Введение: Навигация по глобальному рынку запчастей для автомобильных стартеров

В сложном ландшафте глобального рынка автомобильных запчастей поиск высококачественных деталей автомобильного стартера представляет собой серьезную проблему для международных покупателей B2B. С различными стандартами, правилами и динамикой рынка предприятия в таких регионах, как Африка, Южная Америка, Ближний Восток и Европа (включая такие страны, как Саудовская Аравия и Вьетнам), должны ориентироваться в огромном количестве вариантов, чтобы убедиться, что они принимают обоснованные решения о покупке. Данное всеобъемлющее руководство призвано упростить этот процесс, предоставляя важные сведения о типах доступных стартерных двигателей, их применении в различных моделях автомобилей и эффективных стратегиях проверки поставщиков.

Как покупатель B2B, понимание тонкостей ценообразования, гарантийных опций и важности гарантий соответствия может существенно повлиять на вашу стратегию закупок. В руководстве также рассматриваются такие ключевые факторы, как различия между запчастями OEM и вторичного рынка, логистика доставки и экономически эффективные методы поиска поставщиков. Вооружившись этими знаниями, вы сможете уверенно взаимодействовать с поставщиками и заключать более выгодные сделки, отвечающие вашим производственным потребностям.

В конечном итоге этот ресурс призван помочь вам принять стратегические решения, которые повысят эффективность вашей цепочки поставок, сократят время простоя и обеспечат надежность ваших автомобильных предложений. Независимо от того, являетесь ли вы опытным покупателем или новичком на рынке, представленные здесь сведения помогут вам сориентироваться в сложностях поиска запчастей для автомобильных стартеров на мировом рынке.

Содержание

- Список производителей и поставщиков 4 лучших частей автомобильного стартера

- Введение: Навигация по глобальному рынку запчастей для автомобильных стартеров

- Понимание типов и разновидностей деталей автомобильного стартера

- Основные промышленные применения автомобильных деталей стартерного двигателя

- 3 распространенных болевых точки пользователей для ‘автомобильные запчасти стартера двигателя’ и их решения

- Руководство по выбору стратегических материалов для деталей автомобильных стартеров

- Глубокий взгляд: Производственные процессы и обеспечение качества деталей автомобильного стартера

- Практическое руководство по поиску: Пошаговый контрольный список для ‘автомобильных деталей стартера двигателя’

- Всесторонний анализ стоимости и ценообразования для автомобильных стартерных деталей двигателя Поиск

- Анализ альтернатив: Сравнение деталей автомобильного стартера с другими решениями

- Основные технические свойства и торговая терминология для деталей автомобильного стартера

- Навигация по динамике рынка и тенденциям поиска в секторе запчастей для автомобильных стартеров

- Часто задаваемые вопросы (FAQ) для B2B покупателей автомобильных деталей стартера двигателя

- Выводы и перспективы стратегического сорсинга для деталей автомобильного стартера

- Важное предупреждение и условия использования

Понимание типов и разновидностей деталей автомобильного стартера

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Стартовое устройство с постоянным магнитом | Компактная конструкция, легкий вес, высокая эффективность | Пассажирские автомобили, малотоннажные грузовики | Плюсы: Энергоэффективный, быстрый запуск. Минусы: Ограниченный крутящий момент для тяжелых условий эксплуатации. |

| Редукторный стартер | Использует шестерни для усиления крутящего момента, больший размер | Тяжелые грузовики, автомобили с высокими эксплуатационными характеристиками | Плюсы: Высокий крутящий момент, подходит для больших двигателей. Минусы: Более громоздкие, потенциально более дорогие. |

| Стартер раневого поля | Электромагнитное поле, создаваемое обмотками, надежная конструкция | Промышленное применение, коммерческий транспорт | Плюсы: Надежность в экстремальных условиях. Минусы: Более тяжелая и сложная конструкция. |

| Восстановленный стартер | Перестроен из подержанных деталей, экономичный | Бюджетные покупатели, услуги автопарка | Плюсы: Низкая стоимость, экологичность. Минусы: Срок службы может быть меньше, чем у новых деталей. |

| Высокопроизводительный стартер | Повышенная мощность, разработанная для гоночных и производительных приложений | Автоспорт, модифицированные автомобили | Плюсы: Превосходная пусковая мощность, оптимизированная для работы. Минусы: Более высокая цена, может потребоваться специальная подгонка. |

Каковы основные характеристики стартеров с постоянными магнитами?

Стартеры с постоянными магнитами известны своей компактной и легкой конструкцией, что делает их идеальными для легковых автомобилей и малотоннажных грузовиков. Они работают эффективно, обеспечивая быстрый запуск при минимальном потреблении энергии. Покупателям B2B следует учитывать требования к применению, поскольку эти стартеры могут не обладать крутящим моментом, необходимым для больших двигателей, что делает их непригодными для использования в тяжелых условиях.

Чем отличаются редукторные стартеры?

Редукторные стартеры используют систему шестерен для усиления крутящего момента, что делает их особенно подходящими для тяжелых грузовиков и мощных автомобилей. Их больший размер позволяет получить более высокий крутящий момент, необходимый для запуска больших двигателей. Покупателям следует оценить совместимость с техническими характеристиками своего автомобиля, поскольку более громоздкая конструкция может подойти не ко всем типам двигателей.

Какие преимущества имеют стартеры для раневого поля?

Пускатели с обмоткой возбуждения генерируют электромагнитное поле через обмотки, обеспечивая прочную конструкцию, которая надежно работает в экстремальных условиях. Они широко используются в промышленных установках и коммерческих автомобилях, где долговечность имеет решающее значение. Однако их более тяжелая и сложная конструкция может не подойти для более легких автомобилей, поэтому необходимо тщательно продумать их применение.

Почему стоит выбирать восстановленные стартеры?

Восстановленные стартеры собираются из бывших в употреблении деталей, предлагая экономически выгодное решение для экономных покупателей и автопарков. Они представляют собой экологически чистый вариант, позволяющий сократить количество отходов за счет повторного использования компонентов. Хотя такие стартеры могут быть более доступными по цене, покупателям следует помнить, что срок их службы может быть меньше, чем у новых деталей, что требует тщательной оценки гарантийных обязательств и ожидаемых эксплуатационных характеристик.

Что делает высокопроизводительные стартеры уникальными?

Высокопроизводительные стартеры предназначены для гоночных и модифицированных автомобилей, обеспечивая повышенную мощность для оптимального запуска в сложных условиях. Они незаменимы в автоспорте, где надежность и производительность имеют первостепенное значение. Однако их более высокая цена и потенциальные проблемы с установкой должны тщательно оцениваться покупателями для обеспечения совместимости с конкретными модификациями автомобилей.

Основные промышленные применения автомобильных деталей стартерного двигателя

| Отрасль/сектор | Конкретное применение автомобильных частей стартерного двигателя | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Производство пассажирских и коммерческих автомобилей | Обеспечивает надежный запуск автомобиля, повышая удовлетворенность клиентов | Обеспечение качества, соответствие спецификациям OEM, время выполнения заказа |

| Тяжелое оборудование | Системы запуска в строительной и сельскохозяйственной технике | Повышает эффективность работы и сокращает время простоя | Долговечность в экстремальных условиях, совместимость с различными моделями |

| Управление автопарком | Обслуживание парка коммерческих автомобилей | Сокращение общих расходов на техническое обслуживание и повышение надежности автопарка | Наличие оптовых закупок, условия гарантии |

| Услуги по ремонту автомобилей | Послепродажная замена неисправных стартеров | Обеспечивает быстрое обслуживание клиентов, повышая деловую репутацию | Поиск восстановленных и новых деталей, гарантии соответствия. |

| Транспортные средства с возобновляемой энергией | Интеграция в системы электрических и гибридных транспортных средств | Поддерживает переход к устойчивым энергетическим решениям | Совместимость с аккумуляторными системами, легкая конструкция |

Как детали автомобильного стартера используются в автомобильном производстве?

В автомобилестроении детали стартера имеют решающее значение для производства как легковых, так и грузовых автомобилей. Эти компоненты предназначены для обеспечения надежного и эффективного запуска двигателя, который необходим для функционирования автомобиля. Производители должны уделять первостепенное внимание обеспечению качества и соблюдению спецификаций OEM, чтобы сохранить свою репутацию и соответствовать нормативным стандартам. Международные покупатели, особенно с развивающихся рынков Африки и Южной Америки, должны уделять особое внимание закупке деталей, доказавших свою долговечность и работоспособность в различных условиях.

Какую роль играют детали автомобильного стартера в тяжелой технике?

В таких отраслях тяжелой техники, как строительство и сельское хозяйство, в значительной степени используются детали стартера двигателя для таких машин, как экскаваторы и тракторы. Эти компоненты предназначены для работы в суровых условиях и обеспечивают эффективность работы. Надежная система запуска сводит к минимуму время простоя, что очень важно для предприятий, от которых зависит своевременное завершение проектов. Покупателям из регионов с экстремальными погодными условиями следует обратить внимание на приобретение стартерных двигателей, которые отличаются долговечностью и надежностью, что гарантирует их работоспособность в сложных условиях.

Как детали стартера необходимы для управления автопарком?

При управлении автопарком поддержание надежной системы запуска коммерческих автомобилей имеет жизненно важное значение для эффективности работы. Детали стартера напрямую влияют на надежность автомобиля, что сказывается на общих затратах на обслуживание. Операторам автопарков выгодно приобретать высококачественные компоненты, которые минимизируют поломки и увеличивают время безотказной работы автомобиля. Международным покупателям следует обратить внимание на поставщиков, предлагающих оптовые закупки и гибкие условия гарантии, чтобы оптимизировать свою стратегию закупок.

Почему детали стартера важны для ремонта автомобилей?

Автосервисы часто сталкиваются с неисправными стартерами, что требует эффективных решений по их замене на вторичном рынке. Приобретая качественные детали стартеров, автосервисы могут обеспечить быстрое выполнение заказов клиентов, что повышает их репутацию. Для таких предприятий важно оценивать преимущества восстановленных и новых деталей, обеспечивая доступ к гарантиям пригодности для удовлетворения различных потребностей клиентов. Такое внимание к качеству и надежности может существенно повлиять на удовлетворенность и удержание клиентов.

Как детали стартера поддерживают транспортные средства, работающие на возобновляемых источниках энергии?

В растущем секторе транспортных средств, работающих на возобновляемых источниках энергии, особенно электрических и гибридных моделей, детали стартерного двигателя играют жизненно важную роль в интеграции традиционных систем запуска с передовыми аккумуляторными технологиями. Эти компоненты должны быть легкими и совместимыми с различными энергетическими системами, чтобы поддержать переход к устойчивым транспортным решениям. Международные покупатели в таких регионах, как Европа и Ближний Восток, должны уделять первоочередное внимание поиску инновационных решений для стартеров, которые соответствуют их экологическим целям, обеспечивая при этом производительность и эффективность.

3 распространенных болевых точки пользователей для ‘автомобильные запчасти стартера двигателя’ и их решения

Сценарий 1: Поиск качественных деталей стартера для различных моделей автомобилей

Проблема: Покупатели B2B часто пытаются найти надежных поставщиков, которые могут предоставить детали автомобильного стартера, совместимые с широким спектром марок и моделей автомобилей. Эта проблема усугубляется, когда речь идет о менее распространенных или старых автомобилях, где наличие запчастей OEM (Original Equipment Manufacturer) может быть ограничено. Покупатели могут столкнуться с задержками в цепочке поставок, что приведет к потенциальным простоям их клиентов, что может негативно сказаться на их деловой репутации и прибыльности.

Решение: Чтобы решить эту проблему, покупатели B2B должны сотрудничать с поставщиками, которые специализируются на широком ассортименте как оригинальных, так и запасных частей для стартеров. Важно проводить тщательные исследования и проверять поставщиков на основе их ассортимента, опыта работы в отрасли и отзывов клиентов. Покупатели также должны отдавать предпочтение поставщикам, которые предлагают комплексные инструменты каталогизации, позволяющие отфильтровать продукцию по спецификациям автомобиля, включая марку, модель и год выпуска. Кроме того, налаживание отношений с несколькими поставщиками может обеспечить безопасность в случае нехватки или задержек. Внедрение систематического подхода к управлению запасами, например, использование системы своевременного заказа, также поможет обеспечить наличие нужных деталей в нужный момент, что минимизирует время простоя и повышает удовлетворенность клиентов.

Сценарий 2: Эффективное решение вопросов, связанных с гарантией и возвратом товара

Проблема: Гарантийные претензии и процессы возврата автомобильных деталей стартера могут быть сопряжены с трудностями. Покупатели могут получать бракованные детали или детали, не соответствующие их спецификациям, что приводит к разочарованию и финансовым потерям. Сложность управления возвратами может привести к ухудшению отношений с поставщиками и повлиять на общее качество обслуживания конечных клиентов.

Решение: Чтобы смягчить эти проблемы, покупатели B2B должны установить четкие каналы связи со своими поставщиками в отношении гарантийной политики и процедур возврата. Перед оформлением заказа крайне важно ознакомиться с условиями гарантии, включая срок и условия ее действия. Покупатели также должны поинтересоваться процедурой возврата, чтобы убедиться, что она понятна и удобна для клиента. Ведение подробных записей всех операций, включая счета-фактуры и переписку, может ускорить разрешение споров. Кроме того, покупатели могут внедрить процесс контроля качества при получении деталей, что позволит сразу же выявить несоответствия и ускорить процесс возврата. Налаживание прочных отношений с поставщиками также может привести к улучшению поддержки во время гарантийных претензий, что повысит вероятность быстрого разрешения спора.

Сценарий 3: преодоление проблем совместимости и установки

Проблема: Частой проблемой для покупателей B2B является обеспечение совместимости заказываемых ими деталей стартера с автомобилями их клиентов. Несоответствие спецификаций может привести к проблемам с установкой, увеличению трудозатрат и неудовлетворенности клиентов. Это особенно проблематично в регионах с различным населением автомобилей, где запчасти с вторичного рынка не всегда соответствуют спецификациям OEM.

Решение: Чтобы решить проблемы совместимости и установки, покупатели должны потратить время на обучение своих сотрудников техническим характеристикам стартерных двигателей, включая номинальные мощности, напряжение и варианты конструкции. Использование передовых платформ поиска поставщиков, предоставляющих подробные данные о соответствии, может помочь обеспечить заказ правильных деталей. Покупателям также следует искать поставщиков, предлагающих техническую поддержку или руководство по установке, которые могут оказать неоценимую помощь в процессе монтажа. Установление обратной связи с техническими специалистами поможет выявить общие проблемы, связанные с совместимостью, что позволит покупателям соответствующим образом скорректировать свои стратегии поиска поставщиков. Кроме того, составление контрольного списка для установки, включающего проверку номеров деталей и спецификаций, может свести к минимуму риск ошибок и повысить общую эффективность обслуживания.

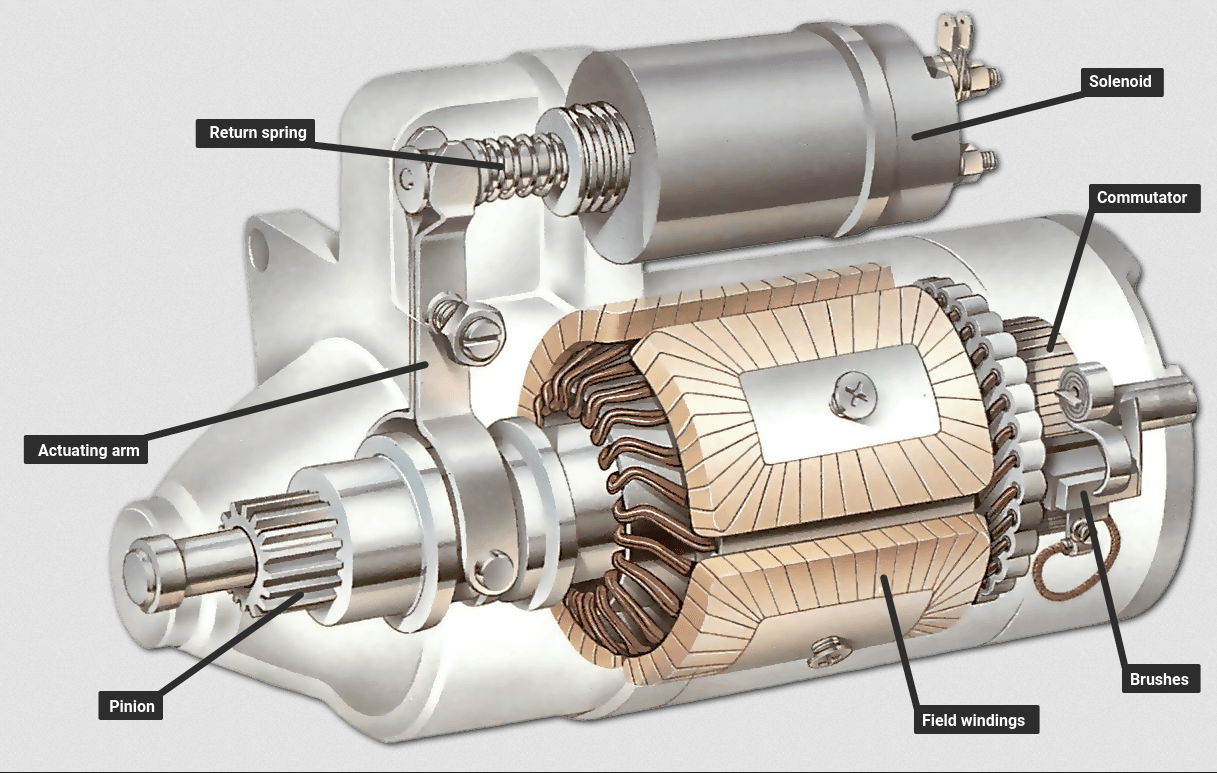

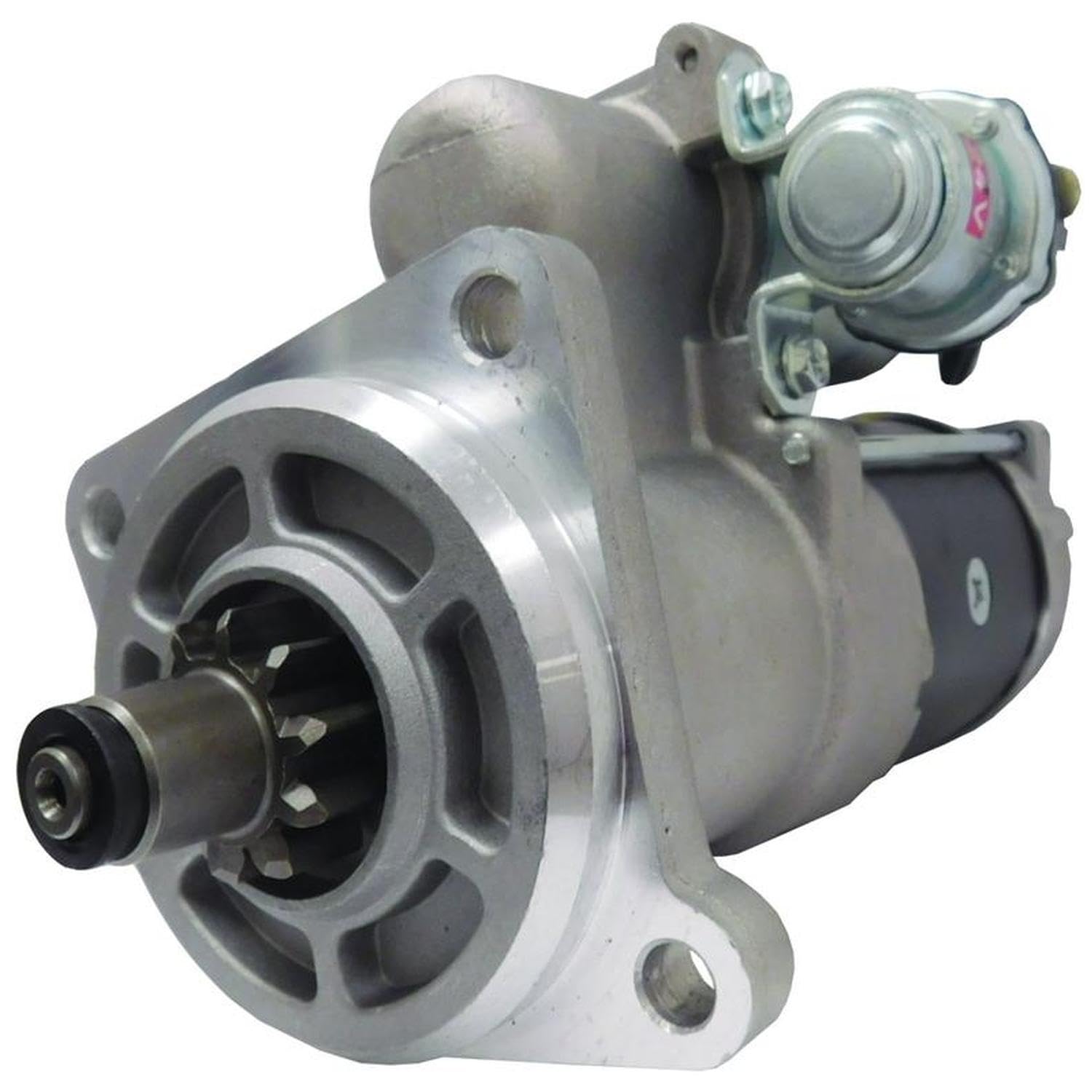

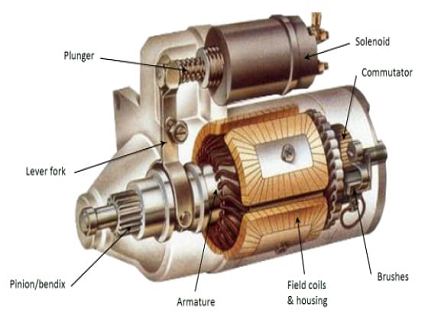

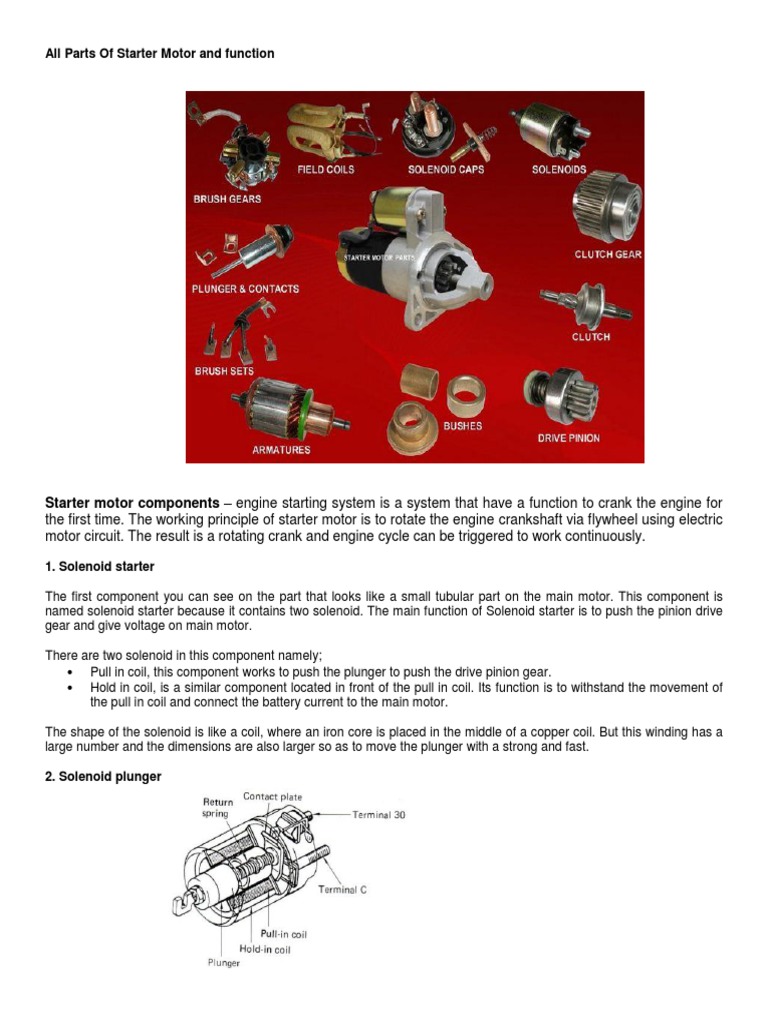

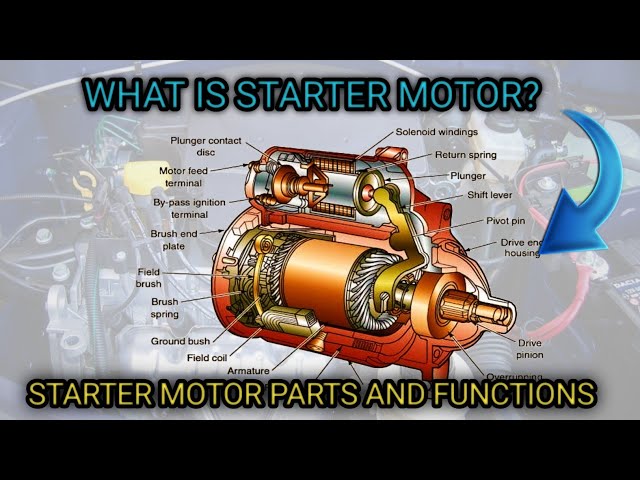

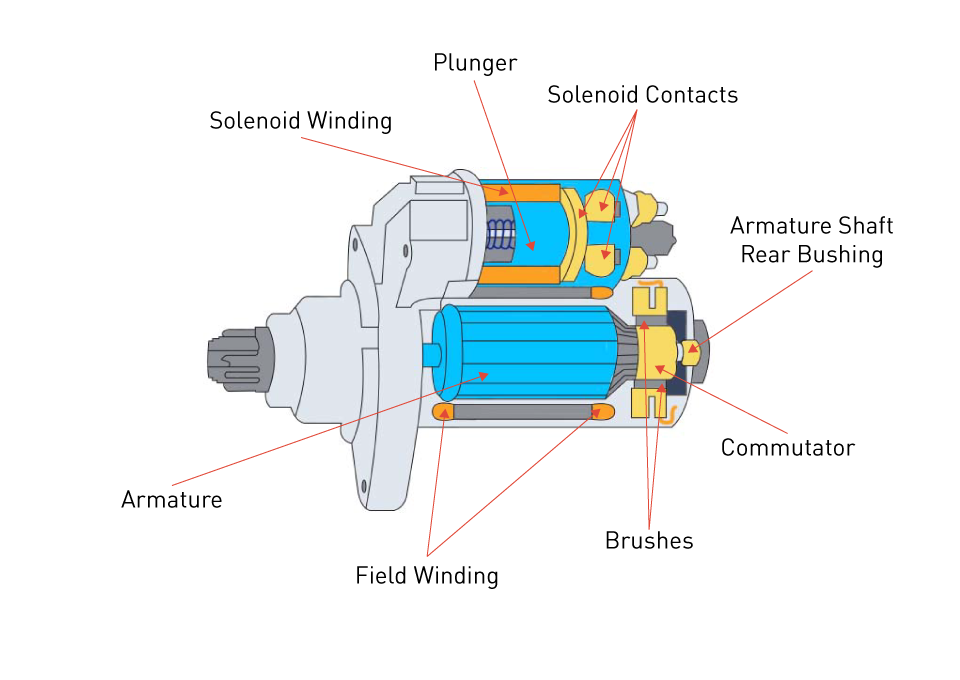

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

Руководство по выбору стратегических материалов для деталей автомобильных стартеров

Какие основные материалы используются в деталях автомобильного стартера?

При выборе материалов для деталей автомобильного стартера важно учитывать их свойства, преимущества и ограничения. Выбор материала может существенно повлиять на производительность, долговечность и экономическую эффективность стартерного двигателя. Ниже мы рассмотрим четыре распространенных материала, используемых при производстве этих компонентов.

Как сталь используется в деталях автомобильных стартеров?

Сталь является одним из наиболее широко используемых материалов для изготовления деталей автомобильного стартера благодаря своей превосходной прочности и долговечности. Как правило, она обладает высокой прочностью на растяжение и способна выдерживать значительные механические нагрузки, что делает ее идеальным материалом для таких компонентов, как корпус стартера и шестерни. Сталь также обладает хорошей термостойкостью и способна эффективно работать в широком диапазоне условий эксплуатации.

Плюсы: К основным преимуществам стали относятся ее высокая прочность и вес, экономичность и простота изготовления. Она легко поддается механической обработке и сварке, что позволяет создавать сложные конструкции.

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

Минусы: Однако сталь подвержена коррозии, что может быть существенным недостатком во влажной или соленой среде. Для повышения коррозионной стойкости часто требуются защитные покрытия или обработка.

Для международных покупателей, особенно в таких регионах, как Африка и Ближний Восток, важно соблюдение местных стандартов коррозионной стойкости. Покупателям следует рассмотреть возможность использования нержавеющей стали или вариантов с покрытием для обеспечения долговечности в суровых условиях.

Какую роль играет алюминий в деталях автомобильного стартера?

Алюминий - еще один популярный выбор для компонентов автомобильных стартеров, особенно для деталей, требующих легких свойств без ущерба для прочности. Благодаря низкой плотности он идеально подходит для применения в тех случаях, когда снижение веса имеет решающее значение, например, в автомобилях с высокими эксплуатационными характеристиками.

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

Плюсы: Алюминий обладает отличной коррозионной стойкостью и теплопроводностью, что повышает эффективность работы стартерных двигателей. Кроме того, он относительно легко обрабатывается, что позволяет создавать сложные конструкции.

Минусы: Основным ограничением алюминия является его более низкая прочность на разрыв по сравнению со сталью, что может не подойти для компонентов, испытывающих высокие нагрузки. Кроме того, он может быть дороже стали.

Международные покупатели должны знать о конкретных сортах алюминия, которые соответствуют местным производственным стандартам, таким как ASTM или JIS, чтобы обеспечить качество и производительность.

Почему медь важна для деталей автомобильного стартера?

Медь необходима в автомобильных стартерах, в первую очередь для электрических компонентов, таких как обмотки и разъемы. Она обладает отличной электропроводностью, что очень важно для эффективной работы двигателя.

Плюсы: Высокая проводимость меди обеспечивает минимальные потери энергии во время работы, повышая общую эффективность. Податливость меди также облегчает ее обработку в процессе производства.

Минусы: Однако медь подвержена коррозии и окислению, что со временем может сказаться на ее эксплуатационных характеристиках. Кроме того, она дороже других материалов, таких как алюминий и сталь.

Для покупателей B2B, особенно в регионах с высокой влажностью, важно учитывать медные сплавы или защитные покрытия для повышения долговечности. Соответствие международным электротехническим стандартам также имеет решающее значение для обеспечения совместимости и безопасности.

Как пластик влияет на детали автомобильного стартера?

Пластик, особенно инженерные пластики, такие как полиамид (нейлон) и поликарбонат, все чаще используется в автомобильных стартерах для изготовления неструктурных компонентов. Эти материалы легкие и могут быть сформованы в сложные формы.

Плюсы: Пластмассы обладают отличной устойчивостью к химическим веществам и влаге, что делает их пригодными для использования в различных автомобильных приложениях. Кроме того, они легкие, что позволяет снизить общий вес стартерного двигателя.

Минусы: Основным недостатком является то, что пластмассы обычно обладают меньшей механической прочностью по сравнению с металлами, что может ограничить их применение в условиях высоких нагрузок. Кроме того, на них могут влиять перепады температур.

Международным покупателям следует обратить внимание на конкретные марки пластика, которые соответствуют местным автомобильным стандартам. Понимание экологических норм, касающихся использования пластика, также крайне важно, особенно в регионах с жесткими требованиями к их соблюдению.

Сводная таблица выбора материалов для деталей автомобильного стартерного двигателя

| Материал | Типичный пример использования для деталей автомобильного стартера | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Сталь | Корпус стартера, шестерни | Высокая прочность и долговечность | Подвержен коррозии | Средний |

| Алюминий | Легкие компоненты, корпуса | Отличная коррозионная стойкость | Более низкая прочность на разрыв | Высокий |

| Медь | Электрические обмотки, разъемы | Отличная электропроводность | Склонный к коррозии | Высокий |

| Пластик | Неструктурные компоненты | Легкий и влагостойкий | Низкая механическая прочность | Низкий |

Понимая свойства, преимущества и ограничения этих материалов, международные покупатели B2B могут принимать взвешенные решения, которые соответствуют их специфическим потребностям и требованиям соответствия на их соответствующих рынках.

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

Глубокий взгляд: Производственные процессы и обеспечение качества деталей автомобильного стартера

Каковы основные этапы производственного процесса автомобильных деталей стартера?

Производство деталей автомобильного стартера включает в себя несколько критических этапов, которые обеспечивают высокое качество продукции. К основным этапам относятся подготовка материала, формовка, сборка и отделка.

Подготовка материалов

Процесс начинается с выбора высококачественных материалов, как правило, таких металлов, как сталь и алюминий, известных своей прочностью и электропроводностью. Эти материалы подвергаются различным видам обработки, таким как термообработка и поверхностная закалка, для улучшения их механических свойств. Для обеспечения соответствия материалов отраслевым спецификациям проводятся проверки качества.

Техника формовки

После подготовки материалов они подвергаются таким методам формовки, как штамповка, механическая обработка и литье. Штамповка часто используется для создания плоских деталей, а механическая обработка обеспечивает точность деталей, таких как корпус стартерного двигателя. Литье используется для деталей сложной формы, таких как корпус стартерного двигателя. Передовые технологии, такие как обработка с ЧПУ (компьютерное числовое управление), позволяют добиться высокой точности и повторяемости, что необходимо для сохранения целостности деталей.

Процесс сборки

После того как отдельные компоненты сформированы, начинается процесс сборки. На этом этапе происходит соединение различных деталей, включая якорь, соленоид и корпус. Для повышения эффективности и снижения человеческого фактора часто используются автоматизированные сборочные линии. Каждая сборочная линия разработана с учетом конкретных конфигураций стартерных двигателей, что обеспечивает совместимость с широким спектром моделей автомобилей.

Отделочные операции

На заключительном этапе производства выполняются финишные операции, включающие обработку поверхности, покраску и проверку качества. Такие виды обработки поверхности, как анодирование или порошковое покрытие, применяются для предотвращения коррозии и повышения эстетической привлекательности. Финишная обработка имеет решающее значение для обеспечения того, чтобы детали не только хорошо работали, но и соответствовали визуальным стандартам.

Как обеспечивается качество при производстве деталей автомобильных стартеров?

Обеспечение качества (QA) при производстве деталей автомобильных стартеров имеет первостепенное значение для обеспечения надежности и производительности. Оно включает в себя ряд международных стандартов, отраслевых норм и строгих мер контроля качества (КК).

Соответствующие международные стандарты обеспечения качества

ISO 9001 - наиболее признанный стандарт управления качеством, ориентированный на постоянное качество и удовлетворение потребностей клиентов. Соответствие стандарту ISO 9001 свидетельствует о том, что производитель внедрил эффективную систему управления качеством. Для автомобильных деталей критически важным является соблюдение таких стандартов, как IATF 16949, поскольку в них особое внимание уделяется постоянному совершенствованию и предотвращению дефектов именно в автомобильном секторе.

Отраслевые сертификаты

В дополнение к стандартам ISO производители автомобилей могут обращаться за сертификатами, такими как CE (Conformité Européenne) для соответствия европейским стандартам безопасности или API (American Petroleum Institute) для смазочных компонентов. Эти сертификаты указывают на то, что продукция соответствует строгим критериям безопасности и производительности, обеспечивая уверенность покупателям B2B.

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

Каковы ключевые контрольные точки контроля качества на протяжении всего производственного процесса?

Контроль качества - это многогранный подход, включающий различные контрольные точки на протяжении всего производственного процесса. К ключевым точкам контроля относятся входной контроль качества (IQC), контроль качества в процессе производства (IPQC) и окончательный контроль качества (FQC).

Входящий контроль качества (IQC)

Этот начальный этап включает в себя проверку сырья и компонентов по прибытии на производство. Поставщики должны предоставить сертификаты соответствия, а материалы часто проверяются на химический состав и физические свойства. Этот этап крайне важен для предотвращения попадания бракованных материалов на производственную линию.

Контроль качества в процессе производства (IPQC)

В процессе производства IPQC контролирует операции, чтобы обеспечить соблюдение стандартов качества. Это может включать регулярные проверки размеров, допусков и функциональных испытаний. Автоматизированные системы могут облегчить мониторинг в режиме реального времени, позволяя немедленно принимать корректирующие меры в случае возникновения отклонений.

Окончательный контроль качества (FQC)

FQC проводится после сборки и отделки, чтобы убедиться, что конечный продукт соответствует всем спецификациям и критериям производительности. На этом этапе часто проводятся строгие испытания, такие как функциональные тесты на непрерывность электрического тока и нагрузочные тесты для имитации условий эксплуатации. FQC - это последняя линия защиты от дефектов перед отправкой продукции заказчику.

Какие общие методы испытаний используются для обеспечения качества деталей стартерных двигателей?

Для обеспечения соответствия деталей автомобильного стартера стандартам производительности и безопасности используются различные методы испытаний. К общим методам относятся:

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

- Электрические испытания: Включает в себя проверку напряжения, потребляемого тока и сопротивления для обеспечения надлежащей функциональности электрооборудования.

- Механические испытания: Компоненты подвергаются стресс-тестам для оценки долговечности и усталостной прочности. Это может включать испытания на растяжение и вибрационные испытания.

- Экологические испытания: Детали подвергаются воздействию таких условий, как экстремальные температуры, влажность и коррозия, чтобы оценить их устойчивость в реальных условиях.

Как покупатели B2B могут проверить процессы контроля качества поставщиков?

Для международных покупателей B2B, особенно из таких регионов, как Африка, Южная Америка, Ближний Восток и Европа, проверка процессов контроля качества поставщика имеет большое значение для снижения рисков. Вот несколько шагов, которые можно предпринять:

Проведение аудита поставщиков

Регулярные аудиты могут дать представление о производственной практике поставщика и мерах по обеспечению качества. Во время таких проверок покупатели должны обращать внимание на наличие сертификатов и соответствие международным стандартам.

Запросить отчеты о качестве

Поставщики должны предоставлять полные отчеты о качестве, включая результаты этапов IQC, IPQC и FQC. Эта документация помогает покупателям оценить эффективность системы менеджмента качества поставщика.

Привлечение сторонних инспекторов

Использование услуг сторонней инспекции может придать дополнительную уверенность. Эти инспекторы могут проверить соответствие отраслевым стандартам и провести непредвзятую оценку производственного процесса и конечной продукции.

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

Каковы нюансы контроля качества и сертификации для международных покупателей?

Международные покупатели должны ориентироваться в различных сертификационных требованиях и требованиях к качеству, которые могут отличаться в зависимости от региона. Например, если стандарт ISO 9001 признан во всем мире, то специальные сертификаты для автомобильной промышленности, такие как IATF 16949, могут быть более важны в Европе и Северной Америке.

В таких регионах, как Африка и Южная Америка, покупатели могут столкнуться с поставщиками, не знакомыми с международными стандартами, что приведет к потенциальному несоответствию качества. Покупатели должны отдавать предпочтение работе с производителями, которые имеют проверенный опыт соблюдения и обеспечения качества, гарантируя, что их продукция соответствует необходимым международным стандартам.

Заключение

Понимание производственных процессов и методов обеспечения качества деталей автомобильного стартера крайне важно для покупателей B2B. Сосредоточив внимание на ключевых этапах производства, придерживаясь международных стандартов качества и осуществляя тщательный контроль качества, поставщики могут обеспечить надежность и производительность своей продукции. Покупатели могут защитить свои интересы, проверяя практику поставщиков, запрашивая документацию и привлекая сторонних инспекторов, что в конечном итоге будет способствовать успешным международным торговым отношениям.

Практическое руководство по поиску: Пошаговый контрольный список для ‘автомобильных деталей стартера двигателя’

Введение

Данное практическое руководство по поиску поставщиков предназначено для покупателей B2B, желающих приобрести детали автомобильного стартера. Автомобильная промышленность быстро развивается, и обеспечение приобретения высококачественных и надежных деталей имеет важное значение для поддержания эффективности работы и удовлетворенности клиентов. Этот контрольный список поможет вам эффективно управлять процессом поиска поставщиков, начиная с определения технических спецификаций и заканчивая оценкой поставщиков.

Шаг 1: Определите свои технические характеристики

Начните с четкого определения технических требований к необходимым вам деталям стартерного двигателя. Учитывайте такие факторы, как совместимость с автомобилем, номинальная мощность (кВт) и характеристики напряжения (12 В, 24 В и т. д.).

– Почему это важно: Определение этих спецификаций помогает предотвратить дорогостоящие ошибки и гарантирует, что детали, которые вы приобретаете, будут правильно подходить и функционировать.

– Что искать: Убедитесь, что у вас есть подробная информация о моделях, спецификациях OEM и любых альтернативных вариантах, которые могут быть применимы на вторичном рынке.

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

Шаг 2: Исследование и выявление потенциальных поставщиков

Проведите всестороннее исследование, чтобы найти поставщиков, специализирующихся на запчастях для автомобильных стартеров. Воспользуйтесь отраслевыми справочниками, выставками и онлайн-платформами, чтобы составить список потенциальных поставщиков.

– Почему это важно: Хорошо изученный список поставщиков позволит вам эффективно сравнивать качество, цены и уровень обслуживания.

– Что искать: Ориентируйтесь на поставщиков с хорошей репутацией, положительными отзывами клиентов и подтвержденным опытом работы на целевых рынках, таких как Африка, Южная Америка и Европа.

Шаг 3: Оценивайте сертификаты поставщиков и соответствие требованиям

Убедитесь, что потенциальные поставщики имеют соответствующие сертификаты и соблюдают международные стандарты качества. Это может включать сертификаты ISO, соответствие экологическим нормам и соблюдение правил безопасности.

– Почему это важно: Сертификация - это убедительный показатель приверженности поставщика качеству и надежности.

– Что искать: Проверьте наличие специальных сертификатов, признанных в вашей отрасли и регионе, и убедитесь, что они соответствуют вашим требованиям к поставщикам.

Шаг 4: Запрашивайте образцы и проводите проверку качества

Перед размещением оптового заказа запросите образцы деталей стартерного двигателя, чтобы оценить их качество и соответствие. Этот шаг очень важен для проверки соответствия продукции вашим спецификациям и ожиданиям по производительности.

– Почему это важно: Отбор образцов помогает снизить риски, связанные с дефектными или несовместимыми деталями.

– Что искать: Оцените используемые материалы, мастерство и общие характеристики образцов.

Шаг 5: Оцените политику гарантийного обслуживания и возврата товаров

Ознакомьтесь с условиями гарантии и возврата, предлагаемыми поставщиками. Надежная гарантия может обеспечить душевное спокойствие и защитить ваши инвестиции в случае обнаружения дефектов или проблем с производительностью.

– Почему это важно: Строгие гарантийные условия помогут вам сэкономить значительные средства и обеспечить защиту в случае возникновения проблем с деталями.

– Что искать: Ищите поставщиков, предлагающих щедрые гарантии, удобные процедуры возврата и поддержку клиентов для решения любых вопросов.

Шаг 6: Обсудите условия и завершите покупку

После того как вы выбрали поставщика, начните переговоры о ценах, условиях оплаты и графиках поставок. Установление выгодных условий может повысить вашу рентабельность и эффективность работы.

– Почему это важно: Эффективные переговоры могут привести к установлению более выгодных цен и условий, отвечающих потребностям вашего бизнеса.

– Что искать: Четко определите бюджетные ограничения и сроки поставки, чтобы обе стороны были согласны.

Шаг 7: Разработайте план коммуникации

После завершения покупки разработайте план взаимодействия с поставщиком, чтобы обеспечить бесперебойную работу и оперативно решать любые потенциальные проблемы.

– Почему это важно: Хорошая коммуникация помогает построить крепкое партнерство и обеспечивает информированность обеих сторон на протяжении всего процесса поиска поставщиков.

– Что искать: Регулярное обновление информации о состоянии заказа, деталях доставки и возможных задержках поможет вам эффективно управлять запасами.

Всесторонний анализ стоимости и ценообразования для автомобильных стартерных деталей двигателя Поиск

Каковы ключевые компоненты стоимости деталей автомобильного стартера?

При поиске запчастей для автомобильных стартеров понимание структуры затрат имеет решающее значение для принятия обоснованных решений о покупке. Основные компоненты затрат включают:

-

Материалы: Выбор материалов существенно влияет на стоимость. Высококачественные металлы и композитные материалы, используемые в стартерных двигателях, повышают долговечность, но могут увеличить первоначальную стоимость.

-

Трудовые ресурсы: Стоимость рабочей силы зависит от региона и сложности производственного процесса. Квалифицированный труд может потребоваться для сборки и контроля качества.

-

Производственные накладные расходы: Сюда входят расходы на коммунальные услуги, аренду и другие операционные расходы, связанные с управлением производственным предприятием.

-

Инструменты: Первоначальные инвестиции в оснастку могут быть значительными, особенно для нестандартных деталей. Эти затраты обычно амортизируются в зависимости от объема производства.

-

Контроль качества (КК): Обеспечение соответствия деталей промышленным стандартам требует инвестиций в процессы тестирования и контроля качества.

-

Логистика: Транспортные расходы, включая доставку и обработку, играют значительную роль в общей стоимости, особенно при международных сделках.

-

Маржа: Поставщики включают в конечную цену свою норму прибыли, которая варьируется в зависимости от рыночных условий и конкуренции.

Как факторы, влияющие на цену, влияют на решения о закупках?

На цену деталей автомобильного стартера влияют несколько факторов:

-

Объем/MOQ (минимальный объем заказа): Поставщики часто предоставляют более выгодные цены при оптовых заказах. Понимание MOQ может помочь покупателям договориться о более выгодных условиях.

-

Технические характеристики и индивидуальная настройка: Нестандартные детали или детали с особыми техническими требованиями могут привести к повышению стоимости. Стандартизированные детали обычно имеют более низкие цены благодаря эффекту масштаба.

-

Материалы: Выбор материалов влияет не только на долговечность, но и на стоимость. Покупатели должны соизмерять преимущества материалов премиум-класса с ограничениями бюджета.

-

Качество и сертификаты: Детали, соответствующие специальным отраслевым сертификатам, могут стоить дороже. Покупатели должны оценить баланс между качеством и стоимостью.

-

Факторы, связанные с поставщиками: Отношения с поставщиками могут влиять на ценообразование. Долгосрочные партнерские отношения могут обеспечить более выгодные цены и условия благодаря доверию и надежности.

-

Инкотермс: Понимание инкотермс, оговоренных в контракте, может повлиять на общую стоимость, поскольку они определяют, кто несет ответственность за доставку, страхование и тарифы.

Какие советы по ведению переговоров могут повысить эффективность затрат для международных покупателей?

Покупатели B2B, особенно из Африки, Южной Америки, Ближнего Востока и Европы, могут использовать несколько стратегий для повышения эффективности затрат:

-

Общая стоимость владения (TCO): Учитывайте долгосрочные затраты, связанные с деталями, включая техническое обслуживание и возможные поломки. Более низкая начальная цена не всегда является оптимальным вариантом.

-

Используйте связи: Построение прочных отношений с поставщиками может привести к установлению более выгодных цен и более благоприятных условий. Частое общение и обратная связь могут улучшить сотрудничество.

-

Будьте в курсе тенденций рынка: Понимание динамики рынка, например, сбоев в цепочке поставок или нехватки материалов, может стать рычагом влияния на переговоры.

-

Изучите нескольких поставщиков: Работа с несколькими поставщиками позволяет сравнивать цены и условия, создавая конкурентную среду, которая может привести к экономии средств.

-

Обсудить условия оплаты: Гибкие условия оплаты могут облегчить движение денежных средств, позволяя покупателям более эффективно управлять своим бюджетом.

Какие нюансы ценообразования следует учитывать международным покупателям?

Международные покупатели должны ориентироваться в специфических нюансах ценообразования при поиске деталей автомобильного стартера:

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

-

Колебания курсов валют: Волатильность валютных курсов может повлиять на затраты, поэтому необходимо учитывать этот фактор в ценовых стратегиях.

-

Импортные пошлины и налоги: Понимание местных правил, касающихся тарифов и налогов, крайне важно для точного прогнозирования затрат.

-

Расходы на доставку и обработку: Они могут значительно отличаться в зависимости от способа доставки и расстояния. Покупатели должны оценивать эти расходы в зависимости от срочности доставки.

-

Культурные различия: Стили ведения переговоров и деловые практики в разных регионах могут сильно различаться. Знание культурных особенностей может способствовать более гладким сделкам.

Отказ от ответственности в отношении цен

Цены на запчасти для автомобильных стартеров подвержены колебаниям в зависимости от рыночных условий, ценовых стратегий поставщиков и изменений в стоимости материалов. Приведенные цифры являются ориентировочными и должны быть проверены путем прямого взаимодействия с поставщиками. Покупателям рекомендуется проводить тщательные исследования и анализ рынка для обеспечения конкурентоспособных цен и качества при поиске поставщиков.

Анализ альтернатив: Сравнение деталей автомобильного стартера с другими решениями

Изучение альтернатив автомобильным деталям стартера

В автомобильной промышленности выбор деталей стартера имеет решающее значение для надежной работы транспортных средств. Однако покупатели часто ищут альтернативные решения, которые могут удовлетворить аналогичные потребности. В этом разделе анализируются автомобильные детали стартера в сравнении с другими жизнеспособными альтернативами, что помогает покупателям B2B принимать обоснованные решения, основанные на производительности, стоимости и общей полезности.

| Аспект сравнения | Запчасти для автомобильных стартеров | Пусковые системы на литий-ионных аккумуляторах | Гибридные электрические стартерные системы |

|---|---|---|---|

| Производительность | Высокий крутящий момент для эффективного запуска двигателя | Быстрый запуск двигателя с минимальными потерями энергии | Плавный переход от одного двигателя к другому и топливная экономичность |

| Стоимость | Умеренный, в зависимости от выбора между OEM и вторичным рынком | Более высокие первоначальные инвестиции, но потенциальная экономия в долгосрочной перспективе | Как правило, выше, чем у традиционных систем, из-за технологии |

| Простота внедрения | Стандартная установка; совместимость с большинством автомобилей | Требуются специальные модификации для интеграции | Сложная установка; может потребоваться профессиональная поддержка |

| Техническое обслуживание | Текущие проверки; замена деталей по мере необходимости | Минимальное обслуживание; более длительный срок службы | Требуется регулярная проверка системы и обновление программного обеспечения |

| Лучший вариант использования | Обычные автомобили с двигателем внутреннего сгорания | Высокопроизводительные и роскошные автомобили | Экологичные автомобили, стремящиеся к эффективности |

Каковы преимущества и недостатки литий-ионных стартерных систем?

Стартерные системы на литий-ионных аккумуляторах представляют собой передовую альтернативу традиционным стартерам. Они обеспечивают быстрый запуск двигателя при меньшем потреблении энергии, что делает их идеальными для высокопроизводительных и роскошных автомобилей. Однако первоначальные инвестиции могут быть значительно выше, и для их установки могут потребоваться специальные модификации автомобиля. Техническое обслуживание минимально, что может привести к снижению долгосрочных затрат, но сложность установки может отпугнуть некоторых покупателей.

Как сравниваются гибридные электрические стартеры?

Гибридные электрические системы запуска представляют собой еще одно инновационное решение, сочетающее в себе электрические технологии и технологии сгорания топлива. Эти системы обеспечивают плавный переход от двигателя к электричеству, повышая топливную экономичность и снижая уровень вредных выбросов. Несмотря на то, что они предлагают неоспоримые преимущества для экологичных автомобилей, сложность установки и более высокая стоимость могут оказаться непосильными для некоторых предприятий. Кроме того, для поддержания оптимальной производительности необходимо регулярно проверять систему и обновлять программное обеспечение.

Правильный выбор для ваших автомобильных нужд

Выбирая между автомобильными деталями стартера и альтернативными решениями, покупатели B2B должны учитывать свои специфические требования. Если вы ищете простое и экономичное решение для обычных автомобилей, вам могут подойти традиционные детали стартера. Однако для предприятий, ориентированных на производительность и устойчивость, инвестиции в литий-ионные или гибридные системы могут принести значительные долгосрочные выгоды. Оценка общей стоимости владения, сложности установки и потребностей в обслуживании поможет покупателям выбрать наиболее подходящий вариант для достижения их целей.

Основные технические свойства и торговая терминология для деталей автомобильного стартера

Каковы основные технические свойства деталей автомобильного стартера?

При выборе деталей автомобильного стартера понимание важнейших технических характеристик необходимо для обеспечения совместимости и производительности. Вот некоторые ключевые характеристики, которые необходимо учитывать:

-

Мощность кВт: Это относится к мощности пускового двигателя. Обычно мощность варьируется от 0,4 кВт до более чем 9 кВт. Более высокие показатели кВт означают большую пусковую мощность, что очень важно для больших двигателей. Покупатели B2B должны убедиться, что номинал кВт соответствует требованиям автомобиля, чтобы избежать недостаточной производительности.

-

Напряжение: Двигатели стартера обычно работают при напряжении 6 В, 12 В или 24 В. Напряжение должно соответствовать электрической системе автомобиля, чтобы обеспечить надлежащую функциональность. Неправильное напряжение может привести к повреждению или выходу из строя, поэтому покупателям важно проверить эту спецификацию перед покупкой.

-

Направление вращения: Это свойство указывает, вращается ли двигатель стартера по часовой стрелке или против нее. Выбор правильного направления вращения имеет решающее значение для совместимости с конструкцией двигателя. Несоответствующее вращение может привести к проблемам с установкой или невозможности зацепления маховика.

-

Количество зубьев шестерни: Шестерня входит в зацепление с маховиком двигателя, и количество зубьев может повлиять на посадку и производительность. Обычно число зубьев шестерни варьируется от 8 до 16. Покупатели должны убедиться, что количество зубьев соответствует спецификации двигателя, чтобы обеспечить правильное зацепление.

-

Тип конструкции: Стартерные двигатели можно разделить на различные конструкции, такие как прямой привод или редуктор. Каждая конструкция имеет свои преимущества с точки зрения эффективности и занимаемого места. Понимание типа конструкции помогает покупателям выбрать стартер, соответствующий техническим характеристикам автомобиля и имеющемуся пространству.

-

Марка материала: Материалы, используемые при производстве стартерных двигателей, такие как высококачественная сталь или алюминий, могут влиять на долговечность и производительность. Материалы более высокого класса обычно обеспечивают лучшую термостойкость и долговечность. Покупателям B2B следует обратить внимание на качество материала, особенно в регионах с экстремальными погодными условиями.

Каковы общие торговые термины в индустрии автомобильных стартерных двигателей?

Знание отраслевого жаргона имеет решающее значение для эффективного общения и принятия решений в сделках B2B. Вот несколько ключевых терминов:

-

OEM (производитель оригинального оборудования): Этот термин относится к деталям, изготовленным производителем автомобиля или его авторизованными поставщиками. Запчасти OEM обычно предпочитают за их гарантированную совместимость и качество, что делает их надежным выбором для покупателей, ищущих высокопроизводительные компоненты.

-

MOQ (минимальный объем заказа): MOQ - это наименьшее количество товара, которое поставщик готов продать. Понимание MOQ важно для покупателей, чтобы планировать свои запасы и избегать затоваривания или недозагрузки.

-

RFQ (запрос предложения): RFQ - это документ, отправляемый поставщикам с запросом цены и условий на конкретную продукцию. Покупатели используют RFQ для сравнения предложений и заключения более выгодных сделок, что делает их важным этапом в процессе закупок.

-

Инкотермс: Это международные коммерческие термины, которые определяют обязанности покупателей и продавцов в международной торговле. Понимание терминов Инкотермс, таких как FOB (Free on Board) или CIF (Cost, Insurance, and Freight), помогает покупателям эффективно управлять транспортными расходами и рисками.

-

Запасные части: Это детали, изготовленные не оригинальным производителем автомобиля. Зачастую они более доступны по цене, однако качество запасных частей может отличаться. Покупателям необходимо оценить надежность и производительность этих альтернатив.

-

Основной сбор: Это плата, которую поставщики взимают за стартерный двигатель, который можно вернуть для восстановления. Понимание сути этих сборов важно для составления бюджета, особенно для компаний, которые часто заменяют стартерные двигатели.

Понимая эти технические свойства и торговые термины, покупатели B2B могут принимать обоснованные решения о покупке, гарантируя, что они выбирают правильные детали автомобильного стартерного двигателя для своих нужд.

Навигация по динамике рынка и тенденциям поиска в секторе запчастей для автомобильных стартеров

Каковы основные тенденции развития рынка и поиска поставщиков, влияющие на сектор автомобильных деталей стартера?

Рынок запчастей для автомобильных стартеров переживает значительные изменения, вызванные технологическим прогрессом, изменением потребительских предпочтений и глобальными экономическими факторами. Основным фактором является растущий спрос на электромобили (EV), что побуждает производителей внедрять инновационные системы стартера, которые подходят для гибридных и полностью электрических моделей. Международные B2B-покупатели, особенно в таких регионах, как Африка, Южная Америка, Ближний Восток и Европа, должны быть в курсе этих событий, поскольку они напрямую влияют на стратегии поиска поставщиков и управление запасами.

Новые технологии, такие как интеллектуальное производство и автоматизация, также меняют представление о производстве и распределении деталей стартерных двигателей. Эта тенденция к Индустрии 4.0 позволяет повысить эффективность, сократить время выполнения заказа и улучшить контроль качества. Покупателям B2B следует обратить внимание на поставщиков, использующих эти технологии, поскольку они могут обеспечить более выгодные цены и надежность.

Кроме того, растет тенденция к глобализации в сфере закупок, когда поставщики все чаще устанавливают трансграничные партнерские отношения для выхода на различные рынки. Покупателям следует сосредоточиться на налаживании отношений с поставщиками, имеющими надежную логистическую сеть, поскольку это может снизить риски, связанные с нарушением цепочки поставок. В условиях геополитической напряженности и нестабильной торговой политики понимание нюансов международных торговых соглашений будет иметь большое значение для эффективного поиска поставщиков.

Как устойчивое и этичное снабжение формирует рынок деталей стартера автомобильных двигателей?

Устойчивое развитие и этический подход к поиску поставщиков стали важными факторами для покупателей B2B в секторе автомобильных запчастей. Влияние производственных процессов на окружающую среду находится под пристальным вниманием, что побуждает компании внедрять более устойчивые методы. Покупатели теперь отдают предпочтение поставщикам, которые могут продемонстрировать приверженность к сокращению углеродного следа и использованию экологически чистых материалов.

Важность этичных цепочек поставок трудно переоценить. Покупатели должны искать производителей, придерживающихся стандартов социальной ответственности, обеспечивающих справедливую практику труда и минимизирующих деградацию окружающей среды. Такие сертификаты, как ISO 14001 по экологическому менеджменту и другие ‘зеленые’ сертификаты, могут служить индикаторами приверженности поставщика принципам устойчивого развития.

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

Кроме того, все большее распространение получает использование переработанных и подлежащих вторичной переработке материалов в деталях стартера двигателя. Это не только помогает сократить количество отходов, но и привлекает потребителей, которые все больше заботятся об окружающей среде. Покупателям B2B рекомендуется сотрудничать с поставщиками, для которых эти методы являются приоритетными, поскольку они соответствуют растущему спросу на экологичные автомобильные решения.

Каковы исторические тенденции, сформировавшие отрасль автомобильных деталей стартера?

С момента появления электрических стартеров в начале XX века отрасль производства запчастей для автомобильных стартеров претерпела значительные изменения. Изначально разработанные для бензиновых двигателей, стартеры адаптировались к достижениям автомобильных технологий, включая переход на дизельные двигатели и, в последнее время, появление гибридных и электрических автомобилей.

Исторически сложилось так, что основное внимание уделялось функциональности и долговечности стартерных двигателей. Однако по мере ужесточения экологических норм и изменения потребительских предпочтений в отрасли все больше внимания уделяется эффективности и экологичности. Эта эволюция привела к инновациям в области дизайна и материалов, что позволило производителям выпускать более легкие и эффективные стартерные двигатели, потребляющие меньше энергии.

Поскольку международные рынки продолжают расширяться, понимание этих исторических тенденций дает ценные сведения для покупателей B2B. Понимание траектории развития отрасли может стать основой для разработки стратегий поиска поставщиков и поможет покупателям определить поставщиков, способных удовлетворить будущие потребности автомобильного сектора.

Часто задаваемые вопросы (FAQ) для B2B покупателей автомобильных деталей стартера двигателя

-

Как выбрать подходящий стартерный двигатель для своего автомобиля?

Выбор подходящего стартера предполагает понимание технических характеристик вашего автомобиля, включая объем двигателя, требуемое напряжение и направление вращения. Сверьте номера деталей с руководством по эксплуатации автомобиля или проконсультируйтесь с надежным поставщиком. Важно учитывать, нужна ли вам новая или восстановленная деталь, поскольку это может повлиять как на стоимость, так и на доступность. Во избежание проблем с установкой убедитесь, что стартерный двигатель совместим с вашей конкретной маркой и моделью. -

Как лучше всего проверить поставщика автомобильных стартеров?

Чтобы проверить поставщика, начните с изучения его репутации через онлайн-обзоры и отраслевые рейтинги. Запросите рекомендации у предыдущих клиентов и проверьте их опыт работы в секторе автомобильных запчастей. Убедитесь, что они имеют необходимые сертификаты и соответствуют международным стандартам качества. Кроме того, оцените, насколько оперативно они работают с клиентами и предоставляют ли подробную информацию о продукции, гарантии и послепродажную поддержку. -

Каковы типичные условия оплаты международных заказов автомобильных запчастей?

Условия оплаты могут значительно отличаться в зависимости от поставщика и региона. Распространенными вариантами являются аккредитивы, банковские переводы и PayPal для небольших сделок. Рекомендуется договориться об условиях, устраивающих обе стороны, например о частичной предоплате с остатком по факту поставки. Во избежание непредвиденных расходов всегда уточняйте любые дополнительные сборы, связанные с конвертацией валют или международными транзакциями. -

Каковы минимальные объемы заказа (MOQ) для автомобильных стартерных двигателей?

Минимальные объемы заказов могут отличаться в зависимости от поставщика и конкретной линейки продукции. У некоторых поставщиков MOQ может составлять всего 10-20 единиц, в то время как другие могут требовать более крупных заказов для обеспечения экономической эффективности. При ведении переговоров учитывайте свои потребности в запасах и возможность будущих заказов, так как некоторые поставщики могут предлагать скидки при больших объемах закупок или допускать гибкость в отношении MOQ для первых покупателей. -

Какие меры по обеспечению качества следует искать в автомобильных стартерах?

Меры по обеспечению качества включают сертификаты, такие как стандарты ISO, которые указывают на соответствие международным практикам управления качеством. Поинтересуйтесь, как поставщик проводит испытания стартерных двигателей, включая тесты на функциональность и оценку долговечности. Кроме того, убедитесь, что они предлагают гарантии, покрывающие дефекты и эксплуатационные характеристики, поскольку это отражает их уверенность в качестве продукции. -

Как обеспечить своевременную доставку автомобильных стартеров при международных перевозках?

Чтобы обеспечить своевременную доставку, четко обговорите с поставщиком необходимые вам сроки. Обсудите способы доставки и выберите надежных перевозчиков с хорошей репутацией в сфере международной логистики. Воспользуйтесь услугами по отслеживанию груза и рассмотрите возможность сотрудничества с поставщиками, имеющими склады в вашем регионе, чтобы сократить время доставки. -

Какие варианты настройки доступны для автомобильных стартерных двигателей?

Варианты настройки могут включать изменения напряжения, мощности и конструктивных характеристик в соответствии с требованиями конкретного автомобиля. Некоторые поставщики предлагают возможность модификации таких компонентов, как зубья шестерен или направление вращения. Обсудите свои конкретные потребности с потенциальными поставщиками, чтобы узнать, смогут ли они удовлетворить специальные запросы или модификации для вашего заказа. -

Как обрабатывать возврат или обмен автомобильных стартерных двигателей?

Прежде чем совершить покупку, ознакомьтесь с правилами возврата товара поставщиком. Большинство поставщиков разрешают возврат бракованных товаров или неправильно оформленных заказов в течение определенного срока, часто составляющего от 30 до 90 дней. Убедитесь, что вы сохранили оригинальную упаковку и все сопроводительные документы. При возникновении проблем незамедлительно свяжитесь со службой поддержки поставщика, чтобы начать процесс возврата и уточнить возможную стоимость возврата.

Список производителей и поставщиков 4 лучших частей автомобильного стартера

1. BuyAutoParts - Стартер

Домен: buyautoparts.com

Зарегистрирован: 2001 (24 года)

Введение: Ключевые детали продукта:

- Тип продукта: Стартовый

- Бренд: BuyAutoParts

- Гарантия: 1 год гарантии без ограничения пробега

- Состояние: Доступны новые и восстановленные модели

- Номера деталей: 30-07447AR, 30-07357AN, 30-07665AR, 30-07692AR, 30-07673AR, 30-07525AR, 30-07318AR, 30-06355AN, 30-07646AR

- Бесплатная доставка: При заказе свыше $99

- Быстрая доставка: Отправка с нескольких складов по всей стране

- Легкое возвращение...

2. Facebook - Компоненты соленоидов

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: Эта компания, Facebook - Solenoid Components, является заметным субъектом на рынке. Для получения подробной информации о продукции рекомендуется посетить их сайт.

3. Bosch - Стартеры и генераторы переменного тока

Домен: boschautoparts.com

Зарегистрирован: 2004 (21 год)

Введение: Стартеры и генераторы переменного тока - важнейшие компоненты электрической системы автомобиля. Стартеры отвечают за запуск двигателя, а генераторы вырабатывают электроэнергию для питания электрических систем автомобиля и подзарядки аккумулятора. Bosch предлагает ряд высококачественных стартеров и генераторов переменного тока, предназначенных для различных марок и моделей автомобилей и обеспечивающих надежность и производительность...

4. Advance Auto Parts - Двигатель стартера

Домен: shop.advanceautoparts.com

Зарегистрирован: 1997 (28 лет)

Введение: Стартер - это электродвигатель, запускающий процесс сгорания топлива в двигателе. Он активируется при повороте ключа зажигания или нажатии кнопки, обеспечивая усилие, необходимое для запуска двигателя. Стартеры требуют замены, когда они проявляют признаки износа или не могут запустить двигатель. Advance Auto Parts предлагает доступные стартеры для всех марок и моделей автомобилей от таких брендов, как Carquest Pro...

Выводы и перспективы стратегического сорсинга для деталей автомобильного стартера

В динамичном ландшафте автомобильных запчастей для стартеров стратегический поиск поставщиков становится ключевым фактором для международных покупателей B2B. Используя надежную цепочку поставок и уделяя особое внимание качеству, совместимости и надежности, покупатели могут обеспечить удовлетворение растущих потребностей своих рынков, особенно в таких регионах, как Африка, Южная Америка, Ближний Восток и Европа. Сотрудничество с поставщиками, предоставляющими гарантии точного соответствия и комплексные гарантии, может значительно повысить удовлетворенность клиентов и снизить количество возвратов.

Инвестиции в долгосрочные отношения с авторитетными производителями позволяют компаниям использовать технологический прогресс и инновации в производстве. Такой проактивный подход не только снижает риски, связанные с нарушением цепочки поставок, но и позволяет компаниям оперативно реагировать на изменения рынка и потребительских предпочтений.

В будущем автомобильную промышленность ожидают перемены, вызванные развитием электромобилей и инициативами в области устойчивого развития. Сейчас самое время для международных покупателей привести свои стратегии поиска поставщиков в соответствие с этими тенденциями, чтобы быть уверенными в том, что они смогут ориентироваться в меняющемся ландшафте. Воспользуйтесь стратегическим подбором поставщиков сегодня, чтобы обеспечить себе конкурентное преимущество и способствовать устойчивому росту автомобильного сектора.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Иллюстративное изображение, относящееся к запчасти автомобильного двигателя стартера

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.