Introduction: Navigating the Global Market for starter components

In the ever-evolving landscape of global commerce, sourcing high-quality starter components poses a significant challenge for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The complexities involved in identifying reliable suppliers, ensuring compliance with international standards, and managing costs can overwhelm even the most seasoned procurement professionals. This comprehensive guide serves as an essential resource, meticulously outlining the various types of starter components, their applications across multiple industries, and effective strategies for vetting suppliers.

By delving into the intricacies of starter motors, solenoids, and associated components, this guide empowers international B2B buyers to make informed purchasing decisions. It provides a detailed exploration of critical factors such as cost analysis, performance benchmarks, and supply chain considerations. Additionally, the guide highlights best practices for establishing robust relationships with manufacturers and distributors, ensuring that buyers can confidently navigate the complexities of the global market.

Whether you are a procurement specialist in Germany seeking advanced automotive solutions or a business leader in Brazil looking for reliable industrial starters, this guide equips you with the insights needed to optimize your sourcing strategy, enhance operational efficiency, and ultimately drive business success.

Содержание

- Top 5 Starter Components Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter components

- Understanding starter components Types and Variations

- Key Industrial Applications of starter components

- 3 Common User Pain Points for ‘starter components’ & Their Solutions

- Strategic Material Selection Guide for starter components

- In-depth Look: Manufacturing Processes and Quality Assurance for starter components

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter components’

- Comprehensive Cost and Pricing Analysis for starter components Sourcing

- Alternatives Analysis: Comparing starter components With Other Solutions

- Essential Technical Properties and Trade Terminology for starter components

- Navigating Market Dynamics and Sourcing Trends in the starter components Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter components

- Strategic Sourcing Conclusion and Outlook for starter components

- Важное предупреждение и условия использования

Understanding starter components Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Электромагнитный стартер | Uses an electromagnet to engage the pinion | Автомобилестроение, тяжелое машиностроение | Pros: Reliable, compact. Cons: Can be susceptible to heat. |

| Редукторный стартер | Features a gear system for increased torque | Construction Equipment, Marine Applications | Pros: High torque output, efficient. Cons: More complex, larger size. |

| Стартовое устройство с постоянным магнитом | Utilizes permanent magnets for operation | Small Engine Applications, Motorcycles | Pros: Lightweight, energy-efficient. Cons: Limited torque in larger applications. |

| Высокопроизводительный стартер | Designed for extreme conditions and high demands | Racing, Performance Vehicles | Pros: Enhanced durability, faster engagement. Cons: Higher cost, may require specific installation. |

| Remote Starter | Allows for ignition from a distance | Fleet Management, Security Systems | Pros: Convenience, enhanced security. Cons: Installation complexity, potential interference issues. |

What Are Solenoid Starters and Their Applications?

Solenoid starters are widely recognized for their reliability and compact design. They function by utilizing an electromagnet to engage the pinion, which then turns the engine over. These starters are commonly used in automotive applications and heavy machinery where space is limited. When considering a solenoid starter, B2B buyers should evaluate the operating temperature range and potential heat-related vulnerabilities that could affect performance.

How Do Gear Reduction Starters Benefit Heavy Equipment?

Gear reduction starters incorporate a gear system to enhance torque output, making them ideal for construction equipment and marine applications. Their ability to deliver high torque even in challenging conditions is a significant advantage. However, buyers should be aware of the increased complexity and size, which may require specific installation considerations. Evaluating the torque requirements of the application is essential when choosing this type of starter.

What Makes Permanent Magnet Starters Suitable for Small Engines?

Permanent magnet starters are characterized by their lightweight and energy-efficient design, making them suitable for small engine applications, such as motorcycles and lawn equipment. They operate using permanent magnets instead of electromagnets, which reduces energy consumption. Buyers should consider the torque limitations of permanent magnet starters, as they may not be effective for larger or more demanding applications.

Why Choose High-Performance Starters for Racing?

High-performance starters are engineered for extreme conditions and high-demand applications, such as racing and performance vehicles. Their enhanced durability and faster engagement capabilities make them a preferred choice for professionals seeking reliability under pressure. However, buyers should be prepared for a higher cost and ensure compatibility with their specific vehicle requirements, as installation may vary.

What Are the Advantages of Remote Starters in Fleet Management?

Remote starters provide the convenience of igniting engines from a distance, making them particularly useful in fleet management and security systems. This feature enhances operational efficiency and adds a layer of security by allowing users to start vehicles without being physically present. However, potential buyers must consider the complexity of installation and the possibility of interference issues, ensuring that the chosen system meets their operational needs.

Key Industrial Applications of starter components

| Отрасль/сектор | Specific Application of Starter Components | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Engine Start-Up Systems | Ensures reliable engine ignition, reducing downtime and maintenance costs. | Quality certifications, compatibility with various engine types, and reliability in harsh conditions. |

| Горнодобывающая промышленность и тяжелое оборудование | Diesel Engine Start-Up for Machinery | Enhances operational efficiency by ensuring quick machinery start-up, vital in remote locations. | Durability against environmental factors, power requirements, and ease of installation. |

| Agriculture and Farming | Starter Motors for Tractors and Harvesters | Improves productivity and reduces the risk of crop loss due to equipment failure. | Adaptability to different agricultural machinery and availability of spare parts. |

| Возобновляемые источники энергии | Wind Turbine Starter Systems | Facilitates turbine activation, essential for energy generation in off-grid areas. | Compliance with energy standards, efficiency in cold weather, and sourcing from sustainable manufacturers. |

| Морской транспорт и судоходство | Starter Components for Vessel Engines | Ensures reliable ignition systems, crucial for safety and operational efficiency at sea. | Resistance to corrosion, compatibility with marine engines, and availability of global support services. |

How Are Starter Components Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, starter components play a critical role in engine start-up systems. These components ensure reliable ignition, which is essential for minimizing downtime and maintenance costs. For B2B buyers, sourcing starter components requires attention to quality certifications and compatibility with various engine types. Additionally, reliability in harsh operating conditions is a must, especially in regions with extreme climates, such as Africa and South America.

What Is the Role of Starter Components in Mining and Heavy Equipment?

Starter components are vital for diesel engine start-up in mining and heavy equipment. The ability to quickly ignite machinery is crucial for enhancing operational efficiency, particularly in remote locations where time is of the essence. B2B buyers in this sector should consider the durability of these components against environmental factors, power requirements, and ease of installation. This ensures that machinery remains operational under challenging conditions.

How Do Starter Motors Benefit Agriculture and Farming?

In the agriculture sector, starter motors are essential for tractors and harvesters, improving productivity and reducing the risk of crop loss due to equipment failure. Farmers depend on these components for reliable operation during critical planting and harvesting seasons. Buyers should focus on the adaptability of starter components to different agricultural machinery and the availability of spare parts, ensuring minimal disruption to their operations.

Why Are Starter Systems Important in Renewable Energy?

In the renewable energy sector, particularly in wind energy, starter systems are necessary for the activation of turbines. This functionality is crucial for energy generation, especially in off-grid areas where reliable power is needed. B2B buyers should prioritize compliance with energy standards, efficiency in cold weather, and sourcing from manufacturers committed to sustainability, which can enhance their corporate social responsibility (CSR) profile.

How Do Starter Components Support Marine and Shipping Operations?

In the marine and shipping industry, starter components are essential for the reliable ignition of vessel engines. This reliability is crucial for safety and operational efficiency at sea. Buyers must consider resistance to corrosion, compatibility with marine engines, and the availability of global support services when sourcing these components. Such considerations ensure that vessels remain operational and safe across diverse maritime environments.

3 Common User Pain Points for ‘starter components’ & Their Solutions

Scenario 1: Difficulty in Identifying Compatible Starter Components

Проблема: B2B buyers often face the challenge of sourcing starter components that are compatible with their existing machinery or vehicles. With the vast array of models and specifications available, it can be overwhelming to ensure that the selected starter motor or related components will fit seamlessly into their systems. Misidentification can lead to costly delays, operational downtime, and increased repair costs, negatively impacting overall productivity. Buyers may also struggle with the lack of clear specifications and compatibility information from suppliers, leading to further confusion.

Решение: To address this issue, buyers should prioritize working with reputable suppliers who offer comprehensive product catalogs with detailed specifications. Utilize online tools or databases that allow you to input your vehicle or machinery model to generate a list of compatible starter components. Additionally, establish a close relationship with your suppliers for expert advice on compatibility. When placing orders, always verify part numbers and specifications, and consider investing in a product lifecycle management (PLM) system that helps maintain accurate records of your machinery and its components. This proactive approach not only ensures compatibility but also mitigates the risk of errors during procurement.

Scenario 2: Performance Issues Due to Poor Quality Starter Components

Проблема: A common concern for B2B buyers is the subpar performance of starter components, which can lead to engine starting problems, increased wear on other engine parts, and ultimately, higher maintenance costs. Many buyers may opt for cheaper alternatives to save costs upfront, but these products often lead to reliability issues and frequent replacements, eroding any initial savings. This scenario is particularly detrimental for businesses that rely on their machinery for daily operations, as unexpected failures can disrupt workflows and diminish customer satisfaction.

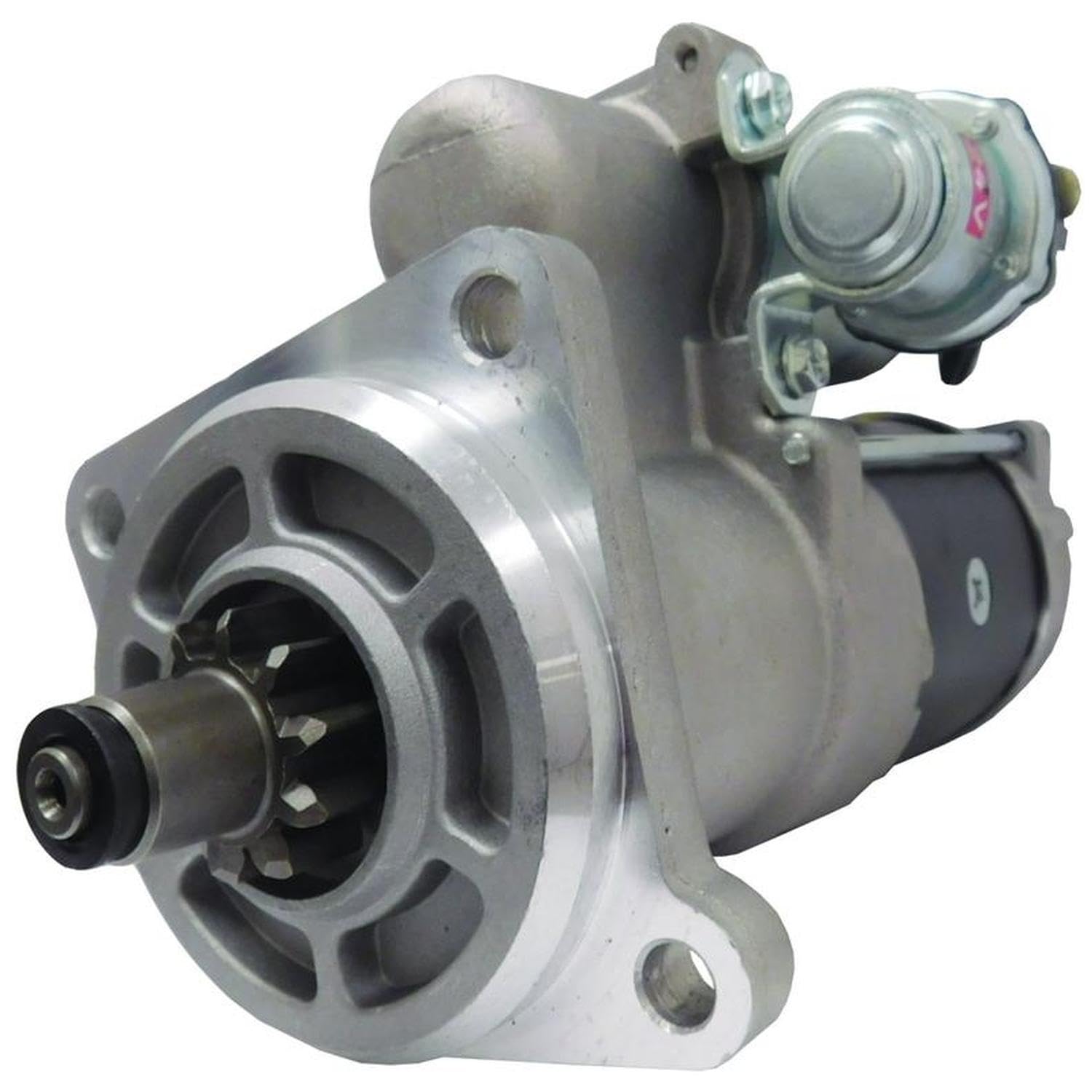

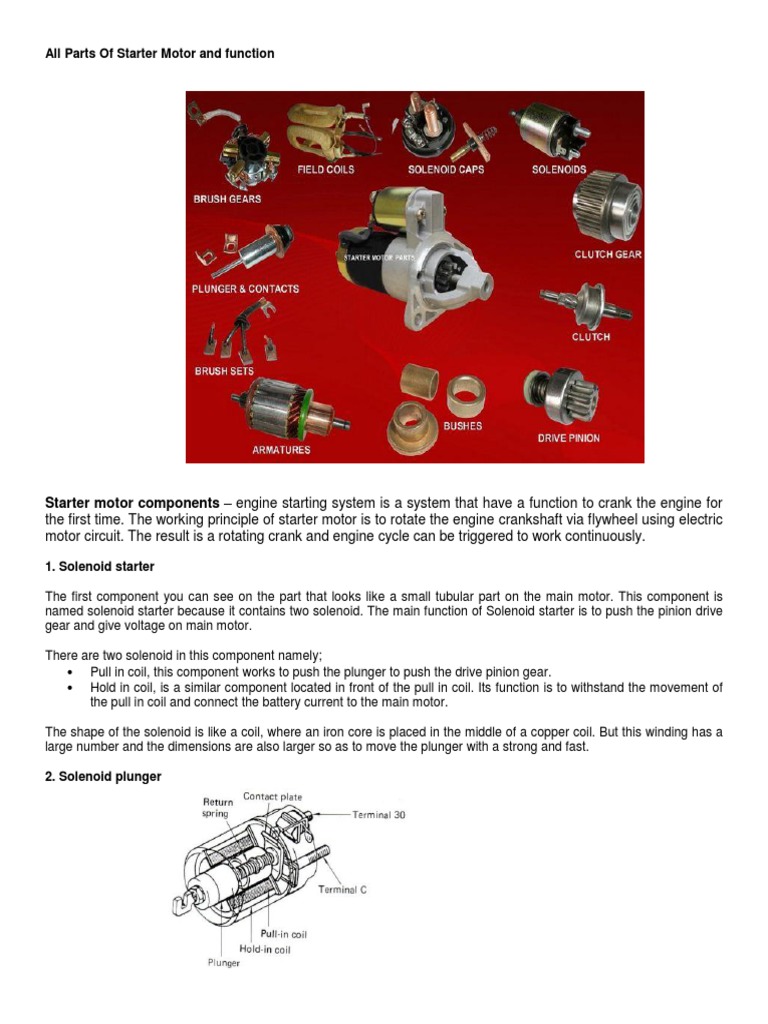

Illustrative image related to starter components

Решение: To combat performance issues, buyers should focus on sourcing high-quality starter components from established manufacturers with proven track records. Conduct thorough research into product reviews and case studies to gauge reliability and performance metrics. It’s also beneficial to request samples or trial units before making bulk purchases. Additionally, consider implementing a maintenance schedule that includes regular inspections and testing of starter components, ensuring that any potential issues are identified and addressed early. This proactive maintenance not only extends the lifespan of your components but also enhances overall operational efficiency.

Scenario 3: Navigating Global Supply Chain Challenges

Проблема: International B2B buyers often encounter significant supply chain disruptions when sourcing starter components, especially given the geopolitical and economic complexities that can affect shipping and logistics. Delays in shipment, fluctuating prices, and inconsistent availability can hinder production schedules and lead to unexpected operational challenges. Buyers may find themselves in a position where they cannot fulfill customer orders or meet project deadlines due to these disruptions, impacting their business reputation.

Решение: To mitigate supply chain risks, B2B buyers should diversify their supplier base and not rely on a single source for starter components. Establishing relationships with multiple suppliers across different regions can provide more flexibility and options in times of disruption. Additionally, consider adopting just-in-time inventory practices to maintain a lean inventory while ensuring that essential components are readily available. Leveraging technology, such as supply chain management software, can also aid in monitoring inventory levels, predicting potential disruptions, and facilitating better communication with suppliers. By taking these proactive steps, buyers can enhance their resilience against supply chain challenges and maintain steady operations.

Strategic Material Selection Guide for starter components

What Are the Key Materials Used in Starter Components?

When selecting materials for starter components, it’s essential to consider their physical and chemical properties, manufacturing complexities, and how they align with specific application requirements. Below is an analysis of four common materials used in starter components, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Metals Like Steel and Aluminum Perform in Starter Components?

Сталь is widely used in starter components due to its high strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for high-performance applications. Steel also offers good corrosion resistance when treated, which is crucial in environments with varying humidity and temperature fluctuations.

Плюсы: Steel is relatively inexpensive and widely available, making it a cost-effective option for manufacturers. Its strength ensures longevity, which is vital in automotive applications.

Минусы: The weight of steel can be a disadvantage, especially in applications where reducing weight is a priority. Additionally, untreated steel may corrode, necessitating protective coatings that can increase manufacturing complexity.

International buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or DIN, particularly regarding corrosion resistance specifications.

Какую роль играет медь в электрических компонентах стартеров?

Медь is essential for electrical connections in starter components due to its excellent conductivity. It can handle high current loads, making it ideal for components like brushes and solenoids.

Плюсы: Copper’s superior electrical properties enhance performance and efficiency, leading to better engine cranking. It is also relatively easy to work with during manufacturing.

Минусы: Copper is more expensive than many other metals, which can impact overall production costs. Additionally, it is susceptible to corrosion, particularly in harsh environments, which may necessitate protective coatings.

For international buyers, understanding local copper standards and regulations is crucial, especially in regions with stringent electrical safety requirements, such as Europe.

How Does Plastic Compare for Non-Structural Components?

Пластик materials, particularly high-performance polymers, are increasingly used in non-structural components of starter systems, such as housings and insulation parts. These materials can withstand a range of temperatures and are resistant to many chemicals.

Плюсы: Plastics are lightweight and can be molded into complex shapes, allowing for innovative designs. They also tend to be less expensive than metals and can reduce overall production costs.

Минусы: While plastics offer good insulation properties, they may not withstand extreme temperatures or mechanical stresses as well as metals. This limitation can affect their suitability for high-performance applications.

International buyers should consider the specific plastic grades and their compliance with standards like JIS or ISO, especially in automotive applications where durability is critical.

What About Composite Materials for Advanced Applications?

Композитные материалы, such as carbon fiber reinforced plastics, are becoming popular in high-end starter applications due to their high strength-to-weight ratio and resistance to environmental factors.

Illustrative image related to starter components

Плюсы: Composites can significantly reduce weight without sacrificing strength, making them ideal for performance vehicles. They also exhibit excellent corrosion resistance.

Минусы: The manufacturing process for composites can be complex and costly, impacting the overall price. Additionally, they may not be suitable for all applications due to their specific mechanical properties.

For buyers in regions like the Middle East and Europe, understanding the specific performance characteristics of composites and their compliance with industry standards is crucial for ensuring product reliability.

Сводная таблица выбора материалов для компонентов стартера

| Материал | Typical Use Case for starter components | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Сталь | Structural components (housing, gears) | Высокая прочность и долговечность | Heavy and may corrode without treatment | Средний |

| Медь | Electrical connections (brushes, solenoids) | Отличная электропроводность | Высокая стоимость и подверженность коррозии | Высокий |

| Пластик | Non-structural components (insulation, housings) | Легкий и экономичный | Ограниченная устойчивость к перепадам температур и нагрузкам | Низкий |

| Композитный | Высокопроизводительные приложения | Высокое соотношение прочности и веса | Complex manufacturing and high cost | Высокий |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions tailored to specific regional requirements and standards.

Illustrative image related to starter components

In-depth Look: Manufacturing Processes and Quality Assurance for starter components

What Are the Main Stages of Manufacturing Starter Components?

Manufacturing starter components involves a well-defined sequence of processes, each critical to ensuring the final product meets quality and performance standards. The main stages of manufacturing include material preparation, forming, assembly, and finishing.

-

Подготовка материалов: The first step is selecting high-quality raw materials, such as copper for electrical components and steel for the housing. These materials undergo several processes, including cutting, machining, and heat treatment, to achieve the desired properties. For instance, copper may be treated to enhance its conductivity, while steel components are often heat-treated to improve strength and durability.

-

Формирование: This stage involves shaping the prepared materials into the required components. Techniques such as stamping, forging, and casting are commonly used. For example, the pinion gear is often produced through precision forging to ensure it can withstand the high torque generated during engine cranking. Advanced forming technologies, such as CNC machining, provide higher precision and repeatability, which are crucial for ensuring the components fit perfectly.

-

Сборка: Once individual components are formed, they are assembled into the final starter motor. This step typically involves the integration of the armature, commutator, brushes, solenoid, and other parts. Automated assembly lines are increasingly used to enhance efficiency and consistency. Robotics may assist in tasks such as placing components and ensuring that electrical connections are secure. Each assembly station often includes checks to confirm correct alignment and functionality.

-

Отделка: The final stage involves applying protective coatings, surface treatments, and final inspections. Coatings such as galvanization or powder coating protect against corrosion and enhance the component’s lifespan. Additionally, components may undergo polishing or other surface treatments to meet aesthetic and functional requirements. Finishing processes are crucial in ensuring that the starter components can withstand harsh environments, especially for international buyers in regions with extreme weather conditions.

How Is Quality Assurance Integrated into Starter Component Manufacturing?

Quality assurance (QA) is integral to the manufacturing of starter components, ensuring that each product meets stringent international and industry-specific standards. Key standards include ISO 9001, which focuses on quality management systems, and CE marking, which indicates conformity with health, safety, and environmental protection standards.

-

Контрольные точки контроля качества: The manufacturing process includes several critical quality control checkpoints:

– Входящий контроль качества (IQC): This initial checkpoint involves inspecting raw materials and components for compliance with specifications before they enter production. Suppliers must provide certification of material quality.

– Контроль качества в процессе производства (IPQC): During the manufacturing process, regular inspections are conducted to monitor parameters such as dimensions, tolerances, and functionality. Automated systems may be employed to track these metrics in real time.

– Окончательный контроль качества (FQC): Upon completion, each starter component undergoes comprehensive testing to verify that it meets performance criteria. This may include electrical testing, functional testing, and durability assessments. -

Общие методы тестирования: Various testing methods are employed to ensure quality. Electrical tests check the functionality of the starter motor, while mechanical tests evaluate the structural integrity of components. Vibration and thermal cycling tests can simulate real-world conditions to confirm reliability under stress. Non-destructive testing (NDT) techniques, such as ultrasonic or X-ray inspections, are also used to detect internal flaws without damaging the components.

Как покупатели B2B могут проверить процессы контроля качества поставщиков?

B2B buyers must be proactive in verifying the quality control processes of their suppliers to ensure they receive reliable products. Here are several strategies to consider:

-

Аудит поставщиков: Conducting on-site audits is one of the most effective ways to assess a supplier’s manufacturing and quality assurance processes. During an audit, buyers can evaluate the supplier’s adherence to quality standards, review documentation, and inspect manufacturing practices. This direct engagement provides insight into the supplier’s commitment to quality.

-

Отчеты по обеспечению качества: Requesting detailed quality assurance reports can help buyers understand a supplier’s QC methodologies. These reports should outline testing procedures, results, and compliance with relevant standards. Look for documentation that includes batch testing results, certifications, and any corrective actions taken in response to quality issues.

-

Проверки третьей стороной: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections and tests to verify that products meet specified requirements before they are shipped. This is particularly important for international buyers who may not have the ability to conduct on-site inspections.

Каковы нюансы контроля качества для международных покупателей?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, face unique challenges and considerations when it comes to quality control in starter components.

-

Понимание региональных стандартов: Different regions may have varying quality standards and regulations. For instance, buyers in Europe must ensure compliance with CE marking, while those in the Middle East may need to adhere to specific local standards. Understanding these requirements is crucial to avoid regulatory issues and ensure product acceptance in the target market.

-

Логистические соображения: The logistics of shipping starter components across borders can introduce risks. Components may be subject to additional inspections at customs, and delays can occur if documentation is not in order. Buyers should work closely with suppliers to ensure that all necessary documentation, including certifications and test reports, is included with shipments.

-

Культурные и коммуникационные барьеры: Cultural differences can impact communication and expectations regarding quality. Building strong relationships with suppliers through regular communication and visits can foster a better understanding of quality needs and expectations. Utilizing local representatives or consultants who understand both cultures can also bridge any gaps.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols for starter components is essential for B2B buyers. By focusing on the stages of manufacturing, implementing rigorous quality control measures, and being proactive in verifying supplier practices, businesses can ensure they are sourcing reliable and high-quality starter components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter components’

In the competitive landscape of B2B procurement, sourcing starter components requires a strategic approach. This checklist is designed to guide international buyers through the essential steps to ensure a successful purchasing experience.

Шаг 1: Определите свои технические характеристики

Clearly outlining your technical requirements is the cornerstone of effective sourcing. This includes understanding the specifications of the starter components needed, such as voltage ratings, size, and compatibility with existing systems. A well-defined specification helps in communicating your needs to potential suppliers, ensuring that the components meet your operational requirements.

Шаг 2: Исследование потенциальных поставщиков

Thorough research is vital to identify reliable suppliers. Utilize online platforms, industry directories, and trade shows to compile a list of potential vendors. Focus on suppliers with experience in your industry and region, as they are more likely to understand local market conditions and regulatory requirements.

Шаг 3: Проверка сертификатов поставщиков

Before engaging with suppliers, it is essential to verify their certifications and compliance with industry standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. Ensure that the supplier adheres to safety and environmental regulations relevant to your region, as this can significantly impact product reliability and safety.

Шаг 4: Request Samples and Technical Data

Requesting samples and detailed technical data from shortlisted suppliers is a critical step. Evaluate the quality and functionality of the starter components through hands-on testing. Additionally, review technical documentation such as installation manuals and product specifications to ensure they align with your requirements.

Illustrative image related to starter components

Шаг 5: Оцените цены и условия оплаты

Engage in discussions regarding pricing structures and payment terms. It is crucial to obtain detailed quotations that outline the costs associated with each component, including shipping and handling. Consider the payment terms offered, as favorable terms can enhance cash flow and financial planning.

Шаг 6: Evaluate After-Sales Support and Warranty Policies

After-sales support is a key factor that can influence the overall satisfaction with your purchase. Inquire about warranty policies and the level of technical support available post-purchase. A supplier that offers robust after-sales service can help resolve issues quickly, minimizing downtime in your operations.

Шаг 7: Finalize Contracts and Delivery Terms

Once you’ve selected a supplier, it’s time to formalize the agreement. Review the contract thoroughly, paying attention to delivery timelines, penalties for non-compliance, and service level agreements. Clear terms can help prevent misunderstandings and ensure that both parties are aligned on expectations.

By following this structured sourcing checklist, B2B buyers can navigate the complexities of procuring starter components effectively, ensuring that they secure quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for starter components Sourcing

Каковы основные составляющие затрат при поиске компонентов стартера?

When sourcing starter components, understanding the cost structure is critical for effective budgeting and financial planning. The primary cost components include:

Illustrative image related to starter components

-

Материалы: The cost of raw materials such as steel, copper, and plastics is a significant factor. Prices can fluctuate based on global demand, availability, and geopolitical factors. High-quality materials are essential for durability and performance, which can influence the overall cost.

-

Трудовые ресурсы: Labor costs vary significantly by region and can impact the final pricing of starter components. Skilled labor is often more expensive but may result in higher-quality products. Countries with lower labor costs, such as those in parts of Africa and South America, may provide competitive pricing options.

-

Производственные накладные расходы: This encompasses expenses related to the factory operations, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, making the final product more competitive in the market.

-

Инструменты: Tooling costs involve the design and fabrication of molds and dies required for production. These costs are typically amortized over the production volume, meaning larger orders can lead to lower per-unit costs.

-

Контроль качества (КК): Implementing stringent quality control measures is essential for ensuring product reliability. However, this adds to the overall cost structure. Companies must balance the costs of QC with the potential risks of defective products.

-

Логистика: Transportation and warehousing costs can significantly impact the total cost of ownership. Factors such as distance, shipping method, and import/export regulations play a crucial role in logistics expenses.

-

Маржа: Suppliers will include a profit margin in their pricing. This margin can vary based on market competition, perceived value, and relationship with buyers.

What Influences Pricing for Starter Components?

Several factors can influence the pricing of starter components, which are crucial for international B2B buyers to consider:

-

Объем/MOQ (минимальный объем заказа): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs without overextending their budgets.

-

Технические характеристики и индивидуальная настройка: Customized components often incur additional costs due to design and manufacturing adjustments. Buyers should assess the necessity of customization against standard options.

-

Качество материалов и сертификаты: Components that meet international quality standards or certifications (e.g., ISO, CE) may command higher prices. Buyers should weigh the importance of certifications against their project requirements.

-

Факторы, связанные с поставщиками: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their products, reflecting their quality assurance processes and customer service capabilities.

-

Инкотермс: The terms of trade defined by Incoterms can significantly impact pricing. Buyers must understand whether they are responsible for shipping costs, insurance, and duties, which can alter the total cost of ownership.

How Can Buyers Negotiate for Better Pricing on Starter Components?

To secure the best possible pricing for starter components, international B2B buyers should consider the following strategies:

-

Проведение маркетинговых исследований: Understanding market trends, average pricing, and competitor offerings can empower buyers during negotiations. This knowledge can help justify requests for lower prices or better terms.

-

Build Strong Relationships: Establishing long-term relationships with suppliers can lead to better pricing, more favorable terms, and priority during supply shortages.

-

Оцените совокупную стоимость владения (TCO): Instead of focusing solely on the purchase price, buyers should consider the TCO, which includes maintenance, durability, and potential downtime costs. This broader perspective can help justify investments in higher-quality components.

-

Изучите нескольких поставщиков: Soliciting quotes from various suppliers can provide leverage during negotiations. Buyers can use competing offers to negotiate better pricing or terms.

-

Понимание нюансов ценообразования при международных сделках: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and potential tariffs that can affect pricing. Clear communication about these factors with suppliers can aid in achieving favorable pricing.

Заключение

Navigating the complexities of sourcing starter components requires a thorough understanding of the cost components and pricing influencers. By employing strategic negotiation tactics and considering the total cost of ownership, buyers can make informed decisions that align with their financial goals while securing high-quality components for their needs. It is advisable to note that indicative prices may vary based on the aforementioned factors, and buyers should conduct diligent market comparisons to ensure the best value.

Illustrative image related to starter components

Alternatives Analysis: Comparing starter components With Other Solutions

Understanding Alternatives to Starter Components in Automotive Applications

In the automotive sector, starter components play a crucial role in initiating the engine’s operation. However, as technology evolves, several alternative solutions have emerged that can provide similar functionalities. B2B buyers must consider these alternatives to ensure they select the most effective and cost-efficient option for their specific needs.

| Аспект сравнения | Starter Components | Альтернатива 1: интегрированный стартер-генератор (ISG) | Alternative 2: Hybrid Electric Systems |

|---|---|---|---|

| Производительность | Надежный запуск двигателя | Provides both starting and generating functions | Reduces fuel consumption significantly |

| Стоимость | Умеренная первоначальная стоимость | Higher upfront investment | High initial cost but savings on fuel |

| Простота внедрения | Стандартная установка | Requires modifications to the existing system | Complex integration with existing vehicles |

| Техническое обслуживание | Regular maintenance needed | Similar maintenance to conventional starters | Более низкий уровень технического обслуживания благодаря меньшему количеству движущихся частей |

| Лучший вариант использования | Traditional combustion engines | Vehicles requiring better fuel efficiency | Hybrid vehicles and electric powertrains |

Подробная разбивка альтернатив

What Are Integrated Starter Generators (ISG)?

Integrated Starter Generators combine the functions of a starter motor and an alternator. They not only start the engine but also provide additional electrical power while the engine runs. This dual functionality improves fuel efficiency and reduces emissions, making it an attractive option for modern vehicles. However, ISGs typically require more extensive modifications to the vehicle’s electrical system, leading to higher installation costs.

How Do Hybrid Electric Systems Compare?

Hybrid electric systems utilize both internal combustion engines and electric motors. They can significantly reduce fuel consumption and emissions by optimizing energy use. These systems often require complex integration with existing vehicle architectures, which can increase the initial costs and installation complexities. However, they offer long-term savings on fuel and maintenance, as they have fewer moving parts compared to traditional systems.

Заключение: Как покупателям B2B выбрать правильное решение?

When selecting between starter components and their alternatives, B2B buyers must weigh performance, cost, ease of implementation, and maintenance requirements against their specific operational needs. For traditional vehicles, standard starter components may suffice. However, for businesses looking to enhance fuel efficiency and reduce environmental impact, exploring options like Integrated Starter Generators or Hybrid Electric Systems could be beneficial. The right choice ultimately depends on the buyer’s unique requirements, budget constraints, and long-term operational goals.

Illustrative image related to starter components

Essential Technical Properties and Trade Terminology for starter components

What Are the Essential Technical Properties of Starter Components?

When sourcing starter components, understanding the technical specifications is crucial for ensuring compatibility, reliability, and performance. Here are some key properties to consider:

-

Марка материала

The material used in starter components significantly impacts their durability and performance. Common materials include high-grade steel for strength and resistance to wear, copper for electrical conductivity, and various polymers for insulation. Selecting the right material grade ensures that the components can withstand operational stresses, which is essential for minimizing downtime and maintenance costs. -

Уровни толерантности

Tolerance refers to the allowable deviation from a specified dimension. In starter components, tight tolerances are critical for ensuring that parts fit and function correctly. For instance, a tolerance of ±0.01mm might be required for components that must mesh precisely to engage the engine flywheel. Proper tolerances enhance performance and reduce the risk of mechanical failure, making it a vital consideration for B2B buyers. -

Номинальное напряжение

The voltage rating indicates the maximum voltage the starter component can handle without risk of failure. Common ratings for automotive starter motors range from 12V to 24V. Understanding voltage ratings is essential for selecting components that match the electrical systems of different vehicles, especially in regions with varying automotive standards. -

Технические характеристики крутящего момента

Torque specifications indicate the rotational force a starter motor can generate, which is crucial for cranking the engine. Higher torque ratings are often required for larger engines or those in harsher environments. Buyers should consider torque requirements based on the specific applications and engine sizes to ensure reliable performance under diverse conditions. -

Диапазон рабочих температур

The operating temperature range specifies the temperatures within which the starter components can function optimally. Components that can withstand extreme temperatures are essential in regions with significant temperature fluctuations, such as the Middle East or parts of Africa. Selecting components with appropriate temperature ratings helps ensure reliability and longevity.

What Are Common Trade Terms Used in the Starter Component Industry?

Familiarity with trade terminology is equally important for effective communication and negotiation in B2B transactions. Here are several commonly used terms:

-

OEM (производитель оригинального оборудования)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the starter component industry, OEM parts are often preferred due to their guaranteed compatibility with specific vehicle models. Buyers should prioritize OEM components for reliability and performance assurance. -

MOQ (минимальный объем заказа)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it affects inventory management and purchasing strategies. Buyers should negotiate MOQs that align with their operational needs while ensuring favorable pricing. -

RFQ (запрос предложения)

An RFQ is a formal request for price quotes from suppliers for specific quantities of products. Submitting an RFQ is a common practice in B2B transactions, allowing buyers to compare prices and terms from multiple suppliers. This process aids in making informed purchasing decisions and negotiating better deals. -

Инкотермс (Международные торговые термины)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers engaged in global sourcing, as they clarify shipping responsibilities, risk management, and cost allocation. -

Время выполнения заказа

Lead time refers to the amount of time required to fulfill an order from the moment it is placed until delivery. It is critical for inventory planning and ensuring that production schedules are met. Buyers should inquire about lead times to align their procurement processes with operational needs. -

Запасные части

Aftermarket parts are components produced by third-party manufacturers, rather than the OEM. While they can offer cost savings, buyers must assess the quality and compatibility of aftermarket parts to ensure they meet performance expectations. Understanding the differences between OEM and aftermarket options is vital for making cost-effective and reliable purchasing decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and ensure the successful integration of starter components into their operations.

Navigating Market Dynamics and Sourcing Trends in the starter components Sector

What Are the Current Market Dynamics for Starter Components?

The starter components market is experiencing significant growth driven by several global factors. The automotive industry’s ongoing shift toward electric vehicles (EVs) is reshaping demand, as traditional starter motors are being replaced by advanced systems that facilitate electric ignition. Additionally, the increase in vehicle production in emerging markets, particularly in Africa and South America, is fostering demand for reliable starter components. In Europe, regulatory frameworks aimed at reducing carbon emissions are pushing manufacturers toward more efficient and innovative starter technologies.

Emerging trends in B2B sourcing include a heightened focus on digital procurement platforms that enhance transparency and efficiency. Platforms utilizing AI and machine learning enable buyers to make informed decisions based on real-time data and analytics. Furthermore, the integration of Internet of Things (IoT) technologies in starter components is becoming prevalent, as these innovations enhance performance monitoring and predictive maintenance, thus reducing downtime for end users.

International buyers should also consider the geopolitical landscape, as supply chain disruptions caused by trade policies and global events can impact sourcing strategies. Establishing relationships with local suppliers in targeted markets like Brazil and Germany can mitigate risks and provide access to tailored solutions that meet specific regional demands.

How Can Sustainability and Ethical Sourcing Impact the Starter Components Sector?

Sustainability has emerged as a critical consideration for B2B buyers in the starter components sector. The environmental impact of manufacturing processes and materials used in starter motors is under scrutiny, with increasing pressure from consumers and regulatory bodies for more sustainable practices. Buyers are now prioritizing suppliers who implement green manufacturing processes, reduce waste, and utilize recyclable materials.

Ethical sourcing is also gaining traction, with businesses seeking to ensure that their supply chains adhere to fair labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to ethical practices. By choosing suppliers who are transparent about their sourcing and manufacturing processes, B2B buyers can enhance their brand reputation and align with the growing consumer preference for responsible products.

Additionally, the adoption of alternative materials—such as biodegradable composites and recycled metals—can further reduce the environmental footprint of starter components. This aligns with the global shift toward circular economies, where the emphasis is on reusing and recycling materials rather than relying on virgin resources.

What is the Historical Context of Starter Components?

The evolution of starter components can be traced back to the early 20th century when the introduction of electric starters revolutionized vehicle ignition systems. Prior to this, vehicles relied on hand cranks, which were not only labor-intensive but also dangerous. The first electric starter was developed in 1912, allowing for easier and safer vehicle operation.

Over the decades, advancements in electric motor technology and materials have significantly improved the performance and reliability of starter motors. The introduction of microprocessor-controlled systems in the 1990s marked a turning point, leading to increased efficiency and integration with vehicle electronics. Today, as the automotive landscape shifts towards electrification, starter components are evolving once again, adapting to new technologies and sustainability demands. This historical context underscores the importance of innovation in meeting current and future market needs, providing B2B buyers with insights into the trajectory of product development in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of starter components

-

How do I choose the right starter components for my business needs?

Selecting the right starter components requires a thorough understanding of your equipment specifications and operational requirements. Assess the power requirements, compatibility with existing systems, and environmental factors such as temperature and humidity. Consult with manufacturers or suppliers for detailed product specifications and consider performance ratings. Additionally, customer reviews and case studies can provide insights into reliability and efficiency, ensuring you make an informed decision. -

What are the key features to look for in a quality starter motor?

When evaluating starter motors, prioritize features such as durability, efficiency, and compatibility with your engine type. Look for components made from high-quality materials that can withstand heat and vibration. Consider the motor’s torque rating, as it directly impacts starting performance. Additionally, check for features like integrated protection systems against overheating or short circuits, which can enhance longevity and reliability. -

What is the importance of supplier vetting in sourcing starter components?

Vetting suppliers is crucial to ensure you receive high-quality starter components that meet your standards. Research potential suppliers by checking their certifications, industry experience, and customer feedback. Request samples to assess product quality and reliability. Establishing clear communication about your requirements, timelines, and quality expectations will also help build a strong relationship and minimize risks associated with international trade. -

What customization options are typically available for starter components?

Many manufacturers offer customization options for starter components, including specific voltage ratings, size adjustments, and unique connector types. Customization may also extend to design alterations that enhance performance for particular applications. When discussing your needs with suppliers, provide detailed specifications and performance criteria to ensure they can meet your requirements effectively. -

Какова минимальная партия заказа (MOQ) для компонентов стартера?

Minimum order quantities (MOQs) for starter components can vary significantly based on the supplier and the complexity of the components. Generally, larger orders may result in lower per-unit costs, while smaller orders may incur higher prices. When negotiating with suppliers, clarify the MOQ and explore potential flexibility based on your specific needs. Some suppliers may offer lower MOQs for first-time buyers or bulk discounts for future orders. -

What payment terms should I expect when purchasing starter components internationally?

Payment terms for international purchases of starter components often include options like upfront payment, partial payments, or credit terms. Common methods include wire transfers, letters of credit, or escrow services for added security. Be sure to negotiate favorable terms that align with your cash flow and consider any currency exchange risks. Clarifying payment terms upfront can help prevent misunderstandings and ensure smoother transactions. -

How can I ensure quality assurance (QA) for the starter components I purchase?

To ensure quality assurance for starter components, request detailed product specifications and certifications from your supplier. Many reputable manufacturers perform rigorous quality checks throughout the production process. Inquire about their QA protocols, including testing methods and inspection standards. Consider arranging for third-party inspections or audits to verify compliance with your standards before shipment, especially for large orders. -

What logistics considerations should I keep in mind when sourcing starter components internationally?

When sourcing starter components internationally, logistics plays a crucial role in ensuring timely delivery and cost efficiency. Evaluate shipping options, customs regulations, and potential tariffs that may affect your total costs. Collaborate with your supplier to establish clear shipping timelines and choose reliable freight forwarders. Additionally, consider the implications of lead times on your production schedule to avoid disruptions in your supply chain.

Top 5 Starter Components Manufacturers & Suppliers List

1. АвтоЭлектро - Стартерные двигатели

Домен: autoelectro.co.uk

Зарегистрирован: 1999 (26 лет)

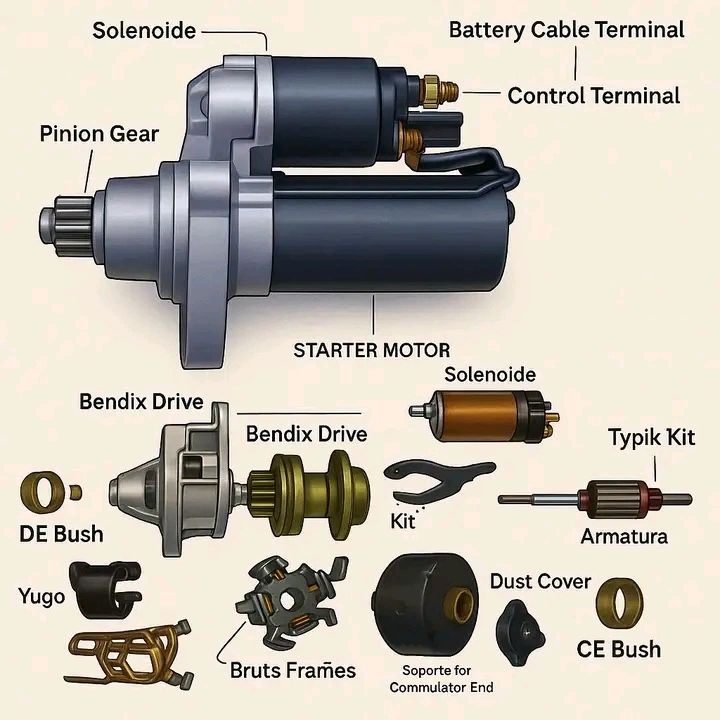

Введение: Стартерные двигатели отвечают за вращение двигателя во время зажигания, позволяя воздуху и топливу поступать для сгорания. Основные компоненты включают:

– Armature: An electromagnet mounted on the drive shaft, made of laminated soft iron core with conductor loops.

– Commutator: A section of the shaft with two plates that provide connections for the electromagnet coil.

– Brushes: Conduct electricity b…

2. Facebook – Starter Motor Parts

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: Starter motor parts explained: key components and their functions. A starter motor is essential for starting an engine.

3. DB Electrical – Starter and Tilt Trim Motor Parts

Домен: dbelectrical.com

Зарегистрирован: 2000 (25 лет)

Введение: [{‘item’:‘Стартер для Polaris ATV Drive Bendix 2&4 Stroke Engine’,‘item_number’:‘220-54005’,‘was_price’:‘$39.03’}, {‘item’:‘Tilt Trim Motor Brush Set for Prestolite 42-32, ESQ12S, Q12S’,‘item_number’:‘143-20026’,‘was_price’:‘$20.51’}, {‘item’: ‘Starter Drive fits Kawasaki Polaris Yamaha ATV PWC Snowmobile More’, ‘item_number’: ‘220-54004’, ‘was_price’: ‘$45.41’}, {‘item’: ‘Harley-Davidso...

4. Eaton – Starters

Домен: eaton.com

Зарегистрирован: 1996 (29 лет)

Введение: Starters are devices that control the use of electrical power to equipment, primarily used to start motors. They consist of two main components: contactors and overloads.

Contactors:

– Control the electric current to the motor.

– Function to repeatedly establish and interrupt an electrical power circuit.

– Operate electromechanically using a small control current.

– Used in applications where eq…

5. Scribd – Starter Motor Components

Домен: scribd.com

Зарегистрирован: 2006 (19 лет)

Введение: The starter motor consists of several main components that work together to start the engine. Key components include: 1. Solenoid Starter: Uses electrical current to engage the drive pinion gear. 2. Field Coils: Generate a magnetic field. 3. Armature Coils: React to induce movement. 4. Brushes: Transfer current between static and rotating parts. 5. Drive Pinion Clutch: Connects and disconnects the…

Strategic Sourcing Conclusion and Outlook for starter components

What Are the Key Takeaways for International B2B Buyers on Starter Components?

In the rapidly evolving landscape of starter components, strategic sourcing remains crucial for international B2B buyers. By understanding the intricate mechanics of starter motors and their components, buyers can make informed decisions that enhance operational efficiency and reliability. The value of sourcing high-quality starter components from reputable manufacturers cannot be overstated; it directly impacts the longevity and performance of machinery.

How Can Strategic Sourcing Enhance Your Supply Chain?

Leveraging strategic sourcing allows businesses to optimize their supply chains, ensuring access to the latest technologies and innovations in starter components. By fostering strong relationships with suppliers across diverse regions, such as Africa, South America, the Middle East, and Europe, buyers can secure competitive pricing and favorable terms. This not only reduces costs but also enhances responsiveness to market demands.

What Is the Future Outlook for Sourcing Starter Components?

Looking ahead, the demand for reliable starter components will continue to rise, driven by advancements in automotive technology and increasing production rates. International buyers are encouraged to stay ahead of industry trends and invest in partnerships that prioritize sustainability and innovation. As you explore your sourcing strategies, consider the potential for growth and collaboration in this dynamic market. Embrace the future of starter components with confidence—your strategic sourcing decisions today will shape your success tomorrow.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.