aftermarket refers to parts not made by the original manufacturer but designed to fit specific vehicles. Aftermarket alternators can offer cost savings but may vary in quality and performance. B2B buyers should consider the trade-offs between aftermarket and OEM parts when determining installation costs. -

Время выполнения заказа

– Lead time is the period between placing an order and receiving the product. Understanding lead times for alternators is essential for B2B buyers to manage inventory effectively and minimize downtime for vehicles needing repairs. Faster lead times can enhance customer satisfaction and operational efficiency.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions regarding the installation and procurement of alternators, ultimately optimizing their operations and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the how much does it cost to install an alternator Sector

What Are the Key Trends Affecting the Cost of Installing an Alternator?

In recent years, the global automotive industry has undergone significant changes, influencing the cost of installing an alternator. The demand for electric vehicles (EVs) and hybrid models has surged, prompting manufacturers to innovate and adapt their alternator designs. This shift not only increases the complexity of sourcing components but also introduces advanced technologies that can impact pricing. Moreover, the rise of digital platforms has enabled B2B buyers to access a wider range of suppliers, facilitating competitive pricing and sourcing options across regions, including Africa, South America, the Middle East, and Europe.

Another critical trend is the increasing emphasis on local sourcing to mitigate supply chain disruptions, which have been exacerbated by geopolitical tensions and the COVID-19 pandemic. Buyers are now more inclined to partner with local suppliers who can offer faster turnaround times and reduced shipping costs. Additionally, the growing focus on aftermarket services, such as remanufacturing and rebuilding alternators, is changing the cost landscape. Remanufactured alternators can often be a more cost-effective solution, appealing to budget-conscious buyers while still meeting performance standards.

Illustrative image related to how much does it cost to install an alternator

Moreover, the integration of technology in diagnostics and installation processes is reshaping the service landscape. Tools that facilitate remote diagnostics can enhance the efficiency of repairs and installations, ultimately affecting labor costs. As technology continues to evolve, buyers must stay informed about the latest tools and practices that can impact the total cost of alternator installation.

How Is Sustainability Influencing the Sourcing of Alternators?

Sustainability has emerged as a critical factor in the sourcing of automotive components, including alternators. The environmental impact of manufacturing processes and the sourcing of raw materials is prompting buyers to prioritize suppliers who adhere to sustainable practices. Ethical sourcing not only enhances a company’s brand reputation but also aligns with global initiatives aimed at reducing carbon footprints.

Buyers are increasingly looking for suppliers who offer ‘green’ certifications or utilize eco-friendly materials in their products. For instance, some manufacturers are exploring alternatives to conventional materials, such as recycled metals and biodegradable components, which can significantly reduce the environmental impact of alternators. Additionally, companies that engage in responsible waste management practices and demonstrate transparency in their supply chains are becoming more attractive to B2B buyers.

Furthermore, the lifecycle of automotive parts is gaining attention. Sustainable sourcing involves considering the entire lifecycle of the alternator, from production to disposal. This includes evaluating the potential for recycling old alternators and the availability of remanufactured options. As sustainability continues to be a priority for consumers and businesses alike, B2B buyers must be proactive in seeking suppliers who are committed to ethical practices and innovative solutions that minimize environmental impact.

What Is the Historical Context of Alternator Sourcing and Costs?

The alternator has evolved significantly since its inception in the early 20th century, transitioning from a simple generator to a sophisticated component integral to modern vehicles. Initially, alternators were primarily used in commercial vehicles, but as automotive technology advanced, they became standard in passenger cars by the 1960s. This evolution has led to increased complexity in design, which in turn affects sourcing and installation costs.

In the past, sourcing alternators was largely localized, with manufacturers relying on regional suppliers for parts. However, globalization has transformed this landscape, enabling international trade and competition. Today, buyers can source alternators from various global markets, each with its own pricing dynamics influenced by factors such as labor costs, material availability, and technological advancements.

Moreover, the rise of e-commerce has revolutionized how B2B buyers purchase alternators. Digital platforms allow for easy comparison of prices and suppliers, empowering buyers to make informed decisions. As the market continues to evolve, staying abreast of historical trends will enable B2B buyers to better navigate current and future sourcing challenges.

Frequently Asked Questions (FAQs) for B2B Buyers of how much does it cost to install an alternator

-

What factors influence the cost of installing an alternator?

The cost of installing an alternator can vary widely due to several factors. These include the vehicle’s make, model, and year, as well as the specific type of alternator required. Labor costs also play a significant role, as more complex installations may demand higher fees. Additionally, geographical location can affect pricing due to varying market rates and availability of skilled labor. It’s advisable to compare quotes from multiple suppliers and service centers to understand the full scope of potential costs. -

Как найти надежных поставщиков генераторов переменного тока?

To identify reliable suppliers for alternators, start by conducting thorough research online and through industry networks. Look for suppliers with a strong reputation, positive reviews, and established business histories. Attend trade shows and industry events to connect with manufacturers and distributors directly. Additionally, consider asking for references from previous clients to gauge their reliability. Certifications and quality assurance processes can also indicate a supplier’s commitment to delivering high-quality products. -

Каковы типичные условия оплаты при оптовой покупке генераторов?

Payment terms for bulk purchases of alternators can vary widely depending on the supplier and the buyer’s relationship. Common terms include net 30, net 60, or even net 90 days, where payment is due within 30, 60, or 90 days after the invoice date. Some suppliers may offer discounts for upfront payments or larger orders. It’s crucial to negotiate terms that work for both parties, ensuring cash flow is managed effectively while maintaining good supplier relations. -

Каков минимальный объем заказа (MOQ) для генераторов?

Minimum order quantities (MOQs) for alternators can differ significantly among suppliers. Typically, MOQs range from 10 to 100 units, depending on the manufacturer and the specific alternator model. Some suppliers may be willing to negotiate lower MOQs for first-time buyers or long-term partnerships. Understanding your inventory needs and discussing them with suppliers can help in obtaining favorable terms that align with your business strategy. -

What should I consider regarding quality assurance when sourcing alternators?

Quality assurance is critical when sourcing alternators, as substandard products can lead to increased repair costs and customer dissatisfaction. Ensure that suppliers adhere to international quality standards, such as ISO certifications. Request detailed documentation regarding the manufacturing process, materials used, and warranty terms. Additionally, consider conducting third-party inspections or audits to verify the quality of the products before shipment, especially when dealing with international suppliers. -

How do logistics impact the cost of alternator installation?

Logistics can significantly affect the overall cost of alternator installation. Import duties, shipping fees, and transportation costs must be factored into the total expenditure. Additionally, the speed of delivery can influence costs; expedited shipping options may be more expensive but can be necessary for urgent replacements. Work with logistics partners experienced in automotive parts to ensure timely and cost-effective delivery while minimizing risks associated with international trade. -

What are the common signs that an alternator needs replacement?

Common indicators that an alternator may need replacement include dimming headlights, a battery warning light on the dashboard, unusual noises from the engine bay, or electrical malfunctions within the vehicle. If these symptoms arise, it is crucial to diagnose the issue promptly. Ignoring these signs can lead to more extensive electrical problems and increased repair costs. Regular maintenance checks can also help in early detection, ensuring the longevity of your vehicle’s electrical system. -

How does the amperage of an alternator affect its cost?

The amperage rating of an alternator directly influences its cost due to the amount of electrical power it can generate. Higher amperage alternators typically contain more high-value materials, such as copper windings, which increases production costs. When sourcing alternators, ensure that the amperage aligns with your vehicle’s requirements to avoid overpaying for unnecessary capacity. Balancing cost with performance needs is key to making a sound investment in automotive electrical systems.

Top 2 How Much Does It Cost To Install An Alternator Manufacturers & Suppliers List

1. J.D. Power – Затраты на замену генератора

Домен: jdpower.com

Зарегистрирован: 1995 (30 лет)

Введение: Alternator replacement costs range from $350 to $900, with part costs averaging $100 to $350 for standard models and $500 to $700 for luxury models. Labor costs can add another $350 to $500 if performed by a dealership. Rebuilt alternators are available and typically come with a warranty. DIY installation can save on labor costs, but requires some skill and time. An alternator lasts approximately …

2. CarTalk – Alternator Replacement Cost

Домен: cartalk.com

Зарегистрирован: 1995 (30 лет)

Введение: The cost to replace an alternator ranges from $600 to $1,500. An alternator is a critical component that converts mechanical force into electrical energy, powering the engine, lights, and charging the battery. Signs of a failing alternator include a check engine light, dimming headlights, and the need for jump starts. Alternators can fail mechanically or electrically, and while they are covered un…

Strategic Sourcing Conclusion and Outlook for how much does it cost to install an alternator

As the demand for reliable automotive components continues to grow in emerging markets across Africa, South America, the Middle East, and Europe, understanding the cost implications of alternator installation becomes crucial for B2B buyers. The price range for alternator replacement typically falls between $100 and $1,000, influenced by factors such as vehicle make, model, and the specifics of the alternator itself. Buyers should prioritize strategic sourcing to secure high-quality parts at competitive prices, considering factors like warranty, compatibility, and supplier reliability.

Investing in a robust procurement strategy not only ensures cost-effectiveness but also enhances operational efficiency, particularly in regions where vehicle maintenance is vital for business continuity. By leveraging local suppliers and remanufactured options, businesses can optimize their supply chains while supporting local economies.

Looking ahead, it is imperative for international B2B buyers to stay informed about market trends and pricing fluctuations. Engaging with trusted suppliers and exploring new partnerships can lead to better deals and improved service. By prioritizing strategic sourcing, companies can navigate the complexities of alternator installation costs and drive sustainable growth in their automotive operations.

Illustrative image related to how much does it cost to install an alternator

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.