Introduction: Navigating the Global Market for diagram of an alternator

In today’s rapidly evolving automotive landscape, understanding the intricacies of an alternator diagram is crucial for B2B buyers looking to optimize their purchasing strategies. Sourcing high-quality alternators can be a daunting challenge, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe, where market dynamics and supplier reliability vary widely. This comprehensive guide aims to demystify the complexities surrounding alternator diagrams by providing in-depth insights into their components, functionality, and applications across various automotive sectors.

Within this guide, you will explore the different types of alternators available in the market, from standard models to specialized variants designed for unique vehicle requirements. We will also cover essential aspects of supplier vetting to ensure you partner with reputable manufacturers and distributors, minimizing the risk of subpar products. Additionally, we will discuss cost considerations, helping you navigate pricing structures and negotiate favorable terms.

By equipping you with actionable knowledge and practical tools, this guide empowers international B2B buyers to make informed decisions when sourcing alternators. Whether you are in Nigeria, Vietnam, or any other market, you will gain the confidence needed to enhance your supply chain and drive efficiency in your operations. Join us as we delve into the world of alternators, unlocking the potential for your business to thrive in a competitive global market.

Содержание

- Top 6 Diagram Of An Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for diagram of an alternator

- Understanding diagram of an alternator Types and Variations

- Key Industrial Applications of diagram of an alternator

- 3 Common User Pain Points for ‘diagram of an alternator’ & Their Solutions

- Strategic Material Selection Guide for diagram of an alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for diagram of an alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘diagram of an alternator’

- Comprehensive Cost and Pricing Analysis for diagram of an alternator Sourcing

- Alternatives Analysis: Comparing diagram of an alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for diagram of an alternator

- Navigating Market Dynamics and Sourcing Trends in the diagram of an alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of diagram of an alternator

- Strategic Sourcing Conclusion and Outlook for diagram of an alternator

- Важное предупреждение и условия использования

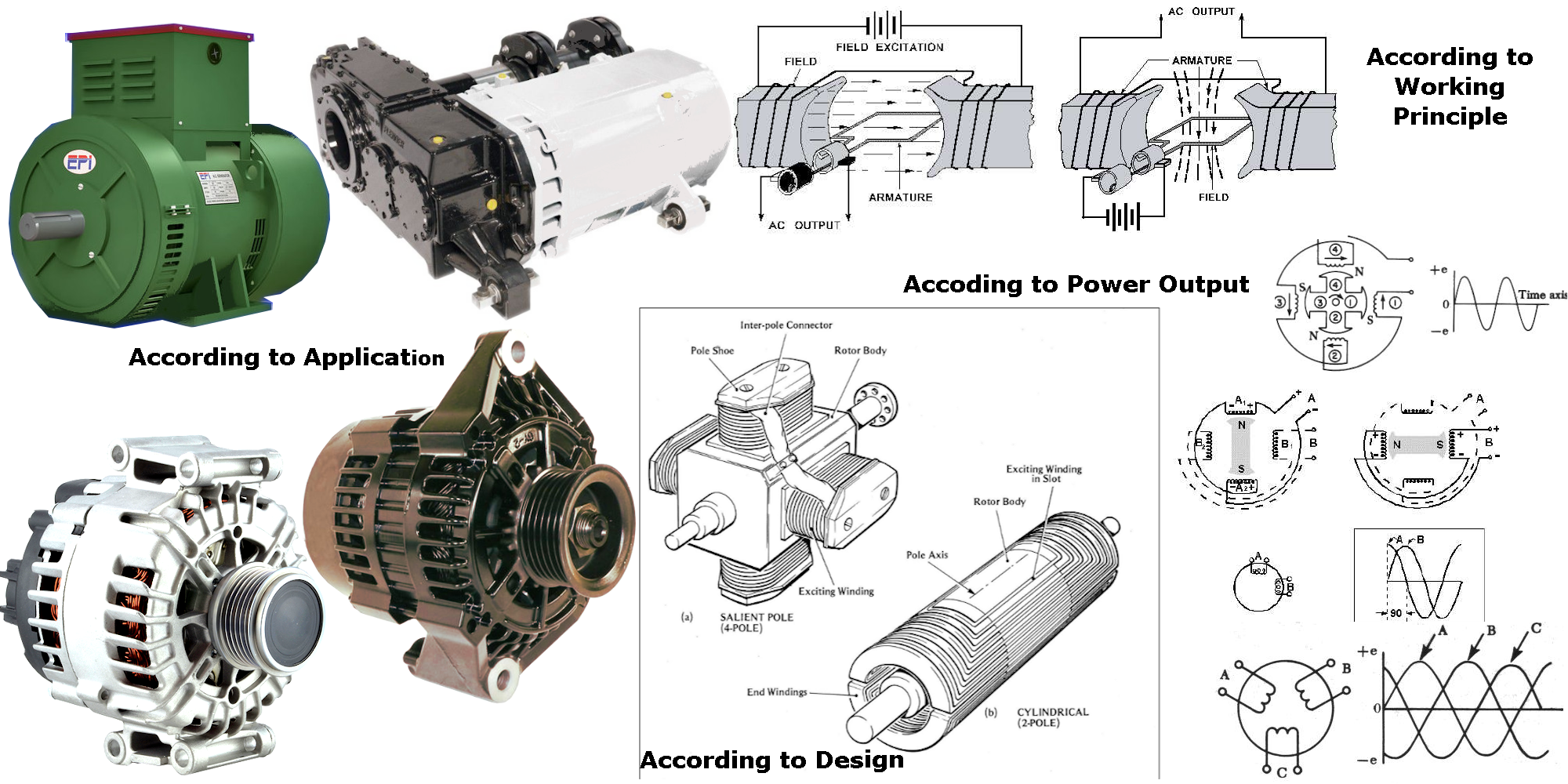

Understanding diagram of an alternator Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Belt-Driven Alternator | Driven by a serpentine belt; standard in most vehicles. | Автомобильное производство, обслуживание автопарков | Плюсы: Экономичный, широко доступный. Минусы: Limited power output for heavy-duty applications. |

| Gear-Driven Alternator | Utilizes gears for direct connection to the engine. | Heavy machinery, industrial equipment | Плюсы: Higher efficiency, better for high-demand systems. Минусы: More complex installation and maintenance. |

| Бесщеточный генератор | No brushes; uses electronic controls for excitation. | Renewable energy systems, marine applications | Плюсы: Более длительный срок службы, сокращение технического обслуживания. Минусы: Higher initial cost, requires specialized knowledge for installation. |

| Генератор с постоянным магнитом | Вместо электромагнитов используются постоянные магниты. | Small engines, portable generators | Плюсы: Compact size, lightweight. Минусы: Limited output capacity, not suitable for large applications. |

| Variable Speed Alternator | Adjusts output voltage based on demand and engine speed. | Advanced automotive systems, electric vehicles | Плюсы: Optimizes fuel efficiency, adaptable to various loads. Минусы: Повышенная сложность и стоимость. |

What Are the Characteristics of a Belt-Driven Alternator?

Belt-driven alternators are the most common type, found in a vast majority of passenger vehicles. They are connected to the engine via a serpentine belt, which transfers mechanical energy to generate electrical power. These alternators are suitable for standard automotive applications where moderate power output is sufficient. B2B buyers should consider their compatibility with existing systems and the ease of replacement, as they are readily available and generally cost-effective.

How Does a Gear-Driven Alternator Differ from Other Types?

Gear-driven alternators are typically used in heavy-duty machinery and industrial applications. They connect directly to the engine through a gear system, allowing for higher efficiency and output. This type is ideal for systems that require significant power, such as construction equipment. Buyers should assess the installation complexity and maintenance needs, as these alternators can be more intricate than belt-driven models.

Какие преимущества дают бесщеточные генераторы?

Brushless alternators are designed without brushes, relying on electronic controls for excitation. This design significantly reduces wear and tear, resulting in longer operational lifespans. They are particularly advantageous in renewable energy systems and marine applications where reliability is crucial. Buyers should weigh the initial investment against long-term savings on maintenance and replacement, as the upfront cost is generally higher.

When Are Permanent Magnet Alternators the Best Choice?

Permanent magnet alternators utilize fixed magnets to generate power, making them compact and lightweight. They are commonly found in small engines and portable generators, where space and weight are critical factors. However, their output capacity is limited, making them unsuitable for larger applications. B2B buyers should consider their specific power needs and the potential trade-offs in performance versus size.

How Do Variable Speed Alternators Enhance Efficiency?

Variable speed alternators adjust their output voltage based on real-time demand and engine speed, optimizing fuel efficiency. They are increasingly used in advanced automotive systems and electric vehicles, where energy management is essential. While they offer significant benefits in terms of adaptability, buyers must be prepared for higher costs and complexity in installation, requiring specialized knowledge for effective integration.

Key Industrial Applications of diagram of an alternator

| Отрасль/сектор | Specific Application of diagram of an alternator | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобильная промышленность | Design and manufacturing of automotive alternators | Повышает надежность и производительность автомобиля | Quality certifications, compatibility with vehicle models, and local regulations |

| Возобновляемые источники энергии | Integration in wind and solar energy systems | Efficient energy conversion and reliability | Adaptability to various energy sources and environmental conditions |

| Тяжелое оборудование | Power generation for construction and mining equipment | Provides reliable electrical power for operations | Durability, resistance to harsh environments, and maintenance support |

| Морские применения | Power supply for boats and ships | Ensures consistent operation of onboard systems | Corrosion resistance, compliance with maritime standards, and size constraints |

| Промышленное оборудование | Backup power systems for manufacturing facilities | Minimizes downtime and production losses | Scalability, energy efficiency, and service availability in target regions |

How is the diagram of an alternator utilized in the automotive industry?

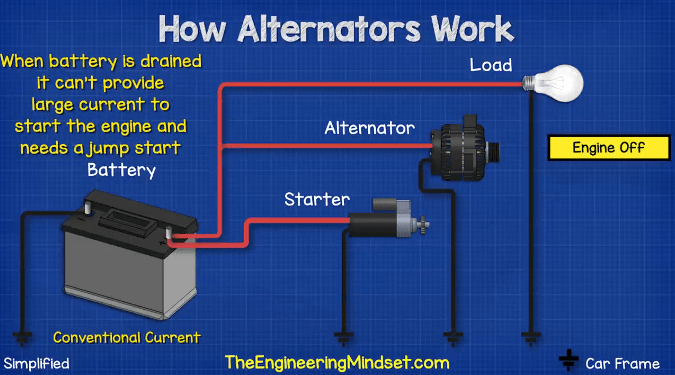

In the automotive sector, the diagram of an alternator is crucial for the design and manufacturing of vehicle electrical systems. It helps engineers understand how mechanical energy is converted into electrical energy, ensuring the reliability of power supply for vehicle accessories and battery charging. B2B buyers in this industry need to consider quality certifications and compatibility with specific vehicle models to ensure optimal performance and compliance with local regulations.

What role does the diagram of an alternator play in renewable energy applications?

In renewable energy systems, particularly wind and solar, the alternator’s diagram is vital for integrating energy conversion technologies. It illustrates how mechanical energy from turbines or solar trackers is transformed into usable electrical energy. For international buyers, especially from regions like Africa and South America, sourcing alternators that can adapt to diverse environmental conditions and efficiently convert energy is essential for maximizing system reliability and performance.

How is the diagram of an alternator applied in heavy machinery?

Heavy machinery, such as construction and mining equipment, relies on the alternator for consistent power generation. The diagram aids manufacturers in designing robust alternators that can withstand harsh operational environments. Buyers in this sector should focus on durability and maintenance support, ensuring that the alternators can operate efficiently with minimal downtime, which is critical for maintaining productivity on job sites.

Why is the diagram of an alternator important for marine applications?

In marine applications, the alternator provides electrical power for various onboard systems, including navigation and communication equipment. The diagram assists marine engineers in designing systems that ensure reliable power supply under different sea conditions. B2B buyers must consider corrosion resistance and compliance with maritime standards, as well as size constraints due to limited space on vessels.

How does the diagram of an alternator enhance industrial equipment operations?

The diagram of an alternator is essential for designing backup power systems in manufacturing facilities. It illustrates the processes involved in generating electrical power that can prevent production losses during outages. For buyers in industrial sectors, focusing on scalability and energy efficiency is crucial, as these factors directly impact operational continuity and cost-effectiveness in regions with unreliable power supply.

3 Common User Pain Points for ‘diagram of an alternator’ & Their Solutions

Scenario 1: Understanding the Complexities of Alternator Diagrams

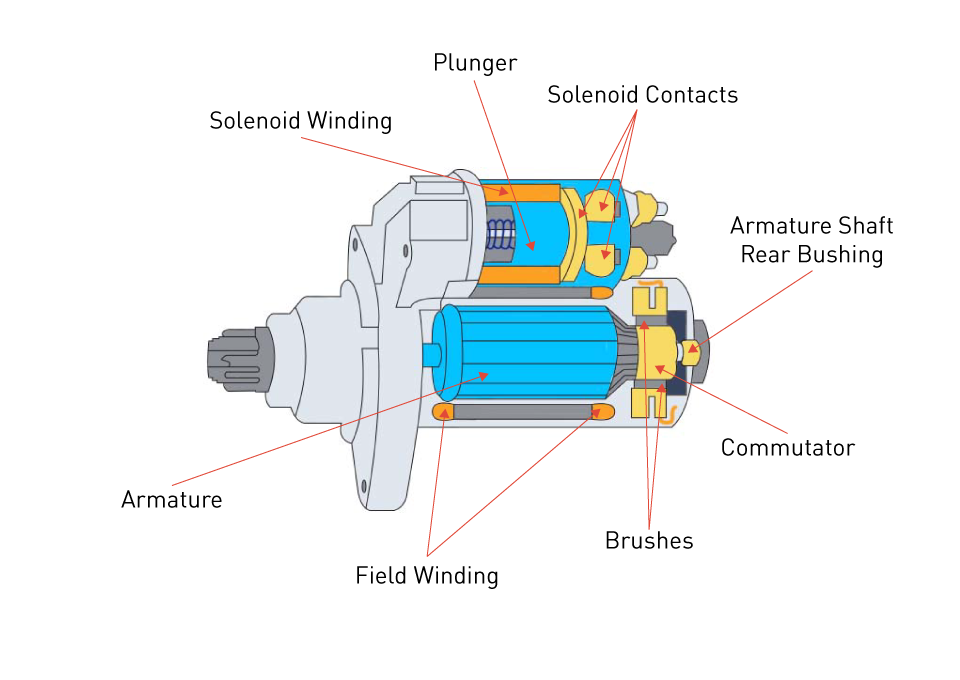

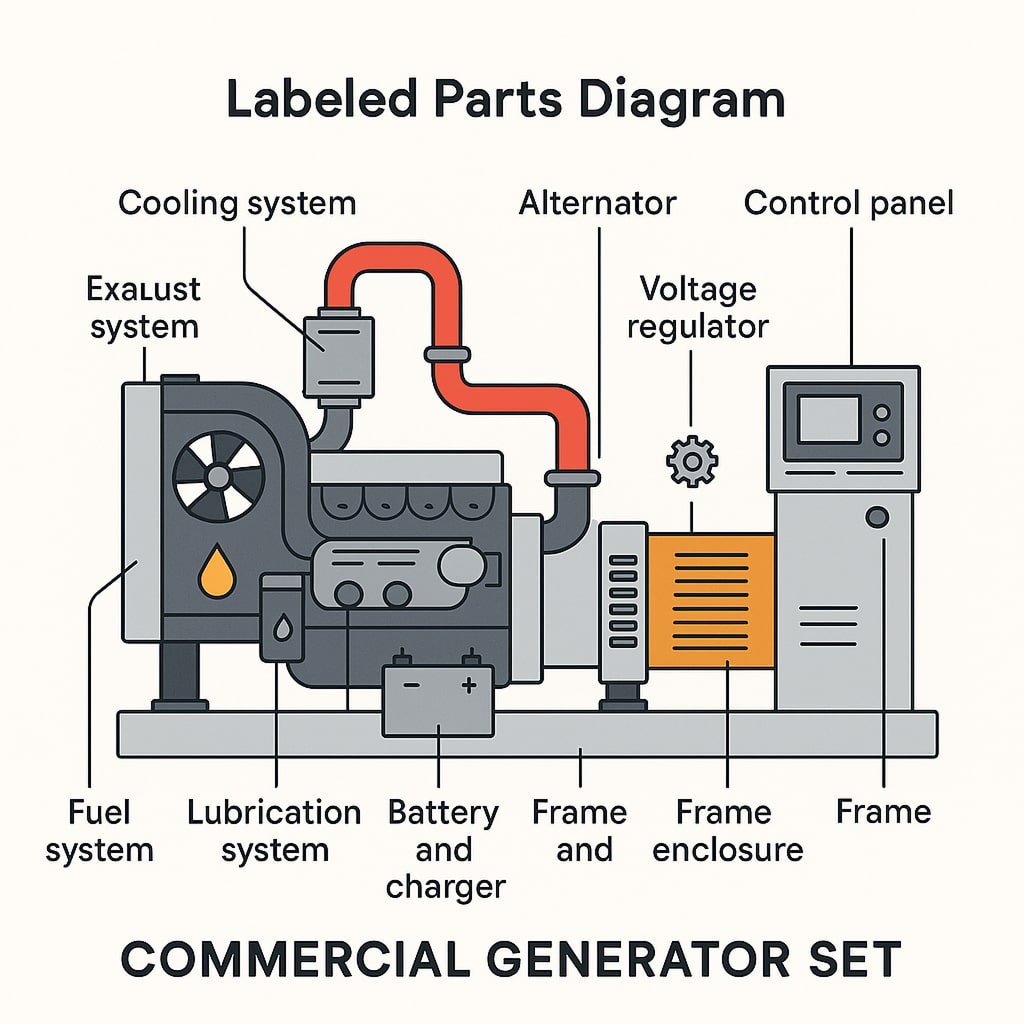

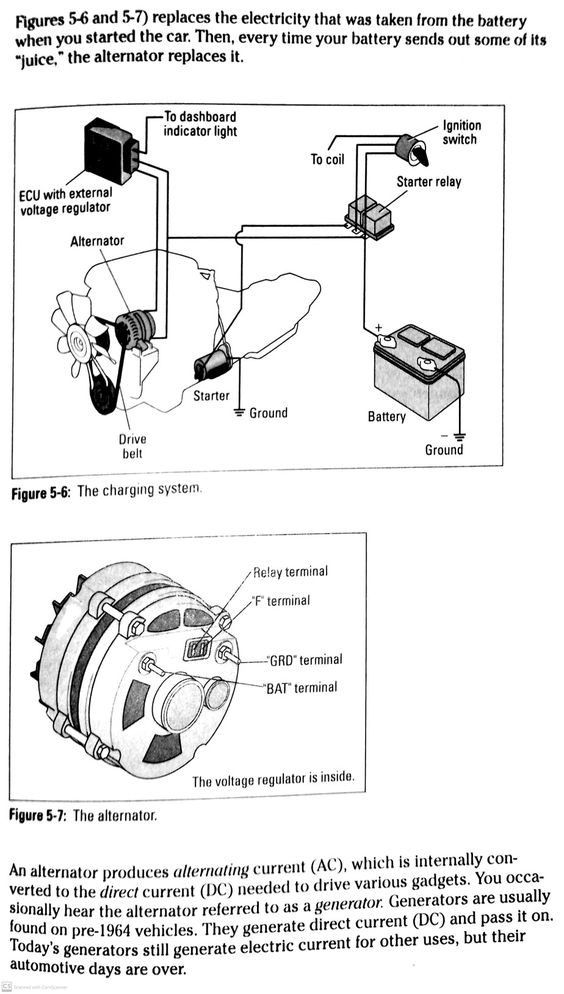

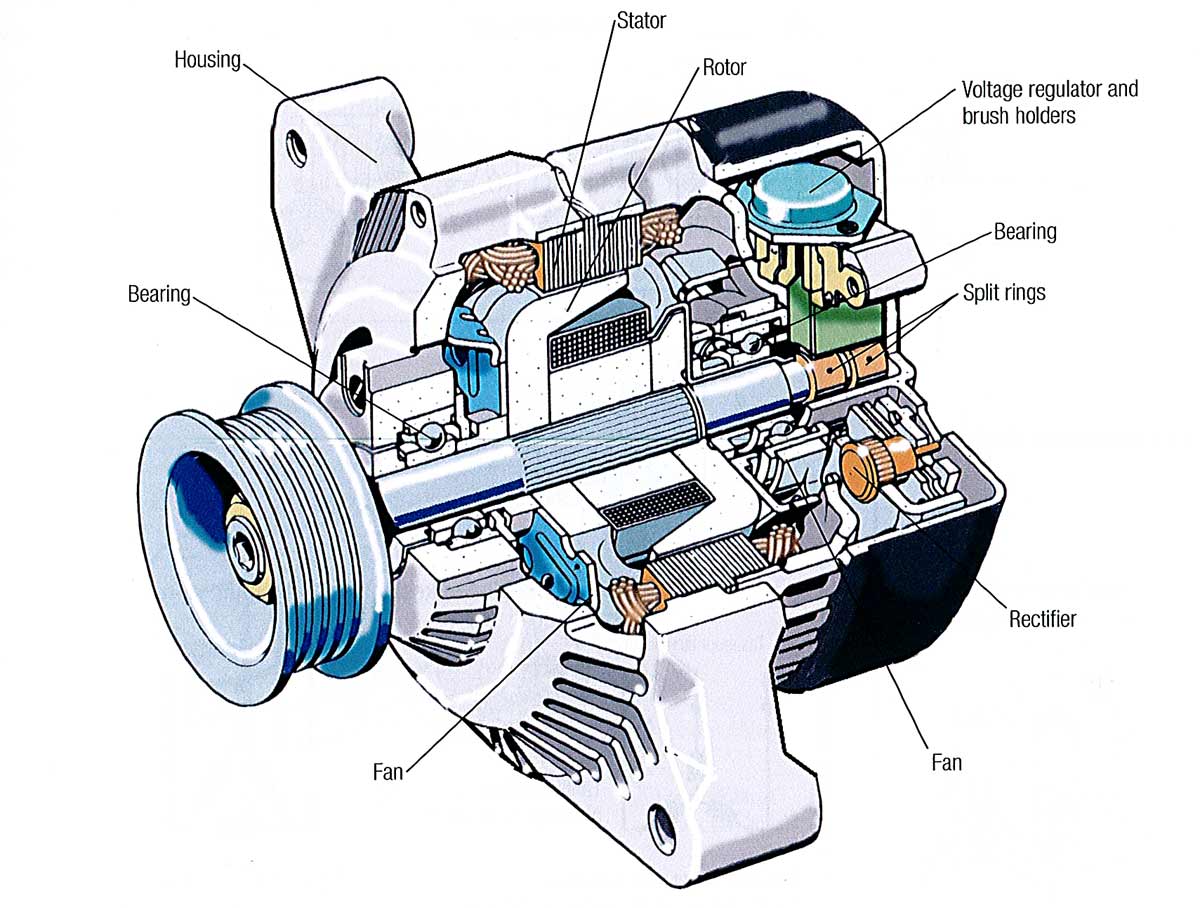

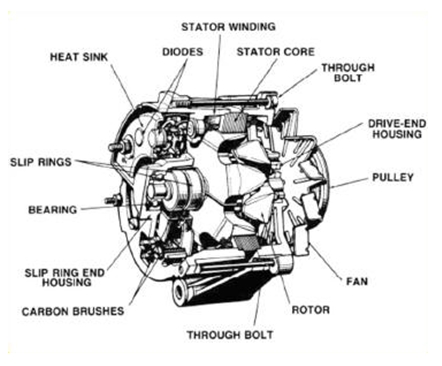

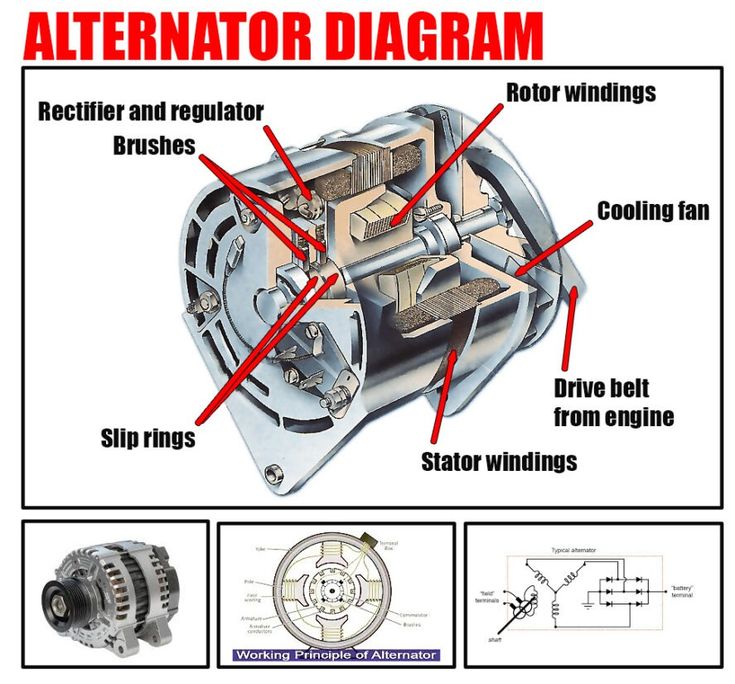

Проблема: B2B buyers, especially those in automotive or machinery sectors, often struggle with the intricate details of alternator diagrams. These diagrams can be overwhelming due to their technical nature, which includes numerous components like rotors, stators, rectifiers, and voltage regulators. Buyers may find it difficult to decipher these diagrams, leading to misinterpretations that can result in incorrect installations or maintenance practices. This confusion can have serious implications, including reduced efficiency and increased operational costs.

Решение: To effectively utilize alternator diagrams, buyers should invest in comprehensive training resources that simplify these complex illustrations. One effective approach is to source detailed instructional materials or workshops that break down each component’s function within the diagram. These resources can provide visual aids, such as animations or interactive diagrams, that help in understanding how the alternator works as a whole. Additionally, buyers should collaborate with suppliers who can provide expert guidance on reading and interpreting these diagrams, ensuring that their teams are well-equipped to handle installations or repairs with confidence.

Scenario 2: Sourcing Quality Diagrams for Diverse Applications

Проблема: In international markets, particularly in regions like Africa and South America, sourcing quality diagrams for alternators can be challenging. Buyers often face a lack of localized resources that cater to specific vehicle or machinery types relevant to their markets. This scarcity can lead to reliance on generic or outdated diagrams, resulting in inefficiencies in troubleshooting and repairs, ultimately affecting the performance of their equipment.

Решение: To address this issue, buyers should establish partnerships with reputable manufacturers and distributors who offer tailored diagrams that cater to local applications. This can involve negotiating access to proprietary diagrams that include region-specific alternator designs and configurations. Buyers should also seek out online platforms or databases that specialize in automotive or machinery diagrams, ensuring they have access to up-to-date and accurate information. Regular communication with suppliers can facilitate updates on new diagrams as they become available, ensuring that the buyer’s operations remain efficient and effective.

Scenario 3: Integrating Diagrams into Technical Training

Проблема: Many B2B organizations overlook the importance of integrating alternator diagrams into their technical training programs. This oversight can lead to a workforce that lacks the necessary knowledge to diagnose and repair alternator-related issues effectively. Without proper training, employees may struggle with hands-on tasks, leading to increased downtime and higher costs due to errors in repairs or maintenance.

Решение: To enhance workforce competency, companies should develop a structured training program that incorporates alternator diagrams as a core component. This program should include both theoretical and practical sessions where employees can learn to interpret diagrams and apply their knowledge in real-world scenarios. Collaboration with technical experts or training organizations can provide valuable insights and methodologies for effective teaching. Furthermore, utilizing modern learning tools, such as virtual simulations or augmented reality applications, can significantly improve engagement and retention of information. By investing in this comprehensive training approach, organizations can ensure their teams are proficient in understanding and utilizing alternator diagrams, ultimately improving operational efficiency.

Strategic Material Selection Guide for diagram of an alternator

What Are the Key Materials Used in the Construction of an Alternator?

When selecting materials for the construction of an alternator, several factors must be considered, including thermal properties, corrosion resistance, and manufacturing complexity. Below, we analyze four common materials used in alternators, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Benefit Alternator Manufacturing?

Aluminum is the primary material used for the housing of alternators due to its lightweight nature and excellent thermal conductivity. It has a high resistance to corrosion, making it suitable for various environments, including those found in Africa and South America, where humidity and temperature variations can be significant.

Плюсы: Aluminum is relatively inexpensive, easy to manufacture, and can be extruded into complex shapes, which is advantageous for creating intricate designs in alternator housings.

Минусы: While it is durable, aluminum may not withstand extreme mechanical stresses as well as some other metals, which could be a concern in heavy-duty applications.

Влияние на применение: Aluminum’s lightweight nature aids in overall vehicle efficiency, particularly in hybrid and electric vehicles. However, care must be taken to ensure that the aluminum components meet international standards such as ASTM or DIN to ensure compatibility in different markets.

Почему медь необходима для электрических компонентов генераторов?

Copper is widely used for electrical windings within the alternator due to its excellent electrical conductivity. This property is crucial for efficient power generation and distribution.

Illustrative image related to diagram of an alternator

Плюсы: Copper is highly durable, resistant to corrosion, and provides superior conductivity, which enhances the overall performance of the alternator.

Минусы: The primary drawback of copper is its relatively high cost compared to other conductive materials, which can affect the overall manufacturing cost of the alternator.

Влияние на применение: In regions with high electrical demand, such as Europe and the Middle East, the use of copper can significantly improve the reliability of electrical systems. Buyers should ensure that copper components conform to international standards to avoid issues with compatibility and performance.

Как сталь влияет на структурную целостность генераторов?

Steel is often used for the rotor and stator components due to its strength and ability to withstand high mechanical loads.

Плюсы: Steel provides excellent durability and can handle the stresses associated with high-speed rotation, making it suitable for heavy-duty applications.

Illustrative image related to diagram of an alternator

Минусы: Steel is heavier than aluminum and can be prone to corrosion if not properly treated, which may limit its applications in certain environments.

Влияние на применение: For buyers in regions with high humidity or corrosive environments, such as coastal areas in Africa or South America, selecting steel components with appropriate coatings or treatments is essential to ensure longevity and performance.

What Role Does Plastic Play in Alternator Design?

Plastic materials are increasingly used in alternators for components such as housings, insulators, and covers due to their lightweight and corrosion-resistant properties.

Illustrative image related to diagram of an alternator

Плюсы: Plastics can be molded into complex shapes, reducing manufacturing complexity and costs. They are also resistant to corrosion, making them suitable for various environmental conditions.

Минусы: Plastics may not withstand high temperatures or mechanical stresses as well as metals, which could limit their use in certain critical components.

Влияние на применение: In regions with varying temperatures, such as the Middle East, selecting high-performance plastics that can withstand heat is crucial. Compliance with international standards for plastics is also important to ensure product reliability.

Illustrative image related to diagram of an alternator

Сводная таблица выбора материалов для генераторов

| Материал | Typical Use Case for diagram of an alternator | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Корпус и структурные компоненты | Легкий и коррозионно-стойкий | Less durable under extreme mechanical stress | Низкий |

| Медь | Электрические обмотки | Отличная проводимость и долговечность | Higher cost compared to alternatives | Высокий |

| Сталь | Компоненты ротора и статора | Высокая прочность и долговечность | Более тяжелый и подверженный коррозии | Средний |

| Пластик | Корпуса и изоляторы | Легкий и коррозионно-стойкий | Ограниченная термостойкость и стрессоустойчивость | Средний |

This strategic material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions when sourcing components for alternators tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for diagram of an alternator

What Are the Main Stages of Manufacturing an Alternator Diagram?

The manufacturing process of an alternator diagram involves several critical stages, each contributing to the overall quality and functionality of the final product. Understanding these stages is vital for B2B buyers looking to ensure that their suppliers adhere to high standards of production.

Material Preparation: What Materials Are Used for Alternators?

The primary materials used in alternators include high-grade aluminum for the housing, copper for the windings, and various composite materials for insulation. The choice of materials is crucial as they impact the efficiency, weight, and durability of the alternator. Prior to production, these materials undergo rigorous inspection to ensure they meet industry standards.

Как осуществляется процесс формовки для генераторов?

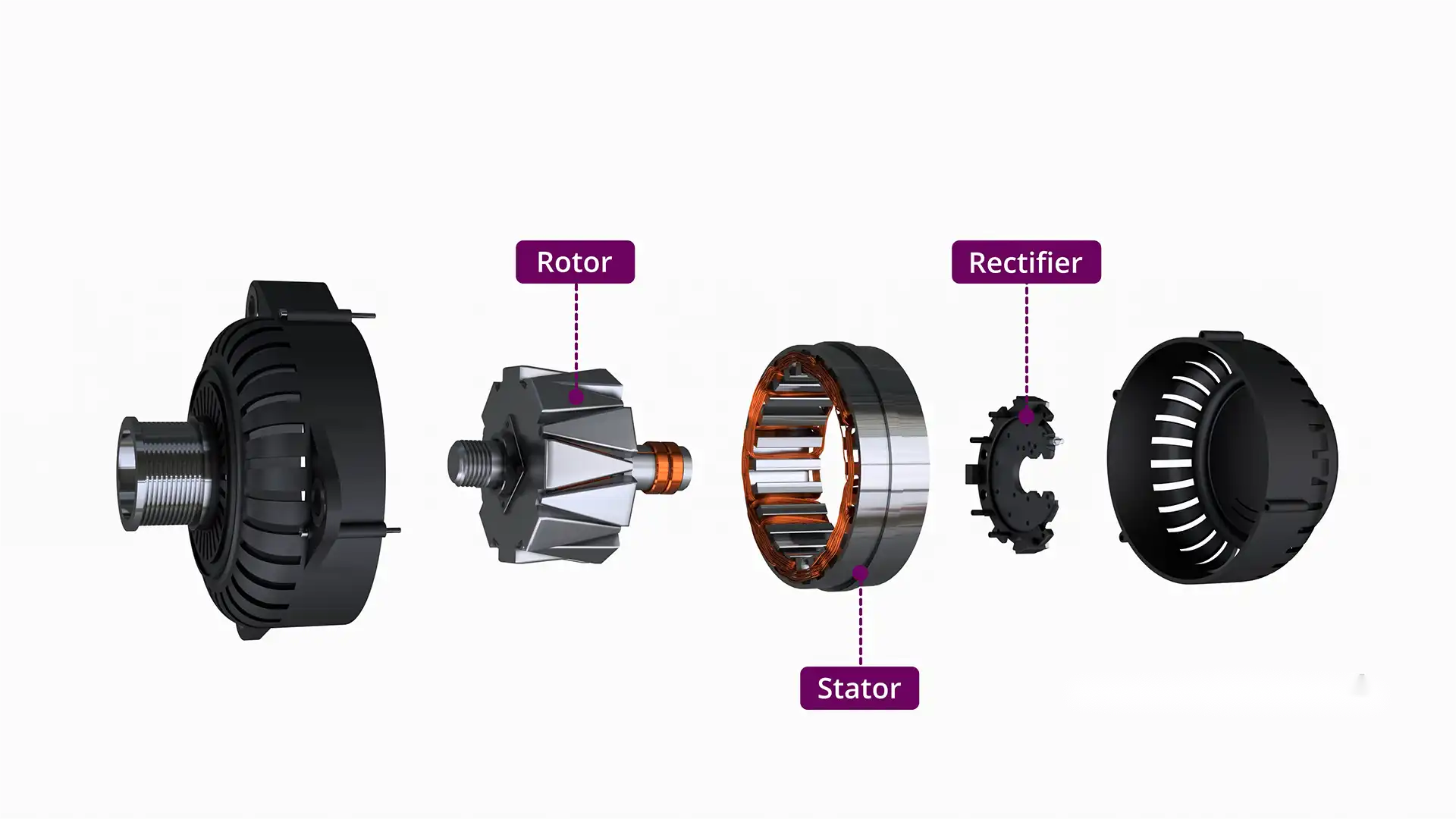

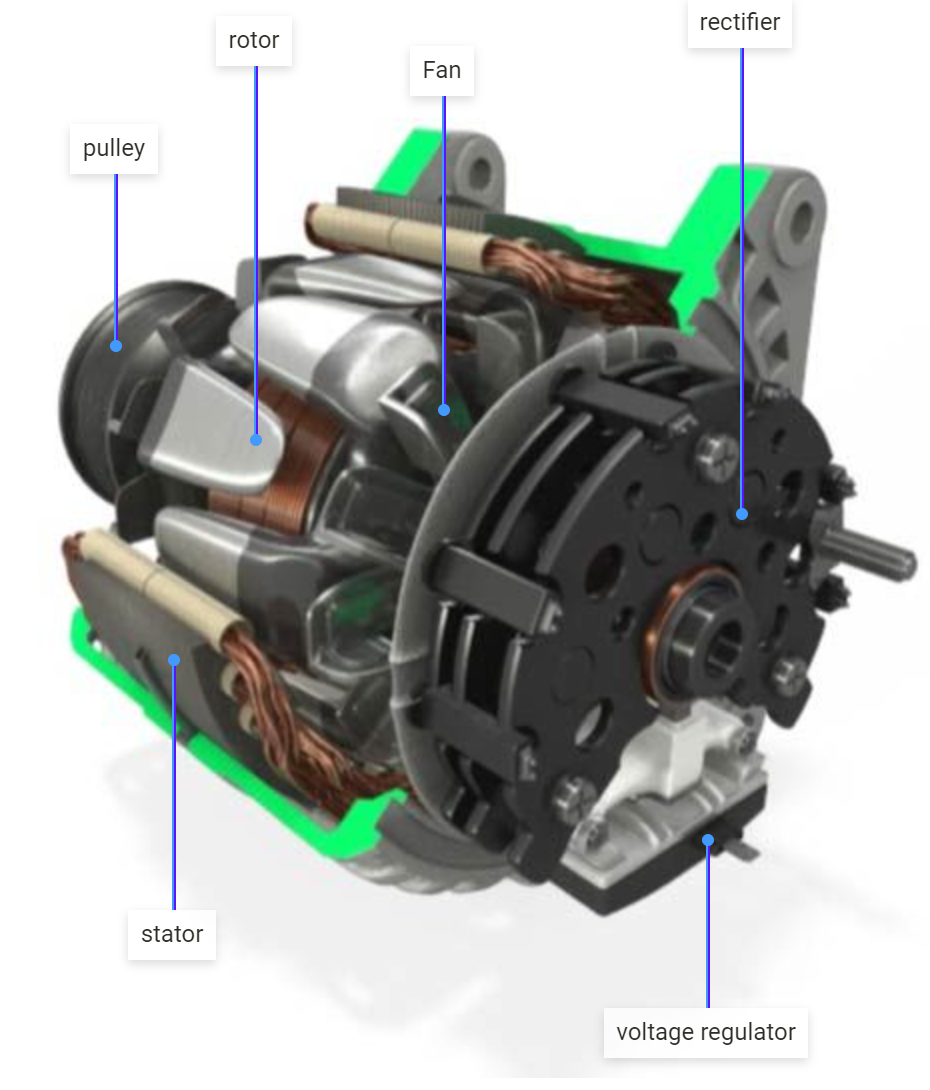

The forming process typically involves several techniques, including die casting for the aluminum housing and precision machining for components like the rotor and stator. The rotor and stator are often fabricated using stamping processes that create the necessary magnetic poles and windings. Ensuring accuracy in this phase is essential, as even minor discrepancies can lead to performance issues.

Что включает в себя процесс сборки?

During the assembly stage, all components are meticulously put together. This includes the installation of the rotor, stator, rectifier, and voltage regulator. Each component is secured and connected according to precise specifications to ensure optimal performance. Automation plays a significant role here, but manual checks are also performed to catch any potential errors.

What Finishing Techniques Are Used in Alternator Manufacturing?

Finishing processes often involve surface treatments to enhance corrosion resistance and improve aesthetic qualities. These may include anodizing the aluminum housing and applying protective coatings to other components. Quality assurance at this stage ensures that the alternator is not only functional but also visually appealing.

Как обеспечивается качество при производстве генераторов?

Quality assurance is a critical aspect of the manufacturing process for alternators. B2B buyers should be aware of the various international and industry-specific standards that govern quality control.

Illustrative image related to diagram of an alternator

Какие международные стандарты должны знать покупатели B2B?

Many manufacturers adhere to ISO 9001 standards, which outline requirements for a quality management system. This certification signifies that a company consistently provides products that meet customer and regulatory requirements. Additionally, certifications like CE mark, indicating compliance with European safety standards, can be crucial for buyers in Europe and other regions.

Каковы ключевые контрольные точки контроля качества в процессе производства?

Quality control checkpoints are strategically placed throughout the manufacturing process. These include:

- Входящий контроль качества (IQC): Inspection of raw materials to ensure they meet specified standards.

- Контроль качества в процессе производства (IPQC): Continuous monitoring during production to catch defects early.

- Окончательный контроль качества (FQC): Comprehensive testing of the finished alternator to verify performance and safety.

Какие общие методы тестирования используются для обеспечения качества?

Common testing methods for alternators include electrical testing to ensure proper voltage output, thermal testing to assess heat dissipation capabilities, and mechanical testing for durability. These tests can help identify potential failure points and ensure that the alternator meets performance specifications.

Illustrative image related to diagram of an alternator

Как покупатели B2B могут проверить контроль качества поставщиков?

B2B buyers can employ several methods to verify the quality control practices of potential suppliers.

What Steps Should Buyers Take for Supplier Audits?

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers should request documentation of past audits and certifications, as well as access to their quality management system. This transparency can help buyers gauge the supplier’s commitment to quality.

Как покупатели могут использовать отчеты и инспекции третьих сторон?

Requesting detailed quality control reports from suppliers can provide insights into their manufacturing processes and any issues encountered. Additionally, third-party inspections can offer an unbiased assessment of the supplier’s compliance with industry standards, giving buyers greater confidence in their choices.

Illustrative image related to diagram of an alternator

What Nuances Should International B2B Buyers Consider?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different countries may have varying standards and regulations, which can affect the importation and use of alternators.

Как региональные стандарты влияют на обеспечение качества?

Regional standards can influence everything from material selection to testing methods. Buyers should familiarize themselves with local regulations and ensure that their suppliers are compliant. This knowledge can prevent costly delays and ensure that the products meet local market requirements.

What Should Buyers Look for in Supplier Certifications?

When evaluating suppliers, buyers should look for certifications that are recognized internationally. For example, certifications like ISO 9001 or CE mark can indicate a commitment to quality that transcends regional differences. This is especially important for buyers in emerging markets who may face challenges in sourcing high-quality components.

Заключение: Обеспечение качества при производстве генераторов

Understanding the manufacturing processes and quality assurance measures involved in producing alternators is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control standards, buyers can make informed decisions. Verifying supplier practices through audits, reports, and third-party inspections will further ensure that the products meet the necessary standards for reliability and performance in various international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diagram of an alternator’

To aid B2B buyers in procuring a reliable ‘diagram of an alternator,’ this practical sourcing guide offers a structured checklist. This guide will help ensure that the diagrams meet technical specifications and are sourced from reputable suppliers, ultimately enhancing the efficiency of your procurement process.

Шаг 1: Определите свои технические характеристики

Establishing clear technical specifications is critical for ensuring that the alternator diagram meets your operational needs. This includes determining the required details such as dimensions, component labeling, and any specific functionalities you need to highlight. Engaging with your engineering team can provide insights into these requirements.

Шаг 2: Исследование потенциальных поставщиков

Conduct thorough research to identify potential suppliers who specialize in automotive components and diagrams. Look for companies with a strong reputation in the industry, particularly those that have experience in your target markets, such as Africa, South America, the Middle East, and Europe. Utilize industry forums, trade shows, and online directories to compile a list of candidates.

Шаг 3: Оценить сертификаты поставщиков

Before proceeding, verify that potential suppliers hold relevant certifications that demonstrate compliance with industry standards. Certifications such as ISO 9001 for quality management systems can indicate a supplier’s commitment to quality. Additionally, ensure that they meet local regulations pertinent to your region, which can vary significantly across continents.

Шаг 4: Запрос образцов или прототипов

Request samples or prototypes of the diagrams from shortlisted suppliers. This step allows you to assess the quality and accuracy of the diagrams, ensuring they align with your technical specifications. Pay attention to the clarity of labels, detail in the diagrams, and overall presentation, as these elements are crucial for effective communication and understanding.

Шаг 5: Assess Technical Support and Services

Consider the level of technical support and additional services offered by the suppliers. This includes their willingness to provide customization options or modifications to the diagrams based on your feedback. Effective communication channels and post-purchase support are essential for resolving any issues that may arise during implementation.

Шаг 6: Сравнить цены и условия

Conduct a thorough comparison of pricing structures among your shortlisted suppliers. Look beyond the initial costs; consider factors such as shipping fees, payment terms, and potential discounts for bulk orders. This comprehensive assessment will help you find the best value while ensuring the quality of the diagrams is not compromised.

Шаг 7: Finalize Your Order and Confirm Delivery Timelines

Once you have selected a supplier, finalize your order with clear specifications and confirm delivery timelines. It’s crucial to establish expectations regarding delivery dates and any penalties for delays. Make sure to keep open lines of communication with the supplier throughout the process to address any unforeseen issues promptly.

By following this step-by-step checklist, B2B buyers can confidently procure high-quality diagrams of alternators that meet their technical requirements while fostering strong relationships with reputable suppliers.

Comprehensive Cost and Pricing Analysis for diagram of an alternator Sourcing

Analyzing the comprehensive cost and pricing structure for sourcing a diagram of an alternator involves understanding various cost components and price influencers that play a crucial role in the B2B marketplace. This analysis is particularly relevant for international buyers from regions such as Africa, South America, the Middle East, and Europe, where sourcing practices can vary significantly.

What Are the Key Cost Components in Sourcing a Diagram of an Alternator?

-

Материалы: The primary material costs for an alternator diagram include the quality of the paper or digital format used for printing or distribution. High-quality diagrams that utilize durable materials or advanced digital formats will naturally incur higher costs.

-

Трудовые ресурсы: This encompasses the wages paid to designers, engineers, and technical illustrators involved in creating the diagrams. Skilled labor is essential for producing accurate and informative diagrams that accurately depict the alternator’s components and functionality.

-

Производственные накладные расходы: This includes costs associated with utilities, rent, and other indirect expenses related to the production of the diagrams. Efficient management of overhead can significantly impact the overall cost structure.

-

Инструменты: In some cases, specific tools may be required to create high-quality diagrams, especially if custom illustrations are needed. This cost can vary based on the complexity and customization level of the diagrams.

-

Контроль качества (КК): Ensuring that the diagrams meet certain quality standards may involve additional costs. This includes testing for accuracy and clarity, which is particularly important for technical documentation.

-

Логистика: For physical copies, logistics costs such as shipping and handling must be factored in. International shipping can add significant expenses, especially if the buyer is located far from the supplier.

-

Маржа: Suppliers will typically include a profit margin in their pricing. Understanding the average margin in the industry can help buyers negotiate better deals.

What Influences the Pricing of Alternator Diagrams?

-

Объем/минимальный объем заказа: The minimum order quantity (MOQ) can significantly affect pricing. Larger orders often result in lower per-unit costs, making bulk purchasing an attractive option for businesses.

-

Технические характеристики и индивидуальная настройка: Custom diagrams tailored to specific requirements can lead to higher costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Качество материалов и сертификаты: Higher quality materials or certifications (e.g., ISO standards) can increase costs but may also enhance the diagram’s reliability and usability.

-

Факторы, связанные с поставщиками: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their experience and quality assurance.

-

Инкотермс: Understanding the Incoterms agreed upon in the contract is essential for budgeting. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can alter the total landed cost.

How Can Buyers Negotiate for Better Prices?

-

Исследования и бенчмаркинг: Buyers should conduct thorough market research to understand prevailing prices and identify potential suppliers. This information can empower them during negotiations.

-

Скидки за объем: Engaging suppliers in discussions about volume discounts can lead to significant savings. Consider combining orders with other companies to achieve bulk pricing.

-

Общая стоимость владения (TCO): Evaluating the TCO, which includes all costs associated with acquiring and using the diagram over its lifecycle, can provide insights into the true value of the purchase.

-

Flexibility on Specifications: Being open to slight variations in specifications or materials can lead to cost reductions. Suppliers may offer alternatives that maintain quality while lowering prices.

-

Рассмотрите местных поставщиков: Sourcing from local suppliers can reduce logistics costs and lead times, making it a viable option for international buyers looking to optimize their budgets.

Final Thoughts

While this analysis provides a comprehensive overview of the cost and pricing structure for sourcing diagrams of alternators, it is important to note that prices can vary widely based on specific circumstances and supplier agreements. Buyers should always seek multiple quotes and assess the total value offered by potential suppliers to make informed purchasing decisions.

Alternatives Analysis: Comparing diagram of an alternator With Other Solutions

Exploring Alternatives to the Diagram of an Alternator

In the realm of electrical energy generation, particularly in automotive applications, understanding various solutions is crucial for B2B buyers. While the diagram of an alternator serves as a foundational representation of how this key component operates, several alternative technologies and methods can also achieve similar outcomes. This section will provide a comprehensive comparison of the diagram of an alternator against two viable alternatives: Системы управления аккумуляторами (BMS) и Integrated Starter-Generator Systems (ISG).

Сравнительная таблица

| Аспект сравнения | Diagram of an Alternator | Системы управления аккумуляторами (BMS) | Integrated Starter-Generator Systems (ISG) |

|---|---|---|---|

| Производительность | High efficiency in converting mechanical energy to electrical energy | Optimizes battery performance, extends lifespan | Combines starting and generating functions efficiently |

| Стоимость | Moderate initial investment; low operational costs | Higher upfront costs due to complexity | Higher initial costs but potential for fuel savings |

| Простота внедрения | Relatively straightforward installation in traditional vehicles | Requires advanced installation and integration | Complex installation requiring specialized knowledge |

| Техническое обслуживание | Low maintenance; regular checks recommended | Regular updates and monitoring needed | Low maintenance if integrated into the vehicle system |

| Лучший вариант использования | Ideal for conventional vehicles with internal combustion engines | Best for electric and hybrid vehicles needing efficient battery use | Suitable for modern vehicles aiming for enhanced fuel efficiency and reduced emissions |

Подробная разбивка альтернатив

Системы управления аккумуляторами (BMS)

Battery Management Systems are designed to optimize the performance of batteries, particularly in electric and hybrid vehicles. They monitor battery health, manage charge cycles, and ensure safety during operation. One of the primary advantages of BMS is its ability to prolong battery life through precise energy management. However, the complexity of installation and higher upfront costs can deter some buyers. BMS is best suited for businesses operating electric fleets or developing hybrid vehicles, where battery performance is paramount.

Integrated Starter-Generator Systems (ISG)

Integrated Starter-Generator Systems combine the functions of a starter motor and an alternator into a single unit, facilitating smoother engine starts and enhanced energy recovery during braking. The ISG system is particularly beneficial in modern vehicles, where efficiency and emissions reduction are critical. While the initial investment for ISG can be higher than that of a traditional alternator, the potential for fuel savings and reduced emissions makes it a compelling option for forward-thinking automotive manufacturers. The complexity of installation may require specialized expertise, making it less accessible for some businesses.

Заключение: выбор правильного решения для ваших нужд

When selecting between the diagram of an alternator and its alternatives, B2B buyers must consider their specific requirements. For traditional vehicles, the diagram of an alternator offers a proven and efficient solution. Conversely, businesses focused on electric or hybrid technology may find greater value in Battery Management Systems for optimized battery performance. Meanwhile, manufacturers aiming for cutting-edge efficiency might lean towards Integrated Starter-Generator Systems. By thoroughly assessing performance, cost, implementation ease, maintenance needs, and the best use case, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for diagram of an alternator

Каковы основные технические характеристики генератора переменного тока?

Understanding the technical properties of an alternator is crucial for B2B buyers, especially when sourcing or negotiating purchases. Here are some key specifications to consider:

1. Марка материала

The outer casing of most alternators is made from aluminum due to its lightweight and non-magnetic properties. This material choice is vital for heat dissipation during operation. Buyers should ensure that the material grade meets industry standards for durability and thermal management, particularly in regions with high ambient temperatures.

2. Уровни толерантности

Precision in manufacturing tolerances is critical to ensure the rotor spins freely within the stator. A typical tolerance might be within 0.01 mm. This specification is essential for maintaining efficiency and preventing mechanical failure, which could lead to costly downtimes or repairs.

3. Выходное напряжение

Most automotive alternators generate a voltage output ranging from 12V to 14.5V. It is crucial for buyers to specify the required voltage output based on the application, as insufficient voltage can lead to battery undercharging, while excessive voltage can damage electronic components.

4. Эффективность охлаждения

Alternators require effective cooling mechanisms to operate efficiently. Understanding the cooling design—whether it employs internal fans or external vents—can help buyers assess performance under heavy loads. Adequate cooling is especially important in warmer climates or in applications with high energy demands.

5. Вес

The weight of an alternator can significantly impact vehicle dynamics and fuel efficiency. Most modern alternators weigh between 4 to 10 kg. Buyers should consider weight specifications, especially for applications that prioritize lightweight components.

6. Рейтинг мощности

Power ratings, usually measured in amperes (A), indicate the alternator’s ability to supply electrical current. A common power rating for passenger vehicles ranges from 50A to 150A. Understanding the power requirements of the vehicle or machinery is essential for selecting an appropriately rated alternator.

Which Trade Terminology Should B2B Buyers Know When Sourcing Alternators?

Familiarity with trade terminology can enhance negotiations and ensure clarity in transactions. Here are some common terms to understand:

Illustrative image related to diagram of an alternator

1. OEM (производитель оригинального оборудования)

OEM refers to companies that produce parts that are used in the original assembly of vehicles. When sourcing alternators, buyers should determine if they require OEM parts for warranty and compatibility purposes, or if aftermarket options are acceptable.

2. MOQ (минимальный объем заказа)

MOQ indicates the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for businesses looking to maintain a consistent supply of parts.

3. RFQ (запрос предложения)

An RFQ is a document sent to suppliers to request pricing for specific products. It is an essential tool for buyers to ensure competitive pricing and to clarify specifications and delivery timelines.

4. Инкотермс (Международные торговые термины)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects like shipping, insurance, and delivery. Familiarity with Incoterms helps buyers mitigate risks and understand their obligations in the transaction.

5. Время выполнения заказа

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for inventory planning and ensuring that production schedules are met.

Illustrative image related to diagram of an alternator

6. Гарантийный срок

The warranty period specifies the duration during which the alternator is guaranteed against defects. Buyers should inquire about warranty terms to ensure they are covered for potential failures, which can significantly impact operational costs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators, ultimately enhancing their procurement processes and ensuring operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the diagram of an alternator Sector

What are the Current Market Dynamics and Key Trends in the Alternator Sector?

The alternator sector is witnessing significant growth driven by the increasing demand for reliable electrical systems in automotive applications. As global automotive production ramps up, particularly in emerging markets like Africa and South America, the need for efficient alternators becomes paramount. Key trends include the integration of advanced technologies such as smart voltage regulators and improved cooling systems, which enhance the performance and efficiency of alternators. Additionally, the rise of electric vehicles (EVs) is reshaping the sector, leading to innovations in alternator designs that cater to hybrid and fully electric vehicles.

B2B buyers should also be aware of the impact of digitalization on sourcing practices. The adoption of Industry 4.0 technologies allows manufacturers to optimize production processes and reduce lead times. This trend is particularly relevant for international buyers from regions like the Middle East and Europe, where competitive pricing and rapid delivery are crucial. Furthermore, the expansion of e-commerce platforms is facilitating easier access to suppliers, enabling buyers to compare products and prices more effectively.

How is Sustainability and Ethical Sourcing Influencing the Alternator Sector?

Sustainability is increasingly becoming a focal point for businesses in the alternator sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt greener practices. This includes the use of recyclable materials and energy-efficient manufacturing techniques. B2B buyers should consider suppliers that prioritize sustainability, as these practices not only reduce carbon footprints but also align with global regulatory standards.

Illustrative image related to diagram of an alternator

Ethical sourcing is equally important in establishing a responsible supply chain. Buyers are encouraged to seek suppliers who adhere to ethical labor practices and demonstrate transparency in their sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By choosing partners that prioritize these values, businesses can enhance their brand reputation and appeal to a growing consumer base that values corporate responsibility.

What is the Brief Evolution and History of Alternators?

The evolution of alternators can be traced back to the early 20th century when they were first introduced as a more efficient alternative to generators. Initially, these devices were bulky and primarily used in industrial applications. However, with advancements in technology, the automotive sector began adopting alternators in the 1960s, leading to significant improvements in vehicle electrical systems.

Over the decades, alternators have transformed from simple devices into complex systems featuring integrated electronics that enhance functionality and performance. The shift towards lighter materials, such as aluminum, and the introduction of smart technology have further revolutionized the sector. As the demand for electric and hybrid vehicles grows, the alternator’s role continues to evolve, driving innovation and adaptation to meet new market needs. This historical context highlights the importance of staying informed about technological advancements, which can significantly impact sourcing decisions for B2B buyers today.

Frequently Asked Questions (FAQs) for B2B Buyers of diagram of an alternator

-

How do I ensure the quality of alternator diagrams from suppliers?

To ensure the quality of alternator diagrams, request samples or prototypes before making a larger order. Evaluate the clarity and accuracy of the diagrams, checking if they include essential components such as the rotor, stator, rectifier, and voltage regulator. Collaborate with suppliers who have a proven track record and positive reviews from previous clients. Additionally, consider requesting certifications or quality assurance documents that affirm adherence to industry standards. -

What are the essential components to look for in an alternator diagram?

An effective alternator diagram should clearly depict key components such as the rotor, stator, rectifier, voltage regulator, and the cooling mechanism. Ensure it also includes the connections for power output, ground, and control voltage. Diagrams that illustrate the flow of electrical current and the interaction between components can provide deeper insights into functionality, which is crucial for maintenance and troubleshooting. -

What is the best sourcing strategy for alternator diagrams for international markets?

The best sourcing strategy for alternator diagrams involves identifying reputable manufacturers with experience in your target markets. Utilize online platforms to connect with verified suppliers, and leverage trade shows or industry fairs for face-to-face interactions. Ensure that suppliers understand local regulations and preferences, particularly in regions like Africa and South America, to ensure compliance and relevance of the diagrams. -

How do I vet suppliers for alternator diagrams?

To vet suppliers for alternator diagrams, review their business credentials, including years in operation and industry certifications. Request references from other clients who have sourced similar diagrams, and assess their response time and customer service quality. Conduct background checks to verify their financial stability and production capabilities, ensuring they can meet your specific demands, including customization options. -

What is the minimum order quantity (MOQ) for alternator diagrams?

Minimum order quantities (MOQ) for alternator diagrams can vary significantly between suppliers. Generally, MOQs may range from a few dozen to several hundred units, depending on the complexity of the diagrams and the supplier’s production capabilities. Discuss your specific needs directly with suppliers, as some may offer flexibility or tiered pricing structures based on order volume, which can be beneficial for smaller or first-time orders. -

What payment terms should I expect when ordering alternator diagrams internationally?

Payment terms for international orders of alternator diagrams typically include options like upfront payment, partial payment upon order confirmation, and balance payment upon delivery. Common methods include bank transfers, letters of credit, or escrow services for larger transactions. It’s important to clarify these terms in advance to avoid misunderstandings and to ensure that payment methods align with your company’s financial practices. -

How can I customize the alternator diagrams to suit my needs?

Customization of alternator diagrams can often be achieved by directly communicating your specific requirements to the supplier. Discuss aspects such as language preferences, inclusion of additional components, or unique labeling that aligns with your operational standards. Some suppliers may offer bespoke services for an additional fee, so ensure you outline your needs clearly and confirm timelines for any custom work. -

What logistics considerations should I keep in mind when sourcing alternator diagrams?

When sourcing alternator diagrams, consider logistics factors such as shipping methods, delivery times, and customs regulations specific to your country. Collaborate with suppliers who have experience in international shipping to navigate potential delays or compliance issues. Additionally, discuss packaging options to ensure that the diagrams arrive in pristine condition, which is vital for maintaining their usability and quality.

Top 6 Diagram Of An Alternator Manufacturers & Suppliers List

1. Electude – автомобильный генератор

Домен: electude.com

Зарегистрирован: 2005 (20 лет)

Введение: An alternator is a crucial automotive component that converts mechanical energy into electrical energy, generating power for the vehicle’s electrical systems and battery. Key components include:

– Шкив: передает механическую энергию от двигателя.

– Ротор: создает магнитное поле для генерации переменного тока.

– Статор: статическая часть, в которой генерируется напряжение.

– Rectifier: Convert…

2. Pinterest – Exploded View of an Alternator

3. HowStuffWorks – Alternators

Домен: auto.howstuffworks.com

Зарегистрирован: 1998 (27 лет)

Введение: Генераторы небольшие и легкие, размером примерно с кокос, с алюминиевым внешним корпусом для отвода тепла. Ключевые компоненты включают:

– Приводной шкив, прикрепленный к валу ротора, преобразующий механическую энергию в электрическую.

– Terminals: S terminal (senses battery voltage), IG terminal (ignition switch), L terminal (warning lamp circuit), B terminal (main output to ba…

4. Facebook – Alternator

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: Alternator: A vital component in modern vehicles responsible for generating electrical power to charge the battery and supply electricity to various systems. Key Components: Rotor – rotating part with magnets or windings; Stator – stationary part with windings; Rectifier – converts AC to DC; Pulley – drives alternator via belt; Front and Rear brackets – secure alternator; Brush holder – contains c…

5. Shop PKYS – Key to Identifying Alternator Terminals

Домен: shop.pkys.com

Зарегистрирован: 1999 (26 лет)

Введение: Key to identifying alternator terminals: A – Battery positive connection, B – Battery positive connection, B+ – Battery positive connection, C – Centre point of a Y stator, COM – Computer connection, D+ – Warning light (from ‘Dynamo Positive’), DFM – Dynamo Field Modulation, E – Warning light (from ‘Excitation’), F – Field (for externally regulated alternators), FR – Field Regulation Voltage Signa…

6. Scribd – Alternator Electrical System Diagram

Домен: scribd.com

Зарегистрирован: 2006 (19 лет)

Введение: The document is a diagram of the electrical system of an alternator. It illustrates the terminal wire located at the back of the alternator, which connects the alternator to the battery and other electrical components in a vehicle. The diagram helps explain how an alternator generates electricity to charge a battery and power various electrical systems in automobiles.

Strategic Sourcing Conclusion and Outlook for diagram of an alternator

As the global demand for reliable power generation continues to rise, understanding the intricacies of alternators is paramount for international B2B buyers. The strategic sourcing of alternators not only involves evaluating their fundamental components—such as the rotor, stator, rectifier, and voltage regulator—but also recognizing their critical role in automotive and industrial applications. By leveraging quality diagrams and technical specifications, buyers can make informed decisions that enhance operational efficiency and vehicle performance.

Investing in high-quality alternators ensures a consistent power supply, minimizes downtime, and supports the longevity of electrical systems. As markets in Africa, South America, the Middle East, and Europe evolve, the emphasis on advanced technologies, such as intelligent voltage regulation and efficient cooling systems, will become increasingly significant.

Illustrative image related to diagram of an alternator

Looking ahead, B2B buyers are encouraged to engage with reputable suppliers who prioritize innovation and quality. By fostering strategic partnerships, companies can not only secure superior products but also contribute to sustainable growth in their respective markets. It is time to act—evaluate your sourcing strategies and align with manufacturers that deliver excellence in alternator technology.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.