Introduction: Navigating the Global Market for parts of alternator

In an increasingly competitive global market, sourcing high-quality parts of alternators poses a significant challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As demand for reliable automotive components continues to rise, understanding the intricacies of alternator components—including rotors, stators, rectifiers, and voltage regulators—becomes essential for informed procurement. This guide offers a comprehensive exploration of the various types of alternator parts, their applications, and the critical factors to consider when vetting suppliers.

Navigating this complex landscape requires more than just knowledge of the components; it necessitates a strategic approach to sourcing and cost management. By delving into the specifications, performance metrics, and compatibility of different parts, international buyers can optimize their purchasing decisions to align with specific operational needs. Furthermore, this guide highlights best practices for supplier evaluation, emphasizing quality assurance and reliability, which are paramount in avoiding costly downtime and ensuring customer satisfaction.

Empowering B2B buyers with actionable insights, this resource serves as a vital tool for those looking to streamline their supply chains and enhance their competitive edge in the automotive sector. Whether you are based in bustling cities like Ho Chi Minh or Frankfurt, understanding the global market for alternator parts will position your business for sustainable growth and success.

Содержание

- Top 5 Parts Of Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts of alternator

- Understanding parts of alternator Types and Variations

- Key Industrial Applications of parts of alternator

- 3 Common User Pain Points for ‘parts of alternator’ & Their Solutions

- Strategic Material Selection Guide for parts of alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for parts of alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of alternator’

- Comprehensive Cost and Pricing Analysis for parts of alternator Sourcing

- Alternatives Analysis: Comparing parts of alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for parts of alternator

- Navigating Market Dynamics and Sourcing Trends in the parts of alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts of alternator

- Strategic Sourcing Conclusion and Outlook for parts of alternator

- Важное предупреждение и условия использования

Understanding parts of alternator Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Обычные генераторы | Simple design with rotor and stator, uses slip rings and brushes for current conduction. | Automotive manufacturing, light-duty vehicles. | Плюсы: Экономически эффективен; широко доступен. Минусы: Higher maintenance due to brushes wear. |

| Альтернаторы с постоянным магнитом | Utilizes permanent magnets for rotor, eliminating the need for brushes. | Marine applications, small engines, and wind turbines. | Плюсы: Lower maintenance; higher efficiency. Минусы: More expensive upfront; limited output range. |

| Бесщеточные генераторы | No brushes; uses electronic controls to manage output, enhancing durability. | Heavy machinery, commercial vehicles, and industrial equipment. | Плюсы: Longer lifespan; reduced maintenance. Минусы: Higher initial costs; complex electronics. |

| Высокопроизводительные генераторы | Designed for increased power output, often with upgraded cooling systems. | Performance vehicles, audio systems, and heavy-duty applications. | Плюсы: Supports higher electrical demands; improved reliability. Минусы: Heavier; may require modifications for installation. |

| Интеллектуальные генераторы | Incorporates advanced electronics for real-time monitoring and efficiency optimization. | Electric vehicles, hybrid systems, and modern automotive applications. | Плюсы: Enhanced fuel efficiency; adaptive charging. Минусы: Higher cost; complex integration into existing systems. |

Каковы основные характеристики обычных генераторов переменного тока?

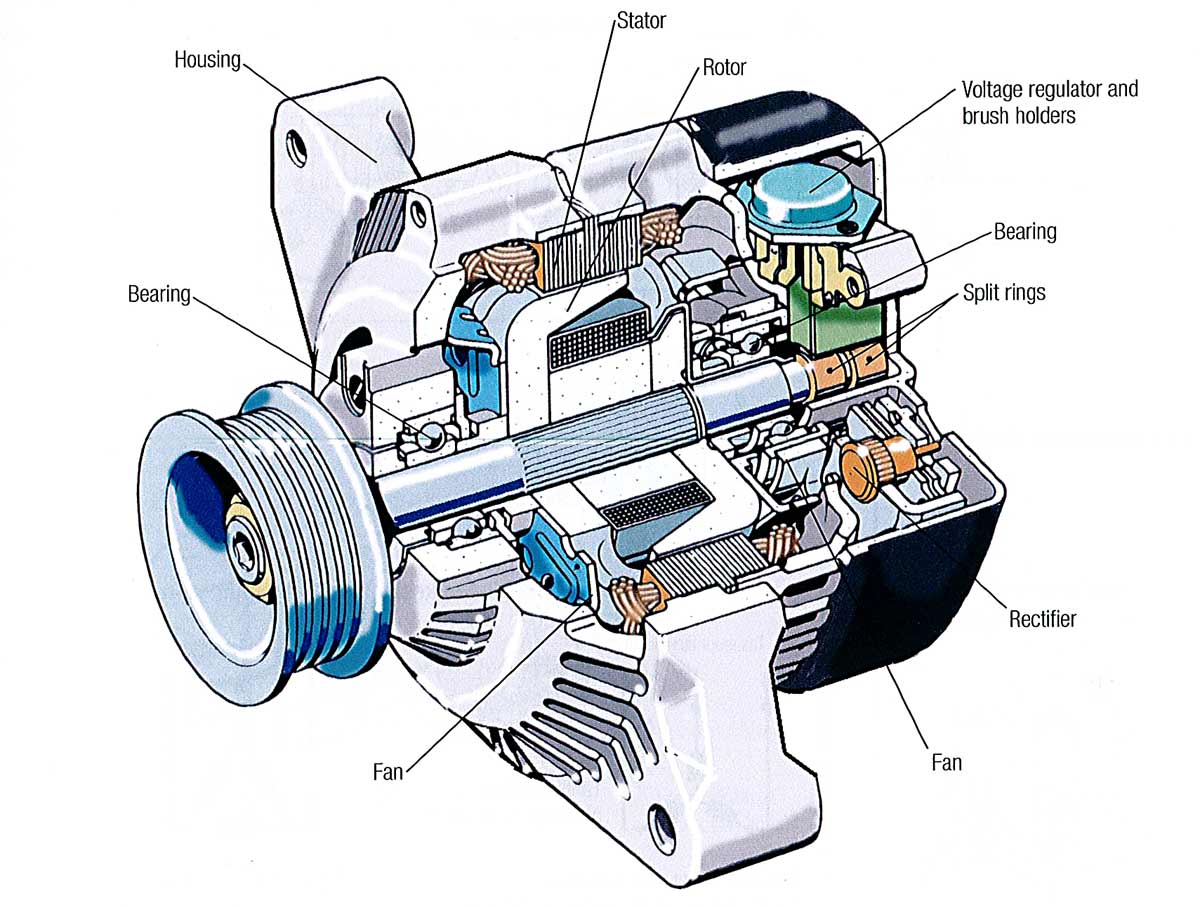

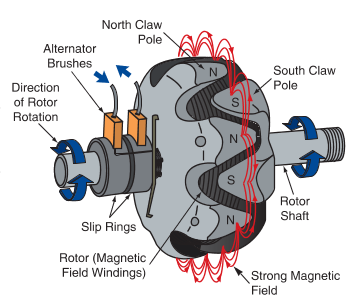

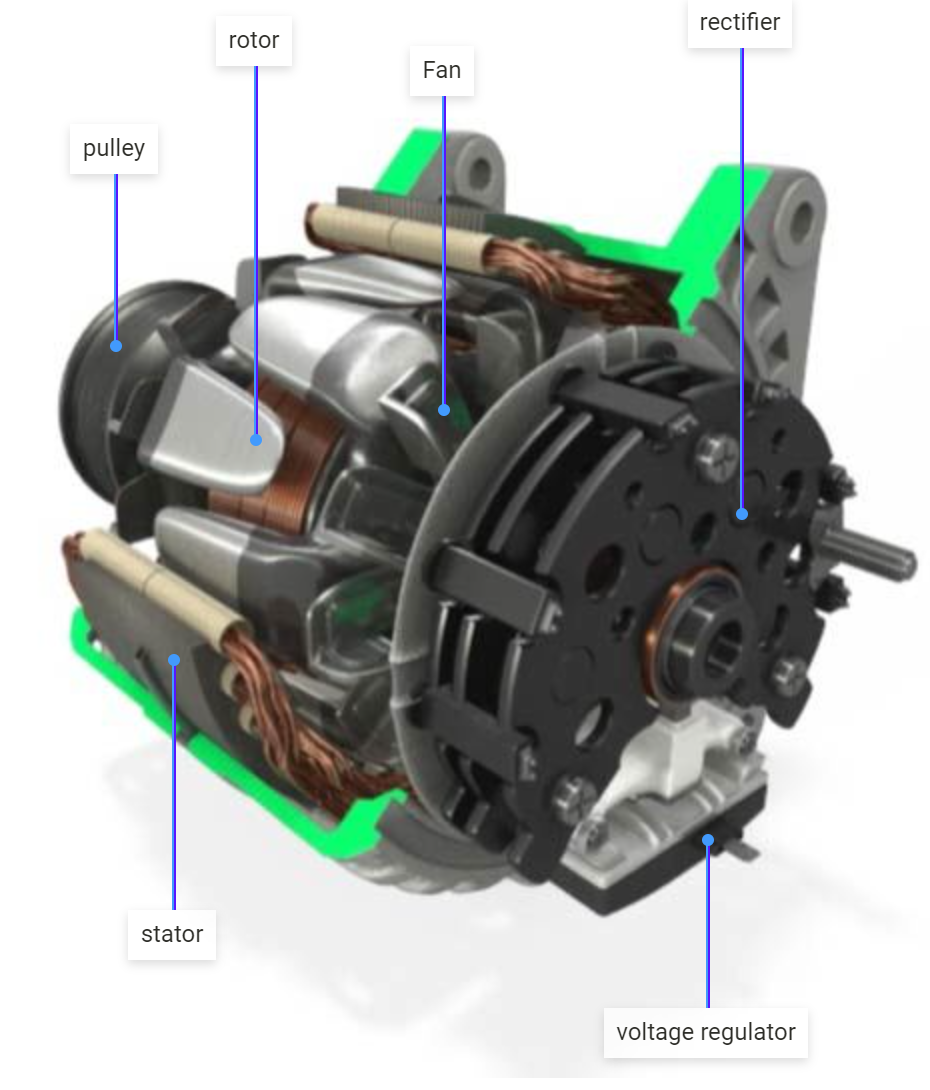

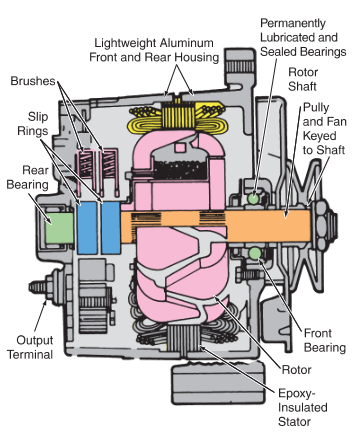

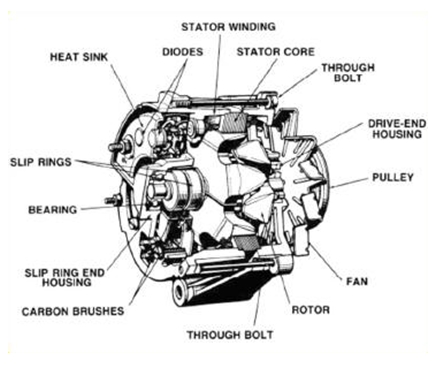

Conventional alternators are characterized by their straightforward design, featuring a rotor and stator with slip rings and brushes. These components work together to convert mechanical energy into electrical energy for vehicles. Their simplicity makes them a popular choice for light-duty vehicles and standard automotive applications. However, B2B buyers should consider the maintenance requirements, as the brushes can wear out and necessitate replacement, potentially increasing long-term operational costs.

How Do Permanent Magnet Alternators Differ from Other Types?

Permanent magnet alternators stand out by using permanent magnets in the rotor, which eliminates the need for brushes. This design results in lower maintenance needs and higher efficiency, making them suitable for applications like marine engines and small wind turbines. B2B buyers should weigh the higher initial investment against the long-term savings on maintenance and potential efficiency gains, especially in low-power applications.

Какие преимущества дают бесщеточные генераторы?

Brushless alternators utilize electronic controls instead of brushes, significantly enhancing durability and lifespan. These alternators are ideal for heavy machinery and commercial vehicles, where reliability is paramount. While the initial cost may be higher, the reduced maintenance requirements and longer service life make them an attractive option for B2B buyers looking to minimize downtime and maintenance costs.

What Makes High-Output Alternators Suitable for Performance Applications?

High-output alternators are specifically designed to provide increased power output, often featuring enhanced cooling systems to handle the additional load. They are commonly used in performance vehicles and applications requiring robust electrical support, such as high-powered audio systems. Buyers should consider the balance between the added weight and the performance benefits, as installation may require modifications to accommodate the larger units.

Why Are Smart Alternators Important for Modern Vehicles?

Smart alternators incorporate advanced electronics to optimize efficiency and monitor performance in real-time. They are particularly relevant in electric and hybrid vehicles, where energy management is crucial. While they come with a higher price tag and integration complexity, the potential for improved fuel efficiency and adaptability to varying electrical demands makes them a valuable investment for B2B buyers in the automotive sector.

Key Industrial Applications of parts of alternator

| Отрасль/сектор | Specific Application of parts of alternator | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Rotor and Stator in Electric Vehicles | Enhanced energy efficiency and battery performance | Quality standards, compatibility with vehicle models |

| Сельское хозяйство | Alternators in Agricultural Equipment (e.g., tractors) | Reliable power generation for remote operations | Durability, resistance to harsh environments |

| Возобновляемые источники энергии | Alternators in Wind Turbines | Sustainable energy production | Efficiency ratings, maintenance support |

| Морской | Alternators in Marine Generators for Boats | Consistent power supply for onboard systems | Corrosion resistance, weight specifications |

| Строительство | Alternators in Heavy Machinery (e.g., excavators) | Dependable power for construction tools | Performance under load, serviceability |

How Are Parts of Alternators Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, the rotor and stator are crucial for electric vehicles (EVs). These components convert mechanical energy into electrical energy, enhancing battery performance and overall vehicle efficiency. International buyers must ensure that these parts meet stringent quality standards and are compatible with various vehicle models. The integration of high-efficiency alternators can significantly reduce energy consumption, providing a competitive edge in the growing EV market.

What Role Do Alternators Play in Agriculture?

In agriculture, alternators are vital for powering equipment like tractors and irrigation systems. The reliability of these components is essential for operations in remote areas where access to electricity may be limited. Buyers in this sector should prioritize sourcing durable alternators that can withstand harsh environmental conditions and heavy usage. Investing in high-quality alternators can lead to increased operational efficiency and reduced downtime during critical farming seasons.

How Are Alternators Used in Renewable Energy Solutions?

Renewable energy applications, particularly in wind turbines, rely on alternators for effective energy generation. These components convert kinetic energy from wind into electrical energy, contributing to sustainable power solutions. Buyers should consider the efficiency ratings of alternators, as higher efficiency leads to better energy output. Additionally, maintenance support is crucial to ensure long-term performance and reliability in energy production.

What Are the Applications of Alternators in Marine Industries?

In the marine industry, alternators are essential for generating power in boats and ships. They provide a consistent power supply for onboard systems, such as navigation and communication equipment. Buyers need to focus on sourcing alternators that offer corrosion resistance and meet specific weight specifications to optimize performance in marine environments. Ensuring that these components are robust can prevent failures during voyages, enhancing safety and operational reliability.

How Are Alternators Integral to Construction Machinery?

Heavy machinery used in construction, such as excavators and bulldozers, relies on alternators for power generation. These components ensure that construction tools operate reliably under load, which is crucial for maintaining productivity on job sites. Buyers should look for alternators that not only perform well but also offer easy serviceability to minimize downtime. Investing in high-quality alternators can lead to better performance and longevity of construction equipment, ultimately impacting project timelines and costs.

3 Common User Pain Points for ‘parts of alternator’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Alternator Parts for Diverse Applications

Проблема: Many B2B buyers face challenges in sourcing high-quality alternator parts that meet specific requirements for various vehicle types. With the wide range of vehicles on the market, including passenger cars, light trucks, and hybrids, the diversity in alternator designs can make it difficult to find parts that fit precisely and perform reliably. Buyers often encounter substandard components that do not meet OEM specifications, leading to premature failures and increased operational costs.

Решение: To overcome this sourcing challenge, B2B buyers should establish relationships with reputable suppliers who specialize in alternator parts and have a proven track record of quality assurance. When evaluating suppliers, prioritize those who provide detailed specifications, certifications, and test results for their components. It is beneficial to utilize a standardized parts catalog that includes OEM part numbers and compatibility information for different vehicles. Additionally, consider leveraging digital platforms that allow for real-time inventory checks and customer reviews to ensure you are selecting reliable parts. Engaging in regular communication with suppliers can also facilitate tailored solutions for specific applications, ensuring that the right parts are always available when needed.

Scenario 2: Understanding the Functionality and Integration of Alternator Components

Проблема: B2B buyers often struggle to understand the intricate functions of various alternator components, such as the rotor, stator, voltage regulator, and rectifier. This lack of knowledge can lead to misordering parts, improper installation, and ultimately, performance issues in the vehicles they maintain or manufacture. Misunderstandings about how these components interact can result in downtime and increased repair costs.

Решение: To address this issue, buyers should invest time in comprehensive training for their purchasing and technical teams. Workshops, webinars, and detailed product documentation can enhance understanding of how alternator components work together to generate electrical power. Collaborating with manufacturers to receive training on the latest technologies and innovations in alternator design can also provide insights into best practices for installation and maintenance. Furthermore, creating a resource library that includes diagrams and technical manuals can serve as a quick reference guide for employees, minimizing the chances of errors in ordering or installation.

Scenario 3: Managing Inventory and Reducing Costs of Alternator Parts

Проблема: Inventory management can be a significant pain point for B2B buyers dealing with alternator parts. Many companies struggle with overstocking certain components while running low on others, leading to inefficient use of capital and space. This imbalance can cause delays in production or service fulfillment, ultimately impacting customer satisfaction and profitability.

Решение: Implementing a robust inventory management system can help streamline the procurement process for alternator parts. Buyers should consider utilizing advanced inventory tracking software that integrates with their existing supply chain management systems to monitor stock levels in real-time. Employing just-in-time (JIT) inventory practices can minimize excess stock and reduce holding costs. Establishing strong partnerships with suppliers can also facilitate quicker replenishment of critical components, ensuring that inventory levels align closely with demand. Regularly analyzing sales trends and historical data can provide valuable insights into which parts are most frequently needed, allowing buyers to make informed purchasing decisions that optimize inventory levels and reduce costs effectively.

Strategic Material Selection Guide for parts of alternator

Какие материалы обычно используются в деталях генератора?

When selecting materials for alternator components, several key factors must be considered, including performance, durability, cost, and regional compliance standards. Here, we analyze four common materials used in alternator parts: aluminum, copper, steel, and plastic.

Как алюминий работает в генераторах переменного тока?

Aluminum is widely used for the outer housing of alternators due to its lightweight and non-magnetic properties. It has excellent thermal conductivity, allowing for effective heat dissipation, which is critical given the heat generated during operation. Aluminum also has a good corrosion resistance, particularly when anodized.

Плюсы: The primary advantages of aluminum include its low weight, which enhances fuel efficiency in vehicles, and its ability to dissipate heat effectively. Additionally, aluminum is relatively cost-effective and easy to manufacture, making it suitable for mass production.

Минусы: However, aluminum can be less durable than other metals, particularly under high-stress conditions. It may also be more prone to deformation under extreme temperatures, which can affect the alternator’s performance over time.

Влияние на применение: Aluminum is compatible with various automotive fluids, making it suitable for use in alternators. However, buyers should ensure that the aluminum used meets international standards such as ASTM or DIN to ensure quality and reliability.

What Role Does Copper Play in Alternator Components?

Copper is primarily used in the windings of the rotor and stator due to its excellent electrical conductivity. This property allows for efficient energy transfer, which is essential for the alternator’s performance.

Плюсы: The key advantage of copper is its superior conductivity, which enhances the alternator’s efficiency and output. It also has good thermal properties, allowing it to handle the heat generated during operation effectively.

Минусы: On the downside, copper is heavier than aluminum and can be more expensive. It is also susceptible to corrosion, which can lead to performance degradation over time.

Влияние на применение: Given its electrical properties, copper is crucial for applications where high efficiency is required. International buyers should consider the copper’s purity and compliance with standards such as JIS to ensure optimal performance.

Why Is Steel Used in Certain Alternator Parts?

Steel is often used for components such as the rotor shaft and housing due to its strength and durability. It can withstand high mechanical stress and is less prone to deformation compared to aluminum.

Плюсы: The main advantage of steel is its exceptional strength, which makes it suitable for high-load applications. It is also relatively inexpensive and widely available.

Минусы: However, steel is heavier than aluminum and can be prone to rust if not properly treated. Its thermal conductivity is lower than that of aluminum, which may affect heat dissipation in some designs.

Влияние на применение: Steel components must be treated to resist corrosion, especially in regions with high humidity or salt exposure. Buyers should ensure that the steel used complies with relevant standards to guarantee longevity.

How Is Plastic Utilized in Alternator Manufacturing?

Plastic is commonly used for non-structural components such as covers and insulators. It is lightweight and can be molded into complex shapes, making it versatile for various applications.

Плюсы: The main advantages of plastic include its low cost and ease of manufacturing. It also offers good electrical insulation properties, which are essential for safety.

Минусы: However, plastic may not withstand high temperatures or mechanical stress as well as metals. It can also degrade over time when exposed to certain automotive fluids.

Влияние на применение: Buyers should consider the type of plastic used and its compatibility with automotive environments. Compliance with international standards for plastics is also crucial to ensure safety and performance.

Summary Table of Material Selection for Alternator Parts

| Материал | Typical Use Case for parts of alternator | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Outer housing, heat dissipation components | Lightweight and excellent heat dissipation | Менее прочные при высоких нагрузках | Средний |

| Медь | Rotor and stator windings | Превосходная электропроводность | Heavier and susceptible to corrosion | Высокий |

| Сталь | Rotor shaft, structural components | Exceptional strength and durability | Heavier and lower thermal conductivity | Низкий |

| Пластик | Крышки и изоляторы | Low cost and good electrical insulation | Ограниченная термостойкость и стрессоустойчивость | Низкий |

This strategic material selection guide provides essential insights for B2B buyers in diverse regions, ensuring that they make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of alternator

What Are the Main Stages of Manufacturing Parts of an Alternator?

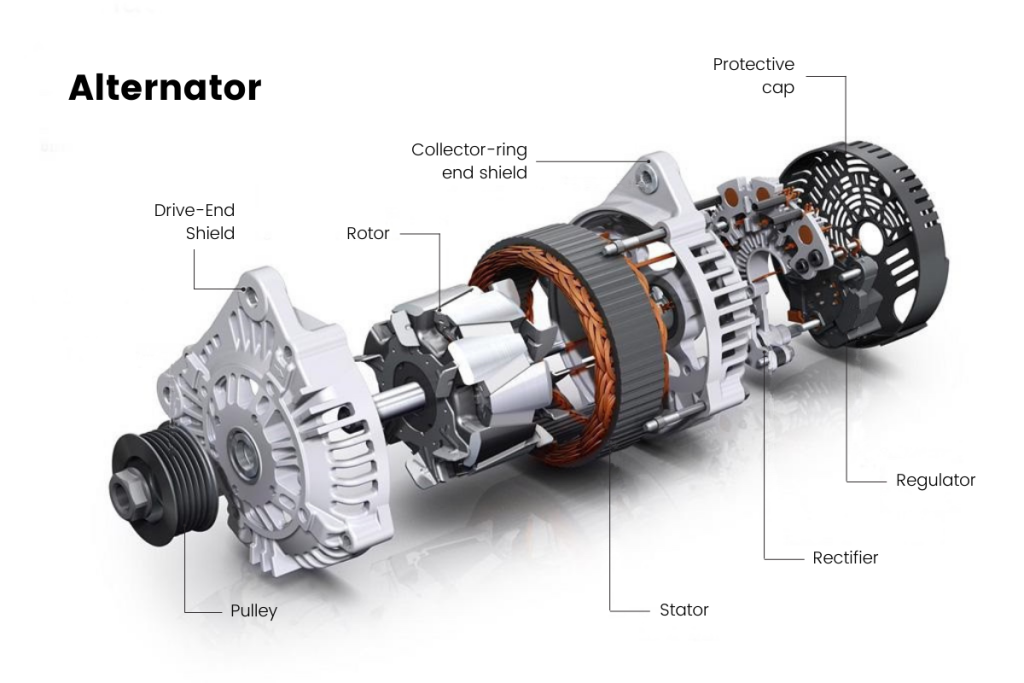

The manufacturing of alternator parts involves several critical stages, each designed to ensure that components meet the stringent requirements of performance and reliability. The primary stages of production include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Alternator Parts?

The process begins with the selection of high-quality raw materials. For instance, aluminum is commonly used for the outer housing of the alternator due to its lightweight and heat-dissipating properties. Other materials include copper for the windings and high-grade steel for the rotor.

Material preparation involves several steps:

- Контроль качества: Raw materials undergo initial quality checks to verify their specifications and mechanical properties. This step is crucial for ensuring that the final product meets industry standards.

- Обработка: Depending on the component, materials may be cut, shaped, or otherwise machined to prepare for further processing. CNC (Computer Numerical Control) machines are often employed for precision in cutting and shaping.

What Techniques Are Used in Forming Alternator Parts?

Once the materials are prepared, forming techniques come into play. These techniques vary based on the specific part being manufactured:

- Кастинг: For components like the alternator housing, casting techniques such as die-casting or sand casting are employed. This allows for complex shapes and structures while maintaining strength and durability.

- Штамповка: Stamping is often used for flat components like the stator and rotor laminations. This process involves pressing sheets of metal into desired shapes using dies, which enhances production speed and consistency.

- Намотка: The stator windings are created by wrapping insulated copper wire around the laminated core. This process requires precision to ensure that the winding is uniform and adheres to specifications.

How Are Alternator Parts Assembled?

Assembly is a crucial stage where various components are brought together to form the complete alternator unit.

- Подборка: Components such as the rotor, stator, and rectifier are typically assembled separately before final assembly. This may involve the installation of slip rings, brushes, and bearings, which are critical for the alternator’s operation.

- Заключительная сборка: In this stage, the sub-assemblies are combined. The rotor is fitted into the stator, and additional components, including the voltage regulator and cooling fans, are integrated. Proper alignment and torque specifications are critical during this phase to ensure functionality.

- Интеграция электрических компонентов: Connectors and terminals are attached, ensuring that all electrical connections are secure and meet the required standards.

What Finishing Techniques Are Applied to Alternator Parts?

Finishing processes enhance the durability and aesthetic quality of alternator parts. Common finishing techniques include:

- Обработка поверхности: Coatings, such as anodizing for aluminum parts or galvanizing for steel components, are applied to prevent corrosion and improve wear resistance.

- Полировка: For aesthetic components, polishing may be employed to enhance appearance and reduce friction.

- Контроль качества: Before moving to the next stage, parts undergo final inspections to ensure they meet specifications.

What Are the Key Quality Assurance Processes for Alternator Parts?

Quality assurance (QA) is essential in manufacturing alternator parts, ensuring that they meet both international and industry-specific standards.

Какие международные стандарты следует учитывать покупателям B2B?

B2B buyers should be aware of various international standards that govern manufacturing practices:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- Маркировка CE: Particularly relevant in Europe, CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- Стандарты API: For automotive components, adhering to API (American Petroleum Institute) standards may also be necessary, particularly for parts involved in energy transfer.

Каковы общие контрольные точки контроля качества?

Quality control checkpoints throughout the manufacturing process include:

- Входящий контроль качества (IQC): This initial phase involves inspecting raw materials for compliance with specifications before they enter the production line.

- Контроль качества в процессе производства (IPQC): During production, random samples are tested at various stages to ensure adherence to quality standards. This can include dimensional checks, visual inspections, and performance tests.

- Окончательный контроль качества (FQC): Once assembly is complete, the entire alternator unit undergoes a final inspection. This may include functional testing to verify electrical performance and mechanical integrity.

Как покупатели B2B могут проверить контроль качества поставщиков?

B2B buyers should adopt several strategies to ensure the quality of alternator parts sourced from suppliers:

- Аудит поставщиков: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards.

- Отчеты по обеспечению качества: Requesting detailed quality assurance reports can help buyers understand the specific QA processes employed by suppliers, including documentation of tests performed.

- Проверки третьей стороной: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and the quality of the finished products. This is particularly valuable when sourcing from international suppliers in regions like Africa and South America, where standards may vary.

What QC and Certification Nuances Should International Buyers Be Aware Of?

International buyers must navigate various nuances when it comes to quality control and certification:

- Региональные стандарты: Different regions may have varying standards and certifications. For example, while CE marking is essential in Europe, other regions may prioritize different certifications. It’s vital to understand these differences to avoid compliance issues.

- Культурные аспекты: Understanding cultural attitudes towards quality and reliability in different regions can aid in establishing effective communication and expectations with suppliers.

- Traceability: Buyers should ensure that suppliers maintain traceability of their components, which is critical in case of recalls or quality issues.

By being diligent about manufacturing processes and quality assurance, B2B buyers can secure reliable alternator parts that meet their operational needs while fostering strong supplier relationships across diverse global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of alternator’

In the competitive landscape of B2B procurement, sourcing parts for alternators demands careful consideration and strategic planning. This practical guide offers a structured checklist to help international buyers, particularly from Africa, South America, the Middle East, and Europe, effectively navigate the sourcing process.

Шаг 1: Определите свои технические характеристики

Begin by clearly outlining the technical specifications required for the alternator parts you need. This includes dimensions, materials, voltage ratings, and compatibility with existing systems. Having precise specifications not only ensures that you receive the correct components but also helps suppliers understand your requirements, reducing the risk of errors and delays.

Illustrative image related to parts of alternator

- Ключевые соображения:

- Identify the specific alternator model and part numbers.

- Consider environmental factors like temperature and humidity that may affect part performance.

Шаг 2: Исследование потенциальных поставщиков

Conduct thorough research to identify potential suppliers who specialize in alternator parts. Utilize online platforms, trade directories, and industry forums to compile a list of reputable manufacturers and distributors. This step is crucial for ensuring that you partner with suppliers who can meet your quality and reliability expectations.

- Key Actions:

- Check supplier reviews and ratings on industry websites.

- Look for suppliers with a proven track record in your geographical region.

Шаг 3: Оценивайте сертификаты поставщиков и соответствие требованиям

Verify that your shortlisted suppliers hold the necessary certifications and comply with international quality standards. This is essential for ensuring that the parts meet safety and performance criteria, particularly in regulated industries such as automotive and aerospace.

- Важные сертификаты:

- ISO 9001 для систем менеджмента качества.

- Specific automotive industry certifications like IATF 16949.

Шаг 4: Запросите образцы и техническую документацию

Before making a large order, request samples of the alternator parts along with relevant technical documentation. Evaluating samples allows you to assess the quality and compatibility of the components with your existing systems. Technical documents provide insights into specifications and installation requirements.

- На что обратить внимание:

- Material quality and finish.

- Detailed installation guidelines and performance metrics.

Шаг 5: Обсудить условия и положения

Once you have selected a supplier, negotiate the terms and conditions of the purchase. This includes pricing, payment terms, delivery schedules, and warranties. Clear agreements help prevent misunderstandings and ensure a smooth procurement process.

Illustrative image related to parts of alternator

- Советы по ведению переговоров:

- Be transparent about your budget constraints while seeking competitive pricing.

- Discuss options for bulk purchasing discounts or long-term partnership agreements.

Шаг 6: Установите каналы связи

Set up effective communication channels with your chosen supplier. Regular communication is vital for addressing any issues that may arise during the sourcing process and for fostering a strong working relationship.

- Best Practices:

- Use dedicated points of contact for technical queries and order updates.

- Schedule regular check-ins to discuss progress and any potential changes.

Шаг 7: Monitor and Evaluate Supplier Performance

After procurement, continuously monitor and evaluate the supplier’s performance. Assess the quality of the parts received, delivery timelines, and customer service responsiveness. This evaluation will inform future sourcing decisions and help you build a reliable supply chain.

- Evaluation Criteria:

- Timeliness of delivery and accuracy of orders.

- Quality of parts and responsiveness to issues or concerns.

By following this structured checklist, international B2B buyers can streamline their procurement processes for alternator parts, ensuring quality, reliability, and satisfaction in their sourcing endeavors.

Comprehensive Cost and Pricing Analysis for parts of alternator Sourcing

What Are the Key Cost Components for Sourcing Alternator Parts?

When sourcing alternator parts, understanding the cost structure is crucial for effective budgeting and procurement. The main components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Материалы: The primary materials used in alternator parts include aluminum for housings, copper for windings, and various alloys for internal components like the rotor and stator. Fluctuations in global metal prices can significantly impact costs, so buyers should stay informed about market trends.

-

Трудовые ресурсы: Labor costs vary based on the geographical location of the manufacturer. In regions with lower labor costs, such as some parts of Asia or South America, the overall cost may be lower. However, consider the trade-off in quality and expertise.

-

Производственные накладные расходы: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturers often have lower overhead, which can translate into better pricing for buyers.

-

Инструменты: Custom tooling for specific alternator parts can be a significant initial investment. Buyers should evaluate whether the tooling costs can be amortized over large production runs to minimize the impact on unit pricing.

-

Контроль качества: Effective QC processes ensure that parts meet specifications and standards. This may involve additional costs, but high-quality components reduce the risk of failures and associated warranty claims.

-

Логистика: Transportation costs can vary widely depending on the distance from the supplier to the buyer and the chosen shipping method. Incoterms also play a vital role in determining responsibilities for shipping costs, insurance, and tariffs.

-

Маржа: Supplier margins can vary based on brand reputation, market demand, and the complexity of the parts. Established suppliers may charge higher margins due to perceived reliability and quality.

How Do Price Influencers Affect Alternator Parts Sourcing?

Several factors influence pricing for alternator parts, which are particularly important for international B2B buyers.

-

Объем и минимальное количество заказов (MOQ): Larger orders often lead to lower per-unit prices. Buyers should negotiate MOQs that align with their demand forecasts to optimize costs.

-

Технические характеристики и индивидуальная настройка: Customized parts may incur additional costs due to unique tooling or materials. Buyers should balance the need for customization with budget constraints.

-

Выбор материала: The choice of materials impacts not only the initial cost but also the durability and performance of the alternator parts. High-quality materials may result in higher upfront costs but lower maintenance and replacement expenses.

-

Сертификаты качества: Suppliers with ISO certifications or other quality assurances may charge a premium, but they often provide better reliability and performance, which can save costs in the long run.

-

Факторы, связанные с поставщиками: The reputation and reliability of the supplier can influence pricing. Well-established suppliers may offer better warranty terms and customer support, which can justify higher prices.

-

Инкотермс: Understanding Incoterms is essential for managing shipping costs and responsibilities. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect total landed costs.

What Are Some Buyer Tips for Cost-Efficiency in Alternator Parts Procurement?

B2B buyers should adopt strategies to ensure cost-efficiency when sourcing alternator parts.

-

Обсудить условия: Always negotiate pricing, payment terms, and delivery schedules. Building strong relationships with suppliers can lead to better deals.

-

Учитывайте совокупную стоимость владения (TCO): Evaluate the TCO, which includes purchase price, maintenance, and operational costs. Cheaper parts may lead to higher long-term costs due to frequent failures or replacements.

-

Используйте рыночную информацию: Stay updated on industry trends, material costs, and supplier capabilities. This knowledge can empower buyers during negotiations and decision-making.

-

Explore Global Suppliers: For buyers in Africa, South America, the Middle East, and Europe, exploring global suppliers can yield competitive pricing. However, factor in logistics and potential delays.

-

Будьте внимательны к нюансам ценообразования: International buyers should be mindful of currency fluctuations, import tariffs, and local regulations that could impact pricing.

Отказ от ответственности в отношении ориентировочных цен

Prices for alternator parts can vary significantly based on the factors mentioned above. It’s essential for buyers to obtain quotes from multiple suppliers and consider all cost components before making purchasing decisions.

Alternatives Analysis: Comparing parts of alternator With Other Solutions

Understanding the Alternatives to Parts of an Alternator

In the automotive industry, the efficient generation of electrical power is crucial, leading to the development of various technologies beyond traditional alternators. As B2B buyers evaluate their options, understanding the strengths and weaknesses of these alternatives can aid in selecting the best solution for specific needs. This section compares the traditional parts of an alternator with two viable alternatives: the Встроенный стартер-генератор (ISG) и Battery Electric Systems.

Сравнительная таблица

| Аспект сравнения | Детали генератора | Встроенный стартер-генератор (ISG) | Battery Electric Systems |

|---|---|---|---|

| Производительность | Reliable, generates AC power | Combines starting and generating functions | High efficiency, relies on battery charge |

| Стоимость | Умеренные начальные инвестиции | Выше из-за сложности | Varies significantly, often higher upfront cost |

| Простота внедрения | Established technology, easy to install | Requires advanced integration | Complex installation and infrastructure |

| Техническое обслуживание | Moderate; regular checks needed | Lower; fewer moving parts | Minimal; battery maintenance required |

| Лучший вариант использования | Обычные транспортные средства | Hybrid and stop-start vehicles | Fully electric vehicles |

Analyzing the Alternatives: What are the Pros and Cons?

Встроенный стартер-генератор (ISG)

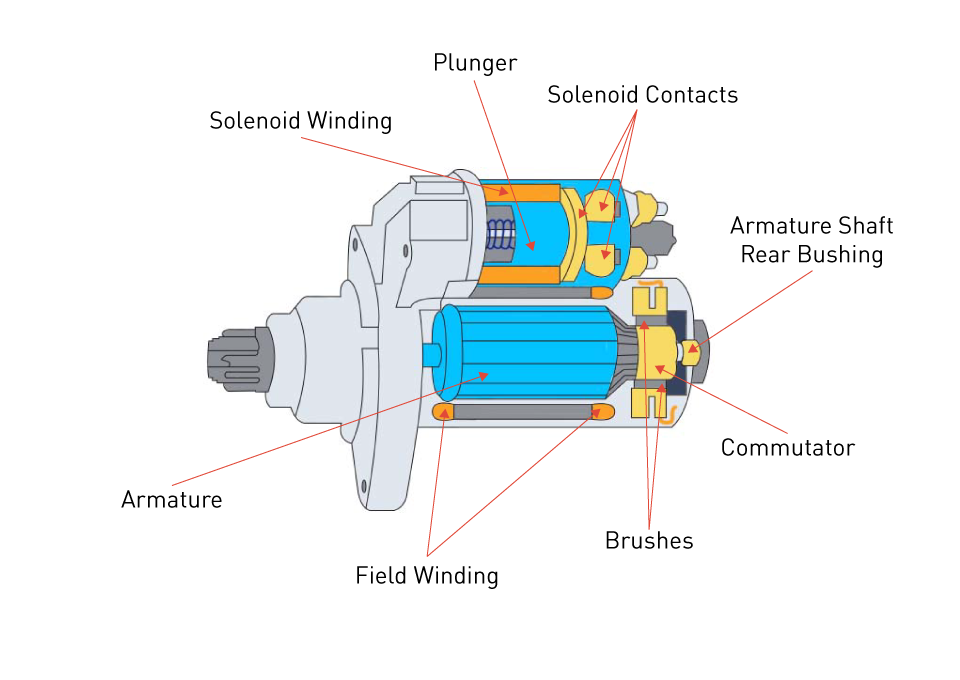

The ISG merges the functionality of a starter motor and an alternator into one unit, making it a popular choice in hybrid vehicles. One significant advantage is its ability to recover energy during braking (regenerative braking), enhancing overall vehicle efficiency. However, the complexity of installation and integration into existing systems can lead to a higher initial investment. Additionally, while maintenance requirements are lower, the sophisticated electronics may necessitate specialized knowledge for repairs.

Battery Electric Systems

Battery electric systems represent a paradigm shift in automotive technology, relying solely on battery power for operation. These systems are highly efficient, producing zero emissions and reducing dependency on fossil fuels. The main drawback lies in the initial cost of electric vehicles, which can be higher than traditional combustion engines. Furthermore, the need for robust charging infrastructure can complicate implementation, especially in regions where such infrastructure is still developing. However, once established, maintenance is minimal compared to conventional systems.

Сделайте правильный выбор в соответствии с вашими потребностями

Selecting the most appropriate solution for generating electrical power in vehicles depends on various factors, including performance needs, budget constraints, and the intended application. For traditional vehicles, the parts of an alternator remain a reliable and cost-effective choice. In contrast, for those investing in hybrid or electric technologies, exploring ISG or battery electric systems may yield long-term benefits in efficiency and sustainability. Buyers should assess their operational requirements, maintenance capabilities, and the existing infrastructure to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for parts of alternator

Каковы основные технические характеристики деталей генератора?

When evaluating alternator components, several technical properties are critical for ensuring performance, reliability, and longevity. Here are some essential specifications to consider:

1. Марка материала

Alternators typically utilize aluminum for their housings due to its lightweight and non-magnetic properties. The choice of material affects heat dissipation and corrosion resistance. For high-performance applications, consider components made from higher-grade materials, such as stainless steel or specialized alloys, which may offer better durability and resistance to wear.

2. Уровни толерантности

Precision in manufacturing alternator parts, such as the rotor and stator, is crucial. Tolerance levels dictate the acceptable range of variation in dimensions. Tight tolerances ensure proper fit and function, reducing the risk of mechanical failure due to misalignment. This is especially important in high-speed applications where even minor deviations can lead to significant performance issues.

3. Электрические номиналы

Understanding the electrical specifications of components, such as the voltage and current ratings of the rectifier and voltage regulator, is vital. These ratings determine the maximum load the alternator can handle without overheating or failing. Buyers should verify that the alternator meets or exceeds the electrical requirements of the intended application.

4. Эффективность охлаждения

The cooling design of an alternator, including internal and external fans, plays a significant role in its performance. Effective cooling mechanisms prevent overheating, thereby extending the life of the alternator and its components. Buyers should evaluate the cooling features, especially for applications in high-temperature environments.

Illustrative image related to parts of alternator

5. Качество подшипников

Bearings are critical to the smooth operation of the rotor. High-quality bearings reduce friction and wear, improving the alternator’s efficiency and lifespan. Consider the type of bearings used (e.g., sealed or open) and their load ratings, as these will impact overall performance and maintenance needs.

What Are Common Trade Terms Used in Alternator Component Sourcing?

Знание отраслевого жаргона необходимо для эффективного общения и ведения переговоров в сделках B2B. Вот некоторые распространенные термины:

1. OEM (производитель оригинального оборудования)

This term refers to companies that produce components that are used in the assembly of another company’s products. For alternator parts, OEM specifications ensure that the components meet the original design and performance standards, which is crucial for maintaining vehicle warranty and reliability.

2. MOQ (минимальный объем заказа)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers as it can impact inventory management and cash flow. Some manufacturers may offer flexible MOQs, which can be advantageous for smaller businesses or those testing new products.

3. RFQ (запрос предложения)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. Including detailed specifications in the RFQ helps ensure accurate quotes. For alternator components, providing part numbers and material requirements can streamline the procurement process.

Illustrative image related to parts of alternator

4. Инкотермс (Международные торговые термины)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who bears the costs and risks associated with shipping, insurance, and customs clearance. Familiarity with Incoterms can help avoid misunderstandings and additional costs during the import/export process.

5. Время выполнения заказа

Lead time is the time taken from placing an order to receiving the goods. In the context of alternator parts, understanding lead times is crucial for project planning and inventory management. Suppliers with shorter lead times may offer a competitive advantage, especially in industries where downtime is costly.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternator parts, ensuring that they meet their operational needs and quality standards.

Illustrative image related to parts of alternator

Navigating Market Dynamics and Sourcing Trends in the parts of alternator Sector

What Are the Key Market Dynamics and Trends in the Parts of the Alternator Sector?

The alternator parts market is experiencing robust growth, driven by several global factors. Increasing vehicle production and sales, especially in emerging markets like Africa and South America, are significant contributors to this expansion. As automotive manufacturers focus on enhancing fuel efficiency and reducing emissions, there is a rising demand for high-quality alternator components that can support advanced technologies such as hybrid and electric vehicles.

Emerging technologies such as automation and digitalization are reshaping the sourcing landscape. B2B buyers are increasingly leveraging data analytics and supply chain management software to streamline procurement processes. This trend enables them to make informed decisions based on real-time data, enhancing efficiency and reducing costs. Moreover, the adoption of Industry 4.0 practices is prompting manufacturers to adopt smart manufacturing techniques, which optimize production and improve product quality.

Furthermore, international buyers, particularly from Europe and the Middle East, are increasingly seeking partnerships with suppliers who can offer not only competitive pricing but also superior quality and reliability. This shift is evident in the growing emphasis on long-term relationships with manufacturers that can ensure consistent supply and adhere to stringent quality standards.

How Is Sustainability Influencing Sourcing Decisions for Alternator Parts?

Sustainability is becoming a pivotal consideration in the procurement of alternator parts. As global awareness of environmental issues rises, B2B buyers are prioritizing suppliers that demonstrate a commitment to reducing their environmental impact. This includes sourcing materials that are recyclable or produced through sustainable methods.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices, looking for transparency in sourcing and production processes. Certifications such as ISO 14001 for environmental management and ISO 50001 for energy management are becoming essential criteria for selecting suppliers. These certifications not only indicate a commitment to sustainability but also assure buyers that the suppliers adhere to international best practices.

In addition to certifications, the use of ‘green’ materials in the production of alternator components is gaining traction. For instance, aluminum, widely used in alternator housings, is favored for its lightweight properties and recyclability. Suppliers that invest in sustainable practices and materials are likely to gain a competitive edge in the market, appealing to buyers who value corporate responsibility alongside product performance.

What Is the Historical Context of the Alternator Parts Industry?

The alternator has evolved significantly since its introduction in the early 20th century. Initially used in large industrial machines, it became a standard component in automobiles by the 1960s, replacing the less efficient generator systems. This transition was driven by the need for more reliable and efficient power generation to support increasingly complex electrical systems in vehicles.

Over the decades, advancements in materials and technology have transformed alternator design. The introduction of lightweight materials, such as aluminum, has improved efficiency and performance. Additionally, modern alternators are designed to handle the demands of advanced vehicle technologies, including start-stop systems and regenerative braking in hybrids and electric vehicles. This evolution reflects the industry’s ongoing adaptation to changing market needs and technological advancements, influencing sourcing strategies for B2B buyers today.

In summary, understanding the dynamics of the alternator parts market, the importance of sustainability, and the historical context can empower B2B buyers to make informed sourcing decisions that align with their operational goals and ethical standards.

Illustrative image related to parts of alternator

Frequently Asked Questions (FAQs) for B2B Buyers of parts of alternator

-

1. How do I determine the right alternator parts for my vehicle?

To select the appropriate alternator parts, start by identifying the make, model, and year of your vehicle. Cross-reference these details with manufacturer specifications or part catalogs. It’s crucial to consider the specific requirements of your engine type, as alternators vary significantly across different vehicles. Additionally, consult with suppliers who can provide part compatibility information and technical support. Engaging with industry experts can also help ensure that you select the best parts suited for your application. -

2. What is the best way to source high-quality alternator components?

Sourcing high-quality alternator components involves researching and vetting suppliers rigorously. Look for manufacturers with established reputations, positive customer reviews, and certifications that demonstrate adherence to international quality standards, such as ISO 9001. Request samples to evaluate quality firsthand and inquire about their production processes. Engaging in trade shows or industry events can also provide valuable insights into potential suppliers and their offerings. -

3. How can I negotiate favorable payment terms when purchasing alternator parts?

To negotiate favorable payment terms, begin by clearly communicating your purchasing volume and frequency. Suppliers may be more flexible with terms for larger orders or long-term contracts. Propose payment options such as net 30 or net 60 terms, which can help manage cash flow. Additionally, consider offering upfront payments for discounts or inquire about installment plans for larger purchases. Building a strong relationship with your supplier can also facilitate better terms over time. -

4. What should I know about minimum order quantities (MOQs) for alternator parts?

Minimum order quantities (MOQs) vary significantly among suppliers and can depend on factors like part type, manufacturing capabilities, and production costs. When sourcing alternator parts, inquire about MOQs upfront to avoid unexpected costs. If MOQs are high, consider consolidating orders with other buyers to meet the requirement. Some suppliers may offer flexibility in MOQs for new customers or repeat clients, so it’s worth discussing your needs to explore potential options. -

5. How do I ensure compliance with international trade regulations when importing alternator parts?

To ensure compliance with international trade regulations, familiarize yourself with the customs laws of your country as well as those of the exporting country. Consult with a customs broker to understand tariffs, duties, and necessary documentation like invoices and packing lists. Verify that the components meet any relevant safety or environmental standards required in your region. Staying informed about trade agreements can also benefit your importation process by reducing costs or simplifying procedures. -

6. What logistics considerations should I keep in mind when importing alternator parts?

Logistics considerations include selecting reliable shipping partners, understanding shipping timelines, and ensuring proper packaging to prevent damage during transit. Evaluate whether to use air or sea freight based on cost, urgency, and volume. Also, consider customs clearance processes and potential delays that may arise. Finally, maintain clear communication with your supplier regarding shipment tracking and delivery expectations to ensure a smooth import experience. -

7. How can I customize alternator components to meet specific requirements?

Customizing alternator components typically involves discussing your specific needs with the supplier early in the sourcing process. Provide detailed specifications, such as dimensions, materials, and performance characteristics. Some suppliers may have capabilities for bespoke manufacturing or can recommend modifications to existing parts. Be prepared to meet minimum order requirements for custom parts, and request prototypes to evaluate fit and performance before full-scale production. -

8. What quality assurance processes should I expect from suppliers of alternator parts?

Expect suppliers to have rigorous quality assurance processes in place, including inspections at various production stages, testing for electrical performance, and adherence to industry standards. Request documentation of quality control measures, such as ISO certifications or test reports. Establish clear expectations regarding warranty and return policies for defective parts, which can help mitigate risks associated with quality issues. Engaging in regular communication with your supplier about quality concerns can also foster a proactive approach to quality assurance.

Top 5 Parts Of Alternator Manufacturers & Suppliers List

1. HowStuffWorks – Генераторы

Домен: auto.howstuffworks.com

Зарегистрирован: 1998 (27 лет)

Введение: Alternators are small, lightweight devices roughly the size of a coconut, constructed with an aluminum outer housing for heat dissipation and non-magnetization. Key components include a drive pulley, S terminal (senses battery voltage), IG terminal (ignition switch), L terminal (warning lamp circuit), B terminal (main output to battery), and F terminal (full-field bypass). Cooling is essential, wi…

2. Electude – Основы генератора переменного тока

Домен: electude.com

Зарегистрирован: 2005 (20 лет)

Введение: Генератор переменного тока — важнейший автомобильный компонент, который преобразует механическую энергию в электрическую, генерируя энергию для электрических потребителей и аккумулятора автомобиля. Ключевые компоненты включают:

– Шкив: передает механическую энергию от двигателя.

– Ротор: создает магнитное поле для генерации переменного тока.

– Статор: статическая часть, в которой генерируется напряжение.

– Выпрямитель: …

3. Facebook – Parts of Alternator

4. AutoElectro – Alternators

Домен: autoelectro.co.uk

Зарегистрирован: 1999 (26 лет)

Введение: Alternator Function: Generates energy to feed the electrical system and charge the battery when the car is running. Output: Direct Current (DC). Working Mechanism: Alternating Current (AC) is generated when the alternator pulley is rotated, which is then converted to DC via a rectifier. Components: 1. Regulator – Controls power distribution to the battery. 2. Rectifier – Converts AC to DC. 3. Roto…

5. Bermantec – Alternator Components

Домен: bermantec.com

Зарегистрирован: 2018 (7 лет)

Введение: Parts of the alternator include: 1. Rotor – A rotating magnetic field that spins and creates electromagnetic flow. 2. Stator – The static part that consists of an outer frame, stator core, and stator winding, creating alternating current. 3. Rectifier – Converts AC to DC using diodes, available in positive and negative polarity variants. 4. Voltage Regulator – Maintains voltage between 13.5 and 30…

Strategic Sourcing Conclusion and Outlook for parts of alternator

As the global automotive industry continues to evolve, the strategic sourcing of alternator parts presents significant opportunities for B2B buyers. Understanding the critical components—such as rotors, stators, rectifiers, and voltage regulators—enables organizations to make informed purchasing decisions that enhance operational efficiency and product reliability. Prioritizing quality and compatibility in sourcing not only reduces downtime but also improves overall vehicle performance, thereby enhancing customer satisfaction.

In regions like Africa, South America, the Middle East, and Europe, the demand for reliable electrical systems is on the rise. Strategic partnerships with reputable suppliers can ensure access to high-quality alternator parts that meet regional standards. Buyers should leverage this opportunity to negotiate favorable terms, explore bulk purchasing options, and consider local suppliers to minimize shipping costs and lead times.

Looking ahead, the importance of integrating sustainable practices in sourcing will only grow. As the automotive industry shifts towards electrification, aligning with suppliers who prioritize innovation and eco-friendly manufacturing processes will be crucial. By adopting a proactive approach to sourcing, international B2B buyers can position themselves at the forefront of the market, ready to meet future challenges and seize emerging opportunities.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Illustrative image related to parts of alternator

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.