Introduction: Navigating the Global Market for how to know if it’s the alternator or battery

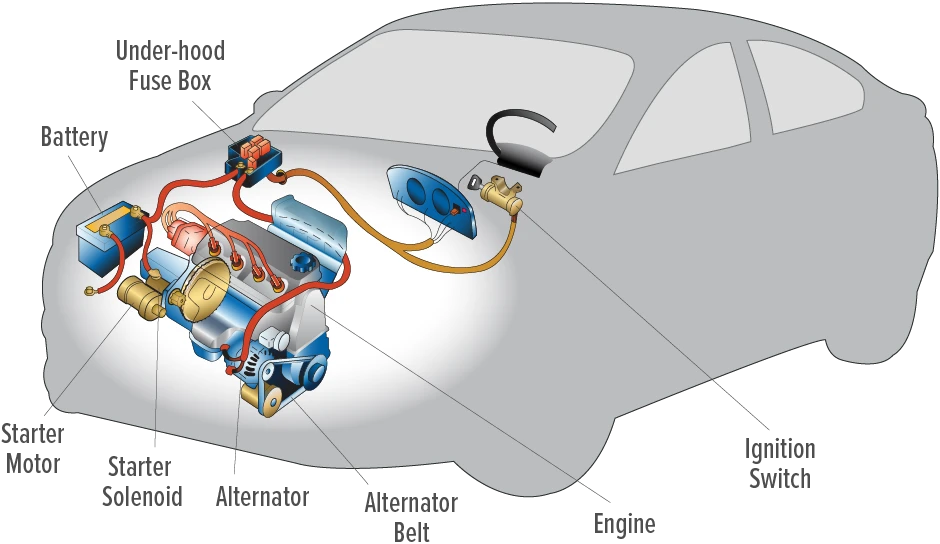

When faced with vehicle performance issues, one of the most common challenges for fleet managers and automotive suppliers is discerning whether the problem lies with the alternator or the battery. Understanding how to know if it’s the alternator or battery is crucial for minimizing downtime and reducing repair costs. This comprehensive guide delves into the intricacies of automotive electrical systems, offering insights into the distinct roles of these components, common symptoms of failure, and practical testing methods.

Throughout this guide, international B2B buyers will find valuable information on various types of alternators and batteries, their applications across different vehicle models, and effective supplier vetting processes to ensure quality parts. Additionally, we will explore cost considerations, helping businesses from Africa, South America, the Middle East, and Europe—such as Germany and Saudi Arabia—make informed purchasing decisions that align with their operational needs.

By equipping buyers with the knowledge needed to accurately diagnose electrical issues and select the right components, this guide empowers them to enhance their procurement strategies, reduce operational risks, and ultimately improve the reliability of their fleet. Whether you are sourcing replacement parts or seeking to optimize maintenance procedures, this resource will serve as an essential tool in navigating the complexities of automotive electrical systems.

Содержание

- Top 2 How To Know If It’S The Alternator Or Battery Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to know if it’s the alternator or battery

- Understanding how to know if it’s the alternator or battery Types and Variations

- Key Industrial Applications of how to know if it’s the alternator or battery

- 3 Common User Pain Points for ‘how to know if it’s the alternator or battery’ & Their Solutions

- Strategic Material Selection Guide for how to know if it’s the alternator or battery

- In-depth Look: Manufacturing Processes and Quality Assurance for how to know if it’s the alternator or battery

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if it’s the alternator or battery’

- Comprehensive Cost and Pricing Analysis for how to know if it’s the alternator or battery Sourcing

- Alternatives Analysis: Comparing how to know if it’s the alternator or battery With Other Solutions

- Essential Technical Properties and Trade Terminology for how to know if it’s the alternator or battery

- Navigating Market Dynamics and Sourcing Trends in the how to know if it’s the alternator or battery Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to know if it’s the alternator or battery

- Strategic Sourcing Conclusion and Outlook for how to know if it’s the alternator or battery

- Важное предупреждение и условия использования

Understanding how to know if it’s the alternator or battery Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Voltage Measurement | Uses a multimeter to measure voltage at battery terminals | Авторемонтные мастерские, автопарки | Pros: Safe, reliable; Cons: Requires equipment and knowledge |

| Нагрузочное тестирование | Tests battery under load to assess its health | Battery suppliers, service centers | Pros: Accurate diagnosis; Cons: Equipment cost and complexity |

| Визуальный осмотр | Проверяет наличие физических признаков износа или повреждений | Automotive maintenance providers | Плюсы: Быстро и легко; Минусы: Могут быть упущены основные проблемы |

| Indicator Lights | Utilizes dashboard warning lights to indicate issues | Fleet management, vehicle rentals | Pros: Simple alerts; Cons: Not specific to alternator/battery |

| Профессиональные диагностические инструменты | Employs advanced tools for comprehensive diagnostics | Автомобильные сервисные центры | Pros: Thorough analysis; Cons: High cost, requires training |

How to Differentiate Between Alternator and Battery Issues Using Voltage Measurement

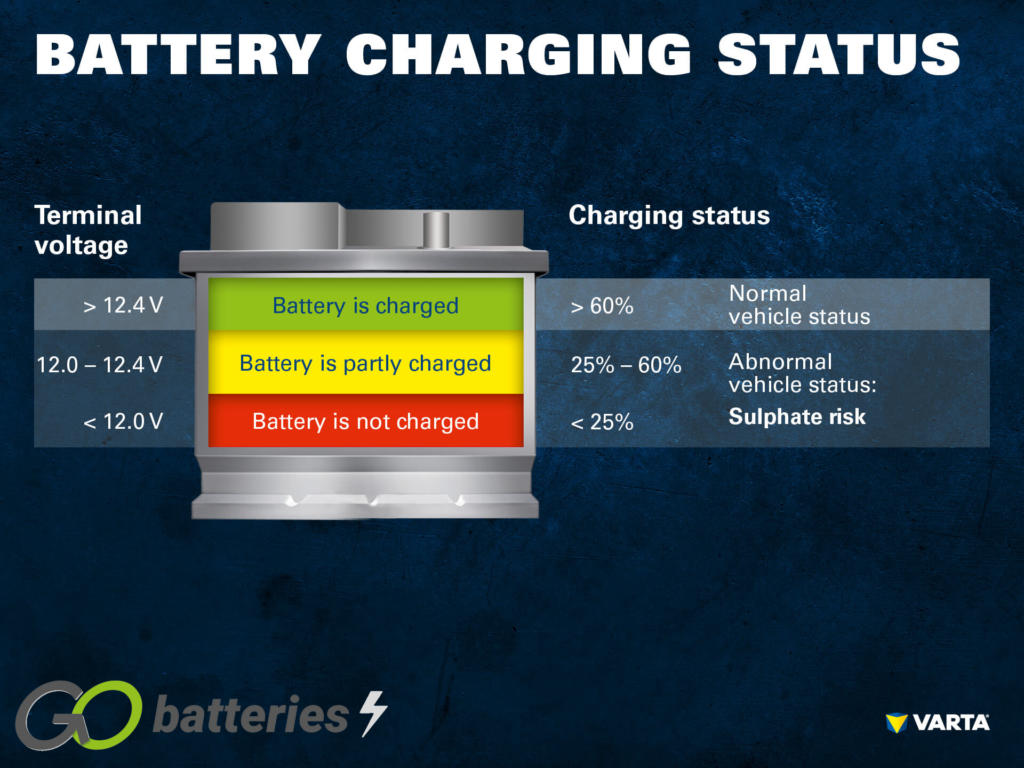

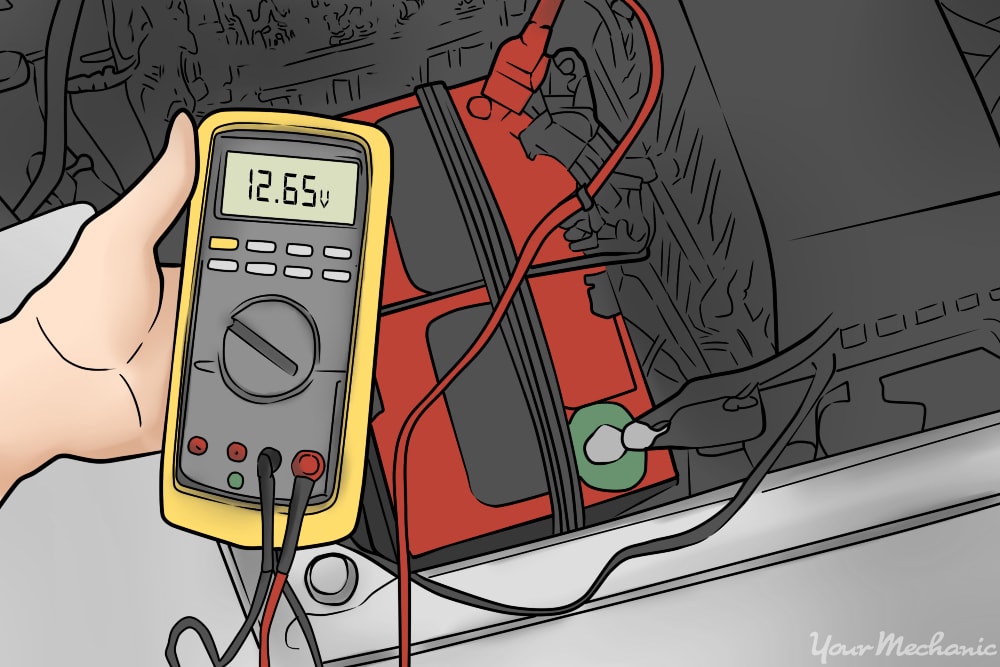

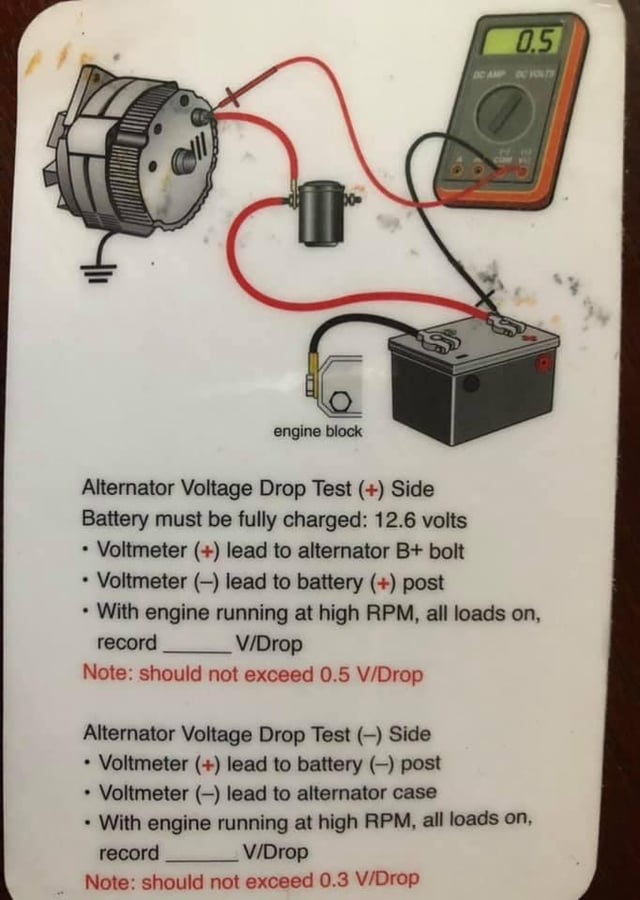

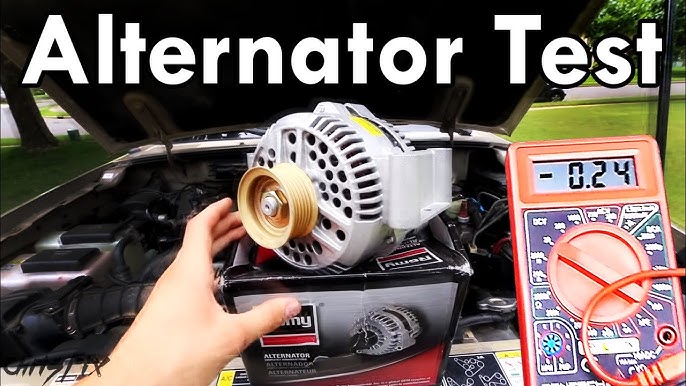

Voltage measurement is a straightforward and effective method for diagnosing battery and alternator issues. By using a multimeter, technicians can assess the voltage output while the vehicle is running. A healthy alternator typically maintains a voltage between 13.8V and 14.4V. This method is particularly suitable for automotive repair shops and fleets, as it provides a quick assessment without risking damage to vehicle electronics. However, it requires proper training and equipment, which may be a consideration for budget-conscious buyers.

What is Load Testing and Its Relevance in B2B?

Load testing involves applying a specific load to the battery while measuring its voltage output to determine its health under operational conditions. This method is essential for battery suppliers and service centers, as it accurately identifies weak batteries that may fail under stress. Load testers are relatively affordable and can provide immediate results, making them a valuable tool in inventory management and customer service. However, the need for specialized equipment and training can be a barrier for some smaller operations.

How Does Visual Inspection Aid in Identifying Battery and Alternator Problems?

Visual inspection is the simplest diagnostic method, focusing on physical signs such as corrosion on terminals, frayed cables, or leaks in batteries. This technique is often employed by automotive maintenance providers who need quick assessments to decide on further testing or replacement. While it is cost-effective and requires minimal tools, its main drawback is that it may overlook deeper electrical issues, potentially leading to unresolved problems.

How Do Indicator Lights Function in Vehicle Diagnostics?

Indicator lights on a vehicle’s dashboard serve as a basic alert system for both battery and alternator issues. They are useful for fleet management and vehicle rental companies to quickly identify vehicles needing attention. While this method is user-friendly and requires no technical expertise, it may not provide detailed information on the specific nature of the problem, necessitating further diagnostics.

Why Invest in Professional Diagnostic Tools for Comprehensive Analysis?

Professional diagnostic tools offer in-depth analysis for automotive service centers, enabling technicians to diagnose complex electrical issues accurately. These tools can communicate with a vehicle’s onboard computer to retrieve fault codes and assess the health of both the battery and alternator. While they provide thorough insights, the initial investment can be significant, and proper training is essential to maximize their effectiveness. This is a crucial consideration for businesses looking to enhance their service offerings.

Key Industrial Applications of how to know if it’s the alternator or battery

| Отрасль/сектор | Specific Application of how to know if it’s the alternator or battery | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Ремонт автомобилей | Diagnosing vehicle electrical issues during routine maintenance | Reduces downtime and repair costs, enhances customer satisfaction | Quality diagnostic tools, training for technicians, local regulations |

| Транспорт и логистика | Ensuring fleet vehicles operate efficiently | Minimizes breakdowns and delays, improves operational efficiency | Reliable parts supply, service agreements, warranty options |

| Горное и тяжелое оборудование | Maintaining machinery reliability in harsh environments | Prevents costly equipment failures, increases productivity | Durable components, supplier reliability, local support services |

| Возобновляемые источники энергии | Troubleshooting solar-powered battery systems | Ensures energy efficiency, extends equipment lifespan | Compatibility with existing systems, technical support, certifications |

| Сельское хозяйство | Monitoring battery performance in farming equipment | Enhances equipment reliability, reduces maintenance costs | Robust battery systems, local sourcing of parts, service availability |

How is ‘how to know if it’s the alternator or battery’ used in Automotive Repair?

In the automotive repair industry, understanding whether an issue is due to the alternator or battery is crucial during routine maintenance. Technicians utilize diagnostic tools to assess the vehicle’s electrical system, ensuring optimal functionality. By accurately diagnosing problems, repair shops can reduce vehicle downtime and minimize repair costs, thereby enhancing customer satisfaction. B2B buyers in this sector should consider sourcing high-quality diagnostic tools and ensuring their technicians are adequately trained to handle electrical systems, adhering to local regulations for safety.

What role does this knowledge play in Transportation & Logistics?

In the transportation and logistics sector, ensuring that fleet vehicles operate efficiently is vital for minimizing breakdowns and delays. Fleet managers often rely on the ability to distinguish between battery and alternator issues to maintain vehicle performance. This proactive approach not only reduces maintenance costs but also improves operational efficiency. Key sourcing considerations include establishing reliable parts supply chains and service agreements that guarantee quick turnaround times for repairs, ensuring that vehicles remain on the road.

Illustrative image related to how to know if it’s the alternator or battery

How does it impact Mining & Heavy Equipment operations?

In mining and heavy equipment operations, maintaining machinery reliability in harsh environments is critical. Operators must be able to quickly identify whether electrical issues stem from the alternator or battery to prevent costly equipment failures. This knowledge is essential for ensuring that machinery operates at peak performance, thereby increasing productivity. B2B buyers should focus on sourcing durable components that can withstand extreme conditions, as well as ensuring supplier reliability and local support services for timely maintenance.

Why is this knowledge important for Renewable Energy systems?

In the renewable energy sector, particularly with solar-powered battery systems, troubleshooting is essential for ensuring energy efficiency. Understanding whether the problem lies with the battery or alternator can help technicians maintain system performance and extend equipment lifespan. Buyers in this sector should prioritize compatibility with existing systems and seek suppliers that provide comprehensive technical support and necessary certifications, ensuring that installations meet industry standards.

How does this apply to Agriculture?

In agriculture, monitoring battery performance in farming equipment is crucial for enhancing reliability and reducing maintenance costs. Farmers must determine if electrical issues are caused by the alternator or battery to ensure their equipment operates efficiently, especially during critical planting or harvesting periods. Buyers should consider robust battery systems that can endure agricultural environments, prioritize local sourcing of parts, and ensure service availability to minimize downtime during peak operational seasons.

Illustrative image related to how to know if it’s the alternator or battery

3 Common User Pain Points for ‘how to know if it’s the alternator or battery’ & Their Solutions

Сценарий 1: Неправильная диагностика проблем с электрооборудованием в транспортных средствах автопарка

Проблема: B2B buyers managing fleets of vehicles often face the challenge of diagnosing electrical issues accurately. When a vehicle fails to start or experiences intermittent power loss, operators may be unsure if the problem lies with the alternator or the battery. This uncertainty can lead to unnecessary downtime, increased maintenance costs, and potential delays in service delivery. Moreover, without a clear understanding, technicians might replace parts that don’t need replacing, further straining budgets and resources.

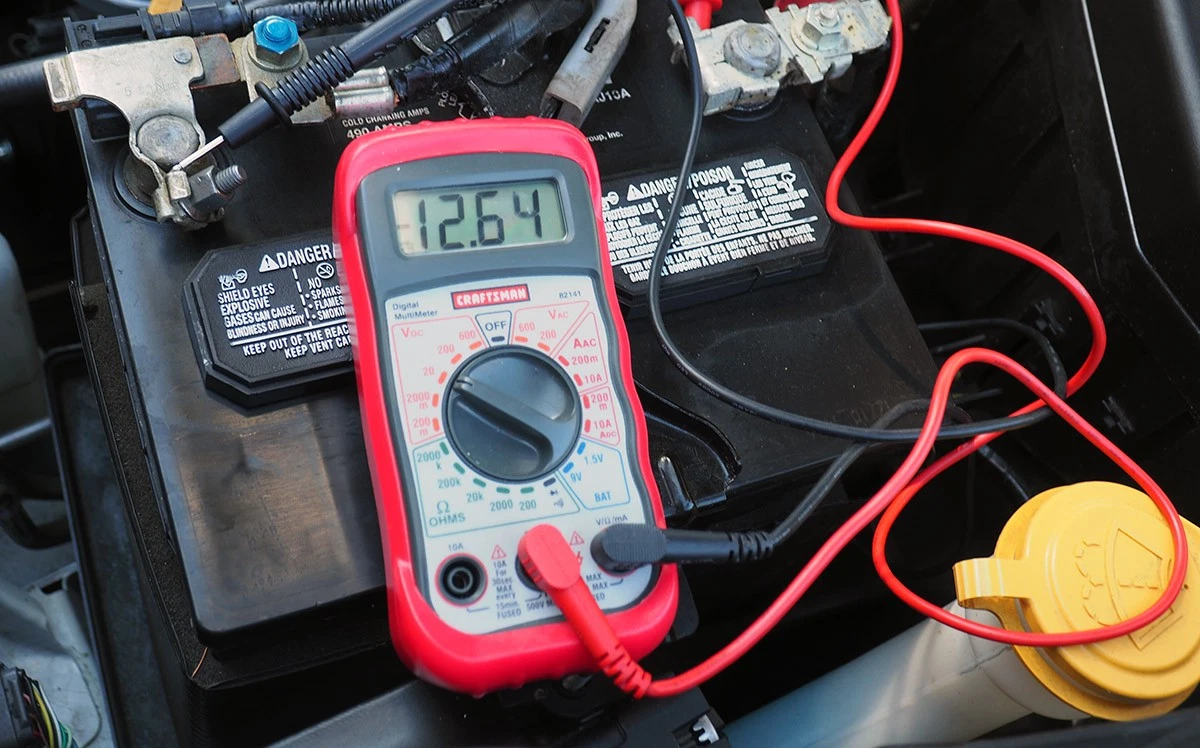

Решение: Implement a systematic diagnostic approach that includes using a multimeter to assess both the battery and alternator performance. Start by measuring the battery voltage when the vehicle is off; it should read around 12.6 volts. Then, with the engine running, check the voltage again; a healthy alternator will produce a reading of approximately 14 volts. This method allows technicians to pinpoint the faulty component without guesswork. Training staff on these diagnostic procedures can greatly enhance their troubleshooting skills and reduce costs associated with misdiagnoses. Additionally, consider investing in portable diagnostic tools that can be used on-site for quick assessments, helping to maintain fleet efficiency.

Scenario 2: Inconsistent Battery and Alternator Performance in Remote Areas

Проблема: For B2B buyers operating in remote regions, the challenges of inconsistent battery and alternator performance can be significant. Extreme weather conditions, such as high temperatures or humidity, can affect battery life and alternator efficiency, leading to unexpected failures. When these issues arise, the inability to quickly determine the source of the problem can halt operations, especially in industries reliant on heavy machinery or transport services.

Решение: To address this issue, establish a preventive maintenance schedule that includes regular checks of both batteries and alternators, particularly in adverse weather conditions. Encourage the use of battery maintainers and voltage regulators to ensure batteries are charged properly and alternators function optimally. Additionally, implement a training program for staff on environmental effects on these components, equipping them with the knowledge to conduct simple tests and maintenance. By being proactive, businesses can minimize unexpected failures and ensure operational continuity, even in challenging environments.

Scenario 3: Costly Repairs from Incorrect Testing Methods

Проблема: Many B2B buyers encounter costly repairs resulting from incorrect testing methods when diagnosing battery and alternator issues. A common misconception is that disconnecting the battery while the engine is running can determine if the alternator is functioning. This method can not only lead to inaccurate diagnostics but also damage the vehicle’s electrical system, resulting in expensive repairs that could have been avoided.

Решение: Educate employees on safe and effective testing methods to eliminate the use of outdated practices. Instead of relying on potentially damaging techniques, promote the use of multimeters for testing the alternator’s output and the battery’s condition. Encourage businesses to invest in training sessions or workshops focused on modern diagnostic techniques. Furthermore, creating a detailed troubleshooting guide that outlines proper procedures can serve as a valuable resource for technicians. By standardizing these practices, companies can avoid unnecessary repairs, protect their assets, and ultimately save on maintenance costs.

Strategic Material Selection Guide for how to know if it’s the alternator or battery

What Materials Are Commonly Used in Diagnosing Alternator or Battery Issues?

When diagnosing whether an issue lies with the alternator or the battery, various materials are employed in the tools and equipment used for testing. Understanding the properties, advantages, and limitations of these materials can significantly impact the effectiveness and reliability of the diagnostic process.

1. Медь

Ключевые свойства: Copper is known for its excellent electrical conductivity, making it a preferred choice for wiring and connectors in automotive applications. It has a high melting point (1,984°F or 1,085°C) and good corrosion resistance when properly coated.

Illustrative image related to how to know if it’s the alternator or battery

Плюсы и минусы: Copper’s high conductivity ensures minimal energy loss during testing, which is crucial for accurate diagnostics. However, it is relatively expensive compared to alternatives like aluminum and can be prone to corrosion if not properly maintained.

Влияние на применение: Copper is highly compatible with electrical systems in vehicles, facilitating effective voltage and current measurements. Its performance can be affected by environmental factors, which is important for international buyers operating in diverse climates.

Особые соображения для международных покупателей: Compliance with international standards such as ASTM B170 for copper wire is essential. Buyers in regions like Europe and the Middle East should also consider local regulations regarding material sourcing and environmental impact.

2. Алюминий

Ключевые свойства: Aluminum is lightweight and has decent electrical conductivity, though it is less conductive than copper. It has a melting point of around 1,221°F (660.3°C) and exhibits good resistance to corrosion due to its natural oxide layer.

Плюсы и минусы: The primary advantage of aluminum is its lower cost and weight, making it suitable for applications where weight is a concern. However, its lower conductivity can lead to higher energy losses, which may affect diagnostic accuracy.

Влияние на применение: Aluminum is often used in battery terminals and connectors. Its compatibility with various automotive systems makes it a viable option, but users must be cautious of potential galvanic corrosion when paired with copper.

Особые соображения для международных покупателей: Buyers should ensure compliance with standards like ASTM B221 for aluminum extrusions. In regions like Africa and South America, sourcing may be influenced by local availability and cost considerations.

3. Plastic (Polypropylene)

Ключевые свойства: Polypropylene is a thermoplastic polymer known for its chemical resistance and durability. It can withstand temperatures up to 212°F (100°C) and is often used in battery casings.

Плюсы и минусы: The primary advantage of polypropylene is its resistance to chemical degradation, making it ideal for battery applications. However, it is not as strong as metals and can be susceptible to UV degradation over time.

Illustrative image related to how to know if it’s the alternator or battery

Влияние на применение: Polypropylene is essential for safely housing batteries, preventing leaks and corrosion. Its lightweight nature aids in overall vehicle efficiency, but its performance can diminish in extreme temperatures.

Особые соображения для международных покупателей: Compliance with standards such as ISO 1043 for plastic materials is crucial. Buyers in Europe may prioritize materials with high recyclability due to stringent environmental regulations.

4. Silicone

Ключевые свойства: Silicone is a synthetic rubber known for its flexibility and temperature resistance, typically ranging from -76°F to 500°F (-60°C to 260°C). It also exhibits excellent electrical insulation properties.

Плюсы и минусы: Silicone’s flexibility and durability make it ideal for gaskets and seals in battery and alternator applications. However, it can be more expensive than traditional rubber materials and may not be suitable for high-stress mechanical applications.

Illustrative image related to how to know if it’s the alternator or battery

Влияние на применение: Silicone is often used in sealing applications to prevent moisture ingress, which is crucial for maintaining the integrity of electrical components. Its insulating properties enhance safety during diagnostics.

Особые соображения для международных покупателей: Buyers should consider compliance with standards such as ASTM D412 for silicone rubber. In regions like the Middle East, where temperatures can be extreme, silicone’s thermal stability becomes a significant advantage.

Сводная таблица

| Материал | Typical Use Case for how to know if it’s the alternator or battery | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Медь | Wiring and connectors for voltage testing | Отличная электропроводность | Высокая стоимость, подверженность коррозии | Высокий |

| Алюминий | Battery terminals and connectors | Легкий и экономичный | Более низкая проводимость, чем у меди | Средний |

| Пластик | Battery casings and housings | Chemical resistance and durability | Susceptible to UV degradation | Низкий |

| Силикон | Seals and gaskets for moisture protection | Flexibility and excellent insulation | Higher cost, not suitable for high-stress applications | Средний |

In-depth Look: Manufacturing Processes and Quality Assurance for how to know if it’s the alternator or battery

What Are the Key Stages in Manufacturing Alternators and Batteries?

The manufacturing processes for alternators and batteries are complex and require several distinct stages to ensure quality and reliability. Understanding these processes can aid B2B buyers in making informed purchasing decisions.

Подготовка материалов: Какие материалы используются в производстве?

The first stage involves selecting high-quality raw materials. For alternators, critical components include copper wire, iron for the rotor and stator, and various electronic components such as diodes and voltage regulators. In battery manufacturing, lead, sulfuric acid, and plastic for casings are essential. Suppliers should ensure that materials meet international standards, which can affect the durability and performance of the final product.

Формовка: как формируются и собираются компоненты?

Once materials are prepared, they undergo forming processes. For alternators, wire winding machines are utilized to create stator windings, while rotors are formed through precision machining. Battery plates are cast or stamped into shape, and separators are produced to prevent short-circuiting. These processes require advanced technology and skilled labor to ensure that components meet specified tolerances.

Illustrative image related to how to know if it’s the alternator or battery

Assembly: What Are the Key Steps in Final Assembly?

The assembly stage is crucial for both alternators and batteries. In alternator production, components are assembled in a clean environment to prevent contamination. This includes integrating the rotor and stator, installing diodes, and connecting the voltage regulator. For batteries, plates are stacked and separated before being filled with electrolyte and sealed. Each assembly line should be designed to minimize errors and optimize workflow.

Finishing: How Is Quality Ensured in the Final Product?

The finishing stage involves testing the assembled units for performance and reliability. For alternators, this can include load testing to ensure proper output voltage and current. Battery units undergo capacity testing and leak testing to verify their integrity. Adequate finishing processes ensure that products meet industry standards and customer expectations.

What Quality Assurance Practices Are Essential for Alternators and Batteries?

Quality assurance is critical in the manufacturing of both alternators and batteries, as it directly impacts performance and safety.

Which International Standards Should Be Followed?

Compliance with international standards, such as ISO 9001, is essential for manufacturers. ISO 9001 focuses on quality management systems and ensures that companies maintain consistent quality in their products. Additionally, industry-specific standards like CE (Conformité Européenne) for Europe and API (American Petroleum Institute) for specific automotive components should be adhered to, particularly for B2B buyers in regions like Africa and the Middle East.

Illustrative image related to how to know if it’s the alternator or battery

Каковы ключевые контрольные точки контроля качества?

Quality control checkpoints are integral to the manufacturing process. These include:

- Входящий контроль качества (IQC): Inspection of raw materials upon arrival to ensure compliance with specifications.

- Контроль качества в процессе производства (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

- Окончательный контроль качества (FQC): Comprehensive testing of finished products to ensure they meet performance standards.

Implementing these checkpoints helps reduce defects and enhances product reliability.

Как покупатели B2B могут проверить контроль качества поставщиков?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. This can include:

Conducting Audits: What Should Be Included in Supplier Audits?

Buyers should consider conducting regular audits of potential suppliers. These audits should assess the manufacturer’s adherence to quality standards, including:

- Review of quality management systems and certifications.

- Examination of manufacturing processes and equipment.

- Evaluation of employee training and competence.

Requesting Quality Reports: What Information Should Be Included?

Buyers should request detailed quality reports from suppliers, including information on testing methods and results. This documentation should outline how products are tested, the criteria used, and any corrective actions taken for failures.

Utilizing Third-Party Inspections: How Can Third-Party Services Help?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services can conduct audits, perform product testing, and verify compliance with industry standards.

Каковы нюансы контроля качества для международных B2B-покупателей?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must consider regional nuances in quality control.

How Do Regulatory Differences Impact Quality Assurance?

Different regions may have varying regulatory requirements and standards. For instance, CE marking is essential for products sold in the European market, while other certifications may be required in the Middle East or Africa. Buyers must ensure that their suppliers are compliant with relevant local regulations to avoid legal issues and ensure product acceptance in their markets.

What Are the Best Practices for Managing Quality Across Borders?

To effectively manage quality across borders, buyers should establish clear communication channels with suppliers. This includes regular updates on quality control processes and expectations. Additionally, investing in training and development for suppliers can help improve their quality assurance practices.

By understanding the manufacturing processes and quality assurance practices for alternators and batteries, B2B buyers can make more informed decisions, ensuring they source reliable and high-quality products that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if it’s the alternator or battery’

Введение

This guide serves as a practical checklist for B2B buyers tasked with determining whether a vehicle’s issue stems from the alternator or the battery. Understanding the distinction between these two critical components is essential for making informed purchasing decisions, ensuring operational efficiency, and minimizing downtime. This checklist will provide a structured approach to troubleshooting, which can help you source the right parts or services effectively.

Illustrative image related to how to know if it’s the alternator or battery

Шаг 1: Identify Symptoms of the Problem

Begin by documenting the specific issues the vehicle is experiencing. Common symptoms include dimming lights, difficulty starting, or strange noises when the engine runs.

- Battery-related symptoms often manifest as slow cranking or clicking sounds when attempting to start the vehicle.

- Alternator-related symptoms may include flickering dashboard lights or a warning light indicating battery issues.

Шаг 2: Perform a Voltage Test

Utilize a multimeter to measure the voltage at the battery terminals while the vehicle is running. A healthy alternator should produce a voltage reading between 13.5 to 14.5 volts.

- If the voltage is below 12.5 volts, this indicates a battery issue.

- If the voltage exceeds 14.5 volts, the alternator may be overcharging, which can damage the battery and other electronic components.

Шаг 3: Check Battery Condition

Inspect the battery for visible signs of wear or damage, such as corrosion around the terminals or a bloated casing.

- Consider the age of the battery; most lead-acid batteries have a lifespan of 3-5 years.

- If the battery appears compromised, it may need replacement regardless of alternator functionality.

Шаг 4: Evaluate Alternator Performance

If the battery checks out, focus on the alternator. Look for abnormal noises, such as whining or grinding sounds, which could indicate internal issues.

Illustrative image related to how to know if it’s the alternator or battery

- Test the alternator’s output with a multimeter while the engine is running; it should consistently provide adequate voltage.

- Additionally, inspect the drive belt for wear, as a loose or worn belt can affect alternator performance.

Шаг 5: Inspect Electrical Connections

Ensure that all connections between the battery, alternator, and other components are secure and free from corrosion. Poor connections can cause voltage drops, leading to misdiagnosis.

- Clean any corroded terminals and ensure that connections are tight.

- This step can often resolve issues without needing to replace either component.

Шаг 6: Consult Technical Resources

Use technical manuals or online resources specific to the vehicle make and model to understand common issues related to the battery and alternator.

- Look for troubleshooting guides that provide additional tests or checks that may not be immediately obvious.

- This knowledge can guide your sourcing decisions and help you communicate effectively with suppliers.

Шаг 7: Engage with Qualified Suppliers

Once you have determined the source of the issue, contact suppliers for batteries or alternators. Provide them with detailed information about your findings.

- Request product specifications that match the required performance parameters.

- Ensure that potential suppliers can provide warranties and support for their products, which is crucial for minimizing future risks and ensuring reliability.

By following this checklist, B2B buyers can efficiently identify whether a vehicle’s issues are due to the alternator or battery, facilitating informed decisions when sourcing replacement parts or services.

Comprehensive Cost and Pricing Analysis for how to know if it’s the alternator or battery Sourcing

What Are the Key Cost Components in Sourcing Alternators and Batteries?

When evaluating the sourcing of alternators and batteries, understanding the cost structure is crucial. The primary cost components include:

-

Материалы: The quality and type of materials used directly influence the overall cost. High-grade metals for alternators and durable components for batteries typically command higher prices but offer enhanced performance and longevity.

-

Трудовые ресурсы: Labor costs vary significantly depending on the region. Skilled labor in regions with higher living costs, such as Europe, may increase manufacturing costs, whereas labor in developing markets may be more economical.

-

Производственные накладные расходы: This includes utilities, rent, and equipment depreciation. Factories with advanced technology might have lower overhead costs per unit due to efficiency but require higher initial investments.

-

Инструменты: The initial cost of tooling for custom or specialized components can be substantial. However, once amortized over high production volumes, this cost can become negligible per unit.

-

Контроль качества (КК): Rigorous QC processes ensure product reliability but add to the cost. Certifications for quality, especially for exports to regions like Europe, can also increase overall expenses.

-

Логистика: Transportation costs can vary based on distance and mode of transport. Sourcing from international suppliers often entails additional costs for customs clearance and tariffs.

-

Маржа: Suppliers typically add a profit margin to the base costs, influenced by market demand and competition.

How Do Price Influencers Affect the Sourcing of Alternators and Batteries?

Several factors can influence pricing in the B2B market for alternators and batteries:

-

Объем/минимальный объем заказа: Bulk purchasing often leads to significant discounts. Establishing a minimum order quantity (MOQ) can help buyers negotiate better terms.

-

Технические характеристики и индивидуальная настройка: Custom specifications may lead to higher costs due to the need for specialized materials and manufacturing processes. Standard products often have more competitive pricing.

-

Качество материалов и сертификаты: Higher quality materials and necessary certifications for compliance with international standards can increase costs but are vital for ensuring reliability and safety.

-

Факторы, связанные с поставщиками: The reputation, reliability, and financial stability of suppliers can impact pricing. Established suppliers may charge a premium for their proven track record.

-

Инкотермс: The choice of Incoterms can affect the total landed cost. Buyers should understand how shipping terms can shift responsibilities and costs between buyers and sellers.

What Tips Can Help B2B Buyers Negotiate Better Prices for Alternators and Batteries?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, considering the following tips can enhance cost-efficiency:

-

Переговоры: Engage in open discussions with suppliers to explore pricing flexibility, especially for bulk orders. Building a strong relationship with suppliers can lead to better terms and pricing.

-

Сосредоточьтесь на общей стоимости владения (TCO): Evaluate not just the purchase price but the total cost associated with ownership, including maintenance, lifespan, and potential downtime. This holistic view can justify higher initial costs for superior products.

-

Понимание нюансов ценообразования: Be aware that prices can fluctuate based on global market conditions, currency exchange rates, and local economic factors. Staying informed can aid in timing purchases more strategically.

-

Leverage Local Suppliers: Whenever feasible, consider local suppliers to minimize logistics costs and tariffs. This can also simplify communication and streamline the supply chain.

-

Request Samples and Perform Testing: Before making significant investments, request samples to assess quality and performance. This can prevent costly mistakes and ensure that the products meet your standards.

Отказ от ответственности в отношении ориентировочных цен

Prices for alternators and batteries can vary widely based on the factors discussed above. It is advisable to obtain quotes from multiple suppliers and conduct thorough market research to ensure competitive pricing.

Alternatives Analysis: Comparing how to know if it’s the alternator or battery With Other Solutions

Exploring Alternatives for Diagnosing Vehicle Electrical Issues

In the automotive industry, diagnosing whether an issue stems from the alternator or the battery is crucial for effective maintenance and repair. While the traditional approach of testing each component has its merits, exploring alternative methods can offer additional insights and efficiencies. Below, we compare the conventional diagnosis method with two viable alternatives: using a multimeter for voltage testing and relying on a professional diagnostic tool.

| Аспект сравнения | How To Know If It’s The Alternator Or Battery | Multimeter Voltage Testing | Профессиональный диагностический инструмент |

|---|---|---|---|

| Производительность | Effective for basic diagnosis but can lead to misdiagnosis if not executed properly. | High accuracy in measuring voltage output, but requires user knowledge. | Comprehensive diagnostics including error codes and component health. |

| Стоимость | Minimal cost if DIY; potential costs for parts if misdiagnosis occurs. | Low-cost tool, typically under $20. | Higher initial investment, ranging from $100 to $500, depending on features. |

| Простота внедрения | Requires some technical knowledge and can be risky if performed incorrectly. | Simple to use, but accuracy depends on the user’s understanding of readings. | User-friendly interface, often guided by software, making it accessible for all skill levels. |

| Техническое обслуживание | Requires no ongoing maintenance but can lead to more significant repairs if misdiagnosed. | Minimal maintenance; just battery checks needed for the multimeter. | Regular software updates may be needed, along with periodic calibration. |

| Лучший вариант использования | Suitable for basic troubleshooting in a controlled environment. | Ideal for quick checks by mechanics or DIY enthusiasts. | Best for professional workshops needing detailed diagnostics for various vehicles. |

Multimeter Voltage Testing: Pros and Cons

Using a multimeter for voltage testing is a straightforward alternative that allows users to measure the battery and alternator voltage directly. The primary advantage of this method is its accuracy; a healthy alternator should produce around 14 volts when the engine is running. However, this method requires some knowledge about interpreting voltage readings, which can be a barrier for less experienced users. Furthermore, while it can effectively identify a failing alternator or battery, it does not provide a comprehensive overview of the vehicle’s electrical system health.

Illustrative image related to how to know if it’s the alternator or battery

Professional Diagnostic Tool: Advantages and Disadvantages

Professional diagnostic tools represent a more advanced alternative that can streamline the process of identifying electrical issues. These devices are equipped to read error codes and provide insights into the overall health of various vehicle components, including the battery and alternator. Their user-friendly interfaces make them accessible to technicians at all skill levels. However, they come with a higher upfront cost and may require regular updates to maintain accuracy. For businesses operating in regions with diverse vehicle types, this investment can pay off by reducing diagnostic time and improving service efficiency.

Заключение: выбор правильного решения для ваших нужд

When selecting the most suitable method for diagnosing alternator or battery issues, B2B buyers should consider their specific operational needs, budget constraints, and the skill level of their technicians. For businesses seeking a quick, cost-effective solution, voltage testing with a multimeter may suffice. Conversely, those looking for comprehensive diagnostics and improved service turnaround might find that investing in a professional diagnostic tool is the better choice. Ultimately, the right solution will enhance operational efficiency and contribute to effective vehicle maintenance, thereby supporting overall business goals.

Essential Technical Properties and Trade Terminology for how to know if it’s the alternator or battery

Understanding the technical properties and terminology associated with alternators and batteries is crucial for B2B buyers, especially when determining the cause of vehicle electrical issues. Here, we outline key specifications and trade terms that will aid in making informed decisions.

What Are the Key Technical Properties to Identify Battery and Alternator Issues?

1. Выход напряжения

Определение: The voltage output of a battery or alternator indicates its performance level. A healthy alternator typically outputs between 13.5V to 14.5V when the engine is running.

Важность: For B2B buyers, understanding voltage output is essential when assessing whether an alternator is functioning correctly. If the output falls below this range, it may signal a failing alternator, which can lead to operational disruptions.

2. Amp Rating

Определение: The amp rating of a battery indicates its ability to deliver current. For example, a battery might be rated at 600 CCA (Cold Cranking Amps).

Важность: This specification is vital for businesses that rely on vehicles in demanding conditions. A battery’s amp rating affects its starting power and longevity, making it a critical factor in purchasing decisions.

3. Жизнь цикла

Определение: Cycle life refers to the number of discharge and recharge cycles a battery can undergo before its capacity drops significantly.

Важность: Understanding cycle life is crucial for buyers in sectors like transportation and logistics. A battery with a longer cycle life minimizes replacement costs and downtime, enhancing operational efficiency.

4. Internal Resistance

Определение: Internal resistance is a measure of how much the battery resists the flow of electricity. Lower resistance indicates better performance.

Важность: For B2B buyers, a battery with low internal resistance can deliver higher currents efficiently. This is especially significant in applications requiring rapid energy delivery, like starting engines.

5. Temperature Range

Определение: The temperature range indicates the ambient temperatures in which a battery or alternator can operate effectively.

Важность: Buyers in regions with extreme climates should consider temperature ranges to ensure reliability. Products that can withstand higher or lower temperatures reduce the risk of failure in harsh environments.

Каковы общие торговые термины, связанные с генераторами и батареями?

1. OEM (производитель оригинального оборудования)

Определение: OEM refers to products made by the original manufacturer of the vehicle or component.

Важность: Understanding OEM parts is crucial for buyers seeking quality assurance. OEM parts typically have a better fit and reliability, which can reduce long-term costs.

Illustrative image related to how to know if it’s the alternator or battery

2. MOQ (минимальный объем заказа)

Определение: MOQ is the smallest number of units a supplier is willing to sell.

Важность: B2B buyers should be aware of MOQ as it impacts purchasing decisions and inventory management. Knowing the MOQ can help in negotiating better deals and ensuring adequate stock levels.

3. RFQ (запрос предложения)

Определение: An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific goods.

Важность: Utilizing RFQs can streamline the procurement process. B2B buyers can compare quotes from different suppliers, ensuring they get competitive pricing and favorable terms.

4. Инкотермс (Международные торговые термины)

Определение: Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery terms.

Важность: Knowledge of Incoterms is vital for B2B transactions, as they clarify who bears the risk during transit. This understanding can help buyers mitigate risks associated with international shipping.

5. Гарантийный срок

Определение: The warranty period is the time frame during which a manufacturer guarantees the performance of their product.

Важность: Buyers should consider warranty periods as they provide insight into the manufacturer’s confidence in their products. A longer warranty often signifies higher quality and reliability.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions regarding alternators and batteries, leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the how to know if it’s the alternator or battery Sector

What Are the Key Market Dynamics Affecting the Alternator and Battery Sourcing Sector?

The global automotive sector is witnessing a transformative shift, driven by advancements in technology, evolving consumer preferences, and environmental considerations. B2B buyers in regions such as Africa, South America, the Middle East, and Europe, particularly Germany and Saudi Arabia, must stay attuned to these dynamics. The increasing adoption of electric vehicles (EVs) is one of the most significant trends, prompting a heightened demand for both high-capacity batteries and efficient alternators. With governments worldwide imposing stricter emissions regulations, manufacturers are pivoting towards more sustainable and efficient solutions.

Illustrative image related to how to know if it’s the alternator or battery

Emerging technologies, such as smart diagnostics and IoT-enabled vehicles, are reshaping how businesses approach sourcing alternators and batteries. B2B buyers can leverage these technologies to enhance operational efficiency and reduce downtime. For instance, predictive maintenance tools allow companies to identify battery or alternator issues before they escalate, ensuring a smoother supply chain. Moreover, as the market evolves, buyers must also consider the localization of supply chains to mitigate risks associated with global disruptions, such as those seen during the COVID-19 pandemic.

How Can Sustainability and Ethical Sourcing Impact the Alternator and Battery Industry?

Sustainability is becoming a cornerstone of the B2B sourcing strategy, particularly in the alternator and battery sectors. The environmental impact of battery production, especially concerning lithium extraction and heavy metal waste, is prompting buyers to seek suppliers who prioritize ethical sourcing practices. Companies that adopt transparent supply chains and demonstrate commitment to sustainability are likely to gain a competitive edge in the marketplace.

Certifications such as ISO 14001 (Environmental Management) and adherence to Responsible Lithium Guidelines are becoming increasingly important. B2B buyers should prioritize suppliers who can provide these certifications, as they reflect a commitment to minimizing environmental harm. Additionally, the demand for recyclable materials in battery production is rising, with buyers encouraged to seek out products made from sustainable resources. By aligning with environmentally responsible suppliers, businesses can not only improve their brand image but also contribute to global sustainability goals.

What Is the Historical Context of the Alternator and Battery Market?

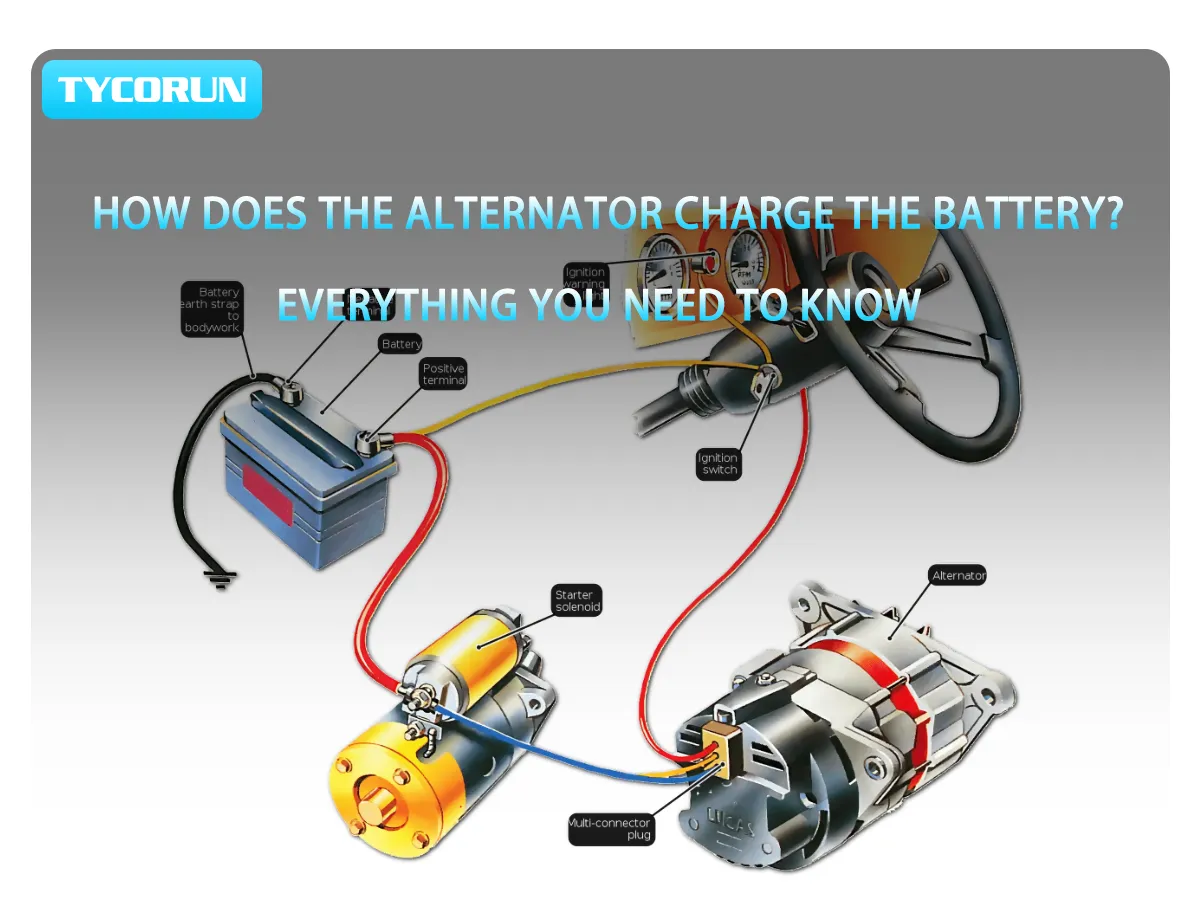

The alternator and battery market has evolved significantly over the last century. Initially, vehicles relied on simple lead-acid batteries and generators, which were less efficient and required frequent maintenance. The introduction of the alternator in the 1960s marked a pivotal shift, as it allowed for more efficient energy generation and improved vehicle reliability. This innovation facilitated the rise of modern electrical systems in vehicles, including enhanced lighting and entertainment options.

As technology progressed, the emergence of hybrid and electric vehicles further transformed the landscape, creating a burgeoning demand for advanced battery technologies. The focus has shifted from merely providing power to incorporating smart technologies that enhance performance and safety. This historical context underscores the need for B2B buyers to understand the evolution of these components as they navigate current market dynamics and sourcing trends. By recognizing the past, businesses can better anticipate future developments and align their sourcing strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of how to know if it’s the alternator or battery

-

How do I determine if the issue is with the alternator or the battery?

To ascertain whether the problem lies with the alternator or the battery, start by checking the battery voltage using a multimeter. A fully charged battery should read around 12.6 volts. Next, start the vehicle and check the voltage again; a functioning alternator should produce between 13.7 to 14.7 volts. If the voltage remains below 12.6 volts while the engine is running, the alternator may be malfunctioning. Additionally, inspect for signs of corrosion on battery terminals and ensure all connections are secure. -

What are the most common signs of a failing alternator?

Common indicators of a failing alternator include dimming headlights, dashboard warning lights, unusual noises (such as grinding or whining), and a battery that frequently discharges. If the vehicle struggles to start or shows signs of electrical failure, these may also point to alternator issues. Regular maintenance checks can help identify these problems early, ensuring your fleet remains operational and minimizing downtime. -

How can I test an alternator safely without risking damage?

The safest method to test an alternator involves using a multimeter. With the vehicle running, measure the voltage at the battery terminals. A healthy alternator should read between 13.7 and 14.7 volts. Avoid risky methods such as disconnecting the battery while the engine is running, as this can damage both the alternator and the vehicle’s electrical systems. Regular checks using a multimeter can prevent costly repairs and ensure reliability. -

What should I consider when sourcing batteries and alternators for my fleet?

When sourcing batteries and alternators, consider the specifications that match your vehicle types, including voltage, size, and capacity. Evaluate supplier reliability, quality certifications, and product warranties. Additionally, inquire about customization options to meet specific operational needs. Building relationships with trusted suppliers can also facilitate better pricing and availability, especially for bulk orders or replacements. -

How do I verify the credibility of a supplier for automotive components?

To verify a supplier’s credibility, check for industry certifications such as ISO or other relevant quality standards. Request references from previous clients and look for online reviews or ratings. Additionally, assess their financial stability and operational history. Engaging in direct communication to discuss your specific needs can also provide insights into their customer service and responsiveness. -

What are the typical payment terms for international purchases of automotive parts?

Payment terms for international purchases can vary significantly based on the supplier and the buyer’s relationship. Common terms include upfront payment, letters of credit, or payment on delivery. Always clarify terms before proceeding, and consider using secure payment methods to protect your investment. It’s advisable to negotiate terms that allow for flexibility, especially in bulk orders. -

Какие логистические соображения следует учитывать при импорте батарей и генераторов?

When importing automotive components, consider shipping methods, lead times, and customs regulations specific to your country. Evaluate potential tariffs and taxes that may apply to your import. Ensure that the supplier can provide the necessary documentation for customs clearance. Additionally, consider local warehousing options to reduce delivery times and enhance inventory management. -

What are the minimum order quantities (MOQ) for automotive parts, and how does it impact pricing?

Minimum order quantities (MOQ) for automotive parts can vary by supplier and product type. Generally, larger orders can lead to reduced per-unit pricing, making it cost-effective for businesses with high volume needs. However, small businesses should negotiate MOQs to avoid overstocking. Understanding the supplier’s pricing structure and flexibility on MOQs can help optimize your purchasing strategy and cash flow.

Top 2 How To Know If It’S The Alternator Or Battery Manufacturers & Suppliers List

1. Nationwide – Alternator and Battery Insights

Домен: blog.nationwide.com

Зарегистрирован: 1994 (31 год)

Введение: Альтернатор: Обеспечивает питание автомобиля при работающем двигателе, служит в течение всего срока службы автомобиля, но может износиться. Признаками неисправности генератора являются тусклый свет в салоне, тусклые или слишком яркие фары, рычащие звуки и запах гари. Аккумулятор: аккумулирует энергию, запускает двигатель, подает электричество в систему зажигания, работает с генератором и регулирует напряжение. Признаками неисправности аккумулятора являются тусклое ...

2. Испытание генератора - риски и рекомендации

Домен: mechanics.stackexchange.com

Зарегистрирован: 2009 (16 лет)

Введение: The text discusses a technique to test an alternator by removing a 12V battery lead while the vehicle is running. It highlights that this method is not recommended due to potential damage to the vehicle’s electronics and the alternator itself. The battery serves to filter spikes and transients, and removing it can lead to damaging the voltage regulator and other components. A safer alternative sug…

Strategic Sourcing Conclusion and Outlook for how to know if it’s the alternator or battery

How Can Strategic Sourcing Enhance Your Understanding of Alternator and Battery Issues?

In the complex landscape of automotive maintenance, distinguishing between alternator and battery failures is crucial for minimizing downtime and maximizing operational efficiency. Key takeaways include the importance of utilizing proper testing methods—such as voltage checks with a multimeter—to accurately diagnose issues. This approach not only ensures that businesses avoid costly misdiagnoses but also fosters a culture of informed decision-making.

Strategic sourcing plays a pivotal role in this process. By partnering with reliable suppliers of automotive components and diagnostic tools, businesses can enhance their service offerings and ensure access to high-quality products. This is particularly vital for international buyers from regions such as Africa, South America, the Middle East, and Europe, where the automotive market is rapidly evolving.

Looking ahead, the integration of advanced diagnostic technologies and strategic supplier relationships will become increasingly essential. By embracing these practices, businesses can not only improve their operational efficiency but also position themselves as leaders in the automotive sector. Engage with trusted suppliers today to optimize your diagnostic capabilities and drive future success.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.