Introduction: Navigating the Global Market for how do i know if its the battery or alternator

In the dynamic landscape of automotive maintenance, understanding how to determine whether it’s the battery or alternator causing electrical issues can be a significant challenge for international B2B buyers. This guide offers a comprehensive examination of the diagnostic processes, helping you navigate the complexities of sourcing reliable parts and services. From recognizing the symptoms of battery and alternator failures to evaluating the best suppliers, this resource is designed to enhance your decision-making capabilities.

As businesses across Africa, South America, the Middle East, and Europe, including markets in Saudi Arabia and Germany, face increasing demands for efficient and reliable automotive solutions, being equipped with the right knowledge is crucial. This guide covers various types of batteries and alternators, their specific applications, and essential tips for vetting suppliers to ensure quality and reliability. Additionally, we delve into cost considerations, allowing you to balance budget constraints with the need for high-performance components.

By empowering you with actionable insights and expert recommendations, this guide will facilitate informed purchasing decisions, ultimately helping your business maintain a competitive edge in the global market. Whether you’re a fleet manager, automotive retailer, or service provider, understanding how to identify the root cause of electrical problems will enhance operational efficiency and customer satisfaction.

Содержание

- Top 3 How Do I Know If Its The Battery Or Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do i know if its the battery or alternator

- Understanding how do i know if its the battery or alternator Types and Variations

- Key Industrial Applications of how do i know if its the battery or alternator

- 3 Common User Pain Points for ‘how do i know if its the battery or alternator’ & Their Solutions

- Strategic Material Selection Guide for how do i know if its the battery or alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how do i know if its the battery or alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do i know if its the battery or alternator’

- Comprehensive Cost and Pricing Analysis for how do i know if its the battery or alternator Sourcing

- Alternatives Analysis: Comparing how do i know if its the battery or alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how do i know if its the battery or alternator

- Navigating Market Dynamics and Sourcing Trends in the how do i know if its the battery or alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do i know if its the battery or alternator

- Strategic Sourcing Conclusion and Outlook for how do i know if its the battery or alternator

- Важное предупреждение и условия использования

Understanding how do i know if its the battery or alternator Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Испытание напряжением | Measures battery voltage with a multimeter; readings indicate health | Авторемонтные мастерские, управление автопарком | Плюсы: Quick diagnostics; Минусы: Requires equipment and knowledge. |

| Нагрузочное тестирование | Тестирование батареи под нагрузкой для оценки производительности | Battery suppliers, automotive service | Плюсы: Accurate health check; Минусы: Equipment needed for testing. |

| Alternator Output Testing | Checks voltage output from alternator while running | Auto parts retailers, vehicle maintenance | Плюсы: Identifies charging issues; Минусы: Requires vehicle to be running. |

| Визуальный осмотр | Looks for physical signs of wear or damage | Fleet operators, vehicle maintenance | Плюсы: No tools required; Минусы: Может не заметить глубинных проблем. |

| Diagnostic Scan Tools | Uses OBD-II scanners to read error codes related to electrical systems | Automotive diagnostics, repair services | Плюсы: Comprehensive insights; Минусы: Requires knowledge of codes. |

What are the Key Features of Voltage Testing for Battery and Alternator Diagnosis?

Voltage testing is a straightforward method to diagnose battery health. By measuring the voltage with a multimeter, businesses can quickly determine if a battery is functioning properly. A healthy battery should read around 12.6 volts. This method is particularly useful for automotive repair shops and fleet management operations where quick diagnostics are essential. However, it requires some technical knowledge and proper equipment, which may not be feasible for all companies.

Какую пользу приносит нагрузочное тестирование покупателям B2B?

Load testing evaluates a battery’s performance under simulated operational conditions. It helps in identifying batteries that may appear healthy but fail under strain. This method is crucial for battery suppliers and automotive service providers to ensure reliability and longevity in their offerings. While it provides accurate assessments, it necessitates specialized testing equipment, which could be a barrier for smaller businesses.

Why is Alternator Output Testing Important for Vehicle Maintenance?

Alternator output testing checks the voltage output while the vehicle is running, ensuring that the alternator is charging the battery effectively. This test is crucial for auto parts retailers and vehicle maintenance services to confirm that the alternator is functioning properly. It typically requires the vehicle to be operational, which may limit its application in some scenarios, but it provides critical insights into the vehicle’s electrical health.

What Advantages Does Visual Inspection Offer?

Visual inspection is a no-cost, immediate approach to identifying potential issues with batteries and alternators. By examining components for signs of wear, corrosion, or physical damage, fleet operators and vehicle maintenance teams can perform basic diagnostics. While this method is accessible and quick, it may overlook hidden problems that require more in-depth testing.

How Do Diagnostic Scan Tools Enhance Electrical System Troubleshooting?

Diagnostic scan tools, particularly OBD-II scanners, provide comprehensive insights into vehicle electrical systems by reading error codes. This technology is invaluable for automotive diagnostics and repair services, offering detailed information about potential issues related to the battery and alternator. Although this method requires a good understanding of the codes and their implications, it significantly enhances troubleshooting efficiency and accuracy.

Illustrative image related to how do i know if its the battery or alternator

Key Industrial Applications of how do i know if its the battery or alternator

| Отрасль/сектор | Specific Application of how do i know if its the battery or alternator | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Ремонт автомобилей | Диагностика неисправностей электрооборудования автомобилей в ремонтных мастерских | Reduces downtime, enhances customer satisfaction, and increases service efficiency | Access to diagnostic tools and training for technicians |

| Транспорт и логистика | Управление автопарком коммерческих транспортных средств | Ensures reliability and safety, minimizes operational disruptions | Durable components suited for varying climates and load conditions |

| Возобновляемые источники энергии | Техническое обслуживание электромобилей и гибридных систем | Promotes sustainability, reduces costs associated with battery failures | Sourcing high-quality batteries and alternators that meet specific energy requirements |

| Строительное оборудование | Power management in heavy machinery | Improves operational efficiency and reduces maintenance costs | Availability of robust electrical components designed for harsh environments |

| Сельское хозяйство | Power systems for agricultural machinery | Enhances productivity and reliability during critical farming operations | Dependable sourcing of batteries and alternators that withstand outdoor conditions |

How is ‘how do I know if it’s the battery or alternator’ used in Automotive Repair?

In automotive repair shops, diagnosing whether a vehicle’s issue stems from the battery or alternator is crucial for efficient service. Technicians utilize diagnostic tools to assess electrical systems, ensuring quick identification of faults. This not only reduces vehicle downtime but also enhances customer satisfaction by providing timely repairs. For international B2B buyers, sourcing reliable diagnostic equipment and training for technicians is vital, particularly in regions with diverse climatic conditions that can affect battery and alternator performance.

What role does ‘how do I know if it’s the battery or alternator’ play in Transportation & Logistics?

In the transportation and logistics sector, fleet management hinges on the reliability of vehicle electrical systems. Knowing whether a battery or alternator issue exists allows fleet managers to preemptively address potential failures, ensuring safety and minimizing operational disruptions. This is especially important in regions like Africa and South America, where road conditions may exacerbate mechanical issues. Buyers should consider sourcing durable components that can withstand varying climates and heavy usage to maintain fleet efficiency.

How does ‘how do I know if it’s the battery or alternator’ benefit Renewable Energy applications?

In the renewable energy sector, particularly with electric and hybrid vehicles, understanding battery and alternator functionality is essential for maintenance. Ensuring that these components operate efficiently promotes sustainability and reduces costs related to battery failures. For buyers in Europe and the Middle East, sourcing high-quality batteries and alternators that meet specific energy requirements is critical. These components must comply with local regulations and standards to ensure reliability and performance.

Illustrative image related to how do i know if its the battery or alternator

Why is ‘how do I know if it’s the battery or alternator’ important for Construction Equipment?

For construction equipment, effective power management is vital for operational efficiency. Knowing whether issues arise from the battery or alternator helps operators maintain machinery reliability, thereby reducing maintenance costs. Given the harsh environments in which construction equipment often operates, international buyers should prioritize sourcing robust electrical components designed to withstand extreme conditions. This ensures that machinery remains functional, which is crucial for meeting project deadlines.

How is ‘how do I know if it’s the battery or alternator’ applied in Agriculture?

In agriculture, the reliability of power systems in machinery is critical for enhancing productivity. Diagnosing whether a battery or alternator issue exists can prevent costly delays during critical farming operations. For B2B buyers in the agricultural sector, sourcing dependable batteries and alternators that can endure outdoor conditions is essential. This includes considering components that offer extended lifespans and can handle the unique challenges posed by agricultural environments.

3 Common User Pain Points for ‘how do i know if its the battery or alternator’ & Their Solutions

Scenario 1: Difficulty Diagnosing Electrical Issues in Fleets

Проблема: For fleet managers overseeing multiple vehicles, diagnosing whether an issue lies with the battery or alternator can be a time-consuming and costly endeavor. A vehicle that won’t start can disrupt logistics and lead to increased operational costs. Moreover, misdiagnosing the problem can result in unnecessary replacements or repairs, further draining resources and impacting fleet efficiency.

Illustrative image related to how do i know if its the battery or alternator

Решение: To effectively determine whether the battery or alternator is at fault, fleet managers should implement a standardized diagnostic protocol. First, invest in quality multimeters to measure battery voltage. A fully charged battery should read around 12.6 volts; anything lower indicates a potential battery issue. If the battery is healthy, start the vehicle and measure the voltage across the battery terminals again. A reading between 13 and 14.5 volts suggests the alternator is functioning correctly. If the voltage fluctuates or remains below 13 volts, it points to alternator failure. Additionally, consider investing in training for your maintenance staff on these diagnostic techniques to reduce downtime and repair costs.

Scenario 2: Unpredictable Electrical Failures in Commercial Vehicles

Проблема: Businesses that rely on commercial vehicles often face unpredictable electrical issues, particularly in harsh environments. Factors like extreme temperatures or water exposure can rapidly degrade battery and alternator performance. When vehicles experience sudden electrical failures, it can jeopardize operations, leading to delays and customer dissatisfaction.

Решение: To mitigate these risks, businesses should establish a preventive maintenance schedule that includes regular inspections of both batteries and alternators. This schedule should incorporate testing under various conditions, such as high temperatures or after exposure to water. Use weatherproof battery enclosures and ensure that alternator belts are not over-tensioned, which can lead to premature wear. Additionally, consider sourcing high-quality, climate-adapted batteries and alternators specifically designed for the regional climate conditions. Educating drivers on recognizing early signs of electrical issues, like dimming lights or slow starts, can also lead to timely interventions before failures occur.

Scenario 3: Costly Repairs Due to Lack of Knowledge

Проблема: Many businesses lack the technical knowledge necessary to effectively troubleshoot battery and alternator issues. This knowledge gap can lead to costly repairs, as employees may not know when to seek professional help or how to accurately diagnose issues. Consequently, businesses risk wasting money on unnecessary replacements, which impacts their bottom line.

Решение: To address this knowledge gap, businesses should invest in training sessions for their staff on the basics of automotive electrical systems. Workshops can cover essential diagnostic techniques, such as how to use a multimeter and interpret voltage readings. Consider partnering with automotive experts or local repair shops to provide these training sessions. Furthermore, creating a simple guide or checklist for diagnosing common symptoms can empower employees to make informed decisions before escalating issues to professional mechanics. This proactive approach not only saves costs but also fosters a culture of knowledge-sharing and continuous improvement within the organization.

Strategic Material Selection Guide for how do i know if its the battery or alternator

Какие материалы обычно используются в аккумуляторах и генераторах?

When diagnosing issues related to vehicle batteries and alternators, the materials used in these components play a crucial role in their performance, durability, and overall effectiveness. Understanding these materials helps B2B buyers make informed decisions, especially when sourcing parts for automotive applications across diverse regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to how do i know if its the battery or alternator

Каковы основные свойства свинцово-кислотных аккумуляторов?

Lead-acid batteries are the most common type used in vehicles. They consist of lead dioxide (PbO2) and sponge lead (Pb) plates submerged in sulfuric acid (H2SO4).

- Ключевые свойства: Lead-acid batteries operate effectively at temperatures ranging from -20°C to 50°C and have a high discharge capacity, making them suitable for starting engines.

- Плюсы и минусы: They are relatively inexpensive and have a proven track record. However, they are heavy, have a limited lifespan (typically 3-5 years), and can suffer from sulfation if not maintained properly.

- Влияние на применение: These batteries are suitable for high current applications, such as starting vehicles, but can be less effective in extreme temperatures without proper insulation.

- Соображения для международных покупателей: Compliance with local environmental regulations regarding lead disposal is critical. Standards such as DIN for performance and safety can guide buyers in Europe and the Middle East.

How Do Lithium-Ion Batteries Compare?

Lithium-ion batteries are gaining traction in automotive applications due to their lightweight and high energy density.

- Ключевые свойства: They operate efficiently at temperatures between -20°C and 60°C and can handle a higher number of charge cycles compared to lead-acid batteries.

- Плюсы и минусы: Their lightweight nature and longer lifespan (up to 10 years) are significant advantages. However, they are more expensive and sensitive to overcharging, which can lead to thermal runaway.

- Влияние на применение: Ideal for electric vehicles and hybrid systems, lithium-ion batteries require advanced management systems to monitor charge levels and temperature.

- Соображения для международных покупателей: Buyers must ensure compliance with international shipping regulations for lithium batteries, especially in regions like Africa and South America, where infrastructure may vary.

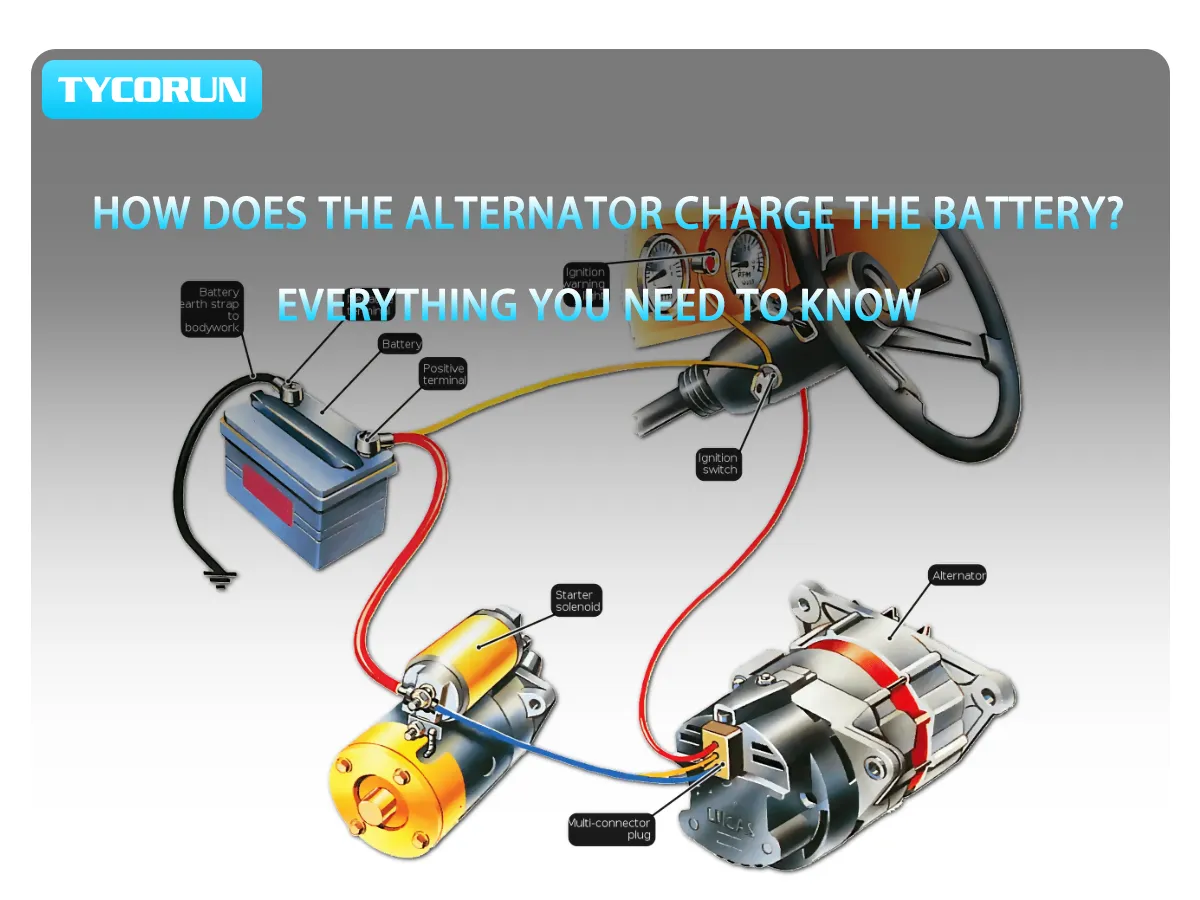

What Materials Are Used in Alternators?

Alternators typically utilize materials like aluminum for the casing and copper for the windings.

- Ключевые свойства: Aluminum is lightweight and corrosion-resistant, while copper offers excellent conductivity, crucial for efficient energy transfer.

- Плюсы и минусы: Aluminum is cost-effective and easy to manufacture, but it may not withstand extreme temperatures as well as other metals. Copper, while more expensive, provides superior performance.

- Влияние на применение: The choice of materials affects the alternator’s efficiency and lifespan. High-quality copper windings can significantly enhance performance under load.

- Соображения для международных покупателей: Buyers should be aware of local manufacturing standards, such as ASTM or JIS, which may dictate material specifications for automotive components.

What Role Does Plastic Play in Battery and Alternator Components?

Plastics are often used for battery casings and alternator housings due to their insulating properties.

- Ключевые свойства: Durable plastics can withstand various environmental conditions, including moisture and temperature fluctuations.

- Плюсы и минусы: They are lightweight and resistant to corrosion, but may degrade over time when exposed to UV light or extreme heat.

- Влияние на применение: The choice of plastic can affect the overall durability of the battery or alternator, especially in regions with harsh climates.

- Соображения для международных покупателей: Compliance with safety standards regarding flammability and chemical resistance is essential, particularly in Europe and the Middle East.

Сводная таблица выбора материалов

| Материал | Typical Use Case for how do i know if its the battery or alternator | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Свинцово-кислотная батарея | Starting vehicles and powering accessories | Экономичный и надежный | Тяжелые и с ограниченным сроком службы | Низкий |

| Литий-ионный аккумулятор | Электрические и гибридные автомобили | Lightweight and long-lasting | Expensive and sensitive to charge | Высокий |

| Алюминий | Alternator casings | Устойчивый к коррозии и легкий | May not withstand extreme heat | Средний |

| Медь | Обмотки в генераторах переменного тока | Отличная проводимость | Higher cost than aluminum | Высокий |

| Пластик | Battery casings and alternator housings | Легкий и прочный | Ультрафиолетовое разрушение с течением времени | Средний |

This analysis provides B2B buyers with a comprehensive understanding of the materials involved in battery and alternator applications, enabling informed purchasing decisions tailored to specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how do i know if its the battery or alternator

What Are the Main Stages in Manufacturing Batteries and Alternators?

The manufacturing processes for batteries and alternators involve several critical stages, each requiring precision and adherence to strict quality standards. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

1. Material Preparation: What Raw Materials Are Essential?

The first step involves sourcing high-quality raw materials. For batteries, this typically includes lead, sulfuric acid, and plastic for the casing. In alternators, copper wire, aluminum housing, and various electronic components are essential. Suppliers must ensure that these materials meet international standards, such as ISO 9001, to guarantee reliability and safety.

2. Формование: как формируются компоненты?

In the forming stage, raw materials are shaped into the necessary components. For batteries, lead plates are cast and then treated to enhance their performance. In alternators, the rotor and stator are fabricated using high-precision machining techniques to ensure they fit together seamlessly. Advanced techniques, such as injection molding for battery casings and stamping for alternator housings, are commonly employed to achieve high production efficiency and consistency.

3. Assembly: What Techniques Are Used for Integration?

The assembly process is crucial for both batteries and alternators. For batteries, lead plates are stacked, and separators are placed between them before being filled with electrolyte. In alternators, the rotor is installed into the stator, and components such as rectifiers and voltage regulators are integrated. Automation is often utilized in assembly lines to minimize human error and enhance productivity. This stage is where quality control measures are critical, as any misalignment can lead to product failure.

4. Finishing: How Are Products Prepared for Market?

The finishing stage involves several processes, including testing, painting, and packaging. For batteries, this might involve applying protective coatings to prevent corrosion. In alternators, electrical testing is performed to ensure that output specifications are met. Both products undergo rigorous inspection to ensure they meet industry standards and are ready for distribution.

What Quality Control Measures Are Essential in Manufacturing?

Quality assurance is paramount in the manufacturing of batteries and alternators. A robust quality control system ensures that products are safe, reliable, and compliant with international standards.

Relevant International Standards: Which Ones Should B2B Buyers Know?

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. In addition, certifications like CE (Conformité Européenne) for compliance in Europe and API (American Petroleum Institute) for specific components are critical. These standards ensure that products meet regulatory and safety requirements in various markets.

Каковы ключевые контрольные точки контроля качества?

Контроль качества обычно включает в себя несколько контрольных точек на протяжении всего производственного процесса:

-

Входящий контроль качества (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. Suppliers should provide certificates of conformity to validate that materials meet specified standards.

-

Контроль качества в процессе производства (IPQC): During manufacturing, IPQC checks are conducted to monitor production processes. This includes inspections at various stages to catch defects early.

-

Окончательный контроль качества (FQC): Before products are shipped, FQC ensures that the finished goods meet all quality and performance standards. This often includes electrical testing for batteries and alternators.

Какие общие методы тестирования используются для обеспечения качества?

Various testing methods are utilized in the quality assurance process:

-

Voltage and Current Testing: For batteries, voltage tests are performed to ensure they are fully charged and capable of delivering the required current. Alternators undergo similar tests to verify their output voltage and amperage under load.

-

Испытания на выносливость: Batteries may be subjected to cycling tests to assess their lifespan and performance under repeated charge and discharge cycles. Alternators are tested for durability under various operating conditions.

-

Экологические испытания: This involves simulating extreme conditions to evaluate product performance and reliability, particularly important for markets with harsh climates.

Как покупатели B2B могут проверить контроль качества поставщиков?

Due diligence is essential when selecting suppliers for batteries and alternators. B2B buyers can take several steps to verify the quality control practices of potential partners:

What Role Do Audits and Reports Play?

Conducting supplier audits can provide insight into their quality management systems. Buyers should request reports detailing quality control processes, including results from IQC, IPQC, and FQC. These documents can reveal the supplier’s commitment to maintaining high standards.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can offer an additional layer of assurance. These independent evaluators assess compliance with international standards and verify that the supplier’s quality control measures are effective. This is particularly valuable in international trade, where standards may vary by region.

Каковы нюансы контроля качества для международных B2B-покупателей?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Соблюдение нормативных требований: Different regions have varying regulatory requirements. Understanding these can help buyers ensure that products meet local standards, avoiding costly delays and penalties.

-

Культурные аспекты: Building relationships with suppliers may require understanding cultural differences in business practices. Open communication about quality expectations is vital for successful partnerships.

-

Logistics and Supply Chain Management: International shipping can introduce risks to product integrity. Buyers should inquire about how suppliers manage logistics and what measures they take to ensure that products arrive in optimal condition.

In conclusion, the manufacturing processes and quality assurance for batteries and alternators are intricate and require adherence to rigorous standards. B2B buyers must be proactive in assessing potential suppliers, focusing on quality control measures, and ensuring compliance with international standards. By understanding these processes, buyers can make informed decisions that enhance their operations and minimize risks in their supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do i know if its the battery or alternator’

Введение

In the automotive sector, understanding whether a vehicle’s issue stems from the battery or alternator is crucial for efficient troubleshooting and maintenance. This guide provides B2B buyers with a comprehensive checklist to ensure they make informed decisions when sourcing components or services related to battery and alternator diagnostics.

Шаг 1: Identify Your Diagnostic Needs

Before sourcing, clearly define what specific problems you are addressing. Understanding whether you need diagnostic tools, replacement parts, or maintenance services will help narrow down potential suppliers. Consider the common issues faced in your region, such as temperature extremes or frequent short trips, which may affect battery and alternator performance.

Шаг 2: Экспертиза поставщиков

Assess suppliers based on their expertise in automotive electrical systems. Look for suppliers that specialize in batteries and alternators, as they are more likely to provide accurate diagnostics and quality products. Verify their experience in your specific market conditions, especially if you operate in regions like Africa or the Middle East, where environmental factors can significantly impact component longevity.

Шаг 3: Evaluate Component Quality

Quality is paramount when selecting batteries and alternators. Request specifications and certifications that ensure the products meet international standards. Pay attention to warranties offered, as a longer warranty can indicate a manufacturer’s confidence in their product’s reliability and performance.

Шаг 4: Check for Compatibility

Ensure that the components you are considering are compatible with the vehicles in your fleet. Different vehicles require specific battery sizes and alternator outputs. Use manufacturer specifications to cross-reference and validate compatibility, which helps prevent costly errors and downtime.

Шаг 5: Assess Technical Support and After-Sales Service

Reliable technical support can be invaluable, especially when troubleshooting complex electrical issues. Inquire about the availability of after-sales services, such as installation support, warranty claims, and customer service responsiveness. A supplier that offers robust support can help minimize disruptions to your operations.

Шаг 6: Gather Customer Feedback and Reviews

Seek out customer testimonials and case studies from other businesses that have purchased from the suppliers you are considering. Positive feedback regarding product performance and supplier reliability can guide your decision. Engage with industry forums and networks to gain insights from peers about their experiences with specific brands and suppliers.

Шаг 7: Переговоры об условиях и ценах

Once you have shortlisted potential suppliers, engage in discussions about pricing and terms. Don’t hesitate to negotiate, especially if you are looking to make bulk purchases or establish long-term partnerships. A favorable agreement can improve your margins and ensure a sustainable supply chain.

By following this checklist, B2B buyers can ensure they are equipped to accurately diagnose battery and alternator issues, leading to more effective maintenance and ultimately enhancing vehicle reliability.

Comprehensive Cost and Pricing Analysis for how do i know if its the battery or alternator Sourcing

Understanding the cost structure and pricing factors associated with diagnosing battery or alternator issues is crucial for B2B buyers in the automotive sector. This section outlines the key components that influence costs and pricing, providing actionable insights for international buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

What Are the Main Cost Components in Sourcing Battery and Alternator Diagnostics?

When sourcing components or services related to diagnosing battery or alternator issues, several cost components come into play:

-

Материалы: The primary materials include batteries, alternators, and diagnostic tools (like multimeters). Quality materials can significantly affect both performance and longevity, impacting the total cost.

-

Трудовые ресурсы: Skilled technicians are required for diagnostics and repairs. Labor costs can vary greatly by region, with higher wages typically found in Europe compared to South America or Africa. Additionally, training costs for technicians can also be factored in.

-

Производственные накладные расходы: This includes costs related to factory operations, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can lower overhead costs and ultimately influence pricing.

-

Инструменты: Specialized tools for diagnostics and repairs, such as multimeters and diagnostic software, contribute to initial setup costs. The investment in quality tooling can lead to more accurate diagnostics and reduced labor time.

-

Контроль качества (КК): Ensuring that components meet industry standards requires investment in quality control processes. This is essential for maintaining reliability in battery and alternator diagnostics.

-

Логистика: Shipping costs can vary based on the distance and method of transportation. International shipping can introduce additional fees, customs duties, and potential delays, affecting the overall cost.

-

Маржа: Suppliers typically build a margin into their pricing, which can vary based on competition, market demand, and the perceived value of the products or services.

How Do Price Influencers Affect the Cost of Battery and Alternator Diagnostics?

Several factors influence the final price of battery and alternator diagnostic services and components:

Illustrative image related to how do i know if its the battery or alternator

-

Объем/MOQ (минимальный объем заказа): Larger orders often attract bulk pricing discounts. Buyers should consider pooling orders with other businesses to achieve better pricing.

-

Технические характеристики/Индивидуальная настройка: Custom specifications can lead to higher costs. Standardized parts are generally less expensive, so buyers should weigh the benefits of customization against the potential cost increases.

-

Материалы: The choice of materials impacts durability and performance. Higher-quality materials often come at a premium but may reduce long-term costs due to fewer replacements.

-

Качество/Сертификаты: Products that meet specific industry certifications may be priced higher due to the added assurance of quality. B2B buyers should prioritize certified products for reliability.

-

Факторы, связанные с поставщиками: Supplier reputation and reliability can affect pricing. Established suppliers may charge more but offer better support and warranty options.

-

Инкотермс: Understanding international shipping terms is crucial. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact total costs and risk management during transport.

What Are the Best Practices for B2B Buyers in Negotiating Costs?

To optimize costs and ensure value, B2B buyers should consider the following strategies:

-

Переговоры: Engage suppliers in discussions about pricing. Highlighting long-term partnerships or potential bulk orders can lead to favorable terms.

-

Экономическая эффективность: Assess the total cost of ownership, which includes purchase price, maintenance, and operational costs. Sometimes, lower upfront costs may lead to higher long-term expenses.

-

Нюансы ценообразования для международных покупателей: Be aware of currency fluctuations and local economic conditions that may affect pricing. Additionally, consider the implications of tariffs and import duties when sourcing from different regions.

Заключение

This comprehensive analysis equips B2B buyers with essential knowledge about the cost structure and pricing dynamics associated with battery and alternator diagnostics. By understanding these components and leveraging best practices, buyers can make informed decisions that optimize their procurement strategies while ensuring quality and reliability in their operations. Please note that prices can vary widely based on specific circumstances and supplier relationships, so it’s advisable to obtain multiple quotes and conduct thorough market research.

Alternatives Analysis: Comparing how do i know if its the battery or alternator With Other Solutions

Introduction: Exploring Alternatives to Diagnosing Battery and Alternator Issues

In the automotive industry, diagnosing issues related to battery and alternator failures is crucial for maintaining vehicle performance and reliability. While understanding whether a problem lies with the battery or alternator is essential, exploring alternative solutions can provide B2B buyers with a broader perspective on diagnosing electrical system issues effectively. This analysis compares traditional diagnostic methods with newer technologies and approaches that can aid in identifying these problems accurately and efficiently.

Сравнительная таблица

| Аспект сравнения | How Do I Know If It’s The Battery Or Alternator | Диагностические сканеры | Battery Load Testers |

|---|---|---|---|

| Производительность | Effective in identifying specific issues | High accuracy, can read multiple systems | Good for battery health, limited for alternators |

| Стоимость | Low-cost, requires basic tools like multimeter | Moderate to high investment | Moderate investment |

| Простота внедрения | Requires basic knowledge of vehicle systems | User-friendly with training | Simple to use, requires some knowledge |

| Техническое обслуживание | Minimal; periodic checks recommended | Необходимы обновления программного обеспечения | Calibration required occasionally |

| Лучший вариант использования | Quick checks for DIY enthusiasts | Comprehensive diagnostics for professionals | In-depth battery testing in workshops |

Подробная разбивка альтернатив

1. Diagnostic Scanners

Diagnostic scanners are advanced tools used to diagnose a wide range of vehicle issues, including problems with the battery and alternator. They connect to the vehicle’s onboard diagnostics (OBD-II) port and can provide real-time data on various systems.

Плюсы:

– High accuracy and efficiency in diagnosing multiple vehicle systems beyond just the battery and alternator.

– User-friendly interfaces make it accessible for technicians with varying levels of expertise.

Минусы:

– Higher upfront costs can deter small businesses or individual mechanics.

– Requires software updates and occasional training to keep up with new vehicle technologies.

Illustrative image related to how do i know if its the battery or alternator

2. Battery Load Testers

Battery load testers are specialized tools designed to measure the health and capacity of a vehicle’s battery under load conditions. This method simulates the battery’s performance during engine start-up, providing a clear indication of its ability to hold a charge.

Плюсы:

– Provides in-depth insights into battery health, helping to prevent future failures.

– Simple to use, making it suitable for quick checks in various settings.

Минусы:

– Limited ability to diagnose alternator issues; primarily focuses on battery performance.

– Calibration may be required occasionally to ensure accurate readings, adding to maintenance needs.

Заключение: выбор правильного решения для ваших нужд

Selecting the right diagnostic method for identifying battery or alternator issues depends on specific business needs, budget constraints, and technical expertise. For B2B buyers, understanding the performance, cost, and ease of implementation of each alternative is essential. Diagnostic scanners may be ideal for businesses looking for comprehensive solutions, while battery load testers provide a focused approach for battery health checks. Ultimately, aligning the chosen method with the operational requirements and technical capabilities of the team will ensure efficient and effective vehicle maintenance.

Essential Technical Properties and Trade Terminology for how do i know if its the battery or alternator

What Are the Key Technical Properties to Consider for Batteries and Alternators?

When evaluating whether a battery or alternator is the source of electrical issues in vehicles, understanding critical technical specifications is essential for B2B buyers. Here are several key properties:

-

Номинальное напряжение

The voltage rating indicates the electrical potential difference that a battery or alternator can provide. A standard car battery typically has a nominal voltage of 12 volts, while an alternator generally outputs between 13 to 14.5 volts. For B2B buyers, this specification is crucial for compatibility with vehicle electrical systems and ensuring adequate power supply for vehicle operations. -

Выходная сила тока

Amperage measures the electric current a battery or alternator can deliver. Alternators range from 130 to over 400 amps, depending on the vehicle type and electrical demands. Understanding amperage is vital when considering vehicles with high-power accessories, such as sound systems or additional lighting, ensuring that the alternator can sufficiently support all electrical loads. -

Амперы холодного пуска (CCA)

CCA is a critical specification for batteries, representing their ability to start an engine in cold temperatures. A higher CCA rating means better performance in harsh climates. For businesses operating in regions with extreme temperatures, selecting batteries with appropriate CCA ratings can prevent operational downtime and enhance vehicle reliability. -

Срок службы

Cycle life refers to the number of charge and discharge cycles a battery can undergo before its capacity significantly degrades. This property is particularly important for companies managing fleets, as longer cycle life can result in reduced replacement costs and improved operational efficiency over time. -

Состав материала

The materials used in battery and alternator construction, such as lead-acid for batteries or aluminum and copper for alternators, affect durability and performance. B2B buyers should consider material properties to ensure longevity and resistance to environmental conditions, which is particularly relevant in diverse climates across Africa, South America, the Middle East, and Europe.

What Are Common Trade Terms Relevant to Battery and Alternator Procurement?

Understanding industry jargon is equally important for B2B buyers. Here are some commonly used terms:

-

OEM (производитель оригинального оборудования)

OEM refers to parts made by the original manufacturer of the vehicle. Using OEM components ensures compatibility and reliability. For buyers, opting for OEM parts can reduce the risk of performance issues and warranty claims. -

MOQ (минимальный объем заказа)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for inventory management, as it helps businesses plan their purchasing strategies to avoid excess stock or shortages. -

RFQ (запрос предложения)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This term is critical for B2B buyers looking to source batteries or alternators, as it helps in comparing costs and negotiating favorable terms. -

Инкотермс (Международные торговые термины)

Incoterms define the responsibilities of buyers and sellers in international shipping. They clarify who pays for shipping, insurance, and tariffs, helping businesses navigate cross-border transactions efficiently. -

Гарантийный срок

The warranty period is the time frame during which a product is guaranteed to be free from defects. For B2B buyers, understanding warranty terms is crucial for assessing long-term costs and ensuring protection against potential failures. -

Испытания на стенде

Bench testing refers to evaluating the performance of a battery or alternator outside of the vehicle. This process can identify issues before installation, minimizing the risk of operational failures and ensuring that purchased components meet specified standards.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding the procurement of batteries and alternators, ultimately enhancing the reliability and efficiency of their operations.

Navigating Market Dynamics and Sourcing Trends in the how do i know if its the battery or alternator Sector

What Are the Key Market Trends Impacting Battery and Alternator Sourcing?

The global market for automotive batteries and alternators is evolving rapidly, influenced by technological advancements and changing consumer preferences. One of the primary drivers is the increasing adoption of electric vehicles (EVs) and hybrids, which rely on advanced battery technology. This shift is particularly pronounced in regions like Europe and the Middle East, where stringent emissions regulations are pushing manufacturers to innovate. Additionally, the rise of smart automotive technologies, including diagnostic tools for troubleshooting battery and alternator issues, is reshaping sourcing strategies.

International B2B buyers, especially from Africa and South America, are also seeing a surge in demand for reliable automotive parts due to growing vehicle ownership and infrastructure development. Suppliers are increasingly utilizing e-commerce platforms to reach these markets, allowing for easier access to quality parts. Emerging trends include the integration of IoT in battery management systems, enabling real-time monitoring and predictive maintenance, which can significantly reduce downtime and improve fleet management.

Illustrative image related to how do i know if its the battery or alternator

How Is Sustainability Shaping the Sourcing of Batteries and Alternators?

Sustainability is becoming a critical consideration for B2B buyers in the automotive sector. The environmental impact of battery production and disposal has prompted a shift towards ethical sourcing and sustainable materials. Buyers are increasingly seeking suppliers that prioritize eco-friendly practices, such as using recycled materials in battery manufacturing and ensuring responsible sourcing of raw materials. This trend is especially relevant in markets like Europe, where consumers are more environmentally conscious.

Furthermore, certifications such as ISO 14001 for environmental management systems are becoming essential for suppliers looking to establish credibility in the market. By investing in sustainable practices, businesses not only comply with regulations but also enhance their brand reputation and appeal to a growing segment of eco-aware consumers. This shift towards sustainability can also lead to cost savings in the long run, as efficient practices reduce waste and resource consumption.

What Is the Historical Context of Battery and Alternator Development for B2B Buyers?

The evolution of automotive batteries and alternators has been marked by significant technological advancements. Initially, lead-acid batteries dominated the market due to their low cost and adequate performance. However, with the increasing demand for more efficient and longer-lasting power sources, lithium-ion batteries have gained prominence, especially in the EV sector. This transition has been accompanied by innovations in alternator technology, which now often includes features like variable output to better support modern vehicle electrical systems.

For B2B buyers, understanding this historical context is vital as it informs sourcing decisions. As manufacturers continue to innovate, buyers must stay informed about the latest technologies and their implications for vehicle performance and maintenance. This knowledge enables buyers to make strategic decisions that align with market trends and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of how do i know if its the battery or alternator

-

How do I determine if my vehicle’s issue is with the battery or alternator?

To diagnose whether the problem lies with the battery or alternator, start by observing your vehicle’s behavior. If the engine fails to start and you hear a clicking sound, it’s likely a battery issue. Conversely, if the vehicle starts but dies shortly after, the alternator may not be charging the battery properly. Use a multimeter to measure battery voltage; a healthy battery should read around 12.6 volts. For the alternator, check the voltage while the engine runs; it should be between 13 to 14.5 volts. If fluctuating, the alternator may need inspection. -

What symptoms indicate a failing battery versus a failing alternator?

Common symptoms of a failing battery include slow engine cranking, clicking sounds upon starting, and dim headlights. In contrast, a failing alternator often manifests as flickering dashboard lights, unusual noises, or a battery warning light on the dashboard. Additionally, if electrical accessories malfunction or the vehicle stalls after starting, it points to alternator issues. Understanding these symptoms can help you source the right replacement parts quickly. -

What are the common causes of battery and alternator failures?

Battery and alternator failures can stem from various factors, including age, extreme temperatures, and poor driving habits like frequent short trips that prevent full recharging. Corrosion at battery terminals can also impede performance. For alternators, exposure to moisture or improper installation can lead to premature failure. Regular maintenance, including cleaning terminals and ensuring proper installation, can mitigate these issues. -

How can I ensure quality when sourcing batteries or alternators internationally?

When sourcing batteries or alternators from international suppliers, prioritize vendors with a strong reputation for quality and reliability. Look for certifications that comply with international standards, such as ISO or CE. Request samples and conduct thorough quality assurance tests before bulk purchases. Additionally, consider suppliers that provide detailed product specifications and have a transparent return policy in case of defects. -

What is the minimum order quantity (MOQ) for batteries and alternators from suppliers?

MOQs for batteries and alternators vary significantly by supplier and product type. Some manufacturers may allow orders as low as 50 units, while others may require a minimum of 500 or more. It’s crucial to discuss MOQ directly with suppliers during negotiations and assess if they can accommodate smaller orders, especially for new or trial products. This flexibility can be beneficial for businesses looking to test market demand before committing to larger quantities. -

What payment terms should I expect when purchasing batteries or alternators?

Payment terms can vary widely among suppliers. Common terms include net 30, net 60, or cash in advance, especially for first-time buyers. It’s advisable to negotiate terms that provide sufficient time for product inspection and market response. Consider using secure payment methods such as letters of credit or escrow services to protect your investment, particularly for larger transactions or new supplier relationships. -

How can I manage logistics when importing batteries or alternators?

Effective logistics management is crucial for importing batteries or alternators. Work with freight forwarders experienced in handling automotive parts, as they understand the specific regulations and documentation required. Ensure compliance with local customs regulations and tariffs in your country. Additionally, plan for potential delays by allowing extra time in your supply chain for customs clearance and transportation. -

What are the best practices for maintaining batteries and alternators to extend their lifespan?

To extend the lifespan of batteries and alternators, implement regular maintenance practices. For batteries, ensure terminals are clean and free of corrosion, and consider using a trickle charger for vehicles that are not frequently driven. For alternators, monitor the voltage output and inspect for loose or worn belts regularly. Educating drivers about proper vehicle operation can also help minimize wear and tear on these components.

Top 3 How Do I Know If Its The Battery Or Alternator Manufacturers & Suppliers List

1. Nissan Altima – Power Diagnosis Essentials

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: The discussion revolves around diagnosing issues related to a 2009 Nissan Altima that has no power. Key components involved are the battery, alternator, and starter. The battery provides power to the vehicle’s electronics and the starter, while the alternator charges the battery when the engine is running. A dead battery is suspected, potentially due to a bad alternator that failed to charge it, l…

2. Nationwide – Alternator and Battery Insights

Домен: blog.nationwide.com

Зарегистрирован: 1994 (31 год)

Введение: Alternator: Powers the car when the engine is running, charges the battery, typically lasts the lifetime of the car but can wear out. Signs of a bad alternator include dim interior lights, fluctuating headlights, growling noises, and burning smells. Battery: Stores power, starts the engine, powers electronics, regulates voltage, lasts 3-5 years. Signs of a bad battery include dim dashboard lights,…

3. Protyre – Automotive Services & Premium Tyres

Домен: protyre.co.uk

Зарегистрирован: 1999 (26 лет)

Введение: Protyre offers a range of automotive services including battery replacement, MOTs, servicing, and vehicle repairs. They provide premium tyres from leading brands such as Michelin, Pirelli, Goodyear, and Bridgestone, as well as mid-range and economy options. Customers can book services online or over the phone and can find local garages using their postcode.

Strategic Sourcing Conclusion and Outlook for how do i know if its the battery or alternator

In navigating the complexities of diagnosing whether a battery or alternator issue is at play, strategic sourcing emerges as an invaluable asset for B2B buyers. Understanding the interplay between these two components is essential for making informed purchasing decisions, especially in international markets where vehicle reliability is paramount. By leveraging detailed diagnostics and sourcing quality parts, businesses can mitigate downtime and enhance operational efficiency.

Investing in high-quality batteries and alternators not only supports vehicle performance but also aligns with a proactive maintenance strategy. This approach can significantly reduce long-term costs associated with frequent replacements and repairs. Furthermore, fostering relationships with reputable suppliers ensures access to the latest technology and advancements in automotive components, catering to diverse market needs across Africa, South America, the Middle East, and Europe.

As the automotive landscape continues to evolve, staying ahead of potential electrical issues will be crucial for maintaining a competitive edge. We encourage international buyers to engage with trusted suppliers and invest in robust diagnostic tools. This proactive stance will not only improve vehicle longevity but also drive overall business success in a rapidly changing market environment.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.