Introduction: Navigating the Global Market for different parts of automobile

In today’s dynamic automotive landscape, navigating the global market for different parts of automobiles presents a unique challenge for international B2B buyers. Sourcing reliable components is essential for maintaining operational efficiency and ensuring the safety and performance of vehicles. This comprehensive guide addresses key aspects of the automotive parts market, covering a wide array of components from engines and transmissions to braking systems and electrical systems. It also delves into supplier vetting processes, cost considerations, and the latest trends impacting the automotive sector.

This resource is specifically tailored for B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Nigeria. By providing detailed insights into the types and applications of various automotive parts, this guide empowers buyers to make informed purchasing decisions. Understanding the intricacies of component specifications and supplier reliability is crucial for optimizing supply chain operations and achieving competitive advantages in the marketplace.

Whether you are looking to enhance your procurement strategy or seeking to understand the nuances of different automotive parts, this guide equips you with the knowledge needed to thrive in a globalized environment. With actionable insights and expert recommendations, you can confidently navigate the complexities of sourcing automotive components, ensuring you meet your business needs effectively.

Содержание

- Top 2 Different Parts Of Automobile Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for different parts of automobile

- Understanding different parts of automobile Types and Variations

- Key Industrial Applications of different parts of automobile

- 3 Common User Pain Points for ‘different parts of automobile’ & Their Solutions

- Strategic Material Selection Guide for different parts of automobile

- In-depth Look: Manufacturing Processes and Quality Assurance for different parts of automobile

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘different parts of automobile’

- Comprehensive Cost and Pricing Analysis for different parts of automobile Sourcing

- Alternatives Analysis: Comparing different parts of automobile With Other Solutions

- Essential Technical Properties and Trade Terminology for different parts of automobile

- Navigating Market Dynamics and Sourcing Trends in the different parts of automobile Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of different parts of automobile

- Strategic Sourcing Conclusion and Outlook for different parts of automobile

- Важное предупреждение и условия использования

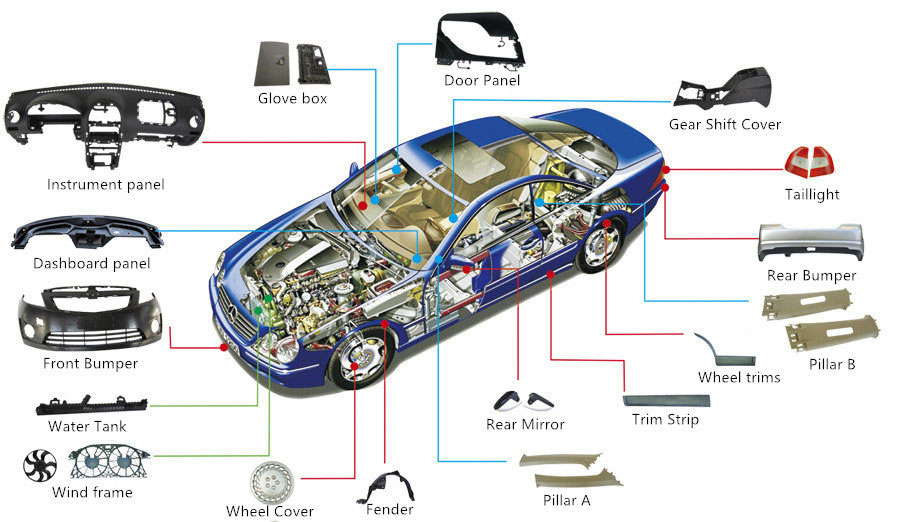

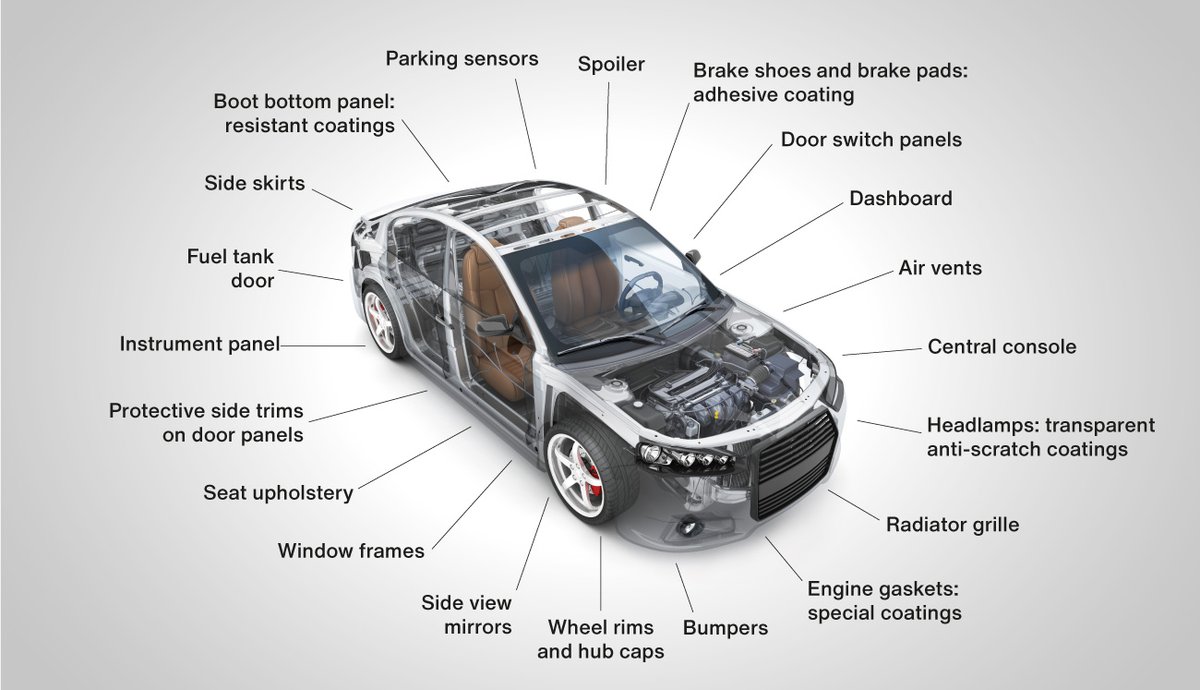

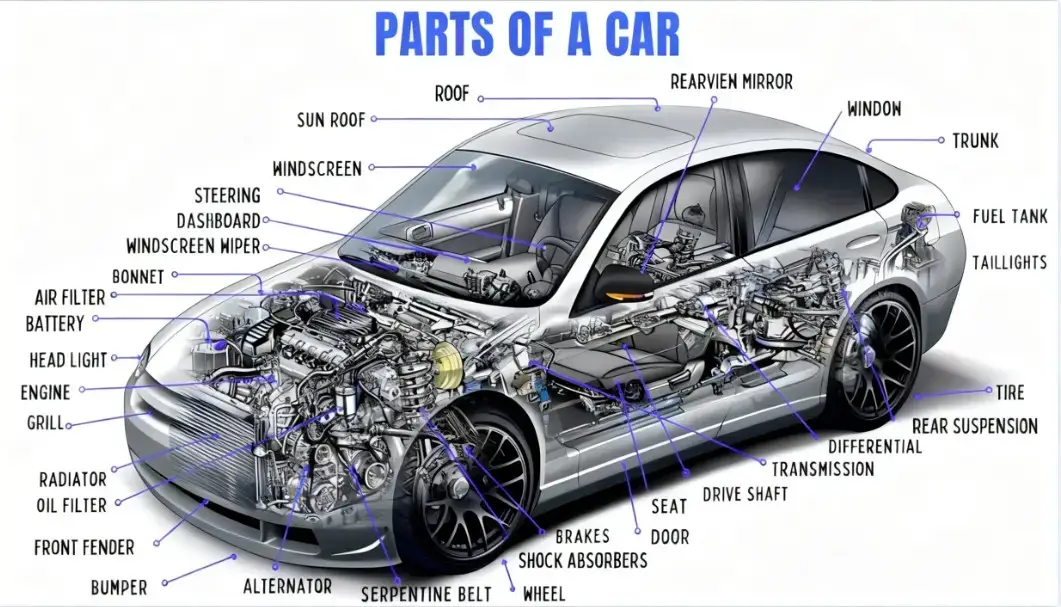

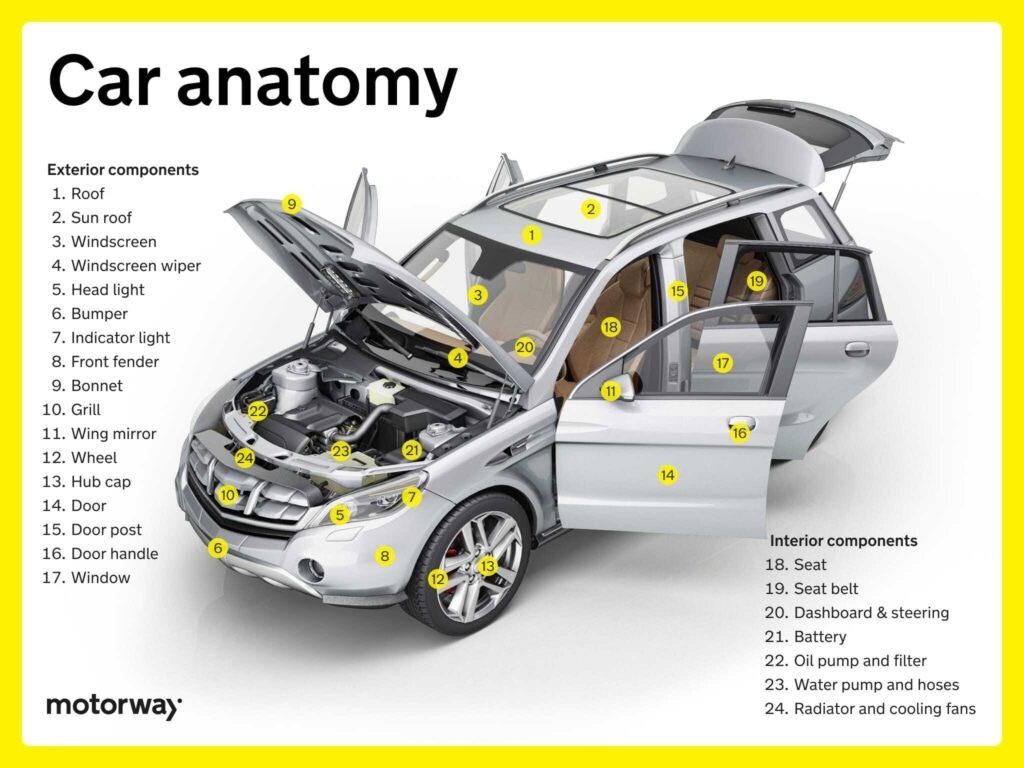

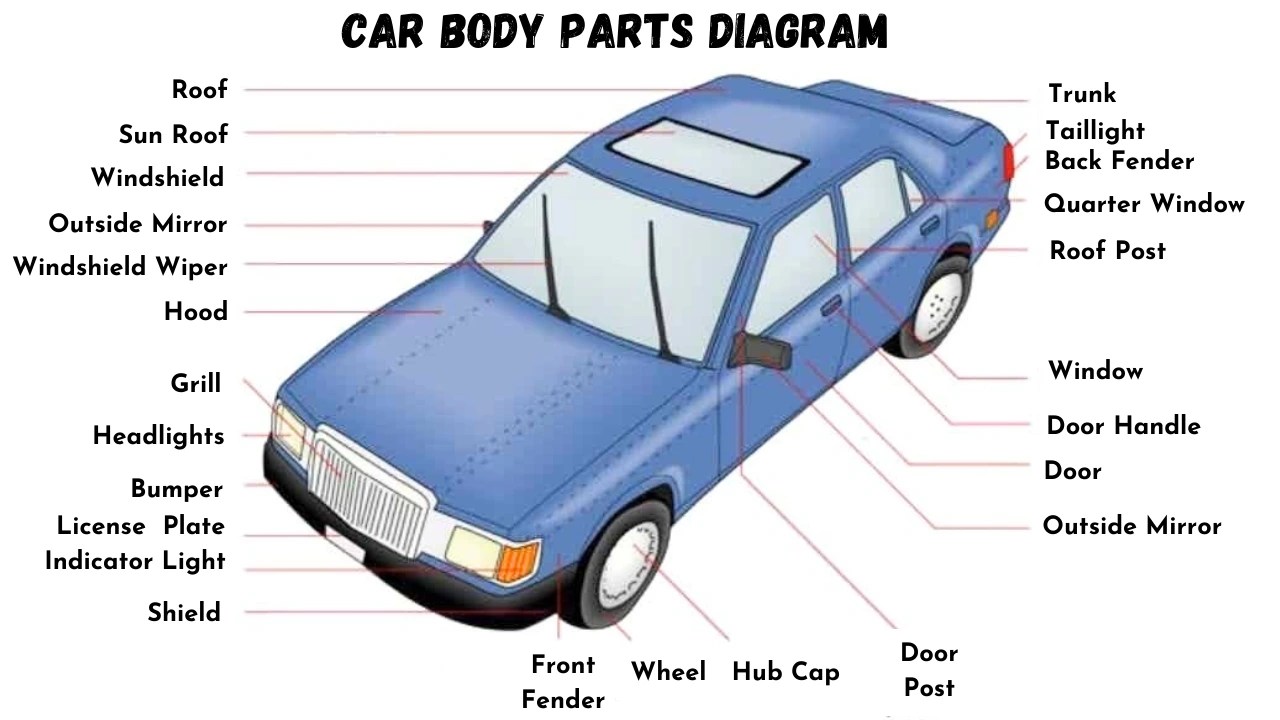

Understanding different parts of automobile Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

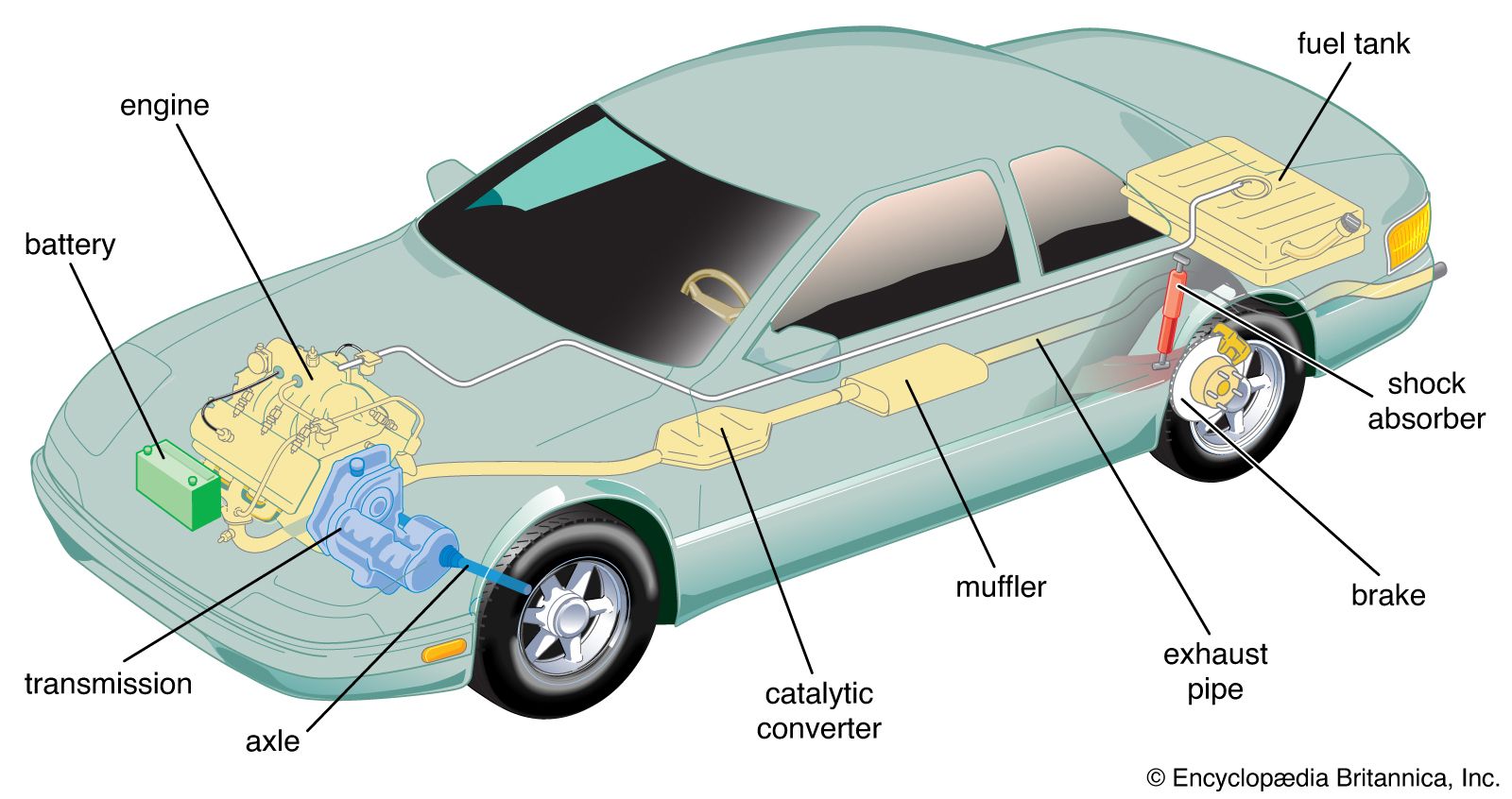

| Компоненты двигателя | Includes pistons, crankshaft, camshaft, and manifolds. | Manufacturing, repair, and aftermarket services. | Плюсы: Essential for vehicle performance. Минусы: High replacement costs. |

| Системы передачи | Types include manual, automatic, and CVT. | Vehicle assembly, repair, and aftermarket parts. | Плюсы: Different options for various driving needs. Минусы: Сложность может привести к повышению стоимости ремонта. |

| Подвесные системы | Comprises front and rear suspension components. | Vehicle assembly, aftermarket, and repair. | Плюсы: Improves ride quality and handling. Минусы: Wear and tear can lead to safety issues. |

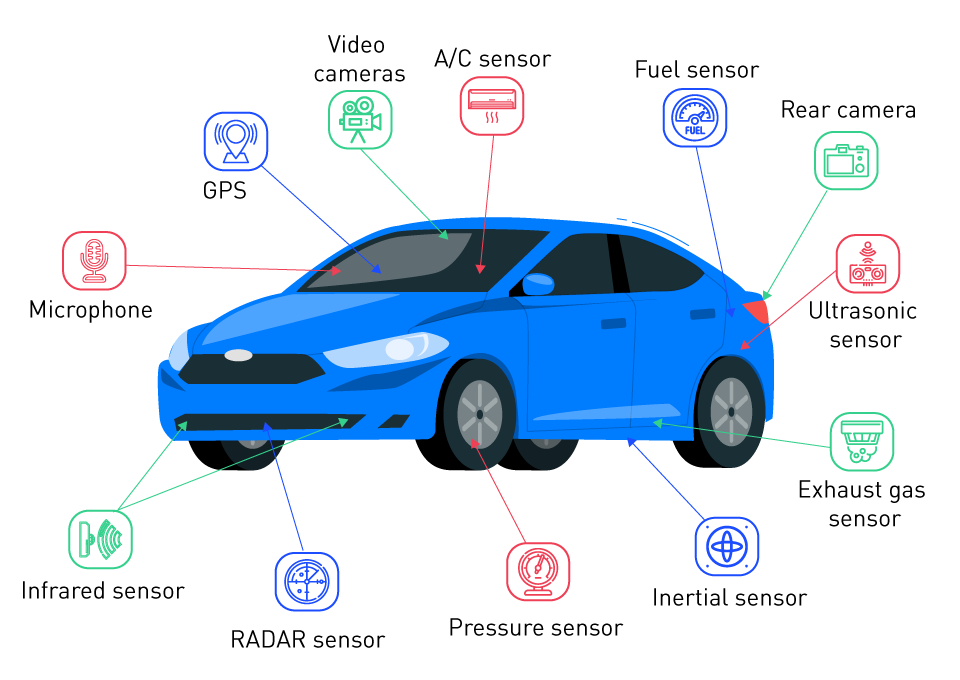

| Электрические системы | Includes batteries, alternators, and wiring harnesses. | Manufacturing, repair, and aftermarket sales. | Плюсы: Critical for vehicle operation. Минусы: Electrical issues can be complex to diagnose. |

| Выхлопные системы | Включает в себя каталитические нейтрализаторы, глушители и выхлопные трубы. | Manufacturing, repair, and emissions compliance. | Плюсы: Reduces emissions and noise. Минусы: Can be costly to replace and repair. |

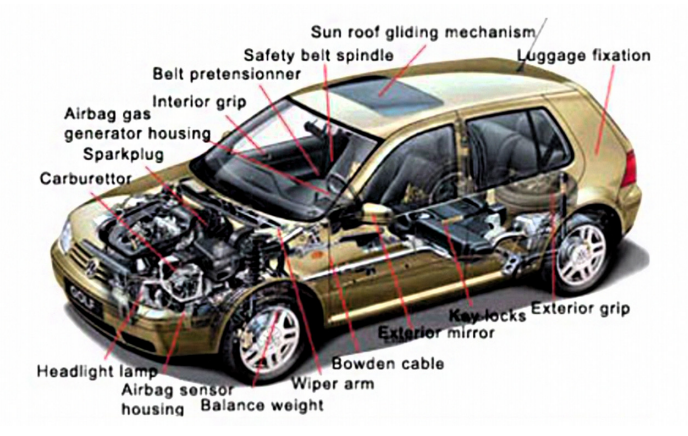

What are the Key Characteristics of Engine Components?

Engine components are fundamental to the vehicle’s operation, comprising elements like pistons, crankshafts, and camshafts. These parts are responsible for converting fuel into mechanical energy, making their condition vital for performance. B2B buyers should consider the quality and compatibility of these components when sourcing, as they directly impact a vehicle’s efficiency and longevity. Investing in high-quality engine parts can lead to reduced maintenance costs and improved vehicle reliability.

Как различаются системы передачи и каковы области их применения?

Transmission systems are categorized into manual, automatic, and continuously variable transmissions (CVT). Each type has its unique mechanism for shifting gears, affecting driving experience and fuel efficiency. B2B buyers should evaluate the specific needs of their target market when selecting transmissions, as the choice can influence overall vehicle performance and customer satisfaction. Understanding the nuances of each transmission type can aid in making informed purchasing decisions.

What Role Do Suspension Systems Play in Vehicle Performance?

Suspension systems are crucial for maintaining vehicle stability and comfort. They consist of various components that absorb shocks and support the vehicle’s weight. For B2B buyers, understanding the differences between front and rear suspension systems can help in selecting the right parts for specific vehicle models. Quality suspension components can enhance ride quality and safety, making them a worthwhile investment for manufacturers and repair shops alike.

Why Are Electrical Systems Critical for Vehicle Functionality?

Electrical systems encompass batteries, alternators, and wiring, which are essential for powering a vehicle’s electrical components. B2B buyers must prioritize sourcing high-quality electrical parts, as they are integral to vehicle functionality and safety. Additionally, understanding the common issues related to electrical systems can aid in selecting parts that are less prone to failure, ultimately enhancing customer satisfaction and reducing return rates.

What Are the Key Considerations for Exhaust Systems in B2B Purchases?

Exhaust systems include components such as catalytic converters and mufflers, which play a vital role in reducing emissions and managing noise levels. B2B buyers should be aware of regulatory compliance regarding emissions standards when sourcing these parts. Furthermore, investing in durable exhaust components can lead to long-term savings by minimizing the frequency of replacements and repairs. Understanding the importance of these systems can guide buyers in making strategic purchasing decisions that align with market demands.

Key Industrial Applications of different parts of automobile

| Отрасль/сектор | Specific Application of different parts of automobile | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Engine components for assembly lines | Streamlined production processes, enhanced reliability | Quality assurance, compliance with international standards, local availability of parts |

| Логистика и транспорт | Braking systems for fleet vehicles | Improved safety and reduced accident rates | Durability under varied conditions, ease of maintenance, supplier reliability |

| Construction and Heavy Equipment | Suspension systems for utility vehicles | Enhanced stability and load-bearing capacity | Customization for specific vehicle types, performance under heavy loads, local support services |

| Automotive Repair and Maintenance | Electrical systems for diagnostics | Efficient repairs and reduced downtime | Availability of spare parts, compatibility with various vehicle models, warranty terms |

| Розничная торговля запчастями | Performance upgrades (e.g., exhaust systems) | Increased customer satisfaction and retention | Trend analysis for popular upgrades, sourcing from reputable manufacturers, competitive pricing |

How Are Engine Components Used in Automotive Manufacturing?

In automotive manufacturing, engine components such as crankshafts, pistons, and camshafts are critical for assembling internal combustion engines. These parts must meet stringent quality standards to ensure performance and reliability. For international B2B buyers, particularly in regions like Africa and South America, sourcing from manufacturers who comply with local regulations and international standards is essential. Additionally, manufacturers should consider the availability of these parts in local markets to avoid delays in production.

What Role Do Braking Systems Play in Logistics and Transportation?

Braking systems are vital for fleet vehicles in logistics and transportation, as they directly impact safety and operational efficiency. Reliable braking systems minimize accident risks and enhance driver confidence. B2B buyers in the Middle East and Europe should focus on sourcing high-quality, durable braking components that can withstand diverse driving conditions. Additionally, ease of maintenance and the availability of support services are crucial for minimizing vehicle downtime.

Why Are Suspension Systems Important in Construction and Heavy Equipment?

Suspension systems in utility vehicles are essential for ensuring stability and load-bearing capacity, particularly in construction settings. These systems must be robust enough to handle rough terrains and heavy loads. Buyers from regions like Nigeria and Saudi Arabia should seek suppliers that offer customized suspension solutions tailored to specific vehicle types. Furthermore, performance under heavy loads and local support services can significantly influence sourcing decisions.

How Do Electrical Systems Enhance Automotive Repair and Maintenance?

Electrical systems are critical in automotive repair and maintenance, particularly for diagnostics and efficient repairs. Components such as batteries, alternators, and wiring harnesses must be readily available to minimize downtime. B2B buyers should prioritize sourcing from suppliers that offer compatibility with a wide range of vehicle models and ensure robust warranty terms. This approach enhances the repair process and builds long-term relationships with customers.

Illustrative image related to different parts of automobile

What Benefits Do Performance Upgrades Provide in Aftermarket Parts Retail?

In the aftermarket parts retail sector, performance upgrades like exhaust systems can significantly enhance vehicle performance, leading to increased customer satisfaction. Retailers must stay informed about market trends to provide popular upgrades that meet customer demands. Sourcing from reputable manufacturers ensures quality and reliability, which is crucial for maintaining a competitive edge. Additionally, competitive pricing strategies can attract more customers, further boosting sales.

3 Common User Pain Points for ‘different parts of automobile’ & Their Solutions

Scenario 1: Sourcing Quality Engine Components Amidst Supply Chain Disruptions

Проблема: B2B buyers often face significant challenges in sourcing high-quality engine components due to fluctuating supply chain dynamics, particularly in regions like Africa and South America. When buyers attempt to procure parts such as crankshafts, camshafts, or pistons, they may encounter delays, inflated prices, and subpar products that do not meet industry standards. This leads to operational inefficiencies and can compromise vehicle performance, resulting in dissatisfied customers and potential financial losses.

Решение: To mitigate these issues, B2B buyers should establish strong relationships with multiple reputable suppliers and manufacturers. Conducting thorough research on supplier backgrounds and their quality control processes is essential. Leveraging technology, such as supply chain management software, can enhance visibility into inventory levels and lead times. Additionally, buyers should consider implementing a just-in-time (JIT) inventory strategy to reduce excess stock while ensuring that critical components are available when needed. Engaging in long-term contracts with suppliers can also stabilize pricing and availability, allowing for better financial planning and reduced risk.

Scenario 2: Ensuring Compatibility of Transmission Parts with Various Vehicle Models

Проблема: When sourcing transmission parts, such as gearboxes or clutches, B2B buyers frequently encounter compatibility issues. Different vehicle models and manufacturers often require specific parts, leading to confusion and increased return rates. This problem is exacerbated when buyers do not have access to accurate technical specifications or when part numbers vary across manufacturers, resulting in costly delays and inventory mismanagement.

Illustrative image related to different parts of automobile

Решение: To address compatibility concerns, B2B buyers should invest in comprehensive cataloging systems that include detailed technical specifications for each part they procure. Utilizing advanced software solutions that integrate with existing inventory systems can facilitate real-time updates on part compatibility and specifications. Additionally, buyers should engage in training sessions with their procurement teams to enhance their understanding of vehicle systems and part requirements. Collaborating with manufacturers to obtain original equipment manufacturer (OEM) parts or verified aftermarket options can further ensure compatibility and reliability, ultimately reducing the likelihood of returns and enhancing customer satisfaction.

Scenario 3: Managing the Lifecycle of Brake Components to Enhance Safety and Performance

Проблема: Brake system failures pose significant safety risks and can lead to serious accidents. B2B buyers in the automotive parts industry often struggle to manage the lifecycle of brake components, such as pads, rotors, and calipers. Frequent wear and tear, coupled with the challenge of predicting maintenance needs, can result in unexpected breakdowns and costly repairs, impacting both the supplier’s reputation and the end user’s safety.

Решение: Implementing a proactive maintenance and monitoring program is crucial for managing brake component lifecycles effectively. B2B buyers should consider adopting predictive analytics tools that can forecast part wear based on vehicle usage patterns. This data-driven approach allows for timely replacements before failures occur. Additionally, establishing a standardized process for inspecting and replacing brake components at regular intervals can enhance performance and safety. Collaborating with trusted manufacturers that provide high-quality, durable brake parts will not only improve safety but also build long-term trust with clients. Finally, offering clients educational resources about the importance of brake maintenance can foster a culture of safety and reliability, ultimately boosting customer loyalty.

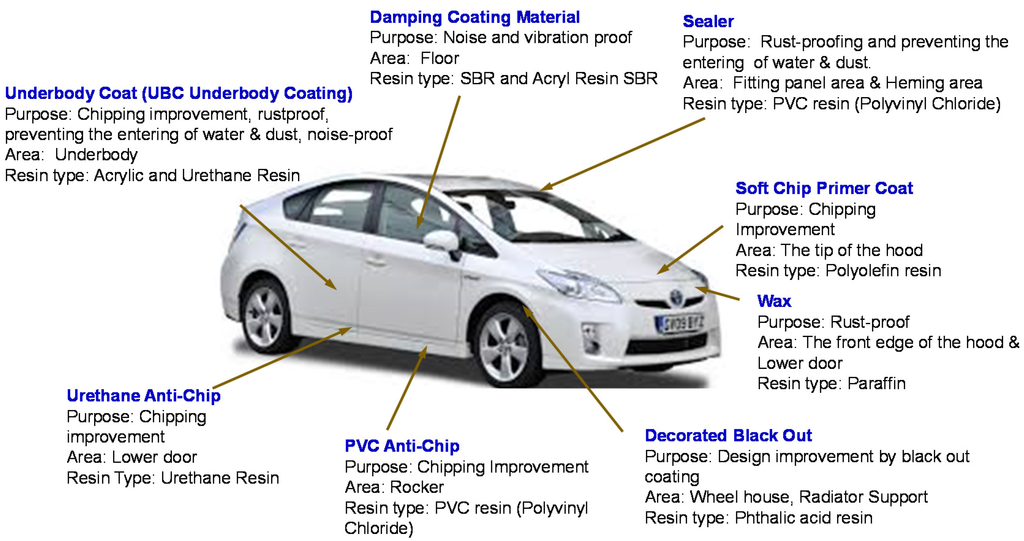

Strategic Material Selection Guide for different parts of automobile

When selecting materials for various parts of automobiles, it is crucial for international B2B buyers to consider the specific properties, advantages, and limitations of each material. This analysis focuses on four common materials used in automotive manufacturing: steel, aluminum, plastic composites, and rubber. Each material presents unique characteristics that can influence product performance, manufacturing processes, and compliance with international standards.

What are the Key Properties of Steel in Automotive Applications?

Steel is widely used in automotive applications due to its high strength and durability. It has excellent temperature and pressure ratings, making it suitable for components such as the chassis, suspension parts, and engine blocks. Steel’s corrosion resistance can be enhanced through galvanization or coatings, which is crucial for vehicles operating in humid or coastal environments.

Плюсы: Steel is relatively low-cost and has high tensile strength, making it ideal for safety-critical components. Additionally, it can be easily welded and formed into complex shapes.

Минусы: Its weight can negatively impact fuel efficiency, and it may require additional processing to improve corrosion resistance.

Illustrative image related to different parts of automobile

Международные соображения: Buyers in regions like Africa and South America should be aware of local steel standards, such as ASTM and EN, to ensure compliance with safety regulations.

How Does Aluminum Benefit Automotive Manufacturing?

Aluminum is increasingly favored for its lightweight properties, which contribute to improved fuel efficiency and performance. It is commonly used in engine components, body panels, and wheels. Aluminum exhibits good corrosion resistance, especially when anodized, and has a high strength-to-weight ratio.

Плюсы: The primary advantage of aluminum is its lightweight nature, which helps reduce overall vehicle weight and enhances fuel economy. It is also recyclable, aligning with sustainability goals.

Минусы: Aluminum is generally more expensive than steel and can be more challenging to weld, requiring specialized techniques.

Международные соображения: Buyers from Europe and the Middle East should consider compliance with aluminum standards like EN and ISO, particularly for vehicles subject to stringent emissions regulations.

What Role Do Plastic Composites Play in Automotive Parts?

Plastic composites are utilized in various automotive applications, including interior components, exterior panels, and under-the-hood parts. These materials can be engineered to provide specific properties, such as impact resistance and thermal stability.

Плюсы: Plastic composites are lightweight and can be molded into intricate shapes, reducing manufacturing complexity. They also offer good corrosion resistance and can be produced at a lower cost compared to metals.

Illustrative image related to different parts of automobile

Минусы: Their durability can be a concern, as they may not withstand high temperatures or mechanical stress as well as metals.

Международные соображения: Buyers should ensure that plastic materials meet relevant standards, such as ASTM and ISO, particularly regarding safety and environmental impact.

Why is Rubber Essential for Automotive Applications?

Rubber is essential for various automotive applications, including tires, seals, and gaskets. It exhibits excellent flexibility and resilience, making it ideal for components that require shock absorption and vibration dampening.

Illustrative image related to different parts of automobile

Плюсы: Rubber’s ability to withstand extreme temperatures and its excellent sealing properties make it invaluable in maintaining vehicle performance.

Минусы: Rubber can degrade over time due to exposure to UV light and ozone, requiring regular maintenance and replacement.

Международные соображения: Buyers should be aware of rubber standards, such as ASTM D2000, to ensure compatibility with various automotive applications, especially in regions with harsh climates.

Illustrative image related to different parts of automobile

Сводная таблица выбора материалов для автомобильных деталей

| Материал | Typical Use Case for different parts of automobile | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Сталь | Chassis, suspension parts, engine blocks | Высокая прочность и низкая стоимость | Heavy, requires corrosion protection | Низкий |

| Алюминий | Engine components, body panels, wheels | Lightweight, recyclable | Higher cost, difficult to weld | Высокий |

| Пластиковые композиты | Interior components, exterior panels, under-the-hood parts | Lightweight, moldable, low manufacturing cost | May lack durability under stress | Средний |

| Резина | Tires, seals, gaskets | Excellent flexibility and sealing properties | Degrades over time, requires maintenance | Средний |

This strategic material selection guide provides B2B buyers with essential insights into the properties and considerations for various materials used in automotive manufacturing. Understanding these factors can lead to more informed purchasing decisions that align with both performance and compliance requirements in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for different parts of automobile

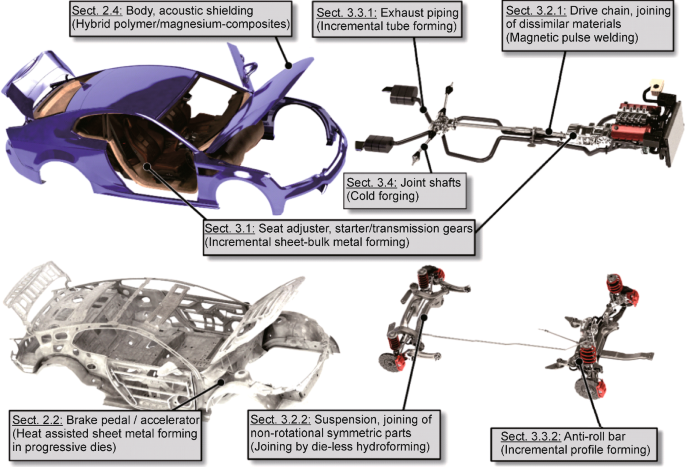

What Are the Typical Manufacturing Processes for Different Parts of Automobiles?

The manufacturing of automobile parts involves a series of intricate stages, each critical to ensuring quality and performance. Understanding these processes is essential for B2B buyers seeking to source components effectively.

How Is Material Prepared for Automobile Part Manufacturing?

Material preparation is the first step in the manufacturing process. It involves selecting appropriate raw materials, which can vary based on the part being produced. Common materials include metals (like steel and aluminum), plastics, and composites.

Illustrative image related to different parts of automobile

Once materials are selected, they undergo several processes, including cutting, machining, and surface treatment. For instance, steel sheets may be cut into specific shapes using laser cutting or shearing techniques, while aluminum parts could undergo extrusion or die casting. Ensuring that the materials meet specific mechanical properties is crucial, as these properties will affect the performance and safety of the final product.

What Forming Techniques Are Used in Automotive Manufacturing?

The forming stage involves shaping the prepared materials into the desired components. Various techniques are employed depending on the part’s complexity and material properties.

-

Штамповка: Commonly used for metal parts, stamping involves placing a flat sheet of metal into a stamping press, where it is shaped into the desired form using dies.

-

Кастинг: This technique is widely used for complex shapes, such as engine blocks. Molten metal is poured into a mold and allowed to solidify.

-

Литье под давлением: For plastic parts, injection molding is a prevalent technique. Plastic pellets are heated until they become liquid and then injected into a mold to take the shape of the desired part.

-

Обработка: For precision parts, machining processes such as turning, milling, and grinding are employed to achieve exact dimensions and surface finishes.

How Are Automobile Parts Assembled?

Assembly is a critical phase where individual parts come together to form a complete component or system. This process can be highly automated or manual, depending on the complexity and volume of production.

Illustrative image related to different parts of automobile

Automotive assembly often involves:

- Подборка: Smaller parts are assembled into modules (like a transmission assembly) before being integrated into the final product.

- Use of Jigs and Fixtures: These tools help ensure accuracy and repeatability during assembly, reducing the likelihood of defects.

- Интеграция электрических компонентов: For modern vehicles, integrating electronic systems requires precise assembly techniques to ensure functionality and reliability.

What Are the Finishing Processes in Automobile Manufacturing?

Finishing processes are vital for ensuring that parts meet aesthetic and functional standards. These processes include:

- Обработка поверхности: Techniques such as painting, anodizing, or powder coating enhance appearance and protect against corrosion.

- Проверка качества: Parts undergo visual inspections, as well as more rigorous testing, to ensure they meet specifications.

What Quality Assurance Measures Are Essential for Automotive Parts?

Quality assurance (QA) is integral to the automotive manufacturing process, ensuring that each part meets both safety and performance standards.

Какие международные стандарты должны знать покупатели B2B?

International standards, such as ISO 9001, provide a framework for quality management systems, ensuring consistent quality across manufacturing processes. Additionally, industry-specific standards like CE marking for Europe and API standards for automotive components are crucial. B2B buyers should verify that suppliers comply with these standards to ensure product quality and safety.

Каковы ключевые точки контроля качества в производстве?

Контроль качества (QC) включает в себя несколько контрольных точек на протяжении всего производственного процесса:

-

Входящий контроль качества (IQC): This initial inspection ensures that raw materials meet specified standards before production begins.

-

Контроль качества в процессе производства (IPQC): During manufacturing, various tests are conducted to monitor processes and detect any deviations from quality standards.

-

Окончательный контроль качества (FQC): After assembly, a thorough inspection is performed to ensure that the final product meets all specifications and is free from defects.

What Testing Methods Are Commonly Used in Automotive Quality Assurance?

Testing methods can vary significantly based on the part and its function. Common testing methods include:

- Dimensional Inspection: Using tools like calipers and micrometers to ensure parts meet specified dimensions.

- Функциональное тестирование: Assessing whether parts perform as intended under operational conditions.

- Неразрушающий контроль (NDT): Techniques such as ultrasonic testing and X-ray inspection help identify internal flaws without damaging the part.

Как покупатели B2B могут проверить контроль качества поставщиков?

Verifying the quality control measures of suppliers is essential for B2B buyers, especially when sourcing internationally. Here are some effective strategies:

- Проведение аудиторских проверок: Regular audits of suppliers’ manufacturing facilities can provide insights into their quality management systems and practices.

- Запрос отчетов о качестве: Buyers should request detailed QC reports, including data on defect rates and compliance with international standards.

- Utilizing Third-Party Inspectors: Engaging third-party inspection services can offer an unbiased assessment of product quality before shipment.

Каковы нюансы контроля качества для международных B2B-покупателей?

International B2B buyers must navigate various quality control nuances. For instance, understanding the certification requirements specific to their region is critical, as different markets may have varying standards and regulations. Additionally, language barriers and cultural differences can affect communication regarding quality expectations.

Buyers should ensure that they establish clear specifications and expectations with their suppliers from the outset and consider engaging local representatives or consultants familiar with the regional market dynamics.

Заключение

Understanding the manufacturing processes and quality assurance measures for automobile parts is crucial for B2B buyers aiming to source high-quality components. By familiarizing themselves with material preparation, forming techniques, assembly, and finishing processes, as well as the relevant quality assurance standards and testing methods, buyers can make informed decisions and foster successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different parts of automobile’

Введение

Navigating the procurement of automobile parts can be complex, especially for international B2B buyers. This guide provides a comprehensive checklist to streamline your sourcing process, ensuring you make informed decisions that align with your operational needs and standards. By following these steps, you can enhance your supply chain efficiency and secure high-quality components.

Шаг 1: Определите свои технические характеристики

Clearly outline the technical requirements for the automobile parts you need. This step is crucial because precise specifications ensure that the parts will be compatible with your vehicle models and meet performance standards.

– Considerations: Include details such as dimensions, materials, and industry standards (e.g., ISO certifications) that the parts must adhere to.

Шаг 2: Проведение маркетинговых исследований

Understanding the market landscape is essential for identifying potential suppliers. Research different manufacturers and distributors in various regions to compare pricing, quality, and availability.

– Action Items: Utilize industry reports and online platforms to gather information on supplier reputation and product offerings. This knowledge can help you negotiate better terms and identify reliable partners.

Шаг 3: Оцените потенциальных поставщиков

Before committing to a supplier, conduct a thorough evaluation to ensure they can meet your needs. Assess their production capabilities, quality control processes, and past performance.

– Verification: Request company profiles, certifications, and references. It’s beneficial to connect with other businesses in your industry for feedback on their experiences with the supplier.

Шаг 4: Проверка сертификатов поставщиков

Ensuring that your suppliers hold relevant certifications can safeguard your business against quality issues. Certifications such as ISO 9001 (Quality Management) or IATF 16949 (Automotive Quality Management) indicate adherence to industry standards.

– Важность: These certifications demonstrate a commitment to quality and consistency, reducing the risk of defects and ensuring compliance with international regulations.

Шаг 5: Request Samples and Test Quality

Before placing a bulk order, request samples of the parts to assess their quality firsthand. This step is vital to confirm that the products meet your specifications and performance criteria.

– Тестирование: Conduct thorough tests on the samples, checking for durability, compatibility, and overall quality. This process can prevent costly mistakes and ensure customer satisfaction.

Шаг 6: Обсудить условия и положения

Once you have selected a supplier, negotiate favorable terms and conditions that protect your interests. Discuss pricing, payment terms, lead times, and warranties to establish a clear agreement.

– Key Considerations: Ensure that all terms are documented in a formal contract to avoid misunderstandings in the future.

Illustrative image related to different parts of automobile

Шаг 7: Establish a Logistics Plan

Finally, develop a logistics plan for the delivery of your parts. Consider factors such as shipping methods, costs, and timelines to ensure timely receipt of components.

– Coordination: Work closely with your supplier to understand their shipping capabilities and address any potential delays in advance.

By following this checklist, you can streamline your sourcing process for automobile parts, ensuring that you make informed decisions that support your business goals and operational efficiency.

Comprehensive Cost and Pricing Analysis for different parts of automobile Sourcing

Understanding the cost structure and pricing for various automobile parts is crucial for B2B buyers aiming to optimize their procurement processes. The automotive supply chain is multifaceted, with several cost components influencing the final price. By breaking down these components and understanding the various price influencers, international buyers can make informed decisions and negotiate effectively.

What Are the Key Cost Components in Automobile Parts?

-

Материалы: The raw materials required for automobile parts, such as steel, aluminum, plastics, and rubber, form a significant portion of the cost. Prices fluctuate based on global supply and demand, so keeping abreast of market trends can help buyers anticipate costs.

-

Трудовые ресурсы: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs, such as parts of Africa and South America, may offer more competitive pricing. However, it’s essential to consider the skill level and training of the workforce, as this can affect quality.

-

Производственные накладные расходы: This includes costs related to utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can lower overhead costs, which, in turn, can reduce the price of parts.

-

Инструменты: The initial investment in tooling can be substantial, particularly for custom parts. Buyers should account for this cost, especially when ordering low volumes, as it can significantly impact the unit price.

-

Контроль качества (КК): Implementing stringent QC measures ensures the reliability and safety of automotive parts. While this adds to the cost, it is crucial for maintaining standards, especially for markets with strict regulations.

-

Логистика: Shipping costs can vary based on distance, mode of transport, and the complexity of the supply chain. Buyers should consider logistics when calculating total costs, as delays or inefficiencies can lead to increased expenses.

-

Маржа: Suppliers typically add a profit margin to cover their risks and operational costs. Understanding the market can help buyers gauge if the margins are reasonable or if they can negotiate better terms.

How Do Price Influencers Affect Automobile Part Costs?

-

Объем/MOQ (минимальный объем заказа): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their purchasing patterns to maximize cost efficiency.

-

Технические характеристики и индивидуальная настройка: Custom parts or those with specific technical requirements may incur additional costs. Buyers should weigh the necessity of customization against the potential price increase.

-

Качество материалов и сертификаты: Parts that require higher-grade materials or specific certifications will naturally cost more. Buyers should evaluate the balance between cost and quality to ensure optimal performance.

-

Факторы, связанные с поставщиками: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their perceived quality and service, while new entrants might offer lower prices to gain market share.

-

Инкотермс: Understanding Incoterms is vital for international transactions. They dictate who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost.

What Negotiation Strategies Can Buyers Use for Cost Efficiency?

-

Используйте скидки за объем: Buyers can negotiate lower prices by committing to larger orders, which can offset the tooling and logistics costs.

-

Изучите альтернативных поставщиков: Evaluating multiple suppliers can create competitive pricing pressure, allowing buyers to negotiate better terms.

-

Сосредоточьтесь на общей стоимости владения (TCO): Buyers should consider not just the purchase price but also the long-term costs associated with maintenance, durability, and performance. A higher upfront cost may lead to lower TCO over time.

-

Understand Regional Market Dynamics: For buyers in Africa, South America, the Middle East, and Europe, being aware of local market conditions, currency fluctuations, and trade regulations can provide leverage in negotiations.

-

Стройте долгосрочные отношения: Establishing strong relationships with suppliers can lead to better pricing and improved service over time.

Заключение

Navigating the complexities of automobile parts sourcing requires a comprehensive understanding of cost structures and price influencers. By leveraging this knowledge, B2B buyers can negotiate effectively and make strategic purchasing decisions that enhance their operational efficiency and profitability. Always remember that pricing can vary significantly based on multiple factors, so maintaining flexibility and adaptability in sourcing strategies is key.

Illustrative image related to different parts of automobile

Alternatives Analysis: Comparing different parts of automobile With Other Solutions

Exploring Alternatives to Traditional Automobile Parts

In the evolving automotive landscape, understanding the alternatives to traditional automobile parts can offer significant advantages to B2B buyers. This section provides a comparative analysis of standard vehicle components against emerging technologies, focusing on their performance, cost, ease of implementation, maintenance, and best use cases. By evaluating these alternatives, businesses can make informed decisions tailored to their operational needs.

| Аспект сравнения | Different Parts Of Automobile | Компоненты для электромобилей | Modular Vehicle Systems |

|---|---|---|---|

| Производительность | High efficiency, proven reliability, but may lag in fuel efficiency compared to electric solutions | Superior efficiency, instant torque, and lower emissions | Customizable performance tailored to specific requirements |

| Стоимость | Generally lower upfront cost, but higher long-term maintenance | Higher initial investment, potential savings on fuel and maintenance | Variable costs depending on configuration and parts used |

| Простота внедрения | Widely available, established supply chains | Requires specialized knowledge and infrastructure for installation | Flexible integration but may require training for installation |

| Техническое обслуживание | Routine maintenance needed, parts are readily available | Generally lower maintenance, fewer moving parts | Maintenance varies based on components chosen, may require specialized support |

| Лучший вариант использования | Suitable for conventional vehicles and established markets | Best for urban environments with charging infrastructure | Ideal for businesses seeking customization and adaptability |

What Are the Advantages and Disadvantages of Electric Vehicle Components?

Electric vehicle (EV) components represent a significant shift from traditional automobile parts. They offer superior efficiency and lower emissions, appealing to environmentally conscious consumers and businesses. The instant torque provided by electric motors enhances performance, making vehicles more responsive. However, the initial investment can be substantial, and businesses may face challenges in adapting to the new technology, including the need for specialized training and infrastructure for charging stations.

How Do Modular Vehicle Systems Compare?

Modular vehicle systems provide flexibility and customization that traditional parts cannot match. Businesses can tailor their vehicles to specific operational needs by selecting components suited for particular tasks, whether for transportation, logistics, or specialized applications. While these systems can be more adaptable and potentially cost-effective over time, they may require more extensive planning and training for implementation. Maintenance can also vary widely based on the components chosen, necessitating a knowledgeable support system.

Illustrative image related to different parts of automobile

Making the Right Choice: Which Solution Fits Your Needs?

When selecting the right automotive solution, B2B buyers should consider their specific operational requirements, budget constraints, and long-term goals. Traditional automobile parts offer reliability and lower initial costs, making them suitable for established markets. In contrast, electric vehicle components and modular systems provide innovative alternatives that may align better with sustainability goals and operational flexibility. Evaluating these options in the context of your unique business needs will facilitate informed decision-making and ultimately enhance operational efficiency and effectiveness.

Essential Technical Properties and Trade Terminology for different parts of automobile

What Are the Key Technical Properties of Automobile Parts?

In the automotive industry, understanding the technical specifications of parts is crucial for B2B buyers. Here are several essential properties that define the performance and reliability of automotive components:

-

Марка материала: This refers to the classification of materials used in manufacturing parts, such as steel, aluminum, or composites. Each material has unique properties affecting durability, weight, and corrosion resistance. For instance, high-grade steel is often used for structural components due to its strength, while aluminum is preferred for parts where weight reduction is essential, such as in engine components. Buyers should prioritize material grade based on the intended application and environmental conditions.

-

Толерантность: Tolerance defines the allowable variation in dimensions for a part. It is critical for ensuring that components fit together correctly and function as intended. Tight tolerances are essential in precision parts like engine components, where even minor deviations can lead to performance issues. Understanding tolerance levels helps buyers assess the manufacturing capabilities of suppliers and ensure compatibility with existing systems.

-

Термообработка: This process enhances the properties of materials, such as hardness and strength, by altering their microstructure through controlled heating and cooling. Parts like gears and shafts often undergo heat treatment to withstand high-stress conditions. Buyers should inquire about heat treatment processes to ensure that components can handle specific operational demands.

-

Surface Finish: The surface finish of a part affects its performance, wear resistance, and aesthetic appeal. Common finishes include anodizing, plating, and polishing. For instance, components exposed to friction, like brake parts, require specific surface treatments to reduce wear and improve lifespan. Buyers should specify the desired surface finish based on functional and aesthetic requirements.

-

Коррозионная стойкость: This property is vital, especially in regions with harsh environmental conditions. Parts made from stainless steel or treated with protective coatings can resist corrosion, ensuring longevity. Buyers should evaluate the corrosion resistance of parts based on their application, particularly in automotive environments where exposure to moisture and chemicals is common.

-

Грузоподъемность: This specification indicates the maximum load a component can safely handle without failure. It is especially important for suspension and braking systems. Buyers must assess load capacity to ensure that parts meet safety standards and performance expectations.

Каковы общие торговые термины в автомобильной промышленности?

Understanding industry jargon can significantly enhance communication and negotiations in B2B transactions. Here are key terms relevant to automotive parts:

-

OEM (производитель оригинального оборудования): This term refers to companies that produce parts that are used in the original manufacturing of vehicles. OEM parts are often seen as higher quality and reliability compared to aftermarket alternatives, making them a preferred choice for many buyers looking for longevity and performance.

-

MOQ (минимальный объем заказа): This is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory levels and budget constraints. Negotiating MOQs can lead to better pricing and supply chain efficiency.

-

RFQ (запрос предложения): An RFQ is a formal process where buyers request price quotes from suppliers for specific parts. It helps buyers compare costs and terms across different vendors, facilitating informed purchasing decisions.

-

Инкотермс (Международные торговые термины): These are standardized trade terms that clarify the responsibilities of buyers and sellers in international transactions, particularly regarding shipping and delivery. Understanding Incoterms is essential for managing logistics and ensuring compliance with international trade regulations.

-

Время выполнения заказа: This refers to the time it takes from placing an order to receiving the parts. Knowing lead times helps buyers plan their production schedules and manage inventory effectively. Longer lead times may necessitate larger safety stocks to avoid production delays.

-

Рынок послепродажного обслуживания: This term encompasses parts and accessories sold for vehicles after the original sale. Aftermarket parts can provide cost-effective alternatives to OEM parts, but buyers should assess quality and compatibility to ensure they meet performance standards.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions that enhance operational efficiency and product reliability in the automotive sector.

Navigating Market Dynamics and Sourcing Trends in the different parts of automobile Sector

What Are the Current Market Dynamics and Key Trends in the Automobile Parts Sector?

The automobile parts sector is undergoing significant transformation influenced by global drivers such as technological advancements, changing consumer preferences, and regulatory demands. In recent years, the rise of electric vehicles (EVs) has reshaped the landscape, driving demand for new components like battery systems and regenerative braking systems. B2B buyers in regions such as Africa, South America, the Middle East, and Europe must navigate these shifts by staying informed about the latest technologies and sourcing strategies.

Illustrative image related to different parts of automobile

Emerging technologies, including Industry 4.0 practices such as IoT and AI, are streamlining supply chains and enhancing operational efficiencies. These innovations enable suppliers to offer real-time tracking of parts, predictive maintenance, and improved inventory management. International buyers should prioritize partnerships with suppliers that leverage these technologies to ensure they remain competitive in a rapidly evolving market.

Furthermore, the impact of globalization on sourcing trends cannot be overlooked. Many businesses are diversifying their supply chains to mitigate risks associated with geopolitical uncertainties and trade tariffs. This trend encourages buyers to explore local sourcing options, particularly in regions like Africa and South America, where there is a growing manufacturing base for automobile parts. By adapting to these market dynamics, B2B buyers can optimize their procurement processes and enhance their supply chain resilience.

How Is Sustainability and Ethical Sourcing Influencing the Automobile Parts Market?

Sustainability has emerged as a critical focus within the automobile parts sector, driven by increasing regulatory pressure and consumer demand for environmentally responsible practices. The environmental impact of automobile production and operation is significant, prompting businesses to consider sustainable sourcing options. For international buyers, this means prioritizing suppliers who adhere to sustainable practices and offer ‘green’ certifications for their products.

Ethical supply chains are becoming paramount, as stakeholders demand transparency in sourcing materials. This includes ensuring that raw materials are obtained responsibly, without contributing to environmental degradation or human rights violations. Buyers should seek out suppliers who can demonstrate compliance with international standards and certifications, such as ISO 14001 for environmental management and SA8000 for social accountability.

In addition, the adoption of recycled materials in the manufacturing of automobile parts is gaining traction. By integrating recycled plastics, metals, and other materials into their products, manufacturers can reduce waste and lower their carbon footprints. B2B buyers should engage with suppliers who are committed to using sustainable materials, as this not only meets regulatory requirements but also appeals to a growing segment of eco-conscious consumers.

What Is the Evolution of the Automobile Parts Sector Relevant to B2B Buyers?

The evolution of the automobile parts sector is marked by significant technological advancements and shifts in consumer behavior. Historically, the industry focused on internal combustion engines, with parts largely centered around mechanical components. However, the advent of electronic vehicles and hybrid technology has necessitated a shift towards more complex electronic and software-driven components.

As the sector continues to evolve, B2B buyers must remain agile and informed about these changes. The transition to electric vehicles, for instance, requires a different set of components such as battery packs, electric motors, and advanced electronic control units. Understanding these trends allows buyers to make informed decisions about sourcing and partnerships, ensuring they are aligned with future market demands.

Moreover, the historical context of globalization has expanded sourcing opportunities, enabling buyers to tap into emerging markets for parts production. As countries like Nigeria and Brazil enhance their manufacturing capabilities, international buyers can leverage these developments to create more resilient and cost-effective supply chains.

By keeping abreast of these historical and contemporary trends, B2B buyers can enhance their strategic sourcing initiatives and better position themselves within the competitive landscape of the automobile parts sector.

Frequently Asked Questions (FAQs) for B2B Buyers of different parts of automobile

-

1. How do I solve the challenge of finding reliable suppliers for automobile parts?

To find reliable suppliers, conduct thorough research by leveraging platforms like Alibaba, Global Sources, or industry-specific trade shows. Verify their credentials through customer reviews, references, and certifications. Initiate small test orders to evaluate product quality and service reliability. Establish direct communication to discuss your specific needs, timelines, and any customization options. Building a relationship with suppliers can lead to better terms and more reliable service. -

2. What is the best way to determine the quality of automobile parts?

Assessing quality involves checking certifications such as ISO standards, conducting factory audits, and reviewing material specifications. Request samples to evaluate the craftsmanship and durability of parts before placing larger orders. Utilize third-party inspection services to ensure compliance with international standards. Understanding the warranty and return policies can also provide insights into the manufacturer’s confidence in their products. -

3. How can I customize automobile parts for specific needs?

Customization typically requires direct communication with the supplier about your specific requirements. Discuss the technical specifications, materials, and design changes you need. Many manufacturers offer custom engineering services and can accommodate variations in size, color, or functionality. Ensure to ask about any minimum order quantities (MOQs) for customized parts, as they can differ significantly from standard products. -

4. What are typical payment terms when sourcing automobile parts internationally?

Payment terms can vary widely among suppliers but generally include options such as upfront payment, letters of credit, or payment upon delivery. Negotiate favorable terms that align with your cash flow and risk tolerance. Using escrow services can provide security for both parties. Always clarify the currency in which transactions will be made and be mindful of any additional fees related to international transfers. -

5. What minimum order quantities (MOQs) should I expect for automobile parts?

MOQs can differ based on the supplier and the type of parts being ordered. Commonly, MOQs range from 50 to 1,000 units, especially for customized items. Suppliers often have lower MOQs for standard parts due to economies of scale. Discuss your needs with potential suppliers to see if they can accommodate smaller orders, especially when starting a new partnership. -

6. How do I ensure compliance with international trade regulations when importing automobile parts?

To ensure compliance, familiarize yourself with the import regulations of your country, including tariffs, customs duties, and safety standards. Work with a customs broker who can guide you through the documentation process. Ensure your suppliers provide necessary certifications and compliance documentation for the parts being imported. Regularly review updates in trade laws as they can affect your sourcing strategy. -

7. What logistics considerations should I keep in mind when sourcing automobile parts internationally?

Logistics involve choosing the right shipping method based on cost, speed, and reliability. Consider factors such as shipping times, customs clearance processes, and the supplier’s location. Collaborate with logistics providers who have experience in handling automotive parts to ensure safe transport. Additionally, be aware of insurance options to cover potential damages during transit. -

8. How can I effectively manage quality assurance (QA) for automobile parts sourced internationally?

Implement a robust QA process by establishing clear specifications for the parts you order. Conduct pre-shipment inspections to verify that parts meet quality standards. Collaborate with suppliers to create a quality control checklist and encourage them to maintain consistent quality. Regularly review and audit supplier performance to ensure ongoing compliance with your standards and address any issues proactively.

Top 2 Different Parts Of Automobile Manufacturers & Suppliers List

1. Moog – Auto Parts

Домен: moogparts.com

Зарегистрирован: 2005 (20 лет)

Введение: Части автомобиля включают в себя: Рулевое колесо, двигатель (с такими деталями, как цепь ГРМ, распределительный вал, коленчатый вал, свечи зажигания, головки блока цилиндров, клапаны, поршни), коробка передач, аккумулятор, генератор, радиатор, передний мост, переднее рулевое управление и подвеска (включая амортизаторы/стойки, шаровые шарниры, наконечники тяг, реечный рулевой механизм, натяжные/карданные рычаги), тормоза (дисковые тормоза с колодками и суппортами, барабанные тормоза...

2. Reddit – Automotive Maintenance

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Эта компания, Reddit - Automotive Maintenance, является заметным субъектом на рынке. Для получения подробной информации о продукции рекомендуем посетить их сайт.

Strategic Sourcing Conclusion and Outlook for different parts of automobile

As the automotive industry continues to evolve, strategic sourcing remains a critical component for international B2B buyers seeking to optimize their supply chains. Understanding the diverse parts of an automobile—from engines and transmissions to braking systems and electrical components—enables businesses to make informed decisions that enhance operational efficiency and drive profitability.

The value of strategic sourcing lies not just in cost savings, but also in building long-term relationships with reliable suppliers who can provide high-quality components that meet stringent safety and performance standards. This is especially pertinent for buyers in regions like Africa, South America, the Middle East, and Europe, where market dynamics and consumer preferences vary widely.

Looking ahead, international buyers are encouraged to leverage data-driven insights and technological advancements to stay ahead of market trends. By prioritizing strategic sourcing, businesses can ensure they are well-equipped to navigate challenges and seize opportunities in the global automotive landscape. Engage with reputable suppliers, invest in robust supply chain practices, and remain agile to adapt to future demands. Your proactive approach today will pave the way for sustained success tomorrow.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Illustrative image related to different parts of automobile

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.