Introduction: Navigating the Global Market for starting system in automobile

In today’s competitive automotive landscape, sourcing reliable starting systems is a pivotal challenge for international B2B buyers. The starting system is not merely a component; it is the heart of a vehicle’s electrical system, vital for ensuring operational efficiency and reliability. This comprehensive guide delves into the intricacies of starting systems, covering essential components such as batteries, ignition switches, starter motors, and their respective applications across various vehicle types.

Understanding the diverse types of starting systems and their specifications can significantly impact purchasing decisions, particularly for businesses operating in emerging markets like Africa, South America, the Middle East, and Europe. By providing insights into supplier vetting, cost considerations, and the latest technological advancements, this guide empowers buyers to make informed choices that align with their operational needs and budget constraints.

Whether you are in Brazil seeking robust solutions for your fleet or in Nigeria looking for cost-effective alternatives, this guide serves as a valuable resource. It equips you with the knowledge to navigate the complexities of the global market for starting systems, ensuring that your procurement strategies are both effective and efficient.

Содержание

- Top 1 Starting System In Automobile Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starting system in automobile

- Understanding starting system in automobile Types and Variations

- Key Industrial Applications of starting system in automobile

- 3 Common User Pain Points for ‘starting system in automobile’ & Their Solutions

- Strategic Material Selection Guide for starting system in automobile

- In-depth Look: Manufacturing Processes and Quality Assurance for starting system in automobile

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starting system in automobile’

- Comprehensive Cost and Pricing Analysis for starting system in automobile Sourcing

- Alternatives Analysis: Comparing starting system in automobile With Other Solutions

- Essential Technical Properties and Trade Terminology for starting system in automobile

- Navigating Market Dynamics and Sourcing Trends in the starting system in automobile Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starting system in automobile

- Strategic Sourcing Conclusion and Outlook for starting system in automobile

- Важное предупреждение и условия использования

Understanding starting system in automobile Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Обычный стартер | Uses an electric motor to crank the engine; relies on a battery. | Производство и ремонт автомобилей | Плюсы: Simple design, widely available. Минусы: Limited efficiency in extreme conditions. |

| Высокопроизводительный стартер | Optimized for high torque; often features advanced materials. | Racing vehicles, heavy-duty trucks | Плюсы: Superior cranking power, durable. Минусы: Более высокая стоимость, может потребоваться специализированная установка. |

| Редукторный стартер | Incorporates gears to amplify motor torque; compact design. | Specialty vehicles, compact cars | Плюсы: Space-efficient, reduces battery strain. Минусы: Potentially more complex repairs. |

| Diesel Starter | Designed for high-compression diesel engines; robust construction. | Commercial trucks, heavy machinery | Плюсы: High reliability, tailored for diesel applications. Минусы: Heavier and bulkier than alternatives. |

| Системы дистанционного запуска | Allows engine start from a distance, often integrated with security features. | Fleet management, high-end vehicles | Плюсы: Convenience, enhanced security. Минусы: Complex installation, potential for electronic failures. |

What Are the Characteristics of Conventional Starters and Their B2B Suitability?

Conventional starters are the most common type used in vehicles today, utilizing a simple electric motor powered by the vehicle’s battery to crank the engine. Their reliability and ease of replacement make them suitable for a wide range of automotive applications, from everyday vehicles to commercial fleets. B2B buyers should consider the availability of parts and support, as well as the specific electrical requirements of the vehicles in their fleet.

How Do High-Performance Starters Differ and What Are Their Key Applications?

High-performance starters are engineered for applications requiring more torque, such as racing vehicles and heavy-duty trucks. They often use advanced materials and construction techniques to withstand the rigorous demands of high-performance engines. B2B buyers in the automotive racing or heavy machinery sectors should evaluate the torque specifications and durability to ensure these starters meet the operational demands of their vehicles.

What Are the Advantages of Gear Reduction Starters for Specialty Vehicles?

Gear reduction starters utilize a gear system to enhance the motor’s torque output, making them ideal for compact cars and specialty vehicles where space is at a premium. Their design allows for reduced strain on the battery, improving overall efficiency. B2B buyers should assess the compatibility of gear reduction starters with their vehicle types and consider potential maintenance complexities in their purchasing decisions.

Why Are Diesel Starters Essential for Heavy Machinery and Commercial Trucks?

Diesel starters are specifically designed for high-compression engines found in commercial trucks and heavy machinery. Their robust construction is tailored to withstand the increased demands of diesel engines, ensuring reliable performance. B2B buyers in the commercial sector should prioritize the starter’s weight and size, as well as its compatibility with various diesel engine models, to ensure optimal performance.

How Do Remote Start Systems Enhance Convenience for Fleet Management?

Remote start systems enable users to start their vehicles from a distance, often integrating security features to enhance vehicle safety. These systems are particularly beneficial for fleet management, allowing companies to pre-warm or cool vehicles before use. B2B buyers should consider the complexity of installation and potential electronic issues when selecting remote start systems for their fleets, balancing convenience with reliability.

Key Industrial Applications of starting system in automobile

| Отрасль/сектор | Specific Application of starting system in automobile | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Integration of starting systems in production vehicles | Enhances vehicle reliability and customer satisfaction | Сертификаты качества, совместимость с моделями автомобилей |

| Управление автопарком | Maintenance of starting systems in commercial vehicles | Reduces downtime and improves operational efficiency | Availability of parts, service support, and bulk pricing |

| Услуги по ремонту автомобилей | Replacement and repair of starting systems | Increases service offerings and customer retention | Access to diverse inventory, warranty terms, and pricing |

| Тяжелое оборудование | Starting systems for construction and agricultural machinery | Ensures equipment readiness and productivity | Durability under extreme conditions, sourcing from trusted brands |

| Electric Vehicles (EV) | Development of advanced starting systems for EVs | Supports innovation and market competitiveness | Technology integration, compatibility with battery systems |

How is the Starting System Used in Automotive Manufacturing?

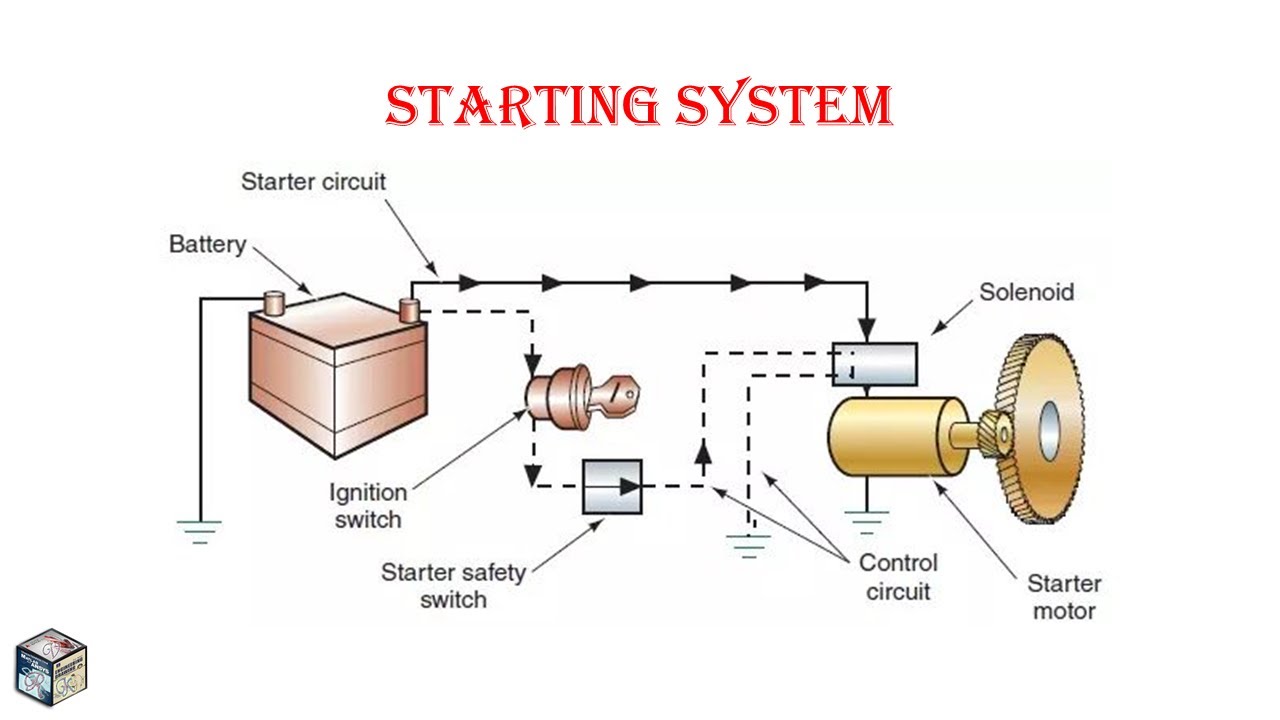

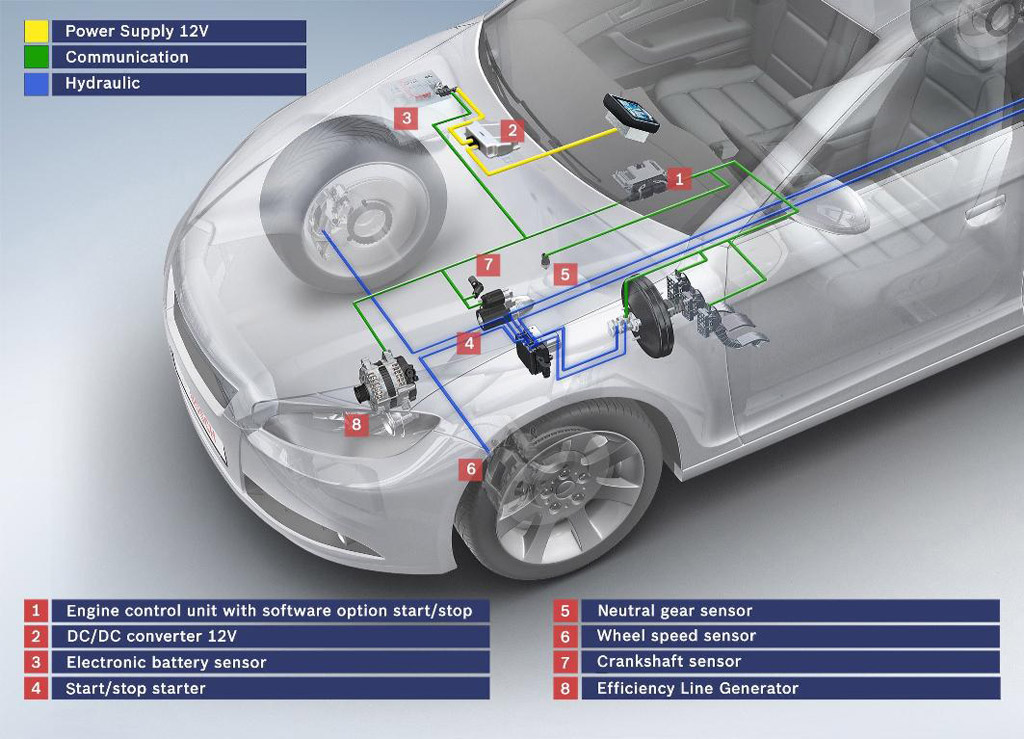

In automotive manufacturing, starting systems are integrated into production vehicles to ensure reliability from the outset. These systems, comprising components like batteries, ignition switches, and starter motors, are essential for vehicle functionality. A robust starting system enhances customer satisfaction by minimizing the risk of vehicle failure. Buyers in this sector should prioritize suppliers that offer quality certifications and ensure compatibility with various vehicle models to maintain production efficiency.

What Role Does the Starting System Play in Fleet Management?

Fleet management relies heavily on the maintenance of starting systems in commercial vehicles, as these systems are critical for operational efficiency. A well-functioning starting system reduces vehicle downtime, allowing fleets to operate smoothly and meet delivery schedules. Fleet managers should consider sourcing parts that are readily available and ensure strong service support for repairs. Bulk pricing can also provide significant savings for large fleets, making it a vital consideration for procurement.

How Can Automotive Repair Services Benefit from Starting System Replacement?

Automotive repair services often deal with the replacement and repair of starting systems, which can significantly expand their service offerings. By providing reliable starting system solutions, these businesses can increase customer retention and build a loyal client base. It is essential for repair shops to have access to a diverse inventory of starting system components, favorable warranty terms, and competitive pricing to effectively meet customer demands and enhance service quality.

In What Ways Do Heavy Equipment Applications Utilize Starting Systems?

Heavy equipment, such as construction and agricultural machinery, utilizes starting systems to ensure equipment readiness and productivity. These systems must be durable and capable of operating under extreme conditions, making reliability a key factor for businesses in this sector. Buyers should focus on sourcing starting systems from trusted brands that can guarantee performance in rugged environments, as this will directly impact operational efficiency and equipment lifespan.

What Innovations Are Emerging in Starting Systems for Electric Vehicles?

The development of advanced starting systems for electric vehicles (EVs) is becoming increasingly important as the automotive industry shifts towards electrification. These systems must integrate seamlessly with battery technology to ensure efficient operation. Businesses involved in EV production should prioritize suppliers that offer cutting-edge technology and compatibility with existing battery systems, as this will support innovation and enhance market competitiveness.

Illustrative image related to starting system in automobile

3 Common User Pain Points for ‘starting system in automobile’ & Their Solutions

Scenario 1: Insufficient Cold Cranking Amps (CCA) Leading to Starting Failures

Проблема: In regions with extreme temperatures, such as northern Europe during winter or higher altitudes in South America, many vehicles experience starting issues due to inadequate battery performance. B2B buyers, particularly those in automotive fleet management or vehicle distribution, often face the challenge of ensuring that the batteries used in their vehicles can deliver sufficient cold cranking amps (CCA) to start engines reliably in these conditions. When a vehicle fails to start, it can lead to costly downtime, unsatisfied customers, and a tarnished reputation.

Решение: To overcome this issue, B2B buyers should prioritize sourcing batteries with a CCA rating that exceeds the minimum requirements for their specific vehicle models, particularly for those operating in colder climates. When selecting batteries, consider factors such as the vehicle’s engine size, the local climate, and the average temperatures during winter months. Conduct thorough research on battery suppliers and ensure that they provide comprehensive specifications, including the CCA rating. It may also be beneficial to invest in maintenance-free batteries that are designed to handle extreme conditions, thus reducing the need for frequent replacements and ensuring reliability. Regular inspections and cleaning of battery terminals should also be part of the maintenance protocol to maximize performance.

Scenario 2: Ignition Switch Failures Causing Starting Delays

Проблема: Ignition switch failures are a common pain point for fleet operators and vehicle service centers. These components can wear out over time, leading to intermittent starting issues that frustrate drivers and can halt operations. Buyers often find themselves in a situation where multiple vehicles are affected, leading to logistical challenges and increased maintenance costs as they seek to replace faulty parts.

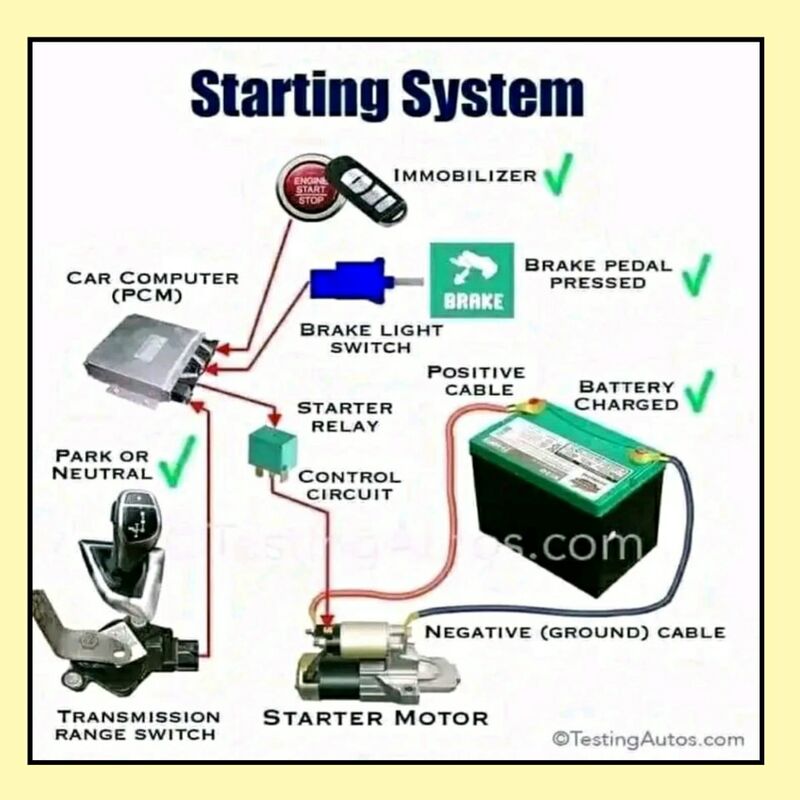

Решение: To mitigate ignition switch failures, B2B buyers should engage with reputable manufacturers who offer high-quality, durable ignition switches designed for their vehicle models. Investing in OEM (original equipment manufacturer) parts can ensure compatibility and reliability. Additionally, it’s crucial to implement a regular inspection schedule for ignition systems, especially in high-use vehicles. Training technicians to recognize early signs of ignition switch problems, such as difficulty in turning the key or dashboard warning lights, can lead to timely replacements and reduced downtime. Keeping an inventory of critical replacement parts on hand can also expedite the repair process.

Scenario 3: Starter Motor Overheating Leading to Performance Issues

Проблема: In hot climates, or during prolonged vehicle operation, starter motors can overheat, leading to performance degradation or complete failure. This scenario is particularly concerning for businesses that rely on vehicles for daily operations, as it can lead to unexpected breakdowns and costly repairs. B2B buyers may struggle to understand the root causes of starter motor overheating and may lack effective solutions to prevent it.

Решение: To address starter motor overheating, buyers should ensure that they are sourcing high-quality starter motors with appropriate thermal protection features. Regular maintenance checks should be performed to monitor the starter motor’s condition, including inspection of wiring and connections for signs of wear or corrosion. Buyers should also educate their drivers on proper starting techniques, such as avoiding excessive cranking and allowing the starter to cool down between attempts. Investing in thermal management solutions, such as heat shields or insulating materials, can also protect the starter motor from excessive heat, thereby extending its lifespan and maintaining reliable performance. By addressing these factors, B2B buyers can minimize the risk of starter motor failures and enhance the overall reliability of their vehicle fleets.

Strategic Material Selection Guide for starting system in automobile

What Are the Key Materials Used in Starting Systems for Automobiles?

In the automotive industry, the starting system is crucial for engine ignition and overall vehicle functionality. The materials selected for components within this system significantly impact performance, durability, and compliance with international standards. Here, we will analyze four common materials: lead-acid, copper, aluminum, and plastic composites, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Lead-Acid Battery Material Affect Starting System Performance?

Lead-acid batteries are the most widely used type of battery in automotive starting systems. They are known for their high energy density and ability to deliver high current, making them ideal for cranking engines.

- Ключевые свойства: Lead-acid batteries can operate effectively in a wide temperature range, typically from -20°C to 50°C. They are also capable of providing high cranking amps (CCA), essential for starting engines in various conditions.

- Плюсы и минусы: The durability of lead-acid batteries is moderate; they can last several years with proper maintenance. However, they are heavy and have a limited cycle life compared to newer technologies like lithium-ion. The manufacturing process is well-established, but the environmental impact of lead disposal is a concern.

- Влияние на применение: Lead-acid batteries are compatible with most automotive starting systems but require regular maintenance to ensure longevity.

- Соображения для международных покупателей: Compliance with environmental regulations regarding lead disposal is critical, particularly in regions like Europe where stringent regulations exist. Buyers should also consider the availability of recycling facilities in their region.

Why is Copper a Preferred Choice for Battery Cables in Starting Systems?

Copper is widely used for battery cables due to its excellent electrical conductivity and flexibility.

Illustrative image related to starting system in automobile

- Ключевые свойства: Copper has a high electrical conductivity rating, which minimizes energy loss. It can withstand high temperatures and has good corrosion resistance when properly coated.

- Плюсы и минусы: The main advantage of copper is its superior conductivity, which allows for efficient power transfer. However, it is more expensive than alternatives like aluminum, and its weight can be a disadvantage in weight-sensitive applications.

- Влияние на применение: Copper cables are essential for ensuring that the starter motor receives sufficient current, especially in cold climates where higher amperage is required.

- Соображения для международных покупателей: Buyers should be aware of copper pricing fluctuations and potential tariffs, particularly in regions like Africa and South America. Compliance with international standards such as ASTM for electrical components is also essential.

What Role Does Aluminum Play in Starting System Components?

Aluminum is increasingly used in various automotive components, including starter motors and housings, due to its lightweight properties.

- Ключевые свойства: Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio, making it suitable for automotive applications.

- Плюсы и минусы: The primary advantage of aluminum is its weight reduction, which can improve overall vehicle efficiency. However, it has lower electrical conductivity than copper, which may necessitate larger cable sizes to achieve the same performance.

- Влияние на применение: Aluminum components can help reduce the overall weight of the starting system, contributing to better fuel efficiency and performance.

- Соображения для международных покупателей: Buyers should ensure that aluminum components meet relevant standards (e.g., DIN) for strength and durability. Additionally, they should consider the availability of aluminum alloys that are suitable for automotive applications.

How Do Plastic Composites Enhance Starting System Durability?

Plastic composites are often used in non-structural components of the starting system, such as housings and insulation.

- Ключевые свойства: These materials are lightweight, resistant to corrosion, and can be molded into complex shapes.

- Плюсы и минусы: The advantage of plastic composites is their versatility and low manufacturing costs. However, they may not withstand high temperatures as effectively as metals, which can limit their use in certain high-heat areas.

- Влияние на применение: Plastic composites can help reduce weight and provide insulation, but their thermal limitations must be considered in high-performance applications.

- Соображения для международных покупателей: Compliance with safety and environmental standards (e.g., REACH in Europe) is essential. Buyers should also evaluate the long-term durability of plastic components in their specific climates.

Summary Table of Material Selection for Starting Systems

| Материал | Typical Use Case for starting system in automobile | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Свинцово-кислотный | Primary battery for engine cranking | High energy density and CCA | Heavy and limited cycle life | Средний |

| Медь | Battery cables and connectors | Превосходная электропроводность | Более высокая стоимость и вес | Высокий |

| Алюминий | Starter motor housings and components | Легкий и коррозионно-стойкий | Более низкая проводимость, чем у меди | Средний |

| Пластиковые композиты | Неструктурные компоненты, такие как корпуса | Versatile and low manufacturing cost | Ограниченное термическое сопротивление | Низкий |

This strategic material selection guide provides valuable insights for international B2B buyers in the automotive industry, helping them make informed decisions regarding the materials used in starting systems.

In-depth Look: Manufacturing Processes and Quality Assurance for starting system in automobile

What Are the Key Stages in the Manufacturing Process of Automotive Starting Systems?

The manufacturing process for automotive starting systems involves several critical stages, each ensuring that the components meet the high standards required for performance and safety. The primary stages include material preparation, forming, assembly, and finishing.

Подготовка материалов: как выбираются и обрабатываются сырьевые материалы?

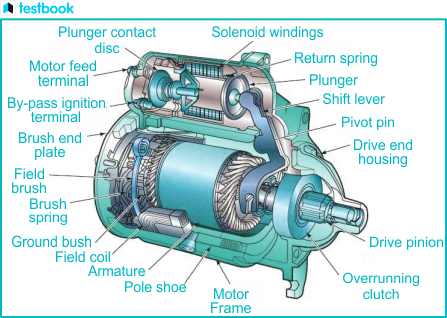

The initial stage involves selecting high-quality raw materials, such as metals, plastics, and electrical components, that meet specific automotive standards. For instance, copper is commonly used for battery cables due to its excellent conductivity, while durable alloys are often selected for starter motors to withstand high torque and thermal conditions.

Once materials are chosen, they undergo various processing techniques, including cutting, machining, and surface treatment. For example, battery terminals may be stamped from metal sheets, while starter motor housings often undergo casting or injection molding. This preparation phase is critical as it lays the foundation for the functionality and longevity of the starting system.

What Techniques Are Used in the Forming Stage of Starting Systems?

The forming stage employs techniques like stamping, forging, and machining to create the necessary components. Each component, from the ignition switch to the starter motor, is manufactured with precision to ensure proper fit and function.

-

Штамповка: This is commonly used for creating parts like battery terminals and starter motor end plates. High-speed presses shape metal sheets into precise forms.

-

Обработка: Components that require intricate details, such as gear teeth in starter motors, undergo CNC machining for accuracy. This process allows for tight tolerances, essential for the smooth operation of the starting system.

-

Литье под давлением: For plastic parts like the ignition switch housing, injection molding is the preferred method. This technique not only allows for complex shapes but also ensures consistency across production runs.

How Are Components Assembled in the Starting System?

The assembly stage is where individual components come together to form the complete starting system. This process usually involves multiple assembly lines, where skilled workers or automated systems fit parts together.

Quality control is integral during assembly, with checkpoints to ensure that each component meets specifications before proceeding. For instance, the assembly of the starter motor involves attaching the pinion gear to the motor shaft, ensuring that it engages correctly with the flywheel.

Automated testing systems may also be employed at this stage to check electrical connections and functionality, ensuring that the assembled parts work as intended before moving on to the finishing stage.

What Finishing Techniques Are Employed to Ensure Durability?

Finishing processes enhance the performance and aesthetic appeal of starting systems. Common techniques include surface treatment, painting, and quality assurance inspections.

-

Обработка поверхности: Components often undergo processes like anodizing or galvanizing to improve corrosion resistance, especially for parts exposed to harsh environments.

-

Painting: Aesthetic finishes may be applied to visible components, while functional coatings may be used to reduce friction in moving parts.

-

Заключительная проверка: Before packaging, each starting system undergoes a final quality check, where tests for electrical performance and mechanical integrity are conducted. This is crucial to ensure that the product meets international standards and customer expectations.

What Quality Assurance Practices Are Essential for Automotive Starting Systems?

Quality assurance is paramount in the manufacturing of automotive starting systems, given the critical role these components play in vehicle operation. Key quality assurance practices include adherence to international standards, systematic inspections, and testing methods.

Which International Standards Apply to Automotive Starting Systems?

Manufacturers must comply with various international standards to ensure product quality and safety. ISO 9001 is a widely recognized standard that outlines requirements for quality management systems. Compliance demonstrates a commitment to consistent quality, which is crucial for B2B buyers looking for reliable suppliers.

In addition to ISO standards, automotive-specific certifications, such as IATF 16949, focus on continuous improvement and defect prevention in the automotive supply chain. This certification is particularly relevant for manufacturers targeting international markets, ensuring that their products meet global automotive quality benchmarks.

Каковы ключевые точки контроля качества в производственном процессе?

Quality control checkpoints are essential throughout the manufacturing process, typically categorized as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Входящий контроль качества (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter production. Any substandard materials are rejected to prevent issues downstream.

-

Контроль качества в процессе производства (IPQC): As components are manufactured, ongoing inspections are conducted to ensure that each part meets quality standards. This includes monitoring dimensions, weight, and electrical characteristics.

-

Окончательный контроль качества (FQC): The final inspection ensures that the complete starting system functions correctly and meets all regulatory requirements. Testing may include simulations of real-world conditions, such as temperature extremes and electrical load tests.

Как покупатели B2B могут проверить процессы контроля качества поставщиков?

B2B buyers can take several steps to verify the quality control processes of potential suppliers.

-

Аудит поставщиков: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This helps ensure that suppliers adhere to international standards and best practices.

-

Отчеты о качестве: Requesting detailed quality reports can provide insights into the supplier’s quality management system, including defect rates, testing results, and compliance with certifications.

-

Проверки третьей стороной: Engaging third-party inspection agencies can offer an unbiased evaluation of a supplier’s quality control processes. These organizations can conduct audits, perform testing, and verify compliance with international standards.

Каковы нюансы контроля качества для международных B2B-покупателей?

For international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital.

-

Соблюдение нормативных требований: Buyers must be aware of specific regulations in their regions, such as CE marking in Europe or local automotive standards in Africa and South America. Ensuring that suppliers comply with these regulations can prevent legal issues and facilitate smoother import processes.

-

Культурные аспекты: Different regions may have varying expectations regarding quality and service. B2B buyers should be prepared to communicate their quality expectations clearly and may need to adapt their approaches to align with local practices.

-

Building Relationships: Establishing strong relationships with suppliers can enhance quality assurance. Ongoing communication and collaboration can lead to improved processes and product quality over time.

By understanding the manufacturing processes and quality assurance practices involved in automotive starting systems, B2B buyers can make informed decisions, ensuring they source reliable and high-quality products for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starting system in automobile’

Введение

This guide serves as a practical checklist for B2B buyers looking to procure starting systems for automobiles. The starting system is a critical component in vehicle operation, comprising several key parts that must work seamlessly together. Ensuring that you source high-quality components from reliable suppliers is essential for maintaining vehicle performance and reliability.

Шаг 1: Определите свои технические характеристики

Before initiating any procurement process, clearly outline your technical requirements. This includes the specifications for the battery, ignition switch, starter relay, and other components of the starting system. Understanding these specifications will help you narrow down your options and communicate effectively with suppliers.

- Consider compatibility with various vehicle models and types.

- Identify specific performance metrics, such as cold cranking amps (CCA) for batteries.

Шаг 2: Исследование потенциальных поставщиков

Conduct thorough research to identify potential suppliers that specialize in automotive starting systems. Look for companies with a solid reputation in the industry, especially those that cater to your target markets in Africa, South America, the Middle East, and Europe.

- Check online reviews and testimonials from other B2B buyers.

- Investigate their market presence and experience in your specific region.

Шаг 3: Оценить сертификаты поставщиков

Before committing to any supplier, verify their certifications and compliance with industry standards. This step is crucial as it ensures that the components meet safety and quality requirements.

- Look for ISO certifications or other relevant quality assurance certifications.

- Запросить документацию that demonstrates compliance with international automotive standards.

Шаг 4: Запросить образцы для тестирования

Once you’ve shortlisted potential suppliers, request samples of the starting system components for testing. This allows you to evaluate the quality and performance of the products firsthand.

- Conduct thorough testing to ensure that all components function as intended under real-world conditions.

- Assess the durability and reliability of the samples, especially in extreme weather conditions typical of your target markets.

Шаг 5: Переговоры об условиях и ценах

After evaluating the samples, it’s time to negotiate terms and pricing. Ensure that you discuss not only the price but also payment terms, delivery timelines, and warranty conditions.

- Compare pricing across multiple suppliers to ensure competitiveness.

- Clarify any additional costs, such as shipping fees or import duties.

Шаг 6: Establish a Supply Chain Plan

Once you’ve selected a supplier, establish a clear supply chain plan. This should outline delivery schedules, inventory management practices, and communication protocols.

- Develop contingency plans for potential supply disruptions.

- Set up regular communication to monitor the status of orders and address any issues promptly.

Шаг 7: Monitor and Evaluate Performance

After procurement, continuously monitor the performance of the starting system components. Regular evaluation helps identify any issues early and maintains the quality of your supply chain.

- Collect feedback from end-users regarding the performance of the starting systems.

- Implement performance metrics to assess reliability and efficiency regularly.

By following this checklist, B2B buyers can ensure that they procure high-quality starting systems that meet their technical requirements and support their operational needs effectively.

Comprehensive Cost and Pricing Analysis for starting system in automobile Sourcing

Understanding the cost structure and pricing analysis for starting systems in automobiles is crucial for international B2B buyers. This analysis will help buyers make informed decisions, ensuring they obtain quality products at competitive prices.

What are the Key Cost Components for Starting Systems in Automobiles?

-

Материалы: The primary materials involved in the production of starting systems include batteries, wiring, motors, and switches. High-quality materials are essential for durability and performance, particularly in varying climates. For instance, batteries with higher Cold Cranking Amps (CCA) tend to cost more but offer better performance in colder regions.

-

Трудовые ресурсы: Labor costs can vary significantly based on geographical location. In regions such as Africa and South America, labor may be less expensive, but it’s important to consider the skill level and training of workers. Skilled labor often translates to higher initial costs but can yield better quality and efficiency in production.

-

Производственные накладные расходы: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. These costs are often distributed across the total units produced, impacting the per-unit cost.

-

Инструменты: The initial investment in tooling for production can be substantial, especially for custom components. Tooling costs can be amortized over large production runs, making it essential to consider minimum order quantities (MOQs) when negotiating pricing.

-

Контроль качества (КК): Implementing stringent QC measures is vital in ensuring the reliability and safety of starting systems. The costs associated with QC can vary depending on the complexity of the system and the certifications required for different markets.

-

Логистика: Shipping and handling costs are significant, especially when sourcing internationally. Factors such as distance, shipping method, and local tariffs can all influence the final price. Understanding Incoterms is crucial for buyers to manage these costs effectively.

-

Маржа: Suppliers will typically include a profit margin in their pricing structure. This margin can vary based on market competition, perceived value, and the supplier’s positioning in the market.

How Do Price Influencers Affect the Cost of Starting Systems?

-

Объем/минимальный объем заказа: Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while considering potential overstock.

-

Технические характеристики и индивидуальная настройка: Custom features or specifications can significantly increase costs. Buyers should be clear about their requirements to avoid unnecessary expenses.

-

Сертификаты качества материалов: The choice of materials and required certifications can drive costs up. For example, sourcing components that meet international safety standards may come with a premium.

-

Факторы, связанные с поставщиками: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but can offer better warranties and support, which can be valuable in the long run.

-

Инкотермс: Understanding Incoterms is essential for managing logistics costs. Different terms can affect who bears the shipping costs and risks, impacting the overall cost structure.

What Are the Best Negotiation Strategies for B2B Buyers?

-

Рычаг Объем: When placing larger orders, use the volume as leverage to negotiate better pricing or additional services.

-

Сосредоточьтесь на общей стоимости владения (TCO): Consider the long-term costs associated with the starting systems, such as maintenance and replacement, rather than just the initial purchase price.

-

Запросить несколько предложений: Obtaining quotes from various suppliers can provide a clearer picture of market rates and help in negotiating better deals.

-

Стройте отношения: Establishing strong relationships with suppliers can lead to better pricing, priority service, and insights into market trends.

-

Будьте внимательны к нюансам ценообразования: International buyers should be cautious of currency fluctuations, local taxes, and tariffs that may affect pricing. Understanding these nuances can lead to more informed purchasing decisions.

Заключение

The comprehensive cost and pricing analysis of starting systems in automobiles reveals a multifaceted structure influenced by various factors. By understanding these components and negotiation strategies, international B2B buyers from regions like Africa, South America, the Middle East, and Europe can enhance their sourcing efficiency and ensure they make cost-effective decisions. It is advisable to approach this market with a clear understanding of both the direct and indirect costs involved, keeping in mind that pricing can vary significantly based on supplier relationships and market dynamics.

Alternatives Analysis: Comparing starting system in automobile With Other Solutions

In today’s automotive industry, the starting system in automobiles plays a crucial role in engine ignition and overall vehicle functionality. However, as technology evolves, alternative solutions are emerging that can enhance or replace traditional starting systems. Evaluating these alternatives allows B2B buyers to make informed decisions based on performance, cost, and maintenance needs.

| Аспект сравнения | Starting System In Automobile | Alternative 1: Keyless Ignition System | Alternative 2: Push-to-Start System |

|---|---|---|---|

| Производительность | Reliable, well-established | High reliability, improved convenience | Quick start, enhanced user experience |

| Стоимость | Умеренная первоначальная стоимость | Higher due to advanced technology | Higher than traditional systems |

| Простота внедрения | Стандартная установка | More complex, requires integration | Requires modifications to existing systems |

| Техническое обслуживание | Необходимы регулярные проверки | Minimal, but electronic components may fail | Low maintenance but may require battery replacements |

| Лучший вариант использования | Обычные транспортные средства | Luxury and modern vehicles | Newer models and tech-savvy consumers |

What Are the Pros and Cons of Keyless Ignition Systems?

Keyless ignition systems have gained popularity due to their convenience and enhanced security features. These systems allow drivers to start their vehicles without inserting a key, using a fob or smartphone instead. Pros include increased ease of use and the elimination of traditional keys, which can be lost. However, they come with higher initial costs and potential security vulnerabilities, as electronic systems can be hacked.

How Do Push-to-Start Systems Compare?

Push-to-start systems offer a modern approach to vehicle ignition by enabling drivers to start their cars with the push of a button. This system is often integrated with keyless entry features, providing a seamless user experience. The advantages include quick engine start-ups and an upscale feel. However, these systems can also present higher costs and complexity during installation, especially in older vehicle models that weren’t designed for such technology.

Как покупателям B2B выбрать правильное решение, отвечающее их потребностям?

When selecting a starting system for automotive applications, B2B buyers should consider their specific needs, including vehicle type, target market, and customer preferences. Traditional starting systems are reliable for standard vehicles, while keyless and push-to-start systems may appeal to luxury or tech-oriented markets. Evaluating the total cost of ownership, including maintenance and potential upgrades, is essential for making a sound investment. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to choose the most suitable solution for their operational requirements.

Essential Technical Properties and Trade Terminology for starting system in automobile

What Are the Key Technical Properties of the Automotive Starting System?

In the automotive industry, understanding the technical specifications of starting systems is vital for ensuring performance, reliability, and safety. Here are some critical properties that B2B buyers should consider:

Illustrative image related to starting system in automobile

-

Амперы холодного пуска (CCA)

CCA measures the battery’s ability to start an engine in cold temperatures. A higher CCA rating indicates that the battery can deliver more power to the starter motor, which is crucial for reliable engine ignition, especially in colder climates. B2B buyers should prioritize batteries with suitable CCA ratings to meet the demands of their specific vehicle applications. -

Состав материала

The materials used in the starter motor, battery cables, and connectors significantly affect durability and performance. For example, copper is often used for battery cables due to its excellent conductivity. Buyers should ensure that components are made from high-quality materials to minimize resistance and heat generation, which can impact the overall efficiency of the starting system. -

Рабочее напряжение

The standard operating voltage for most automotive starting systems is 12 volts. Understanding the voltage requirements is essential when sourcing components, as mismatched voltages can lead to system failures or damage. It’s crucial for buyers to confirm that all parts of the starting system are compatible with the specified voltage. -

Номинальный крутящий момент

The torque rating of the starter motor indicates its ability to turn the engine over. A starter motor with a higher torque rating can initiate combustion more effectively, particularly in high-compression engines. Buyers should assess the torque ratings to ensure they select starters that can meet their engine specifications. -

Термостойкость

The components of the starting system must withstand various environmental conditions. Temperature tolerance indicates how well a part can function in extreme heat or cold. Buyers in regions with fluctuating climates should ensure that the starting system components can operate effectively under local environmental conditions. -

Battery Cycle Life

Cycle life refers to the number of charge and discharge cycles a battery can undergo before its performance deteriorates. Selecting batteries with a longer cycle life can lead to reduced replacement costs and increased reliability. B2B buyers should inquire about cycle life when sourcing batteries to ensure they are making a long-term investment.

Which Trade Terms Are Essential for Understanding Automotive Starting Systems?

Familiarity with industry jargon is crucial for effective communication and negotiation in the automotive sector. Here are some common trade terms that B2B buyers should know:

-

OEM (производитель оригинального оборудования)

OEM refers to parts or components made by the original manufacturer of the vehicle. These parts are generally considered higher quality and are designed to fit seamlessly. Buyers often prefer OEM parts to ensure compatibility and reliability in their starting systems. -

MOQ (минимальный объем заказа)

MOQ represents the smallest quantity a supplier is willing to sell. Understanding MOQ is important for buyers to manage inventory and costs effectively. Suppliers may offer better pricing for larger orders, so buyers should evaluate their needs against the MOQ for each component. -

RFQ (запрос предложения)

An RFQ is a document sent to suppliers to request pricing and terms for specific components. This process allows buyers to compare prices and options from multiple vendors. Utilizing RFQs helps ensure competitive pricing and can lead to better procurement decisions. -

Инкотермс (Международные торговые термины)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international shipping. Understanding these terms is essential for B2B transactions, as they determine who bears the risk and costs associated with shipping, including delivery and customs clearance. -

Запасные части

Aftermarket parts are components made by third-party manufacturers, not the original vehicle manufacturer. While they can often be less expensive, quality may vary. Buyers should conduct due diligence when considering aftermarket options for starting systems to ensure reliability and performance. -

Время выполнения заказа

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory management and ensuring that replacement parts are available when needed. Buyers should clarify lead times with suppliers to align with their operational schedules.

By understanding these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing components for automotive starting systems, ensuring quality, reliability, and compatibility with their specific requirements.

Navigating Market Dynamics and Sourcing Trends in the starting system in automobile Sector

What Are the Key Market Trends Affecting the Starting System in the Automobile Sector?

The global automotive industry is witnessing a transformative phase, driven by several key factors. The increasing demand for fuel-efficient and electric vehicles is reshaping the starting system landscape. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial for strategic sourcing decisions. The proliferation of advanced technologies, such as the integration of smart electronics and battery management systems, is enhancing the efficiency and reliability of starting systems.

Moreover, the push for localization in manufacturing is becoming more pronounced. Buyers are increasingly seeking suppliers that can offer shorter lead times and lower transportation costs, thus prompting suppliers to establish local partnerships or production facilities. Additionally, the rise of e-commerce platforms has enabled B2B buyers to access a broader range of suppliers and products, facilitating competitive pricing and improved supply chain transparency.

Emerging markets, particularly in Africa and South America, are also experiencing a surge in automotive growth, driven by urbanization and rising disposable incomes. This presents an opportunity for suppliers to cater to a growing customer base that seeks quality and reliable starting systems. Buyers in these regions should consider suppliers that not only provide high-quality components but also demonstrate an understanding of local market dynamics and regulatory requirements.

Illustrative image related to starting system in automobile

How Does Sustainability Impact Sourcing for Starting Systems in the Automobile Sector?

Sustainability is increasingly becoming a focal point in the sourcing of automotive components, including starting systems. The environmental impact of production processes and materials used in batteries and electrical systems has led to a demand for more sustainable practices. B2B buyers are now prioritizing suppliers who adhere to ethical sourcing standards and who can provide products that are not only efficient but also environmentally friendly.

The importance of establishing ethical supply chains cannot be overstated. Buyers should seek suppliers that have certifications such as ISO 14001, which denotes effective environmental management systems. Additionally, the use of ‘green’ materials, such as recyclable components and low-impact manufacturing processes, is gaining traction. This not only reduces the carbon footprint associated with automotive production but also aligns with the increasing consumer preference for environmentally responsible products.

In regions like Europe, where regulations around emissions and sustainability are stringent, sourcing from suppliers who demonstrate a commitment to sustainability can also enhance brand reputation. B2B buyers should engage with suppliers that provide transparency regarding their sourcing practices and that can offer innovative solutions for reducing environmental impact, such as battery recycling programs.

Illustrative image related to starting system in automobile

What Are the Historical Developments Shaping Today’s Starting Systems in the Automobile Sector?

The evolution of starting systems in the automobile sector has been marked by significant technological advancements. From the early mechanical cranks to today’s sophisticated electric starter motors, the journey reflects the industry’s drive towards efficiency and reliability. Initially, starting systems relied heavily on manual operation, which posed challenges in terms of user convenience and engine reliability.

With the advent of the electric starter in the 1910s, the industry saw a major shift. This innovation not only enhanced the ease of starting engines but also paved the way for the development of more complex systems, including battery management and ignition control systems. As automotive technology continues to advance, the integration of smart electronics and real-time diagnostics is becoming standard, allowing for greater efficiency and improved performance.

Understanding this historical context is essential for B2B buyers as it highlights the trajectory of innovation that continues to shape sourcing strategies today. By recognizing the foundational developments, buyers can better appreciate the technological advancements and trends that inform current purchasing decisions, ultimately leading to more informed and strategic sourcing practices.

Illustrative image related to starting system in automobile

Frequently Asked Questions (FAQs) for B2B Buyers of starting system in automobile

-

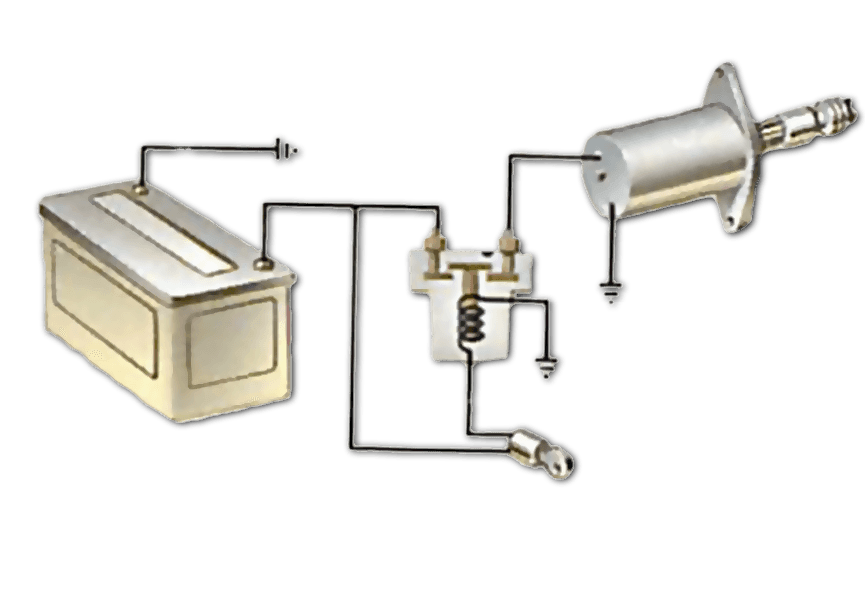

How do I solve starting system failures in vehicles?

Starting system failures can often be traced back to issues with the battery, ignition switch, or starter motor. Begin by testing the battery’s voltage and cold cranking amps (CCA) to ensure it meets specifications. Inspect the ignition switch and neutral safety switch for proper functionality. Check the starter relay and battery cables for corrosion or damage. If the system still fails, consider consulting a qualified technician for a detailed diagnosis. Regular maintenance can also preemptively address many common issues. -

What is the best starter motor for high-performance vehicles?

For high-performance vehicles, look for starter motors that offer high torque and durability, typically rated for higher amperage. Brands known for their performance products often provide lightweight options that can withstand extreme conditions. It’s essential to consider the specific vehicle requirements, including compatibility and installation specifications. Additionally, sourcing motors from reputable manufacturers ensures quality and reliability, which are critical for high-performance applications. -

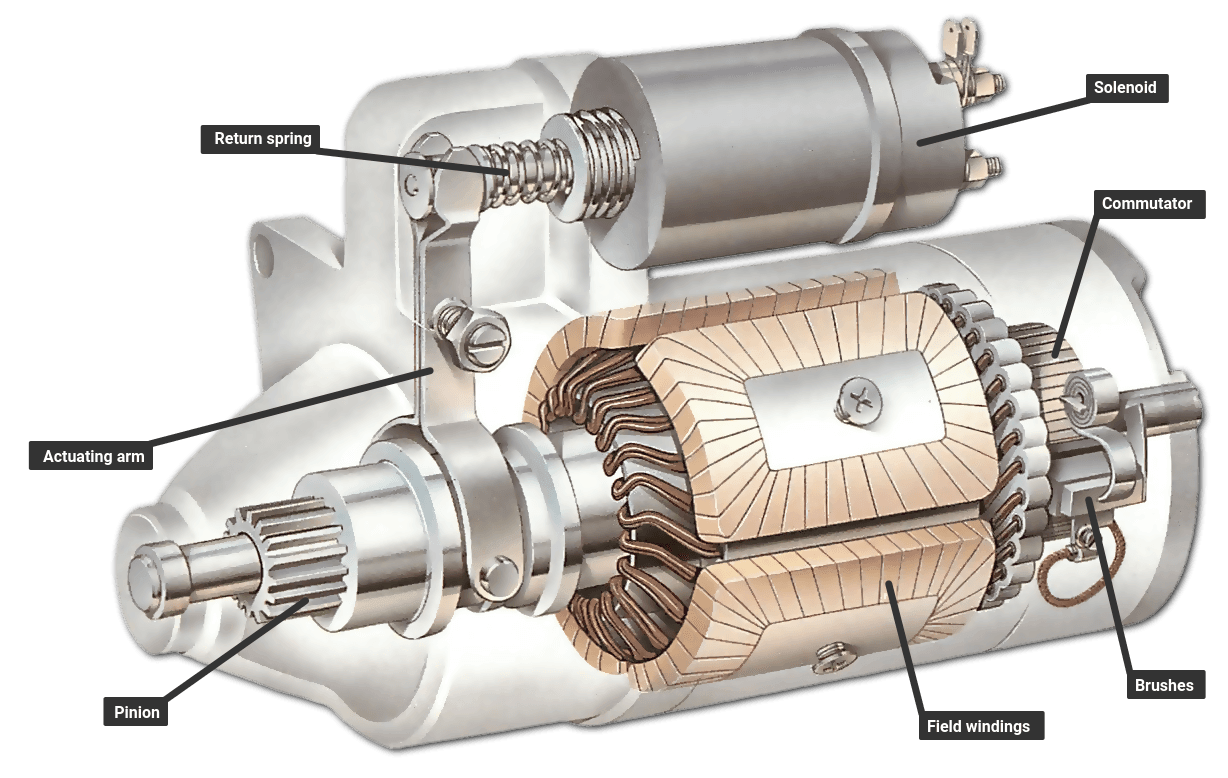

What are the key components of an automobile starting system?

The key components of an automobile starting system include the battery, ignition switch, neutral safety switch, starter relay, battery cables, and starter motor. Each component plays a crucial role in initiating engine operation. The battery provides the necessary power, while the ignition switch controls the electrical flow. The starter relay facilitates the high current needed to engage the starter motor, which cranks the engine for ignition. Understanding these components helps in effective troubleshooting and maintenance. -

How can I evaluate suppliers for starting system components?

When evaluating suppliers for starting system components, consider their reputation, quality certifications, and experience in the automotive industry. Request samples to assess product quality and compatibility with your vehicles. Check for customer reviews and references from other B2B buyers. Additionally, inquire about their production capacity, lead times, and adherence to international quality standards. Establishing clear communication regarding your requirements and expectations is also essential for a successful partnership. -

What are typical minimum order quantities (MOQ) for starting system parts?

Minimum order quantities (MOQ) for starting system parts vary widely depending on the supplier and the specific component. Generally, MOQs can range from 50 to 500 units. It’s advisable to discuss your needs directly with suppliers to negotiate favorable terms, especially if you are a smaller buyer or looking for customized solutions. Some suppliers may offer flexibility on MOQs for first-time orders or bulk purchases, so be sure to explore all options. -

What payment terms should I expect when sourcing starting systems internationally?

Payment terms for international sourcing of starting systems typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit (usually 30-50%) upfront, with the balance due before shipping or upon receipt. Always clarify payment methods accepted, including bank transfers and online payment platforms. Understanding the currency exchange rates and potential fees is also crucial for budgeting and financial planning. -

How can I ensure quality assurance (QA) for starting system components?

To ensure quality assurance for starting system components, request detailed product specifications and certifications from suppliers. Conduct regular audits of the manufacturing process and establish quality control measures, such as inspections at various production stages. Consider implementing a third-party quality inspection service before shipment. Additionally, maintain open communication with suppliers regarding any quality concerns, and establish a clear return policy for defective items. -

What logistics considerations should I keep in mind when importing starting systems?

When importing starting systems, consider logistics factors such as shipping methods, transit times, and customs regulations in your country. Work with a reliable freight forwarder familiar with automotive parts to navigate import duties and tariffs effectively. Ensure that all documentation, including invoices, packing lists, and certificates of origin, is accurate and complete to prevent delays. Plan for potential disruptions in supply chains and establish contingency plans to mitigate risks.

Top 1 Starting System In Automobile Manufacturers & Suppliers List

1. How a Car Works – Starter System Explained

Домен: howacarworks.com

Зарегистрирован: 2011 (14 лет)

Введение: The starting system of a car includes a pre-engaged starter motor that uses a solenoid to engage a small pinion gear with a large gear ring on the engine flywheel. The starter motor requires a heavy electric current from the battery, activated by a large switch controlled by the ignition key. The solenoid operates an electromagnet that closes contacts to complete the circuit. The starter motor fea…

Strategic Sourcing Conclusion and Outlook for starting system in automobile

The strategic sourcing of starting systems in the automotive sector is pivotal for enhancing operational efficiency and ensuring product reliability. By understanding the essential components—such as batteries, ignition switches, and starter motors—international buyers can make informed decisions that align with their specific market needs. Leveraging advanced sourcing strategies can help mitigate risks associated with supply chain disruptions, ensuring that businesses remain competitive and responsive in dynamic environments.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, investing in high-quality starting systems will be crucial. Buyers should prioritize partnerships with reputable suppliers that offer not only superior products but also insights into technological advancements and maintenance best practices. This proactive approach will empower companies to maintain their fleets effectively, reduce downtime, and enhance customer satisfaction.

Looking ahead, the demand for innovative starting systems will likely grow, driven by advancements in automotive technology and increasing consumer expectations. Now is the time for international B2B buyers to engage with leading manufacturers and distributors to secure sustainable sourcing solutions that will drive their business success in the future.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.