Introduction: Navigating the Global Market for cost to install headlights

In today’s global marketplace, sourcing the right components for vehicle maintenance, such as understanding the cost to install headlights, presents a significant challenge for international B2B buyers. With the increasing complexity of automotive lighting systems and the diverse range of options available—from basic halogen bulbs to advanced LED assemblies—making informed purchasing decisions can be daunting. This comprehensive guide delves into the various types of headlights, their applications, and the associated costs, providing a roadmap for businesses looking to enhance their service offerings or manage fleet maintenance effectively.

The guide is tailored to meet the needs of B2B buyers from regions like Africa, South America, the Middle East, and Europe, such as Nigeria and Brazil, where understanding local market dynamics and supplier capabilities is crucial. It offers actionable insights on how to vet suppliers, compare pricing structures, and assess the total cost of ownership, including installation and potential long-term savings through DIY options. By equipping decision-makers with the knowledge to navigate the complexities of headlight installation costs, this guide empowers businesses to make strategic investments, ensuring safety and compliance while optimizing their operational efficiency.

Содержание

- Top 4 Cost To Install Headlights Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cost to install headlights

- Understanding cost to install headlights Types and Variations

- Key Industrial Applications of cost to install headlights

- 3 Common User Pain Points for ‘cost to install headlights’ & Their Solutions

- Strategic Material Selection Guide for cost to install headlights

- In-depth Look: Manufacturing Processes and Quality Assurance for cost to install headlights

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cost to install headlights’

- Comprehensive Cost and Pricing Analysis for cost to install headlights Sourcing

- Alternatives Analysis: Comparing cost to install headlights With Other Solutions

- Essential Technical Properties and Trade Terminology for cost to install headlights

- Navigating Market Dynamics and Sourcing Trends in the cost to install headlights Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cost to install headlights

- Strategic Sourcing Conclusion and Outlook for cost to install headlights

- Важное предупреждение и условия использования

Understanding cost to install headlights Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Галогенные фары | Affordable, widely available, shorter lifespan (500-1,000 hours) | General automotive repairs and maintenance | Плюсы: Low initial cost; Минусы: Frequent replacements needed. |

| HID (высокоинтенсивный разряд) | Brighter than halogen, longer lifespan (2,000-10,000 hours) | Performance vehicles, luxury cars | Плюсы: Enhanced visibility; Минусы: Higher cost and complexity. |

| Светодиод (Light Emitting Diode) | Long lifespan (up to 40,000 hours), energy-efficient, modern design | Newer vehicle models, eco-friendly brands | Плюсы: Cost-effective over time; Минусы: Более высокая первоначальная стоимость. |

| Complete Headlight Assembly | Includes all components, often sealed units, expensive | High-end vehicles, specialty repairs | Плюсы: Comprehensive solution; Минусы: High replacement costs. |

| Адаптивные системы головного света | Advanced features like auto-leveling and directional lighting | Premium automotive markets | Плюсы: Improved safety and visibility; Минусы: Complexity and high costs. |

What are Halogen Headlights and Their Suitability for B2B Buyers?

Halogen headlights are the most commonly used type in vehicles, characterized by their low cost and easy availability. They typically have a lifespan of 500 to 1,000 hours and are suitable for general automotive repairs and maintenance, especially in regions with budget-conscious consumers. B2B buyers should consider the frequency of replacements due to their shorter lifespan, which may affect long-term operational costs.

How Do HID Headlights Stand Out for Performance Applications?

HID headlights provide superior brightness compared to halogen bulbs, making them ideal for performance vehicles and luxury cars. With a lifespan ranging from 2,000 to 10,000 hours, they offer a longer duration of use, which can appeal to businesses focused on high-performance automotive services. However, buyers should note the higher costs and installation complexity, which may require specialized training or tools.

Why Choose LED Headlights for Modern Vehicles?

LED headlights are known for their longevity, lasting up to 40,000 hours, and energy efficiency, making them an attractive option for newer vehicle models and eco-friendly brands. They are increasingly being adopted in various markets due to their cost-effectiveness over time. B2B buyers should evaluate the initial investment against long-term savings, as the higher upfront costs may be justified by reduced replacement frequency and energy consumption.

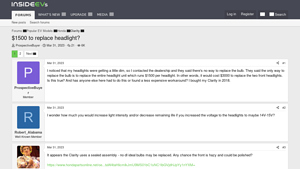

What are the Benefits of Complete Headlight Assemblies?

Complete headlight assemblies include all necessary components for installation, offering a comprehensive solution for B2B buyers dealing with high-end vehicles or specialty repairs. While they can be costly, particularly for sealed units, they ensure that all parts are compatible and functioning correctly. Buyers must weigh the convenience of a complete solution against the significant investment required for these assemblies.

Illustrative image related to cost to install headlights

How Do Adaptive Headlight Systems Enhance Automotive Safety?

Adaptive headlight systems incorporate advanced technologies such as auto-leveling and directional lighting, significantly enhancing visibility and safety on the road. These systems are primarily found in premium automotive markets, attracting B2B buyers focused on high-tech vehicle features. However, the complexity and high costs associated with these systems may require additional training for installation and maintenance, making it essential for buyers to assess their technical capabilities before investing.

Key Industrial Applications of cost to install headlights

| Отрасль/сектор | Specific Application of cost to install headlights | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Авторемонтные мастерские | Headlight replacement services for customers | Increases customer satisfaction and loyalty through quality service | Sourcing reliable headlight parts and skilled technicians for installation |

| Управление автопарком | Regular headlight maintenance for commercial vehicles | Ensures safety and compliance, reducing liability and downtime | Cost-effective bulk purchasing options for replacement parts |

| Транспорт и логистика | Installation of advanced lighting systems in transport vehicles | Enhances safety during night operations, improving operational efficiency | Compliance with local regulations regarding vehicle lighting standards |

| Автомобилестроение | Integration of headlight systems in new vehicle production | Streamlines production processes and ensures quality control | Partnership with quality suppliers for innovative lighting technology |

| Car Dealerships | Offering headlight installation as part of vehicle sales | Adds value to the customer experience and increases upselling opportunities | Sourcing high-quality, branded headlight components for reliability |

How Do Automotive Repair Shops Benefit from Headlight Installation Costs?

Automotive repair shops frequently encounter headlight replacement requests from customers, making the cost to install headlights a vital service. Providing this service not only enhances customer satisfaction but also builds loyalty, as clients appreciate quick and efficient repairs. Repair shops need to source high-quality parts to ensure reliability, which can help minimize repeat visits due to poor-quality replacements. Establishing relationships with reputable suppliers is crucial for maintaining competitive pricing and ensuring timely delivery of components.

Why is Headlight Maintenance Important for Fleet Management?

For fleet management companies, regular headlight maintenance is essential to ensure the safety of drivers and compliance with road regulations. The cost to install headlights becomes a significant aspect of fleet upkeep, as it directly impacts operational efficiency and liability. By sourcing headlight components in bulk, fleet managers can reduce costs while ensuring that all vehicles are equipped with reliable lighting systems. This proactive approach not only enhances safety but also minimizes vehicle downtime, which is critical for maintaining service schedules.

How Do Transportation & Logistics Companies Enhance Safety with Headlight Installation?

In the transportation and logistics sector, the installation of advanced lighting systems in transport vehicles is crucial for safety, especially during nighttime operations. The cost to install headlights, particularly high-quality LED or HID systems, can significantly improve visibility, reducing the risk of accidents. Companies in this sector must consider local regulations regarding vehicle lighting to ensure compliance. Partnering with suppliers who offer innovative lighting solutions can provide a competitive edge by enhancing safety features in the fleet.

What Role Does Headlight Integration Play in Automotive Manufacturing?

Automotive manufacturers must consider the cost to install headlights during the production of new vehicles. Integrating efficient headlight systems is crucial for maintaining quality control and streamlining production processes. Manufacturers benefit from establishing partnerships with suppliers who can provide cutting-edge lighting technology, which not only enhances the vehicle’s appeal but also meets regulatory standards. By investing in reliable headlight systems, manufacturers can improve the overall quality of their vehicles, leading to increased customer satisfaction.

How Can Car Dealerships Leverage Headlight Installation in Sales?

Car dealerships can enhance their customer offerings by including headlight installation as part of vehicle sales. The cost to install headlights can be positioned as an added value that improves the overall customer experience. By sourcing high-quality headlight components, dealerships can ensure that the products they offer are reliable and durable. This strategy not only fosters customer trust but also opens up opportunities for upselling additional services, such as headlight upgrades or maintenance packages, contributing to increased revenue.

3 Common User Pain Points for ‘cost to install headlights’ & Their Solutions

Scenario 1: Confusion Over Headlight Types and Costs

Проблема: B2B buyers often face confusion regarding the different types of headlights available and their associated costs. With a variety of options—halogen, HID, and LED—each with different price points and installation complexities, making informed decisions can be overwhelming. For instance, a buyer may consider a cheaper halogen bulb, only to realize that its shorter lifespan leads to more frequent replacements, ultimately increasing long-term costs. Furthermore, the cost to install these headlights can vary significantly based on the vehicle model and the specific installation requirements, creating additional uncertainty.

Решение: To navigate this complexity, B2B buyers should conduct thorough research on the headlight types best suited for their vehicles. Start by consulting manufacturer guidelines or reputable auto parts suppliers to understand the specifications and lifespan of each type of bulb. Create a cost analysis comparing initial purchase prices, installation costs, and expected longevity. This will help identify the most cost-effective option in the long run. Additionally, consider partnering with a trusted supplier that offers a range of products and can provide expert advice on the best fit for your fleet, ensuring you make a well-informed purchase that aligns with both safety standards and budget constraints.

Illustrative image related to cost to install headlights

Scenario 2: Unexpected Installation Costs

Проблема: Many B2B buyers underestimate the labor costs associated with headlight installation, particularly when dealing with complex headlight assemblies that may require specialized tools or skills. For example, a buyer might assume the installation of a standard halogen bulb will be straightforward, only to encounter additional costs when discovering that the assembly needs removal or that the process is labor-intensive. This can lead to budget overruns and frustration, particularly for businesses operating on tight margins.

Решение: To mitigate unexpected installation costs, it is advisable for buyers to obtain detailed quotes from multiple service providers before proceeding with installation. Ensure that these quotes break down labor costs and any potential additional charges for tools or special equipment required. Additionally, consider investing in training for in-house technicians or purchasing essential tools that can facilitate future installations. This proactive approach not only prepares the team for various installation scenarios but can also lead to significant cost savings over time.

Scenario 3: Quality Concerns with Headlight Replacements

Проблема: A significant concern for B2B buyers is the quality of replacement headlights, especially when sourcing from multiple suppliers. Low-quality bulbs can lead to frequent failures, safety hazards, and compliance issues with local regulations, which can be particularly problematic for businesses managing a fleet of vehicles. This challenge is compounded in regions where counterfeit or substandard products may be more prevalent, leading to serious operational disruptions.

Решение: To ensure high-quality headlight replacements, buyers should prioritize sourcing from reputable manufacturers and suppliers known for their reliability and compliance with safety standards. Conducting a background check on suppliers and reviewing certifications can help mitigate risks associated with quality. Moreover, it’s beneficial to establish long-term relationships with trusted suppliers who can provide consistent product quality and support. Implementing a quality control process for incoming parts can also help catch any substandard products before they are installed, ensuring that all headlights meet safety and performance standards, ultimately enhancing fleet reliability and safety.

Illustrative image related to cost to install headlights

Strategic Material Selection Guide for cost to install headlights

What Are the Key Materials Used in Headlight Manufacturing?

When considering the cost to install headlights, the materials used in their construction significantly impact performance, durability, and overall cost. Below, we analyze four common materials used in the manufacturing of headlights, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Polycarbonate

Ключевые свойства:

Polycarbonate is a thermoplastic known for its high impact resistance and optical clarity. It can withstand temperatures up to 135°C (275°F) and is resistant to UV radiation, making it suitable for outdoor applications.

Плюсы и минусы:

The main advantage of polycarbonate is its lightweight nature and excellent shatter resistance, which enhances safety in automotive applications. However, it is more prone to scratching compared to glass and may require additional coatings to improve durability. The manufacturing process is generally straightforward but can be more costly than traditional materials.

Illustrative image related to cost to install headlights

Влияние на применение:

Polycarbonate is compatible with various automotive lighting technologies, including halogen, HID, and LED systems. Its optical properties ensure effective light transmission, which is crucial for visibility.

Соображения для международных покупателей:

B2B buyers in regions like Africa and South America should consider local regulations regarding material safety and environmental impact. Compliance with standards such as ASTM or ISO is essential to ensure quality and safety.

2. Glass

Ключевые свойства:

Glass has excellent optical clarity and can withstand high temperatures, making it a traditional choice for headlight lenses. It is resistant to scratches and environmental degradation.

Плюсы и минусы:

The primary advantage of glass is its durability and resistance to UV light, which prevents yellowing over time. However, glass is heavier than polycarbonate and can shatter upon impact, posing safety risks. The manufacturing process is more complex and costly due to the need for precise molding and treatment.

Влияние на применение:

Glass is often used in high-end vehicles where premium aesthetics and durability are prioritized. It is compatible with various lighting technologies but may require additional support structures due to its weight.

Illustrative image related to cost to install headlights

Соображения для международных покупателей:

Buyers in Europe and the Middle East should ensure compliance with stringent automotive safety regulations and standards. The preference for glass lenses in luxury vehicles may influence procurement strategies.

3. Алюминий

Ключевые свойства:

Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It can withstand temperatures up to 660°C (1,220°F), making it suitable for heat dissipation in high-performance lighting systems.

Плюсы и минусы:

The key advantage of aluminum is its strength-to-weight ratio, which allows for robust headlight assemblies without adding significant weight to the vehicle. However, it can be more expensive than other materials and may require additional treatments to enhance corrosion resistance.

Влияние на применение:

Aluminum is particularly beneficial in applications where heat management is critical, such as in LED headlight assemblies. It supports the longevity and performance of the lighting system.

Соображения для международных покупателей:

B2B buyers should be aware of the varying costs of aluminum in different regions, particularly in Africa and South America, where import tariffs may apply. Compliance with local recycling regulations is also crucial.

4. Thermoplastic Polyurethane (TPU)

Ключевые свойства:

TPU is a flexible, durable polymer that offers excellent abrasion resistance and elasticity. It can operate effectively within a temperature range of -40°C to 90°C (-40°F to 194°F).

Плюсы и минусы:

The flexibility of TPU allows for innovative design options and can absorb impacts better than rigid materials. However, it may not provide the same level of optical clarity as polycarbonate or glass, and its manufacturing process can be complex and costly.

Влияние на применение:

TPU is suitable for applications requiring flexibility and impact resistance, making it ideal for off-road vehicles or environments with high potential for damage.

Соображения для международных покупателей:

Buyers from regions with fluctuating climates, such as the Middle East, should consider the temperature resilience of TPU. Compliance with international standards for automotive materials is essential for ensuring safety and performance.

Сводная таблица

| Материал | Typical Use Case for cost to install headlights | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Поликарбонат | Standard automotive headlights | Легкий и ударопрочный | Prone to scratching | Средний |

| Стекло | Luxury vehicle headlights | Excellent durability and clarity | Heavier and can shatter | Высокий |

| Алюминий | High-performance LED headlights | Strong and lightweight | Higher cost and corrosion treatment needed | Высокий |

| Thermoplastic Polyurethane | Off-road vehicle headlights | Flexible and impact-absorbing | Lower optical clarity | Средний |

This analysis provides B2B buyers with insights into the materials used in headlight manufacturing, helping them make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for cost to install headlights

What Are the Key Stages in the Manufacturing Process for Headlight Systems?

The manufacturing process of headlight systems involves several critical stages that ensure the final product meets safety and performance standards. Understanding these stages is essential for B2B buyers, as it helps them evaluate suppliers and the quality of the products they offer.

Подготовка материалов: Какие материалы используются при производстве фар?

The first stage involves the selection and preparation of materials. Headlights are typically made from a combination of glass or polycarbonate for the lens, aluminum or plastic for the housing, and various metals for the electrical components. High-performance bulbs, such as Halogen, HID (High-Intensity Discharge), and LED (Light Emitting Diode), require specialized materials that can withstand heat and provide optimal light output.

Illustrative image related to cost to install headlights

During this stage, quality control begins with incoming material inspections (IQC) to ensure that all materials meet specific standards. This is critical for ensuring durability and performance, especially in regions with extreme weather conditions.

Forming: How Are Headlight Components Shaped?

The forming stage employs techniques such as injection molding for plastic components and precision machining for metal parts. For instance, polycarbonate lenses are created through a high-temperature molding process that shapes the material into the desired form while maintaining clarity and strength.

Quality assurance during this phase includes monitoring temperature and pressure parameters to ensure that the components are molded correctly without defects. Any discrepancies can lead to issues such as poor light distribution or compromised safety.

Assembly: What Is Involved in the Assembly Process of Headlights?

Once the components are formed, they move to the assembly stage. This phase often involves automated processes to ensure precision, such as robotic arms for aligning and securing parts. The assembly includes fitting the lens to the housing, installing the bulb, and connecting electrical components.

Illustrative image related to cost to install headlights

Quality checkpoints during assembly (IPQC) focus on verifying the alignment and sealing of the units to prevent moisture ingress, which can cause electrical failures. Each assembly line may have specific protocols to ensure consistency and reliability.

Финишная обработка: как готовится конечный продукт к продаже?

The finishing stage involves applying coatings and performing final inspections. Many headlights receive anti-fogging and UV-resistant coatings to enhance longevity. This stage also includes polishing the lens to achieve the required clarity and light output.

Final quality control (FQC) checks verify that the finished product meets all specifications and performance standards. This may involve light output tests, moisture resistance tests, and durability assessments.

Какие стандарты обеспечения качества следует учитывать покупателям B2B?

For B2B buyers, understanding the quality assurance standards that suppliers adhere to is crucial in ensuring the reliability of headlight products.

What Are the Relevant International Quality Standards?

ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system. Manufacturers that comply with ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction.

Additionally, industry-specific standards such as CE (Conformité Européenne) for products sold in Europe and SAE (Society of Automotive Engineers) standards for automotive lighting can provide further assurance of quality and safety.

How Do Manufacturers Implement Quality Control Checkpoints?

Quality control checkpoints play a pivotal role in maintaining product integrity throughout the manufacturing process. These include:

- Входящий контроль качества (IQC): Проверка сырья по прибытии.

- Контроль качества в процессе производства (IPQC): Continuous monitoring during the manufacturing stages to detect defects early.

- Окончательный контроль качества (FQC): Comprehensive testing of the finished product to ensure it meets all specifications.

Common testing methods include photometric tests for light output, durability tests for lens and housing materials, and electrical tests for bulb functionality.

Как покупатели B2B могут проверить методы контроля качества поставщиков?

Verifying the quality control practices of suppliers is essential for B2B buyers, especially when sourcing from international markets. Here are some actionable insights:

What Should B2B Buyers Look for in Supplier Audits and Reports?

B2B buyers should request detailed quality assurance reports from suppliers, including their testing methodologies, failure rates, and compliance with international standards. Regular audits can reveal insights into a supplier’s quality management practices and their commitment to continual improvement.

Illustrative image related to cost to install headlights

How Can Third-Party Inspections Enhance Supplier Reliability?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing processes and quality control measures. This is particularly important for buyers in regions like Africa and South America, where local regulations and standards may differ significantly from international norms.

Каковы нюансы контроля качества для международных B2B-покупателей?

International B2B buyers must navigate various challenges when ensuring quality control in their supply chains. Understanding local regulations, market demands, and the specific needs of different regions can influence purchasing decisions.

How Do Regional Standards Affect Headlight Manufacturing?

In regions such as Africa and the Middle East, where automotive regulations may not be as stringent, B2B buyers should emphasize sourcing from manufacturers who adhere to international quality standards. This ensures that products not only meet local requirements but also align with global safety and performance expectations.

Illustrative image related to cost to install headlights

What Is the Importance of Building Relationships with Reliable Suppliers?

Establishing long-term relationships with reputable suppliers can enhance quality assurance. Regular communication and collaboration can lead to improvements in product design, manufacturing processes, and ultimately, customer satisfaction.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing headlights, ensuring they receive high-quality products that meet safety and performance standards across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cost to install headlights’

Введение

This guide provides a practical checklist for B2B buyers looking to procure services and products related to the cost of installing headlights. Whether you are a parts distributor, an auto repair shop, or a fleet manager, understanding the nuances of headlight installation costs can enhance your procurement strategy and ensure safety and compliance with local regulations.

Шаг 1: Определите технические характеристики вашего автомобиля

Understanding the specific requirements for the vehicles in your fleet is critical. Different makes and models may require various types of headlight bulbs, such as halogen, HID, or LED. This ensures that you are sourcing the correct parts that fit your vehicles and comply with local safety standards.

- Check vehicle manuals for bulb types.

- Consider any advanced lighting systems that may require entire assembly replacements.

Шаг 2: Изучите варианты поставщиков

A comprehensive supplier search is essential for obtaining competitive pricing and quality products. Look for suppliers with a strong track record in headlight parts and installation services, particularly those that cater to your geographical region.

- Compare at least three suppliers to evaluate pricing and service offerings.

- Assess their experience with your specific vehicle models.

Шаг 3: Оценить сертификаты поставщиков

Before making any commitments, ensure that your selected suppliers meet necessary certifications. Certifications indicate compliance with quality and safety standards, which is vital when dealing with automotive parts.

Illustrative image related to cost to install headlights

- Verify if suppliers have ISO certifications or equivalent.

- Look for compliance with local regulations regarding automotive parts.

Шаг 4: Analyze Total Cost of Ownership

Consider not just the purchase price but also the total cost of ownership (TCO) for headlight installation. This includes labor costs, potential future replacements, and warranty terms, which can significantly impact your long-term budget.

- Calculate labor costs based on regional rates.

- Review warranty terms for both parts and installation services.

Шаг 5: Запрос образцов или демонстраций

If possible, request samples or demonstrations from suppliers. This allows you to assess the quality of the headlight parts and installation services firsthand, ensuring they meet your operational standards.

- Evaluate the build quality of headlight bulbs and assemblies.

- Assess the installation process if a demonstration is available.

Шаг 6: Check for Customer References and Reviews

Gather feedback from other businesses that have worked with your potential suppliers. Customer references and online reviews provide insights into the reliability and service quality of suppliers.

- Ask suppliers for case studies or testimonials.

- Search for independent reviews online to gauge overall satisfaction.

Шаг 7: Finalize Your Order with Clear Terms

Once you have selected a supplier, finalize your order with clear terms and conditions. This should include pricing, delivery timelines, installation services, and any guarantees or warranties.

- Ensure all agreements are documented to avoid misunderstandings.

- Confirm delivery schedules to align with your operational timelines.

By following this checklist, B2B buyers can make informed decisions about procuring headlight installation services and products, ensuring compliance, safety, and cost-effectiveness in their automotive operations.

Comprehensive Cost and Pricing Analysis for cost to install headlights Sourcing

What Are the Key Cost Components for Installing Headlights?

When evaluating the costs associated with installing headlights, several key components contribute to the overall pricing structure. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Материалы: The primary materials involved are the headlight bulbs themselves, which vary in type (halogen, HID, LED) and cost. Bulbs can range from $10 for basic halogen types to over $100 for advanced LED or HID systems. Additionally, the headlight assembly, which may need to be replaced due to damage, can vary significantly in cost, from $30 to several thousand dollars for premium models.

-

Трудовые ресурсы: Labor costs are a significant factor in the total price. Mechanic labor rates can range from $100 to $400 per hour, depending on the complexity of the installation. Simple bulb replacements may take as little as 10 minutes, while full assembly replacements could take an hour or more, directly impacting the labor cost incurred.

-

Производственные накладные расходы и оснастка: The overhead costs associated with production facilities and the specific tooling required for manufacturing headlight assemblies also play a role. Suppliers may need to invest in specialized equipment to produce certain types of headlights, especially those with advanced features like adaptive lighting.

-

Контроль качества (КК): Ensuring that headlight products meet safety and performance standards incurs additional costs. Manufacturers must implement stringent QC processes to comply with regulatory requirements, which can vary by region.

-

Логистика: Shipping and handling costs are particularly relevant for international buyers. The choice of Incoterms can influence the total shipping cost, affecting how expenses are distributed between suppliers and buyers.

-

Маржа: Finally, suppliers typically add a margin to cover business expenses and profit. This margin can vary based on market conditions, supplier reputation, and the competitive landscape.

How Do Price Influencers Impact Headlight Installation Costs?

Several factors can influence the pricing of headlight installations, particularly for international B2B buyers in regions like Africa, South America, the Middle East, and Europe.

-

Объем/минимальный объем заказа: Bulk purchasing can often lead to significant discounts. Suppliers may offer better pricing for larger orders, which can be particularly advantageous for businesses looking to stock inventory.

-

Технические характеристики и индивидуальная настройка: Custom specifications may lead to higher costs, especially if unique designs or features are required. Buyers should clearly communicate their needs to avoid unexpected price hikes.

-

Сертификаты качества материалов: The choice of materials directly influences pricing. High-quality bulbs with certifications (such as DOT compliance) may come at a premium but offer better performance and longevity, which can lead to lower Total Cost of Ownership (TCO).

-

Факторы, связанные с поставщиками: The reputation and reliability of suppliers can affect pricing. Established suppliers with proven track records may charge higher prices, reflecting their reliability and product quality.

-

Инкотермс: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding transportation and insurance, which can significantly impact the final cost.

What Buyer Tips Can Help Achieve Cost Efficiency in Headlight Installations?

International B2B buyers can leverage several strategies to optimize their costs when sourcing headlights.

-

Переговоры: Engage in open discussions with suppliers to negotiate better terms. Understanding the cost components can provide leverage in negotiations.

-

Общая стоимость владения (TCO): Consider not just the initial purchase price but the long-term costs associated with maintenance and replacements. Investing in high-quality components may yield savings over time.

-

Нюансы ценообразования для международных покупателей: Be aware of regional price differences and currency fluctuations. Buying from local suppliers can reduce shipping costs and lead times.

-

Исследуйте и сравнивайте: Conduct thorough market research to compare prices and offerings from different suppliers. Utilizing online platforms and trade shows can provide insights into competitive pricing.

Отказ от ответственности в отношении ориентировочных цен

The prices mentioned are indicative and can vary based on specific circumstances, including vehicle make and model, local market conditions, and supplier pricing strategies. Buyers are encouraged to seek quotes from multiple suppliers to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing cost to install headlights With Other Solutions

Exploring Alternative Solutions for Headlight Installation

When evaluating the cost to install headlights, it’s essential for B2B buyers to consider various alternatives that may offer similar benefits, whether in terms of performance, cost-efficiency, or ease of implementation. This analysis will compare the traditional method of installing headlights with two alternative solutions: upgrading to advanced lighting technologies and utilizing headlight restoration services.

Сравнительная таблица

| Аспект сравнения | Cost To Install Headlights | Upgrading to Advanced Lighting Technologies | Headlight Restoration Services |

|---|---|---|---|

| Производительность | Varies by bulb type; halogens are less effective than LEDs or HIDs | Superior visibility, longer lifespan, and energy-efficient | Restores brightness and clarity to existing headlights |

| Стоимость | $30 – $4,000 (including labor) | $100 – $1,500 for new assemblies or systems | $20 – $100 for DIY kits; $50 – $200 for professional services |

| Простота внедрения | Moderate; requires basic tools and skills | Complex; often requires professional installation | Simple for DIY; professional services are quick |

| Техническое обслуживание | Regular replacement needed, especially for halogens | Minimal; LEDs last longer and require less frequent changes | Requires reapplication every few years |

| Лучший вариант использования | Cost-effective for standard vehicle maintenance | Ideal for luxury vehicles or high-performance applications | Best for restoring aging headlights without full replacement |

Подробная разбивка альтернатив

Upgrading to Advanced Lighting Technologies

Upgrading to advanced lighting technologies such as LED or HID systems can significantly enhance vehicle safety and visibility. While the initial investment can range from $100 to $1,500, the long-term benefits often outweigh the costs. These systems not only provide superior illumination but also have longer lifespans—LEDs can last up to 40,000 hours compared to halogen bulbs, which typically last only 500 to 1,000 hours. However, installation can be complex and may require professional assistance, particularly for vehicles with intricate electrical systems.

Headlight Restoration Services

Headlight restoration services offer a cost-effective solution for vehicles with cloudy or yellowed lenses. For a fraction of the cost of full replacement, typically between $20 and $200, businesses can restore headlights to near-original clarity. This option is particularly beneficial for fleets or companies looking to maintain older vehicles without incurring significant expenses. Restoration is relatively simple, with DIY kits available for those with basic skills, while professional services provide quick turnaround times. However, the effects are temporary, necessitating periodic reapplications.

Conclusion: How to Choose the Right Headlight Solution

Selecting the right solution for headlight installation depends on several factors, including budget, vehicle type, and performance needs. For B2B buyers managing fleets or looking to maintain cost-efficiency, regular replacement of standard halogen bulbs may suffice. Conversely, businesses seeking long-term reliability and superior performance should consider investing in advanced lighting technologies. Finally, for organizations focused on cost-effective maintenance of older vehicles, headlight restoration services present a viable alternative. By carefully assessing the specific needs of their operations, buyers can make informed decisions that enhance safety and efficiency on the road.

Essential Technical Properties and Trade Terminology for cost to install headlights

What Are the Key Technical Properties to Consider for Headlight Installation Costs?

When evaluating the cost to install headlights, several critical technical properties come into play. These specifications not only influence the pricing but also impact the overall performance and safety of the vehicle.

1. Bulb Type and Technology

The type of headlight bulb significantly affects installation costs. Common types include halogen, HID (High-Intensity Discharge), and LED (Light Emitting Diode). Each has distinct pricing and longevity characteristics. For instance, halogen bulbs are generally less expensive but have a shorter lifespan, while LEDs, though pricier, last significantly longer and offer better energy efficiency. Understanding the differences helps B2B buyers select the appropriate type for their needs, balancing upfront costs with long-term value.

2. Headlight Assembly Complexity

The complexity of the headlight assembly can vary widely between vehicle models. Some vehicles feature modular designs that allow for easy bulb replacement, while others require complete assembly changes for bulb failures. This complexity can drive labor costs up, as installation may involve removing additional components like the front bumper. Buyers must consider this when estimating total installation costs.

3. OEM vs. Aftermarket Parts

Original Equipment Manufacturer (OEM) parts are made by the vehicle’s manufacturer, ensuring compatibility and quality. In contrast, aftermarket parts are produced by third parties and can vary in quality. While OEM parts tend to be more expensive, they often come with warranties and reliability assurances. B2B buyers should weigh the cost against the potential risks of using aftermarket components, particularly in high-performance or safety-critical applications.

Illustrative image related to cost to install headlights

4. Labor Rates and Time Estimates

Labor costs are a significant component of the total installation cost. Rates vary by region and shop, but understanding typical labor times—ranging from 30 minutes to several hours depending on the complexity—can help buyers budget effectively. For instance, while a simple bulb replacement may only take 10 minutes, more complicated assemblies could take an hour or more.

5. Material Quality

The materials used in both the bulbs and the assemblies can affect durability and performance. High-quality plastics and glass in assemblies can resist UV damage and physical impacts better than lower-grade materials. B2B buyers should consider the long-term implications of material quality, as investing in durable components can reduce replacement frequency and associated costs.

What Are the Common Trade Terms Used in Headlight Installation?

Familiarity with industry terminology is crucial for B2B buyers to navigate the complexities of headlight installation costs effectively.

1. OEM (производитель оригинального оборудования)

OEM refers to parts produced by the vehicle’s original manufacturer. These parts are generally more reliable and compatible with the vehicle, ensuring optimal performance. Buyers often prefer OEM components to maintain warranty coverage and performance standards.

2. MOQ (минимальный объем заказа)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and avoid overstock situations, especially when dealing with parts that may have varying demand.

3. RFQ (запрос предложения)

An RFQ is a formal document used by buyers to solicit price quotes from suppliers for specific products or services. This process helps buyers compare costs and negotiate terms effectively, ensuring they receive competitive pricing for headlight installations.

4. Инкотермс (Международные торговые термины)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with these terms is vital for B2B transactions, as they clarify who bears the costs and risks at various stages of the shipping process.

5. Гарантийный срок

The warranty period refers to the time frame during which the manufacturer guarantees the performance of their product. Understanding warranty terms is crucial for B2B buyers to assess potential long-term costs related to headlight replacements and repairs.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions regarding headlight installation costs, ensuring they select the best options for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the cost to install headlights Sector

What are the Global Drivers Influencing the Cost to Install Headlights?

The global automotive industry is experiencing dynamic shifts due to technological advancements and changing consumer preferences, impacting the cost to install headlights significantly. Key drivers include the rising demand for energy-efficient lighting solutions such as LED and HID headlights, which, despite their higher upfront costs, offer longer lifespans and reduced energy consumption. Additionally, increasing vehicle safety regulations worldwide necessitate the adoption of advanced lighting technologies, further driving up installation costs.

International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, must navigate these trends carefully. The complexity of modern headlight assemblies often means that buyers must consider not only the price of the bulbs themselves but also the associated labor costs, which can vary widely based on the model and technology employed. The labor market also reflects these changes, with skilled technicians increasingly in demand, thus impacting overall installation costs. Furthermore, the proliferation of online resources and DIY guides has empowered buyers to consider self-installation, which can significantly reduce costs.

Emerging technologies such as adaptive lighting systems are also influencing market dynamics, as these innovations come with higher installation costs but can provide enhanced safety and performance. B2B buyers should be vigilant in monitoring these trends to ensure competitive pricing and sourcing strategies.

How is Sustainability and Ethical Sourcing Impacting the Headlight Installation Market?

Sustainability and ethical sourcing are becoming increasingly important in the automotive sector, particularly concerning headlight installations. The environmental impact of manufacturing and disposing of automotive parts, including headlights, is significant. With growing awareness of climate change and resource depletion, B2B buyers must prioritize sourcing from suppliers that demonstrate a commitment to sustainable practices.

Utilizing ‘green’ materials, such as recyclable plastics and energy-efficient manufacturing processes, can reduce the carbon footprint associated with headlight production. Furthermore, suppliers that hold certifications for environmental responsibility, such as ISO 14001, can provide assurance to buyers regarding their commitment to sustainability. In regions like Africa and South America, where resource scarcity can be a critical issue, sourcing from companies that emphasize ethical supply chains can also foster goodwill and strengthen relationships with local communities.

For B2B buyers, integrating sustainability into procurement strategies not only helps in mitigating environmental impacts but can also lead to cost savings in the long run through improved operational efficiencies. As the global market increasingly shifts toward eco-friendly solutions, buyers who align their sourcing practices with these values will likely gain a competitive edge.

How Has the Headlight Installation Market Evolved Over Time?

The evolution of headlight technology has significantly influenced the cost and complexity of installations in the automotive industry. In the past, headlight systems were relatively simple, predominantly using halogen bulbs that were easy to replace and install. However, the introduction of advanced technologies such as HID and LED lighting has transformed the landscape, offering better illumination and energy efficiency but at a higher cost.

Modern vehicles often come equipped with sealed headlight assemblies, which complicate replacement processes and increase costs. The integration of sophisticated features such as adaptive lighting and automatic leveling systems has made installation more complex, requiring specialized knowledge and tools. This evolution underscores the importance for B2B buyers to stay informed about the latest technologies and market trends to make informed sourcing decisions that align with both budget and safety standards.

In summary, understanding the historical context of headlight technology helps B2B buyers appreciate the current market dynamics and make strategic decisions regarding sourcing and installation costs.

Frequently Asked Questions (FAQs) for B2B Buyers of cost to install headlights

-

How do I determine the cost of installing headlights for my fleet?

To estimate the cost of installing headlights for your fleet, consider both the price of the headlights themselves and the associated labor costs. Headlight prices can vary significantly based on the type (halogen, HID, or LED) and the vehicle model. Labor costs typically range from $30 to $400, depending on the complexity of the installation. For bulk purchases, negotiate with suppliers for discounts. Additionally, factor in potential shipping and customs duties if sourcing from international suppliers. -

What is the best type of headlights for commercial vehicles?

For commercial vehicles, LED headlights are often the best choice due to their longevity, energy efficiency, and superior brightness. Although they can be more expensive upfront compared to halogen or HID options, their longer lifespan (up to 40,000 hours) can lead to lower replacement costs over time. Additionally, consider the specific requirements of your vehicles and local regulations, as this may influence the type of headlights you should purchase. -

How can I vet suppliers for headlight installation components?

To vet suppliers, start by checking their credentials and reputation in the industry. Look for certifications that indicate compliance with international standards, such as ISO or DOT approvals. Request references from other businesses and check reviews online. Additionally, assess their production capabilities and quality assurance processes to ensure they can meet your specific requirements. It’s also beneficial to visit their facilities if possible or conduct virtual assessments. -

What are the minimum order quantities (MOQ) for headlights?

Minimum order quantities can vary significantly between suppliers. Some may offer flexible MOQs for first-time buyers or bulk orders, while others might have a strict MOQ ranging from 50 to several hundred units. When negotiating, discuss your anticipated needs and explore options for lower MOQs if you are just starting. Establishing a long-term relationship with suppliers can also provide leverage for better terms in future orders. -

На какие условия оплаты я должен рассчитывать при покупке фар на международном рынке?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common terms include upfront payment, a deposit with the balance due upon delivery, or net terms (e.g., net 30 or net 60 days). Always clarify payment methods accepted, such as wire transfers, letters of credit, or escrow services. It is advisable to negotiate favorable terms that reduce your financial risk while ensuring the supplier is comfortable with the arrangement. -

How do I ensure quality assurance for headlights purchased internationally?

To ensure quality assurance, request samples before placing a bulk order. Verify that the headlights meet relevant safety and performance standards. Additionally, consider conducting third-party inspections during production or prior to shipment. Establish clear quality specifications in your contract with the supplier and include clauses for returns or replacements if the products do not meet agreed-upon standards. -

Какие логистические соображения следует учитывать при импорте фар?

When importing headlights, consider shipping methods, customs clearance, and potential tariffs or duties that may apply. Choose a reliable logistics partner experienced in handling automotive parts. Ensure that all necessary documentation, such as invoices, packing lists, and certificates of origin, are prepared to facilitate smooth customs processing. Additionally, factor in lead times for shipping, as delays can impact your inventory levels and operational timelines. -

How can I customize headlights for my specific vehicle models?

Customization options for headlights can range from specific bulb types to unique housing designs. Work closely with your supplier to discuss your customization needs, including specifications for brightness, beam patterns, and aesthetic preferences. Many suppliers can accommodate modifications based on vehicle make and model. Ensure that any customized headlights comply with local regulations to avoid legal issues and ensure safety.

Top 4 Cost To Install Headlights Manufacturers & Suppliers List

1. Reddit – Headlight Assembly Replacement Cost

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Cost to replace headlight assembly (labor only): $120 for approximately 45 minutes of work.

2. Honda Clarity - замена фары

Домен: insideevsforum.com

Зарегистрирован: 2017 (8 лет)

Введение: Headlight replacement for Honda Clarity costs $1500 per headlight, totaling $3000 for both front headlights. The Clarity uses a sealed assembly, meaning bulbs cannot be replaced individually. Some users suggest that the dimness may be due to hazy lenses that could potentially be polished. There are alternatives available online, with some listings for headlight assemblies priced around $1300 for a…

3. Toyota – Halogen Bulb Replacement

Домен: community.cartalk.com

Зарегистрирован: 1995 (30 лет)

Введение: 2016 Toyota Camry SE, 2.5L 4-cylinder, Halogen Low Beam Bulb Replacement, Dealer quoted $445 for replacing both bulbs, $35 per bulb, labor cost approximately $375.

4. Kia – Headlight Assembly Replacement Costs

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: Expect to pay anywhere from $203 to $1,400 for the entire replacement for each headlight assembly at a Kia dealership, depending on the type of headlights.

Strategic Sourcing Conclusion and Outlook for cost to install headlights

In the ever-evolving automotive market, understanding the cost implications of headlight installation is crucial for B2B buyers. The price of headlight components, ranging from basic halogen bulbs to advanced LED assemblies, can vary significantly based on vehicle specifications and regional availability. This variability emphasizes the importance of strategic sourcing, enabling businesses to negotiate better terms and secure quality components that align with their operational needs.

Illustrative image related to cost to install headlights

Investing in high-quality headlight systems not only enhances vehicle safety but also reduces long-term maintenance costs. By opting for reliable suppliers and considering bulk purchasing options, companies can achieve substantial savings. Furthermore, staying informed about local regulations and standards ensures compliance and mitigates risks associated with subpar products.

As the automotive landscape continues to innovate, particularly with emerging technologies like adaptive lighting and smart systems, B2B buyers must remain proactive. Embrace strategic sourcing practices to navigate these complexities effectively. Now is the time to evaluate your supply chain and engage with trusted suppliers who can provide the latest products at competitive prices. Make informed decisions that will not only enhance your fleet’s performance but also position your business for future growth in a competitive market.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.