Introduction: Navigating the Global Market for que es un alternador

In today’s rapidly evolving automotive landscape, understanding the role of an alternator is crucial for international B2B buyers looking to optimize their supply chains and enhance their vehicle performance. An alternator is not just a component; it is the heart of a vehicle’s electrical system, responsible for generating the electricity necessary to power all electrical components while the engine is running. As businesses in regions like Africa, South America, the Middle East, and Europe (notably in markets like Nigeria and Brazil) seek reliable sourcing solutions, a comprehensive grasp of the alternator’s function, types, and applications becomes paramount.

This guide delves into the intricate world of alternators, offering insights into various types, their specific applications across different vehicle models, and essential criteria for supplier vetting. Additionally, it addresses cost considerations and the importance of quality assurance in procurement. By equipping B2B buyers with the knowledge necessary to make informed decisions, this guide serves as a vital resource for enhancing operational efficiency and ensuring the longevity of vehicle fleets.

In a market where reliability and performance are non-negotiable, understanding what an alternator is and how to choose the right one can significantly impact your business outcomes. Empower your purchasing strategies today by navigating the essential factors of sourcing the right alternator for your needs.

Содержание

- Top 6 Que Es Un Alternador Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for que es un alternador

- Understanding que es un alternador Types and Variations

- Key Industrial Applications of que es un alternador

- 3 Common User Pain Points for ‘que es un alternador’ & Their Solutions

- Strategic Material Selection Guide for que es un alternador

- In-depth Look: Manufacturing Processes and Quality Assurance for que es un alternador

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘que es un alternador’

- Comprehensive Cost and Pricing Analysis for que es un alternador Sourcing

- Alternatives Analysis: Comparing que es un alternador With Other Solutions

- Essential Technical Properties and Trade Terminology for que es un alternador

- Navigating Market Dynamics and Sourcing Trends in the que es un alternador Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of que es un alternador

- Strategic Sourcing Conclusion and Outlook for que es un alternador

- Важное предупреждение и условия использования

Understanding que es un alternador Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Обычный генератор | Uses electromagnetic induction; standard in most vehicles. | Автомобилестроение, тяжелое машиностроение | Плюсы: Широко доступны, экономически эффективны. Минусы: May require frequent maintenance. |

| Высокопроизводительный генератор | Designed to produce higher amperage; ideal for high-demand vehicles. | Performance Vehicles, RVs | Плюсы: Поддерживает дополнительные электрические аксессуары. Минусы: Typically more expensive. |

| Бесщеточный генератор | Utilizes electronic components instead of brushes for efficiency. | Renewable Energy Systems, Marine | Плюсы: Более длительный срок службы, сокращение технического обслуживания. Минусы: Более высокие первоначальные инвестиции. |

| Двухвольтный генератор переменного тока | Capable of generating both 12V and 24V; versatile for various uses. | Commercial Trucks, Industrial | Плюсы: Flexibility for different applications. Минусы: Complexity may lead to higher repair costs. |

| Умный генератор | Features integrated electronics for optimized performance management. | Hybrid and Electric Vehicles | Плюсы: Enhances fuel efficiency, better battery management. Минусы: Requires compatible systems for full benefits. |

Каковы характеристики обычных генераторов переменного тока?

Conventional alternators are the most common type found in vehicles today. They operate using electromagnetic induction and are primarily designed to recharge the car battery while powering the electrical systems when the engine is running. These alternators are typically cost-effective and readily available, making them a go-to choice for many B2B buyers in the automotive and heavy machinery sectors. However, they may require regular maintenance due to wear on components like brushes.

How Do High-Output Alternators Differ in Application?

High-output alternators are engineered to produce greater amperage, making them ideal for performance vehicles and recreational vehicles (RVs) that require more power for additional electrical accessories. These alternators are particularly beneficial for businesses that rely on high-demand electrical systems, such as mobile food trucks or specialized automotive services. While they can significantly enhance performance, their higher price point may be a consideration for budget-conscious buyers.

Какие преимущества дают бесщеточные генераторы?

Brushless alternators utilize electronic components instead of traditional brushes, resulting in increased efficiency and a longer lifespan. They are commonly used in renewable energy systems and marine applications where durability and low maintenance are crucial. For B2B buyers, the initial investment may be higher, but the reduced maintenance costs and extended operational life can lead to significant savings over time, making them an attractive option for industries focused on sustainability and reliability.

Why Choose Dual-Voltage Alternators for Diverse Needs?

Dual-voltage alternators are versatile units capable of generating both 12V and 24V, making them suitable for a wide range of applications, from commercial trucks to industrial machinery. This flexibility can be a major advantage for businesses that operate various equipment requiring different voltage levels. However, the complexity of these systems may lead to increased repair costs, which is an important factor for buyers to consider when evaluating total cost of ownership.

How Do Smart Alternators Enhance Performance?

Smart alternators come equipped with integrated electronics that optimize performance and battery management. These units are increasingly found in hybrid and electric vehicles, where efficiency is paramount. For B2B buyers, the benefits include enhanced fuel efficiency and improved battery life, making them an appealing choice for businesses focused on reducing operational costs. However, compatibility with existing systems is crucial to fully leverage their advantages, and this may require additional investment in technology upgrades.

Key Industrial Applications of que es un alternador

| Отрасль/сектор | Specific Application of que es un alternador | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Питание электрических систем транспортных средств | Ensures reliable operation of vehicle systems, enhancing safety and performance. | Quality standards, compatibility with various vehicle models, and after-sales support. |

| Возобновляемые источники энергии | Supporting wind and solar power systems | Converts mechanical energy into electrical energy, aiding in renewable energy generation. | Efficiency ratings, durability in harsh environments, and integration with existing systems. |

| Тяжелое оборудование | Generating power for construction equipment | Provides essential electricity for operation, reducing downtime and maintenance costs. | Size, weight, and power output specifications to match equipment needs. |

| Морская промышленность | Питание бортовых электрических систем на судах | Ensures reliable operation of navigation and communication systems, enhancing safety. | Corrosion resistance, compliance with maritime standards, and serviceability. |

| Телекоммуникации | Providing backup power for cell towers and data centers | Maintains operational continuity during power outages, protecting critical infrastructure. | Reliability, energy efficiency, and capacity to support varying load demands. |

How is ‘que es un alternador’ Used in Automotive Manufacturing?

In the automotive manufacturing industry, alternators are crucial for powering a vehicle’s electrical systems, including lights, infotainment, and safety features. They convert mechanical energy from the engine into electrical energy, ensuring that the battery remains charged and the vehicle operates smoothly. For international buyers, particularly in regions like Nigeria or Brazil, sourcing high-quality alternators that meet specific vehicle requirements is essential. Considerations include compliance with local automotive standards, compatibility with various models, and the availability of technical support for installation and maintenance.

What Role Does ‘que es un alternador’ Play in Renewable Energy?

In renewable energy applications, alternators are used to convert mechanical energy generated by wind turbines or solar trackers into electrical energy. This conversion process is vital for integrating renewable sources into the power grid. Businesses in this sector benefit from using efficient alternators that can withstand variable environmental conditions. Buyers should focus on sourcing alternators with high efficiency ratings and durability, ensuring they can operate effectively in remote locations common in Africa and South America.

How is ‘que es un alternador’ Beneficial for Heavy Machinery?

Heavy machinery relies on alternators to generate power for various electrical systems, including hydraulic controls and operator cabins. A reliable alternator minimizes downtime and maintenance costs, which is critical in construction and mining industries. Buyers in this sector, especially in the Middle East and Europe, should prioritize sourcing alternators that meet specific size and power output requirements, ensuring they are tailored to the machinery being used.

Why is ‘que es un alternador’ Important in the Marine Industry?

In the marine industry, alternators are essential for powering onboard electrical systems, including navigation and communication devices. A dependable alternator enhances the safety and efficiency of vessel operations. Buyers should consider sourcing alternators that are corrosion-resistant and compliant with maritime safety standards, ensuring reliability in harsh marine environments, particularly for operations in regions like Africa and the Middle East.

How Does ‘que es un alternador’ Support Telecommunications?

In telecommunications, alternators provide backup power for cell towers and data centers, ensuring uninterrupted service during power outages. This reliability is crucial for maintaining communication networks, especially in regions prone to power instability. Buyers should focus on sourcing alternators that offer high reliability and energy efficiency, with the capacity to support varying load demands, thereby ensuring continuous operation of critical infrastructure.

3 Common User Pain Points for ‘que es un alternador’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Alternators

Проблема:

B2B buyers often face challenges when sourcing alternators that meet the specific needs of their operations. This can arise from a lack of information about the types of alternators available, the varying quality levels, and the reliability of suppliers. For instance, a company in Nigeria looking to import alternators may find it overwhelming to navigate the market, leading to concerns about product quality, warranty terms, and delivery timelines. Additionally, buyers may encounter difficulties in determining which specifications are critical for their vehicle or machinery, leading to costly mistakes.

Решение:

To address these sourcing challenges, B2B buyers should conduct thorough market research to identify reputable suppliers and manufacturers. Utilizing platforms like Alibaba or TradeKey can connect buyers with verified vendors. It’s essential to request detailed product specifications, including voltage ratings, power output, and compatibility with specific vehicle models. Establishing clear communication with suppliers about quality standards and warranty options can help mitigate risks. Furthermore, consider engaging with local distributors who understand the regional market dynamics, as they may offer better support and service. Implementing a sample testing process before making large orders can also ensure that the alternators meet operational requirements.

Scenario 2: Understanding Alternator Specifications and Compatibility

Проблема:

Another common pain point for B2B buyers is the confusion surrounding alternator specifications and compatibility with various vehicle models. Many buyers may not be fully aware of the technical details such as amperage, mounting configurations, and the differences between standard and high-output alternators. This lack of understanding can lead to purchasing the wrong alternator, resulting in operational downtime and additional costs for returns or replacements. For instance, a buyer in Brazil may purchase an alternator that does not match the specifications of their fleet, causing significant delays in their supply chain.

Решение:

To overcome this issue, B2B buyers should invest time in understanding the key specifications and their implications for their specific needs. Creating a checklist that includes vehicle make, model, year, and electrical requirements can streamline the selection process. Additionally, consulting with automotive engineers or technical experts can provide insights into the best alternator options for particular applications. Buyers should also leverage online resources and manufacturer catalogs that detail compatibility charts. Finally, establishing a relationship with a knowledgeable supplier can provide ongoing support and guidance in selecting the right alternators.

Scenario 3: Maintenance and Troubleshooting of Alternators

Проблема:

Once an alternator is purchased and installed, maintaining it and troubleshooting potential issues can be a significant challenge for B2B buyers. Problems such as unusual noises, flickering lights, or failure to start may indicate alternator malfunctions. Buyers in the Middle East, where environmental factors can strain automotive components, might find that their alternators wear out faster than expected, leading to increased maintenance costs and vehicle downtime. This scenario is particularly detrimental for businesses that rely on transportation for their operations.

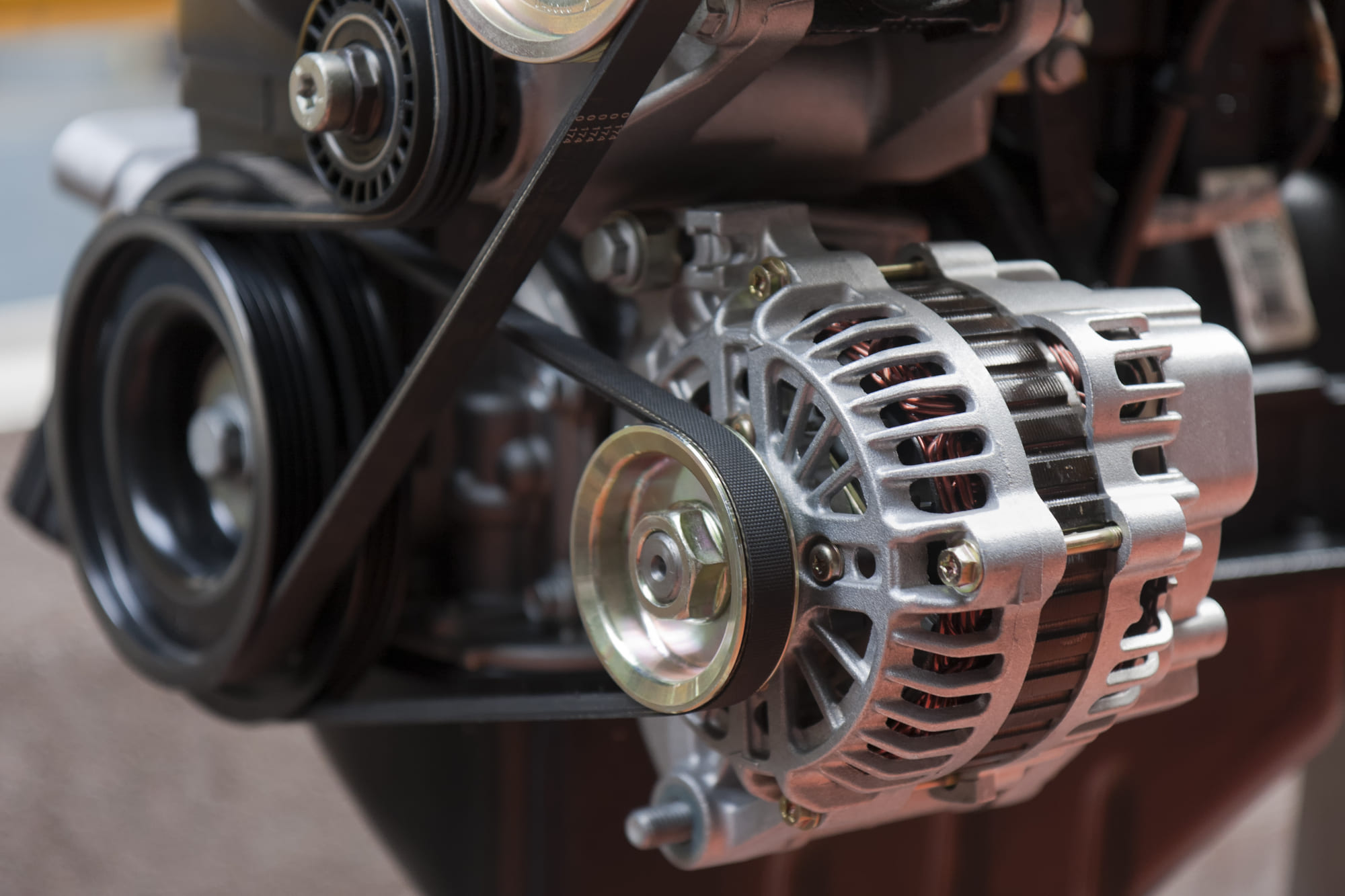

Illustrative image related to que es un alternador

Решение:

To effectively manage alternator maintenance and troubleshooting, B2B buyers should develop a proactive maintenance schedule that includes regular inspections and testing of the alternator’s output and connections. Educating staff on common signs of alternator failure can facilitate early detection and avoid severe issues. Additionally, implementing a training program for technicians that covers alternator operation and maintenance can empower them to handle minor repairs in-house. Creating partnerships with qualified service centers for more complex repairs ensures that issues are addressed promptly and efficiently. Lastly, documenting maintenance activities can help track performance trends and inform future purchasing decisions.

Strategic Material Selection Guide for que es un alternador

What Are the Common Materials Used in Alternators?

When selecting materials for alternators, it is essential to consider their properties, performance, and suitability for various applications. Below, we analyze four common materials used in the manufacturing of alternators, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Алюминий

Ключевые свойства:

Aluminum is lightweight, has excellent thermal conductivity, and offers good corrosion resistance. It typically performs well under moderate temperature ranges, making it suitable for automotive applications.

Плюсы и минусы:

The primary advantage of aluminum is its low weight, which contributes to overall vehicle efficiency. It is also cost-effective and easier to manufacture compared to heavier metals. However, aluminum may not withstand high-temperature environments as effectively as some alternatives, and its mechanical strength can be lower than that of steel.

Влияние на применение:

Aluminum is often used in the casing and housing of alternators, where weight savings are critical. However, it may not be suitable for components exposed to extreme temperatures or mechanical stress.

Соображения для международных покупателей:

Buyers from regions like Africa and South America should ensure compliance with local standards for aluminum alloys, such as ASTM or ISO specifications, to guarantee quality and performance.

2. Медь

Ключевые свойства:

Copper is known for its excellent electrical conductivity and thermal properties. It can handle high temperatures and is resistant to corrosion, making it ideal for electrical components.

Плюсы и минусы:

Copper’s superior conductivity enhances the efficiency of alternators, leading to better performance. However, it is more expensive than aluminum and can be heavy, which may affect overall vehicle weight. Additionally, the manufacturing process can be complex, requiring specialized techniques.

Влияние на применение:

Copper is primarily used in windings and connectors within the alternator, where high conductivity is crucial for performance. Its ability to handle high currents makes it indispensable in these applications.

Соображения для международных покупателей:

B2B buyers should consider the sourcing of copper from reputable suppliers to ensure compliance with environmental regulations, especially in regions with strict mining and processing guidelines.

Illustrative image related to que es un alternador

3. Сталь

Ключевые свойства:

Steel is known for its high tensile strength and durability. It can withstand high pressure and temperature, making it suitable for demanding applications.

Плюсы и минусы:

The durability of steel provides longevity and reliability in alternator components. However, it is heavier than aluminum and copper, which can negatively impact fuel efficiency in vehicles. Additionally, the cost of high-quality steel can be significant.

Влияние на применение:

Steel is often used for structural components of the alternator, such as the frame and mounting brackets, where strength is paramount. Its robustness ensures that the alternator can endure mechanical stresses during operation.

Соображения для международных покупателей:

Buyers should be aware of the different grades of steel and their respective standards (e.g., ASTM, DIN) to ensure compatibility with their specific applications.

Illustrative image related to que es un alternador

4. Пластиковые композиты

Ключевые свойства:

Plastic composites are lightweight and resistant to corrosion and chemicals. They can be molded into complex shapes, allowing for innovative designs.

Плюсы и минусы:

The main advantage of plastic composites is their weight reduction, which can improve vehicle efficiency. They are also cost-effective and can be produced in large quantities. However, they may not withstand high temperatures or mechanical stress as effectively as metals.

Влияние на применение:

Plastic composites are often used for non-structural components, such as covers and insulators, where weight savings are beneficial. They provide adequate protection for sensitive electrical components.

Соображения для международных покупателей:

International buyers should consider the material’s compliance with automotive industry standards, especially regarding flammability and chemical resistance.

Сводная таблица выбора материалов для генераторов

| Материал | Typical Use Case for que es un alternador | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Casing and housing | Легкий и коррозионно-стойкий | Низкая механическая прочность | Средний |

| Медь | Windings and connectors | Отличная электропроводность | Более высокая стоимость и вес | Высокий |

| Сталь | Структурные компоненты | Высокая прочность на разрыв | Heavier and potentially more costly | От среднего до высокого |

| Пластиковые композиты | Крышки и изоляторы | Легкий и экономичный | Ограниченная термическая и механическая стойкость | Низкий |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in alternators, helping them make informed decisions that align with their operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for que es un alternador

Каковы основные этапы процесса производства генератора?

The manufacturing of alternators involves several critical stages, each designed to ensure that the final product meets both performance and durability standards. Understanding these processes is essential for B2B buyers looking to partner with reliable suppliers.

Как подготавливается материал для производства генераторов?

The first step in the manufacturing process is material preparation. Key materials include high-grade steel for the casing, copper for the windings, and various types of magnets. Suppliers must ensure that materials meet specific industry standards to guarantee electrical conductivity and structural integrity. This preparation often involves:

- Выбор материала: Choosing materials that can withstand high temperatures and mechanical stresses.

- Контроль качества: Conducting initial inspections to verify that materials meet specifications before they enter production.

What Techniques Are Used in Forming the Components of an Alternator?

After material preparation, the next stage is forming the various components of the alternator. This typically includes the rotor, stator, and casing. Common techniques include:

- Кастинг: Used for creating the alternator casing, often from aluminum or high-strength plastics.

- Обработка: Precision machining techniques are employed to create the rotor and stator components, ensuring they fit together seamlessly.

- Намотка: Copper wire is wound into coils to create the electromagnetic field necessary for electricity generation.

Each of these processes requires specialized equipment and expertise to maintain tight tolerances and ensure performance standards.

Illustrative image related to que es un alternador

Как собираются компоненты генератора?

Once the components are formed, they undergo assembly. This is a critical stage where attention to detail is paramount. Key steps include:

- Интеграция: The rotor is placed within the stator, and the two are aligned precisely to maximize efficiency.

- Электрические соединения: Diods and regulators are integrated, ensuring the alternator can convert AC to DC power effectively.

- Заключительная сборка: The casing is sealed, and any additional components, such as cooling fans, are added.

Assembly lines often utilize automated systems to enhance consistency and reduce human error.

Какие процессы отделки применяются к генераторам?

Finishing processes are essential to enhance the durability and performance of the alternator. These may include:

- Обработка поверхности: Coatings are applied to protect against corrosion and wear.

- Тестирование качества: Each alternator undergoes rigorous testing to ensure it meets performance standards before leaving the factory.

Finishing processes are vital for ensuring that the alternators can withstand harsh operating conditions.

What Quality Assurance Practices Are Critical for Alternator Manufacturers?

Quality assurance is a non-negotiable aspect of alternator manufacturing, especially for international B2B buyers. Understanding the quality assurance practices helps in selecting reliable suppliers.

Какие международные стандарты следует учитывать покупателям B2B?

When evaluating suppliers, B2B buyers should look for adherence to international standards such as:

- ISO 9001: This standard ensures a quality management system is in place, focusing on customer satisfaction and continuous improvement.

- Маркировка CE: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- Стандарты API: For alternators used in specific industries, such as oil and gas, adherence to API standards may be required.

These certifications help buyers ensure that the products they are sourcing will meet regulatory and performance expectations.

Каковы основные пункты контроля качества при производстве генераторов?

Quality control checkpoints are integral to maintaining product quality throughout the manufacturing process. Common checkpoints include:

- Входящий контроль качества (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- Контроль качества в процессе производства (IPQC): Conducting checks at various stages of the manufacturing process to identify defects early.

- Окончательный контроль качества (FQC): Performing exhaustive tests on finished alternators to verify performance and safety.

These checkpoints ensure that quality issues are addressed promptly and do not reach the customer.

Как покупатели B2B могут проверить методы контроля качества поставщиков?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers:

- Аудиты: Conducting regular audits of the supplier’s manufacturing facilities can provide insights into their quality management practices.

- Отчеты о качестве: Requesting detailed quality reports and performance metrics can help assess the supplier’s commitment to quality.

- Проверки третьей стороной: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control processes.

By leveraging these verification methods, buyers can ensure that they partner with manufacturers who prioritize quality.

What Nuances Should International Buyers Be Aware Of Regarding Quality Control?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

- Культурные различия: Different regions may have varying standards and practices in manufacturing. It’s crucial to understand these to avoid miscommunications.

- Соблюдение нормативных требований: Each region may have specific regulations that affect product standards. Buyers should familiarize themselves with these requirements to ensure compliance.

- Логистика и цепочка поставок: The complexity of international shipping can affect the quality of the product. Buyers should ensure that their suppliers have robust logistics and supply chain management systems in place.

By being aware of these nuances, international buyers can make informed decisions and foster successful partnerships with suppliers.

Illustrative image related to que es un alternador

In summary, understanding the manufacturing processes and quality assurance practices for alternators is vital for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control measures, buyers can ensure that they source reliable and high-performing products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘que es un alternador’

In the competitive landscape of B2B procurement, acquiring quality alternators—essential components for automotive electrical systems—requires a strategic approach. This guide outlines a practical checklist to help international buyers navigate the sourcing process effectively.

Шаг 1: Определите свои технические характеристики

Before initiating your search for alternators, it’s crucial to establish clear technical specifications. Consider the type of vehicles you are focusing on, as alternators vary in size, output voltage, and compatibility with different systems. Specific requirements might include power output (measured in amps), physical dimensions, and mounting configurations.

Шаг 2: Исследование рыночных тенденций и ценообразования

Understanding current market trends and pricing for alternators is essential for making informed purchasing decisions. Look into the average costs within your target regions, such as Africa and South America, to avoid overpaying. Utilize industry reports, online marketplaces, and competitor analysis to gauge pricing benchmarks and product availability.

Шаг 3: Оцените потенциальных поставщиков

Before committing to a supplier, thorough evaluation is critical. Request detailed company profiles, including years in business, production capabilities, and client testimonials. Pay attention to suppliers that specialize in automotive parts, as their expertise can significantly affect quality and reliability.

- Проверить сертификаты: Ensure that the suppliers have relevant certifications, such as ISO or other industry-specific standards, to guarantee compliance with international quality norms.

Шаг 4: Assess Quality Control Processes

Quality control is a key factor in sourcing alternators. Inquire about the supplier’s quality assurance measures, including testing procedures for each batch produced. A reliable supplier should be able to provide documentation of tests performed, such as load testing and electrical performance evaluations.

Шаг 5: Запросить образцы для тестирования

Before placing a bulk order, always request samples of the alternators for testing. This step allows you to evaluate the product’s compatibility with your vehicles and assess its performance under real-world conditions. Look for any signs of defects or inconsistencies that could lead to future issues.

Шаг 6: Понимание гарантийного обслуживания и послепродажной поддержки

A solid warranty and after-sales support are vital when sourcing alternators. Ensure that the supplier offers a reasonable warranty period that covers defects and performance issues. Additionally, inquire about their customer service protocols and how they handle returns or replacements to safeguard your investment.

Шаг 7: Обсудить условия и положения

Once you have identified a suitable supplier, it’s time to negotiate terms and conditions. Discuss pricing, payment terms, and delivery schedules to ensure they align with your operational needs. Be clear about your expectations regarding lead times and order fulfillment to prevent any future disruptions in your supply chain.

By following these steps, B2B buyers can strategically navigate the sourcing process for alternators, ensuring they obtain quality products that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for que es un alternador Sourcing

Understanding the cost structure and pricing analysis for sourcing alternators is essential for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Below, we delve into the critical components of cost, the influencers on pricing, and strategic tips for buyers looking to make informed purchasing decisions.

Каковы основные компоненты затрат при производстве генераторов?

When evaluating the cost of an alternator, several components come into play:

-

Материалы: The primary materials include copper for windings, aluminum for casings, and various other metals for internal components. Fluctuations in raw material prices significantly impact overall costs.

-

Трудовые ресурсы: Skilled labor is required for assembly and quality control. Labor costs vary by region, with countries having lower labor costs potentially offering competitive pricing.

-

Производственные накладные расходы: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient operations can lower overhead, impacting the final product price.

-

Инструменты: The initial investment in tooling can be substantial, particularly for custom or specialized alternators. This cost is amortized over the production volume, influencing unit pricing.

-

Контроль качества (КК): Ensuring the alternators meet industry standards and certifications incurs additional costs. Rigorous QC processes help minimize defects but add to the overall expense.

-

Логистика: Transportation costs, including shipping and customs duties, are crucial, particularly for international buyers. The choice of shipping method can affect delivery timelines and costs.

-

Маржа: Suppliers typically add a profit margin to cover their expenses and risks. Understanding the market dynamics can help buyers negotiate better prices.

Что влияет на цену генераторов?

Several factors can influence the pricing of alternators in the B2B market:

-

Объем/минимальный объем заказа: Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQs) to secure better pricing.

-

Технические характеристики и индивидуальная настройка: Customized alternators that meet specific requirements may incur higher costs due to additional design and manufacturing efforts. Buyers should clearly define specifications to avoid unexpected charges.

-

Качество материалов и сертификаты: Alternators that meet stringent quality standards or certifications (such as ISO or industry-specific certifications) may command higher prices. Buyers should weigh the benefits of investing in higher-quality products against potential long-term savings.

-

Факторы, связанные с поставщиками: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer better quality but at a premium, while newer entrants may provide lower prices to gain market share.

-

Инкотермс: The terms of shipping (Incoterms) can significantly affect total costs. Understanding whether costs include shipping, insurance, and tariffs can help buyers calculate the total landed cost.

What Are the Best Practices for Buyers in Negotiating Prices?

For B2B buyers, particularly those from diverse regions, implementing effective negotiation strategies can yield significant savings:

-

Исследование рыночных тенденций: Stay informed about the current market prices and trends for alternators. This knowledge can empower buyers during negotiations.

-

Учитывайте общую стоимость владения: Look beyond the initial purchase price. Assess factors such as durability, warranty, and maintenance costs, which can affect the total cost of ownership over the product’s lifecycle.

-

Используйте связи: Building strong relationships with suppliers can lead to better pricing, favorable terms, and priority treatment during shortages.

-

Изучите нескольких поставщиков: Obtaining quotes from multiple suppliers can help identify competitive pricing and better understand market dynamics. This approach also provides leverage during negotiations.

-

Обсудить условия оплаты: Flexible payment terms can ease cash flow constraints and may enable buyers to negotiate lower prices.

Отказ от ответственности за ориентировочные цены

Pricing for alternators can vary widely based on the factors discussed above. Buyers should consult directly with suppliers for the most accurate and up-to-date pricing based on their specific needs and circumstances.

Alternatives Analysis: Comparing que es un alternador With Other Solutions

Understanding Alternatives to ‘Que Es Un Alternador’

In the automotive industry, the alternator is a critical component for maintaining electrical systems and charging the battery while the vehicle is running. However, there are alternative technologies and methods available that can serve similar purposes. This analysis will compare the traditional alternator with two viable alternatives: the Генератор постоянного тока и Система управления батареей (BMS), commonly used in electric vehicles.

Сравнительная таблица

| Аспект сравнения | Que Es Un Alternador | Генератор постоянного тока | Система управления батареей (BMS) |

|---|---|---|---|

| Производительность | High efficiency in energy conversion; provides consistent power while the engine runs. | Moderate efficiency; less effective under varying loads. | Highly efficient; optimizes battery life and performance. |

| Стоимость | Moderate initial cost; long-term reliability justifies investment. | Generally lower upfront cost, but less durable. | Higher initial investment; cost-effective in the long run due to enhanced battery life. |

| Простота внедрения | Standard installation in combustion vehicles; requires basic mechanical skills. | Simple setup; often used in older or specialized vehicles. | Requires integration with electric vehicles; more complex installation. |

| Техническое обслуживание | Requires regular checks; can be expensive to replace if failed. | Minimal maintenance; longer lifespan but less reliable under heavy load. | Low maintenance; software updates may be required for optimal performance. |

| Лучший вариант использования | Ideal for internal combustion engine vehicles where continuous power supply is necessary. | Suitable for older vehicles or specific applications needing simple power solutions. | Best for electric vehicles and hybrid systems needing precise battery management. |

Подробная разбивка альтернатив

What are DC Generators and Their Advantages?

DC generators have been a traditional power source for vehicles, converting mechanical energy into electrical energy. They are simpler in design compared to alternators and can be more cost-effective for certain applications. However, their performance can decline under varying load conditions, making them less efficient for modern vehicles that require consistent power for multiple electrical systems. The upfront cost savings can be appealing, but the lack of durability and efficiency may lead to higher long-term costs.

How Does a Battery Management System (BMS) Work?

A Battery Management System (BMS) is primarily used in electric and hybrid vehicles to monitor and manage battery health and charge levels. BMS technology optimizes battery usage, extending its lifespan and improving overall vehicle efficiency. While the initial investment for a BMS can be higher compared to traditional alternators, the long-term benefits, including reduced battery replacement costs and enhanced vehicle performance, often outweigh the initial expense. However, the integration of a BMS can be complex and may require specialized knowledge during installation.

Заключение: выбор правильного решения для ваших нужд

For B2B buyers in the automotive sector, selecting the appropriate technology depends on specific vehicle requirements and operational contexts. If your fleet consists of internal combustion engine vehicles, investing in reliable alternators is typically the best choice due to their performance and proven reliability. Conversely, for electric or hybrid vehicles, a Battery Management System offers advanced capabilities that enhance battery performance and longevity, despite the higher initial costs. Ultimately, understanding the distinct advantages and limitations of each alternative will empower buyers to make informed decisions that align with their operational goals and budget considerations.

Essential Technical Properties and Trade Terminology for que es un alternador

Каковы основные технические свойства генератора?

When considering the procurement of alternators for automotive applications, understanding the essential technical properties is crucial for making informed decisions. Here are some key specifications that B2B buyers should pay attention to:

1. Выходное напряжение

The output voltage of an alternator typically ranges from 12V to 14.5V for automotive applications. This voltage is critical as it determines the amount of electrical power available to charge the battery and power vehicle systems. Buyers must ensure that the alternator’s output voltage aligns with the vehicle’s requirements to avoid electrical failures.

2. Текущий номинальный ток (ампер)

The current rating, measured in amperes (A), indicates the maximum electrical current the alternator can deliver. Common ratings range from 40A to over 200A depending on the vehicle’s electrical demands. For B2B buyers, selecting an alternator with the appropriate amperage is vital to ensure all vehicle components operate efficiently without risking damage or system failures.

3. Физические размеры

The physical dimensions, including diameter and length, are important for fitting the alternator into the vehicle’s engine compartment. Buyers should verify compatibility with existing mounting points and belts. Inaccurate dimensions can lead to installation challenges and increased costs.

4. Механизм охлаждения

Alternators generate heat during operation, which can lead to failure if not managed properly. Understanding the cooling mechanism—whether it relies on built-in fans or external cooling systems—is essential. Buyers should consider alternators with efficient cooling designs to enhance durability and performance.

5. Состав материала

The materials used in an alternator, such as the type of metals and insulation, affect its durability and performance. High-grade materials can improve resistance to corrosion and wear. Buyers should prioritize alternators made with robust materials to ensure longevity, especially in harsh environments.

Каковы распространенные торговые термины, связанные с генераторами?

Understanding industry terminology is essential for B2B transactions. Here are several common terms that buyers should be familiar with:

1. OEM (производитель оригинального оборудования)

OEM refers to parts made by the original manufacturer of the vehicle. Purchasing OEM alternators ensures compatibility and reliability, as they are designed specifically for the vehicle’s make and model. For B2B buyers, opting for OEM parts can help maintain brand integrity and reduce warranty issues.

2. MOQ (минимальный объем заказа)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers looking to optimize inventory levels and manage costs. Understanding the MOQ helps in planning purchases and maintaining sufficient stock without overcommitting financially.

3. RFQ (запрос предложения)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers for specific products, including alternators. By providing detailed specifications, buyers can receive accurate pricing and terms. This process is vital for comparing suppliers and negotiating favorable agreements.

4. Инкотермс (Международные торговые термины)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand the total cost of procurement and logistics when sourcing alternators globally.

5. Гарантийный срок

The warranty period is the timeframe during which the manufacturer guarantees the alternator against defects or failures. A longer warranty often indicates higher confidence in product quality. Buyers should carefully review warranty terms to ensure adequate protection and support for their investment.

By understanding these technical properties and trade terms, B2B buyers can make informed purchasing decisions regarding alternators, ensuring they select the right components for their specific applications.

Illustrative image related to que es un alternador

Navigating Market Dynamics and Sourcing Trends in the que es un alternador Sector

What Are the Key Market Dynamics and Trends for Alternators?

The global alternator market is witnessing substantial growth, driven by several key factors. Firstly, the surge in automotive production across emerging economies, particularly in Africa and South America, is propelling demand for efficient power generation systems. Countries like Nigeria and Brazil are experiencing a boom in the automotive sector, leading to increased demand for reliable alternators that can support advanced vehicle electronics and power management systems. Additionally, the growing trend towards electric vehicles (EVs) is reshaping the landscape, as manufacturers adapt alternator designs to cater to hybrid and fully electric vehicles, integrating advanced technologies such as regenerative braking systems.

Current B2B sourcing trends indicate a shift towards digital platforms for procurement, enabling international buyers to access a wider range of suppliers and compare products effectively. Blockchain technology is also being explored for enhancing supply chain transparency, ensuring that buyers can track the provenance of components and verify supplier claims. Furthermore, the push for smart manufacturing is leading to innovations in alternator design, emphasizing modularity and customization to meet diverse client needs. As a result, B2B buyers are encouraged to engage with suppliers who demonstrate technological adaptability and can offer tailored solutions.

How Is Sustainability Influencing the Sourcing of Alternators?

Sustainability is becoming a pivotal consideration in the sourcing of alternators, reflecting a broader trend towards environmentally responsible manufacturing practices. The environmental impact of alternators primarily stems from the materials used and the energy consumed during production. B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices, such as using recycled materials and minimizing waste in the production process.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are seeking partners who comply with international labor standards and environmental regulations. Certifications such as ISO 14001 for environmental management and the use of ‘green’ materials are becoming benchmarks for supplier evaluation. These certifications not only ensure compliance with regulatory requirements but also enhance brand reputation among environmentally conscious consumers. As the market evolves, buyers who prioritize sustainability will likely gain a competitive edge, appealing to a growing demographic that values corporate responsibility.

What Is the Historical Context of Alternators in the Automotive Sector?

The alternator’s evolution has been marked by significant technological advancements since its inception. Initially developed in the early 20th century, alternators replaced the less efficient dynamo system, providing a reliable source of electrical power for automotive applications. The shift from direct current (DC) to alternating current (AC) technology allowed for more efficient energy conversion and better performance under varying load conditions.

Over the decades, advancements in materials and electronics have led to the development of compact and lightweight alternators that deliver higher output with improved reliability. The introduction of smart alternators, which can adjust output based on demand, exemplifies the integration of technology in enhancing vehicle efficiency and performance. As the automotive industry continues to innovate, the alternator remains a critical component, evolving to meet the demands of modern vehicles and the challenges of sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of que es un alternador

-

How do I identify quality alternators for my business needs?

To identify quality alternators, conduct thorough research on suppliers, focusing on their reputation, certifications, and customer reviews. Look for manufacturers that adhere to international quality standards such as ISO 9001. Request product samples to assess build quality and performance. Additionally, consider suppliers who offer warranties and after-sales support, as these can indicate their commitment to quality and customer satisfaction. -

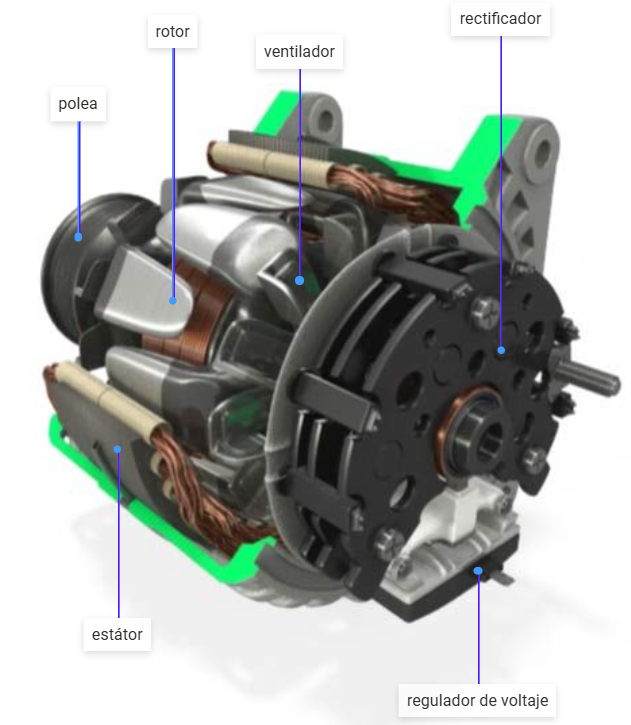

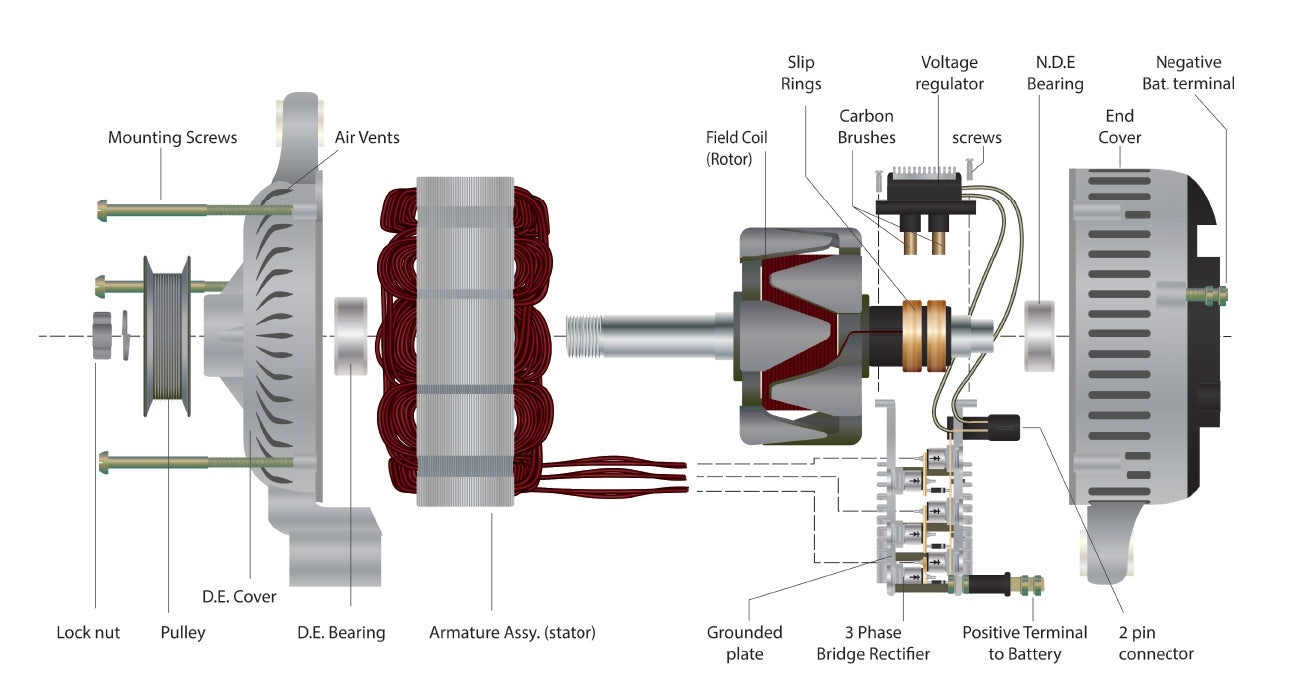

What are the key components of an alternator I should understand?

Understanding the key components of an alternator is crucial. The main parts include the rotor, stator, rectifier, and voltage regulator. The rotor generates a magnetic field, while the stator converts this into electrical energy. The rectifier then transforms alternating current (AC) into direct current (DC) for use in the vehicle. Familiarizing yourself with these components can aid in making informed purchasing decisions and understanding product specifications. -

Какие факторы следует учитывать при выборе поставщиков генераторов переменного тока на международном рынке?

When sourcing alternators internationally, consider factors such as supplier reliability, shipping logistics, and import regulations in your country. Verify the supplier’s manufacturing capabilities, quality assurance processes, and compliance with local standards. Additionally, assess the total landed cost, including shipping, tariffs, and taxes, to ensure competitive pricing. It’s also beneficial to establish clear communication regarding lead times and payment terms. -

How can I vet suppliers for alternators effectively?

Vetting suppliers involves several steps. Start by checking their business credentials and financial stability. Look for reviews or testimonials from other buyers, and consider visiting their facilities if possible. Request certifications that demonstrate compliance with industry standards. Engaging in a trial order can also provide insights into their reliability and product quality before committing to larger purchases. -

Какие варианты настройки доступны для генераторов?

Many manufacturers offer customization options for alternators to meet specific requirements, such as size, voltage output, and design modifications. Discuss your needs with potential suppliers to explore available options. Customization may also include branding, packaging, and performance enhancements. Ensure that the supplier can accommodate these changes within your desired timeline and budget. -

Каковы типичные минимальные объемы заказа (MOQ) для генераторов переменного тока?

Minimum order quantities (MOQ) for alternators can vary significantly based on the supplier and the complexity of the product. Generally, MOQs can range from 50 to several hundred units. It’s essential to clarify this with potential suppliers, as some may offer flexibility for new customers or larger contracts. Understanding MOQ will help in planning your inventory and budgeting for initial purchases. -

На какие условия оплаты следует рассчитывать при поставке генераторов?

Payment terms can vary widely among suppliers. Common practices include upfront payments, payment upon delivery, or net 30/60/90 days terms. It’s crucial to negotiate favorable terms that align with your cash flow needs. Be cautious of suppliers requiring full payment in advance, especially if you are unfamiliar with them. Consider using secure payment methods that provide buyer protection. -

How do logistics and shipping impact the sourcing of alternators?

Logistics and shipping are vital components in sourcing alternators. Factors like shipping methods, lead times, and customs clearance can affect delivery schedules and costs. Engage with suppliers who have experience in international shipping and can provide reliable logistics solutions. Additionally, consider the potential for delays due to customs regulations in your region and plan accordingly to avoid disruptions in your supply chain.

Top 6 Que Es Un Alternador Manufacturers & Suppliers List

1. Infinity Auto – Alternador

Домен: infinityauto.com

Зарегистрирован: 2002 (23 года)

Введение: Генератор переменного тока - это генератор, который распределяет электричество по автомобилю и заряжает аккумуляторную батарею. Функционирует, преобразуя механическую энергию в электрическую, которая поступает от двигателя через серпантин. Основные компоненты включают в себя: 1. Ротор: цилиндрическая часть, покрытая иманами, вращающаяся внутри корпуса. 2. Эстатор: часть фиджи, содержащая кабели из кобры. 3. ...

2. Sadi Transmisiones – Alternadores

Домен: saditransmisiones.com

Зарегистрирован: 1999 (26 лет)

Введение: Un alternador es un dispositivo electromecánico que convierte energía mecánica en energía eléctrica, esencial en vehículos y maquinaria. Consta de un rotor, estator y sistema de excitación. El rotor gira impulsado por una correa, creando un campo magnético que induce corriente eléctrica en el estator, que se rectifica a corriente continua para cargar baterías y alimentar componentes eléctricos. Lo…

3. Electude – Alternador Automotriz

Домен: electude.com

Зарегистрирован: 2005 (20 лет)

Введение: Un alternador es un componente crucial en los sistemas automotrices que convierte energía mecánica en energía eléctrica. Sus componentes principales incluyen:

– Polea: Transfiere energía mecánica del motor al alternador.

– Rotor: Crea el campo magnético para generar corriente alterna.

– Estator: Parte estática donde se genera la tensión.

– Rectificador: Convierte corriente alterna en corriente…

4. Kia – Alternador Esencial

Домен: kia.com

Зарегистрирован: 1996 (29 лет)

Введение: Un alternador es un componente esencial en vehículos con motor de combustión, encargado de convertir energía química en energía eléctrica para cargar la batería y alimentar otros componentes eléctricos. Funciona en conjunto con la batería y el regulador de voltaje, generando corriente alterna que se transforma en corriente continua para cargar la batería. Los alternadores suelen durar entre 7 y 10…

5. Electrojufer – Generadores de Energía Eléctrica

Домен: electrojufer.es

Введение: This company, Electrojufer – Generadores de Energía Eléctrica, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Facebook – Alternador de Auto

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: El alternador de un auto sirve para generar electricidad y cargar la batería del vehículo. Funciona convirtiendo la energía mecánica del motor en energía eléctrica, asegurando que los sistemas eléctricos del auto, como las luces y el sistema de audio, funcionen correctamente.

Strategic Sourcing Conclusion and Outlook for que es un alternador

In conclusion, understanding the integral role of the alternator in vehicle functionality is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The alternator not only recharges the battery but also powers essential electrical components, ensuring optimal vehicle performance. Recognizing the importance of sourcing high-quality alternators can significantly impact operational efficiency and reliability.

Strategic sourcing of alternators involves assessing supplier capabilities, evaluating quality standards, and ensuring competitive pricing, which can lead to cost savings and enhanced supply chain resilience. Buyers should prioritize suppliers that demonstrate innovation and reliability, as these factors are essential in maintaining a competitive edge in the automotive market.

As we move forward, it’s imperative for businesses to stay informed about advancements in alternator technology and market trends. Engaging with trusted suppliers and investing in quality components will be key to meeting the demands of an evolving automotive landscape. We encourage B2B buyers to act decisively and leverage strategic sourcing to secure a reliable supply of alternators that support their operational goals and enhance overall vehicle performance.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.