Введение: Навигация по глобальному рынку стоимости установки стартера

В условиях конкуренции в сфере технического обслуживания автомобилей понимание стоимости установки стартера имеет решающее значение для покупателей B2B, стремящихся оптимизировать свои операционные бюджеты. Идет ли речь о поиске запчастей для автопарка в Нигерии или об оценке поставщиков в Германии, сложности, связанные со стоимостью установки стартера, могут представлять значительные трудности. В данном руководстве подробно рассматриваются факторы, влияющие на эти расходы, включая тип двигателя стартера, трудозатраты и последствия выбора OEM-комплектующих по сравнению с послепродажными компонентами.

Наш всеобъемлющий ресурс охватывает различные аспекты установки стартеров, от различных типов стартеров до их применения на различных моделях автомобилей. Кроме того, мы предоставляем информацию об эффективных процессах проверки поставщиков, чтобы помочь вам найти надежных партнеров на мировом рынке. Рассматривая такие ключевые моменты, как стоимость труда в разных регионах, возможные дополнительные ремонтные работы и баланс между "сделай сам" и профессиональными услугами, это руководство предоставляет международным покупателям B2B знания, необходимые для принятия обоснованных решений о покупке.

Это руководство поможет вам сориентироваться в хитросплетениях затрат на установку стартеров и поможет вашей организации найти экономически эффективные решения, которые повысят эффективность работы. Уделяя особое внимание рынкам Африки, Южной Америки, Ближнего Востока и Европы, мы гарантируем, что у вас будут инструменты для адаптации к региональным изменениям и принятия стратегических решений, соответствующих вашим бизнес-целям.

Содержание

- Список производителей и поставщиков: ТОП 7 Стоимость установки стартера

- Введение: Навигация по глобальному рынку стоимости установки стартера

- Понимание стоимости установки стартера Типы и разновидности

- Основные промышленные применения стоимости установки стартера

- 3 распространенные болевые точки пользователей при ‘стоимости установки стартера’ и их решения

- Руководство по выбору стратегических материалов для стартовой стоимости установки

- Глубокий взгляд: Производственные процессы и контроль качества для стоимости установки стартера

- Практическое руководство по поиску: Пошаговый контрольный список для ‘стоимости установки стартера’

- Всесторонний анализ затрат и цен для поиска источников информации о стоимости установки стартера

- Анализ альтернатив: Сравнение стоимости установки стартера с другими решениями

- Основные технические свойства и торговая терминология для определения стоимости установки стартера

- Навигация по динамике рынка и тенденциям поиска в секторе затрат на установку стартеров

- Часто задаваемые вопросы (FAQ) для B2B-покупателей о стоимости установки стартера

- Стратегический поиск Заключение и перспективы стоимости установки стартера

- Важное предупреждение и условия использования

Понимание стоимости установки стартера Типы и разновидности

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Установка штатного стартера | Использует детали производителя оригинального оборудования (OEM). | Автомобильные дилерские центры, компании по управлению автопарками | Плюсы: Гарантированная совместимость и качество. Минусы: Более высокая стоимость по сравнению с вариантами для вторичного рынка. |

| Установка стартера послепродажного обслуживания | Использует не оригинальные детали, часто более доступные по цене. | Независимые ремонтные мастерские, экономные покупатели | Плюсы: Экономически эффективные решения. Минусы: Качество и долговечность могут варьироваться. |

| Установка восстановленного стартера | Используются восстановленные стартеры, как правило, по более низкой цене. | Небольшие ремонтные мастерские, предприятия, чувствительные к затратам | Плюсы: Доступнее, чем новые стартеры. Минусы: Потенциально меньший срок службы и проблемы с надежностью. |

| Установка стартера своими руками | Предполагает самостоятельную замену с использованием покупных деталей. | Индивидуальные механики, энтузиасты DIY | Плюсы: Значительная экономия средств на оплату труда. Минусы: Риск неправильной установки может привести к дальнейшим проблемам. |

| Установка стартера Premium Performance | Высокопроизводительные стартеры для специализированных автомобилей. | Автомастерские, гоночные команды | Плюсы: Повышенная надежность и мощность. Минусы: Более высокие первоначальные затраты и могут потребовать специальных знаний для установки. |

Каковы основные характеристики установки стартеров OEM?

Для установки стартера OEM характерно использование деталей, полученных непосредственно от производителя автомобиля. Это гарантирует, что заменяемый стартер соответствует оригинальным спецификациям, что очень важно для поддержания производительности и надежности автомобиля. Покупателям B2B, особенно тем, кто управляет автопарками или дилерскими центрами, стоит обратить внимание на OEM-установки из-за их гарантированной совместимости и качества. Однако более высокая стоимость, связанная с OEM-деталями, может стать существенным фактором для предприятий с ограниченным бюджетом.

Чем отличается установка стартера на вторичном рынке?

При установке стартеров на вторичном рынке используются не оригинальные компоненты, которые часто можно найти по более низкой цене. Такие детали могут подойти для независимых ремонтных мастерских или предприятий, стремящихся минимизировать расходы. Однако покупатели B2B должны быть осторожны, так как качество и долговечность стартеров вторичного рынка могут значительно отличаться. Рассматривая варианты вторичного рынка, предприятия должны оценивать репутацию поставщиков и предлагаемые гарантийные условия.

Каковы преимущества и недостатки восстановленных стартеров?

Установка восстановленных стартеров предполагает использование отремонтированных стартеров, которые были приведены в рабочее состояние. Этот вариант идеально подходит для небольших ремонтных мастерских или предприятий с ограниченным бюджетом. Хотя восстановленные стартеры обычно более доступны по цене, чем новые, покупателям следует помнить о возможных проблемах с надежностью. Важно приобретать восстановленные детали у надежных поставщиков, которые предоставляют гарантии, чтобы снизить риски.

Почему стоит обратить внимание на установку стартеров "сделай сам"?

Установка стартера "сделай сам" привлекательна для индивидуальных механиков или предприятий с собственными ремонтными возможностями. Этот вариант позволяет значительно сэкономить на трудозатратах, однако он сопряжен с определенными рисками. B2B-покупатели, рассматривающие вариант "сделай сам", должны убедиться, что их технические специалисты обладают необходимым опытом и инструментами, чтобы избежать дорогостоящих ошибок при установке. Правильное обучение и четкие инструкции помогут снизить эти риски и повысить общую удовлетворенность от подхода "сделай сам".

Что делает установку стартеров Premium Performance уникальной?

Стартеры премиум-класса предназначены для высокопроизводительных или специализированных автомобилей. Такие стартеры часто обеспечивают повышенную надежность и мощность, что делает их подходящими для автосервисов или гоночных команд. Хотя первоначальные затраты обычно выше, преимущества улучшенной производительности могут оправдать инвестиции для предприятий, ориентированных на качество и производительность. Покупателям также следует учитывать опыт, необходимый для установки, поскольку эти системы могут требовать специальных знаний.

Основные промышленные применения стоимости установки стартера

| Отрасль/сектор | Конкретное применение стоимости установки стартера | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Авторемонтные мастерские | Оценка затрат на замену стартеров | Точное составление бюджета и конкурентоспособное ценообразование | Качество деталей, стоимость работ и региональные цены |

| Транспорт и логистика | Техническое обслуживание и ремонт автопарка | Обеспечивает надежность и минимизирует время простоя | Запчасти OEM и вторичного рынка, гарантия и репутация поставщика |

| Строительное оборудование | Установка стартера для тяжелых машин | Повышает время безотказной работы оборудования и производительность | Наличие запчастей, сервисная поддержка и сроки выполнения заказа |

| Сельское хозяйство | Замена стартеров в сельскохозяйственных машинах | Повышает эффективность и надежность работы | Совместимость с различными моделями автомобилей и стоимость поставок |

| Промышленное производство | Техническое обслуживание машин и транспортных средств | Сокращение сбоев в работе и расходов | Варианты оптовых закупок, гарантии качества и соглашения об обслуживании |

Как ‘стоимость установки стартера’ используется в автосервисах?

В автосервисах точная оценка стоимости установки стартера имеет решающее значение для эффективного составления бюджета и ценовых стратегий. Понимая среднюю стоимость запчастей и трудозатрат, автосервисы могут предложить клиентам конкурентоспособные цены. Кроме того, четкая разбивка потенциальных дополнительных ремонтных работ обеспечивает прозрачность и укрепляет доверие клиентов. Международные покупатели, особенно из таких регионов, как Африка и Южная Америка, должны учитывать местные расценки на труд и наличие запчастей, что может существенно повлиять на общую стоимость.

Какую роль играет стоимость установки стартера при транспортировке и логистике?

В секторе транспорта и логистики стоимость установки стартера имеет жизненно важное значение для обслуживания автопарка. Обеспечение работы автомобилей с минимальным временем простоя напрямую влияет на производительность и рентабельность. Руководители автопарков должны учитывать соотношение между запчастями OEM и вторичного рынка, а также потенциальные последствия для гарантии и надежности. Для международных покупателей понимание местных правил и стандартов обслуживания транспортных средств может повлиять на решения о выборе поставщиков и операционные расходы.

Почему стоимость установки стартера важна для строительного оборудования?

Стоимость установки стартеров для тяжелой техники в строительной отрасли необходима для поддержания работоспособности оборудования. Задержки из-за отказов стартеров могут привести к значительным финансовым потерям, поэтому строительным компаниям крайне важно иметь надежный процесс оценки затрат. Покупатели в этом секторе должны сосредоточиться на поиске высококачественных деталей, совместимых с различными марками техники, что позволит им свести к минимуму перебои в работе. Кроме того, понимание доступности местной сервисной поддержки может повысить эффективность работы.

Как стоимость установки стартера влияет на сельское хозяйство?

В сельскохозяйственном секторе транспортные средства и машины часто полагаются на стартеры для обеспечения оптимальной работы. Расходы на установку стартеров могут повлиять на общий бюджет технического обслуживания сельскохозяйственных предприятий. Инвестируя в качественные компоненты стартеров, сельскохозяйственные предприятия могут повысить надежность своего оборудования, что приведет к повышению производительности в критические сезоны сбора урожая. Покупатели должны уделять первостепенное внимание совместимости с различными моделями автомобилей и учитывать общую стоимость владения, включая интервалы технического обслуживания и замены.

Какое значение имеет стоимость установки стартера в промышленном производстве?

В промышленном производстве стоимость установки стартера является неотъемлемой частью технического обслуживания оборудования и транспортных средств, поддерживающих производственные процессы. Сокращение перебоев в работе благодаря своевременной замене стартера может привести к значительной экономии средств. Предприятиям необходимо рассмотреть варианты оптовых закупок запчастей, чтобы оптимизировать цепочку поставок и эффективно управлять бюджетом. Международные покупатели должны оценивать надежность поставщиков и качество деталей, чтобы обеспечить стабильную работу и соответствие отраслевым стандартам.

3 распространенные болевые точки пользователей при ‘стоимости установки стартера’ и их решения

Сценарий 1: Непредвиденные расходы, связанные с установкой стартера

Проблема:

Для многих покупателей B2B, особенно для тех, кто управляет автопарками или автомобильными предприятиями, расходы, связанные с установкой стартера, могут быстро превысить первоначальную смету. Когда стартер выходит из строя, предприятия часто сталкиваются не только с расходами на замену деталей и оплату труда, но и с непредвиденными расходами, связанными с дополнительным ремонтом. Например, если неисправность стартера связана с неисправным аккумулятором или поврежденной проводкой, эти проблемы могут не проявиться до начала установки, что приведет к непредвиденным расходам и длительному простою автомобилей.

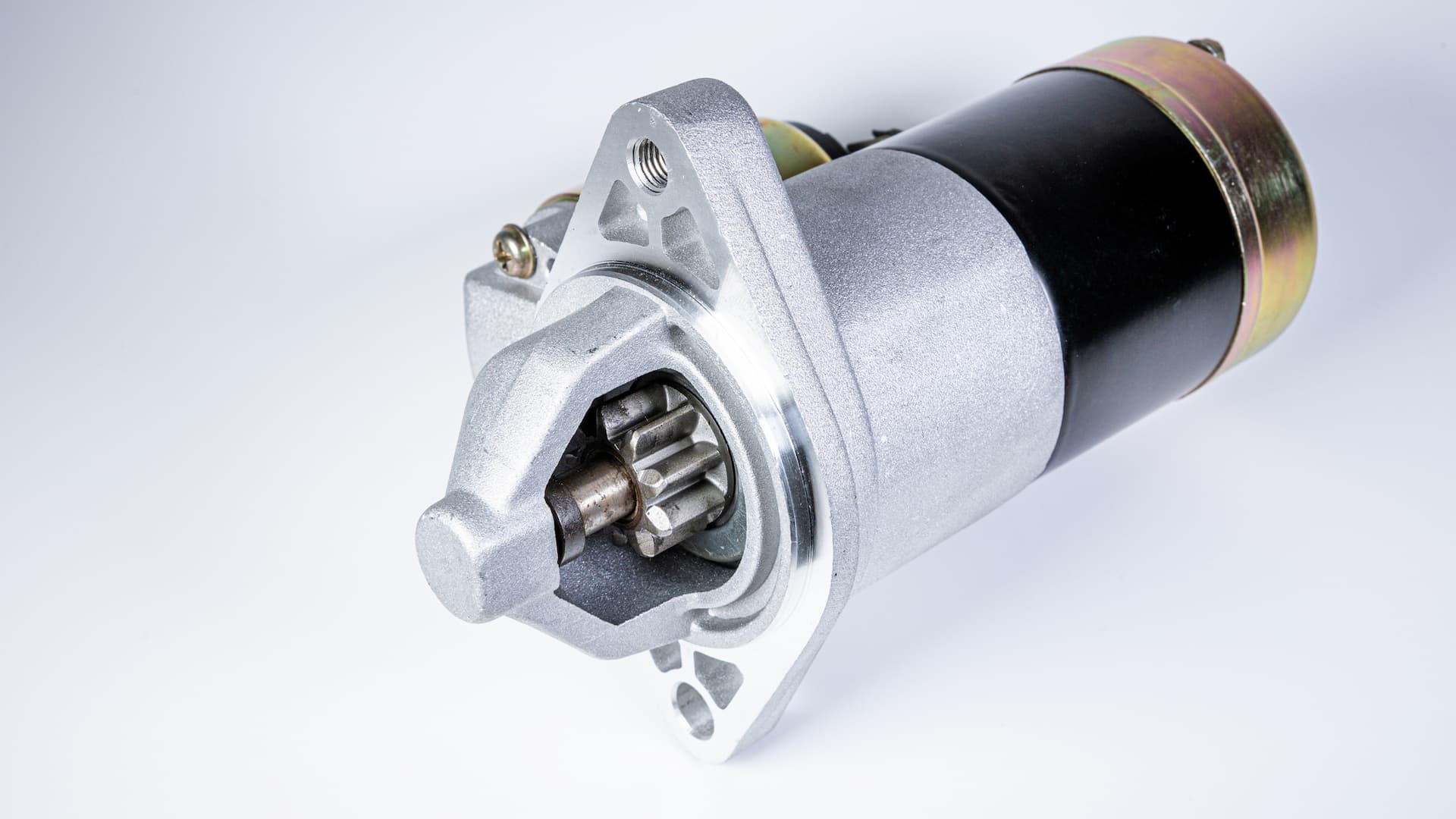

Иллюстративное изображение, относящееся к стоимости установки стартера

Решение:

Чтобы снизить непредвиденные расходы, покупатели B2B должны использовать упреждающий подход, проводя тщательную диагностику, прежде чем приступать к замене стартера. Использование комплексных диагностических инструментов для оценки всей системы запуска и зарядки поможет выявить основные проблемы, которые могут привести к отказу стартера. Кроме того, приобретение деталей у надежных поставщиков, предоставляющих гарантию, снизит риск преждевременной замены. При оценке стоимости установки всегда учитывайте возможные дополнительные ремонтные работы, получив подробные расценки от нескольких поставщиков услуг. Таким образом, предприятия смогут более эффективно составить бюджет и избежать неожиданных расходов.

Сценарий 2: путаница с качеством и типом деталей стартера

Проблема:

Покупатели B2B часто мучаются выбором между OEM (Original Equipment Manufacturer) деталями, компонентами вторичного рынка и восстановленными стартерами. Такая путаница может привести к неправильным решениям о покупке, которые могут поставить под угрозу надежность и производительность автомобиля. Например, выбор в пользу более дешевого послепродажного стартера может сэкономить средства на начальном этапе, но в дальнейшем это может привести к увеличению числа отказов и дополнительных трудозатрат. Это особенно важно для предприятий, работающих в регионах со сложными дорожными условиями, где надежность имеет первостепенное значение.

Решение:

Чтобы принять взвешенное решение, покупатели должны провести детальное сравнение различных типов стартеров, учитывая такие факторы, как технические характеристики автомобиля, ожидаемый срок службы и условия гарантии. Инвестиции в оригинальные детали могут поначалу показаться более дорогими, но долгосрочная надежность может перевесить эти затраты, сократив частоту замен и связанные с ними трудозатраты. Кроме того, покупателям следует сотрудничать с поставщиками, которые могут предоставить информацию об истории эксплуатации различных марок и моделей стартеров, что позволит им выбрать оптимальный вариант для своих эксплуатационных нужд. Установление отношений с надежным поставщиком автомобильных запчастей также поможет упростить процесс покупки, обеспечив доступ к высококачественным компонентам.

Сценарий 3: Затраты на оплату труда усугубляют расходы на установку

Проблема:

Трудозатраты могут значительно варьироваться в зависимости от сложности установки стартера, что часто удивляет покупателей B2B, которые не готовы к более высоким, чем ожидалось, расценкам. Компании, управляющие различными автопарками, могут обнаружить, что для замены стартера на разных типах автомобилей требуется разный уровень трудоемкости, что может привести к проблемам с составлением бюджета и сбоям в работе. Например, автомобили класса люкс могут потребовать специальных навыков и дополнительной разборки, что приведет к увеличению трудозатрат, в то время как более простые модели могут этого не делать.

Решение:

Чтобы лучше управлять затратами на оплату труда, покупателям B2B следует стандартизировать процедуры обслуживания автомобилей и договориться с проверенными поставщиками услуг о фиксированных расценках на услуги. Установив долгосрочные партнерские отношения с авторемонтными мастерскими, компании смогут добиться более предсказуемых цен и снизить непостоянство трудозатрат. Кроме того, регулярное проведение технического обслуживания поможет выявить проблемы со стартером на ранней стадии, что позволит проводить плановое обслуживание, а не срочный ремонт, который зачастую обходится дороже. Обучение штатных механиков навыкам базовой замены стартера также может снизить зависимость от привлечения сторонней рабочей силы, предлагая более экономичное решение для рутинного технического обслуживания.

Руководство по выбору стратегических материалов для стартовой стоимости установки

Какие материалы являются ключевыми для стоимости установки стартера?

При рассмотрении затрат на установку стартеров выбор материалов играет решающую роль в определении общей производительности, долговечности и экономической эффективности. Ниже мы проанализируем четыре распространенных материала, используемых при установке пускателей: сталь, алюминий, медь и пластиковые композиты. Каждый материал обладает уникальными свойствами, преимуществами и соображениями, которые особенно актуальны для международных покупателей B2B.

Как сталь влияет на стоимость установки стартера?

Сталь - широко используемый материал в пусковых устройствах благодаря своей прочности и долговечности. Как правило, она обладает отличными показателями температуры и давления, что делает ее пригодной для использования в условиях высоких нагрузок. Стальные компоненты устойчивы к деформации под нагрузкой, что необходимо для надежной работы стартеров.

Плюсы: Сталь отличается высокой прочностью и способна выдерживать суровые условия окружающей среды, что особенно выгодно в регионах с экстремальными температурами. Кроме того, она относительно недорога по сравнению с другими материалами.

Минусы: Основным недостатком стали является ее подверженность коррозии, особенно во влажной или прибрежной среде. Со временем это может привести к увеличению затрат на обслуживание. Кроме того, сложность производства может быть выше из-за необходимости нанесения защитных покрытий.

Влияние на применение: Сталь совместима с различными средами, включая масло и топливо, но может потребовать дополнительной обработки для повышения коррозионной стойкости.

Иллюстративное изображение, относящееся к стоимости установки стартера

Соображения для международных покупателей: Покупатели в Африке и Южной Америке должны быть осведомлены о местных условиях окружающей среды, которые могут повлиять на характеристики стали. Соблюдение стандартов качества материалов, таких как ASTM, имеет большое значение.

Какую роль играет алюминий в стартерных установках?

Алюминий - еще один распространенный материал, используемый в производстве стартеров. Он легок и обладает хорошей коррозионной стойкостью, что делает его пригодным для использования в автомобильной промышленности.

Плюсы: Легкость алюминия способствует повышению общей эффективности автомобиля, улучшая экономию топлива. Кроме того, естественная коррозионная стойкость алюминия снижает потребность в защитных покрытиях.

Минусы: Несмотря на прочность алюминия, в условиях высоких нагрузок он, как правило, менее прочен, чем сталь. При неправильном проектировании это может привести к потенциальным поломкам. Стоимость алюминия также может быть выше, чем стоимость стали.

Влияние на применение: Алюминий подходит для применения в тех случаях, когда экономия веса имеет решающее значение, но он может оказаться не идеальным для стартеров, работающих в тяжелых условиях.

Соображения для международных покупателей: Покупатели в Европе, особенно в Германии, могут предпочесть алюминий за его легкие свойства. Соответствие европейским стандартам, таким как DIN, имеет решающее значение.

Почему медь важна для стартерных узлов?

Медь используется в основном для электрических соединений в пусковых системах благодаря своей превосходной проводимости. Ее тепловые свойства также позволяют использовать ее в высокопроизводительных системах.

Иллюстративное изображение, относящееся к стоимости установки стартера

Плюсы: Высокая электропроводность меди обеспечивает эффективную передачу энергии, что крайне важно для работы стартера. Она также обладает хорошей коррозионной стойкостью, особенно если на нее нанесено покрытие.

Минусы: Основным ограничением меди является ее стоимость, которая может быть значительно выше, чем у стали или алюминия. Кроме того, она менее прочна механически, что делает ее непригодной для изготовления структурных компонентов.

Влияние на применение: Медь необходима для электрических соединений, но для обеспечения целостности конструкции она должна использоваться в сочетании с другими материалами.

Соображения для международных покупателей: Покупатели должны убедиться в соответствии электротехническим стандартам, действующим в их регионе, таким как JIS в Японии или IEC во всем мире.

Как пластиковые композиты влияют на стоимость установки стартера?

Пластиковые композиты находят все большее применение в стартовых узлах, особенно в корпусах и неструктурных компонентах. Они обладают уникальными преимуществами с точки зрения веса и коррозионной стойкости.

Иллюстративное изображение, относящееся к стоимости установки стартера

Плюсы: Пластиковые композиты имеют малый вес, что может способствовать повышению общей эффективности автомобиля. Они также обеспечивают отличную коррозионную стойкость и могут быть сформованы в сложные формы.

Минусы: Механическая прочность пластиковых композитов обычно ниже, чем у металлов, что может ограничить их применение в условиях высоких нагрузок. Кроме того, процесс производства может быть более сложным и дорогостоящим.

Влияние на применение: Пластиковые композиты подходят для применения в тех случаях, когда приоритетом является снижение веса и коррозионная стойкость, но они могут не подойти для несущих компонентов.

Соображения для международных покупателей: Покупатели должны оценить характеристики пластиковых композитов в конкретных условиях окружающей среды и убедиться в соответствии соответствующим стандартам.

Сводная таблица выбора материалов для установки стартера

| Материал | Типичный пример использования для определения стоимости установки стартера | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Сталь | Структурные компоненты в стартерах | Высокая прочность и долговечность | Подвержен коррозии | Низкий |

| Алюминий | Облегченные корпуса стартеров | Отличная коррозионная стойкость | Менее прочные при высоких нагрузках | Мед |

| Медь | Электрические соединения в стартерах | Высокая электропроводность | Высокая стоимость и низкая механическая прочность | Высокий |

| Пластиковые композиты | Неструктурные компоненты в стартерах | Легкий и коррозионно-стойкий | Низкая механическая прочность | Мед |

Этот анализ предоставляет покупателям B2B критически важные сведения о выборе материалов для стартовых установок, позволяя принимать обоснованные решения, соответствующие их производственным потребностям и региональным особенностям.

Глубокий взгляд: Производственные процессы и контроль качества для стоимости установки стартера

Каковы основные этапы процесса производства заквасок?

Процесс производства стартерных двигателей включает в себя несколько критических этапов, которые обеспечивают соответствие конечного продукта стандартам качества и производительности. Понимание этих этапов жизненно важно для покупателей B2B, особенно для тех, кто работает на различных рынках, таких как Африка, Южная Америка, Ближний Восток и Европа.

Подготовка материалов: Какие материалы используются для начинающих?

На начальном этапе необходимо найти и подготовить такие материалы, как сталь, медь и различные сплавы. Сталь обычно используется для изготовления корпуса, а медь необходима для электрических компонентов благодаря своей отличной проводимости. Перед началом производства эти материалы проходят тщательное тестирование на чистоту и прочность, что гарантирует их соответствие отраслевым спецификациям. Покупателям следует поинтересоваться источником и качеством этих материалов, поскольку они напрямую влияют на производительность и долговечность стартера.

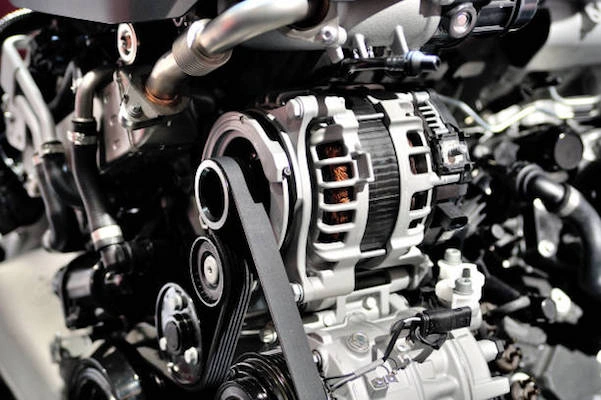

Иллюстративное изображение, относящееся к стоимости установки стартера

Формовка: как формируются компоненты стартера?

На этапе формовки материалы превращаются в различные компоненты стартерного двигателя. Основные методы включают штамповку, ковку и механическую обработку. Штамповка обычно используется для изготовления металлического корпуса, в то время как ковка формирует более прочные компоненты, такие как маховик. Прецизионная механическая обработка обеспечивает безупречное прилегание всех компонентов друг к другу, что очень важно для эффективности работы стартера. Покупателям следует искать производителей, использующих передовые технологии формовки для обеспечения точности и сокращения отходов.

Сборка: Какие процессы происходят при сборке стартеров?

После того как компоненты сформированы, они переходят на сборочную линию. На этом этапе происходит сборка различных деталей, включая двигатель, соленоид и электрические соединения. Все большее распространение получают автоматизированные сборочные линии, позволяющие ускорить производство и повысить его последовательность. Ручная сборка может по-прежнему использоваться для сложных моделей, где квалифицированные специалисты следят за правильностью установки всех компонентов. Покупателям B2B следует обратить внимание на поставщиков, которые поддерживают баланс между автоматизацией и квалифицированным трудом для обеспечения высокого качества сборки.

Отделка: какие техники отделки используются для стартеров?

Финишная обработка включает в себя несколько процессов, направленных на повышение долговечности и улучшение внешнего вида стартера. Для защиты от коррозии и износа используются такие методы, как покраска, нанесение покрытий. Например, цинкование может использоваться для металлических компонентов, чтобы предотвратить появление ржавчины. Покупателям следует поинтересоваться, какие отделочные процессы используются поставщиками, поскольку эффективная отделка может значительно продлить срок службы стартера.

Какие меры контроля качества необходимы для производства стартеров?

Контроль качества (QC) имеет первостепенное значение при производстве пусковых двигателей, гарантируя, что каждая единица продукции соответствует международным стандартам и ожиданиям клиентов. Покупатели B2B должны понимать различные пункты контроля качества и методы оценки надежности поставщика.

Какие международные стандарты следует принимать во внимание?

Международная организация по стандартизации (ISO) 9001 - это ключевой стандарт для систем управления качеством, применимый к производству стартеров. Соответствие стандарту ISO 9001 указывает на приверженность качеству и удовлетворенность клиентов. Кроме того, качество продукции могут гарантировать отраслевые сертификаты, такие как CE (Conformité Européenne) для европейских рынков и стандарты API (American Petroleum Institute) для автомобильных компонентов. Покупатели должны отдавать предпочтение поставщикам с такими сертификатами, поскольку они отражают следование строгим стандартам качества.

Каковы ключевые контрольные точки контроля качества при производстве стартеров?

Контроль качества при производстве стартеров обычно включает в себя несколько контрольных точек:

-

Входящий контроль качества (IQC): На этом этапе проверяется качество сырья перед началом производства. Он включает в себя инспекции и испытания, чтобы убедиться, что материалы соответствуют установленным стандартам.

-

Контроль качества в процессе производства (IPQC): В процессе производства IPQC контролирует процессы и компоненты на различных этапах, чтобы выявить дефекты на ранней стадии. Это может включать в себя измерения и визуальный осмотр.

-

Окончательный контроль качества (FQC): После сборки FQC включает в себя комплексное тестирование готовых пусковых двигателей. Это включает в себя функциональные испытания, чтобы убедиться, что каждый блок работает правильно в различных условиях.

Покупатели B2B должны убедиться, что их поставщики имеют надежные процессы контроля качества, так как это минимизирует риск попадания на рынок бракованной продукции.

Какие общие методы тестирования используются при контроле качества стартеров?

Для обеспечения функциональности и надежности пусковых двигателей используются различные методы испытаний:

-

Электрические испытания: Оцениваются электрические характеристики стартера, включая потребляемый ток и выходное напряжение, на предмет соответствия эксплуатационным характеристикам.

-

Механические испытания: Включает в себя проверку физических размеров и допусков, гарантируя, что компоненты правильно подогнаны друг к другу и работают так, как задумано.

-

Термические испытания: Оценивает работу стартера в условиях высоких температур, имитируя реальные сценарии.

-

Испытания на долговечность: Некоторые производители проводят ускоренные испытания на срок службы, чтобы смоделировать длительную эксплуатацию и выявить потенциальные точки отказа.

Покупатели должны запрашивать подробную информацию о протоколах тестирования, которым следуют поставщики, поскольку такая прозрачность может свидетельствовать о приверженности поставщика качеству.

Как покупатели B2B могут проверить контроль качества поставщиков?

Проверка мер контроля качества поставщика очень важна для покупателей B2B. Вот несколько эффективных стратегий:

-

Проведение аудитов: Регулярные аудиты поставщиков могут дать представление об их производственных процессах и мерах контроля качества. Такие аудиты могут проводиться группой обеспечения качества покупателя или сторонними инспекторами.

-

Запросить отчеты о качестве: Поставщики должны предоставить документацию о своих процессах контроля качества, включая отчеты IQC, IPQC и FQC. Эти документы обеспечивают прозрачность и гарантию качества продукции.

-

Привлечение сторонних инспекционных служб: Использование независимых инспекционных служб может обеспечить непредвзятую оценку практики контроля качества поставщика. Эти службы могут проверить соответствие международным стандартам и предоставить подробные отчеты.

Каковы нюансы контроля качества для международных B2B-покупателей?

Международные покупатели B2B сталкиваются с уникальными проблемами при обеспечении контроля качества. Культурные различия, разные стандарты и нормативные требования могут усложнить отношения с поставщиками. Покупатели в таких регионах, как Африка, Южная Америка, Ближний Восток и Европа, должны знать о следующих нюансах:

Иллюстративное изображение, относящееся к стоимости установки стартера

-

Соблюдение нормативных требований: В разных странах действуют особые правила в отношении автомобильных компонентов. Покупатели должны убедиться, что поставщики соблюдают местные законы, что может повлиять на приемлемость продукции на целевом рынке.

-

Культурные ожидания: Понимание культурного контекста поставщиков может улучшить коммуникацию и способствовать улучшению отношений. Это особенно важно при установлении стандартов качества и ожиданий.

-

Соображения, касающиеся цепочки поставок: Международная логистика может повлиять на контроль качества. Покупатели должны оценивать всю цепочку поставок, от поиска материалов до конечной доставки, чтобы обеспечить стабильное качество на всех этапах.

Понимая эти факторы и внедряя тщательные процессы проверки, покупатели B2B могут снизить риски и получить высококачественные пусковые двигатели, отвечающие их эксплуатационным потребностям.

Практическое руководство по поиску: Пошаговый контрольный список для ‘стоимости установки стартера’

Чтобы помочь B2B-покупателям сориентироваться в сложностях поиска источников затрат на установку стартеров, в этом практическом руководстве описаны основные шаги для обеспечения хорошо продуманного процесса закупок. Следуя этому контрольному списку, покупатели смогут оптимизировать свои инвестиции и свести к минимуму потенциальные риски, связанные с установкой пускателей.

Шаг 1: Оцените ваши специфические требования

Начните с определения точных спецификаций для установки стартера. Учитывайте тип транспортных средств в вашем парке, ожидаемые стандарты производительности и любые уникальные условия эксплуатации. Такая оценка поможет сузить круг возможных вариантов и обеспечит совместимость с существующими системами.

- Типы транспортных средств: Определите, нужны ли вам стартеры для компактных автомобилей, грузовиков или автомобилей класса люкс, поскольку это существенно влияет на стоимость и доступность.

- Условия эксплуатации: Определите, должны ли ваши стартеры выдерживать экстремальные температуры или интенсивное использование, что может повлиять на выбор материалов и технологий.

Шаг 2: Исследование рынка ценообразования

Понимание рыночного диапазона цен на установку стартеров имеет решающее значение. Проведите тщательное исследование, чтобы собрать смету и определить среднюю стоимость для вашего региона и типа автомобиля.

- Расходы на оплату труда: В разных регионах может быть разная стоимость труда, поэтому учитывайте это в общем бюджете.

- Качество деталей: Знайте о различиях между экономичными, OEM- и высокопроизводительными стартерами, поскольку они могут существенно повлиять как на первоначальные затраты, так и на долгосрочную надежность.

Шаг 3: Оцените потенциальных поставщиков

Тщательно проверяйте поставщиков, прежде чем брать на себя какие-либо обязательства. Этот шаг необходим для того, чтобы убедиться, что вы сотрудничаете с авторитетными компаниями, которые могут предоставить качественные продукты и услуги.

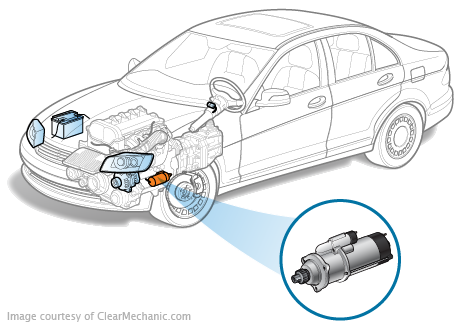

Иллюстративное изображение, относящееся к стоимости установки стартера

- Сертификация поставщиков: Ищите сертификаты, которые указывают на соответствие промышленным стандартам, что может гарантировать качество продукции.

- Ссылки и отзывы: Запросите тематические исследования или отзывы у других компаний, которые поставляли аналогичную продукцию, особенно в вашей отрасли или регионе.

Шаг 4: Запрос подробных котировок

После того как вы определили потенциальных поставщиков, запросите подробные расценки, в которых будут указаны все расходы. Такая прозрачность поможет вам эффективно сравнивать предложения.

- Расходы по статьям: Убедитесь, что в расценках указаны детали, трудозатраты, налоги и любые дополнительные платежи.

- Информация о гарантии: Уясните условия гарантии, предоставляемой как на компоненты пускового устройства, так и на услуги по установке, поскольку это может повлиять на долгосрочные расходы.

Шаг 5: Рассмотрите дополнительные услуги

Многие поставщики предлагают дополнительные услуги, которые могут оказаться полезными, например, обучение установке, постоянную поддержку или пакеты технического обслуживания. Оцените, соответствуют ли эти дополнительные услуги вашим операционным потребностям.

- Обучение: Если у вас есть штатные специалисты по техническому обслуживанию, обучение может расширить их возможности по установке и ремонту.

- Пакеты технического обслуживания: Подумайте, сможет ли постоянная поддержка предотвратить будущие проблемы и сократить время простоя.

Шаг 6: Обсудить условия и положения

Прежде чем оформить заказ, обсудите условия и сроки. Сюда могут входить условия оплаты, сроки доставки и правила возврата.

- Гибкие варианты оплаты: Обсудите варианты, которые могут облегчить движение денежных средств, например, рассрочку платежа.

- Политика возврата: Убедитесь, что вы четко понимаете правила возврата бракованных деталей, так как это поможет сэкономить средства в случае возникновения проблем.

Шаг 7: Завершите покупку и оформите все документы

После того как вы выбрали поставщика и согласовали условия, завершите покупку. Убедитесь, что все соглашения задокументированы, чтобы защитить ваши деловые интересы.

Иллюстративное изображение, относящееся к стоимости установки стартера

- Контракты: Заключите официальный договор, в котором будут прописаны все оговоренные условия, включая ожидания по доставке и обслуживанию.

- Документация: Ведите записи всей переписки, расценок и соглашений для дальнейшего использования, что может оказаться крайне важным в случае возникновения споров.

Следуя этим шагам, покупатели B2B смогут эффективно справиться со сложностями, связанными со стоимостью установки стартеров, обеспечивая надежные инвестиции и работу автомобиля.

Всесторонний анализ затрат и цен для поиска источников информации о стоимости установки стартера

Каковы основные составляющие стоимости установки стартера?

При анализе структуры затрат на установку стартера учитываются несколько ключевых компонентов. Основные затраты включают в себя материалы, рабочую силу, производственные накладные расходы, оснастку, контроль качества (QC), логистику и маржу прибыли.

-

Материалы: Стоимость самого двигателя стартера может значительно варьироваться в зависимости от того, является ли он новым, восстановленным или запчастью с рынка. Цены обычно варьируются от $75 до более чем $1 000, в зависимости от качества и спецификаций. Высокопроизводительные или оригинальные детали обычно стоят дороже из-за своей надежности и долговечности.

-

Трудовые ресурсы: Стоимость работ может варьироваться в зависимости от сложности установки и местных расценок. Базовые установки могут стоить от $100 до $250, в то время как более сложные установки на роскошных автомобилях могут превышать $600. Квалифицированная работа имеет решающее значение для обеспечения правильной установки во избежание проблем в будущем.

-

Производственные накладные расходы и оснастка: Эти затраты включают в себя расходы, связанные с производственными помещениями, оборудованием и инструментами, необходимыми для производства стартеров. Эффективная производственная практика может помочь снизить эти накладные расходы, что позволит установить более конкурентоспособные цены.

-

Контроль качества (КК): Убедиться в том, что каждый стартер соответствует строгим стандартам качества, крайне важно. Этот процесс может включать в себя тестирование и проверки, что может увеличить общую стоимость, но в конечном итоге приводит к уменьшению количества отказов и повышению удовлетворенности клиентов.

-

Логистика: Стоимость доставки и обработки значительна, особенно для международных покупателей. Такие факторы, как расстояние, вид транспорта и таможенные пошлины, могут повлиять на конечную цену.

-

Маржа прибыли: Поставщики обычно добавляют маржу прибыли, чтобы покрыть свои операционные расходы и обеспечить устойчивость. Эта маржа может варьироваться в зависимости от рыночных условий и ценовой стратегии поставщика.

Как факторы, влияющие на цену, влияют на стоимость установки стартера?

Несколько факторов, влияющих на цену, могут повлиять на общую стоимость установки стартера, особенно для международных покупателей B2B.

-

Объем/MOQ (минимальный объем заказа): Оптовые закупки могут значительно сократить расходы. Поставщики часто предоставляют скидки при крупных заказах, что помогает предприятиям экономить на стоимости единицы продукции.

-

Технические характеристики и индивидуальная настройка: Нестандартные стартеры, разработанные для конкретных моделей автомобилей или с учетом их технических характеристик, могут потребовать дополнительных расходов. Покупателям следует оценить, могут ли стандартные детали соответствовать их требованиям, чтобы избежать лишних расходов.

-

Качество материалов и сертификаты: Высококачественные материалы и сертификаты могут привести к увеличению первоначальной стоимости, но в результате общая стоимость владения (TCO) может снизиться благодаря повышенной долговечности и меньшему количеству замен.

-

Факторы, связанные с поставщиками: Надежность и репутация поставщика могут влиять на цену. Известные поставщики могут взимать дополнительную плату, но часто предоставляют лучшие гарантии и обслуживание клиентов.

-

Инкотермс: Понимание условий доставки очень важно для международных покупателей. Инкотермс определяют обязанности продавцов и покупателей при доставке, что может повлиять на общую стоимость товара.

Какие советы покупателям могут помочь в переговорах о стоимости установки стартера?

Международные покупатели B2B должны рассмотреть несколько стратегий, чтобы оптимизировать свои решения о покупке и сократить расходы.

-

Обсудить условия: Привлекайте поставщиков к обсуждению цен, особенно при оптовых закупках или долгосрочных контрактах. Изучение условий оплаты, графиков поставок и вариантов гарантии может привести к заключению более выгодных сделок.

-

Сосредоточьтесь на общей стоимости владения (TCO): Вместо того чтобы рассматривать только первоначальную цену покупки, оцените совокупную стоимость владения, которая включает в себя затраты на установку, обслуживание и возможное время простоя. Инвестиции в более качественные стартеры могут привести к снижению долгосрочных затрат.

-

Понимание нюансов ценообразования на международных рынках: В разных регионах могут различаться стоимость рабочей силы и импортные пошлины. Покупатели должны изучать условия на местном рынке, чтобы принимать взвешенные решения о покупке.

-

Используйте отношения с поставщиками: Построение прочных отношений с поставщиками может принести такие выгоды, как приоритетное обслуживание, эксклюзивные скидки и доступ к новым продуктам.

-

Будьте в курсе тенденций рынка: Слежение за тенденциями в отрасли поможет покупателям предвидеть изменения в ценах и наличии товаров, что позволит принимать стратегические решения о покупке.

Отказ от ответственности

Цены, приведенные в данном анализе, являются ориентировочными и могут меняться в зависимости от местоположения, рыночных условий и требований к конкретному автомобилю. Для получения наиболее точной и актуальной информации о ценах в соответствии с вашими потребностями всегда обращайтесь к поставщикам.

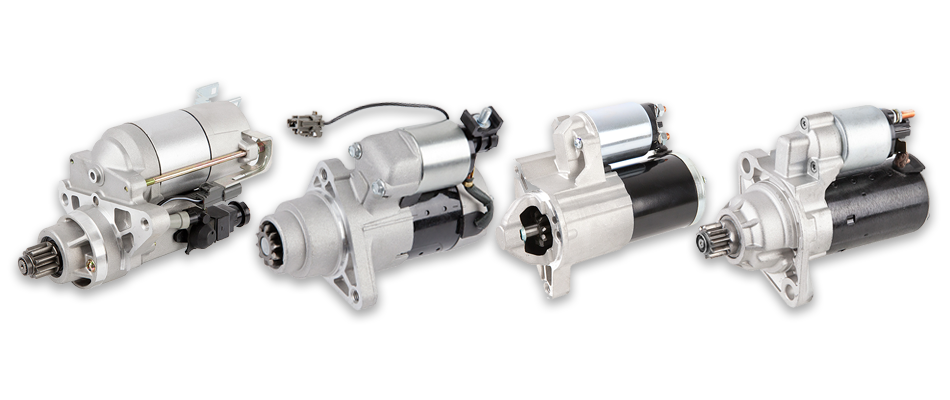

Иллюстративное изображение, относящееся к стоимости установки стартера

Анализ альтернатив: Сравнение стоимости установки стартера с другими решениями

Понимание важности альтернатив при установке стартера

При рассмотрении стоимости установки стартера покупателям B2B следует изучить альтернативные решения, которые могут эффективно удовлетворить их операционные потребности. Такое сравнение может помочь организациям принимать обоснованные решения относительно стратегии технического обслуживания автомобилей, особенно в регионах, где стоимость и доступность запчастей существенно различаются.

Сравнительная таблица стоимости установки стартера по сравнению с альтернативными вариантами

| Аспект сравнения | Стоимость установки стартера | Восстановленные стартеры | Jump Start Solutions |

|---|---|---|---|

| Производительность | Высокая надежность в новом состоянии | Умеренная надежность; может меняться | Временное решение; надежность зависит от состояния батареи |

| Стоимость | $531 - $773 | $150 - $400 | $50 - $150 (стоимость оборудования) |

| Простота внедрения | Умеренный; требуется профессиональная установка | Умеренный; можно сделать самому, но часто требуется опыт. | Простота; обычно требуется минимальная настройка |

| Техническое обслуживание | Низкий уровень; заменяйте по мере необходимости | Умеренный; продолжительность жизни может варьироваться | Низкий; зависит от состояния батареи |

| Лучший вариант использования | Долгосрочная надежность автомобиля | Бюджетный ремонт | Экстренные ситуации или временные решения |

Восстановленные стартеры: Плюсы и минусы

Восстановленные стартеры - это экономичная альтернатива для предприятий, стремящихся сократить расходы. Эти стартеры, цена которых обычно составляет от $150 до $400, восстанавливаются и тестируются для обеспечения функциональности. Однако, несмотря на то, что они могут служить в качестве бюджетного варианта, их надежность может не соответствовать надежности новых деталей OEM. Это может привести к сокращению срока службы и потенциальным будущим расходам в случае преждевременного выхода стартера из строя. Покупателям B2B следует сопоставить экономию с потенциальным увеличением расходов на обслуживание и замену в долгосрочной перспективе.

Решения Jump Start: Плюсы и минусы

Портативные пусковые устройства или аккумуляторные блоки идеально подходят для предприятий, которым требуется быстрое решение проблем в чрезвычайных ситуациях. Они обычно варьируются от $50 до $150 и могут использоваться для запуска автомобиля с разряженным аккумулятором без необходимости замены стартера. Однако такое решение является временным: если причина кроется в неисправном стартере, то автомобилю вскоре потребуется профессиональное обслуживание. Кроме того, эффективность решения проблемы "прыжкового старта" зависит от состояния аккумулятора автомобиля, что делает его менее надежным для длительного использования.

Заключение: как выбрать правильное решение для ваших нужд

Выбор правильного решения для стартовой установки зависит от нескольких факторов, включая бюджет, тип транспортного средства и эксплуатационные требования. Покупатели B2B должны тщательно оценить свои конкретные потребности, учитывая баланс между первоначальными затратами и долгосрочной надежностью. Для предприятий, ориентированных на поддержание работоспособности автомобиля и минимизацию времени простоя, инвестиции в новые стартеры могут быть лучшим вариантом. И наоборот, для тех, кто хочет сократить расходы или решить насущные проблемы, восстановленные стартеры или решения для ускоренного запуска могут быть жизнеспособными альтернативами. В конечном счете, тщательный анализ каждого варианта поможет покупателям сделать наиболее экономичный и надежный выбор для своих потребностей в управлении автопарком.

Основные технические свойства и торговая терминология для определения стоимости установки стартера

Каковы основные технические характеристики, влияющие на стоимость установки стартера?

Понимание основных технических характеристик, связанных со стоимостью установки стартера, имеет решающее значение для покупателей B2B. Эти свойства не только влияют на цену, но и на общее качество и надежность компонентов стартера. Вот некоторые критические характеристики, которые необходимо учитывать:

Иллюстративное изображение, относящееся к стоимости установки стартера

1. Марка материала

Марка материала, из которого изготовлен двигатель стартера, существенно влияет на его долговечность и производительность. Материалы более высокого класса, такие как усиленная сталь или высококачественный алюминий, повышают устойчивость стартера к износу. В сделках B2B выбор компонентов из высококачественных материалов может привести к увеличению срока службы и снижению затрат на обслуживание, что делает его выгодным вложением средств.

2. Уровни толерантности

Под допуском понимается допустимое отклонение в размерах компонентов стартерного двигателя. Точные допуски обеспечивают правильную посадку деталей и их функционирование в соответствии с назначением. Для покупателей B2B понимание уровней допусков очень важно, так как более жесткие допуски часто указывают на более высокое качество изготовления, что может привести к лучшей производительности и меньшему количеству проблем с установкой.

3. Рейтинг мощности

Мощность двигателя стартера, обычно измеряемая в вольтах (В) и амперах (А), указывает на его способность запускать двигатель. Для разных автомобилей требуются стартеры с разной мощностью, в зависимости от размера и конструкции двигателя. Для покупателей B2B важно убедиться, что стартер соответствует требованиям к мощности автомобиля, для надежной работы и предотвращения преждевременных поломок.

4. Тип соленоида

Соленоид - это важный компонент, который включает двигатель стартера при повороте ключа зажигания. Существуют различные типы соленоидов, включая втягивающие и удерживающие. Понимание типа соленоида важно для покупателей B2B, поскольку неправильный выбор может привести к проблемам совместимости и повлиять на эффективность работы стартера.

5. Гарантийный срок

Гарантийный срок, предлагаемый производителями, может быть ключевым показателем качества. Более длительная гарантия часто отражает уверенность в долговечности и надежности продукта. Для покупателей B2B оценка условий гарантии очень важна, поскольку она может дать представление о потенциальных долгосрочных затратах и ожиданиях от обслуживания.

Каковы общие торговые термины, связанные с затратами на установку стартера?

Знакомство с торговой терминологией может значительно улучшить общение между покупателями и поставщиками B2B. Вот несколько основных терминов, которые необходимо понимать:

1. OEM (производитель оригинального оборудования)

Запчасти OEM производятся оригинальным производителем автомобиля. Они разработаны в точном соответствии с техническими характеристиками автомобиля, обеспечивая оптимальную совместимость и производительность. Покупатели B2B часто предпочитают OEM-запчасти из-за их надежности и гарантийных преимуществ, несмотря на потенциально более высокую стоимость.

2. MOQ (минимальный объем заказа)

MOQ - это наименьшее количество продукта, которое поставщик готов продать. Понимание MOQ очень важно для покупателей B2B, поскольку оно влияет на управление запасами и принятие решений о закупках. Более высокая MOQ может привести к увеличению предварительных затрат, в то время как более низкая MOQ может обеспечить гибкость, но может привести к повышению цены за единицу товара.

3. RFQ (запрос предложения)

RFQ - это документ, отправляемый поставщикам с запросом цены и условий на конкретную продукцию. Покупатели B2B используют RFQ для сравнения цен и эффективного обсуждения условий. Хорошо структурированный RFQ может упростить процесс закупок и гарантировать, что покупатели получат конкурентоспособные предложения.

4. Инкотермс (Международные торговые термины)

Инкотермс определяют обязанности покупателей и продавцов в международной торговле, включая обязательства по доставке, страхованию и тарифам. Знание Инкотермс жизненно важно для покупателей B2B, участвующих в международных сделках, поскольку оно проясняет ответственность и помогает избежать споров.

5. Запасные части

Запчасти для вторичного рынка - это компоненты, изготовленные не оригинальным производителем автомобиля. Эти детали могут быть более доступными по цене, но могут отличаться по качеству и совместимости. Покупателям B2B следует взвесить выгоду от стоимости и потенциальные риски при рассмотрении вариантов вторичного рынка.

Понимая эти технические свойства и торговые термины, покупатели B2B могут принимать обоснованные решения относительно стоимости установки стартеров, улучшать свои стратегии закупок и обеспечивать оптимальные эксплуатационные характеристики автомобилей.

Иллюстративное изображение, относящееся к стоимости установки стартера

Навигация по динамике рынка и тенденциям поиска в секторе затрат на установку стартеров

Каковы основные тенденции рынка, влияющие на стоимость установки стартеров?

В мировом автомобильном секторе происходят значительные преобразования, которые напрямую влияют на стоимость установки стартеров. Одним из основных факторов является растущее внедрение электромобилей (EV). По мере того как производители переходят на электрические модели, традиционные системы стартеров эволюционируют, что может привести к снижению спроса на замену традиционных стартеров. Кроме того, растущая сложность автомобилей, особенно моделей класса люкс, способствует повышению стоимости установки из-за необходимости использования специализированной рабочей силы и запчастей.

Новые технологии, такие как телематика и предиктивное обслуживание, меняют подход к поиску и установке оборудования. Эти достижения позволяют покупателям B2B прогнозировать потенциальные поломки стартеров, что позволяет заранее подобрать компоненты и минимизировать время простоя. Кроме того, поскольку рынки Африки, Южной Америки, Ближнего Востока и Европы становятся все более взаимосвязанными, международные покупатели используют цифровые платформы для повышения конкурентоспособности цен и оптимизации цепочек поставок. Тенденция к управлению запасами "точно в срок" также набирает обороты, позволяя предприятиям сократить расходы на хранение, обеспечивая при этом доступ к необходимым компонентам.

Как устойчивое развитие влияет на поиск поставщиков в секторе стартовых установок?

Устойчивое развитие становится ключевым фактором при выборе компонентов для стартеров. Воздействие процессов производства автомобилей на окружающую среду привело к тому, что все большее внимание уделяется этичным методам поиска поставщиков. Покупатели B2B все чаще ищут поставщиков, которые придерживаются строгих экологических стандартов и обеспечивают прозрачность своих цепочек поставок. Этот сдвиг связан не только с соблюдением норм, но и с потребительским спросом на экологически чистую продукцию.

В связи с этим материалы, используемые при производстве стартеров, подвергаются тщательному анализу. Например, производители изучают возможность использования переработанных металлов и экологически чистых материалов, чтобы свести к минимуму количество отходов. Такие сертификаты, как ISO 14001 для систем экологического менеджмента, становятся обязательными для поставщиков, стремящихся привлечь международных покупателей. Отдавая предпочтение устойчивому развитию, B2B-компании могут укрепить репутацию своего бренда и соответствовать глобальному движению в сторону экологически ответственной деловой практики, что в конечном итоге повлияет на их решения по выбору поставщиков.

Иллюстративное изображение, относящееся к стоимости установки стартера

Какова эволюция стоимости установки стартеров в автомобильной промышленности?

За последние десятилетия стоимость установки стартеров значительно изменилась. На заре автомобилестроения системы стартеров были относительно простыми, что приводило к снижению стоимости замены. По мере того как автомобили становились все более совершенными, интегрируя сложные электрические системы и высокопроизводительные стартеры, стоимость стала расти. Переход от чисто механических систем к электронным системам зажигания также способствовал увеличению сложности установки и трудозатрат.

Сегодня рынок характеризуется разнообразием вариантов стартеров, от экономичных моделей до высокопроизводительных вариантов, что отражает растущее предпочтение потребителей к индивидуальным автомобильным решениям. Такая эволюция потребовала развития специализированных навыков у рабочей силы, что еще больше увеличило стоимость установки. Понимание этого исторического контекста крайне важно для покупателей B2B, поскольку оно позволяет понять текущую структуру цен и будущие тенденции в автомобильном секторе.

Заключение

Поскольку автомобильная промышленность продолжает развиваться, международные покупатели B2B должны быть в курсе динамики рынка, тенденций устойчивого развития и исторического контекста стоимости установки стартеров. Используя технологические достижения и уделяя первостепенное внимание этичному поиску поставщиков, компании могут эффективно ориентироваться в этих изменениях, что позволит им оставаться конкурентоспособными в условиях быстро меняющегося ландшафта.

Часто задаваемые вопросы (FAQ) для B2B-покупателей о стоимости установки стартера

1. Как определить стоимость установки стартера на мой автомобиль?

Чтобы оценить стоимость установки стартера, учитывайте такие факторы, как марка и модель автомобиля, стоимость работ в вашем регионе и качество детали стартера. В среднем стоимость установки варьируется от $531 до $773, включая трудозатраты и запчасти. Рекомендуется получить расценки от нескольких поставщиков и ремонтных мастерских, чтобы убедиться в конкурентоспособности цен. Кроме того, с помощью онлайн-оценки можно получить более точную цифру с учетом вашего местоположения и типа автомобиля.

2. Какие ключевые факторы влияют на стоимость установки стартера?

На стоимость установки стартера влияет несколько факторов, включая сложность автомобиля, доступность деталей и региональные расценки на работу. Автомобили класса люкс и с высокими техническими характеристиками обычно стоят дороже из-за сложной разборки, необходимой для доступа. Кроме того, выбор между OEM- и послепродажными деталями может существенно повлиять на общую цену. Наконец, любые дополнительные ремонтные работы, такие как замена аккумулятора или ремонт проводки, добавят к общей стоимости установки.

3. Как проверить поставщиков деталей стартера?

При проверке поставщиков запчастей для стартеров учитывайте их репутацию, качество продукции и надежность. Ищите поставщиков с положительными отзывами, сертификатами и историей обслуживания предприятий вашей отрасли. Прежде чем делать оптовые закупки, запросите образцы или подробные спецификации продукции, чтобы оценить ее качество. Кроме того, поинтересуйтесь их гарантийной политикой и послепродажной поддержкой, чтобы убедиться, что они гарантируют качество своей продукции.

4. Какие условия оплаты обычно предлагают поставщики деталей для установки стартера?

Условия оплаты у разных поставщиков могут существенно различаться. Обычно это предоплата, чистые 30 или чистые 60 дней, а также рассрочка при крупных заказах. Во избежание недоразумений всегда уточняйте условия оплаты до заключения соглашения. Рекомендуется согласовывать условия с вашими денежными потоками и стратегией закупок, особенно если вы планируете размещать повторяющиеся заказы.

5. Какова минимальная партия заказа (MOQ) для деталей стартера?

Минимальное количество заказа (MOQ) для стартовых деталей часто зависит от поставщика и конкретной заказываемой детали. У некоторых поставщиков MOQ может составлять всего 10 единиц, в то время как другие могут требовать заказа 50 или более штук, чтобы получить выгодную цену. При ведении переговоров учитывайте свои потребности в запасах и возможность будущих заказов, чтобы найти баланс, который устроит и вас, и поставщика.

6. Как обеспечить контроль качества (QA) деталей стартера?

Чтобы гарантировать качество деталей стартера, установите четкий процесс контроля качества с поставщиками. Запрашивайте документацию, например сертификаты ISO, отчеты о проверках и соответствие отраслевым стандартам. Проводите регулярные аудиты производственных процессов и мер контроля качества поставщика. Кроме того, рассмотрите возможность выборочного контроля поступающих деталей, чтобы выявить любые дефекты до того, как они попадут на сборочный конвейер.

7. Какие логистические соображения следует иметь в виду при международной закупке деталей стартера?

При поставке деталей стартера за границу учитывайте такие факторы логистики, как стоимость доставки, сроки поставки и таможенные правила. Оцените надежность вариантов доставки и способность поставщика обрабатывать документацию для соблюдения требований импорта/экспорта. Очень важно учитывать возможные задержки из-за таможенных проверок и работать с логистическими партнерами, имеющими опыт международной торговли, чтобы упростить процесс.

Иллюстративное изображение, относящееся к стоимости установки стартера

8. Могу ли я изготовить детали стартера по индивидуальному заказу?

Многие поставщики предлагают варианты изготовления деталей стартера на заказ в соответствии с конкретными требованиями. Это может включать изменения в размерах, напряжении или технических характеристиках. При обсуждении возможности изготовления на заказ четко сформулируйте свои потребности и убедитесь, что поставщик имеет возможность их удовлетворить. Имейте в виду, что изготовление деталей по индивидуальному заказу может занять больше времени и повлечь за собой дополнительные расходы, поэтому планируйте свою стратегию закупок соответствующим образом.

Список производителей и поставщиков: ТОП 7 Стоимость установки стартера

1. Reddit - Услуги по замене стартера

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Замена стартера, трудозатраты, диагностика, OEM-запчасти, ценообразование, наценка на детали.

2. Авторемонт в последнем шансе - стоимость замены стартера

Домен: lastchanceautorepairs.com

Зарегистрирован: 2009 (16 лет)

Введение: Стоимость замены стартера: Стартеры эконом-класса: $75 - $200, ОЕМ стартеры: $150 - $400, Высокопроизводительные стартеры: $300 - $1000+. Трудозатраты: Базовая замена стартера автомобиля: $100 - $250, Сложные установки: $300 - $600+. Факторы, влияющие на стоимость: Тип и модель автомобиля, Новые и восстановленные стартеры, Дополнительные ремонтные работы. Затраты на самостоятельную установку: Только запчасти: $100 - $400, Временные затраты: 2-6 часов. Профессиональный б...

3. Facebook - Затраты на ремонт автомобиля

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: стоимость доставки автомобиля в магазин и замены стартера

4. CarBuzz - Стоимость замены двигателя стартера

Домен: carbuzz.com

Зарегистрирован: 2003 (22 года)

Введение: Стоимость замены стартера в среднем варьируется от $450 до $600, а на конкретные модели, такие как Toyota Tundra (2000-2005), цена составляет от $650 до $900 из-за трудоемкости демонтажа впускного коллектора. Стоимость замены Honda Civic оценивается в $490 - $760. Факторы, влияющие на стоимость, включают трудозатраты (1,5-2,5 часа для большинства стартеров, до четырех часов для стартеров, установленных в долине...

5. CarTalk - Замена стартера

Домен: cartalk.com

Зарегистрирован: 1995 (30 лет)

Введение: Стоимость замены стартера: от $600 до $900 для обычных автомобилей; от $900 до $1 400 для моделей класса люкс. Функция стартера: Запускает двигатель, используя электричество от аккумулятора. Симптомы неисправного стартера: щелкающий звук, скрип, прерывистая работа. Варианты ремонта: Обычно заменяется восстановленным стартером; ремонт часто оказывается нерентабельным. Современные стартеры разработаны таким образом, чтобы не...

6. Carfax - Руководство по стоимости двигателя стартера

Домен: carfax.com

Зарегистрирован: 1997 (28 лет)

Введение: Стоимость стартера: $700 - $1,000; Стоимость работ и запчастей: 15% работы, 85% запчасти; Срок службы: Обычно хватает на весь срок службы автомобиля, обычно заменяется после 150 000 миль пробега; Подержанный стартерный двигатель: Может быть бюджетным вариантом, если приобретается из надежного источника; Признаки неисправного стартера: Жужжание, скрежет или щелчки, двигатель медленно крутится, все работает, кроме двигателя, много дыма; Реп...

7. Compustar - дистанционные пусковые устройства

Домен: compustar.com

Зарегистрирован: 1995 (30 лет)

Введение: Дистанционные пусковые устройства - это модернизация автомобиля, стоимость которой варьируется от $349,99 до $449,99 за базовые системы малого радиуса действия, устанавливаемые на автомобили не класса люкс. Цены зависят от года выпуска, марки и модели автомобиля. Установщики дистанционного запуска Compustar берут примерно от $319,99 до $449,99 за системы плюс установку. Дополнительные расходы могут возникнуть при покупке пультов дистанционного управления с увеличенным радиусом действия, модулей интеграции обхода, л...

Стратегический поиск Заключение и перспективы стоимости установки стартера

В заключение следует отметить, что понимание тонкостей стоимости установки стартера имеет решающее значение для международных B2B-покупателей, стремящихся оптимизировать свои стратегии закупок. Средняя стоимость замены колеблется между $531 и $773, на нее влияют такие факторы, как тип автомобиля, трудозатраты и качество деталей. Стратегический выбор высококачественных компонентов позволяет компаниям снизить риски, связанные с некачественной заменой, и обеспечить долговечность своих автомобильных инвестиций.

Для покупателей в таких регионах, как Африка, Южная Америка, Ближний Восток и Европа, важность нюансов местного рынка трудно переоценить. Привлечение надежных поставщиков, предлагающих OEM-запчасти и квалифицированные услуги по установке, может обеспечить значительную экономию средств и повышение эффективности работы. Кроме того, учет дополнительных ремонтных работ, которые могут возникнуть в результате поломки стартера, повысит точность составления общего бюджета.

Ориентируясь в сложностях, связанных с затратами на установку стартеров, отдавайте предпочтение стратегическим партнерствам с надежными поставщиками, чтобы повысить устойчивость цепочки поставок. Инвестируя в качественные компоненты сегодня, вы обеспечите будущее своего автопарка, сохранив его работоспособность и эффективность. Воспользуйтесь возможностью использовать стратегический поиск поставщиков в качестве конкурентного преимущества на вашем рынке.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.