Введение: Навигация по глобальному рынку пусковых двигателей

Поиск поставщиков пускателей электродвигателей может стать сложной задачей для международных покупателей B2B, особенно для тех, кто работает на различных рынках Африки, Южной Америки, Ближнего Востока и Европы. При наличии различных типов пускателей электродвигателей, каждый из которых предназначен для конкретных областей применения - от промышленного оборудования до систем отопления, вентиляции и кондиционирования воздуха - задача заключается в выборе правильного продукта, отвечающего эксплуатационным требованиям и обеспечивающего надежность и эффективность. Данное руководство призвано разъяснить мир пускателей электродвигателей, предоставив исчерпывающий обзор различных типов, областей их применения и важнейших характеристик, влияющих на принятие решения о покупке.

Помимо изучения технических характеристик продукции, в данном руководстве рассматриваются такие важные аспекты, как процессы проверки поставщиков, стоимость и соответствие международным стандартам. Понимание этих факторов очень важно для принятия взвешенных решений, соответствующих стратегическим целям вашего бизнеса. Вооружив вас знаниями, необходимыми для навигации по глобальному рынку, мы дадим вам возможность уверенно взаимодействовать с поставщиками, оптимизировать стратегию закупок и, в конечном счете, повысить эксплуатационные характеристики вашего оборудования. Независимо от того, являетесь ли вы опытным покупателем или новичком на рынке, данное руководство послужит вам бесценным источником информации, позволяющим приобрести пускатели электродвигателей, наилучшим образом отвечающие вашим потребностям.

Содержание

- Список лучших 2 производителей и поставщиков стартера двигателя

- Введение: Навигация по глобальному рынку пусковых двигателей

- Понимание типов и разновидностей стартеров для электродвигателей

- Основные промышленные применения пускового двигателя стартера

- 3 распространенных болевых точки пользователей для ‘starter motor starter’ и их решения

- Руководство по выбору стратегических материалов для пускателя двигателя

- Глубокий взгляд: Производственные процессы и контроль качества для стартера двигателя

- Практическое руководство по поиску: Пошаговый контрольный список для ‘стартер двигателя стартер’

- Всесторонний анализ затрат и цен на пусковой двигатель стартера Sourcing

- Анализ альтернатив: Сравнение стартера двигателя с другими решениями

- Основные технические свойства и торговая терминология для пускового двигателя стартера

- Навигация по динамике рынка и тенденциям поиска поставщиков в секторе стартеров для электродвигателей

- Часто задаваемые вопросы (FAQ) для B2B покупателей стартера двигателя стартера

- Стратегическое заключение по поиску и перспективы для пускателя двигателя

- Важное предупреждение и условия использования

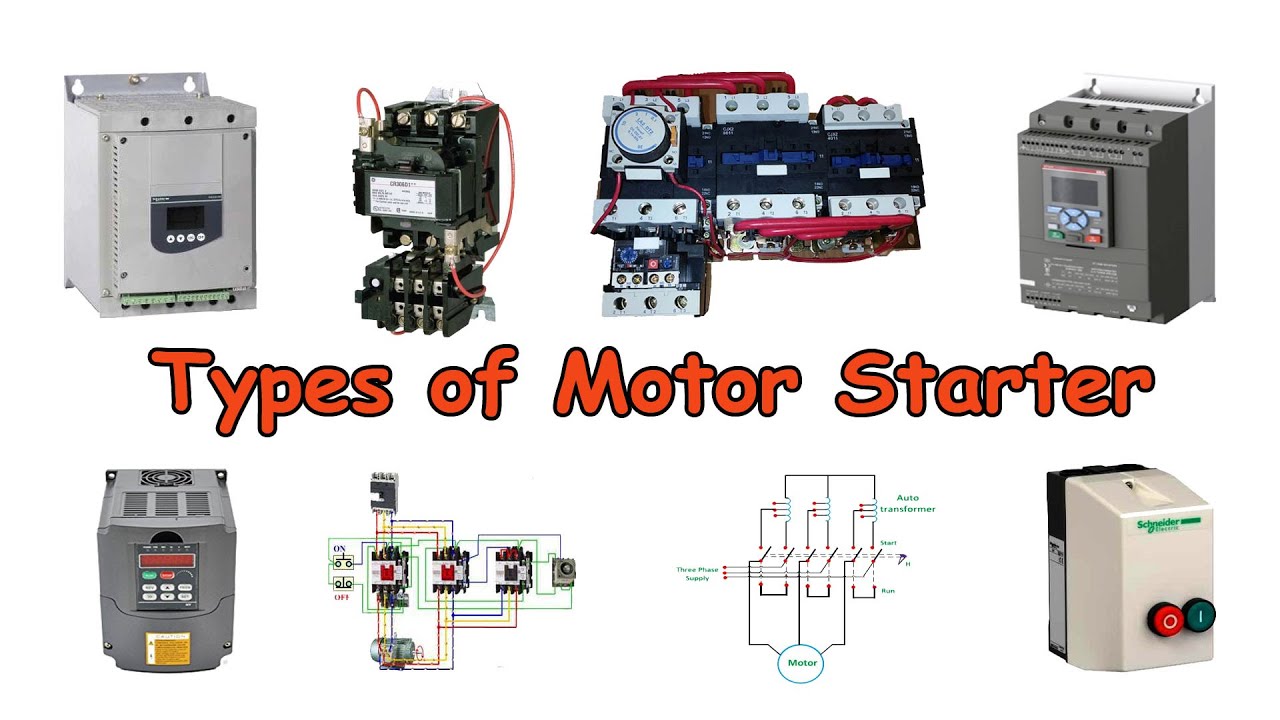

Понимание типов и разновидностей стартеров для электродвигателей

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Ручной пускатель двигателя | Простое включение/выключение, без автоматического перезапуска | Малое оборудование, системы отопления, вентиляции и кондиционирования воздуха | Плюсы: Экономичность, простота установки. Минусы: Риск автоматического перезапуска после потери питания. |

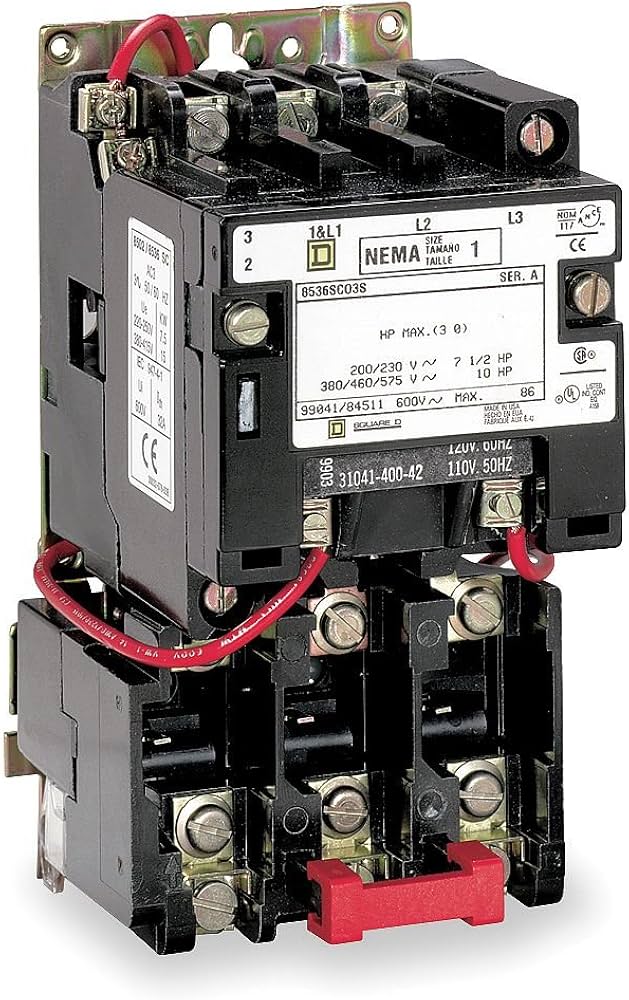

| Магнитный пускатель двигателя | Использует катушку для подачи напряжения на контакты, включает реле перегрузки | Промышленные двигатели, насосы, конвейеры | Плюсы: Надежность, встроенная защита, компактность. Минусы: Ограниченно подходит для двигателей малой мощности, высокий пусковой ток. |

| Стартер через линию (ATL) | Работа при полном напряжении, требует перезапуска после потери питания | Насосы, системы отопления, вентиляции и кондиционирования воздуха, общепромышленное применение | Плюсы: Экономичный, защита от перегрузки. Минусы: Высокий пусковой ток может повредить оборудование. |

| Полный реверс напряжения (FVR) | Позволяет изменять направление вращения двигателя, использует контакторы с блокировкой | Конвейерные системы, краны | Плюсы: Универсальны для управления направлением, защиты от перегрузки. Минусы: Сложность в проводке. |

| Автоматический трансформаторный пускатель | Снижение пускового напряжения, высокий пусковой момент | Крупные промышленные двигатели, тяжелое оборудование | Плюсы: Минимизирует электрическое напряжение, увеличивает срок службы двигателя. Минусы: Более высокая начальная стоимость. |

Каковы характеристики ручных пускателей двигателей?

Ручные пускатели двигателей отличаются простой конструкцией, позволяющей пользователям вручную запускать и останавливать двигатели с помощью кнопки или поворотной ручки. Такие пускатели обычно используются в небольших машинах и системах отопления, вентиляции и кондиционирования воздуха, где простота и экономичность имеют первостепенное значение. Хотя они просты в установке и обслуживании, покупателям следует помнить о риске автоматического перезапуска после перебоев в подаче электроэнергии, что может создать проблемы с безопасностью в некоторых областях применения.

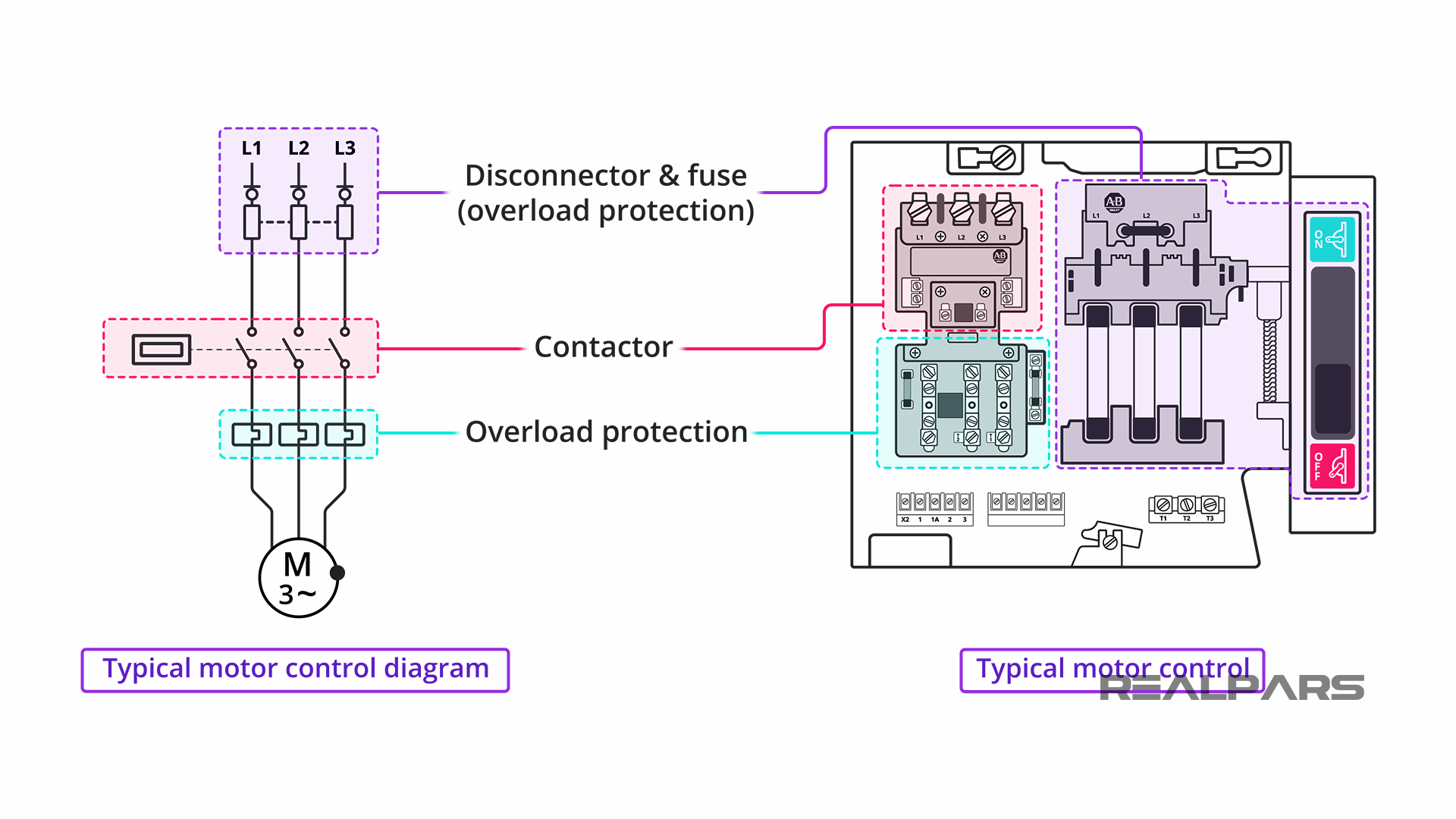

Как работают магнитные пускатели двигателей?

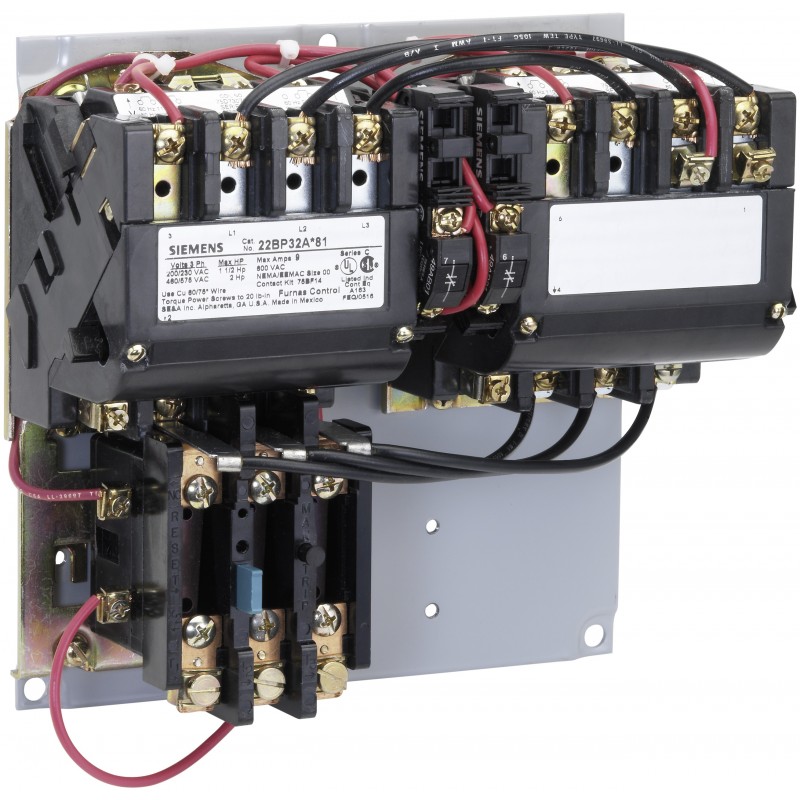

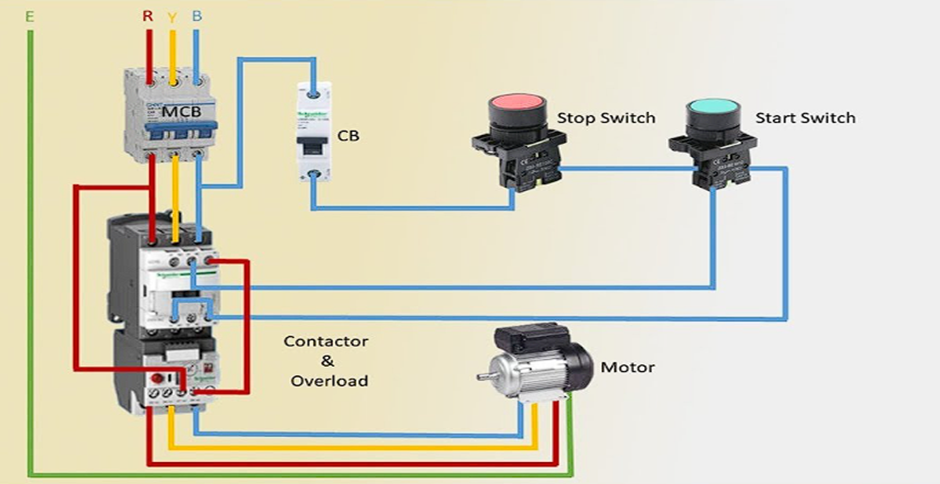

Магнитные пускатели двигателей работают за счет подачи напряжения на катушку для размыкания и замыкания контактов, обеспечивая надежный способ управления работой двигателя. Они оснащены реле перегрузки для защиты двигателей от перегрева и перегрузки по току, что делает их подходящими для промышленных установок, насосов и конвейеров. Покупателям B2B стоит обратить внимание на их компактную конструкцию и встроенные функции защиты, хотя они ограничены применениями малой мощности и могут создавать высокие пусковые токи, которые могут повлиять на стабильность системы.

Каковы преимущества стартеров Across the Line (ATL)?

Пускатели ATL подают полное напряжение на двигатели, что делает их простыми и экономичными для использования в различных промышленных приложениях, таких как насосы и системы отопления, вентиляции и кондиционирования воздуха. Они требуют ручного перезапуска после потери питания, что может быть полезно для безопасности в определенных сценариях. Хотя они обеспечивают защиту от перегрузки, покупатели должны учитывать, что высокие пусковые токи могут привести к потенциальным повреждениям и перепадам напряжения, что требует тщательного рассмотрения при выборе.

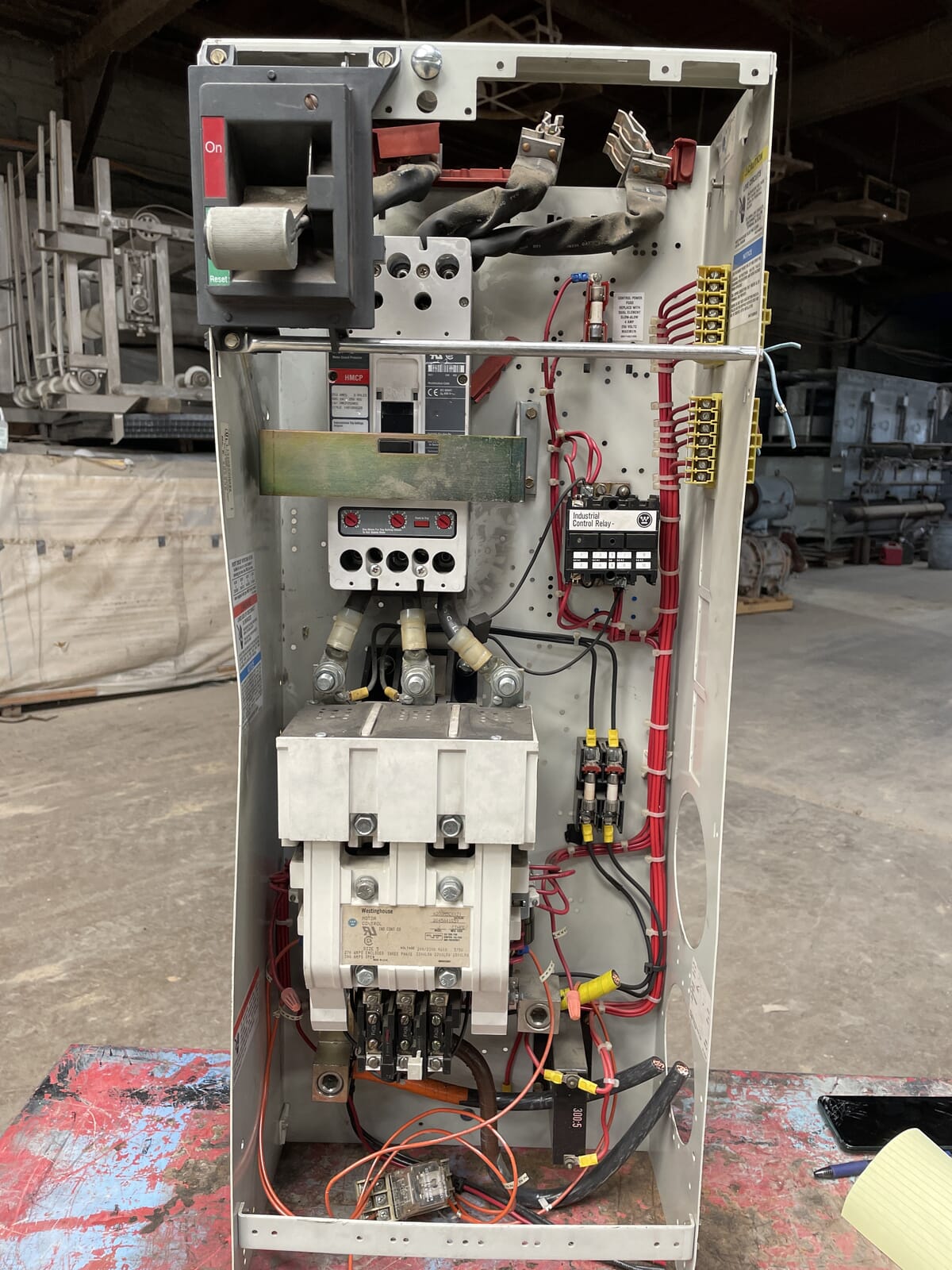

Иллюстративное изображение, относящееся к стартеру двигателя стартера

Когда следует обратить внимание на пускатели с полным реверсом напряжения (FVR)?

Реверсивные пускатели полного напряжения идеально подходят для систем, требующих управления направлением вращения двигателя, таких как конвейерные системы и краны. В этих пускателях используются блокированные контакторы, предотвращающие одновременное замыкание, что повышает безопасность. Хотя они обеспечивают универсальность в работе, сложность подключения и установки может стать недостатком для некоторых покупателей. Необходимо взвесить преимущества управления направлением и потенциальные затраты на установку.

Почему стоит выбрать автотрансформаторные пускатели для больших двигателей?

Автотрансформаторные пускатели предназначены для снижения пускового напряжения, что минимизирует электрическую нагрузку на крупные промышленные двигатели, тем самым увеличивая их срок службы и производительность. Они особенно полезны в тяжелом оборудовании, где требуется высокий пусковой момент. Однако первоначальные инвестиции обычно выше, чем у других типов пускателей, поэтому покупателям B2B следует оценить их долгосрочные эксплуатационные преимущества в сравнении с первоначальными затратами, чтобы определить их пригодность для своих нужд.

Основные промышленные применения пускового двигателя стартера

| Отрасль/сектор | Специфическое применение пускового двигателя | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Производство | Управление двигателями для конвейерного оборудования | Повышает эффективность работы и минимизирует время простоя | Совместимость с существующим оборудованием и номинальное напряжение |

| Сельское хозяйство | Системы управления ирригационными насосами | Обеспечивает надежное водоснабжение сельскохозяйственных культур, повышая урожайность | Устойчивость к воздействию окружающей среды и требования к питанию |

| Горная промышленность | Управление ленточными конвейерами и механизмами | Повышает безопасность и производительность в суровых условиях | Долговечность и защита от перегрузок |

| HVAC | Управление вентиляторами в системах отопления и охлаждения | Оптимизация энергопотребления и надежности системы | Соответствие региональным электротехническим стандартам |

| Нефть и газ | Питание буровых установок и насосов | Повышает эффективность работы и безопасность | Взрывозащищенные сертификаты и прочная конструкция |

Как используются стартеры для запуска двигателей в производстве?

На производстве пускатели двигателей необходимы для управления оборудованием сборочных линий. Они обеспечивают безопасную и эффективную работу электродвигателей, приводящих в движение конвейеры, роботизированные манипуляторы и другие автоматизированные системы. Обеспечивая защиту от тепловой перегрузки и облегчая дистанционное управление, эти устройства минимизируют время простоя и повышают производительность. Покупателям B2B в этом секторе следует обратить внимание на совместимость с существующим оборудованием, номинальное напряжение и простоту установки, чтобы обеспечить беспроблемную интеграцию.

Какую роль играют стартеры в сельском хозяйстве?

Пускатели широко используются в сельском хозяйстве, в частности, для управления насосами ирригационных систем. Эти устройства обеспечивают надежное водоснабжение, что имеет решающее значение для здоровья и урожайности сельскохозяйственных культур. Обеспечивая защиту от перегрузок и эффективную работу, они помогают фермерам эффективно управлять ресурсами. Международные покупатели, особенно из таких регионов, как Африка и Южная Америка, должны оценивать устойчивость к внешним воздействиям и требования к мощности, чтобы соответствовать местным условиям и обеспечить надежность работы.

Как применяются пусковые двигатели в горной промышленности?

В горнодобывающей промышленности пускатели электродвигателей жизненно необходимы для управления конвейерными лентами и тяжелым оборудованием. Они повышают безопасность, обеспечивая надежное управление двигателями в сложных условиях, снижая риск выхода оборудования из строя. Кроме того, эти пускатели способствуют бесперебойной работе оборудования, что приводит к повышению производительности. При выборе оборудования покупатели должны уделять первостепенное внимание его долговечности и защите от перегрузок, чтобы оно могло выдержать сложные условия, характерные для горнодобывающей промышленности.

Почему пускатели электродвигателей важны для систем отопления, вентиляции и кондиционирования воздуха?

Пускатели электродвигателей играют важную роль в системах ОВКВ для управления работой вентиляторов. Они помогают оптимизировать энергопотребление, сохраняя при этом надежность системы, что крайне важно для управления климатом в коммерческих и промышленных помещениях. Обеспечивая защиту от тепловой перегрузки, эти пускатели предотвращают повреждение двигателя и снижают затраты на обслуживание. Покупателям в Европе и на Ближнем Востоке следует обратить внимание на соответствие региональным электротехническим стандартам, чтобы обеспечить безопасность и эффективность своих систем ОВКВ.

Какие преимущества дают пусковые устройства для двигателей в нефтегазовом секторе?

В нефтегазовой промышленности пускатели двигателей используются для питания буровых установок и насосов, повышая эффективность и безопасность работы. Эти устройства рассчитаны на высокие требования к мощности и обеспечивают надежную защиту от перегрузок. Для международных покупателей, особенно в регионах с жесткими нормами безопасности, поиск пускателей с сертификатами взрывозащиты и прочной конструкцией имеет важное значение для удовлетворения эксплуатационных требований и соблюдения нормативных требований.

3 распространенных болевых точки пользователей для ‘starter motor starter’ и их решения

Сценарий 1: Трудности с поиском подходящего стартерного двигателя для конкретного применения

Проблема: Многие покупатели B2B сталкиваются с проблемой выбора подходящего пускового двигателя для конкретного применения. При наличии множества вариантов, включая ручные и магнитные пускатели, каждый из которых обладает уникальными характеристиками и спецификациями, сделать правильный выбор может оказаться непростой задачей. Кроме того, покупатели могут столкнуться с трудностями в понимании совместимости пускателей с существующими системами, такими как номинальное напряжение, требования к фазам и защита от перегрузки. Такая сложность может привести к дорогостоящим ошибкам, включая приобретение неправильного оборудования или простои в работе.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

Решение: Чтобы преодолеть эти трудности, покупатели должны провести тщательную оценку потребностей, прежде чем искать пусковой двигатель. Это включает в себя оценку конкретных требований к применению, таких как тип используемого двигателя, рабочая среда и ожидаемые условия нагрузки. Покупатели должны проконсультироваться с производителями или поставщиками, чтобы получить подробные спецификации и рекомендации, отвечающие их потребностям. Кроме того, в принятии обоснованных решений может помочь использование таких ресурсов, как технические паспорта и руководства по совместимости. Обращение к отраслевым экспертам за консультацией по лучшим решениям для пусковых двигателей также может снизить риск ошибок и гарантировать, что выбранное оборудование будет полностью соответствовать эксплуатационным требованиям.

Сценарий 2: Частые отказы оборудования из-за неадекватной защиты от перегрузки

Проблема: Частой проблемой для предприятий, использующих оборудование с пусковыми двигателями, являются частые поломки, вызванные неадекватной защитой от перегрузки. Без надлежащей защиты двигатели могут страдать от перегрева и чрезмерного потребления тока, что приводит к преждевременному выходу из строя и дорогостоящему ремонту. Эта проблема особенно актуальна в промышленных условиях, где оборудование работает непрерывно, и ставки на время простоя высоки. Покупатели часто попадают в цикл замены двигателей из-за неадекватных механизмов защиты в пусковых двигателях.

Решение: Чтобы решить эту проблему, покупатели должны отдавать предпочтение пусковым двигателям, оснащенным встроенной защитой от тепловой перегрузки и чувствительностью к обрыву фаз. При оценке вариантов важно искать пускатели, соответствующие отраслевым стандартам, таким как UL508A и IEC, поскольку эти сертификаты указывают на надежные меры безопасности. Кроме того, регулярное техническое обслуживание и системы мониторинга помогут обнаружить проблемы на ранней стадии. Инвестиции в интеллектуальные пускатели электродвигателей, обеспечивающие мониторинг в режиме реального времени, могут дать представление о производительности электродвигателя и предупредить пользователей о потенциальных перегрузках до того, как они перерастут в серьезные проблемы.

Сценарий 3: Проблемы с установкой и настройкой стартерных двигателей

Проблема: Многие покупатели B2B сталкиваются с трудностями при установке и настройке пусковых двигателей, что приводит к задержке готовности к эксплуатации. Эта проблема часто усугубляется сложностью прокладки проводов и интеграции пускателя с цепями управления. Новые команды могут не обладать необходимым техническим опытом, что приводит к неправильной установке, которая может поставить под угрозу безопасность и функциональность. Кроме того, отсутствие четких инструкций может привести к путанице и неправильной конфигурации, что еще больше затягивает сроки реализации проекта.

Решение: Чтобы упростить процесс установки, покупателям стоит обратить внимание на пусковые двигатели, которые поставляются с полным руководством по установке и готовыми вариантами подключения. Выбор продукции с подробными схемами и пошаговыми инструкциями может значительно снизить риск ошибок при установке. Кроме того, сотрудничество с опытными электриками или службами технической поддержки на этапе установки может дать ценные рекомендации и помощь. Для компаний, не обладающих собственным опытом, следует рассмотреть программы обучения или семинары, предлагаемые производителями, чтобы повысить квалификацию имеющегося персонала, что в конечном итоге приведет к более эффективной установке и сокращению времени простоя. Внедрение поэтапного подхода к установке - начиная с более простых конфигураций и переходя к более сложным - также может быть полезно для укрепления доверия и компетентности команды.

Руководство по выбору стратегических материалов для пускателя двигателя

Какие распространенные материалы используются в стартерах электродвигателей?

При выборе материалов для пускателей необходимо учитывать их свойства, преимущества, недостатки и соответствие специфическим требованиям международных рынков. Ниже мы проанализируем четыре распространенных материала, используемых в конструкции пускателей: низкоуглеродистая сталь, нержавеющая сталь, алюминий и термопластик.

Как работает низкоуглеродистая сталь в стартерах двигателей?

Мягкая сталь широко используется в пускателях электродвигателей благодаря своей прочности и экономичности. Она обладает высокой прочностью на растяжение, что позволяет использовать ее в тяжелых условиях эксплуатации. Мягкая сталь обычно имеет температуру до 300°C и может выдерживать умеренное давление.

Плюсы:

– Долговечность: Обладает хорошей механической прочностью и износостойкостью.

– Стоимость: Как правило, недорогой, что делает его экономичным выбором для производителей.

– Сложность производства: Легко изготавливается и сваривается, упрощая производственный процесс.

Минусы:

– Устойчивость к коррозии: Склонны к образованию ржавчины при отсутствии надлежащего покрытия или ухода, что может повлиять на долговечность.

– Вес: Тяжелее, чем альтернативные варианты, такие как алюминий, что может быть важным фактором в чувствительных к весу приложениях.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

Влияние на применение: Мягкая сталь совместима с различными средами, но требует защитных покрытий для повышения коррозионной стойкости, особенно во влажных или соленых условиях.

Соображения для международных покупателей: Соответствие стандартам, таким как ASTM A36, имеет решающее значение. Покупатели в таких регионах, как Африка и Южная Америка, могут отдавать предпочтение стоимости, а не коррозионной стойкости, в то время как европейские покупатели могут требовать более качественных материалов.

Каковы преимущества использования нержавеющей стали?

Нержавеющая сталь известна своей превосходной коррозионной стойкостью и эстетической привлекательностью, что делает ее пригодной для использования в средах, где присутствуют влага и химические вещества. Она может выдерживать температуру до 800°C, что делает ее идеальной для высокотемпературных применений.

Плюсы:

– Устойчивость к коррозии: Высокая устойчивость к ржавчине и коррозии продлевает срок службы изделия.

– Долговечность: Прочные и устойчивые, подходят для суровых промышленных условий.

– Эстетика: Обеспечивает чистый, полированный вид, что может быть выгодно при использовании на видных местах.

Минусы:

– Стоимость: Как правило, дороже низкоуглеродистой стали, что может повлиять на бюджетные ограничения.

– Сложность производства: Более сложная обработка и сварка по сравнению с низкоуглеродистой сталью.

Влияние на применение: Нержавеющая сталь особенно эффективна в средах, где существует опасность воздействия коррозионных веществ, например, в пищевой промышленности и производстве напитков.

Соображения для международных покупателей: Соответствие стандартам, таким как ASTM A240, является обязательным. Покупатели в Европе часто предпочитают нержавеющую сталь за ее долговечность и эстетические качества.

Чем отличается алюминий от других материалов?

Алюминий легок и обладает хорошей коррозионной стойкостью, что делает его популярным выбором для применения в тех случаях, когда вес является критическим фактором. Он может выдерживать температуру до 400°C.

Плюсы:

– Вес: Значительно легче стали, что позволяет повысить энергоэффективность применения.

– Устойчивость к коррозии: Естественным образом образует защитный оксидный слой, повышающий долговечность.

– Гибкость производства: Легко поддается экструзии и механической обработке, позволяя создавать сложные формы.

Минусы:

– Сила: Не такой прочный, как сталь, что может ограничить его применение в тяжелых условиях.

– Стоимость: Дороже, чем низкоуглеродистая сталь, что может повлиять на общий бюджет проекта.

Влияние на применение: Алюминий подходит для применения в областях, где требуются легкие компоненты, например, в автомобильной или аэрокосмической промышленности.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

Соображения для международных покупателей: Важное значение имеет соответствие стандартам, таким как ASTM B221. Покупатели в регионах со строгими требованиями к весу, например, в Европе, могут предпочесть алюминий.

Какую роль играют термопласты в стартерах электродвигателей?

Термопластики, такие как поликарбонат или нейлон, все чаще используются в пусковых устройствах электродвигателей благодаря своим изоляционным свойствам и легкости. Они могут выдерживать температуру до 120°C.

Плюсы:

– Электрическая изоляция: Отличные изоляторы, снижающие риск электрических сбоев.

– Вес: Очень легкий, что позволяет снизить общий вес системы.

– Экономичность: Как правило, более низкая стоимость по сравнению с металлами.

Минусы:

– Температурная устойчивость: Ограниченная термическая стабильность по сравнению с металлами, что может ограничить использование в высокотемпературных приложениях.

– Механическая прочность: Не такие прочные, как металлы, что может ограничить их использование в тяжелых условиях эксплуатации.

Влияние на применение: Идеально подходит для применения в условиях, требующих электроизоляции, и там, где вес имеет значение, например, в портативном оборудовании.

Соображения для международных покупателей: Соответствие стандартам, таким как UL 94, по воспламеняемости имеет решающее значение. Покупатели на Ближнем Востоке могут отдавать предпочтение экономичности, в то время как европейские покупатели могут сосредоточиться на эксплуатационных характеристиках.

Сводная таблица выбора материалов для пускателей электродвигателей

| Материал | Типичный пример использования пускового двигателя | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Мягкая сталь | Сверхмощные промышленные приложения | Экономичность и долговечность | Склонный к коррозии | Низкий |

| Нержавеющая сталь | Коррозионные среды | Отличная коррозионная стойкость | Более высокая стоимость | Высокий |

| Алюминий | Легкие приложения | Легкий вес и хорошая коррозионная стойкость | Более низкая прочность по сравнению со сталью | Мед |

| Термопластик | Переносное оборудование | Отличная электроизоляция | Ограниченная термостойкость | Низкий |

Данное руководство содержит исчерпывающий обзор вариантов материалов для пускателей электродвигателей, позволяя покупателям B2B принимать обоснованные решения с учетом специфики их применения и региональных требований.

Глубокий взгляд: Производственные процессы и контроль качества для стартера двигателя

Каковы основные этапы производственного процесса для пускателей электродвигателей?

Процесс производства стартеров для электродвигателей обычно включает в себя несколько важнейших этапов: подготовку материала, формовку, сборку и отделку. Каждый этап играет ключевую роль в обеспечении качества и производительности конечного продукта.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

Как подготавливается материал для стартеров двигателей?

Первый шаг в производстве - это поиск высококачественного сырья, в первую очередь металлов, таких как мягкая сталь для корпусов и медь для электрических компонентов. Поставщики часто выбираются на основе их способности поставлять материалы, соответствующие определенным отраслевым стандартам. После приобретения материалов они проходят тщательную проверку на соответствие заданным спецификациям, включая толщину, прочность на разрыв и электропроводность.

После проверки материалы разрезаются по размеру с помощью современных технологий резки, таких как лазерная или плазменная резка, которые обеспечивают точные размеры и сокращают количество отходов. Этот этап очень важен, поскольку качество материалов напрямую влияет на долговечность и эффективность пускателей электродвигателей.

Какие методы формовки используются при производстве стартеров электродвигателей?

После подготовки материала наступает следующий этап - формовка. Она заключается в придании металлическим компонентам формы, необходимой для обеспечения функциональности пускового двигателя. Такие методы, как штамповка и гибка, обычно используются для создания таких деталей, как корпуса, контакторы и реле перегрузки.

Помимо механической формовки, некоторые производители используют такие передовые технологии, как обработка с ЧПУ, для деталей, требующих высокой точности. Сформированные детали затем подвергаются процессам удаления заусенцев и обработки поверхности для удаления острых кромок и повышения коррозионной стойкости. Такое внимание к деталям гарантирует, что при сборке все детали будут плотно прилегать друг к другу, что необходимо для оптимальной работы.

Что включает в себя процесс сборки стартеров для двигателей?

В процессе сборки различные компоненты собираются вместе, образуя готовый пускатель двигателя. Этот этап обычно включает в себя несколько шагов:

Иллюстративное изображение, относящееся к стартеру двигателя стартера

-

Интеграция компонентов: Каждая деталь, включая контактор, реле перегрузки и схему управления, тщательно собрана. Операторы следуют подробным инструкциям по сборке, чтобы убедиться, что каждый компонент правильно установлен и закреплен.

-

Проводка: Электрические соединения выполняются с использованием высококачественной проводки, способной выдержать эксплуатационные требования стартера двигателя. Правильная изоляция и разгрузка от натяжения имеют решающее значение для предотвращения сбоев в работе электрооборудования.

-

Тестирование: Первоначальное тестирование проводится во время сборки, чтобы выявить все ближайшие проблемы. Оно может включать в себя испытания на целостность и функциональные проверки, чтобы убедиться, что пускатель работает так, как нужно.

Как выполняется финишная обработка стартеров двигателей?

После сборки пусковой двигатель подвергается финишной обработке, которая улучшает как эстетику, так и функциональность. Часто это включает покраску или покрытие корпуса для повышения долговечности и устойчивости к воздействию факторов окружающей среды.

Кроме того, производится окончательная настройка компонентов, например, калибровка параметров реле перегрузки. Эти последние штрихи не только улучшают внешний вид изделия, но и обеспечивают соответствие международным стандартам безопасности и производительности.

Какие меры по обеспечению качества применяются при производстве стартеров для электродвигателей?

Обеспечение качества (QA) является жизненно важным компонентом производственного процесса, особенно для международных покупателей B2B, которым требуется надежная продукция. Производители обычно придерживаются международных стандартов, таких как ISO 9001, в котором изложены принципы управления качеством для обеспечения стабильного качества продукции.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

О каких международных стандартах следует знать покупателям B2B?

Помимо ISO 9001, большое значение имеют такие отраслевые сертификаты, как маркировка CE для европейских рынков и стандарты API для нефтегазовой отрасли. Эти сертификаты означают, что продукция соответствует строгим критериям безопасности и производительности, что делает ее пригодной для различных областей применения.

Каковы ключевые контрольные точки контроля качества при производстве стартеров для электродвигателей?

Контроль качества (QC) интегрирован в производственный процесс, с несколькими контрольными точками для обеспечения соответствия стандартам:

- Входящий контроль качества (IQC): Это включает в себя проверку сырья по прибытии, чтобы убедиться в его соответствии установленным стандартам до начала производства.

- Контроль качества в процессе производства (IPQC): В процессе производства проводятся выборочные проверки для контроля критических параметров, гарантирующие, что процессы остаются в допустимых пределах.

- Окончательный контроль качества (FQC): Перед упаковкой и отгрузкой каждый пускатель двигателя проходит комплексное тестирование, включая функциональное тестирование и оценку производительности.

Какие общие методы испытаний используются для пускателей электродвигателей?

Методы тестирования зависят от компонентов и приложений, но часто включают в себя:

- Электрические испытания: Проверка эксплуатационной целостности электрических компонентов с помощью испытаний на целостность и сопротивление изоляции.

- Термические испытания: Оценка тепловой защиты от перегрузки для обеспечения ее правильного функционирования в условиях нагрузки.

- Экологические испытания: Моделирование условий эксплуатации, таких как влажность и экстремальные температуры, для обеспечения надежности в различных средах.

Как покупатели B2B могут проверять практику контроля качества поставщиков?

Для международных покупателей проверка практики контроля качества поставщика имеет важное значение для обеспечения надежности продукции. Этого можно достичь с помощью:

Иллюстративное изображение, относящееся к стартеру двигателя стартера

- Аудит поставщиков: Проведение аудитов на местах для проверки производственных процессов, мер контроля качества и соответствия международным стандартам.

- Просмотр отчетов по контролю качества: Запрашивать подробную документацию по контролю качества, включая результаты испытаний и сертификаты соответствия, чтобы оценить приверженность поставщика качеству.

- Проверки третьей стороной: Привлечение независимых инспекционных агентств для оценки производственного процесса и качества продукции перед отгрузкой.

Каковы нюансы контроля качества для международных B2B-покупателей?

При взаимодействии с поставщиками из разных регионов, в частности Африки, Южной Америки, Ближнего Востока и Европы, покупатели B2B должны знать о региональных различиях в производственных стандартах и практике. Понимание местных сертификатов, нормативных требований и культурного отношения к качеству может существенно повлиять на процесс поиска поставщиков.

Установление четких каналов связи и ожиданий в отношении стандартов качества очень важно для успешного партнерства. Покупатели также должны учитывать логистические аспекты поиска поставщиков за рубежом, включая время выполнения заказа, доставку и потенциальные тарифы, которые могут повлиять на общую стоимость и эффективность закупок.

В заключение следует отметить, что понимание производственных процессов и мер по обеспечению качества пускателей электродвигателей имеет решающее значение для покупателей B2B. Сосредоточив внимание на ключевых этапах производства, соответствующих международных стандартах и эффективных методах контроля качества, предприятия могут принимать обоснованные решения и гарантировать, что они приобретают высококачественную продукцию, которая отвечает их производственным потребностям.

Практическое руководство по поиску: Пошаговый контрольный список для ‘стартер двигателя стартер’

В условиях конкуренции при закупках промышленного оборудования выбор правильного пускателя электродвигателя имеет решающее значение для обеспечения эффективности и безопасности работы. Данное руководство служит практическим контрольным списком, который поможет покупателям B2B сориентироваться в сложностях приобретения пускателей электродвигателей, обеспечивая принятие обоснованных решений, соответствующих их техническим требованиям и бизнес-целям.

1. Определите свои технические характеристики

Понимание ваших конкретных потребностей - это первый шаг в процессе поиска поставщиков. Четко определите напряжение, требования к фазам и номинальную мощность, необходимые для вашего применения. Такая ясность поможет обеспечить совместимость с существующим оборудованием и избежать дорогостоящих ошибок в дальнейшем.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

- Уровни напряжения: Распространенные варианты: 120 В переменного тока, 240 В переменного тока и 480 В переменного тока.

- Номинальная мощность: Убедитесь, что стартер способен выдержать мощность двигателя, которая обычно составляет от 0,5 л.с. до 10 л.с. и более.

2. Определите тип необходимого пускателя двигателя

Пускатели электродвигателей бывают разных типов, включая ручные, магнитные и автотрансформаторные. Каждый тип служит для различных целей и имеет уникальные эксплуатационные характеристики.

- Ручные стартеры: Идеально подходит для простых приложений, где контроль пользователя имеет первостепенное значение.

- Магнитные пускатели: Подходит для автоматизированных систем, требующих дистанционного управления и защиты от перегрузки.

3. Оценить сертификаты поставщиков

При выборе пускателей электродвигателей необходимо проверять сертификаты потенциальных поставщиков. Обратите внимание на соответствие международным стандартам, таким как UL508A и IEC, которые обеспечивают безопасность и надежность продукции.

- Сертификаты безопасности: Убедитесь, что продукция соответствует стандартам безопасности, действующим в вашем регионе.

- Обеспечение качества: Проверьте, есть ли у производителя надежная система управления качеством.

4. Оцените репутацию и опыт поставщика

История поставщика и его присутствие на рынке могут дать представление о его надежности и качестве продукции. Ищите поставщиков с проверенным послужным списком на рынке пускателей электродвигателей.

- Отзывы клиентов: Изучите отзывы и примеры из практики компаний, похожих на вашу.

- Опыт работы в отрасли: Поставщики с большим опытом работы в отрасли зачастую лучше понимают и удовлетворяют ваши специфические потребности.

5. Запросить подробную информацию о продукте

Прежде чем совершить покупку, запросите полные технические характеристики и паспорта изделия. В них должны быть подробно описаны характеристики пускателя, включая защиту от перегрузки, чувствительность к потере фазы и требования к установке.

- Руководства по установке: Убедитесь, что поставщик предоставляет четкие инструкции по установке, чтобы свести к минимуму время простоя.

- Техническая поддержка: Подтвердите наличие технической помощи после покупки для устранения неполадок.

6. Сравните цены и варианты гарантии

Хотя стоимость является важным фактором, она не должна быть единственным критерием для принятия решения. Сравните цены разных поставщиков, учитывая при этом ценность включенных функций и гарантийных обязательств.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

- Срок действия гарантии: Более длительная гарантия может свидетельствовать об уверенности производителя в надежности своего продукта.

- Общая стоимость владения: Учитывайте расходы на установку, обслуживание и возможные простои, связанные с каждым вариантом.

7. Завершение покупки и логистика

Выбрав поставщика, убедитесь, что логистика доставки согласуется с вашими сроками работы. Уточните способы доставки, сроки выполнения заказа и правила возврата.

- Сроки доставки: Установите четкие ожидания по доставке, чтобы избежать задержек в реализации проекта.

- Правила возврата: Поймите условия возврата или обмена в случае, если товар не соответствует техническим требованиям.

Следуя этому контрольному списку, покупатели B2B могут принимать обоснованные решения при поиске пускателей электродвигателей, гарантируя, что они выбирают лучшие продукты для своих операционных потребностей, минимизируя риски и максимизируя стоимость.

Всесторонний анализ затрат и цен на пусковой двигатель стартера Sourcing

При закупке пускателей для электродвигателей понимание структуры затрат и динамики цен имеет решающее значение для покупателей B2B. В данном анализе рассматриваются различные компоненты, формирующие общую стоимость, факторы, влияющие на ценообразование, и важные советы для покупателей, особенно на международных рынках, таких как Африка, Южная Америка, Ближний Восток и Европа.

Каковы ключевые компоненты затрат при производстве стартеров для электродвигателей?

Структура затрат на пускатели электродвигателей обычно состоит из нескольких ключевых компонентов:

-

Материалы: Сырьевые материалы, используемые в производстве, такие как сталь для корпусов и медь для проводки, значительно влияют на стоимость. Высококачественные материалы могут повысить долговечность и производительность, но они также повышают цену.

-

Трудовые ресурсы: Стоимость рабочей силы зависит от места производства. Регионы с более низкой стоимостью рабочей силы могут предложить конкурентоспособные цены, но это также может повлиять на качество и надежность продукции.

-

Производственные накладные расходы: Сюда входят расходы, связанные с эксплуатацией завода, коммунальными услугами и обслуживанием оборудования. Эффективные производственные процессы позволяют снизить накладные расходы и, соответственно, конечную цену.

-

Инструменты: Первоначальные инвестиции в оснастку и оборудование для производства могут быть значительными. Индивидуальная оснастка для специализированных пускателей двигателей увеличивает первоначальные затраты, которые могут быть амортизированы при увеличении объемов производства.

-

Контроль качества (КК): Внедрение строгих процессов контроля качества обеспечивает надежность продукции и соответствие сертификатам (например, UL508A, стандарты IEC). Хотя это увеличивает расходы, это необходимо для поддержания целостности продукции, особенно в сложных промышленных условиях.

-

Логистика: Стоимость доставки и обработки может варьироваться в зависимости от расстояния, вида транспорта и согласованных Инкотермс. Покупатели должны учитывать эти расходы при оценке общей цены.

-

Маржа: Поставщики обычно включают маржу прибыли в свои цены. Эта маржа может варьироваться в зависимости от позиционирования поставщика на рынке, конкуренции и воспринимаемой ценности его продукции.

Как влияют факторы, влияющие на цену, на стоимость пускового двигателя?

На цену пускателей для электродвигателей может влиять несколько факторов:

-

Объем/минимальный объем заказа: Большие объемы закупок часто приводят к снижению стоимости единицы продукции. Производители могут предлагать более низкие цены при оптовых заказах, поэтому переговоры о минимальном количестве заказа (MOQ) могут быть выгодными.

-

Технические характеристики и индивидуальная настройка: Нестандартные функции, такие как защита от перегрузок, рейтинги NEMA или особые требования к напряжению, могут увеличить стоимость. Покупатели должны четко определить свои потребности, чтобы избежать непредвиденных расходов.

-

Качество материалов и сертификаты: Высококачественные материалы и сертификаты могут повысить надежность, но могут и увеличить стоимость. Покупатели должны соизмерять требования к качеству с бюджетными ограничениями.

-

Факторы, связанные с поставщиками: Репутация и надежность поставщика могут влиять на ценообразование. Известные поставщики могут взимать премию за свою проверенную репутацию, в то время как новички могут предлагать более низкие цены, чтобы завоевать долю рынка.

-

Инкотермс: Выбранные Инкотермс влияют на логистические затраты и ответственность. Например, использование DDP (Delivered Duty Paid) может привести к более высоким предварительным затратам, но может упростить процесс покупки за счет включения пошлин и налогов.

Какие существуют лучшие советы по ведению переговоров о ценах на стартерные двигатели?

Для покупателей B2B, особенно на разнообразных международных рынках, эффективные переговоры и стратегические закупки могут привести к значительной экономии средств:

-

Понимание совокупной стоимости владения (TCO): Учитывайте не только цену покупки, но и затраты на установку, обслуживание и эксплуатацию в течение всего срока службы продукта. Более низкая первоначальная стоимость может привести к повышению TCO, если продукт менее надежен.

-

Используйте маркетинговые исследования: Будьте в курсе тенденций рынка и цен конкурентов. Эти знания могут повысить эффективность переговоров и помочь добиться лучших условий.

-

Стройте долгосрочные отношения: Установление прочных отношений с поставщиками может привести к установлению более выгодных цен, приоритету заказов и улучшению обслуживания.

-

Рассмотрите местных поставщиков: Приобретение продукции у местных производителей позволяет сократить расходы на доставку и сроки выполнения заказа, что особенно важно для срочных проектов.

-

Обсудить условия оплаты: Гибкие условия оплаты могут улучшить движение денежных средств. Обсуждение таких вариантов, как продление сроков оплаты или рассрочка платежа, может быть выгодным.

Заключение

В заключение следует отметить, что полное понимание структуры затрат и динамики цен на пускатели электродвигателей необходимо для покупателей B2B. Зная различные компоненты затрат и факторы, влияющие на цену, а также применяя стратегические методы закупок, покупатели могут оптимизировать свои стратегии поиска поставщиков и добиться лучшей стоимости. Следует помнить, что цены, указанные в различных источниках, являются ориентировочными и могут меняться в зависимости от рыночных условий и конкретных требований.

Анализ альтернатив: Сравнение стартера двигателя с другими решениями

Изучение альтернатив пускателям электродвигателей в промышленности

В сфере промышленной автоматизации выбор правильного решения для управления двигателем имеет решающее значение для обеспечения оптимальной производительности и эффективности. Несмотря на то, что пускатели широко используются благодаря своей надежности и функциональности, существует несколько альтернативных решений, которые могут служить аналогичным целям. В этом разделе представлен сравнительный анализ пускателей с другими технологиями, что позволит покупателям B2B принять обоснованное решение.

| Аспект сравнения | Стартер Двигатель стартера | Частотно-регулируемый привод (VFD) | Устройство плавного пуска |

|---|---|---|---|

| Производительность | Надежность при запуске/остановке двигателей; предусмотрена защита от тепловой перегрузки. | Позволяет контролировать скорость и управлять крутящим моментом; высокоэффективен. | Снижает пусковой ток; защищает двигатель при запуске. |

| Стоимость | Обычно варьируется от $200 до $275. | Более высокие первоначальные затраты, от $232 до более $2 300. | Умеренная стоимость, обычно ниже, чем у VFD, около $500 - $1 500. |

| Простота внедрения | Простая установка с предварительно подключенными компонентами; удобство для пользователя. | Более сложная настройка; может потребоваться программирование и конфигурирование. | В целом прост в установке; требуется минимальная настройка. |

| Техническое обслуживание | Не требует особого ухода; долговечные компоненты. | Умеренный уход; требует регулярного мониторинга. | Низкая стоимость обслуживания; меньший износ двигателей. |

| Лучший вариант использования | Идеально подходит для простых приложений, требующих управления включением/выключением. | Лучше всего подходит для приложений, требующих переменной скорости и управления крутящим моментом. | Подходит для применений, требующих снижения механических нагрузок при запуске. |

Каковы преимущества и недостатки частотно-регулируемого привода (VFD)?

Частотно-регулируемые приводы (ЧРП) представляют собой сложную альтернативу традиционным пускателям электродвигателей. ЧРП обеспечивают точное регулирование скорости, позволяя двигателям работать с разной скоростью в зависимости от требований приложения. Такая гибкость повышает энергоэффективность, особенно в процессах, где не требуется постоянная скорость. Однако сложность систем с ЧРП может быть недостатком, поскольку они часто требуют более сложной установки и программирования, что может потребовать привлечения квалифицированных технических специалистов. Кроме того, первоначальные инвестиции значительно выше, чем у стандартных пускателей, что может отпугнуть покупателей с ограниченным бюджетом.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

Чем отличается устройство плавного пуска от пускателя двигателя?

Устройства плавного пуска - еще одна альтернатива, обеспечивающая уникальный подход к управлению двигателем. Они предназначены для снижения пускового тока при запуске двигателя, что минимизирует механическую нагрузку на двигатель и подключенное оборудование. Эта особенность позволяет продлить срок службы двигателя и снизить затраты на техническое обслуживание. Устройства плавного пуска обычно проще в установке, чем ЧРП, и требуют меньше конфигурации. Однако они не обеспечивают возможности регулирования скорости, что делает их менее универсальными, чем ЧРП, и пригодными в основном для тех применений, где плавный пуск является первостепенной задачей.

Правильный выбор для нужд вашего бизнеса

При выборе решения для управления двигателем покупатели B2B должны учитывать различные факторы, включая требования к применению, бюджетные ограничения и долгосрочные эксплуатационные цели. Стартерные пускатели отлично подходят для простых приложений, требующих надежного управления включением/выключением, в то время как частотно-регулируемые двигатели (ЧРП) отлично подходят для сценариев, требующих переменной скорости и эффективности. Устройства плавного пуска занимают промежуточное положение, обеспечивая преимущества в конкретных ситуациях, когда снижение нагрузки при пуске имеет решающее значение. В конечном счете, понимание уникальных преимуществ и ограничений каждого решения позволит покупателям выбрать наиболее подходящий вариант для своих производственных нужд.

Основные технические свойства и торговая терминология для пускового двигателя стартера

Каковы основные технические свойства пускателей электродвигателей?

Понимание технических характеристик пускателей электродвигателей имеет решающее значение для покупателей B2B, желающих принять обоснованное решение о покупке. Вот несколько основных характеристик, которые необходимо учитывать:

1. Марка материала

Корпус пускателя двигателя обычно изготавливается из таких материалов, как низкоуглеродистая сталь или алюминий. Выбор материала влияет на прочность, устойчивость к коррозии и общую долговечность в промышленных условиях. Например, корпус из сверхпрочной стали с классом NEMA 1 подходит для использования внутри помещений, обеспечивая защиту от пыли и попадания света. Покупатели должны отдавать предпочтение материалам, соответствующим условиям эксплуатации, чтобы минимизировать затраты на обслуживание.

2. Номинальные значения напряжения

Пускатели электродвигателей рассчитаны на работу при определенных уровнях напряжения, обычно от 120 до 480 В переменного тока. Понимание этих номиналов необходимо для совместимости с существующими электрическими системами. Неправильный выбор напряжения может привести к поломке оборудования или угрозе безопасности, поэтому покупателям крайне важно проверить рабочее напряжение перед закупкой.

3. Конфигурация фазы

Пускатели двигателей могут быть однофазными или трехфазными, что влияет на их применение в различных типах двигателей. Однофазные пускатели часто используются для небольших двигателей, в то время как трехфазные пускатели предпочтительны для промышленных применений, требующих более высокой мощности. Выбор правильной конфигурации фаз обеспечивает оптимальную производительность и эффективность, что крайне важно для повышения производительности.

4. Защита от перегрузки

Встроенная защита от тепловой перегрузки является стандартной функцией большинства пускателей электродвигателей. Этот механизм предотвращает повреждения, вызванные чрезмерным током, помогая продлить срок службы двигателя. Покупателям следует оценить регулируемые параметры тока срабатывания, чтобы обеспечить возможность настройки защиты в соответствии с конкретными требованиями, снижая риск непредвиденного простоя.

5. Проектирование схем управления

Цепь управления в пускателе двигателя обычно имеет двухпроводную или трехпроводную конфигурацию. Двухпроводной метод проще, в нем используются поддерживаемые контакты, в то время как трехпроводной метод обеспечивает более широкую функциональность за счет кратковременных контактов. Понимание этих конструкций позволяет покупателям выбрать пускатель, который наилучшим образом соответствует их эксплуатационным потребностям и улучшает контроль над функциями двигателя.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

Какие существуют общепринятые торговые термины, связанные с пусковыми устройствами двигателя?

Знание отраслевого жаргона необходимо для эффективной коммуникации в сделках B2B. Вот некоторые распространенные термины:

1. OEM (производитель оригинального оборудования)

OEM - это компании, которые производят детали или оборудование, которые могут быть представлены на рынке другим производителем. В контексте стартерных двигателей OEM-производители обеспечивают соответствие компонентов определенным стандартам качества и совместимости. Покупатели часто предпочитают OEM-продукцию за надежность и гарантийную поддержку.

2. MOQ (минимальный объем заказа)

MOQ - это наименьшее количество единиц товара, которое поставщик готов продать. Понимание MOQ очень важно для покупателей, чтобы эффективно управлять запасами и не допускать финансовых перегрузок. Этот термин может повлиять на составление бюджета и управление цепочкой поставок.

3. RFQ (запрос предложения)

RFQ - это документ, направляемый покупателями поставщикам с запросом информации о ценах на конкретные товары или услуги. Этот процесс крайне важен для сравнения вариантов и согласования выгодных условий. Хорошо подготовленный RFQ может упростить процесс закупок и привести к лучшему ценообразованию.

4. Инкотермс (Международные торговые термины)

Инкотермс определяют обязанности покупателей и продавцов в отношении доставки, страхования и тарифов. Знакомство с этими терминами помогает понять стоимость доставки и обязанности по доставке, что особенно важно для международных сделок.

5. Номинальные значения NEMA (Национальная ассоциация производителей электрооборудования)

Рейтинги NEMA классифицируют электрические шкафы в зависимости от их пригодности к определенным условиям окружающей среды. Эти рейтинги необходимы для того, чтобы убедиться, что выбранный пускатель двигателя выдержит условия эксплуатации, что влияет на решение покупателя.

Понимая эти технические свойства и торговые условия, покупатели B2B могут принимать обоснованные решения при закупке пускателей электродвигателей, что в конечном итоге повышает эффективность работы и снижает риски.

Навигация по динамике рынка и тенденциям поиска поставщиков в секторе стартеров для электродвигателей

Каковы основные тенденции и динамика рынка в секторе стартерных двигателей?

Сектор пусковых двигателей переживает значительные изменения, вызванные технологическим прогрессом и меняющимися требованиями рынка. Глобальные движущие силы включают в себя рост автоматизации и растущую потребность в эффективных энергетических решениях в промышленности. Покупатели B2B, особенно из таких регионов, как Африка, Южная Америка, Ближний Восток и Европа, все чаще ищут надежные пускатели электродвигателей, которые обеспечивают эффективность работы и минимизируют время простоя.

Современные тенденции указывают на переход к более интегрированным решениям, таким как пускатели электродвигателей со встроенными функциями защиты, такими как защита от тепловой перегрузки и чувствительность к потере фазы. Это не только повышает долговечность двигателя, но и снижает затраты предприятий на техническое обслуживание. Кроме того, растет внедрение цифровых технологий: пускатели электродвигателей с поддержкой IoT обеспечивают мониторинг и управление в режиме реального времени, оптимизируя тем самым производительность и энергопотребление.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

Новые тенденции в области поиска поставщиков свидетельствуют о том, что все большее предпочтение отдается поставщикам, которые могут предложить комплексные решения, а не отдельные продукты. Покупатели теперь отдают предпочтение партнерству с производителями, которые предоставляют возможности адаптации к конкретным отраслевым потребностям, таким как ОВКВ, водоподготовка и производство. Эта тенденция особенно ярко выражена в таких регионах, как Вьетнам и Германия, где промышленные приложения требуют высококачественных и адаптируемых решений.

Как устойчивое развитие влияет на закупку стартерных двигателей?

Устойчивое развитие стало важнейшим фактором в секторе пусковых двигателей, поскольку экологические нормы ужесточаются, а потребители требуют более экологичных продуктов. Производство и утилизация пусковых двигателей могут оказывать значительное воздействие на окружающую среду, что побуждает компании искать варианты устойчивого поиска поставщиков. Покупатели B2B все чаще отдают предпочтение поставщикам, которые придерживаются устойчивой практики, включая использование перерабатываемых материалов и энергоэффективных производственных процессов.

Этичный поиск поставщиков также набирает обороты, поскольку компании признают важность прозрачности цепочек поставок. Покупатели более склонны сотрудничать с производителями, которые могут продемонстрировать соответствие экологическим стандартам и сертификатам, таким как ISO 14001 для систем экологического менеджмента. Кроме того, использование “зеленых” сертификатов, указывающих на то, что продукция произведена с минимальным воздействием на окружающую среду, может повысить привлекательность поставщика для добросовестных покупателей.

Внедрение устойчивых практик не только помогает соответствовать нормативным требованиям, но и повышает репутацию бренда и лояльность клиентов. По мере развития рынка компании, которые уделяют приоритетное внимание устойчивому развитию в своих стратегиях поиска поставщиков, вероятно, получат конкурентное преимущество, особенно в регионах с высоким уровнем экологической осведомленности.

Каков исторический контекст сектора стартерных двигателей?

Эволюция сектора стартерных двигателей отражает более широкий технологический прогресс в электротехнике. Изначально разработанные в начале XX века стартеры были необходимы для работы двигателей внутреннего сгорания, обеспечивая более легкий запуск автомобиля. Со временем прогресс в технологии производства стартеров привел к созданию более эффективных и надежных систем, включающих такие функции безопасности, как защита от перегрузок и механизмы автоматического отключения.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

С расширением сферы применения в промышленности вырос спрос на надежные пускатели электродвигателей, что привело к появлению таких инноваций, как магнитные пускатели и частотно-регулируемые приводы (ЧРП). Эти разработки позволили лучше контролировать работу двигателя, повышая энергоэффективность и эксплуатационную надежность. Сегодня рынок продолжает развиваться благодаря интеграции интеллектуальных технологий и решений IoT, создавая основу для новой эры автоматизации и эффективности систем управления электродвигателями.

Понимание этого исторического контекста может дать покупателям B2B представление о производительности, надежности и технологических достижениях, которые они должны ожидать при выборе стартерных двигателей на современном динамичном рынке.

Часто задаваемые вопросы (FAQ) для B2B покупателей стартера двигателя стартера

-

Как выбрать подходящий пусковой двигатель для моего применения?

Выбор подходящего пускового двигателя предполагает понимание специфических требований вашего приложения, включая напряжение, мощность и фазу. Оцените условия, в которых будет работать двигатель, такие как температура и влажность, а также любые нормативные стандарты (например, UL или IEC). Проконсультируйтесь с поставщиками по поводу подробных технических характеристик и подумайте, нужны ли вам такие функции, как защита от тепловой перегрузки или чувствительность к потере фазы. Кроме того, оцените совместимость с существующими системами, чтобы обеспечить беспроблемную интеграцию. -

Какой тип пускателя двигателя лучше всего подходит для промышленного применения?

Для промышленного применения магнитные пускатели двигателей часто являются лучшим выбором благодаря своей надежности и безопасности. Они обеспечивают защиту от низкого напряжения и перегрузки по току, что делает их подходящими для двигателей различных размеров и типов. Нереверсивные пускатели полного напряжения (FVNR) обычно используются для прямолинейных операций, а реверсивные пускатели полного напряжения (FVR) идеальны при необходимости изменения направления вращения. Всегда подбирайте тип пускателя в соответствии с конкретными эксплуатационными потребностями и техническими характеристиками двигателя. -

Каковы типичные условия оплаты при международных закупках стартерных двигателей?

Условия оплаты международных закупок могут сильно различаться в зависимости от кредитоспособности поставщика и покупателя. Обычные условия включают предоплату, аккредитив или чистые 30/60/90 дней после отгрузки. Очень важно договориться об условиях, которые будут соответствовать вашим денежным потокам и одновременно обеспечивать безопасность для обеих сторон. Помните о курсах обмена валют и дополнительных комиссиях, которые могут взиматься при международных сделках, а также используйте надежные платежные платформы для снижения рисков. -

Как проверить поставщиков стартерных двигателей?

Проверка поставщиков включает в себя несколько этапов: проверьте их репутацию в отрасли, сертификаты и соответствие международным стандартам. Запросите рекомендации у предыдущих клиентов и оцените их опыт работы на вашем конкретном рынке. Оцените их производственные возможности и процессы контроля качества, включая любые сертификаты, например ISO. Посещение объекта или виртуальная инспекция могут дать представление об их деятельности. Кроме того, проверьте отзывы и рейтинги клиентов на таких платформах, как Alibaba или Trustpilot. -

Какие варианты индивидуальной настройки доступны для стартеров?

Варианты настройки пусковых двигателей могут включать в себя изменение напряжения, номинальной мощности, а также дополнительные функции, такие как защита от перегрузки, типы корпусов и конфигурации цепей управления. Некоторые производители могут предлагать индивидуальные решения, разработанные с учетом конкретных промышленных потребностей или условий окружающей среды. Обсудите свои требования с потенциальными поставщиками, чтобы изучить возможные варианты настройки и убедиться, что они соответствуют вашим производственным целям и требованиям к соблюдению норм. -

Каков минимальный объем заказа (MOQ) для стартеров?

Минимальные объемы заказов (MOQ) могут значительно отличаться у разных поставщиков. У одних производителей MOQ может составлять всего несколько единиц, в то время как другие могут требовать больших заказов для обеспечения экономической эффективности. При переговорах с поставщиками поинтересуйтесь их политикой MOQ и возможной гибкостью, особенно для первых покупателей или пробных заказов. Понимание MOQ поможет вам более эффективно планировать свои запасы и бюджет. -

На какие меры по обеспечению качества следует обратить внимание при поиске поставщиков пусковых двигателей?

Меры по обеспечению качества могут включать сертификаты от признанных организаций по стандартизации (например, UL или CE), подробные протоколы испытаний и гарантии, предоставляемые производителем. Запросите информацию о процессах контроля качества поставщика, включая проверки и методы тестирования, используемые в процессе производства. Понимание их подхода к качеству поможет вам убедиться, что пусковые двигатели соответствуют требуемым стандартам производительности и надежности для ваших приложений. -

Как логистика и доставка влияют на поставку стартерных двигателей на международный рынок?

Логистика и доставка играют важную роль в международном снабжении стартерных двигателей. Учитывайте сроки производства и доставки, которые могут варьироваться в зависимости от места происхождения и назначения. Оцените доступные варианты доставки, включая авиаперевозки для ускорения доставки или морские перевозки для экономии средств. Кроме того, обратите внимание на таможенные правила и пошлины, которые могут применяться, поскольку они могут повлиять на общую стоимость и сроки выполнения заказа. Сотрудничество с опытными партнерами по логистике может упростить процесс и уменьшить возможные задержки.

Список лучших 2 производителей и поставщиков стартера двигателя

1. Cook MFG - пускатели двигателей

Домен: cookmfg.com

Зарегистрирован: 2020 (5 лет)

Введение: Эта компания, Cook MFG - Motor Starters, является заметным субъектом на рынке. Для получения подробной информации о продукции рекомендуется посетить их сайт.

2. Haynes - Стартерный двигатель

Домен: us.haynes.com

Зарегистрирован: 1996 (29 лет)

Введение: Эта компания, Haynes - Starter Motor, является заметным субъектом на рынке. Для получения подробной информации о продукции рекомендуется посетить их сайт.

Стратегическое заключение по поиску и перспективы для пускателя двигателя

В условиях конкуренции промышленных электродвигателей стратегический выбор пускателей имеет жизненно важное значение для оптимизации эффективности работы и минимизации затрат. Как подчеркивается в данном руководстве, правильный выбор пускателя двигателя не только обеспечивает надежную работу двигателя, но и повышает безопасность благодаря встроенным функциям защиты, таким как тепловая перегрузка и чувствительность к обрыву фазы. При выборе этих важных компонентов покупатели должны учитывать такие характеристики, как совместимость по напряжению, номинальные параметры корпуса и конкретные потребности своих приложений.

Инвестиции в качественные пускатели электродвигателей от надежных производителей могут привести к долгосрочной экономии и сокращению времени простоя, особенно в сложных условиях эксплуатации в Африке, Южной Америке, на Ближнем Востоке и в Европе. Поскольку в промышленности все большее внимание уделяется устойчивости и эффективности, интеграция передовых технологий, таких как частотно-регулируемые приводы (VFD), может стать более распространенной, обеспечивая больший контроль над работой двигателя.

В будущем международным покупателям рекомендуется налаживать партнерские отношения с надежными поставщиками, которые понимают динамику местного рынка и могут предложить индивидуальные решения. Используя стратегический поиск поставщиков, компании могут не только расширить свои операционные возможности, но и внедрить инновации в свои приложения с электродвигателями. Настало время действовать - инвестируйте в надежные пусковые устройства для электродвигателей, чтобы обеспечить себе конкурентное преимущество в своей отрасли.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Иллюстративное изображение, относящееся к стартеру двигателя стартера

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.