Introduction: Navigating the Global Market for every car parts name

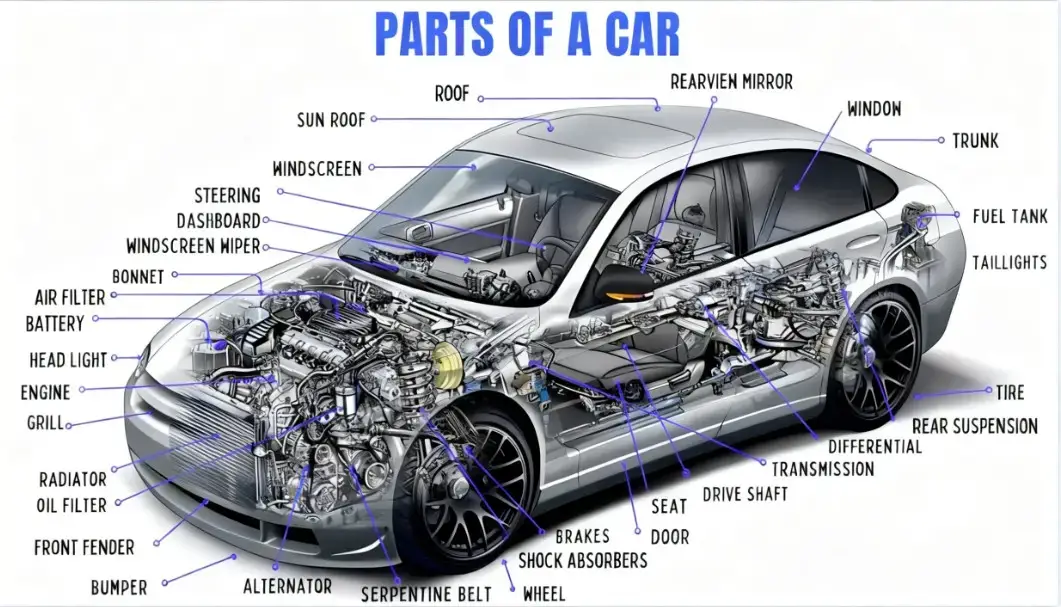

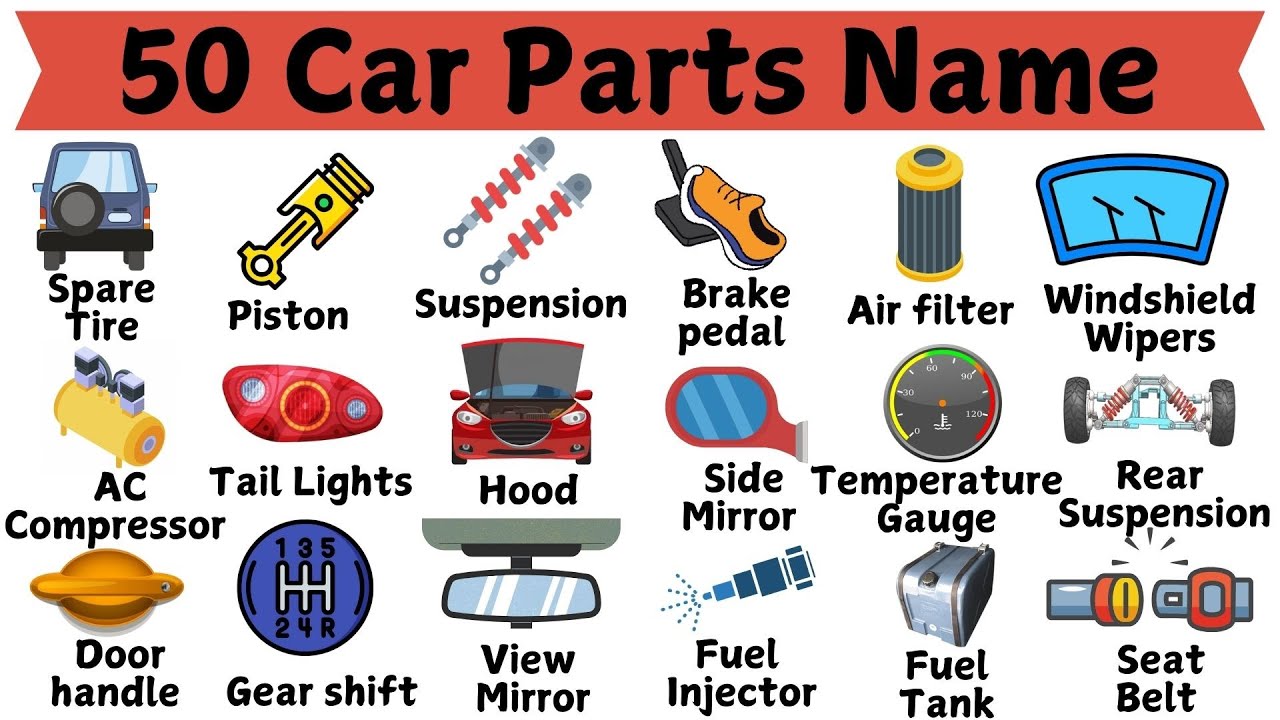

In the dynamic landscape of the global automotive industry, sourcing every car parts name can present significant challenges for B2B buyers. From navigating complex supply chains to ensuring compliance with regional regulations, businesses must equip themselves with the right knowledge to make informed purchasing decisions. This comprehensive guide delves into the intricacies of car parts, covering a wide array of components—from essential systems like the engine and transmission to critical safety features such as brakes and suspension.

Our guide not only categorizes various car parts but also highlights their specific applications, helping buyers understand the relevance of each component in different vehicle types. Additionally, we provide insights on supplier vetting processes, cost considerations, and logistics strategies tailored for international markets. Whether you are sourcing parts for a fleet of vehicles in Brazil or managing supply chains across Europe, Africa, or the Middle East, this resource empowers you to make strategic decisions that enhance operational efficiency and product quality.

By leveraging this guide, international B2B buyers can navigate the complexities of the automotive parts market with confidence, ensuring they secure the best components to meet their unique business needs. With expert insights and actionable strategies at your fingertips, you’re poised to optimize your purchasing process and drive your business forward.

Содержание

- Top 4 Every Car Parts Name Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for every car parts name

- Understanding every car parts name Types and Variations

- Key Industrial Applications of every car parts name

- 3 Common User Pain Points for ‘every car parts name’ & Their Solutions

- Strategic Material Selection Guide for every car parts name

- In-depth Look: Manufacturing Processes and Quality Assurance for every car parts name

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘every car parts name’

- Comprehensive Cost and Pricing Analysis for every car parts name Sourcing

- Alternatives Analysis: Comparing every car parts name With Other Solutions

- Essential Technical Properties and Trade Terminology for every car parts name

- Navigating Market Dynamics and Sourcing Trends in the every car parts name Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of every car parts name

- Strategic Sourcing Conclusion and Outlook for every car parts name

- Важное предупреждение и условия использования

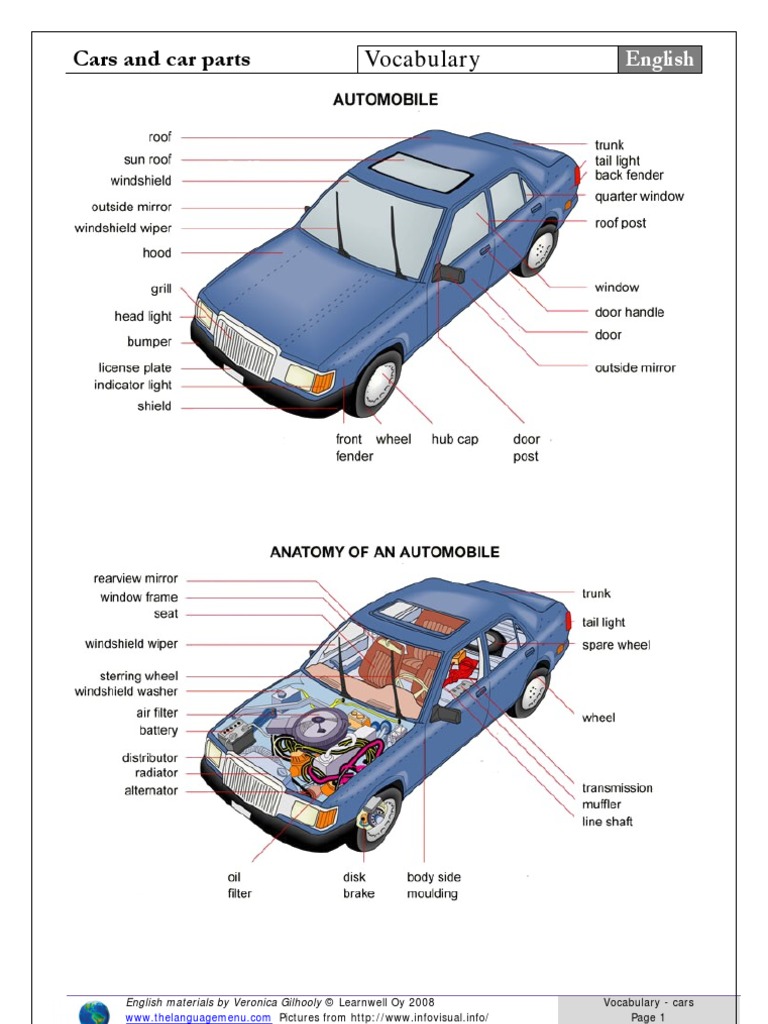

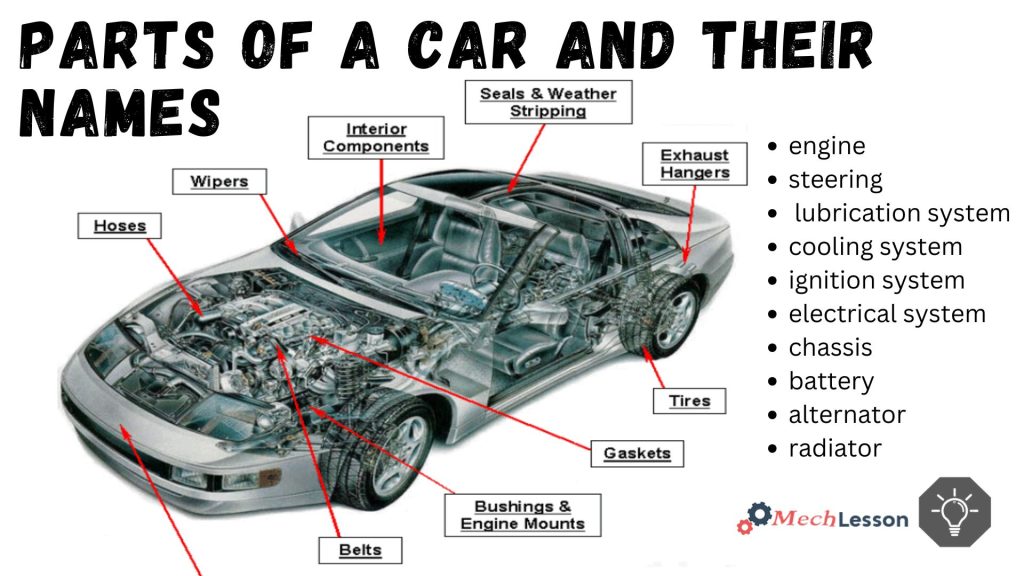

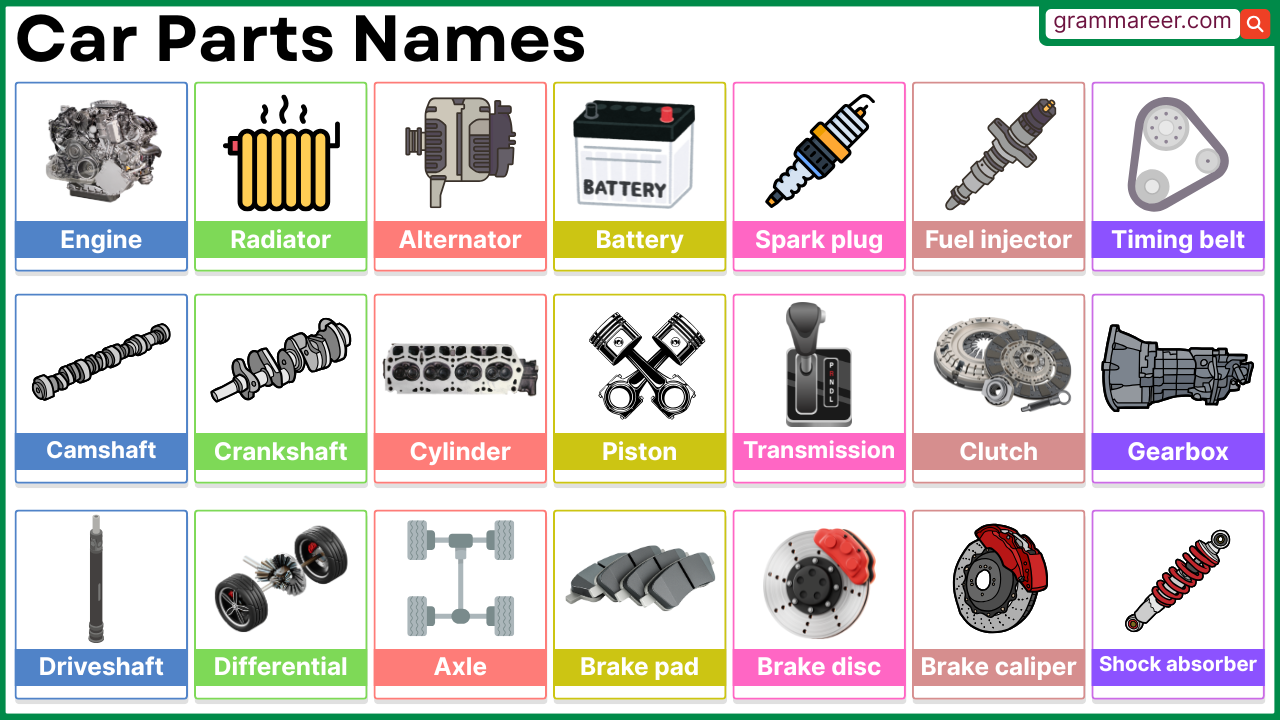

Understanding every car parts name Types and Variations

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Двигатель внутреннего сгорания | Comprises components like pistons, crankshaft, and valves. | Automotive manufacturing, engine remanufacturing | Плюсы: High power output; established technology. Минусы: Less fuel-efficient compared to electric. |

| Системы передачи | Includes automatic and manual types, utilizing gear ratios. | Vehicle assembly, aftermarket upgrades | Плюсы: Enhances driving experience; varied options. Минусы: Complex repair; cost can be high. |

| Электрические системы | Encompasses batteries, alternators, and wiring harnesses. | Electrical component suppliers, automotive repair | Плюсы: Critical for vehicle functionality; diverse suppliers. Минусы: Rapidly evolving technology can complicate sourcing. |

| Подвесные системы | Consists of shocks, struts, and control arms for vehicle stability. | Automotive parts distribution, repair shops | Плюсы: Improves ride quality; essential for safety. Минусы: Requires regular maintenance; can be costly to replace. |

| Выхлопные системы | Features components like catalytic converters and mufflers. | Environmental compliance, aftermarket parts | Плюсы: Reduces emissions; enhances engine performance. Минусы: Regulatory changes can impact design and sourcing. |

What Are the Key Characteristics of Internal Combustion Engines for B2B Buyers?

Internal combustion engines (ICE) are integral to traditional vehicles, featuring components such as pistons, crankshafts, and valves that work in unison to convert fuel into mechanical energy. For B2B buyers, understanding the specifications and variations of ICE is crucial, especially when sourcing engines for manufacturing or remanufacturing. Factors like engine displacement, power output, and fuel type significantly influence purchasing decisions. While ICEs are reliable and powerful, they face challenges regarding fuel efficiency and environmental regulations.

How Do Transmission Systems Differ and What Should Buyers Consider?

Transmission systems, available in automatic and manual variations, play a vital role in vehicle performance by managing gear ratios to optimize power delivery. B2B buyers should consider the intended use of vehicles, as different applications may require specific transmission types. The complexity of repair and maintenance should also be factored in, as automatic transmissions generally incur higher repair costs than manuals. Understanding the compatibility of transmission systems with various engine types is essential for ensuring seamless integration during vehicle assembly.

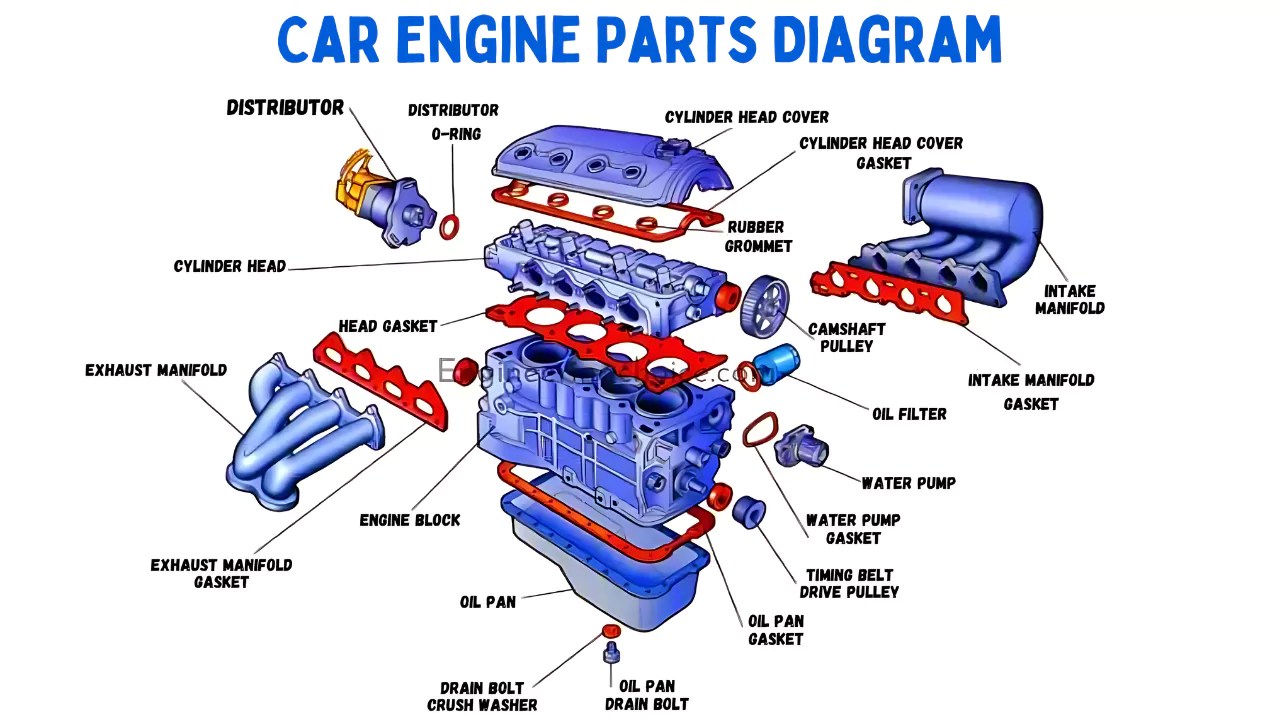

Illustrative image related to every car parts name

Why Are Electrical Systems Critical for Modern Vehicles?

Electrical systems, which include batteries, alternators, and wiring harnesses, are fundamental to the operation of modern vehicles. B2B buyers in the automotive sector must stay abreast of technological advancements, such as the shift towards electric vehicles (EVs), which require more powerful and efficient electrical components. The diversity of suppliers in this sector offers opportunities for competitive pricing, but buyers must also consider the implications of evolving technology, which can affect parts compatibility and availability.

What Are the Benefits of Quality Suspension Systems for Vehicle Safety?

Suspension systems are crucial for vehicle stability, ride comfort, and safety. Comprising components like shocks, struts, and control arms, these systems help maintain tire contact with the road and absorb impacts. For B2B buyers, investing in high-quality suspension parts is essential for ensuring vehicle performance and safety. Regular maintenance is necessary to prevent wear, and buyers should evaluate the cost-effectiveness of different suspension options, considering both initial investment and long-term reliability.

How Do Exhaust Systems Impact Vehicle Compliance and Performance?

Exhaust systems, which include components like catalytic converters and mufflers, are essential for managing vehicle emissions and enhancing engine performance. B2B buyers must navigate regulatory requirements that vary by region, particularly concerning emissions standards. Understanding the latest technologies in exhaust systems can provide competitive advantages, as advancements may lead to better performance and compliance. However, the evolving nature of regulations necessitates careful consideration of sourcing strategies to ensure that parts meet current and future environmental standards.

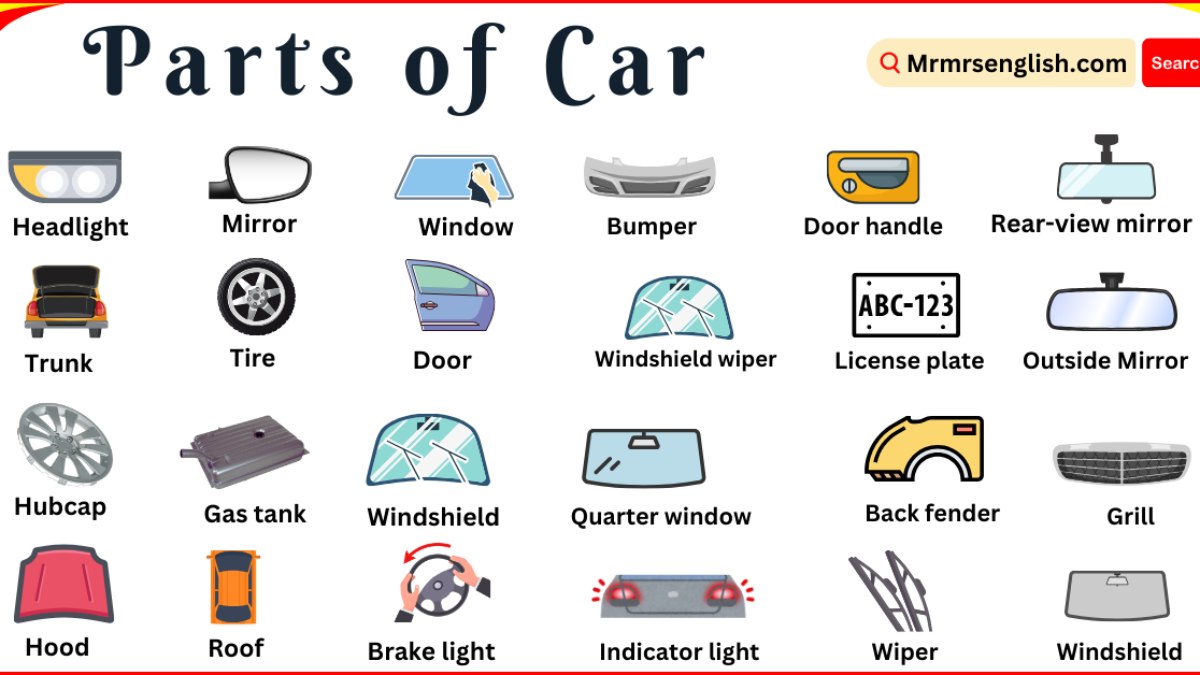

Key Industrial Applications of every car parts name

| Отрасль/сектор | Specific Application of every car parts name | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Engine components like pistons and crankshafts | Повышает эксплуатационные характеристики и надежность автомобиля, снижая количество гарантийных случаев | Quality certifications, supplier reliability, and lead times |

| Транспорт и логистика | Brakes and suspension systems for fleet vehicles | Improves safety and reduces maintenance costs, increasing fleet uptime | Compatibility with various vehicle models, cost-effectiveness |

| Возобновляемые источники энергии | Batteries for electric vehicles | Supports sustainable transportation initiatives and reduces carbon footprint | Capacity, lifecycle, and environmental regulations compliance |

| Строительная и тяжелая техника | Tyres and axles for construction vehicles | Increases durability and performance in rugged environments, enhancing productivity | Load ratings, tread patterns, and sourcing from local suppliers |

| Запасные части | Exhaust systems and catalytic converters | Provides options for vehicle upgrades, improving emissions and performance | Compliance with local emissions regulations and warranty considerations |

How Are Engine Components Used in the Automotive Manufacturing Industry?

In the automotive manufacturing sector, engine components such as pistons and crankshafts are crucial for assembling vehicles. These parts directly influence engine performance, efficiency, and longevity. Manufacturers must ensure that these components meet stringent quality standards to reduce warranty claims and enhance customer satisfaction. For international buyers, particularly in regions like Africa and South America, sourcing from suppliers with ISO certifications and a proven track record is vital to ensure reliability and performance.

What Role Do Brakes and Suspension Systems Play in Transportation & Logistics?

Brakes and suspension systems are integral to fleet vehicles in the transportation and logistics sector, ensuring safety and comfort during transit. Reliable braking systems reduce the risk of accidents, while effective suspension enhances ride quality, leading to lower maintenance costs and improved fleet uptime. International buyers must consider the compatibility of these parts with various vehicle models and prioritize suppliers that offer cost-effective solutions without compromising quality.

Illustrative image related to every car parts name

How Do Batteries Support Renewable Energy Initiatives in Electric Vehicles?

In the renewable energy sector, batteries are essential for electric vehicles (EVs), enabling sustainable transportation solutions. High-capacity batteries not only power the vehicle but also contribute to reducing greenhouse gas emissions. Buyers in this sector need to focus on battery lifecycle, performance metrics, and compliance with environmental regulations. Sourcing from manufacturers who emphasize sustainable practices can further enhance the business’s commitment to environmental responsibility.

Why Are Tyres and Axles Important for Construction & Heavy Machinery?

Tyres and axles are critical components for construction vehicles, as they determine the vehicle’s performance in challenging environments. Durable tyres with appropriate tread patterns enhance traction and stability, while robust axles ensure efficient power transfer. For international buyers, especially in the Middle East, sourcing locally can reduce shipping costs and lead times, while also supporting regional economies. Buyers should also consider load ratings to ensure suitability for specific construction tasks.

How Do Exhaust Systems and Catalytic Converters Benefit the Aftermarket Parts Industry?

Exhaust systems and catalytic converters are vital for aftermarket modifications, enabling vehicle owners to enhance performance and comply with emissions regulations. These parts allow for customization while ensuring vehicles meet legal standards, thus appealing to a broad consumer base. Buyers in Europe and South America need to prioritize suppliers who understand local emissions regulations and can provide warranties, ensuring that the modifications are both effective and compliant.

3 Common User Pain Points for ‘every car parts name’ & Their Solutions

Scenario 1: Navigating Quality Control Issues in Car Parts Procurement

Проблема:

B2B buyers in the automotive sector often face challenges related to quality assurance when sourcing car parts. Inconsistent quality can arise from various suppliers, particularly when dealing with multiple manufacturers across different regions such as Africa, South America, and Europe. Buyers may receive parts that do not meet their specifications, leading to increased costs due to returns, replacements, or even damage to vehicles. This issue can undermine the trust between buyers and suppliers and affect the overall efficiency of operations.

Решение:

To mitigate quality control issues, B2B buyers should establish a robust supplier evaluation process. This includes conducting thorough due diligence on potential suppliers, such as reviewing certifications, customer feedback, and production capabilities. Engaging in regular quality audits and inspections can further ensure that the parts meet necessary standards before they are shipped. Implementing a standardized quality assurance protocol for incoming parts can help identify defects early in the process. Additionally, fostering strong relationships with reliable suppliers allows for better communication regarding quality expectations and the potential for negotiating better terms for quality assurance.

Scenario 2: Overcoming Supply Chain Disruptions for Timely Delivery of Car Parts

Проблема:

Supply chain disruptions are a significant concern for B2B buyers in the automotive industry, particularly in a global market affected by geopolitical tensions, pandemics, or natural disasters. Such disruptions can lead to delays in the delivery of critical car parts, impacting production schedules and customer satisfaction. Buyers may find themselves scrambling to find alternative sources, which can increase costs and lead to further operational inefficiencies.

Решение:

To combat supply chain disruptions, buyers should diversify their supplier base. This involves establishing relationships with multiple suppliers across different geographical locations to reduce dependency on a single source. Additionally, implementing a just-in-time inventory system can help manage stock levels effectively, ensuring that parts are available when needed without overstocking. B2B buyers should also consider leveraging technology, such as supply chain management software, to gain real-time visibility into inventory levels and shipment statuses. This proactive approach allows for quicker responses to potential disruptions and better planning for future needs.

Scenario 3: Understanding and Complying with Local Regulations for Car Parts

Проблема:

B2B buyers often encounter regulatory challenges when sourcing car parts for different markets. Each region, including Africa, South America, the Middle East, and Europe, has specific regulations regarding safety, emissions, and environmental standards. Non-compliance can lead to severe penalties, legal issues, and the inability to sell vehicles equipped with non-compliant parts.

Решение:

To navigate regulatory complexities, buyers should invest in comprehensive market research to understand the specific regulations in each target region. Collaborating with local experts or legal advisors can provide valuable insights into compliance requirements. Additionally, buyers should prioritize suppliers who have a strong track record of adhering to local regulations and who can provide necessary certifications and documentation. Establishing a compliance checklist tailored to each market can further streamline the process, ensuring that all sourced parts meet the required standards. Regular training sessions for procurement teams on regulatory updates can also foster a culture of compliance and awareness within the organization.

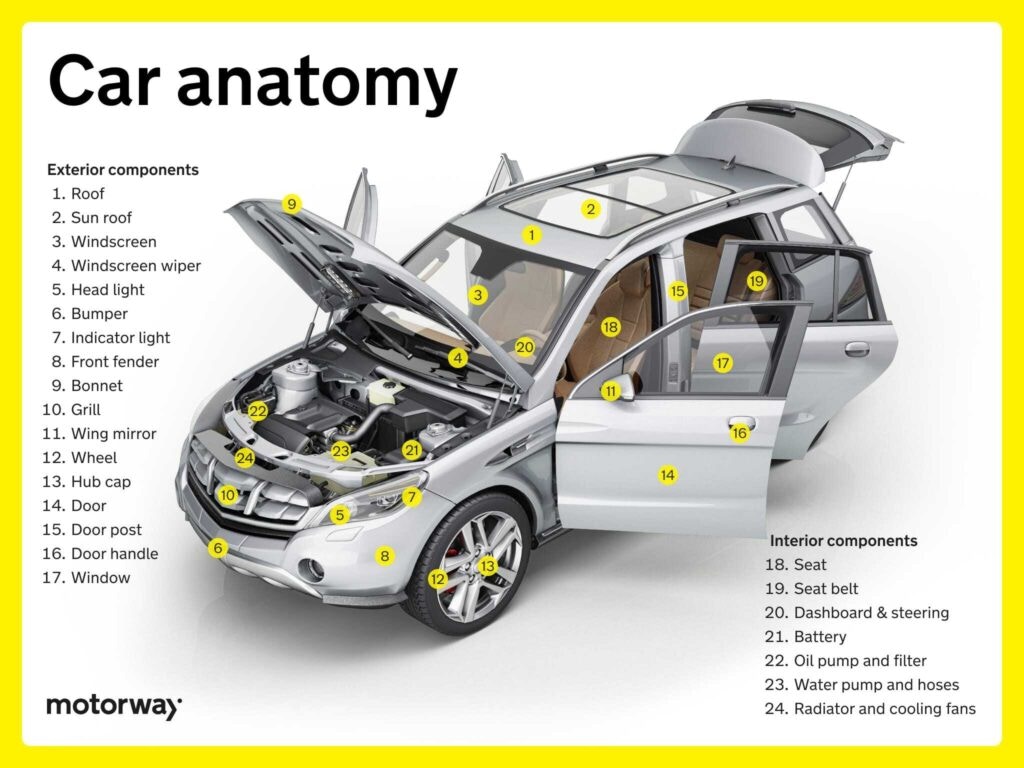

Strategic Material Selection Guide for every car parts name

What Materials are Commonly Used in Car Parts and Their Strategic Implications for B2B Buyers?

When selecting materials for various car parts, international B2B buyers must consider several factors that influence performance, cost, and compliance with regional standards. Here, we analyze four common materials used in car manufacturing: steel, aluminum, plastic, and rubber. Each material has unique properties and implications for application, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Steel Perform in Car Parts Manufacturing?

Steel is widely used in car parts due to its high tensile strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for components subjected to heavy loads, such as the chassis and suspension systems.

Плюсы: Steel is relatively inexpensive and has a long lifespan when properly treated against corrosion. It can be easily formed and welded, allowing for complex shapes in manufacturing.

Минусы: The primary drawback is its weight, which can affect fuel efficiency. Additionally, untreated steel is prone to rust, necessitating protective coatings.

Влияние на применение: Steel’s compatibility with various media, including oil and coolant, makes it a reliable choice for engine components. However, its weight may be a concern in regions focusing on fuel efficiency.

Соображения для международных покупателей: Buyers must ensure compliance with regional standards like ASTM or DIN for quality assurance. In Europe, for instance, the use of high-strength steel is often preferred for safety regulations.

Illustrative image related to every car parts name

What Role Does Aluminum Play in Automotive Parts?

Aluminum is increasingly favored in the automotive industry due to its lightweight properties and resistance to corrosion. It is commonly used in engine blocks, wheels, and body panels.

Плюсы: Aluminum reduces the overall weight of vehicles, enhancing fuel efficiency and performance. It also has excellent thermal conductivity, which is beneficial for engine components.

Минусы: The main limitation is its cost, as aluminum is more expensive than steel. Additionally, it can be more challenging to weld, which may complicate manufacturing processes.

Влияние на применение: Aluminum’s corrosion resistance makes it suitable for parts exposed to harsh environments. However, its compatibility with certain media must be assessed, especially in high-temperature applications.

Соображения для международных покупателей: Buyers should be aware of the different grades of aluminum and their respective standards. Compliance with JIS standards in Japan or EN standards in Europe is essential for ensuring quality.

Illustrative image related to every car parts name

How Do Plastics Enhance Automotive Component Design?

Plastics are used in various automotive applications, including interior parts, dashboards, and some exterior components. Their versatility and lightweight nature make them attractive for manufacturers.

Плюсы: Plastics are cost-effective and can be molded into intricate shapes, allowing for innovative designs. They also offer good chemical resistance, which is crucial for components exposed to fluids.

Минусы: The main drawback is their lower strength compared to metals, which may limit their use in structural applications. Plastics can also degrade under UV exposure unless treated.

Влияние на применение: Plastics are suitable for non-structural components where weight savings are critical. However, the choice of plastic must consider the specific media it will encounter.

Illustrative image related to every car parts name

Соображения для международных покупателей: Buyers should look for plastics that meet international safety and environmental standards, especially in Europe, where regulations on material safety are stringent.

Why is Rubber Essential in Automotive Applications?

Rubber is predominantly used in tires, seals, and suspension components due to its elasticity and ability to absorb shocks.

Плюсы: Rubber provides excellent vibration dampening and is resistant to wear, making it ideal for tires and bushings. It also offers good thermal stability.

Минусы: The main limitation is its susceptibility to degradation from ozone and UV light, which can shorten its lifespan. Additionally, high-quality rubber can be expensive.

Illustrative image related to every car parts name

Влияние на применение: Rubber’s compatibility with various automotive fluids makes it suitable for seals and gaskets, essential for preventing leaks.

Соображения для международных покупателей: Buyers must ensure that rubber components comply with international standards for durability and safety, particularly in regions with extreme weather conditions.

Summary Table of Material Selection for Car Parts

| Материал | Typical Use Case for every car parts name | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Сталь | Chassis, suspension components | Высокая прочность и долговечность | Heavy weight affecting fuel efficiency | Низкий |

| Алюминий | Engine blocks, wheels | Легкий и коррозионно-стойкий | Higher cost and welding challenges | Высокий |

| Пластик | Interior parts, dashboards | Экономичный и универсальный | Снижение прочности и деградация под воздействием ультрафиолета | Средний |

| Резина | Tires, seals, suspension components | Excellent vibration dampening | Degradation from ozone and UV light | Средний |

This guide provides a strategic overview of material selection for car parts, enabling international B2B buyers to make informed decisions tailored to their regional needs and compliance requirements.

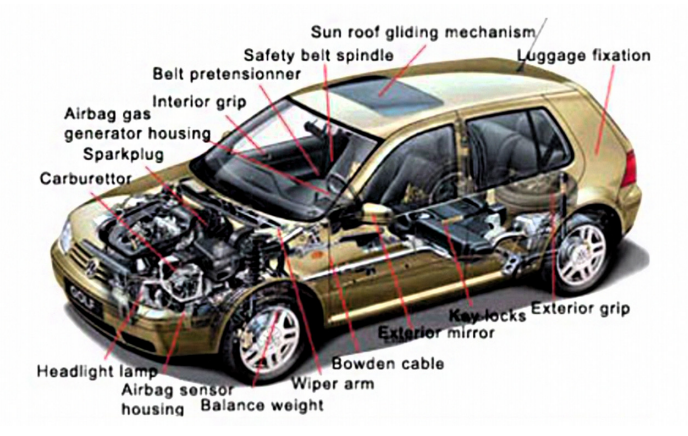

In-depth Look: Manufacturing Processes and Quality Assurance for every car parts name

What Are the Main Manufacturing Processes for Car Parts?

When it comes to manufacturing car parts, several key stages are involved, each critical to ensuring the quality and performance of the final product. Understanding these processes can help B2B buyers make informed decisions when sourcing parts.

How Is Material Prepared for Car Parts Manufacturing?

Material preparation begins with selecting the appropriate raw materials, which can range from metals like steel and aluminum to plastics and composites. Suppliers often conduct an initial inspection of these materials to ensure they meet specified standards. This phase may also involve cutting materials to size and treating them to enhance durability, such as heat treatment for metals or chemical treatments for plastics.

Illustrative image related to every car parts name

Какие методы формовки обычно используются при производстве автомобильных деталей?

The forming stage involves shaping the prepared materials into the desired part configuration. Common techniques include:

- Кастинг: Pouring molten material into a mold to achieve complex shapes. This is particularly useful for engine blocks and transmission cases.

- Ковка: Compressing metal into shape using high pressure, which enhances strength. This method is often used for components like crankshafts and connecting rods.

- Штамповка: Using a die to cut or shape metal sheets, commonly used for body panels and brackets.

- Литье под давлением: For plastic parts, molten plastic is injected into molds. This technique is widely used for interior components and housing for electrical systems.

Each technique has its own merits and is chosen based on the specific requirements of the part being produced.

How Are Car Parts Assembled During Manufacturing?

The assembly process brings together various components into a complete part or system. This stage can be manual or automated, depending on the complexity and volume of production. For example, electronic components may require precise manual assembly, while larger mechanical assemblies may utilize robotic systems for efficiency.

Assembly often includes:

- Joining Techniques: Such as welding, riveting, or using adhesives to bond parts together.

- Integration of Sub-assemblies: Components like engines or transmissions may be assembled separately before being integrated into the larger vehicle assembly.

What Finishing Processes Are Important for Car Parts?

Finishing processes enhance the aesthetic and functional properties of car parts. Common finishing techniques include:

Illustrative image related to every car parts name

- Покрытие: Applying paint or protective coatings to prevent corrosion and improve appearance.

- Обработка поверхности: Processes like polishing, anodizing, or plating can enhance durability and aesthetics.

- Проверки контроля качества: Final inspections to ensure parts meet specifications before shipment.

Какие стандарты обеспечения качества применимы к автомобильным деталям?

Quality assurance is crucial in the automotive industry, where safety and reliability are paramount. International and industry-specific standards help ensure that manufacturers adhere to stringent quality controls.

Which International Standards Should Buyers Consider?

ISO 9001 is a widely recognized quality management standard applicable to manufacturing processes. It ensures that suppliers maintain consistent quality and continually improve their processes.

Additionally, certifications specific to the automotive industry, such as IATF 16949, focus on defect prevention and the reduction of variation and waste in the supply chain.

How Do Quality Control Checkpoints Function in Car Parts Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to catch defects early. Key checkpoints include:

- Входящий контроль качества (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- Контроль качества в процессе производства (IPQC): Monitoring production processes to identify and rectify issues in real-time.

- Окончательный контроль качества (FQC): Conducting thorough inspections and tests on finished products before they leave the facility.

Common testing methods include dimensional inspections, functional testing, and stress testing, which help confirm that parts meet the required standards.

Illustrative image related to every car parts name

Как покупатели B2B могут проверить контроль качества поставщиков?

B2B buyers must conduct due diligence to ensure they are partnering with reputable suppliers. Here are effective methods to verify quality control practices:

What Steps Should Buyers Take for Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. During an audit, buyers can evaluate:

- Manufacturing Facilities: Inspecting equipment, cleanliness, and organization.

- Quality Control Documentation: Reviewing records of inspections, tests, and compliance with standards.

- Employee Training Programs: Ensuring staff are trained in quality control protocols.

How Can Buyers Use Quality Reports and Third-Party Inspections?

Requesting quality reports from suppliers can provide insights into their manufacturing performance. These reports should detail:

- Defect Rates: Historical data on product failures.

- Compliance Records: Evidence of adherence to industry standards.

Additionally, employing third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These inspections can occur at various stages of production, ensuring that parts meet specifications before shipment.

Каковы нюансы контроля качества для международных B2B-покупателей?

International B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance. Buyers should consider:

Illustrative image related to every car parts name

- Соблюдение нормативных требований: Different regions may have varying regulations regarding automotive parts. Understanding these can prevent costly delays or rejections.

- Культурные различия: Communication and expectations regarding quality can vary. Establishing clear guidelines and expectations upfront can mitigate misunderstandings.

- Логистика и транспорт: Ensuring that quality is maintained throughout the supply chain, including storage and shipping conditions.

By understanding these nuances, buyers can better navigate the complexities of sourcing car parts internationally, ensuring they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘every car parts name’

To successfully procure car parts in today’s competitive market, it is vital for B2B buyers to follow a structured approach. This checklist provides actionable steps that will guide you through the sourcing process, ensuring you make informed decisions that meet your business needs.

Шаг 1: Определите свои технические характеристики

Clearly outline the technical specifications for the car parts you need. This includes dimensions, material types, performance requirements, and compatibility with existing systems. Having precise specifications helps in communicating your requirements effectively to suppliers and ensures that you receive the correct parts that meet quality standards.

Шаг 2: Проведение маркетинговых исследований

Take the time to research the market landscape for car parts. Analyze trends, pricing, and the availability of different components. Understanding the market will enable you to identify reliable suppliers and make informed purchasing decisions while ensuring you are aware of any emerging technologies that could benefit your operations.

Шаг 3: Оцените потенциальных поставщиков

Before committing to any supplier, it’s crucial to conduct a thorough evaluation. Request company profiles, certifications, and references from buyers in similar industries. Look for suppliers who have a proven track record of reliability and quality, as this can significantly reduce risks associated with procurement.

- Проверьте наличие сертификатов: Ensure suppliers have relevant industry certifications (e.g., ISO, IATF 16949) that demonstrate adherence to quality standards.

- Обзор тематических исследований: Assess case studies that showcase the supplier’s experience with similar parts or industries.

Шаг 4: Запросите образцы и проведите тестирование

Once you have shortlisted potential suppliers, request samples of the car parts. Conduct rigorous testing to ensure they meet your specifications and quality standards. This step is crucial to mitigate risks related to defective parts that could lead to costly downtime or safety issues.

Шаг 5: Переговоры об условиях и ценах

After testing and confirming the quality of the parts, enter negotiations with your chosen supplier. Discuss pricing, payment terms, and delivery schedules to ensure favorable conditions for both parties. Be transparent about your expectations and any potential volume discounts you may require as a B2B buyer.

Шаг 6: Verify Logistics and Delivery Capabilities

Assess the supplier’s logistics and delivery capabilities to ensure they can meet your timelines. Inquire about their shipping methods, lead times, and any potential challenges they might face in your region. A reliable supplier should be able to provide detailed logistics plans to ensure timely delivery of your car parts.

Шаг 7: Установите долгосрочные отношения

Once you’ve successfully sourced your car parts, focus on building a long-term relationship with your supplier. Regular communication and feedback can lead to better service, improved pricing, and priority access to new products. A strong partnership can provide significant advantages in terms of reliability and support for future procurement needs.

Illustrative image related to every car parts name

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for car parts, ensuring they acquire high-quality components that meet their operational demands.

Comprehensive Cost and Pricing Analysis for every car parts name Sourcing

What Are the Key Cost Components in Sourcing Car Parts?

When sourcing car parts, understanding the cost structure is crucial for international B2B buyers. The primary components influencing costs include:

-

Материалы: The choice of materials significantly affects the cost. For instance, high-grade steel or aluminum may increase expenses but provide better durability and performance. Buyers should assess the trade-off between material quality and price.

-

Труд: Labor costs vary by region, influenced by local wage standards and skill levels. Countries with lower labor costs may offer competitive pricing, but it’s essential to ensure that quality is not compromised.

-

Производственные накладные расходы: This includes costs related to the facilities, utilities, and administrative expenses associated with production. Efficient manufacturers can often keep overhead low, which can translate to better pricing for buyers.

-

Инструментарий: Specialized tools and machinery are required for the production of specific car parts. The initial investment in tooling can be substantial, especially for custom parts, but this cost is amortized over large production runs.

-

Контроль качества (КК): Implementing strict QC measures ensures that parts meet required specifications and standards. While this adds to the overall cost, it is essential for maintaining quality, especially for safety-critical components.

-

Логистика: Transportation and storage costs can vary widely depending on the supplier’s location and the buyer’s destination. Understanding Incoterms is crucial here, as they dictate who is responsible for shipping costs, insurance, and liability.

-

Маржа: Suppliers will include their profit margin in the pricing. Understanding typical margins for specific parts can help buyers negotiate better deals.

How Do Price Influencers Affect Car Parts Sourcing?

Several factors influence the final pricing of car parts, particularly for international transactions:

-

Объем и минимальное количество заказа (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize pricing.

-

Технические характеристики и персонализация: Custom parts tailored to specific vehicle models can significantly increase costs. It’s important for buyers to clearly define their requirements to avoid unexpected expenses.

-

Качество материалов и сертификаты: Parts that meet international quality standards and certifications (e.g., ISO, IATF) may come at a premium. Buyers must assess whether the added cost is justified based on their market requirements.

-

Факторы поставщика: The reputation and reliability of suppliers can affect pricing. Established suppliers with proven track records may charge more, but they often provide better quality assurance and service.

-

Инкотермс: Understanding shipping terms is vital for managing costs. Different Incoterms (e.g., FOB, CIF) can shift financial responsibilities and risks between buyers and suppliers, impacting overall pricing.

What Negotiation Strategies Can Buyers Use to Achieve Cost Efficiency?

International B2B buyers can adopt several strategies to enhance cost efficiency in their sourcing:

-

Research and Benchmarking: Buyers should research market prices and trends for specific car parts to establish a baseline for negotiations. This knowledge empowers them to negotiate confidently.

-

Building Relationships: Developing strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield benefits such as bulk discounts and priority service.

-

Общая стоимость владения (TCO): Buyers should consider TCO rather than just upfront costs. This includes maintenance, warranty, and replacement costs, which can provide a clearer picture of the true value of a part.

-

Flexibility in Specifications: Being open to alternative materials or designs can lead to cost savings. Suppliers may have more flexibility in pricing if they can adjust specifications without compromising quality.

What Are the Pricing Nuances for International Buyers?

When sourcing car parts from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific pricing nuances:

-

Import Duties and Taxes: Understanding local regulations and taxes is critical, as these can add significantly to the total cost.

-

Currency Fluctuations: International buyers must consider exchange rates, which can affect pricing. Utilizing forward contracts can hedge against currency risks.

-

Культурные различия: Negotiation styles and business practices can vary by region. It’s essential to adapt to local customs to foster successful negotiations.

Отказ от ответственности в отношении ориентировочных цен

The prices discussed in this guide are indicative and can vary widely based on market conditions, supplier capabilities, and specific buyer requirements. It is advisable for buyers to conduct thorough market research and engage directly with suppliers to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing every car parts name With Other Solutions

Exploring Alternatives for Car Parts: A Comprehensive Comparison

In the automotive industry, understanding the various components that make up a vehicle is crucial for B2B buyers. However, it’s equally important to consider alternatives to traditional car parts, as innovations in technology and materials can offer enhanced performance, cost savings, and sustainability. This analysis provides a comparative overview of “every car parts name” against two viable alternative solutions, helping international B2B buyers make informed decisions.

Illustrative image related to every car parts name

| Аспект сравнения | ‘Every Car Parts Name’ | Alternative 1 Name: Aftermarket Parts | Alternative 2 Name: Electric Vehicle (EV) Components |

|---|---|---|---|

| Производительность | Standard performance based on OEM specifications | Comparable performance; may vary by brand | Enhanced efficiency and reduced emissions |

| Стоимость | Higher initial investment due to OEM quality | Generally lower cost; price varies by brand | Potentially higher upfront costs but lower long-term maintenance |

| Простота внедрения | Requires specialized knowledge for installation | Easier installation for some parts; wider availability | Requires specialized knowledge for installation |

| Техническое обслуживание | Regular maintenance needed; availability of parts can vary | Maintenance may vary by part quality; some may require more frequent replacement | Более низкий уровень технического обслуживания благодаря меньшему количеству движущихся частей |

| Лучший вариант использования | Ideal for maintaining warranty and reliability | Suitable for budget-conscious buyers looking for replacements | Best for environmentally focused companies or those transitioning to EVs |

Подробная разбивка альтернатив

Alternative 1: Aftermarket Parts

Aftermarket parts are components manufactured by third-party companies rather than the original equipment manufacturers (OEMs). They typically offer a lower cost option while still providing comparable performance. However, the quality can vary significantly between brands, which may affect durability and reliability. B2B buyers should conduct thorough research on aftermarket suppliers to ensure that they select high-quality products that meet their needs.

Alternative 2: Electric Vehicle (EV) Components

EV components represent a significant shift in automotive technology, providing sustainable alternatives to traditional car parts. These components, such as electric motors and battery systems, are designed to enhance efficiency and reduce emissions. While the initial investment may be higher, businesses can benefit from lower long-term maintenance costs due to fewer moving parts and reduced wear and tear. This alternative is particularly relevant for companies looking to invest in eco-friendly technologies and meet emerging regulatory standards.

Заключение: как выбрать правильное решение для ваших нужд

When selecting between “every car parts name” and its alternatives, B2B buyers should carefully assess their specific requirements, including performance, cost, and sustainability goals. Understanding the trade-offs associated with each option can lead to more informed purchasing decisions. By evaluating the advantages and disadvantages of OEM parts, aftermarket options, and EV components, businesses can align their choices with their operational objectives and market demands.

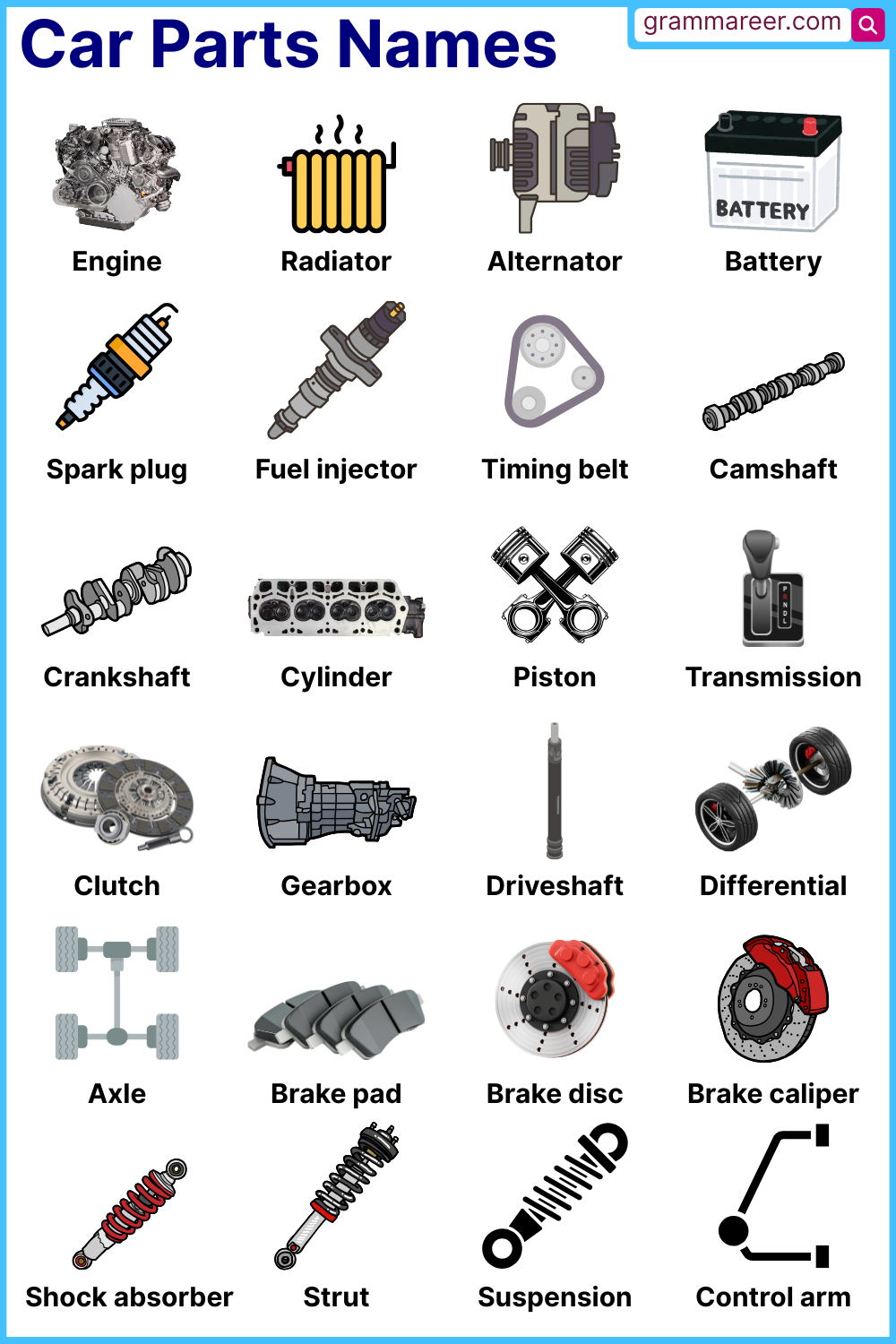

Essential Technical Properties and Trade Terminology for every car parts name

What Are the Key Technical Properties of Car Parts and Why Are They Important for B2B Buyers?

When sourcing car parts, understanding the technical properties is crucial for ensuring compatibility, durability, and overall performance. Here are some critical specifications that B2B buyers should consider:

Illustrative image related to every car parts name

-

Марка материала: The quality of materials used in car parts significantly affects their performance and longevity. Common material grades include steel, aluminum, and various composites. For instance, automotive steel is often graded according to its tensile strength, which is vital for components like suspension systems that endure substantial stress. Buyers should seek detailed material specifications to ensure they are procuring parts that meet industry standards.

-

Уровни толерантности: Tolerance refers to the permissible limit of variation in a physical dimension. Precise tolerances are essential in car parts to ensure proper fit and function. For example, engine components must be manufactured within very tight tolerances to maintain performance and efficiency. Understanding tolerance levels helps buyers avoid costly rework or failures due to misalignment.

-

Термостойкость: Many car parts, especially those in the engine and exhaust systems, must withstand high temperatures. Heat resistance is often quantified by a part’s ability to maintain structural integrity at elevated temperatures. Buyers should inquire about the heat resistance properties of critical components to avoid premature wear or failure.

-

Коррозионная стойкость: Parts exposed to moisture and various chemicals require high corrosion resistance to ensure longevity. For example, brake components often use coatings or specific alloys to resist corrosion. B2B buyers should verify that parts meet relevant corrosion resistance standards, especially in regions with harsh climates.

-

Вес: The weight of car parts can impact fuel efficiency and vehicle handling. Lighter components can improve performance, which is increasingly important in the automotive industry. Buyers should consider weight specifications, particularly when sourcing parts for performance vehicles or electric cars.

-

Lifecycle and Warranty: Understanding the expected lifecycle of car parts and associated warranties can guide purchasing decisions. A longer lifecycle and robust warranty can indicate better quality and reliability, reducing the total cost of ownership.

What Are Common Trade Terminology and Jargon in the Automotive Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B automotive market. Here are some common terms:

-

OEM (производитель оригинального оборудования): This term refers to companies that produce parts that are used in the assembly of new vehicles. OEM parts are typically considered of higher quality since they are made to the vehicle manufacturer’s specifications. B2B buyers often prefer OEM parts for their reliability.

-

MOQ (минимальный объем заказа): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B transactions, as it can affect inventory management and cash flow. Buyers should negotiate MOQs that align with their purchasing needs.

-

RFQ (запрос предложения): An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. This process helps buyers compare pricing and terms across different vendors, ensuring they secure the best deal.

-

Инкотермс (Международные торговые термины): These are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping and logistics. Familiarity with Incoterms helps buyers understand cost implications and liability during transportation, which is critical for international trade.

-

Запасные части: These are parts made by companies other than the OEM. While often less expensive, the quality can vary significantly. B2B buyers need to assess the credibility and reliability of aftermarket suppliers before making purchasing decisions.

-

Время выполнения заказа: This refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory planning and ensuring timely availability of parts, especially in just-in-time manufacturing environments.

By grasping these technical specifications and industry terms, B2B buyers can make informed decisions, negotiate effectively, and ensure they source high-quality car parts that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the every car parts name Sector

Каковы текущая динамика рынка и ключевые тенденции в секторе автозапчастей?

The global car parts market is witnessing significant transformations driven by technological advancements, evolving consumer preferences, and regulatory changes. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it is crucial to stay informed about these dynamics. Key trends include the rise of digital platforms for sourcing and procurement, enabling buyers to access a wider range of suppliers and streamline their purchasing processes. Additionally, the integration of artificial intelligence and machine learning in inventory management and demand forecasting is reshaping how businesses operate, allowing for more responsive supply chains.

Emerging markets are also becoming increasingly important as manufacturers seek to establish production facilities closer to key customer bases. For instance, Brazil and Germany are focusing on enhancing their automotive supply chains to cater to local demand while minimizing logistics costs. Furthermore, the push towards electric vehicles (EVs) is reshaping the car parts landscape, creating new opportunities for suppliers of specialized components such as batteries and electric drivetrains. Understanding these trends will enable B2B buyers to identify strategic partnerships and make informed sourcing decisions.

Illustrative image related to every car parts name

How Is Sustainability Impacting Sourcing Decisions in the Car Parts Industry?

Sustainability is increasingly becoming a priority in the car parts sector, with environmental concerns driving the demand for ethical sourcing practices. B2B buyers are now prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and employing sustainable materials. This shift not only reflects consumer preferences but is also becoming a regulatory requirement in many regions.

The use of green certifications, such as ISO 14001 for environmental management and LEED for sustainable manufacturing, is gaining traction. These certifications help buyers ensure that their suppliers adhere to environmentally friendly practices throughout the supply chain. Additionally, the adoption of recycled materials in car parts manufacturing is an emerging trend, particularly in regions with stringent waste management regulations. By prioritizing sustainability, B2B buyers can enhance their brand reputation, meet regulatory requirements, and appeal to an increasingly eco-conscious market.

What Is the Historical Context of the Car Parts Industry Relevant to Today’s B2B Buyers?

The car parts industry has evolved significantly over the past century, shaped by technological advancements and changing consumer demands. Initially, car parts were predominantly manufactured locally, with a focus on individual components. However, the rise of globalization in the late 20th century led to the establishment of extensive supply chains, enabling manufacturers to source parts from various countries to reduce costs and increase efficiency.

As the automotive industry has transitioned towards automation and electrification, the complexity of car parts has increased, necessitating more sophisticated manufacturing techniques. The introduction of just-in-time production methods has further transformed sourcing practices, requiring B2B buyers to adopt more agile procurement strategies. Understanding this historical context provides valuable insights into current sourcing challenges and opportunities, enabling buyers to navigate the complexities of the global car parts market effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of every car parts name

-

How do I determine the quality of car parts from suppliers?

To assess the quality of car parts, start by checking for certifications and compliance with international standards, such as ISO or IATF 16949. Request samples to evaluate material and craftsmanship firsthand. Additionally, review supplier ratings and customer feedback, focusing on their track record in quality assurance. It’s also beneficial to inquire about their manufacturing processes and whether they have quality control measures in place, such as testing protocols for critical components. -

What is the best type of brake pads for heavy-duty vehicles?

For heavy-duty vehicles, ceramic brake pads are often the best choice due to their excellent performance under high temperatures and reduced brake dust. They offer superior stopping power and longevity, making them ideal for demanding applications. Alternatively, semi-metallic pads provide better heat dissipation and are suitable for extreme conditions, but they may produce more noise and dust. Evaluate your specific vehicle requirements, including weight and intended use, to make an informed decision. -

How can I ensure timely delivery when sourcing car parts internationally?

To ensure timely delivery, establish clear communication with your suppliers regarding lead times and shipping methods. Use reliable logistics partners with experience in international shipping, and consider utilizing air freight for urgent needs, despite higher costs. It’s essential to monitor your orders closely and maintain an open line for updates on production and shipping status. Additionally, consider buffer stock to mitigate delays caused by customs or unforeseen circumstances. -

What are the typical payment terms in B2B car parts transactions?

Payment terms in B2B car parts transactions can vary widely, but common arrangements include 30, 60, or 90 days after invoice (Net 30, Net 60, Net 90). Some suppliers may require a deposit upfront, especially for large orders or custom parts. It’s crucial to negotiate terms that align with your cash flow and establish a secure payment method, such as letters of credit or escrow services, to protect both parties involved. -

What factors should I consider when vetting a car parts supplier?

When vetting a car parts supplier, consider their experience in the industry, reputation, and financial stability. Evaluate their production capabilities, including technology and workforce expertise, to ensure they can meet your quality and volume requirements. Check for certifications and compliance with safety regulations. Additionally, assess their customer service responsiveness and willingness to accommodate special requests or customizations. -

Can I customize car parts according to my specifications?

Yes, many suppliers offer customization options for car parts to meet specific requirements. This can include alterations in size, materials, and design features. When considering customization, clearly communicate your specifications and ensure the supplier has the capability to meet those needs. Keep in mind that custom parts may have higher minimum order quantities (MOQs) and longer lead times, so plan accordingly. -

What is the minimum order quantity (MOQ) for car parts, and why does it matter?

The minimum order quantity (MOQ) for car parts varies by supplier and is determined by production costs and inventory management. MOQs are important because they can impact your cash flow and inventory levels. If the MOQ is higher than your immediate needs, you may need to reconsider your sourcing strategy or negotiate lower MOQs. Understanding MOQs helps ensure that you can maintain adequate stock levels while minimizing excess inventory. -

What are the best practices for quality assurance when sourcing car parts?

To ensure quality assurance when sourcing car parts, implement a robust supplier evaluation process that includes on-site audits if possible. Establish clear quality standards and specifications before placing orders. Regularly inspect received parts and conduct random sampling for tests to verify compliance with standards. Additionally, maintain an ongoing relationship with suppliers to address any quality issues promptly and collaborate on continuous improvement initiatives.

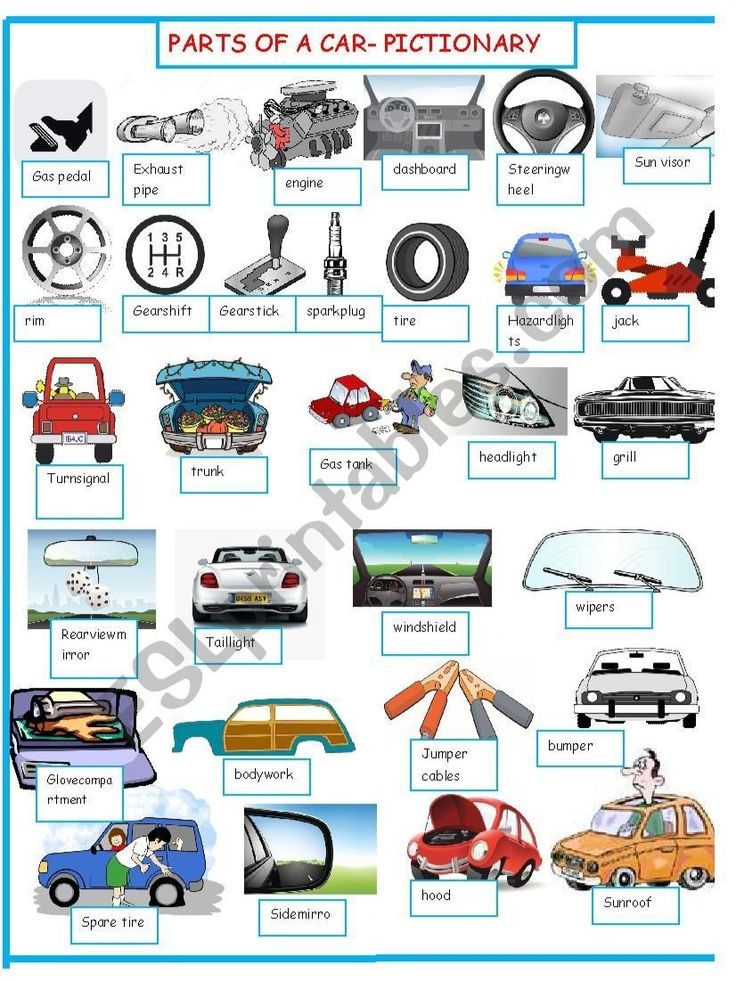

Top 4 Every Car Parts Name Manufacturers & Suppliers List

1. Moog - детали рулевого управления и подвески

Домен: moogparts.com

Зарегистрирован: 2005 (20 лет)

Введение: Steering: Center Drag Links, Idler Arms, Pitman Arms, Steering Stabilizers, Complete Pre-Assembled Steering Linkage, Tie Rods; Suspension: Solid Sway Bar Kits, Alignment Parts, Bushings, Coil Springs, Control Arms, Sway Bar Links, Ball Joints; Driveline: PTO/AG, Universal Joints, Couplers, Constant Velocity Axles; Wheel End: Complete Knuckle Assembly, Hub Assemblies.

2. Mr Tyre – Essential Automotive Components

Домен: mrtyre.com

Зарегистрирован: 2001 (24 года)

Введение: Alternator: Powers electronic components and keeps the battery charged. Battery: Traditional batteries start the vehicle; EV batteries are more powerful and located underneath. Cambelt: Controls engine timing for fuel and air intake. Distributor: Directs voltage to spark plugs in older cars. Exhaust: Guides gases from the engine outside. Flywheel: Stores kinetic energy to conserve power. Gasket: S…

3. Enchanted Learning – Car Parts Word List

Домен: enchantedlearning.com

Зарегистрирован: 1995 (30 лет)

Введение: Car Parts Word List includes terms related to automobiles, organized alphabetically from A-Z. Key terms include: accelerator, air conditioner, air filter, airbag, alternator, battery, brake pedal, catalytic converter, dashboard, engine, fuel gauge, ignition, license plate, muffler, power steering, radiator, seat belt, spark plug, steering wheel, tire, transmission, and windshield wiper.

4. Pinterest – Car Parts & Driving Tips

Домен: pinterest.com

Зарегистрирован: 2009 (16 лет)

Введение: Car Parts Names with Pictures, Driving basics, Car facts, Learn car driving, Information About Cars, Car Part Names, Learn About Cars, Find Car Parts Near Me, Car Parts Names In English, Car Things, Driving Tips For Beginners, Learning To Drive Tips

Strategic Sourcing Conclusion and Outlook for every car parts name

In the competitive landscape of automotive parts sourcing, international B2B buyers must leverage strategic sourcing to optimize their procurement processes. Understanding the diverse components of a vehicle, from engines and transmissions to brakes and exhaust systems, enables buyers to make informed decisions that align with market demands. By developing strong relationships with reliable suppliers, companies can ensure access to high-quality parts, streamline their supply chains, and reduce costs.

Moreover, as global automotive markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the importance of adaptability and innovation in sourcing strategies cannot be overstated. Buyers are encouraged to stay abreast of emerging technologies and trends that can influence the supply chain dynamics.

Looking ahead, it is imperative for B2B buyers to embrace a proactive approach in their sourcing strategies. By investing in partnerships and utilizing data-driven insights, businesses can position themselves for success in a rapidly changing automotive landscape. Engage with suppliers today to enhance your sourcing strategy and drive your business forward in this vital sector.

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Illustrative image related to every car parts name

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.