Introduction: Navigating the Global Market for alternator and battery

In today’s fast-paced global market, sourcing reliable alternators and batteries presents a significant challenge for international B2B buyers, particularly those operating across diverse regions such as Africa, South America, the Middle East, and Europe. The interplay between these two essential components is critical not only for vehicle performance but also for the efficiency of numerous industrial applications, from automotive manufacturing to energy solutions. Understanding the nuances of alternator and battery specifications, compatibility, and performance metrics is crucial for making informed purchasing decisions.

This comprehensive guide serves as a valuable resource, equipping buyers with insights into the various types of alternators and batteries available, their specific applications, and the latest technological advancements. Furthermore, it provides a framework for vetting suppliers, assessing costs, and navigating potential logistical challenges associated with international trade. By addressing key considerations such as quality assurance, warranty options, and after-sales support, this guide empowers businesses to optimize their procurement strategies.

As you explore the complexities of the alternator and battery market, you’ll gain the knowledge necessary to identify high-quality products that meet your operational needs. With a focus on actionable insights and data-driven recommendations, this guide is designed to enhance your purchasing strategy, ensuring that your organization remains competitive in an ever-evolving landscape.

Содержание

- Top 4 Alternator And Battery Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator and battery

- Understanding alternator and battery Types and Variations

- Key Industrial Applications of alternator and battery

- 3 Common User Pain Points for ‘alternator and battery’ & Their Solutions

- Strategic Material Selection Guide for alternator and battery

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator and battery

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator and battery’

- Comprehensive Cost and Pricing Analysis for alternator and battery Sourcing

- Alternatives Analysis: Comparing alternator and battery With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator and battery

- Navigating Market Dynamics and Sourcing Trends in the alternator and battery Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator and battery

- Strategic Sourcing Conclusion and Outlook for alternator and battery

- Важное предупреждение и условия использования

Understanding alternator and battery Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Свинцово-кислотная батарея | Traditional, cost-effective, high discharge rates | Автомобилестроение, промышленное оборудование | Плюсы: Low cost, widely available. Минусы: Shorter lifespan, heavier. |

| Литий-ионный аккумулятор | Lightweight, longer lifespan, fast charging | Electric vehicles, portable electronics | Плюсы: High energy density, longer cycle life. Минусы: Higher upfront cost, sensitive to temperature. |

| Alternator (Belt-driven) | Преобразует механическую энергию в электрическую | Automotive, generators | Плюсы: Efficient power generation, reliable. Минусы: Maintenance required, can fail under high load. |

| Бесщеточный генератор | Отсутствие щеток, снижение износа | Renewable energy systems, automotive | Плюсы: Longer lifespan, less maintenance. Минусы: Более высокие начальные инвестиции, сложная конструкция. |

| Умный генератор | Integrated with vehicle’s computer systems | Modern vehicles, hybrid systems | Плюсы: Optimized performance, energy-efficient. Минусы: Compatibility issues with older vehicles, costlier repairs. |

What Are the Key Characteristics of Lead-Acid Batteries for B2B Buyers?

Lead-acid batteries are the most common type used in automotive applications due to their low cost and high discharge rates. They are particularly suitable for industries that require reliable starting power, such as automotive and industrial machinery. When considering a purchase, B2B buyers should evaluate the battery’s cycle life and maintenance needs, as lead-acid batteries typically have a shorter lifespan and require regular maintenance to avoid corrosion.

How Do Lithium-Ion Batteries Compare for B2B Applications?

Lithium-ion batteries are gaining popularity due to their lightweight design, longer lifespan, and rapid charging capabilities. They are widely used in electric vehicles and portable electronics, making them suitable for businesses in technology and transportation. B2B buyers should consider the higher upfront costs and the sensitivity of these batteries to temperature fluctuations, which can affect performance and longevity.

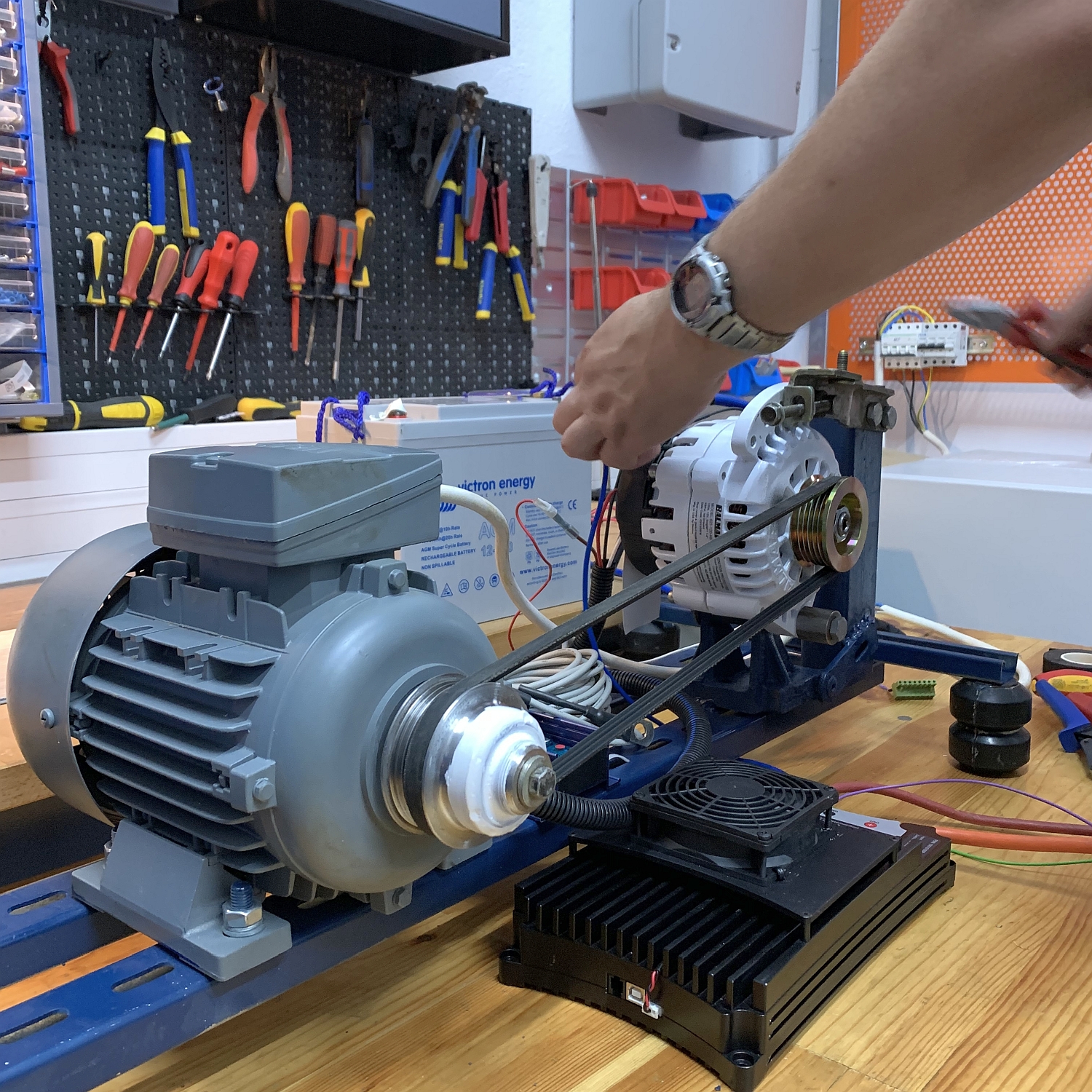

What Are the Advantages of Belt-Driven Alternators?

Belt-driven alternators are essential in converting mechanical energy from the engine into electrical energy. They are prevalent in automotive and generator applications. For B2B buyers, the efficiency of power generation and reliability are key advantages. However, it’s important to factor in maintenance requirements and the potential for failure under high load conditions when making purchasing decisions.

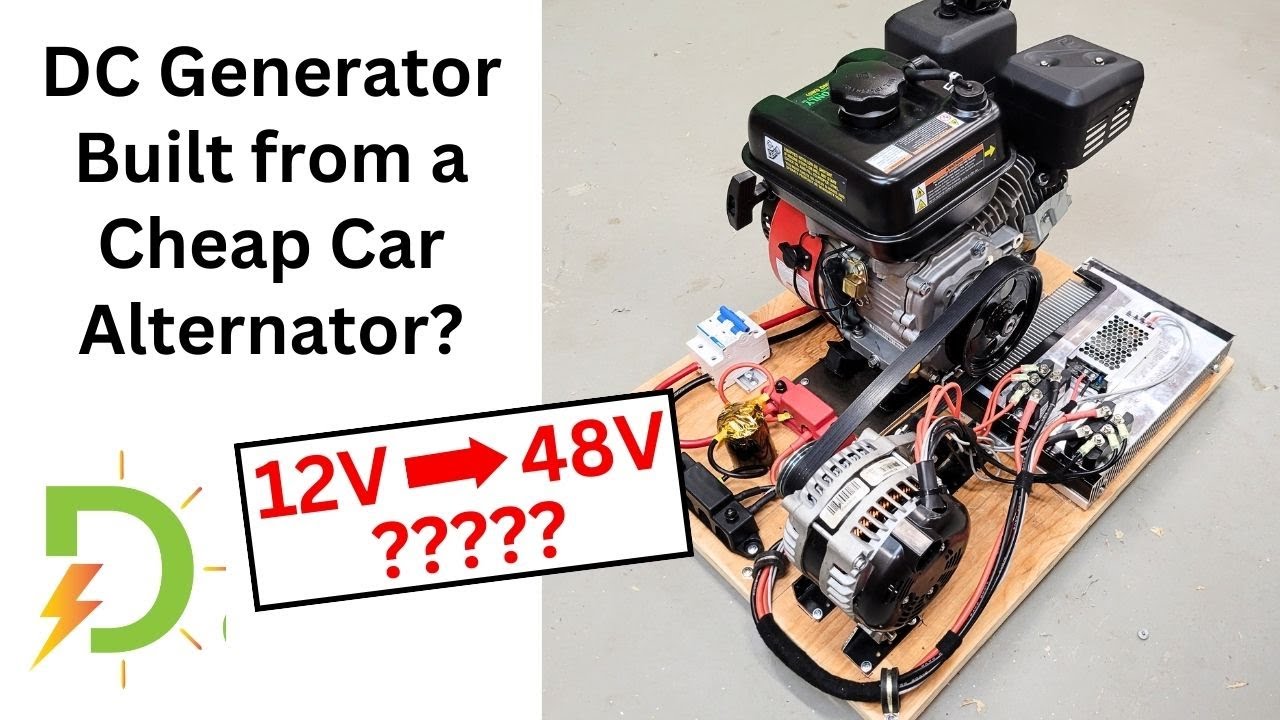

Illustrative image related to alternator and battery

Why Choose Brushless Alternators for Enhanced Performance?

Brushless alternators eliminate the wear and tear associated with traditional brushes, resulting in a longer lifespan and reduced maintenance needs. These alternators are especially beneficial in renewable energy systems and modern automotive applications. B2B buyers should weigh the higher initial investment against the long-term savings from reduced maintenance and increased efficiency.

What Makes Smart Alternators a Valuable Investment?

Smart alternators are designed to integrate with a vehicle’s computer systems, optimizing performance and energy efficiency. They are commonly found in modern vehicles and hybrid systems, making them ideal for businesses focused on innovation and sustainability. However, buyers should be aware of potential compatibility issues with older vehicle models and the cost implications of repairs and replacements.

Key Industrial Applications of alternator and battery

| Отрасль/сектор | Specific Application of alternator and battery | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Power supply for assembly line machinery | Ensures continuous operation and productivity | Reliability, energy efficiency, and compatibility with existing systems |

| Возобновляемые источники энергии | Energy storage and management in solar systems | Enhances energy reliability and reduces costs | Capacity, charge/discharge rates, and integration with solar inverters |

| Телекоммуникации | Backup power for communication towers | Minimizes downtime and service interruptions | Durability, maintenance support, and scalability for future expansion |

| Сельское хозяйство | Power supply for irrigation systems | Increases efficiency and crop yield | Weather resistance, energy output, and compatibility with agricultural machinery |

| Морской транспорт и судоходство | Auxiliary power for vessels | Ensures operational safety and reliability | Corrosion resistance, energy capacity, and compliance with maritime regulations |

How Are Alternators and Batteries Used in Automotive Manufacturing?

In automotive manufacturing, alternators and batteries are crucial for powering assembly line machinery and robotic systems. These components ensure that the production process runs smoothly, minimizing downtime and improving overall productivity. For B2B buyers in this sector, sourcing reliable alternators and batteries is critical. They must consider factors such as compatibility with existing machinery, energy efficiency, and the ability to withstand continuous operation under demanding conditions.

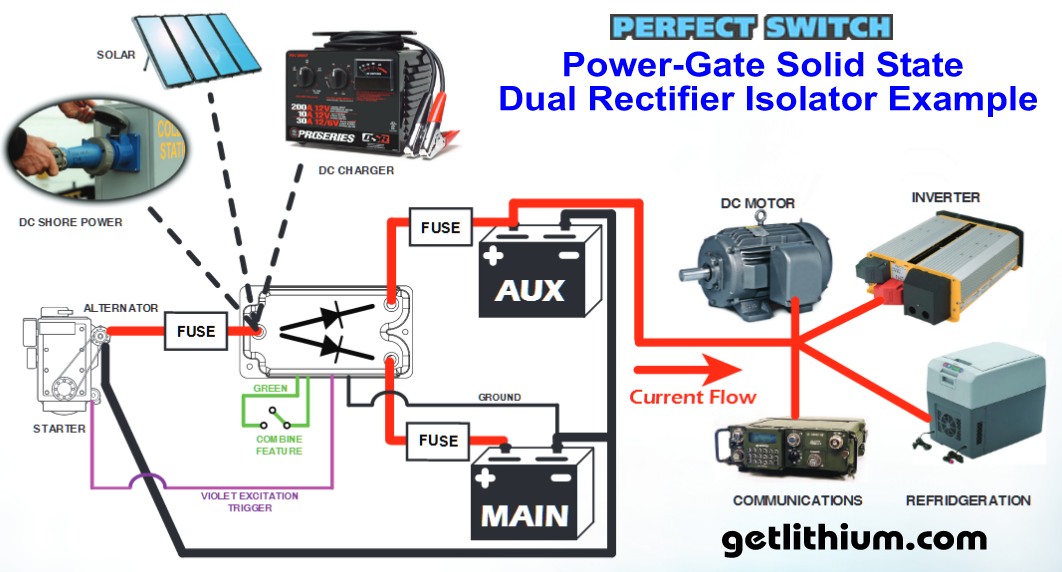

Illustrative image related to alternator and battery

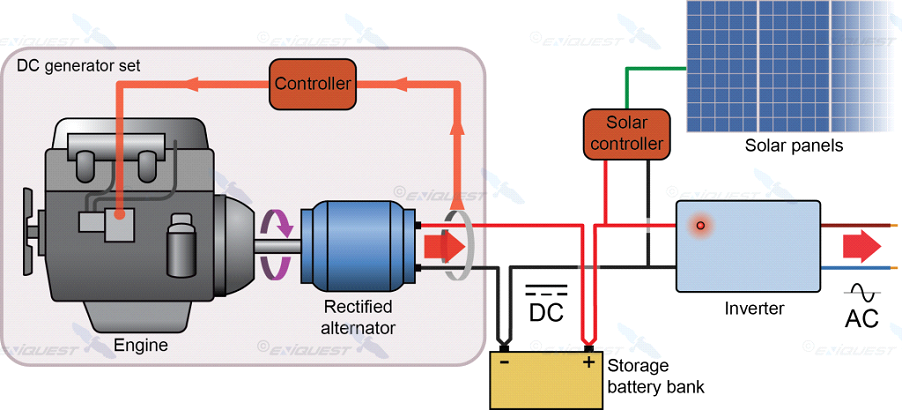

What Role Do Alternators and Batteries Play in Renewable Energy Systems?

In renewable energy applications, particularly solar power systems, alternators and batteries are integral to energy storage and management. They enable the efficient capture and storage of solar energy for later use, enhancing the reliability of power supply, especially in remote areas. International buyers must focus on battery capacity, charge/discharge rates, and the ability to integrate seamlessly with solar inverters to ensure optimal performance and cost-effectiveness.

How Are Alternators and Batteries Essential for Telecommunications?

Telecommunications companies rely on alternators and batteries to provide backup power for communication towers. This ensures that services remain operational during power outages, which is vital for maintaining connectivity. Buyers in this sector should prioritize sourcing durable and high-capacity batteries that can withstand extreme conditions, along with comprehensive maintenance support to mitigate potential service interruptions.

In What Ways Do Alternators and Batteries Benefit Agriculture?

In agriculture, alternators and batteries are used to power irrigation systems, ensuring efficient water distribution to crops. This technology not only enhances crop yield but also optimizes resource use, particularly in regions with limited water supply. When sourcing these components, agricultural businesses should consider weather resistance, energy output, and compatibility with various types of agricultural machinery to meet their operational needs.

Why Are Alternators and Batteries Important in Marine and Shipping Industries?

In the marine and shipping sectors, alternators and batteries serve as auxiliary power sources for vessels. They are essential for ensuring operational safety and reliability, particularly during long voyages or in adverse conditions. Buyers in this industry must seek out batteries that are resistant to corrosion, have adequate energy capacity, and comply with maritime regulations to ensure safe and efficient operations at sea.

3 Common User Pain Points for ‘alternator and battery’ & Their Solutions

Scenario 1: Stranded Due to Battery Failure in Remote Locations

Проблема: For B2B buyers managing fleets or transportation services, encountering battery failure in remote areas can lead to significant operational disruptions. Imagine a delivery truck that won’t start because of a dead battery, leaving drivers stranded and customers waiting. This situation not only affects customer satisfaction but can also incur additional costs for towing and emergency repairs. Buyers often overlook the importance of battery health in fleet management, assuming that batteries will function well without regular checks.

Решение: To mitigate the risk of battery-related failures, implement a proactive battery maintenance program. Start by investing in battery monitoring technology that can provide real-time diagnostics on battery health and charge levels. Regularly scheduled maintenance checks should be mandated, especially before long trips or during seasonal changes that might affect battery performance. Additionally, educate drivers on recognizing early signs of battery failure, such as dimming lights or sluggish starts. This combination of proactive monitoring and driver education can prevent unexpected breakdowns and ensure smooth operations.

Scenario 2: High Replacement Costs from Premature Alternator Wear

Проблема: Many B2B buyers are frustrated by the high costs associated with frequent alternator replacements. This often occurs due to a lack of understanding of the relationship between the battery and the alternator. If one component fails, it can lead to premature wear on the other, resulting in increased maintenance costs and downtime. Companies that rely on machinery or vehicles to maintain their operations can find themselves facing significant financial strain due to these repeated failures.

Решение: To address this issue, establish a comprehensive training program for maintenance staff that emphasizes the interconnected roles of the alternator and battery. Encourage routine testing of both components during scheduled maintenance to catch potential issues before they escalate. Additionally, consider investing in high-quality alternators and batteries that are designed for durability and longer life spans. Use OEM (Original Equipment Manufacturer) parts where possible, as they are often more reliable than generic alternatives. By focusing on quality and thorough maintenance, companies can reduce replacement costs and extend the life of their electrical systems.

Scenario 3: Inconsistent Performance from Electrical Systems

Проблема: Businesses that operate vehicles or equipment with complex electrical systems often face inconsistent performance issues. Symptoms may include flickering lights, erratic dashboard signals, or difficulties starting the engine, which can lead to decreased productivity. Buyers may not recognize that these issues could stem from either a failing battery or alternator, causing confusion and frustration when troubleshooting.

Illustrative image related to alternator and battery

Решение: Implement a systematic approach to diagnosing electrical system issues. Start by utilizing diagnostic tools that can pinpoint whether the battery, alternator, or another electrical component is at fault. Train your technical staff to conduct thorough inspections of the entire electrical system, rather than just focusing on the symptoms. Additionally, establish a routine maintenance schedule that includes checks of the battery and alternator’s health, ensuring they are functioning optimally together. This proactive strategy will enhance reliability and performance, minimizing disruptions and improving operational efficiency.

Strategic Material Selection Guide for alternator and battery

What Are the Key Materials Used in Alternators and Batteries?

When selecting materials for alternators and batteries, it is crucial to consider their performance characteristics, durability, and suitability for specific applications. Below, we analyze four common materials used in these components, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Медь

Ключевые свойства:

Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can handle high temperatures and pressures, making it ideal for electrical components.

Плюсы и минусы:

Copper’s high conductivity ensures efficient energy transfer, which is essential for both alternators and batteries. However, its relatively high cost compared to alternatives like aluminum can be a drawback. Additionally, while copper is durable, it can be susceptible to corrosion if not properly treated.

Влияние на применение:

Copper is often used in wiring and connectors within alternators and batteries. Its compatibility with various media makes it suitable for high-performance applications, particularly in automotive and industrial sectors.

Соображения для международных покупателей:

Buyers should ensure compliance with international standards such as ASTM B170 for copper wire. In regions like Africa and South America, where humidity can be high, selecting corrosion-resistant copper alloys may be beneficial.

2. Алюминий

Ключевые свойства:

Aluminum is lightweight, has good thermal conductivity, and offers decent corrosion resistance. It can withstand moderate temperatures and pressures.

Плюсы и минусы:

The primary advantage of aluminum is its lower cost and weight compared to copper, making it a popular choice for manufacturers looking to reduce overall vehicle weight. However, aluminum’s conductivity is lower than that of copper, which can affect performance in high-demand applications.

Влияние на применение:

Aluminum is commonly used in alternator housings and some wiring applications. Its lightweight nature can enhance fuel efficiency in vehicles.

Соображения для международных покупателей:

Aluminum components must comply with standards such as DIN 1725 for wrought aluminum alloys. Buyers in Europe and the Middle East should consider the impact of local environmental conditions on aluminum’s longevity.

3. Lead-Acid

Ключевые свойства:

Lead-acid batteries are characterized by their ability to deliver high surge currents and have a relatively low cost. They operate effectively at various temperatures but can be heavy.

Плюсы и минусы:

Lead-acid batteries are well-established, with a proven track record in automotive applications. However, they are less environmentally friendly and have a shorter lifespan compared to newer technologies like lithium-ion batteries.

Влияние на применение:

These batteries are widely used in vehicles for starting, lighting, and ignition (SLI) applications. Their robustness makes them suitable for harsh conditions.

Соображения для международных покупателей:

Compliance with regulations regarding lead disposal and recycling is crucial, especially in regions with strict environmental laws like Europe. Buyers should also be aware of the differences in lead-acid battery standards across regions.

4. Lithium-Ion

Ключевые свойства:

Lithium-ion batteries offer high energy density, lightweight design, and long cycle life. They perform well under a wide range of temperatures.

Плюсы и минусы:

The main advantage of lithium-ion technology is its efficiency and longevity compared to lead-acid batteries. However, the higher cost and complex manufacturing processes can be limiting factors for some applications.

Влияние на применение:

Lithium-ion batteries are increasingly being used in hybrid and electric vehicles, providing significant weight savings and extended range.

Соображения для международных покупателей:

International buyers must consider compliance with various safety standards, such as UN 38.3 for lithium batteries. In emerging markets, the cost may be a barrier to widespread adoption.

Сводная таблица

| Материал | Typical Use Case for alternator and battery | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Медь | Wiring and connectors in alternators/batteries | Отличная проводимость | Higher cost, susceptible to corrosion | Высокий |

| Алюминий | Alternator housings, some wiring | Lightweight, lower cost | Более низкая проводимость, чем у меди | Средний |

| Свинцово-кислотный | Starting, lighting, ignition (SLI) batteries | Proven technology, high surge capacity | Shorter lifespan, environmental concerns | Низкий |

| Литий-ионный | Hybrid and electric vehicle batteries | Высокая плотность энергии, длительный срок службы | Более высокая стоимость, сложное производство | Высокий |

This material selection guide provides B2B buyers with essential insights into the properties and implications of different materials used in alternators and batteries, helping them make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator and battery

What Are the Main Stages in the Manufacturing Process of Alternators and Batteries?

The manufacturing process for alternators and batteries involves several critical stages that ensure the final product meets performance and durability standards. Understanding these stages is essential for B2B buyers, particularly those sourcing products from diverse regions.

1. Подготовка материалов

The manufacturing journey begins with material preparation, where raw materials like copper, aluminum, lead, and plastic are sourced. Quality sourcing is essential, as the materials directly influence the longevity and efficiency of the alternators and batteries. Suppliers often conduct tests to verify the purity and integrity of the materials, ensuring they meet industry specifications.

2. Формирование

The forming stage involves shaping the raw materials into usable components. For alternators, this includes creating the rotor and stator, which are critical for electricity generation. Techniques such as stamping, machining, and casting are commonly employed. Battery manufacturing focuses on forming lead plates and separators that will later be assembled into cells.

3. Сборка

Once the components are prepared, they move into the assembly phase. In alternator production, the rotor is mounted onto the stator, and components like diodes and voltage regulators are integrated. Battery assembly involves stacking the formed plates and adding electrolyte solutions before sealing the cells. This stage requires precision to ensure that every part fits correctly, as even minor misalignments can lead to performance issues.

4. Отделка

The finishing stage includes surface treatments and coatings to protect the components from corrosion and wear. For alternators, this might involve applying a protective paint or lacquer, while batteries often receive a final inspection and labeling. This stage ensures that the products not only function well but also maintain their integrity over time.

How Is Quality Assurance Implemented in Alternator and Battery Manufacturing?

Quality assurance (QA) is a vital aspect of manufacturing alternators and batteries. It ensures that products are reliable and meet both international standards and specific customer requirements.

What International Standards Are Relevant for Quality Assurance?

International standards such as ISO 9001 are critical for ensuring consistent quality in manufacturing processes. This standard focuses on quality management systems and emphasizes continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for Europe and API (American Petroleum Institute) for certain battery types are important for compliance in specific markets.

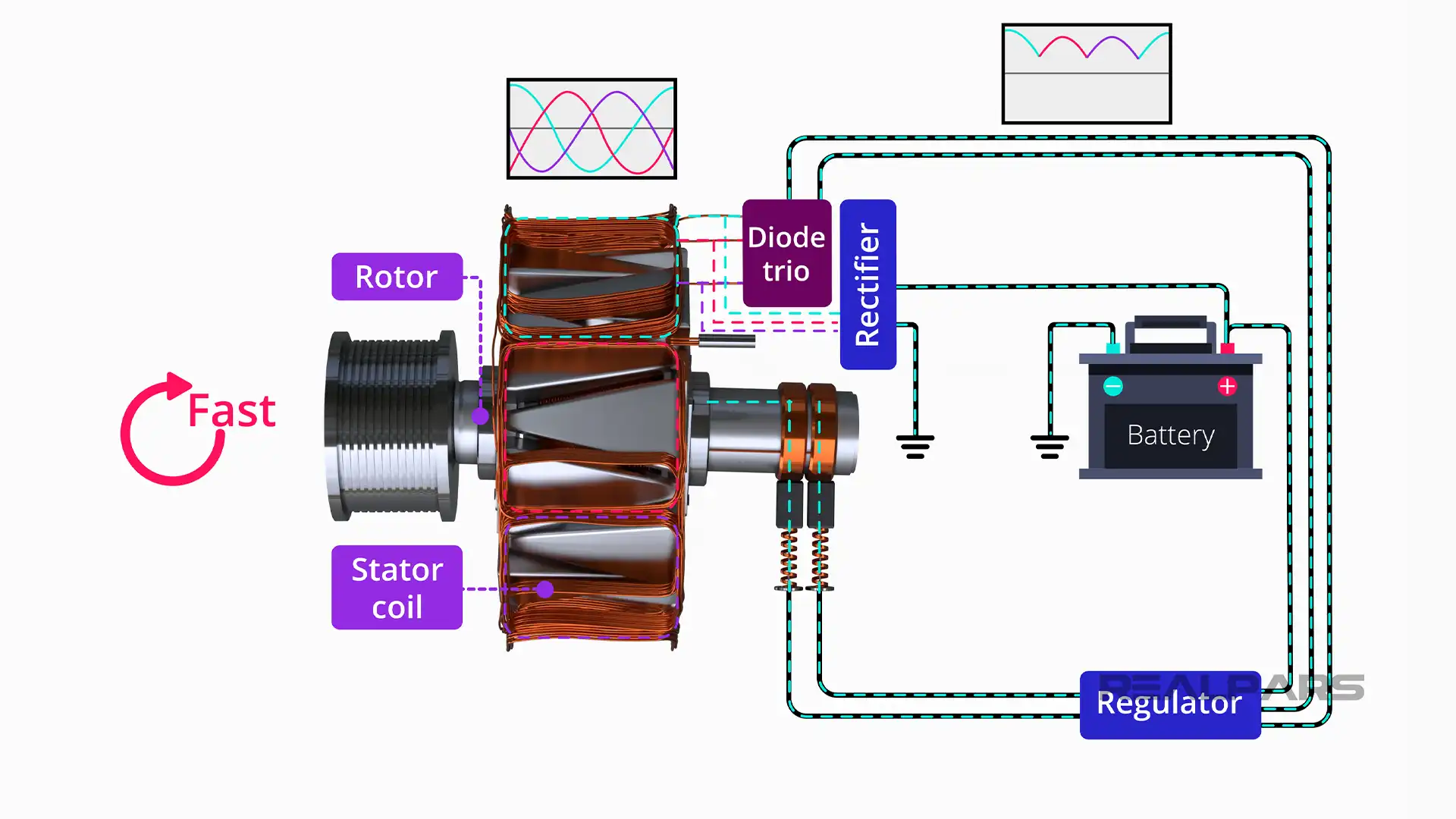

Illustrative image related to alternator and battery

Каковы ключевые контрольные точки контроля качества в производственном процессе?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

-

Входящий контроль качества (IQC): This is the first line of defense, where raw materials are inspected for quality before they enter the production line. Ensuring high-quality materials minimizes defects in the final product.

-

Контроль качества в процессе производства (IPQC): During the assembly and finishing stages, periodic inspections are conducted to catch any deviations from established standards. This includes dimensional checks and visual inspections.

-

Окончательный контроль качества (FQC): Before products are packaged and shipped, a thorough examination is performed. This may involve functional testing, where alternators are tested for electrical output and batteries for capacity and leak resistance.

What Common Testing Methods Are Used for Alternators and Batteries?

Testing methods are crucial for validating the performance and safety of alternators and batteries. Common techniques include:

-

Электрические испытания: For alternators, tests measure output voltage and current. Batteries undergo load testing to assess their ability to hold and deliver charge.

-

Экологические испытания: This simulates real-world conditions, assessing how products perform under extreme temperatures and humidity levels.

-

Испытания на долговечность: Alternators and batteries are subjected to vibration and shock tests to ensure they can withstand operational stresses without failure.

Как покупатели B2B могут проверить меры контроля качества поставщиков?

For B2B buyers, particularly those operating in international markets, verifying supplier quality control measures is essential to mitigate risks associated with product failure.

What Steps Can Buyers Take to Ensure Supplier Compliance?

-

Аудиты: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control systems. This allows buyers to assess compliance with international standards and identify areas for improvement.

-

Запрос отчетов о качестве: Suppliers should be able to provide documentation demonstrating their adherence to quality standards. This includes inspection reports, test results, and compliance certificates.

-

Проверки третьей стороной: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control measures. This is particularly valuable for buyers in regions with varying regulatory standards.

Каковы нюансы контроля качества для международных B2B-покупателей?

International B2B buyers face unique challenges in ensuring quality control across different markets. Factors such as varying regulatory requirements, cultural differences in manufacturing standards, and logistical challenges can complicate the procurement process.

How Can Buyers Navigate These Challenges?

-

Понимание региональных стандартов: Buyers must familiarize themselves with the specific quality standards and certifications required in their target markets. This knowledge can help in selecting suppliers who are already compliant.

-

Building Strong Relationships: Establishing long-term relationships with suppliers can lead to better communication and collaboration on quality assurance practices. This is particularly important in regions where personal relationships influence business operations.

-

Leveraging Technology: Utilizing technology for real-time monitoring of production processes can enhance transparency and accountability. Buyers can use software platforms that allow them to track quality metrics and production timelines.

Заключение

Understanding the manufacturing processes and quality assurance measures for alternators and batteries is crucial for B2B buyers aiming to source reliable products. By focusing on key manufacturing stages, international standards, QC checkpoints, and effective verification methods, buyers can make informed decisions that enhance their supply chain’s reliability and efficiency. This comprehensive approach not only minimizes risks but also builds a foundation for long-term partnerships in the global market.

Illustrative image related to alternator and battery

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator and battery’

To ensure a successful procurement process for alternators and batteries, this guide offers a comprehensive checklist. By following these steps, B2B buyers can make informed decisions that enhance operational efficiency and product reliability.

Шаг 1: Определите свои технические характеристики

Establishing clear technical specifications is the foundation of a successful sourcing strategy. Identify the specific requirements for your alternators and batteries, including voltage, capacity, and size. This clarity helps you communicate effectively with suppliers and ensures that you procure products that meet your operational needs.

Шаг 2: Проведение маркетинговых исследований

Understanding the market landscape is crucial for identifying potential suppliers and competitors. Research trends in alternator and battery technology, pricing, and demand within your target regions. This knowledge enables you to make strategic decisions and negotiate effectively with suppliers.

Шаг 3: Оцените потенциальных поставщиков

Before making a commitment, thorough evaluation of potential suppliers is essential. Request company profiles, product catalogs, and references from other businesses in your industry. Focus on suppliers with proven track records and strong reputations to minimize risks associated with product quality and reliability.

Illustrative image related to alternator and battery

- Key Factors to Consider:

- Supplier experience in the industry

- Customer feedback and reviews

- Financial stability of the supplier

Шаг 4: Проверка сертификатов и соответствия требованиям

Ensure that your suppliers meet the relevant industry standards and certifications. Compliance with international quality standards (e.g., ISO, IEC) guarantees that the alternators and batteries will perform reliably in various conditions. This step protects your investment and ensures product safety.

Шаг 5: Запросите образцы и проведите тестирование

Before finalizing any order, request samples of the alternators and batteries. Conduct thorough testing to verify that the products meet your specifications and performance criteria. Testing helps identify potential issues early, preventing costly returns or failures in the field.

Шаг 6: Обсудить условия и положения

Once you have identified a suitable supplier, it’s time to negotiate terms and conditions. Discuss pricing, payment terms, delivery schedules, and warranty agreements. Clear agreements help establish expectations and can prevent misunderstandings later in the relationship.

Шаг 7: Установите долгосрочные отношения

Building a long-term partnership with your chosen supplier can yield significant benefits. Regular communication and collaboration can lead to better pricing, priority service, and access to new products. A strong relationship fosters trust and can enhance your supply chain resilience.

By adhering to this checklist, B2B buyers can ensure a streamlined and effective procurement process for alternators and batteries, ultimately leading to improved operational performance and customer satisfaction.

Comprehensive Cost and Pricing Analysis for alternator and battery Sourcing

What Are the Key Cost Components in Alternator and Battery Sourcing?

When sourcing alternators and batteries, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Материалы: The choice of raw materials significantly impacts pricing. For alternators, copper for windings, steel for housing, and various electronic components are critical. Batteries require lead, acid, and plastic casings. Fluctuations in commodity prices can directly affect your sourcing costs.

-

Трудовые ресурсы: Labor costs vary based on geographic location and manufacturing practices. Countries with lower labor costs may present opportunities for cost savings, but this can be offset by potential quality issues.

-

Производственные накладные расходы: This includes utilities, rent, and equipment maintenance, which can differ widely among manufacturers. Efficient production processes can lower overhead costs, impacting overall pricing.

-

Инструменты: Initial tooling costs can be significant, especially for custom products. Buyers may need to factor in these costs if they require specialized tooling for unique specifications.

-

Контроль качества (КК): High-quality standards often require more rigorous testing and inspection processes. While this adds to costs, it is essential for minimizing returns and ensuring product reliability.

-

Логистика: Transportation and handling costs can vary based on distance, shipping mode, and the chosen Incoterms. Efficient logistics management can help reduce these expenses.

-

Маржа: Manufacturers typically apply a profit margin that reflects their operational efficiency, market positioning, and competition. Understanding this margin can help buyers negotiate better pricing.

How Do Price Influencers Affect Alternator and Battery Costs?

Several factors influence the final pricing of alternators and batteries, impacting your sourcing strategy.

-

Объем/минимальный объем заказа: Minimum Order Quantities (MOQs) can dictate pricing. Higher order volumes often lead to lower per-unit costs, making bulk purchasing attractive for B2B buyers.

-

Технические характеристики и индивидуальная настройка: Custom specifications can lead to increased costs. Off-the-shelf products are generally cheaper than tailored solutions. Clearly defining your requirements can help in obtaining competitive quotes.

-

Качество материалов и сертификаты: Higher-quality materials and certifications (such as ISO standards) may incur additional costs but can enhance reliability and longevity, ultimately offering better value.

-

Факторы, связанные с поставщиками: Supplier reputation, reliability, and financial stability can influence pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Инкотермс: Understanding Incoterms (International Commercial Terms) is crucial for managing responsibilities regarding shipping, insurance, and tariffs. Choosing the right Incoterms can lead to cost savings and reduce risks.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency.

-

Переговоры: Always engage in negotiations. Suppliers often have room for price adjustments, especially for larger orders or long-term contracts.

-

Общая стоимость владения (TCO): Evaluate the TCO, which includes initial costs, maintenance, warranty, and disposal costs. A cheaper upfront price may not always lead to overall savings.

-

Исследование местных рынков: Understand regional market conditions, which can influence pricing. For instance, sourcing from local manufacturers can reduce shipping costs and lead times.

-

Quality vs. Price Balance: While it’s tempting to choose the lowest price, consider the long-term implications of quality. Investing in higher-quality components can prevent costly failures.

-

Stay Informed on Global Trends: Keep an eye on global market trends and commodity prices, as these can affect material costs and overall pricing strategies.

Conclusion: Why Are Indicative Prices Important?

When evaluating suppliers and costs, remember that indicative prices can fluctuate due to market dynamics. Always request detailed quotes and consider factors beyond the initial price to ensure you make informed purchasing decisions. Understanding the comprehensive cost structure and price influencers will empower you to negotiate effectively and source high-quality alternators and batteries that meet your operational needs.

Alternatives Analysis: Comparing alternator and battery With Other Solutions

Exploring Alternatives for Powering Electrical Systems in Vehicles

In the automotive sector, the combination of an alternator and battery is a well-established solution for powering vehicles. However, as technology evolves, alternative solutions are emerging that can also fulfill these energy needs. Understanding these alternatives is crucial for B2B buyers looking to make informed decisions about vehicle power systems, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Сравнительная таблица

| Аспект сравнения | Alternator and Battery | Технология топливных элементов | Supercapacitors |

|---|---|---|---|

| Производительность | Reliable, continuous power for starting and running electrical systems | Efficient energy conversion, longer range | Quick energy discharge, high power density |

| Стоимость | Moderate initial investment, replacement costs every 4-5 years | High upfront costs, but lower operational costs | Lower initial costs, but limited energy storage |

| Простота внедрения | Standard in most vehicles, easy to install | Requires specialized installation and fuel supply | Требуется интеграция с существующими системами |

| Техническое обслуживание | Regular checks needed, battery replacement necessary | Minimal maintenance, but fuel supply management required | Low maintenance, but may require periodic testing |

| Лучший вариант использования | Общие автомобильные применения | Electric vehicles, public transport | Racing, short-duration applications |

Подробная разбивка альтернатив

1. Fuel Cell Technology

Fuel cells convert chemical energy from hydrogen or other fuels into electricity, offering a clean alternative to traditional battery and alternator systems. The primary advantage of fuel cells is their efficiency and the longer range they provide for electric vehicles. However, the upfront costs for fuel cell systems are significantly higher, and they require a reliable hydrogen supply, which may not be readily available in all regions. Additionally, the installation process can be complex, necessitating specialized knowledge and equipment.

2. Supercapacitors

Supercapacitors are energy storage devices that can store and release energy quickly, making them suitable for applications requiring rapid bursts of power. They have a lower initial cost compared to fuel cells and are relatively easy to integrate with existing systems. Their main disadvantage is the limited energy storage capacity, which makes them less suitable for long-term energy needs. Supercapacitors are ideal for racing and applications where quick energy discharge is critical, but they may not replace the conventional alternator and battery system for everyday vehicle use.

Illustrative image related to alternator and battery

Conclusion: How to Choose the Right Power Solution for Your Needs

When considering alternatives to the traditional alternator and battery setup, B2B buyers must assess their specific requirements, including performance needs, budget constraints, and the operational environment. While fuel cell technology offers high efficiency and reduced emissions, its complexity and cost may not be suitable for all markets. On the other hand, supercapacitors present a promising option for applications requiring rapid power delivery but may lack the capacity for prolonged use. Ultimately, understanding the strengths and limitations of each solution will empower buyers to select the most appropriate technology for their vehicles, enhancing operational efficiency and reliability in diverse market conditions.

Essential Technical Properties and Trade Terminology for alternator and battery

What Are the Key Technical Properties of Alternators and Batteries?

Understanding the essential technical properties of alternators and batteries is crucial for B2B buyers seeking reliable and efficient automotive components. Here are some critical specifications:

-

Марка материала

The materials used in the construction of alternators and batteries significantly influence their performance and durability. For example, high-grade aluminum is often used in alternator housings due to its lightweight and corrosion-resistant properties. Similarly, lead-acid batteries utilize lead plates and a sulfuric acid electrolyte, which must meet specific purity standards to ensure longevity. When sourcing components, B2B buyers should prioritize material grades that align with their performance requirements and environmental conditions. -

Номинальная емкость в ампер-часах (Ач)

The Amp Hour rating indicates the battery’s capacity to store and deliver electrical energy. It defines how long a battery can sustain a particular load before needing a recharge. For instance, a battery rated at 100 Ah can theoretically supply 5 amps for 20 hours. Understanding Ah ratings helps buyers select batteries that meet the energy demands of their applications, ensuring operational efficiency. -

Номинальное напряжение

The voltage rating is a critical specification for both batteries and alternators. Standard automotive batteries typically have a voltage of 12 volts, while alternators are designed to output between 13.5 to 14.5 volts to effectively charge the battery. Ensuring compatibility between the battery and alternator voltage ratings is essential for preventing electrical system failures and optimizing performance. -

Амперы холодного пуска (CCA)

CCA measures a battery’s ability to start an engine in cold temperatures. This specification is particularly important in regions with harsh winters. A higher CCA rating indicates better performance in low-temperature conditions. B2B buyers should consider CCA ratings when selecting batteries for vehicles operating in diverse climates to ensure reliability and prevent starting issues. -

Уровни толерантности

Tolerance levels refer to the acceptable range of variation in dimensions and specifications during manufacturing. For alternators and batteries, maintaining tight tolerances is critical for ensuring proper fit and function within the vehicle’s electrical system. Buyers should inquire about the manufacturing tolerances to avoid compatibility issues that could lead to performance degradation.

What Are the Common Trade Terms Related to Alternators and Batteries?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms used in the alternator and battery sector:

-

OEM (производитель оригинального оборудования)

This term refers to companies that manufacture products that are sold under another company’s brand. In the automotive industry, OEM parts are designed to meet the specifications and performance standards of the vehicle manufacturer. B2B buyers often prefer OEM parts for their reliability and compatibility. -

MOQ (минимальный объем заказа)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost structures. Understanding MOQ helps buyers plan their purchasing strategies and avoid overstocking or understocking issues. -

RFQ (запрос предложения)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. In the context of alternators and batteries, submitting an RFQ allows buyers to compare prices, lead times, and terms from different suppliers, facilitating informed purchasing decisions. -

Инкотермс (Международные торговые термины)

These are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers involved in cross-border trade, as they clarify shipping costs, risks, and logistics responsibilities. -

Рынок послепродажного обслуживания

The aftermarket refers to the market for replacement parts and accessories for vehicles after the original sale. B2B buyers in the aftermarket sector should ensure that the components they source meet quality and compatibility standards to maintain customer satisfaction.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when sourcing alternators and batteries, ultimately leading to improved operational efficiency and customer satisfaction.

Illustrative image related to alternator and battery

Navigating Market Dynamics and Sourcing Trends in the alternator and battery Sector

What Are the Key Trends Shaping the Alternator and Battery Market?

The alternator and battery market is witnessing significant transformations driven by technological advancements, environmental considerations, and shifting consumer demands. A major global driver is the increasing adoption of electric vehicles (EVs), which has propelled the demand for high-efficiency batteries and advanced alternators. In regions like Europe and parts of the Middle East, stringent regulations aimed at reducing carbon emissions are fostering innovation in battery technologies, including lithium-ion and solid-state batteries.

Moreover, the rise of smart technologies and the Internet of Things (IoT) is influencing sourcing trends. B2B buyers are increasingly looking for suppliers that offer integrated solutions, such as battery management systems (BMS) that enhance performance and longevity. The trend towards modularity is also significant, as businesses seek customizable solutions that can adapt to diverse applications, from automotive to renewable energy systems.

International buyers, particularly from Africa and South America, are navigating a market characterized by volatility in raw material prices, such as lithium and cobalt. This necessitates strategic sourcing partnerships that can ensure a stable supply chain while also maintaining competitive pricing. Additionally, buyers are encouraged to remain vigilant about geopolitical risks that could affect material availability and pricing.

How Is Sustainability Influencing Sourcing Decisions in the Alternator and Battery Sector?

Sustainability has become a cornerstone of sourcing strategies within the alternator and battery sector. Companies are under increasing pressure to minimize their environmental footprint, driving the demand for ethical sourcing practices. This includes the procurement of raw materials from suppliers that adhere to responsible mining and production practices, particularly concerning lithium and cobalt, which are vital for battery manufacturing.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly prioritizing suppliers that can demonstrate compliance with environmental regulations and social responsibility initiatives. Certifications such as ISO 14001 for environmental management systems and the Responsible Cobalt Initiative are becoming essential criteria in supplier evaluations.

Moreover, the shift towards circular economy principles is gaining traction. B2B buyers are exploring options for battery recycling and repurposing to extend product life cycles and reduce waste. This not only addresses environmental concerns but also opens new revenue streams for businesses engaged in the recycling and refurbishment of battery systems.

What Is the Historical Context of the Alternator and Battery Industry?

The alternator and battery industry has evolved significantly since the early 20th century. Initially, vehicles relied on simple lead-acid batteries to start engines, with alternators introduced later to improve battery life and efficiency. As automotive technology advanced, so did the need for more robust and efficient power sources, leading to the development of sealed batteries and more sophisticated alternator designs.

The introduction of electric and hybrid vehicles in the late 20th century marked a pivotal shift in the industry, necessitating innovations in battery chemistry and energy management. Today, with the advent of renewable energy technologies and the push for sustainability, the focus is on developing batteries that not only power vehicles but also integrate seamlessly with energy grids and renewable sources.

This historical context is essential for B2B buyers, as understanding past trends can provide valuable insights into current market dynamics and future opportunities. As the sector continues to evolve, staying informed about technological advancements and sustainability practices will be crucial for making strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator and battery

-

How do I solve compatibility issues when sourcing alternators and batteries?

To address compatibility issues, first verify the specifications required by your machinery or vehicle. Check the voltage, amperage, and physical dimensions of the alternator and battery to ensure they match your needs. Consulting with the manufacturer or a reliable supplier can help clarify any doubts. Additionally, consider sourcing from suppliers that offer customization options to tailor products to your specific requirements, ensuring optimal performance. -

What is the best battery type for commercial vehicles?

For commercial vehicles, lead-acid batteries are commonly preferred due to their reliability and cost-effectiveness. However, lithium-ion batteries are gaining traction for their lightweight and longer lifespan, making them suitable for more demanding applications. Evaluate your operational requirements, such as power needs and vehicle usage patterns, to determine which battery type will provide the best performance and value for your fleet. -

What factors should I consider when vetting alternator and battery suppliers?

When vetting suppliers, assess their reputation, experience in the industry, and compliance with international quality standards. Request certifications, such as ISO or CE, to ensure product reliability and safety. Additionally, check references and reviews from other B2B buyers. Evaluate their ability to meet your specific needs, including customization options, minimum order quantities (MOQs), and after-sales support. -

What are the typical minimum order quantities (MOQ) for alternators and batteries?

MOQs for alternators and batteries can vary widely based on the supplier and the type of product. Generally, MOQs range from 100 to 1,000 units for standard products. For specialized or customized products, the MOQ may be higher. It’s advisable to discuss your needs directly with suppliers to negotiate favorable terms that align with your purchasing strategy. -

What payment terms should I expect when importing alternators and batteries?

Payment terms can vary by supplier and region. Common arrangements include upfront payments, letters of credit, or net 30/60/90 days. It’s essential to establish clear terms before finalizing any agreements to protect your financial interests. Consider using escrow services for large transactions to ensure both parties fulfill their obligations. Always verify the supplier’s credibility to mitigate risks associated with payment. -

How can I ensure quality assurance (QA) for alternators and batteries?

Implementing a robust quality assurance process involves selecting suppliers who adhere to international quality standards. Request detailed quality control procedures, including testing protocols for performance, safety, and durability. Conduct periodic audits and inspections of the manufacturing facilities, and consider third-party testing services to verify product quality before shipment. Establishing clear quality criteria in your contracts can also help ensure compliance. -

What logistics considerations are important when importing alternators and batteries?

Logistics considerations include selecting reliable shipping methods, understanding customs regulations, and ensuring proper packaging to prevent damage during transit. Collaborate with logistics partners experienced in handling automotive components to streamline the process. Additionally, factor in lead times for production and shipping to align with your inventory management strategy. Understanding incoterms can also clarify responsibilities for shipping costs and risks. -

How do I handle warranty claims for alternators and batteries?

To handle warranty claims effectively, ensure you understand the warranty terms provided by the supplier, including the duration and coverage details. Keep comprehensive records of purchases, including invoices and installation documentation. If a claim arises, communicate promptly with the supplier, providing all necessary evidence to support your claim. Establishing a good relationship with the supplier can facilitate smoother resolutions and potentially enhance support for future issues.

Top 4 Alternator And Battery Manufacturers & Suppliers List

1. Reddit - Автомобильные силовые установки

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: The battery provides power to all electronics, including the starter. The alternator charges the battery when the engine is running. The starter uses battery power to turn over the engine. Symptoms of a dead battery include no power at all, while a failing alternator may cause the battery light to illuminate when the engine is running. A dead battery may result from a bad alternator not charging i…

2. Шина Matthews - проверка электрической системы

Домен: matthewstire.com

Зарегистрирован: 2001 (24 года)

Введение: Matthews Tire offers a complete electrical system check for just $39.95. They provide services related to battery and alternator maintenance, including wiring a battery tender to ensure the vehicle stays charged. The average life of a battery is 4-5 years, and they advise customers to keep track of when the battery was last changed.

3. По всей стране - Альтернаторы и аккумуляторы

Домен: blog.nationwide.com

Зарегистрирован: 1994 (31 год)

Введение: Alternator: Powers the car when the engine is running, charges the battery, lasts the lifetime of the car but may require repair or replacement due to wear and tear. Signs of a bad alternator include dim interior lights, fluctuating headlights, growling noises, and burning smells. Battery: Stores power, starts the engine, delivers electricity to the ignition system, works with the alternator, regu…

4. aaa.com – Bad Alternator vs. Bad Battery Guide

Домен: aaa.com

Зарегистрирован: 1990 (35 лет)

Введение: 1. Bad Alternator vs. Bad Battery: A Quick Guide 2. Battery provides energy to crank the engine and start the vehicle. 3. Starting a car requires 400-2,000 amps depending on engine size. 4. Battery age affects its ability to hold a charge. 5. Signs of a bad battery: struggles to start, won’t hold charge, electrical systems flicker, corrosion on battery, low voltage icon lit, rotten egg smell, swol…

Strategic Sourcing Conclusion and Outlook for alternator and battery

In the evolving landscape of the alternator and battery market, strategic sourcing is essential for international B2B buyers seeking reliability and efficiency. Understanding the interdependent roles of alternators and batteries is critical; a malfunction in one can directly affect the other. As buyers prioritize quality and performance, sourcing from reputable manufacturers and suppliers ensures longevity and optimal vehicle performance, reducing the risk of costly downtime.

Moreover, as global supply chains become increasingly complex, maintaining strong relationships with suppliers across Africa, South America, the Middle East, and Europe can yield competitive advantages. Buyers should consider leveraging technology for real-time inventory management and predictive maintenance, enhancing operational efficiency and reducing lead times.

Illustrative image related to alternator and battery

Looking ahead, the demand for advanced battery technologies, such as lithium-ion and solid-state batteries, is likely to rise, driven by the shift towards electric vehicles and sustainable practices. This presents an opportunity for buyers to invest in innovative solutions that align with future trends.

By prioritizing strategic sourcing today, international B2B buyers can position themselves for success in the dynamic automotive sector of tomorrow. Engage with trusted suppliers and stay informed on technological advancements to ensure your business thrives in this competitive market.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.