Введение: Навигация по глобальному рынку генераторов переменного тока

При рассмотрении вопроса о стоимости поиска генератора переменного тока многие международные покупатели B2B часто сталкиваются с проблемой оценки того, является ли генератор дорогим по сравнению с их эксплуатационными потребностями. Цена генератора переменного тока может значительно варьироваться в зависимости от таких факторов, как тип, марка, модель и конкретная сила тока, необходимая для различных автомобилей. Данное руководство призвано разъяснить сложности, связанные с ценообразованием на генераторы переменного тока, предоставив полный обзор различных типов, их применения в различных отраслях промышленности и ключевых соображений при проверке поставщиков.

В этом руководстве вы узнаете о важнейших аспектах поиска генератора переменного тока, включая подробную разбивку затрат, связанных с новыми и восстановленными вариантами, а также о влиянии трудозатрат на общую сумму расходов. Кроме того, мы изучим нюансы гарантийных обязательств и то, как они могут повлиять на ваши решения о покупке. Вооружив покупателей B2B из таких регионов, как Африка, Южная Америка, Ближний Восток и Европа, особенно на рынках Германии и Бразилии, полезными сведениями, это руководство позволит вам принимать взвешенные решения, соответствующие вашим бизнес-целям. Независимо от того, хотите ли вы повысить производительность своего автопарка или сократить расходы на обслуживание, понимание тонкостей ценообразования на генераторы переменного тока поможет вам уверенно ориентироваться на мировом рынке.

Содержание

- Список 5 лучших производителей и поставщиков генератора

- Введение: Навигация по глобальному рынку генераторов переменного тока

- Понимание того, что такое генератор переменного тока дорогих типов и разновидностей

- Основные промышленные применения генератора переменного тока

- 3 распространенных болевых точки пользователя для ‘дорого ли стоит генератор’ и их решения

- Руководство по выбору стратегических материалов для дорогостоящего генератора переменного тока

- Глубокий взгляд: Производственные процессы и обеспечение качества для генератора переменного тока

- Практическое руководство по поиску: Пошаговый контрольный список для ‘дорого ли стоит генератор’

- Всесторонний анализ затрат и цен на генератор переменного тока дорогостоящий поиск

- Анализ альтернатив: Сравнение дороговизны генератора с другими решениями

- Основные технические свойства и торговая терминология для генератора переменного тока

- Навигация по динамике рынка и тенденциям поиска поставщиков в дорогом секторе генератора переменного тока

- Часто задаваемые вопросы (FAQ) для B2B покупателей генератора переменного тока.

- Заключение и перспективы стратегического сорсинга для генератора переменного тока

- Важное предупреждение и условия использования

Понимание того, что такое генератор переменного тока дорогих типов и разновидностей

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Новые генераторы | Совершенно новые компоненты с полной гарантией и надежностью | Автомобильное производство, обслуживание автопарков | Плюсы: Длительный срок службы, высокая надежность. Минусы: Более высокая начальная стоимость. |

| Восстановленные генераторы | Восстановленные из бывших в употреблении деталей, часто с ограниченной гарантией | Авторемонтные мастерские, экономные автопарки | Плюсы: Экономичность, сокращение сроков изготовления. Минусы: Срок службы может быть меньше, чем у новых. |

| Высокопроизводительные генераторы | Более высокие показатели силы тока для современных электрических систем | Автомобили с высокими эксплуатационными характеристиками, тяжелые условия эксплуатации | Плюсы: Поддерживает передовые технологии, пользуется большим спросом. Минусы: Более высокая стоимость, может потребоваться специализированная установка. |

| Альтернаторы OEM (Original Equipment Manufacturer) | Разработано в соответствии со спецификациями производителя автомобиля | Дилерские центры, поставщики услуг премиум-класса | Плюсы: Идеальная посадка, одобренная производителем. Минусы: Высокая цена, ограниченная доступность. |

| Универсальные генераторы | Универсальная установка для различных моделей автомобилей | Поставщики запасных частей, механики "сделай сам | Плюсы: Широкая совместимость, часто более низкая стоимость. Минусы: Может не соответствовать специфическим потребностям в мощности для всех автомобилей. |

Каковы характеристики новых альтернаторов и их пригодность для покупателей B2B?

Новые генераторы производятся с нуля, обеспечивая оптимальную производительность и долговечность. Эти компоненты идеально подходят для покупателей B2B, занимающихся производством автомобилей или обслуживанием автопарков, поскольку они поставляются с полной гарантией и отличаются надежностью. Однако более высокая первоначальная стоимость может отпугнуть экономных покупателей. При покупке учитывайте срок гарантии и ожидаемый срок службы, чтобы оправдать вложения.

Чем отличаются восстановленные генераторы от бюджетных покупателей B2B?

Восстановленные генераторы восстанавливаются из бывших в употреблении блоков, представляя собой экономически выгодную альтернативу для таких предприятий, как авторемонтные мастерские и автопарки с ограниченным бюджетом. Как правило, на них предоставляется ограниченная гарантия, что делает их привлекательным вариантом для тех, кто стремится минимизировать расходы. Однако покупателям следует помнить, что, хотя они и дешевле, срок их службы может не соответствовать сроку службы новых генераторов. Оценка условий гарантии и репутации производителя очень важна при рассмотрении этого варианта.

Каковы преимущества высокопроизводительных генераторов переменного тока для применения в технике?

Высокопроизводительные генераторы переменного тока предназначены для обеспечения повышенной силы тока, что позволяет использовать их в автомобилях с усовершенствованными электрическими системами, например, в легковых автомобилях или тяжелых грузовиках. Эти устройства незаменимы для предприятий, ориентированных на повышение производительности, или для тех, кто эксплуатирует оборудование с высокими требованиями к электричеству. Хотя они поддерживают передовые технологии, при принятии решения о покупке следует учитывать сопутствующие расходы и потенциальную сложность установки.

Почему стоит выбрать OEM-альтернаторы для поставщиков услуг премиум-класса?

Генераторы переменного тока OEM изготавливаются в соответствии с точными спецификациями, установленными производителями автомобилей, что обеспечивает их идеальную совместимость. Они часто являются предпочтительным выбором для дилерских центров и сервисных центров премиум-класса, поскольку гарантируют качество и надежность. Однако высокая цена и потенциально ограниченное наличие могут создавать проблемы. Покупателям B2B следует взвесить преимущества гарантированной производительности и более высокую стоимость.

Что делает универсальные генераторы привлекательным вариантом для поставщиков запчастей?

Универсальные генераторы переменного тока обеспечивают гибкость и совместимость с различными моделями автомобилей, что делает их популярным выбором среди поставщиков запчастей для вторичного рынка и механиков-самоучек. Их низкая цена привлекает покупателей с ограниченным бюджетом. Однако важно оценить, могут ли эти генераторы соответствовать специфическим требованиям к мощности различных автомобилей. Обеспечение правильных технических характеристик и совместимости является жизненно важным условием успешного применения.

Основные промышленные применения генератора переменного тока

| Отрасль/сектор | Специфическое применение генератора переменного тока | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Линии сборки автомобилей, требующие надежного электропитания | Обеспечивает непрерывную работу и сокращает время простоя | Совместимость со спецификациями и правилами эксплуатации автомобилей |

| Возобновляемые источники энергии | Ветряные турбины для производства энергии | Обеспечивает постоянную выработку энергии и надежность системы | Поиск долговечных и эффективных генераторов переменного тока для различных условий эксплуатации |

| Строительное оборудование | Тяжелая техника, например, экскаваторы и краны | Повышает эффективность работы и надежность оборудования | Оценка мощности генератора в зависимости от потребностей оборудования в электроэнергии |

| Морская промышленность | Производство электроэнергии на кораблях и судах | Обеспечение бесперебойной работы во время плавания | Использование компонентов морского класса для обеспечения коррозионной стойкости |

| Транспорт и логистика | Системы управления автопарком в грузовиках и автобусах | Оптимизирует эксплуатационные характеристики автомобиля и снижает затраты на техническое обслуживание | Доступность запчастей и сервисной поддержки в различных регионах |

Как дорогостоящий генератор используется в автомобилестроении?

В автомобильном производстве генераторы переменного тока имеют решающее значение для питания оборудования сборочных линий и роботизированных систем. Выход из строя генератора может остановить производство, что приведет к значительным финансовым потерям. Для международных покупателей, особенно в таких регионах, как Африка и Южная Америка, очень важен выбор генераторов переменного тока, отвечающих специфическим требованиям автомобилей и местным нормам. Это обеспечивает совместимость и надежность, сводя к минимуму время простоя оборудования.

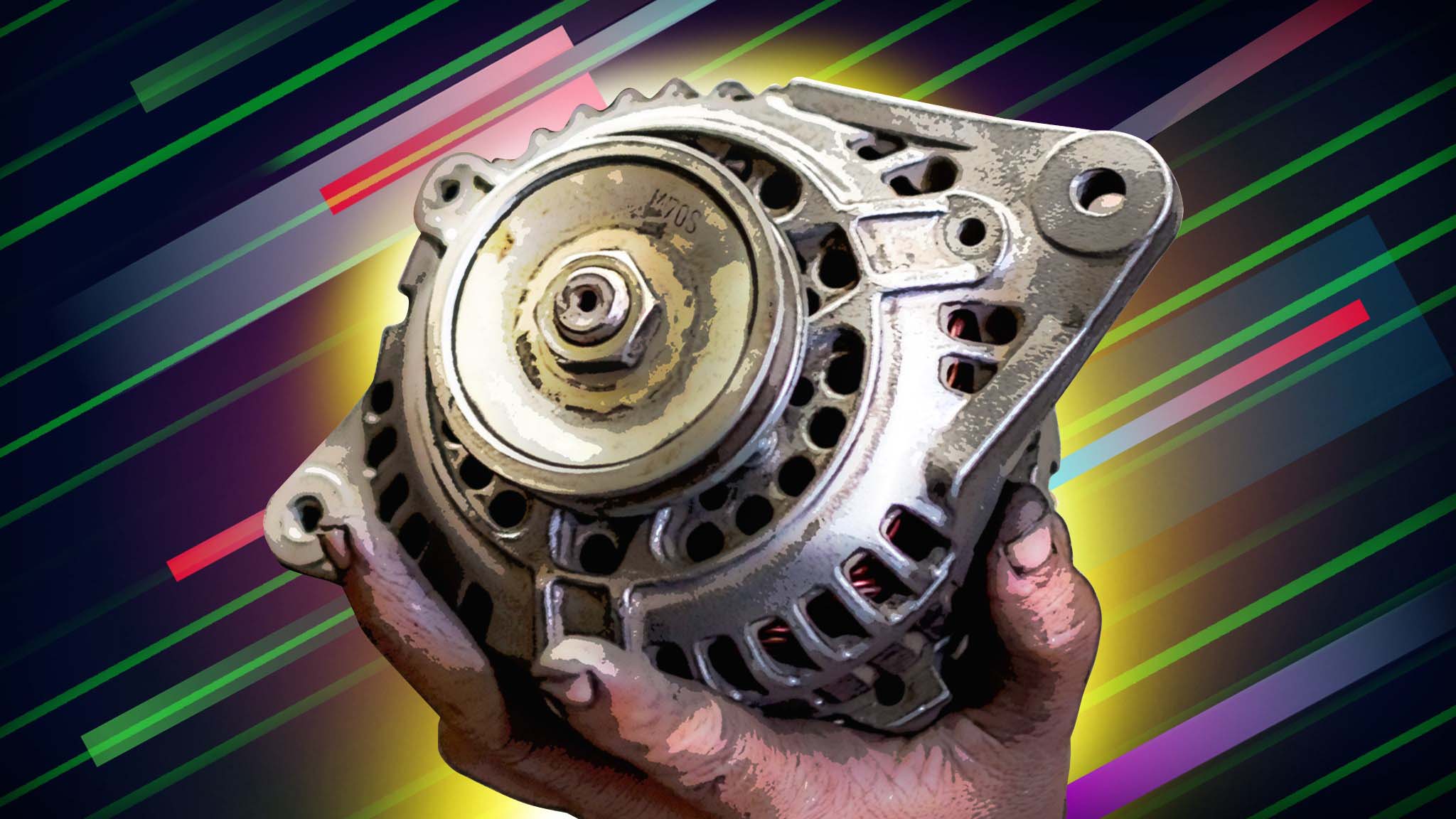

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

Какую роль играет генератор переменного тока в возобновляемых источниках энергии?

В возобновляемых источниках энергии, в частности в ветряных турбинах, генераторы переменного тока преобразуют механическую энергию в электрическую, обеспечивая постоянное энергоснабжение. Первоначальная стоимость высокоэффективных генераторов переменного тока может быть значительной, но долгосрочные преимущества включают в себя снижение затрат на обслуживание и увеличение выработки энергии. Покупателям в Европе и на Ближнем Востоке следует обратить внимание на генераторы переменного тока, которые достаточно надежны, чтобы выдерживать такие неблагоприятные условия окружающей среды, как сильные ветры и перепады температур.

Как генераторы переменного тока повышают эффективность строительного оборудования?

Тяжелая строительная техника, такая как экскаваторы и краны, использует генераторы переменного тока для питания электрических систем и запуска двигателей. Стоимость этих генераторов зависит от их мощности и долговечности. Для предприятий, расположенных в регионах с суровыми условиями эксплуатации, таких как Бразилия, очень важно выбирать генераторы переменного тока, предназначенные для тяжелых условий эксплуатации, чтобы обеспечить надежность и сократить частоту замены.

Почему генераторы переменного тока жизненно важны для морской промышленности?

В морской промышленности генераторы переменного тока необходимы для выработки энергии для бортовых систем, включая навигационное и коммуникационное оборудование. Стоимость генераторов переменного тока морского класса может быть выше из-за их специальной конструкции, которая должна противостоять коррозии от соленой воды. Покупателям с международных рынков следует отдавать предпочтение тем генераторам, которые соответствуют морским стандартам и имеют проверенную репутацию надежных в морских операциях.

Как генераторы переменного тока влияют на управление автопарком в сфере транспорта и логистики?

В сфере транспорта и логистики транспортные средства зависят от генераторов переменного тока для поддержания оптимальной производительности и минимизации затрат на обслуживание. Расходы, связанные с высокопроизводительными генераторами переменного тока, оправданы их способностью поддерживать передовые электронные системы современных автомобилей. Руководители автопарков в таких регионах, как Африка и Европа, должны сосредоточиться на поиске генераторов переменного тока, предлагающих гарантийные опции и доступных для быстрой замены, чтобы обеспечить эффективность работы автопарка.

3 распространенных болевых точки пользователя для ‘дорого ли стоит генератор’ и их решения

Сценарий 1: Понимание различий в стоимости генераторов переменного тока для разных типов автомобилей

Проблема: Покупатели B2B часто сталкиваются со значительными различиями в ценах на генераторы переменного тока в зависимости от типа обслуживаемого ими автомобиля. Например, покупателю, работающему в компании по управлению автопарком, может потребоваться замена генераторов переменного тока для различных транспортных средств, от компактных автомобилей до тяжелых грузовиков. Такое несоответствие может привести к непредвиденным расходам и проблемам с составлением бюджета, особенно когда стоимость высокопроизводительных генераторов для крупных автомобилей может превышать $1 000. Покупатели могут не понимать, почему одни генераторы стоят значительно дороже других, что приводит к путанице и потенциальному финансовому напряжению при управлении бюджетом на ремонт.

Решение: Чтобы эффективно ориентироваться в этих колебаниях стоимости, покупатели B2B должны провести тщательное исследование рынка, чтобы понять специфические потребности в генераторах переменного тока для каждого типа транспортных средств в их автопарке. Использование инструментов анализа данных поможет отследить средние затраты, связанные с различными моделями, и частоту их отказов, что позволит покупателям более точно прогнозировать расходы. Кроме того, налаживание отношений с несколькими поставщиками может дать представление о тенденциях ценообразования и потенциальных скидках при оптовых закупках. Покупатели также должны убедиться в том, что они закупают оборудование, соответствующее силе тока и техническим характеристикам каждого автомобиля, чтобы не переплачивать за ненужные функции. Четко документируя эти требования и используя партнерские отношения с поставщиками, компании могут создать более предсказуемый и управляемый бюджет на замену генератора.

Сценарий 2: Скрытые затраты на отказ генератора в бизнес-операциях

Проблема: Неожиданные поломки генератора могут привести к простою автомобилей, что серьезно скажется на бизнес-операциях. Например, логистическая компания, использующая парк фургонов для доставки грузов, может обнаружить, что неожиданная неисправность генератора может привести к задержке поставок, что приведет к недовольству клиентов и потенциальной потере контрактов. Этот сценарий становится еще более сложным, когда расходы на ремонт усугубляются потерянными доходами за время простоя, создавая каскадный финансовый эффект, который может угрожать нижней границе компании.

Решение: Чтобы снизить риск внезапного выхода из строя генератора переменного тока, покупателям B2B следует внедрить стратегию проактивного технического обслуживания. Регулярные проверки и тестирование генераторов, в идеале включенные в комплексный график технического обслуживания автомобиля, помогут выявить потенциальные проблемы до того, как они приведут к отказу. Покупатели могут инвестировать в обучение своих специалистов по техническому обслуживанию, чтобы они могли распознавать ранние признаки проблем с генератором, такие как тусклый свет или необычные шумы. Кроме того, налаживание партнерских отношений с надежными местными ремонтными мастерскими может ускорить процесс ремонта и свести к минимуму время простоя автомобиля. Уделяя первоочередное внимание профилактическому обслуживанию и разрабатывая планы на случай непредвиденных обстоятельств, предприятия могут снизить вероятность непредвиденных расходов на ремонт и обеспечить бесперебойную работу.

Сценарий 3: Баланс между качеством и стоимостью при поиске альтернаторов

Проблема: Покупатели B2B часто сталкиваются с дилеммой баланса между качеством и стоимостью при поиске генераторов переменного тока. Некоторые из них могут склоняться к более дешевым вариантам, чтобы не выходить за рамки бюджета, рискуя при этом долговечностью и надежностью деталей. Например, покупатель, подбирающий запчасти для автосервиса, может обнаружить, что выбор в пользу восстановленных генераторов позволяет сэкономить деньги на начальном этапе, но может привести к более частой замене, что в конечном итоге сведет на нет все выгоды. Такой процесс принятия решений может привести к разочарованию и неуверенности в том, как сохранить конкурентные преимущества, обеспечив при этом удовлетворенность клиентов за счет качественного ремонта.

Решение: Чтобы найти баланс между качеством и стоимостью, покупателям B2B следует отдавать предпочтение поставщикам, которые предлагают широкий выбор вариантов, включая как новые, так и восстановленные генераторы, предоставляя при этом прозрачную информацию о гарантиях и ожидаемых сроках службы каждого продукта. Проведение анализа затрат и выгод, учитывающего не только первоначальные расходы, но и общую стоимость владения, включая установку, возможные замены в будущем и гарантийные обязательства, может внести ясность. Покупателям также следует обсудить с поставщиками историю производительности различных брендов и моделей, чтобы получить рекомендации, соответствующие их конкретным потребностям. Составив матрицу критериев, в которой взвешиваются качество, цена и гарантийные обязательства, покупатели смогут принимать обоснованные решения, обеспечивающие удовлетворенность клиентов без ущерба для их финансового состояния.

Руководство по выбору стратегических материалов для дорогостоящего генератора переменного тока

Какие материалы обычно используются в генераторах и какова их стоимость?

При оценке стоимости генераторов переменного тока необходимо учитывать материалы, используемые в их конструкции. Различные материалы влияют на производительность, долговечность и, в конечном счете, на цену. Ниже мы проанализируем распространенные материалы, используемые в генераторах, обратив внимание на их свойства, преимущества, недостатки и соображения для международных покупателей B2B.

Как медь влияет на производительность и стоимость генератора?

Ключевые свойства: Медь известна своей превосходной электропроводностью и теплопроводностью, что делает ее идеальным материалом для обмоток генераторов. Она выдерживает высокие температуры и устойчива к коррозии.

Плюсы и минусы: Основным преимуществом меди является ее превосходная проводимость, что повышает эффективность работы генератора. Однако медь относительно дорога по сравнению с такими альтернативами, как алюминий. Производственные процессы с использованием меди также могут быть сложными, что приводит к увеличению стоимости производства.

Влияние на применение: Медные обмотки обеспечивают эффективное преобразование энергии, что крайне важно для автомобилей с высокими требованиями к электричеству, например, оснащенных передовыми технологиями и многочисленными электронными системами.

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

Соображения для международных покупателей: Покупатели из таких регионов, как Европа и Ближний Восток, должны быть осведомлены о росте цен на медь и возможных проблемах с поставками. Соответствие стандартам, таким как ASTM и DIN, также может диктовать использование определенных сортов меди.

Какую роль играет алюминий в производстве генераторов?

Ключевые свойства: Алюминий легок и обладает хорошей электропроводностью, хотя он менее электропроводен, чем медь. Он также очень устойчив к коррозии, что делает его пригодным для использования в различных средах.

Плюсы и минусы: Основным преимуществом алюминия является его низкая стоимость и вес, что позволяет снизить общий вес автомобиля и повысить топливную экономичность. Однако его более низкая проводимость может привести к снижению эффективности передачи энергии по сравнению с медью.

Влияние на применение: Алюминий часто используется в менее требовательных приложениях или в генераторах для небольших автомобилей, где экономия веса является приоритетом перед максимальной эффективностью.

Соображения для международных покупателей: Покупатели в Южной Америке и Африке могут счесть алюминиевые генераторы более экономичными, но им следует учитывать компромиссы в производительности. Соответствие местным стандартам и нормам также имеет решающее значение.

Как пластики и композиты улучшают конструкцию генератора?

Ключевые свойства: Пластмассы и композиты имеют небольшой вес и могут быть сформованы в сложные формы. Они обладают хорошей устойчивостью к нагреву и коррозии, в зависимости от конкретного типа.

Плюсы и минусы: Использование пластмасс позволяет значительно уменьшить вес и сложность производства, что ведет к снижению стоимости. Однако их механические свойства могут не соответствовать свойствам металлов, что может негативно сказаться на долговечности и термостойкости.

Влияние на применение: Пластмассы часто используются в неструктурных компонентах генераторов, таких как корпуса или крышки, где экономия веса выгодна, но они могут не подходить для областей с высокой нагрузкой.

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

Соображения для международных покупателей: Покупатели должны убедиться, что используемые пластики соответствуют соответствующим стандартам, таким как JIS или ASTM. Кроме того, влияние пластиковых материалов на окружающую среду становится важным фактором, особенно в Европе.

Какое значение имеет сталь в конструкции генератора?

Ключевые свойства: Сталь известна своей прочностью и долговечностью, что делает ее отличным выбором для конструктивных элементов генераторов. Она выдерживает высокие температуры и механические нагрузки.

Плюсы и минусы: Основным преимуществом стали является ее прочность, которая обеспечивает долговечность и надежность. Однако она тяжелее таких альтернатив, как алюминий, что может повлиять на топливную экономичность.

Влияние на применение: Сталь широко используется в корпусе и монтажных кронштейнах генераторов, где прочность необходима для поддержки компонентов устройства и противостояния вибрациям.

Соображения для международных покупателей: Покупатели должны знать о различных сортах стали и их соответствии международным стандартам. Кроме того, стоимость стали может колебаться в зависимости от конъюнктуры мирового рынка, что влияет на общую стоимость генераторов.

Сводная таблица материалов для генераторов переменного тока

| Материал | Типичный пример использования - дорогой генератор переменного тока | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Медь | Обмотки и электрические соединения | Превосходная электропроводность | Высокая стоимость и сложность производства | Высокий |

| Алюминий | Легкие генераторы переменного тока для небольших автомобилей | Экономичный и легкий | Более низкая проводимость, чем у меди | Средний |

| Пластмассы | Неструктурные компоненты (корпуса, крышки) | Малый вес и простота изготовления | Проблемы долговечности в зонах с высокими нагрузками | Низкий |

| Сталь | Конструктивные элементы (корпуса, кронштейны) | Высокая прочность и долговечность | Более тяжелые, что влияет на топливную экономичность | Средний |

Этот анализ предоставляет ценные сведения для покупателей B2B, рассматривающих материалы для генераторов, помогая им принимать обоснованные решения, основанные на производительности, стоимости и региональном соответствии.

Глубокий взгляд: Производственные процессы и обеспечение качества для генератора переменного тока

Каковы основные этапы производства генератора?

Процесс производства генераторов переменного тока включает в себя несколько критических этапов, каждый из которых призван обеспечить соответствие конечного продукта требуемым стандартам производительности и качества. Понимание этих этапов может помочь покупателям B2B оценить стоимость генератора переменного тока и связанные с ним расходы.

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

Подготовка материалов: Какие материалы используются в генераторах?

Первый этап производства генератора - подготовка материалов. Ключевыми компонентами являются медь для обмоток, железо для ротора, алюминий или сталь для корпуса, а также различные пластмассы для электроизоляции. Качество этих материалов напрямую влияет на производительность и долговечность генератора. Например, медь высокой чистоты необходима для эффективной электропроводности, а прочные пластмассы - для того, чтобы выдерживать тепловое и электрическое напряжение.

Как формируются и собираются генераторы переменного тока?

После подготовки материалов наступает следующий этап - формовка и сборка. Обычно это включает в себя несколько технологий:

-

Штамповка: Листовой металл штампуется в необходимые формы для корпуса генератора и других компонентов. В этом процессе необходимо соблюдать точность, чтобы обеспечить правильную посадку и функционирование.

-

Намотка: Медная проволока наматывается на катушки, которые создают магнитное поле, необходимое для работы генератора. Количество витков и калибр проволоки могут существенно повлиять на выходную силу тока генератора.

-

Ротор в сборе: Ротор, который является вращающейся частью генератора, собран вместе со статором. Этот узел должен быть точно сбалансирован, чтобы минимизировать вибрацию во время работы.

-

Заключительная сборка: Все компоненты, включая выпрямитель, регулятор напряжения и подшипники, собираются вместе. Этот этап требует квалифицированного труда, чтобы все детали идеально подошли друг к другу и работали так, как нужно.

Какие методы отделки используются при производстве генераторов?

Процессы отделки имеют решающее значение для повышения долговечности и производительности генераторов переменного тока. К ним относятся:

-

Покрытие: Нанесение защитных покрытий для предотвращения коррозии и улучшения электроизоляции. Это особенно важно для компонентов, подверженных жестким условиям эксплуатации.

-

Тестирование: Проведение электрических испытаний, чтобы убедиться, что генератор соответствует спецификациям по напряжению и силе тока. Этот этап необходим для обеспечения качества перед отправкой продукта.

Какие стандарты обеспечения качества имеют отношение к производству генераторов?

Обеспечение качества имеет первостепенное значение при производстве генераторов переменного тока. Международные стандарты, такие как ISO 9001, определяют рамки систем управления качеством, обеспечивая постоянное соответствие производителей требованиям клиентов и регулирующих органов. Кроме того, отраслевые сертификаты, такие как CE (Европейское соответствие) и API (Американский институт нефти), подтверждают соответствие стандартам безопасности и производительности, особенно для генераторов, используемых в специализированных приложениях.

Каковы ключевые контрольные точки контроля качества в производстве генераторов?

Контроль качества (QC) включает в себя множество контрольных точек на протяжении всего производственного процесса:

-

Входящий контроль качества (IQC): На этом этапе сырье проверяется на соответствие установленным стандартам, прежде чем оно будет использовано в производстве. Для покупателей B2B понимание процессов IQC поставщика может дать представление о качестве конечного продукта.

-

Контроль качества в процессе производства (IPQC): Эта контрольная точка контролирует сам процесс производства, обеспечивая соблюдение стандартов качества на каждом этапе. Для отслеживания показателей качества в режиме реального времени могут применяться такие методы, как статистический контроль процесса (SPC).

-

Окончательный контроль качества (FQC): Перед отправкой каждый генератор проходит всесторонние испытания для проверки его работоспособности. Обычно это включает в себя электрические испытания, оценку прочности и визуальный осмотр.

Как покупатели B2B могут проверить контроль качества поставщиков?

Для международных покупателей B2B проверка процессов контроля качества поставщика имеет решающее значение для обеспечения надежности и эффективности продукции. Вот несколько стратегий, которые следует рассмотреть:

-

Проведение аудитов: Регулярные аудиты производственных мощностей помогут проверить соответствие международным стандартам и внутренним процессам контроля качества поставщика. Покупатели должны искать доказательства систематической практики контроля качества и соблюдения таких сертификатов, как ISO 9001.

-

Запросите отчеты о качестве: Поставщики должны быть в состоянии предоставить документацию с подробным описанием процессов контроля качества и результатов любых проведенных испытаний. Это включает в себя отчеты по этапам IQC, IPQC и FQC.

-

Привлеките сторонних инспекторов: Использование услуг сторонней инспекции позволяет непредвзято оценить производственный процесс и качество продукции. Это особенно полезно для покупателей в таких регионах, как Африка, Южная Америка и Ближний Восток, где местные нормативные стандарты могут отличаться.

Какие нюансы контроля качества и сертификации следует учитывать международным покупателям?

Приобретая генераторы переменного тока у зарубежных поставщиков, покупатели должны знать о некоторых нюансах в области контроля качества и сертификации:

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

-

Региональные стандарты: В разных регионах могут существовать особые стандарты, которым необходимо соответствовать. Например, европейские покупатели могут отдавать предпочтение сертификации CE, в то время как покупатели в Северной Америке могут сосредоточиться на соответствии стандартам SAE (Общество автомобильных инженеров).

-

Прозрачность цепочки поставок: Понимание всей цепочки поставок может помочь покупателям оценить потенциальные риски, связанные с качеством. Это включает в себя знание того, откуда берутся материалы и как они обрабатываются.

-

Культурные различия в практике качества: Практика обеспечения качества может существенно различаться в зависимости от региона из-за культурных особенностей производства и качества. Покупатели должны быть готовы учитывать эти различия при установлении отношений с поставщиками.

Заключение: Почему понимание производственных процессов и контроля качества важно для покупателей B2B

Для покупателей B2B, рассматривающих стоимость генераторов переменного тока, жизненно важным является глубокое понимание производственных процессов и методов обеспечения качества. Эти знания не только помогают оценить цену генератора, но и выбрать надежных поставщиков, которые уделяют первостепенное внимание качеству. Используя строгие методы проверки и понимая нюансы международных стандартов, покупатели могут быть уверены, что инвестируют в качественную продукцию, которая отвечает их эксплуатационным потребностям.

Практическое руководство по поиску: Пошаговый контрольный список для ‘дорого ли стоит генератор’

При выборе генераторов переменного тока понимание их стоимости необходимо для принятия обоснованных решений о покупке. В этом руководстве приведен четкий контрольный список, который поможет покупателям B2B оценить цену и качество генераторов переменного тока с учетом их конкретных потребностей и факторов регионального рынка.

Шаг 1: Определите свои технические характеристики

Прежде чем приступить к процессу закупки, необходимо определить технические требования к генераторам переменного тока. Это включает в себя понимание года, марки, модели и объема двигателя автомобилей, для которых они будут использоваться.

– Ключевые соображения:

- Обеспечьте совместимость с вашим автопарком или инвентарем.

- Определите необходимую силу тока в зависимости от электрической нагрузки автомобилей.

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

Шаг 2: Исследование рынка ценообразования

Проведите тщательное исследование рыночных цен на генераторы переменного тока, чтобы установить исходные данные для переговоров. Цены могут сильно варьироваться в зависимости от нескольких факторов, включая тип автомобиля и технические характеристики генератора.

– Что искать:

- Средние затраты обычно составляют от $100 до $500 только на запчасти, а общая стоимость замены (включая трудозатраты) - от $300 до $900.

- Учитывайте географические различия в ценах, особенно если речь идет о закупках у международных поставщиков.

Шаг 3: Оценить сертификаты поставщиков

Обязательно проверьте сертификаты и стандарты качества потенциальных поставщиков. Авторитетный поставщик должен соответствовать международным автомобильным стандартам, что гарантирует надежность и безопасность генераторов.

– Важные проверки:

- Обратите внимание на наличие сертификатов ISO или эквивалентных отраслевых стандартов.

- Ознакомьтесь с любыми специальными сертификатами, относящимися к вашему региону или типу обслуживаемых вами автомобилей.

Шаг 4: Оцените возможности гарантии

Понимание гарантийных обязательств крайне важно при покупке генераторов переменного тока. Разные поставщики могут предлагать различные гарантийные сроки и условия, что влияет на долгосрочные затраты.

– Что нужно учитывать:

- Оцените длительность и условия гарантии - более длительная гарантия может свидетельствовать о более высоком качестве и долговечности.

- Сравните новые и восстановленные варианты, поскольку гарантии на них могут существенно отличаться.

Шаг 5: Проверьте качество продукции

Качество никогда не должно идти на компромисс с ценой. Запросите образцы или подробные спецификации, чтобы оценить качество сборки и материалы, из которых изготовлены генераторы.

– Ключевые показатели:

- Обратите внимание на качественные материалы, такие как медные обмотки и прочная конструкция.

- Поинтересуйтесь процессом производства, чтобы убедиться в соблюдении промышленных стандартов.

Шаг 6: Запрашивайте рекомендации клиентов

Общение с предыдущими клиентами может дать бесценные сведения о надежности поставщика и качестве его продукции. Запросите рекомендации, особенно у компаний из схожих отраслей или регионов.

– О чем просить:

- Поинтересуйтесь их опытом работы с продукцией поставщика и обслуживанием клиентов.

- Спросите, сталкивались ли они с какими-либо трудностями или проблемами после покупки и как они были решены.

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

Шаг 7: Обсудить условия и положения

Наконец, убедитесь, что все условия и положения четко определены до завершения покупки. Сюда входят условия оплаты, сроки доставки и правила возврата.

– Ключевые аспекты, которые необходимо прояснить:

- Поймите общую стоимость, включая доставку и обработку.

- Подтвердите графики поставок, чтобы они соответствовали вашим оперативным потребностям.

Следуя этому контрольному списку, покупатели B2B смогут эффективно ориентироваться в сложностях поиска генераторов переменного тока, обеспечивая принятие обоснованных решений, соответствующих их бизнес-целям.

Всесторонний анализ затрат и цен на генератор переменного тока дорогостоящий поиск

Понимание затрат, связанных с поиском генераторов переменного тока, имеет решающее значение для международных B2B-покупателей, особенно в таких регионах, как Африка, Южная Америка, Ближний Восток и Европа. Цена генератора переменного тока может значительно варьироваться в зависимости от различных факторов, включая его технические характеристики и условия поставки.

Каковы основные составляющие стоимости генераторов?

-

Материалы: Основные материалы, используемые в генераторах, включают медь для обмоток, алюминий для корпусов и различные пластмассы. Качество и количество этих материалов напрямую влияют на стоимость. Для генераторов переменного тока большей мощности, которые необходимы для автомобилей с современными электрическими системами, обычно требуется больше материалов, а значит, и стоимость выше.

-

Трудовые ресурсы: Стоимость рабочей силы может варьироваться в зависимости от географического положения и сложности производственного процесса. В регионах с более высокой стоимостью рабочей силы, таких как Европа, накладные расходы на производство могут существенно повлиять на конечную цену.

-

Производственные накладные расходы: Сюда входят косвенные расходы, связанные с производством, включая коммунальные услуги, аренду и административные расходы. Эффективные производственные процессы могут помочь снизить эти затраты, что приведет к более конкурентоспособным ценам.

-

Инструменты: Первоначальная подготовка к производству включает в себя затраты на оснастку, которые амортизируются в зависимости от объема производства. Нестандартные конструкции или спецификации могут увеличить стоимость оснастки, что влияет на общую структуру цен.

-

Контроль качества (КК): Применение строгих мер контроля качества увеличивает стоимость производства, но очень важно для обеспечения надежности и производительности, особенно для таких критически важных компонентов, как генераторы переменного тока.

-

Логистика: Стоимость доставки и обработки может сильно варьироваться в зависимости от источника и места назначения. Покупатели должны изучить Инкотермс, чтобы понять свою ответственность в отношении перевозки и рисков.

-

Маржа: Поставщики обычно добавляют маржу прибыли, чтобы покрыть свои расходы и обеспечить устойчивость. Эта маржа может варьироваться в зависимости от рыночных условий и конкурентной среды.

Как факторы, влияющие на цену, влияют на стоимость генератора?

-

Объем/минимальный объем заказа: Оптовые закупки часто приводят к скидкам. Покупатели должны договариваться о минимальных объемах заказа (MOQ), которые позволяют экономически эффективно осуществлять закупки без чрезмерных затрат на складские запасы.

-

Технические характеристики и индивидуальная настройка: Специализированные генераторы переменного тока, отвечающие уникальным требованиям, могут стоить дороже. Покупателям следует сопоставить преимущества индивидуальной настройки с дополнительными расходами.

-

Качество и сертификаты: Альтернаторы, соответствующие международным стандартам качества или имеющие специальные сертификаты, могут стоить дороже. Однако эти инвестиции могут снизить общую стоимость владения (TCO) за счет минимизации отказов и гарантийных претензий.

-

Факторы, связанные с поставщиками: Репутация и надежность поставщика могут повлиять на цену. Известные поставщики с проверенным послужным списком могут брать больше, но при этом предоставлять более надежные гарантии качества и обслуживания.

-

Инкотермс: Понимание условий доставки жизненно важно. Инкотермс определяют обязанности продавцов и покупателей, влияя на стоимость логистики. Например, выбор DDP (Delivered Duty Paid) может предложить более предсказуемые цены, но при этом может быть выше стоимость предварительной оплаты.

Какие советы могут помочь покупателям оптимизировать расходы?

-

Эффективные переговоры: Привлекайте поставщиков к обсуждению цен, особенно при размещении крупных заказов. Используйте знание рынка, чтобы договориться о более выгодных условиях.

-

Учитывайте общую стоимость владения: При оценке генераторов переменного тока учитывайте не только цену покупки, но и долгосрочные затраты, связанные с техническим обслуживанием, возможными отказами и энергоэффективностью.

-

Изучите нескольких поставщиков: Диверсификация базы поставщиков может привести к установлению конкурентоспособных цен и снизить зависимость от одного источника, уменьшив риски, связанные с нарушениями в цепочке поставок.

-

Будьте в курсе тенденций рынка: Знание тенденций мирового рынка, таких как стоимость материалов и расценки на рабочую силу, может помочь покупателям предвидеть изменения цен и принимать взвешенные решения о покупке.

Отказ от ответственности в отношении ориентировочных цен

Хотя стоимость генератора переменного тока может варьироваться от $100 до $1 000, эти цены являются ориентировочными и могут колебаться в зависимости от вышеуказанных факторов. Покупатели должны провести тщательное исследование рынка и оценку поставщиков, чтобы получить наиболее точные цены для своих конкретных потребностей.

Анализ альтернатив: Сравнение дороговизны генератора с другими решениями

Изучение альтернатив генераторам переменного тока: Сравнение стоимости и эффективности

В автомобильном и промышленном секторах необходимость в надежных электрических системах является первостепенной. Хотя генераторы переменного тока являются распространенным решением для выработки электроэнергии в транспортных средствах и оборудовании, различные альтернативные технологии могут достигать аналогичных результатов. В этом разделе рассматривается экономическая эффективность и практичность генераторов переменного тока по сравнению с другими решениями, такими как системы управления батареями и солнечные системы питания.

Сравнительная таблица

| Аспект сравнения | Дорогой ли генератор | Система управления аккумулятором | Система солнечной энергии |

|---|---|---|---|

| Производительность | Надежность для стандартных автомобилей; обеспечивает стабильную производительность | Оптимизирует расход заряда батареи; продлевает срок службы батареи | Возобновляемый источник энергии; эффективен в солнечных регионах |

| Стоимость | $300 - $900 (включая установку) | $200 - $600 (зависит от сложности) | $1,000 - $5,000 (первоначальные затраты на установку) |

| Простота внедрения | Умеренный; требуется профессиональная установка | Умеренный; часто требуется профессиональная настройка | Высокая; требует значительных затрат на установку и пространство |

| Техническое обслуживание | Низкая стоимость; обычно служит 7-10 лет при минимальном уходе | Умеренный; требуется периодическая проверка состояния батареи | Низкая стоимость; минимальное техническое обслуживание после установки |

| Лучший вариант использования | Традиционные автомобили со стандартными потребностями в электричестве | Электромобили и гибридные системы | Внесетевые приложения и решения в области устойчивой энергетики |

Подробная разбивка альтернатив

1. Система управления аккумулятором (BMS)

Системы управления аккумуляторами предназначены для контроля и управления процессом зарядки и разрядки аккумуляторов, особенно в электрических и гибридных автомобилях. BMS может значительно увеличить срок службы батареи за счет оптимизации циклов зарядки и балансировки заряда между несколькими элементами. Хотя первоначальные инвестиции обычно ниже, чем в новый генератор, эффективность BMS в значительной степени зависит от конструкции автомобиля и емкости батареи. Однако эти системы могут быть сложными, требующими профессиональной установки и постоянного контроля, что может повлечь за собой дополнительные расходы.

2. Система солнечной энергии

Системы солнечной энергии используют солнечный свет для выработки электроэнергии, что делает их привлекательной альтернативой для решений в области устойчивой энергетики. Они могут эффективно питать электрические системы транспортных средств или оборудования, особенно в удаленных или автономных местах. Первоначальные затраты на установку могут быть значительно выше, чем замена генератора, а эффективность солнечных систем зависит от географического положения и погодных условий. Однако после установки солнечные системы требуют минимального обслуживания и могут обеспечить долгосрочную экономию энергии. Они лучше всего подходят для мест с обилием солнечного света и там, где экологичность является приоритетом.

Заключение: выбор правильного решения для ваших нужд

При выборе генератора переменного тока и его альтернатив покупатели B2B должны учитывать свои конкретные эксплуатационные требования, бюджетные ограничения и долгосрочные цели. В то время как генераторы переменного тока, как правило, надежны и эффективны для традиционных транспортных средств, системы управления батареями обеспечивают более длительный срок службы батарей для электромобилей, а системы солнечной энергии обеспечивают устойчивый источник энергии в соответствующих условиях. Оценив производительность, стоимость и потребности в обслуживании, покупатели смогут выбрать оптимальное решение, соответствующее их эксплуатационным требованиям и финансовым возможностям, обеспечивая оптимальную эффективность и надежность своих электрических систем.

Основные технические свойства и торговая терминология для генератора переменного тока

Какие ключевые технические свойства генераторов влияют на стоимость?

Понимание технических характеристик генераторов переменного тока крайне важно для покупателей B2B, особенно при оценке стоимости. Вот некоторые важные свойства, которые следует учитывать:

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

1. Номинальный ток

Номинальная сила тока указывает на выходную мощность генератора. Более высокие показатели мощности необходимы для автомобилей с современными электрическими системами, например, оснащенных подогревом сидений или аудиосистемами высокого класса. Для покупателей B2B выбор правильного значения силы тока имеет решающее значение для того, чтобы генератор соответствовал требованиям к мощности автомобиля, тем самым предотвращая сбои в работе электрооборудования и потенциальные простои.

2. Марка материала

Материалы, используемые при производстве генераторов, в частности качество меди, применяемой в обмотках, существенно влияют на долговечность и производительность. Материалы более высокого качества обычно обеспечивают лучшую проводимость и более длительный срок службы, что может оправдать более высокую стоимость. Для предприятий инвестиции в высококачественные генераторы переменного тока могут сократить долгосрочные расходы на обслуживание и повысить удовлетворенность клиентов благодаря надежной работе.

3. Тип крепления

Стиль крепления определяет способ установки генератора в автомобиле, что влияет на совместимость и простоту замены. Различия в конструкциях крепления могут повлиять на трудозатраты при установке, поскольку некоторые генераторы могут потребовать более сложного демонтажа компонентов автомобиля. Понимание специфических требований к монтажу важно для покупателей B2B, чтобы избежать непредвиденных трудозатрат.

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

4. Гарантийный срок

Гарантийный срок, предоставляемый на генератор, может свидетельствовать об уверенности производителя в своем продукте. Более длительные гарантии часто сопровождаются более высокими первоначальными затратами, но могут обеспечить душевное спокойствие и экономию средств в случае выхода изделия из строя. Для предприятий оценка вариантов гарантии имеет решающее значение для составления бюджета и управления рисками.

5. Новые и восстановленные

Покупатели B2B часто сталкиваются с выбором между новыми и восстановленными генераторами переменного тока. Новые генераторы, как правило, обладают лучшими характеристиками и надежностью, но стоят дороже. Восстановленные устройства, хотя и стоят дешевле, могут иметь меньший срок службы. Оценка компромиссов между первоначальными затратами и долгосрочной надежностью очень важна для принятия обоснованных решений о покупке.

Каковы общие торговые термины, относящиеся к стоимости генератора?

Знакомство с отраслевым жаргоном имеет решающее значение для эффективного общения и ведения переговоров. Вот некоторые общие термины, имеющие отношение к закупкам генераторов:

1. OEM (производитель оригинального оборудования)

OEM означает детали, изготовленные тем же производителем, что и оригинальные детали для автомобиля. OEM-генераторы обычно стоят дороже из-за гарантированной совместимости и качества, что делает их предпочтительным выбором для многих компаний, ориентированных на надежность.

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

2. MOQ (минимальный объем заказа)

MOQ - это наименьшее количество товара, которое поставщик готов продать. Понимание MOQ важно для покупателей B2B, поскольку оно влияет на управление запасами и первоначальные инвестиционные затраты. Покупатели должны вести переговоры о MOQ, которые соответствуют их операционным потребностям.

3. RFQ (запрос предложения)

RFQ - это документ, в котором запрашиваются котировки поставщиков на конкретную продукцию. В контексте генераторов переменного тока RFQ помогает предприятиям получить конкурентоспособные цены и условия от нескольких поставщиков, способствуя принятию лучших решений о покупке.

4. Инкотермс (Международные торговые термины)

Инкотермс определяют обязанности покупателей и продавцов при международных перевозках. Знакомство с этими терминами помогает покупателям B2B понять свои обязательства в отношении стоимости доставки, страхования и рисков, связанных с поставкой генераторов переменного тока.

5. Время выполнения заказа

Время выполнения заказа - это время, которое проходит с момента размещения заказа до получения товара. Для предприятий понимание сроков поставки генераторов переменного тока имеет решающее значение для планирования запасов и обеспечения своевременного ремонта или графика производства.

Иллюстративное изображение, связанное с генератор переменного тока дорогостоящий

Зная эти технические характеристики и торговые условия, покупатели B2B могут принимать обоснованные решения о покупке генераторов переменного тока, что в конечном итоге оптимизирует эффективность затрат и эксплуатационную надежность.

Навигация по динамике рынка и тенденциям поиска поставщиков в дорогом секторе генератора переменного тока

Какова текущая динамика рынка, влияющая на стоимость генератора?

На мировой рынок генераторов переменного тока влияют несколько ключевых факторов, включая растущий спрос на электромобили (EV), развитие автомобильных технологий и переход к более эффективным энергетическим решениям. Поскольку в автомобильном секторе все чаще используются гибридные и полностью электрические системы, спрос на генераторы переменного тока высокой мощности резко возрос. Для международных B2B-покупателей, особенно из таких регионов, как Африка, Южная Америка, Ближний Восток и Европа, понимание этих тенденций имеет решающее значение. На рынке наблюдается заметный сдвиг в сторону поиска генераторов переменного тока, способных поддерживать передовые электрические системы, что отражает потребность в большей мощности для обеспечения таких функций, как высокопроизводительные аудиосистемы, современные системы безопасности и информационно-развлекательные технологии.

Новые технологические тенденции в сфере B2B включают интеграцию цифровых платформ для поиска поставщиков и автоматизированных систем управления цепочками поставок, которые способствуют более плавному процессу закупок. Эти технологии позволяют покупателям лучше оценивать возможности поставщиков, сравнивать цены и эффективно управлять логистикой. Кроме того, все большую популярность приобретают восстановленные генераторы переменного тока, поскольку предприятия ищут экономичные решения без ущерба для качества. Покупателям рекомендуется рассматривать как новые, так и восстановленные варианты, взвешивая такие факторы, как гарантия, срок службы и требования к производительности.

Как устойчивое развитие влияет на поиск поставщиков генераторов?

Устойчивое развитие становится важным фактором в цепочке поставок генераторов переменного тока, влияя как на стратегии выбора поставщиков, так и на разработку продукции. Воздействие на окружающую среду производственных процессов для генераторов переменного тока, в которых часто используются такие материалы, как медь и алюминий, заставляет уделять особое внимание этичным методам поиска поставщиков. Международные покупатели B2B все чаще отдают предпочтение поставщикам, которые демонстрируют приверженность устойчивой практике, включая использование переработанных материалов и соблюдение экологически безопасных производственных процессов.

Более того, важность этичных цепочек поставок трудно переоценить. Покупатели должны искать поставщиков, которые прозрачны в отношении своей практики выбора поставщиков и могут предоставить сертификаты, подтверждающие их приверженность принципам устойчивого развития. Такие сертификаты, как ISO 14001 (экологический менеджмент), и материалы с ‘зеленой’ маркировкой могут дать покупателям уверенность в том, что они приобретают продукцию, которая наносит минимальный вред окружающей среде. По мере ужесточения экологических стандартов во всем мире сотрудничество с поставщиками, которые уделяют первостепенное внимание устойчивому развитию, не только повысит репутацию бренда, но и снизит риски, связанные с несоблюдением требований.

Каков исторический контекст развития альтернаторов в автомобильной промышленности?

Эволюция генератора началась еще в начале XX века, когда автомобили работали на неэффективных генераторах. Появление генератора переменного тока в 1960-х годах ознаменовало значительный прогресс, позволив автомобилям вырабатывать больше энергии, будучи при этом более легкими и компактными. По мере развития автомобильных технологий генераторы переменного тока стали отвечать растущим требованиям к электрооборудованию современных автомобилей, таким как появление электронных систем управления, информационно-развлекательных систем и систем безопасности.

Понимание этого исторического контекста крайне важно для покупателей B2B, поскольку оно подчеркивает важность выбора генераторов переменного тока, которые не только совместимы с текущими моделями автомобилей, но и рассчитаны на будущее, чтобы учесть предстоящие технологические достижения. Поскольку отрасль продолжает внедрять инновации, постоянное информирование о последних достижениях в области технологий генераторов переменного тока будет иметь ключевое значение для принятия стратегических решений по выбору поставщиков.

Часто задаваемые вопросы (FAQ) для B2B покупателей генератора переменного тока.

-

1. Как определить экономическую эффективность генератора переменного тока для моего автопарка?

Чтобы оценить экономическую эффективность генератора переменного тока для вашего автопарка, учитывайте такие факторы, как общая стоимость владения, включая цену покупки, установку и ожидаемый срок службы. Сравните цены на новые и восстановленные устройства, учитывая условия гарантии. Кроме того, проанализируйте требования к силе тока в соответствии с электрическими системами вашего автомобиля. Экономическая эффективность также включает оценку надежности поставщиков и доступности деталей в вашем регионе, чтобы минимизировать время простоя и затраты на обслуживание. -

2. Какие факторы влияют на цену генератора переменного тока на международных рынках?

Цена генератора переменного тока на международных рынках зависит от нескольких факторов, включая марку и модель автомобиля, силу тока генератора и стоимость местной рабочей силы. Импортные тарифы, стоимость доставки и колебания курсов валют также могут влиять на общую цену. Кроме того, на стоимость влияет выбор между новыми и восстановленными генераторами. Понимание тенденций местного рынка и ценовых стратегий поставщиков имеет решающее значение для эффективного составления бюджета. -

3. Как проверить поставщиков генераторов переменного тока в разных регионах?

Выбирая поставщиков генераторов переменного тока, оцените их репутацию по отзывам и рекомендациям. Проверьте их сертификацию и соответствие международным стандартам, таким как ISO 9001, чтобы гарантировать качество. Запросите образцы или рекомендации у других покупателей B2B в вашей отрасли. Кроме того, оцените их способность удовлетворить ваши конкретные требования, такие как варианты изготовления на заказ и минимальные объемы заказа (MOQ), которые могут различаться в зависимости от региона. -

4. Каковы преимущества приобретения восстановленных генераторов?

Приобретение восстановленных генераторов переменного тока может обеспечить значительную экономию средств по сравнению с новыми устройствами при сохранении надежной работы. Восстановленные генераторы проходят тщательное тестирование и восстановление, на них часто предоставляются гарантии. Этот вариант особенно выгоден для предприятий, стремящихся сократить расходы без ущерба для качества. Однако во избежание возможных сбоев необходимо убедиться в том, что компания-производитель соблюдает строгие процедуры контроля качества. -

5. Какие условия оплаты следует учитывать при покупке генераторов переменного тока на международном рынке?

Приобретая генераторы переменного тока на международном рынке, учитывайте гибкие условия оплаты, которые снижают риски. К таким вариантам относятся аккредитивы, обеспечивающие безопасность как покупателя, так и продавца, или частичная оплата после подтверждения заказа. Установите четкие графики платежей, которые соответствуют срокам поставки. Кроме того, не забывайте о способах оплаты, принимаемых поставщиками, и любых комиссионных, связанных с международными транзакциями, таких как курсы конвертации валют. -

6. Как обеспечить гарантию качества при закупке генераторов переменного тока?

Чтобы гарантировать качество при закупке генераторов переменного тока, перед размещением заказа установите четкие спецификации и стандарты качества. Запрашивайте у поставщиков документацию, например сертификаты и результаты испытаний. Внедрите надежный процесс проверки при получении, включая физические проверки и эксплуатационные испытания. Кроме того, следует периодически проводить аудиты поставщиков для поддержания качества в течение длительного времени, особенно если вы поставляете продукцию из регионов с различными стандартами производства. -

7. На какие логистические аспекты следует обратить внимание при импорте генераторов переменного тока?

При импорте генераторов переменного тока необходимо учитывать такие факторы, как способы доставки, сроки выполнения заказа и таможенные правила. Выбирайте надежного экспедитора, знакомого с автомобильными деталями, чтобы ориентироваться в сложных процессах импорта. Узнайте о местных таможенных пошлинах и тарифах, которые могут применяться к импорту генераторов переменного тока. Кроме того, предусмотрите возможные задержки в доставке из-за проверок регулирующих органов и убедитесь, что каждая партия сопровождается надлежащей документацией, способствующей беспрепятственному таможенному оформлению. -

8. Как часто следует заменять генераторы переменного тока в моем автопарке?

Периодичность замены генераторов переменного тока в вашем автопарке обычно составляет от 7 до 10 лет или от 100 000 до 150 000 миль, в зависимости от условий эксплуатации и окружающей среды. Регулярные осмотры помогут выявить признаки износа, такие как тусклый свет или необычные шумы, указывающие на необходимость замены. Внедрение проактивного графика технического обслуживания поможет сократить количество непредвиденных поломок и связанных с ними расходов, что в конечном итоге повысит надежность вашего автопарка.

Список 5 лучших производителей и поставщиков генератора

1. Toyota - RAV4 Замена генератора

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Замена генератора 2006 Toyota RAV4; стоимость: $450 (включая трудозатраты); стоимость предыдущего генератора: более $350.

2. Milex - Затраты на замену генератора

Домен: milexcompleteautocare.com

Зарегистрирован: 2010 (15 лет)

Введение: Средняя стоимость генератора колеблется от $100 до $500 только за деталь; полная стоимость замены (включая установку) составляет от $300 до $900. Факторы, влияющие на стоимость, включают гарантийное покрытие, размер генератора, мощность или силу тока, трудозатраты, а также то, является ли генератор новым или восстановленным. Общие признаки неисправного генератора включают тусклые или мерцающие фары, мертвые ...

3. CarTalk - Затраты на замену генератора

Домен: cartalk.com

Введение: Стоимость замены генератора составляет примерно от $600 до $1 500. Генератор - это важнейший компонент, преобразующий механическую силу в электрическую энергию, которая питает различные системы автомобиля, включая двигатель и фары, а также заряжает аккумулятор. Признаки неисправности генератора включают в себя лампочку Check Engine, тусклые фары и необходимость в резком старте. Альтернаторы могут...

4. Honda - CRV Альтернатор

Домен: facebook.com

Зарегистрирован: 1997 (28 лет)

Введение: Генератор переменного тока Honda CRV, цена в дилерском центре: $2100, онлайн OEM цена: $1500, местоположение: США

5. Halfords - Замена генератора

Домен: halfords.com

Зарегистрирован: 1997 (28 лет)

Введение: Эта компания, Halfords - Alternator Replacement, является заметным субъектом на рынке. Для получения подробной информации о продукции рекомендуется посетить их сайт.

Заключение и перспективы стратегического сорсинга для генератора переменного тока

В заключение следует отметить, что понимание стоимости, связанной с генераторами переменного тока, необходимо для международных покупателей B2B. Цена генератора переменного тока может значительно варьироваться в зависимости от таких факторов, как тип автомобиля, требуемая сила тока, а также от того, является ли деталь новой или восстановленной. Для предприятий в Африке, Южной Америке, на Ближнем Востоке и в Европе стратегический поиск поставщиков может привести к экономически эффективным решениям, обеспечивающим баланс между качеством и ценой. Инвестиции в высококачественные генераторы переменного тока могут повлечь за собой более высокие первоначальные затраты, но в долгосрочной перспективе могут привести к экономии за счет сокращения объема технического обслуживания и повышения надежности автомобиля.

Разбираясь в сложностях закупок генераторов переменного тока, подумайте о налаживании партнерских отношений с надежными поставщиками, которые предоставляют гарантии и услуги поддержки. Это не только обеспечит стабильные поставки качественных компонентов, но и укрепит вашу операционную устойчивость. Двигаясь вперед, отдавайте предпочтение стратегическому подбору поставщиков, чтобы оптимизировать решения о закупках и повысить эффективность бизнеса. Проактивная стратегия поиска поставщиков позволит вам опережать рыночные тенденции и обеспечит сохранение работоспособности и эффективности вашего автопарка.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.