Введение: Навигация по глобальному рынку компонентов генератора переменного тока

В условиях современной автомобильной конкуренции поиск высококачественных компонентов генератора переменного тока может представлять значительные трудности для международных покупателей B2B. Тонкости выбора нужных деталей - от роторов и статоров до выпрямителей и регуляторов напряжения - требуют всестороннего понимания как технических характеристик, так и динамики рынка. Данное руководство призвано осветить мировой рынок компонентов генераторов переменного тока, предоставляя информацию о различных типах, областях применения и последних тенденциях, влияющих на стратегии закупок.

Поскольку компании в Африке, Южной Америке, на Ближнем Востоке и в Европе ориентируются в сложностях поиска поставщиков, доступ к подробной информации о процессах проверки поставщиков, анализа затрат и обеспечения качества становится незаменимым. Данное руководство дает возможность лицам, принимающим решения, получить действенные сведения, которые помогут сделать осознанный выбор при покупке. Изучив такие ключевые моменты, как соответствие международным стандартам и важность надежности поставщика, покупатели смогут снизить риски и повысить эффективность цепочки поставок.

Кроме того, мы рассматриваем новые технологии и инновации в области компонентов генераторов переменного тока, предоставляя покупателям знания, необходимые для того, чтобы опережать изменения в отрасли. Независимо от того, где вы находитесь - в Саудовской Аравии, Германии или других странах, - этот всеобъемлющий ресурс призван поддержать ваши стратегические инициативы по поиску поставщиков и помочь вам создать устойчивую и эффективную цепочку поставок.

Содержание

- Список 5 лучших производителей и поставщиков компонентов генератора

- Введение: Навигация по глобальному рынку компонентов генератора переменного тока

- Понимание компонентов генератора переменного тока Типы и разновидности

- Основные промышленные применения компонентов генератора переменного тока

- 3 распространенных болевых точки пользователей для ‘компонентов генератора переменного тока’ и их решения

- Руководство по выбору стратегических материалов для компонентов генератора переменного тока

- Глубокий взгляд: Производственные процессы и обеспечение качества компонентов генератора переменного тока

- Практическое руководство по поиску: Пошаговый контрольный список для ‘компонентов генератора переменного тока’

- Всесторонний анализ затрат и цен на поиск компонентов генератора переменного тока

- Анализ альтернатив: Сравнение компонентов генератора с другими решениями

- Основные технические свойства и торговая терминология для компонентов генератора переменного тока

- Навигация по динамике рынка и тенденциям поиска поставщиков в секторе компонентов генератора переменного тока

- Часто задаваемые вопросы (FAQ) для B2B покупателей компонентов генератора переменного тока

- Выводы и перспективы стратегического сорсинга для компонентов генератора переменного тока

- Важное предупреждение и условия использования

Понимание компонентов генератора переменного тока Типы и разновидности

| Тип Название | Основные отличительные особенности | Основные приложения B2B | Краткий обзор преимуществ и недостатков для покупателей |

|---|---|---|---|

| Обычный генератор | Обычно включает в себя ротор, статор, выпрямитель и регулятор. | Автомобили, тяжелое оборудование, морские двигатели | Плюсы: Надежный, широко доступный. Минусы: Менее эффективен на низких скоростях. |

| Высокопроизводительный генератор | Предназначены для более высоких требований к электричеству, часто имеют большие размеры. | Автомобили с высокими эксплуатационными характеристиками, индивидуальные сборки | Плюсы: Повышенная мощность. Минусы: Более высокая стоимость, может потребовать модификации. |

| Бесщеточный генератор | Отказ от щеток и контактных колец снижает износ. | Возобновляемые энергетические системы, авиация | Плюсы: Более длительный срок службы, меньшие затраты на обслуживание. Минусы: Более сложная конструкция, более высокие первоначальные инвестиции. |

| Умный генератор | Передовая электроника обеспечивает оптимальную производительность. | Гибридные автомобили, электромобили | Плюсы: Повышенная эффективность, диагностика в режиме реального времени. Минусы: Повышенная сложность, возможные затраты на ремонт. |

| Морской генератор | Разработан для работы в суровых морских условиях, устойчив к коррозии. | Катера, яхты, морское оборудование | Плюсы: Прочность, надежность в сложных условиях. Минусы: Более тяжелые, часто более дорогие. |

Каковы характеристики и пригодность Обычные генераторы переменного тока для покупателей B2B?

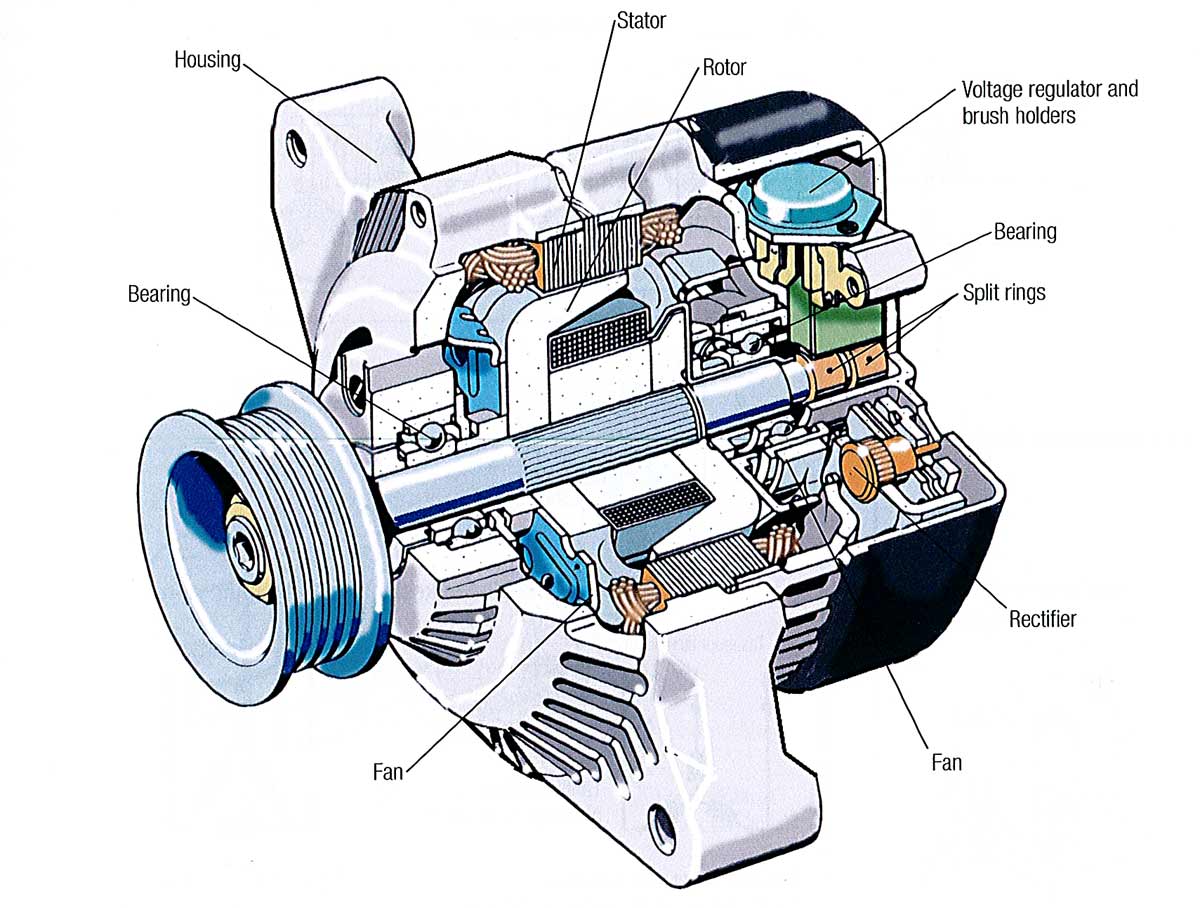

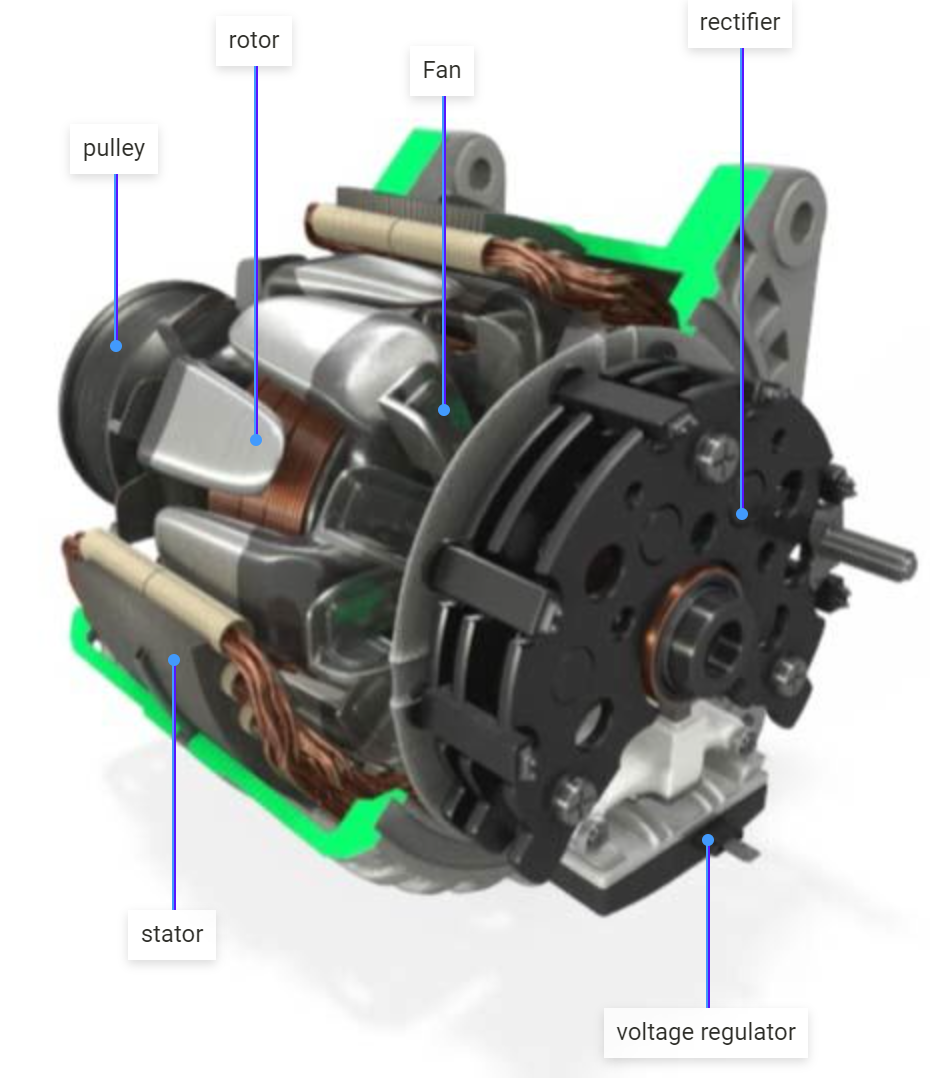

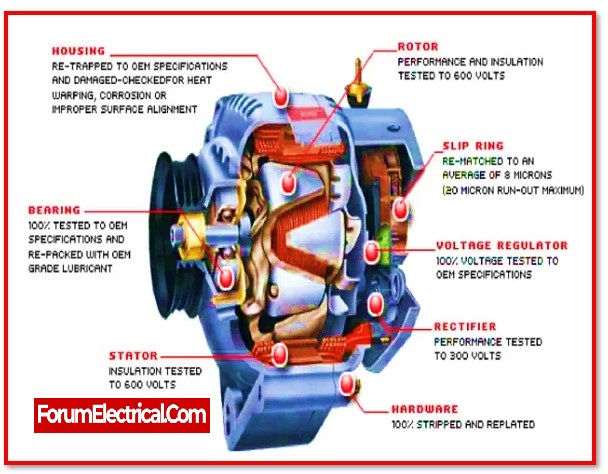

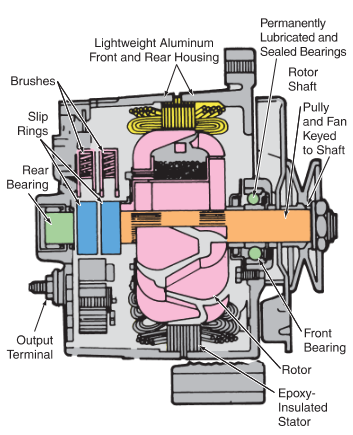

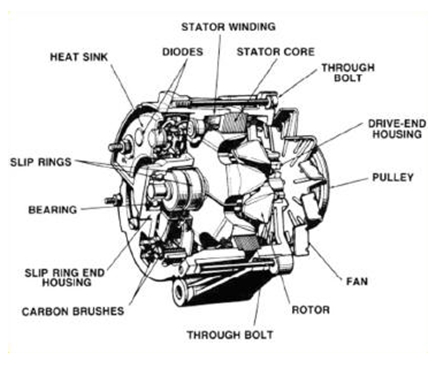

Обычные генераторы переменного тока являются стандартным выбором для многих автомобильных и промышленных применений. Они состоят из таких важных компонентов, как ротор, статор, выпрямитель и регулятор напряжения, что делает их надежными для выработки электроэнергии. Простота и широкая доступность делают их востребованными для покупателей B2B в таких отраслях, как ремонт автомобилей и тяжелое машиностроение. Однако эти генераторы могут быть менее эффективными при низких оборотах двигателя, что может повлиять на производительность в конкретных приложениях.

Как высокопроизводительные генераторы переменного тока отвечают требованиям приложений, ориентированных на производительность?

Высокопроизводительные генераторы переменного тока специально разработаны для удовлетворения потребностей автомобилей, требующих большей мощности, например, автомобилей с высокими эксплуатационными характеристиками или автомобилей, изготовленных по индивидуальному заказу. Эти генераторы имеют большие размеры и могут вырабатывать значительно больший ток, чем обычные модели. Покупатели B2B на рынке автозапчастей или те, кто занимается индивидуальным дизайном автомобилей, найдут эти компоненты необходимыми для поддержки дополнительных электрических аксессуаров, таких как мощные аудиосистемы или современное освещение. Хотя они обеспечивают повышенную мощность, следует учитывать более высокую стоимость и потенциальную необходимость модификаций.

Какие преимущества дают бесщеточные генераторы при длительном использовании?

Бесщеточные генераторы переменного тока разработаны без щеток и контактных колец, что снижает износ и увеличивает срок службы. Такая конструкция особенно выгодна для применения в системах возобновляемой энергетики и авиации, где надежность имеет решающее значение. Покупатели B2B, ищущие решения, не требующие технического обслуживания, оценят долговечность этих генераторов, несмотря на их более сложную конструкцию и более высокие первоначальные инвестиции. Их эффективность и снижение потребности в обслуживании могут привести к долгосрочной экономии средств.

Каким образом "умные" генераторы улучшают производительность и диагностику автомобиля?

Интеллектуальные генераторы переменного тока объединяют в себе передовую электронику для оптимизации работы и диагностики в режиме реального времени. Они становятся все более популярными в гибридных и электрических автомобилях, где управление электрическими нагрузками имеет решающее значение. Покупателям B2B в автомобильном секторе следует обратить внимание на эти генераторы благодаря их способности повышать эффективность и контролировать работу системы. Хотя они обладают значительными преимуществами, сложность и потенциальные затраты на ремонт, связанные с интеллектуальными генераторами, могут вызвать беспокойство у некоторых покупателей.

Почему морские генераторы переменного тока имеют решающее значение для надежной работы в сложных условиях?

Морские генераторы переменного тока специально разработаны для работы в суровых условиях морской среды и отличаются коррозионностойкими материалами и прочной конструкцией. Они необходимы для питания катеров, яхт и морского оборудования. Покупатели B2B в морской отрасли должны уделять первостепенное внимание долговечности и надежности при выборе генераторов переменного тока для своих приложений. Хотя эти специализированные компоненты могут быть тяжелее и дороже стандартных моделей, их работа в сложных условиях оправдывает вложения.

Основные промышленные применения компонентов генератора переменного тока

| Отрасль/сектор | Специфическое применение компонентов генератора | Ценность/выгода для бизнеса | Ключевые факторы, которые нужно учитывать при выборе поставщика для этого приложения |

|---|---|---|---|

| Автомобилестроение | Использование генераторов переменного тока в электромобилях (EV) | Повышение энергоэффективности и снижение выбросов | Сертификация поставщиков, совместимость компонентов, экономическая эффективность |

| Возобновляемые источники энергии | Интеграция компонентов генератора переменного тока в ветровые турбины | Надежное преобразование энергии и стабильность сети | Стандарты качества, долговечность материалов и показатели производительности |

| Строительное оборудование | Компоненты генераторов переменного тока в тяжелой технике | Увеличение времени безотказной работы и надежности | Наличие запасных частей, условия гарантии и сроки выполнения заказа |

| Морские применения | Используется в судовых генераторах для подачи электроэнергии на борт судна | Постоянное электропитание для навигации и оборудования | Соответствие морским правилам, ограничениям по размерам и сервисной поддержке |

| Сельское хозяйство | Альтернаторы в ирригационных системах | Эффективное управление водными ресурсами и экономия энергии | Устойчивость к условиям окружающей среды, энергоэффективность и поддержка технического обслуживания |

Как компоненты генератора используются в автомобильной промышленности?

В автомобилестроении генераторы переменного тока играют важнейшую роль, особенно в электромобилях (EV). Эти компоненты преобразуют механическую энергию двигателя в электрическую, которая питает аксессуары автомобиля и заряжает аккумулятор. Для международных покупателей, особенно в таких регионах, как Африка и Европа, поиск высококачественных компонентов генераторов переменного тока имеет большое значение для обеспечения энергоэффективности и соответствия нормам выбросов. Ключевыми факторами являются сертификация поставщика и совместимость с существующими системами автомобиля.

Какую роль играют компоненты генератора в возобновляемых источниках энергии?

В возобновляемых источниках энергии, в частности в ветряных турбинах, компоненты генератора переменного тока являются неотъемлемой частью процесса преобразования механической энергии в электрическую. Эффективность этих компонентов напрямую влияет на надежность энергоснабжения и стабильность сети. Для покупателей B2B в Южной Америке и на Ближнем Востоке жизненно важны стандарты качества и долговечность материалов. Кроме того, показатели производительности имеют решающее значение для обеспечения долговечности и надежности устанавливаемых систем.

Насколько важны компоненты генератора для строительной техники?

Тяжелая техника, используемая в строительстве, полагается на компоненты генератора переменного тока для обеспечения оптимальной производительности. Эти компоненты обеспечивают стабильное электропитание основных систем, что увеличивает время безотказной работы и надежность. Покупатели в этом секторе должны учитывать доступность запасных частей и условия гарантии при выборе компонентов генератора, поскольку эти факторы могут существенно повлиять на стоимость обслуживания и работоспособность машин.

Каковы области применения компонентов генератора переменного тока в морских условиях?

В морской технике компоненты генератора переменного тока необходимы для выработки электроэнергии на борту. Они обеспечивают постоянное питание навигационных систем и другого критически важного оборудования. Для предприятий, работающих в морской отрасли, соблюдение морских правил является важным фактором при выборе этих компонентов. Кроме того, ограничения по размерам и возможности сервисной поддержки являются жизненно важными для обеспечения эффективной установки и эксплуатации на судах.

Как компоненты генератора приносят пользу сельскохозяйственным предприятиям?

В сельском хозяйстве компоненты генератора переменного тока широко используются в ирригационных системах для обеспечения эффективного управления водными ресурсами. Преобразуя механическую энергию в электрическую, эти компоненты помогают снизить затраты на электроэнергию и повысить эффективность работы. Для международных покупателей в таких регионах, как Африка, такие факторы, как устойчивость к условиям окружающей среды и поддержка технического обслуживания, имеют решающее значение для обеспечения эффективного функционирования систем в различных климатических условиях.

3 распространенных болевых точки пользователей для ‘компонентов генератора переменного тока’ и их решения

Сценарий 1: Поиск высококачественных компонентов генератора переменного тока для различных областей применения

Проблема: Покупатели B2B, особенно в таких регионах, как Африка и Южная Америка, часто сталкиваются с проблемой поиска высококачественных компонентов генератора переменного тока, подходящих для различных областей применения. Эта проблема усугубляется наличием контрафактных деталей, которые могут привести к поломке оборудования, увеличению времени простоя и, в конечном счете, к финансовым потерям. Покупатели могут оказаться перегруженными разнообразием поставщиков и не знать, какие компоненты соответствуют отраслевым стандартам, что приводит к нарушению цепочки поставок.

Решение: Чтобы смягчить эту проблему, покупатели должны тщательно изучить потенциальных поставщиков и их репутацию в отрасли. Ищите поставщиков, которые предоставляют подробные сертификаты и процессы обеспечения качества своей продукции. Установление партнерских отношений с производителями, известными своей надежностью, может обеспечить постоянный доступ к высококачественным компонентам генератора. Кроме того, воспользуйтесь онлайн-платформами, специализирующимися на промышленных компонентах, чтобы сравнить технические характеристики и отзывы клиентов. Такая тщательность в поиске поставщиков не только повысит эффективность работы, но и создаст более надежную цепочку поставок.

Сценарий 2: Понимание технических характеристик компонентов генератора

Проблема: Общей проблемой для покупателей B2B является сложность технических характеристик компонентов генератора переменного тока. Многие покупатели, особенно в небольших компаниях или на развивающихся рынках, могут не обладать техническими знаниями, необходимыми для оценки технических характеристик генераторов переменного тока, таких как номинальное напряжение, сила тока и совместимость с существующими системами. Этот пробел в знаниях может привести к ошибочным покупкам, что приведет к снижению эффективности работы или необходимости дорогостоящего возврата.

Решение: Чтобы преодолеть эту проблему, покупатели должны инвестировать в обучение своих групп закупок, чтобы они могли понять основные технические характеристики компонентов генератора переменного тока. Привлечение технических экспертов или консультантов может дать ценную информацию для точной оценки этих компонентов. Кроме того, поставщики часто предоставляют технические паспорта и руководства по применению; изучение этих документов может помочь покупателям принимать обоснованные решения. Установление четкой связи с поставщиками для получения разъяснений по техническим аспектам еще больше упростит процесс покупки и обеспечит совместимость с существующими системами.

Сценарий 3: решение проблемы длительных сроков поставки и сбоев в цепочке поставок

Проблема: Покупатели часто сталкиваются с длительными сроками поставки и сбоями в цепочке поставок, особенно в регионах с менее стабильной логистической сетью. Задержки в получении компонентов генератора могут остановить производственные линии или привести к срыву сроков выполнения проекта, что негативно сказывается на удовлетворенности клиентов и прибыльности. Эта проблема особенно актуальна для предприятий, которые полагаются на системы инвентаризации "точно в срок".

Решение: Для борьбы с длительными сроками поставки покупателям B2B следует рассмотреть возможность реализации стратегии двойного поиска поставщиков, в рамках которой они развивают отношения с несколькими поставщиками из разных регионов. Такая стратегия поможет снизить риски, связанные с нарушениями в цепочке поставок. Кроме того, поддержание оптимального уровня запасов критически важных компонентов может защитить от непредвиденных задержек. Покупателям также следует использовать такие технологии, как программное обеспечение для управления цепочками поставок, чтобы контролировать уровень запасов и отслеживать работу поставщиков. Проактивное управление цепочками поставок и разработка планов действий на случай непредвиденных обстоятельств позволят предприятиям минимизировать влияние проблем со сроками выполнения заказов и сохранить непрерывность работы.

Руководство по выбору стратегических материалов для компонентов генератора переменного тока

Какие основные материалы используются в компонентах генератора?

При выборе материалов для компонентов генератора переменного тока важно учитывать их эксплуатационные характеристики, сложность производства и стоимость. В данном анализе рассматриваются четыре распространенных материала: алюминий, медь, сталь и пластик, каждый из которых обладает уникальными свойствами и областью применения.

Как алюминий влияет на конструкцию генератора?

Алюминий широко используется для изготовления внешнего корпуса генераторов благодаря своему легкому весу и немагнитным свойствам. Ключевые свойства включают в себя отличную коррозионную стойкость и теплопроводность, что делает его идеальным для рассеивания тепла, выделяемого во время работы. Типичная температура для алюминиевых компонентов может достигать 150°C, что достаточно для большинства автомобильных применений.

Плюсы: Алюминий прочен, легок и экономичен, что упрощает производственные процессы. Его немагнитная природа предотвращает воздействие магнитных полей, создаваемых ротором.

Минусы: Хотя алюминий устойчив к коррозии, в экстремальных условиях он может быть менее прочным, чем другие металлы. Кроме того, его механическая прочность может оказаться непригодной для использования в условиях высоких нагрузок.

Влияние на применение: Алюминий совместим с различными автомобильными жидкостями, что делает его универсальным выбором для изготовления корпусов генераторов. Однако для гарантии качества покупателям следует убедиться в соответствии международным стандартам, таким как ASTM и DIN.

Какую роль играет медь в эффективности генератора?

Медь используется в основном для электрических соединений и обмоток в генераторах благодаря своей высокой электропроводности. Она выдерживает температуру до 200°C, что делает ее пригодной для использования в высокопроизводительных системах.

Плюсы: Превосходная проводимость меди повышает эффективность производства электроэнергии, что приводит к улучшению производительности. Кроме того, она обладает высокой прочностью и устойчивостью к коррозии, особенно если на нее нанесено покрытие.

Минусы: Основным недостатком меди является ее относительно высокая стоимость по сравнению с алюминием и другими материалами. Кроме того, она может быть тяжелее, что может повлиять на общий вес генератора.

Влияние на применение: Совместимость меди с электрическими системами делает ее незаменимым материалом для компонентов генераторов. Международные покупатели должны учитывать доступность меди в своих регионах и обеспечивать соответствие соответствующим стандартам.

Иллюстративное изображение, относящееся к компонентам генератора переменного тока

Почему сталь важна для обеспечения целостности конструкции?

Сталь часто используется для изготовления внутренних компонентов, таких как ротор и статор, благодаря своей прочности и долговечности. Она имеет высокую температуру, обычно превышающую 300°C, что позволяет ей выдерживать тепло, выделяемое во время работы.

Плюсы: Сталь обладает превосходной механической прочностью и износостойкостью, что делает ее пригодной для использования в условиях высоких нагрузок. Кроме того, она относительно недорога по сравнению с другими металлами.

Минусы: Сталь может быть подвержена коррозии, если не обработать ее должным образом или не нанести покрытие, что может привести к преждевременному выходу из строя. Кроме того, процесс производства может быть более сложным, требующим дополнительных этапов обработки поверхности.

Влияние на применение: Прочность стали делает ее идеальной для применения в тяжелых условиях, но покупатели должны убедиться, что она прошла соответствующую антикоррозийную обработку. Соответствие международным стандартам имеет решающее значение для обеспечения качества.

Как пластик улучшает конструкцию компонентов генератора?

Пластик все чаще используется для изготовления неструктурных деталей, таких как крышки и изоляция, благодаря своим легким и изоляционным свойствам. Обычно его температура составляет около 100°C, что подходит для многих автомобильных применений.

Плюсы: Пластик легок, экономичен и может быть сформован в сложные формы, что способствует созданию инновационных конструкций. Он также обеспечивает отличную электроизоляцию.

Минусы: Пластик не выдерживает высоких температур так же эффективно, как металлы, и может разрушаться со временем под воздействием некоторых химических веществ.

Влияние на применение: Хотя пластиковые компоненты могут повысить гибкость конструкции, покупатели должны убедиться в их совместимости с автомобильными жидкостями и условиями окружающей среды. Соответствие международным стандартам является важным условием обеспечения качества и производительности.

Сводная таблица выбора материалов для компонентов генератора

| Материал | Типичный пример использования компонентов генератора переменного тока | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Алюминий | Внешний корпус | Легкий и коррозионно-стойкий | Менее долговечны в экстремальных условиях | Средний |

| Медь | Электрические обмотки | Высокая электропроводность | Более высокая стоимость и вес | Высокий |

| Сталь | Ротор и статор | Отличная механическая прочность | Без обработки подвержен коррозии | Низкий |

| Пластик | Крышки и изоляция | Легкий и формуемый | Ограниченная термостойкость | Низкий |

Это стратегическое руководство по выбору материалов содержит ценные сведения для международных покупателей B2B, которые стремятся оптимизировать производительность и долговечность компонентов генератора переменного тока, обеспечивая при этом соответствие региональным стандартам.

Глубокий взгляд: Производственные процессы и обеспечение качества компонентов генератора переменного тока

Производство компонентов генератора включает в себя ряд тщательных процессов, которые обеспечивают высокую производительность и надежность. Для покупателей B2B понимание этих процессов может помочь в выборе поставщиков, которые придерживаются лучших практик в производстве и обеспечении качества. Ниже мы рассмотрим основные этапы производства, ключевые технологии и меры контроля качества, необходимые для поддержания международных стандартов.

Каковы основные этапы производственного процесса компонентов генератора?

Как подготавливаются материалы для компонентов генератора?

Процесс производства начинается с тщательного отбора и подготовки сырья. Обычно в производстве генераторов используются высококачественный алюминий для корпусов, медь для обмоток и специализированные сплавы для ротора. Этап подготовки материалов включает в себя:

- Поиск материалов: Поставщики должны предоставить материалы, отвечающие определенным механическим и электрическим свойствам, которые часто проверяются с помощью сертификации.

- Испытание материалов: Поступающие материалы проходят проверку (контроль качества при поступлении - IQC), чтобы убедиться в их соответствии заданным спецификациям. Это может включать испытания на прочность при растяжении и оценку электропроводности.

Какие методы формовки используются при производстве генераторов?

После подготовки материалов используются методы формовки для придания компонентам нужной формы. К основным методам относятся:

- Литье под давлением: Алюминиевые корпуса часто изготавливаются методом литья под давлением. Этот метод позволяет создавать сложные конструкции и обеспечивает равномерную толщину, что очень важно для рассеивания тепла.

- Штамповка и механическая обработка: Такие компоненты, как статор и ротор, обычно штампуются и обрабатываются из листового металла. Прецизионная обработка обеспечивает точное соблюдение размеров, что очень важно для производительности.

- Намотка: Для ротора и статора медная проволока наматывается на сердечники с помощью автоматизированных намоточных станков, обеспечивая равномерное формирование катушек, что имеет решающее значение для электромагнитной эффективности.

Как собираются компоненты в процессе производства?

На этапе сборки отдельные компоненты собираются вместе, образуя готовый генератор. Этот этап включает в себя:

- Подборка: Такие компоненты, как контактные кольца, диоды и регуляторы напряжения, собираются в узлы перед окончательной сборкой. Такой модульный подход повышает эффективность и упрощает поиск и устранение неисправностей.

- Заключительная сборка: Квалифицированные специалисты собирают генератор, следя за тем, чтобы все детали правильно подходили и работали вместе. На этом этапе могут использоваться автоматизированные сборочные линии, чтобы увеличить скорость и уменьшить количество человеческих ошибок.

Какие процессы финишной обработки необходимы для компонентов генератора?

Процессы финишной обработки имеют решающее значение для повышения долговечности и эксплуатационных характеристик. Основные методы отделки включают:

- Обработка поверхности: Компоненты могут подвергаться анодированию или покрытию для повышения коррозионной стойкости. Это особенно важно для деталей, подвергающихся воздействию высоких температур и факторов окружающей среды.

- Тестирование и калибровка: Каждый генератор проходит тщательное тестирование, чтобы убедиться в его соответствии эксплуатационным стандартам. Это может включать динамометрические испытания для измерения электрической мощности в условиях нагрузки.

Какие меры контроля качества важны при производстве генераторов?

На какие международные стандарты следует обратить внимание покупателям B2B?

Покупатели B2B должны убедиться, что поставщики соответствуют международным стандартам качества, таким как:

- ISO 9001: Этот стандарт посвящен системам менеджмента качества и гарантирует, что производители постоянно выпускают продукцию, соответствующую требованиям заказчика и нормативных документов.

- Маркировка CE: Для компаний в Европе маркировка CE указывает на соответствие стандартам безопасности, здоровья и защиты окружающей среды.

- Стандарты API: В таких специфических отраслях, как автомобильная или аэрокосмическая, соблюдение стандартов API может иметь решающее значение для обеспечения качества.

Каковы ключевые точки контроля качества в производственном процессе?

Контрольные точки контроля качества необходимы на протяжении всего производственного процесса, чтобы гарантировать, что каждый компонент соответствует требуемым спецификациям. К общим контрольным точкам относятся:

- Входящий контроль качества (IQC): Проверка сырья по прибытии на соответствие спецификациям.

- Контроль качества в процессе производства (IPQC): Мониторинг производственного процесса на различных этапах для раннего обнаружения дефектов. Это включает в себя визуальный осмотр и измерения во время сборки.

- Окончательный контроль качества (FQC): Проведение комплексных испытаний готовой продукции для обеспечения ее соответствия эксплуатационным требованиям перед отправкой. Это может включать электрические испытания и оценку тепловых характеристик.

Как покупатели B2B могут проверять процессы обеспечения качества у поставщиков?

Каковы лучшие практики проведения аудитов поставщиков?

Покупатели B2B должны проводить аудиты поставщиков для проверки практики обеспечения качества. Ключевые аспекты, которые необходимо учитывать при проведении аудита, включают:

Иллюстративное изображение, относящееся к компонентам генератора переменного тока

- Обзор документации: Убедитесь, что поставщик ведет полную документацию по управлению качеством, включая отчеты о проверках и сертификаты соответствия.

- Наблюдение за процессом: Наблюдение за производственными процессами для обеспечения соблюдения стандартов качества и передовой практики.

- Обучение сотрудников: Оцените программы обучения сотрудников, чтобы убедиться, что они обладают необходимыми навыками для обеспечения качества.

Как покупатели могут использовать инспекции третьих лиц?

Привлечение сторонних инспекционных служб может обеспечить непредвзятую оценку процессов контроля качества поставщика. Покупателям следует рассмотреть:

- Предварительные проверки грузов: Приглашение сторонних инспекторов для оценки продукции перед отправкой поможет выявить дефекты и обеспечить соответствие спецификациям.

- Проверка сертификации: Сторонние инспекторы могут проверить наличие у поставщиков соответствующих сертификатов и соответствие международным стандартам.

Каковы нюансы контроля качества для международных B2B-покупателей?

Покупатели B2B из таких регионов, как Африка, Южная Америка, Ближний Восток и Европа, должны знать о специфических нюансах контроля качества, в том числе:

- Культурные различия: Понимание культурного контекста поставщиков может помочь в переговорах об ожидаемом качестве и его соблюдении.

- Различия в нормативных требованиях: Покупателям следует ознакомиться с региональными нормативными требованиями, которые могут повлиять на стандарты качества, особенно при импорте компонентов.

- Логистические соображения: Процессы обеспечения качества могут отличаться в зависимости от логистики, например, методов транспортировки и климата, что может повлиять на целостность продукта.

Понимая производственные процессы и меры по обеспечению качества при производстве компонентов генератора, покупатели B2B могут принимать обоснованные решения, гарантируя, что они сотрудничают с надежными поставщиками, соответствующими международным стандартам. Эти знания не только повышают качество закупаемой продукции, но и укрепляют цепочку поставок, что в конечном итоге приводит к повышению удовлетворенности клиентов и успеху бизнеса.

Практическое руководство по поиску: Пошаговый контрольный список для ‘компонентов генератора переменного тока’

Введение

Данное руководство служит всеобъемлющим контрольным списком для покупателей B2B, желающих приобрести компоненты генератора переменного тока. Эффективный поиск этих деталей необходим для поддержания надежности и производительности электрических систем транспортных средств и оборудования. Следуя этим шагам, покупатели могут гарантировать, что они выберут правильные компоненты и поставщиков для удовлетворения своих конкретных потребностей.

Шаг 1: Определите свои технические характеристики

Прежде чем начать поиск компонентов генератора переменного тока, необходимо определить его технические характеристики. Определите точный тип необходимых вам компонентов генератора, таких как роторы, статоры, выпрямители или регуляторы напряжения. Знание требуемых размеров, номинального напряжения и характеристик материалов поможет сузить круг потенциальных поставщиков и обеспечить совместимость с существующими системами.

Иллюстративное изображение, относящееся к компонентам генератора переменного тока

- Учитывайте требования к производительности: Для различных применений могут потребоваться особые характеристики, такие как выходное напряжение или сила тока.

- Понимание соответствия нормативным требованиям: Убедитесь, что ваши технические характеристики соответствуют всем местным или международным нормам, которые применяются к автомобильным или промышленным компонентам.

Шаг 2: Исследование потенциальных поставщиков

Проведите тщательное исследование, чтобы составить список потенциальных поставщиков, специализирующихся на компонентах генератора переменного тока. Используйте интернет-ресурсы, торговые справочники и отраслевые форумы, чтобы найти авторитетных производителей и дистрибьюторов.

- Обратите внимание на отраслевые сертификаты: Убедитесь, что поставщики имеют соответствующие сертификаты (например, ISO, TS16949), свидетельствующие об обеспечении качества производственных процессов.

- Оцените их репутацию на рынке: Ознакомьтесь с отзывами и комментариями покупателей, чтобы оценить надежность и эффективность их продукции.

Шаг 3: Запросите образцы и техническую документацию

После того как вы составите короткий список поставщиков, запросите образцы интересующих вас компонентов генератора. Кроме того, попросите предоставить техническую документацию, включая спецификации продукции и рекомендации по установке.

- Оцените качество и совместимость: Тестирование образцов позволяет оценить качество и обеспечить совместимость с вашими системами.

- Внимательно изучите документацию: Техническая документация может дать представление об установке, обслуживании и эффективности эксплуатации.

Шаг 4: Проверка сертификатов поставщиков

Прежде чем заключать какие-либо соглашения, убедитесь, что выбранные вами поставщики имеют соответствующие сертификаты и придерживаются отраслевых стандартов. Этот шаг крайне важен для обеспечения соответствия компонентов требованиям качества и безопасности.

- Проверьте соответствие международным стандартам: Такие сертификаты, как ISO 9001 или ISO/TS 16949, свидетельствуют о приверженности управлению качеством.

- Узнайте о протоколах тестирования: Поймите, как поставщики тестируют свои компоненты, чтобы убедиться в их соответствии заданным критериям производительности.

Шаг 5: Обсудить условия и положения

Проведите переговоры с предпочтительными поставщиками, чтобы установить выгодные условия. Сюда входят цены, условия оплаты, графики поставок и гарантийные обязательства.

- Рассмотрите возможность предоставления скидок на оптовые закупки: Обсудите возможные скидки при больших заказах, которые могут значительно снизить общие расходы.

- Разъясните правила гарантийного обслуживания и поддержки: Убедитесь, что вам понятны условия гарантии и доступной технической поддержки компонентов.

Шаг 6: Установите долгосрочные отношения

Построение долгосрочных отношений с надежными поставщиками может принести пользу вашей стратегии поиска поставщиков. Учитывайте такие факторы, как стабильное качество, надежность поставок и оперативность реагирования на запросы.

- Оцените текущую производительность: Регулярно оценивайте качество и надежность поставляемых компонентов для поддержания эффективности работы.

- Регулярно общайтесь: Поддерживайте открытые каналы связи для оперативного решения любых вопросов и укрепления партнерских отношений.

Следуя этому контрольному списку, покупатели B2B могут упростить процесс поиска компонентов генератора, гарантируя, что они выберут лучшие продукты и поставщиков для удовлетворения своих операционных потребностей.

Всесторонний анализ затрат и цен на поиск компонентов генератора переменного тока

При оценке структуры затрат и цен на компоненты генератора переменного тока необходимо учитывать несколько ключевых компонентов. Этот анализ позволит международным покупателям B2B, особенно в таких регионах, как Африка, Южная Америка, Ближний Восток и Европа, получить практические рекомендации по стратегии поиска поставщиков.

Иллюстративное изображение, относящееся к компонентам генератора переменного тока

Каковы ключевые компоненты затрат при поиске компонентов генератора?

-

Материалы: Основные материалы, используемые в компонентах генераторов, включают алюминий для корпусов, медь для обмоток, а также различные пластмассы и резину для изоляции и корпусных деталей. Колебания цен на сырье могут существенно повлиять на общую стоимость. Покупателям следует обратить внимание на закупку материалов у стабильных поставщиков или в регионах, чтобы снизить риски, связанные с волатильностью цен.

-

Трудовые ресурсы: Стоимость рабочей силы значительно варьируется в зависимости от географического расположения производственного предприятия. В регионах с более высокой стоимостью рабочей силы, например в Европе, общая цена может возрасти. И наоборот, в странах Африки или Южной Америки стоимость рабочей силы может быть ниже, что может обеспечить конкурентоспособные цены на компоненты генератора.

-

Производственные накладные расходы: Сюда входят расходы, связанные с эксплуатацией производственных мощностей, включая коммунальные услуги, обслуживание оборудования и административные расходы. Эффективные производственные процессы помогают снизить накладные расходы, что позволяет поставщикам предлагать более конкурентоспособные цены.

-

Инструменты: Изготовление на заказ оснастки для конкретных компонентов генератора переменного тока может потребовать значительных предварительных инвестиций. Покупатели должны определить, включены ли расходы на оснастку в цену или являются отдельной платой. Предварительное понимание этих расходов может помочь в составлении бюджета и управлении общими затратами.

-

Контроль качества (КК): Обеспечение качества с помощью строгих процессов тестирования и контроля качества очень важно. Поставщики, уделяющие первостепенное внимание контролю качества, могут устанавливать более высокие цены, но это может привести к долгосрочной экономии за счет снижения количества отказов и гарантийных претензий.

-

Логистика: Стоимость доставки компонентов генератора переменного тока от производителя до места нахождения покупателя может варьироваться в зависимости от расстояния, способов доставки и таможенных пошлин. Покупателям следует рассмотреть Инкотермс, чтобы уточнить ответственность за стоимость доставки и риски.

-

Маржа: Наценки поставщиков могут сильно отличаться в зависимости от рыночных условий и конкуренции. Покупатели должны знать о типичных отраслевых наценках, чтобы лучше договориться о цене.

Что влияет на цены на компоненты генератора?

-

Объем/минимальный объем заказа: Крупные заказы часто приводят к снижению стоимости единицы продукции благодаря эффекту масштаба. Покупатели должны договариваться о минимальных количествах заказа (MOQ), которые соответствуют их возможностям и потребностям в закупках.

-

Технические характеристики и индивидуальная настройка: Нестандартные спецификации могут увеличить расходы из-за необходимости использования специализированной оснастки или материалов. Покупатели должны четко определить свои требования, чтобы избежать непредвиденных расходов.

-

Качество и сертификаты: Компоненты, соответствующие более высоким стандартам качества или сертификации, могут стоить дороже. Покупатели должны соизмерять потребность в качестве с бюджетными ограничениями, чтобы обеспечить оптимальную производительность без перерасхода средств.

-

Факторы, связанные с поставщиками: Репутация, надежность и местоположение поставщика могут влиять на ценообразование. Известные поставщики могут брать больше за свой опыт и надежность, но они также могут снизить риски, связанные с качеством и доставкой.

-

Инкотермс: Понимание Инкотермс имеет решающее значение для международных сделок. Они определяют обязанности покупателей и продавцов в отношении доставки, страхования и тарифов, которые могут повлиять на общую стоимость компонентов на суше.

Каковы основные советы для покупателей при переговорах о ценах на компоненты генератора?

-

Эффективные переговоры: Обсудите цены, MOQ и условия оплаты. Поставщики могут быть готовы к переговорам о скидках при крупных заказах или долгосрочных контрактах.

-

Сосредоточьтесь на экономической эффективности: Оцените общую стоимость владения (TCO), которая включает в себя цену покупки, стоимость доставки и обслуживания. Иногда выбор в пользу более дорогого компонента с лучшим качеством может привести к экономии в долгосрочной перспективе.

-

Будьте в курсе тенденций рынка: Следите за тенденциями в ценах на сырье и инновациями в производстве. Эти знания могут помочь покупателям во время переговоров и принятия решений о выборе поставщиков.

-

Использование региональных различий: Используйте преимущества региональных производственных возможностей. Например, закупки у местного поставщика в Южной Америке могут сократить расходы на доставку и время выполнения заказа по сравнению с закупками в Европе.

Отказ от ответственности в отношении ориентировочных цен

Цены на компоненты генератора могут сильно варьироваться в зависимости от множества факторов, включая, в частности, рыночный спрос, ценовые стратегии поставщиков и геополитическую обстановку. Всегда запрашивайте подробные котировки у нескольких поставщиков, чтобы убедиться в конкурентоспособности цен.

Анализ альтернатив: Сравнение компонентов генератора с другими решениями

Изучение альтернатив компонентам генератора: Какие есть варианты?

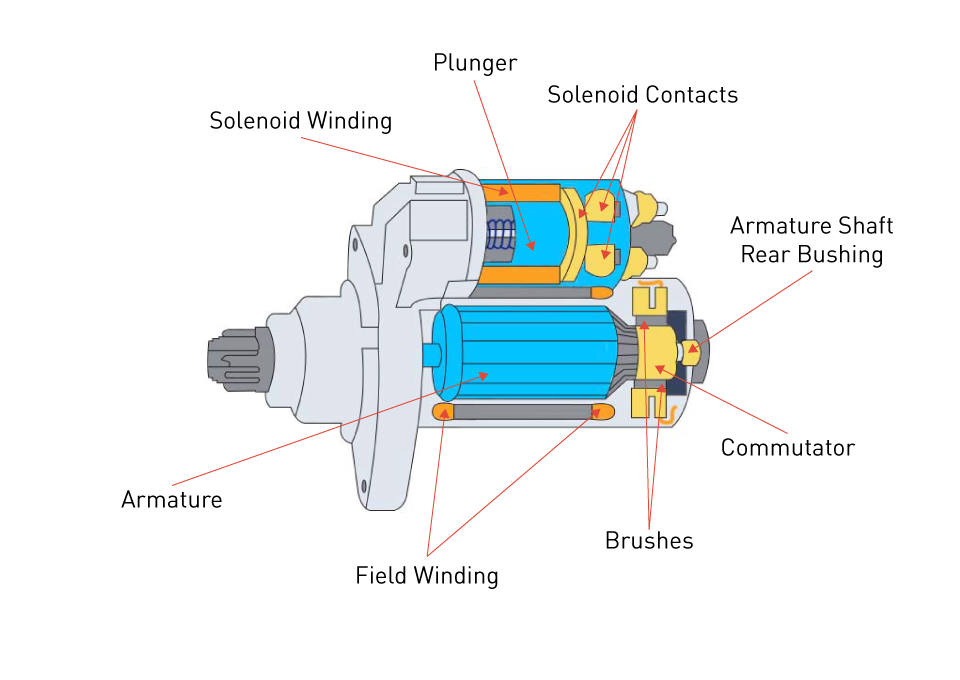

В сфере производства электроэнергии, особенно в автомобильной и промышленной промышленности, понимание альтернатив традиционным компонентам генератора переменного тока имеет решающее значение для покупателей B2B. Различные технологии могут достигать схожих целей преобразования и управления энергией. В данном анализе сравниваются стандартные компоненты генератора переменного тока с двумя жизнеспособными альтернативами: Генераторы постоянного тока и Системы управления аккумуляторами (BMS).

Сравнительная таблица

| Аспект сравнения | Компоненты генератора переменного тока | Генераторы постоянного тока | Системы управления аккумуляторами (BMS) |

|---|---|---|---|

| Производительность | Высокая эффективность преобразования механической энергии в электрическую | Умеренная эффективность, обычно ниже, чем у генераторов переменного тока | Высокая эффективность управления зарядом и разрядом батареи |

| Стоимость | Умеренные первоначальные инвестиции; более длительный срок службы | Как правило, меньшая первоначальная стоимость, но меньший срок службы | Более высокие первоначальные инвестиции из-за передовой технологии |

| Простота внедрения | Стандартная установка; требуется совместимый двигатель | Относительно простая установка; может потребоваться индивидуальное крепление | Сложная установка; требуется интеграция с существующими аккумуляторными системами |

| Техническое обслуживание | Не требует особого ухода; рекомендуется периодическая проверка | Требуется регулярное обслуживание и замена щеток | Минимальное обслуживание; требуется обновление программного обеспечения |

| Лучший вариант использования | Идеально подходит для транспортных средств и машин с высокой потребностью в электроэнергии | Подходит для небольших приложений и портативных источников питания | Лучше всего подходит для электромобилей и систем возобновляемой энергии |

Подробная разбивка альтернатив

Каковы преимущества и недостатки генераторов постоянного тока?

Генераторы постоянного тока преобразуют механическую энергию в электричество постоянного тока, что делает их подходящими для приложений, требующих стабильного напряжения. Они, как правило, менее сложны и более экономичны, чем генераторы переменного тока, но имеют меньший срок службы и более низкую эффективность. Техническое обслуживание более трудоемко из-за необходимости регулярной замены щеток. Эти генераторы идеально подходят для небольших производств электроэнергии, например, для переносных инструментов или освещения, но не могут удовлетворить высокие требования современных автомобилей или тяжелой техники.

Как системы управления аккумуляторами (BMS) улучшают управление энергией?

Системы управления аккумуляторами (BMS) необходимы для оптимизации работы аккумуляторов в электромобилях и системах возобновляемой энергии. Они управляют циклами заряда и разряда, обеспечивая долговечность и эффективность батареи. Хотя технологии BMS требуют больших первоначальных инвестиций и сложной интеграции, они обеспечивают более высокую эффективность управления энергией по сравнению с генераторами переменного тока. Техническое обслуживание минимально и включает в себя в основном обновление программного обеспечения, а не аппаратное вмешательство. BMS лучше всего подходит для приложений, где срок службы и производительность батареи имеют решающее значение, например, в электромобилях и системах солнечной энергии.

Сделайте правильный выбор: Какое решение лучше всего подходит для ваших нужд?

При выборе подходящего решения для производства электроэнергии учитывайте конкретные требования к применению, ограничения по стоимости и возможности обслуживания. Если вам нужна надежная и эффективная система для сценариев с высоким спросом, традиционные компоненты генератора переменного тока остаются сильным выбором. Однако для небольших или специализированных приложений генераторы постоянного тока могут стать экономически эффективным решением. Напротив, если вы ориентируетесь на электромобили или возобновляемые источники энергии, инвестиции в сложную систему управления батареями могут обеспечить значительные долгосрочные преимущества.

В конечном итоге решение должно соответствовать вашим операционным целям, бюджету и технологическому ландшафту вашего целевого рынка. Понимание этих альтернатив позволит покупателям B2B принимать взвешенные решения, которые повысят эффективность их работы и улучшат результаты проектов.

Основные технические свойства и торговая терминология для компонентов генератора переменного тока

Каковы основные технические свойства компонентов генератора?

Понимание технических характеристик компонентов генератора переменного тока имеет решающее значение для покупателей B2B при принятии обоснованных решений о покупке. Вот некоторые важные свойства, которые необходимо учитывать:

1. Марка материала

Внешний корпус генератора обычно изготавливается из алюминия благодаря его легкости и устойчивости к намагничиванию. Алюминий необходим для рассеивания тепла, обеспечивая эффективную работу генератора. При поиске генераторов покупатели должны поинтересоваться маркой материала, чтобы обеспечить долговечность и работоспособность при высоких температурах.

2. Уровни толерантности

Допуск - это допустимое предельное отклонение физического размера. Для компонентов генератора, особенно для ротора и статора, точные допуски необходимы для предотвращения механических отказов. Плохие допуски могут привести к повышенному износу, что скажется на сроке службы генератора. Покупатели должны отдавать предпочтение поставщикам, которые придерживаются строгих производственных допусков для обеспечения надежности.

3. Электрические номиналы

Генераторы переменного тока имеют определенные электрические характеристики, включая напряжение и силу тока. Эти показатели определяют способность генератора заряжать аккумуляторные батареи и питать аксессуары автомобиля. Понимание электрических характеристик имеет решающее значение для обеспечения совместимости с электрической системой автомобиля и удовлетворения эксплуатационных требований.

4. Тепловые характеристики

Тепловые характеристики относятся к способности генератора отводить тепло, выделяемое в процессе работы. Такие компоненты, как внутренние охлаждающие вентиляторы и радиаторы, предназначены для эффективного управления температурой. Высокие тепловые характеристики необходимы для предотвращения перегрева, который может привести к выходу из строя компонентов. Покупателям следует оценить особенности терморегулирования генераторов переменного тока, чтобы обеспечить оптимальную работу в различных климатических условиях.

5. Грузоподъемность

Нагрузочная способность указывает на максимальную электрическую нагрузку, которую может выдержать генератор. Эта характеристика имеет решающее значение для приложений с высокими требованиями к мощности, таких как коммерческие автомобили или тяжелая техника. Понимание мощности нагрузки помогает покупателям выбрать правильный генератор переменного тока, отвечающий их эксплуатационным требованиям без риска перегрузки системы.

Каковы общие торговые термины при закупке компонентов генератора?

Знакомство с отраслевым жаргоном может значительно улучшить общение и переговоры с поставщиками. Вот некоторые распространенные торговые термины, относящиеся к компонентам генератора:

1. OEM (производитель оригинального оборудования)

OEM относится к компаниям, производящим продукцию, которая может быть представлена на рынке другим производителем. В контексте генераторов переменного тока, OEM-детали разработаны в соответствии со спецификациями оригинальных производителей автомобилей. Покупатели часто предпочитают OEM-компоненты за их надежность и совместимость, гарантируя, что замена соответствует тем же стандартам качества, что и оригинальные детали.

2. MOQ (минимальный объем заказа)

MOQ - это наименьшее количество товара, которое поставщик готов продать. Понимание MOQ очень важно для покупателей, особенно для тех, кто стремится управлять затратами на складские запасы. Низкие MOQ могут быть выгодны для небольших компаний или тех, кто тестирует новые продукты, в то время как крупные покупатели могут договориться о более низких ценах при более высоких MOQ.

3. RFQ (запрос предложения)

RFQ - это документ, в котором запрашиваются ценовые предложения от поставщиков на конкретные товары или услуги. В отрасли производства генераторов переменного тока RFQ может помочь покупателям получить конкурентоспособные цены и условия от нескольких поставщиков, что способствует принятию обоснованных решений.

4. Инкотермс (Международные торговые термины)

Инкотермс - это свод международных правил, определяющих обязанности покупателей и продавцов в международных сделках. Понимание Инкотермс жизненно важно для покупателей B2B, работающих с поставщиками из разных стран, поскольку они разъясняют обязанности по доставке, страхованию и таможенному оформлению, снижая риск недоразумений.

5. Время выполнения заказа

Время выполнения заказа - это время, которое проходит с момента размещения заказа до получения товара. На рынке генераторов понимание сроков поставки может помочь покупателям планировать графики технического обслуживания и эффективно управлять запасами. Поставщики с более коротким временем выполнения заказа могут обеспечить конкурентное преимущество, особенно в отраслях, требующих быстрого выполнения заказа.

Зная эти технические свойства и торговые термины, покупатели B2B смогут более эффективно ориентироваться на рынке компонентов генераторов, обеспечивая обоснованный выбор, соответствующий их производственным потребностям.

Навигация по динамике рынка и тенденциям поиска поставщиков в секторе компонентов генератора переменного тока

Какие ключевые тенденции формируют глобальный рынок компонентов генератора?

Мировой рынок компонентов генераторов переменного тока демонстрирует значительный рост, обусловленный несколькими ключевыми факторами. Увеличение производства автомобилей, особенно в странах с развивающейся экономикой в Африке и Южной Америке, стимулирует спрос на высокопроизводительные генераторы переменного тока. В таких регионах, как Ближний Восток и Европа, переход на электромобили (EV) также меняет ландшафт рынка. Покупатели B2B все чаще ищут компоненты, которые не только соответствуют стандартам производительности, но и поддерживают переход на более экологичные технологии.

Новые технологии, такие как современные материалы и интеллектуальные производственные процессы, меняют стратегии поиска поставщиков. Например, интеграция легкого алюминия и высокоэффективных электронных компонентов становится стандартом. Кроме того, автоматизация производственных линий повышает эффективность и сокращает время выполнения заказа, что очень важно для покупателей B2B, стремящихся оптимизировать свои цепочки поставок. В результате международные покупатели все чаще обращают внимание на поставщиков, которые используют эти технологии для предложения инновационных решений.

Кроме того, развитие цифровых закупочных платформ облегчает доступ к глобальным поставщикам, позволяя покупателям из разных регионов сравнивать варианты, договариваться о ценах и обеспечивать своевременные поставки. Эта тенденция особенно важна для покупателей в таких регионах, как Саудовская Аравия и Германия, где надежные цепочки поставок являются важнейшим условием сохранения конкурентных преимуществ в автомобильном секторе.

Как устойчивое и этичное снабжение может повлиять на решения B2B в области комплектующих для генераторов?

Экологичность становится важным фактором для покупателей B2B в секторе компонентов генераторов. Влияние производственных процессов на окружающую среду, включая потребление энергии и образование отходов, находится под пристальным вниманием. Покупатели теперь более склонны сотрудничать с поставщиками, которые отдают предпочтение устойчивым практикам, таким как использование материалов, пригодных для вторичной переработки, или минимизация углеродного следа при производстве.

Не менее важен и этический подход к выбору поставщиков, поскольку компании все чаще несут ответственность за свою цепочку поставок. Все большее значение приобретают гарантии того, что компоненты производятся в справедливых условиях труда, а поставщики соблюдают экологические нормы. Покупатели могут повысить репутацию своего бренда, выбирая поставщиков с признанными ‘зелеными’ сертификатами, такими как ISO 14001 или Global Recycle Standard.

Кроме того, интеграция экологичных материалов в компоненты генератора - например, биоразлагаемых пластиков или экологичных покрытий - может обеспечить конкурентное преимущество. Отдавая предпочтение поставщикам, которые внедряют инновации в этой области, покупатели не только вносят свой вклад в охрану окружающей среды, но и приводят свою деятельность в соответствие с глобальными целями устойчивого развития, привлекая экологически сознательных клиентов.

Как развивался рынок компонентов генератора с течением времени?

Развитие рынка компонентов генераторов переменного тока тесно связано с развитием автомобильных технологий. Изначально генераторы были базовыми механическими устройствами, используемыми в основном в двигателях внутреннего сгорания, но внедрение электронных компонентов в конце XX века значительно повысило их эффективность и функциональность.

С появлением гибридных и электрических автомобилей генераторы переменного тока адаптировались к требованиям этих новых силовых агрегатов. Акцент сместился с простого генерирования энергии на включение интеллектуальных функций, которые оптимизируют использование энергии и улучшают характеристики автомобиля. Поскольку автомобильная промышленность продолжает развиваться, рынок компонентов генераторов переменного тока, вероятно, увидит дальнейшие инновации, что делает необходимым для покупателей B2B оставаться в курсе последних тенденций и технологий, которые могут повлиять на их решения по поиску поставщиков.

Иллюстративное изображение, относящееся к компонентам генератора переменного тока

Таким образом, понимание динамики рынка, приоритетов устойчивости и исторического контекста компонентов генератора позволит международным покупателям B2B принимать обоснованные решения, которые будут соответствовать их производственным целям и этическим стандартам.

Часто задаваемые вопросы (FAQ) для B2B покупателей компонентов генератора переменного тока

1. Как решить проблему совместимости компонентов генератора?

Чтобы решить проблемы совместимости компонентов генератора, начните с изучения спецификаций и требований к существующим системам. Убедитесь, что приобретаемые детали соответствуют напряжению, размерам и типам разъемов ваших существующих генераторов. Полезным может оказаться сотрудничество с поставщиками, предлагающими подробную техническую поддержку. Кроме того, запрос образцов для тестирования поможет убедиться в том, что компоненты легко интегрируются в вашу работу. Сотрудничество с производителями, имеющими опыт работы на вашем конкретном рынке, также может уменьшить потенциальные проблемы.

2. Какой компонент генератора лучше всего подходит для работы при высоких температурах?

Для работы в условиях высоких температур следует выбирать компоненты генератора, изготовленные из материалов, устойчивых к высоким температурам, например алюминиевые корпуса с улучшенными системами охлаждения. Такие компоненты, как высокопроизводительные регуляторы напряжения и диодные выпрямители, выдерживающие повышенные тепловые нагрузки, очень важны. Кроме того, убедитесь, что подшипники и щетки, используемые в генераторе, рассчитаны на повышенные температуры для повышения долговечности. Проконсультируйтесь с производителями, имеющими опыт работы в вашей конкретной области применения, чтобы определить наиболее подходящие продукты.

3. Как проверить качество компонентов генератора от поставщиков?

Чтобы убедиться в качестве компонентов генератора, запросите у потенциальных поставщиков сертификаты, такие как ISO 9001 или соответствующие отраслевые стандарты. Проведение аудита или посещение объектов может дать представление о производственных процессах. Кроме того, попросите образцы, чтобы оценить компоненты воочию, и рассмотрите возможность проведения испытаний критически важных деталей третьей стороной. Отзывы клиентов и тематические исследования также могут дать ценную информацию о надежности поставщика и эффективности его продукции в аналогичных областях применения.

4. Каковы типичные минимальные объемы заказа (MOQ) для компонентов генератора?

Минимальные объемы заказа (MOQ) для компонентов генератора переменного тока могут значительно отличаться в зависимости от поставщика и конкретных компонентов. Как правило, MOQ может составлять от 100 до 1 000 единиц, особенно для стандартизированных деталей. Нестандартные компоненты могут иметь более высокие MOQ из-за расходов, связанных с организацией производства. Рекомендуется обсудить с поставщиками ваши конкретные потребности, поскольку некоторые из них могут предложить гибкие условия для первоначальных заказов или оптовых закупок в соответствии с вашей бизнес-стратегией.

Иллюстративное изображение, относящееся к компонентам генератора переменного тока

5. На какие условия оплаты я должен рассчитывать при поставке компонентов генератора на международный рынок?

При поставках компонентов генератора переменного тока на международном рынке условия оплаты могут сильно различаться в зависимости от поставщика и региона. Общие условия включают авансовые платежи, частичные платежи при подтверждении заказа и окончательные платежи перед отгрузкой. Для крупных заказов часто используются аккредитивы (LC), обеспечивающие безопасность для обеих сторон. Обсудите условия, которые соответствуют вашим потребностям в движении денежных средств, и убедитесь, что поставщик не против такого соглашения. Установление хороших отношений также может способствовать более выгодным условиям со временем.

6. Как решить проблему логистики при импорте компонентов генератора?

Эффективное управление логистикой при импорте компонентов генератора переменного тока включает в себя выбор надежных экспедиторов, знакомых с правилами международных перевозок. Убедитесь, что вся документация, такая как коммерческие счета-фактуры и коносаменты, точна и полна, чтобы избежать таможенных задержек. Рассмотрите возможность использования международных коммерческих терминов (Incoterms), чтобы уточнить ответственность за доставку, страхование и пошлины. Кроме того, предусмотрите возможные задержки, включив в цепочку поставок буферное время для поддержания непрерывности работы.

7. Можно ли изготовить компоненты генератора переменного тока в соответствии с конкретными требованиями?

Да, многие производители предлагают варианты настройки компонентов генератора для удовлетворения конкретных эксплуатационных требований. Заказ может включать изменение размеров, материалов или электрических характеристик. Обращаясь к поставщикам, четко сформулируйте свои требования и любые соответствующие отраслевые стандарты. Будьте готовы к тому, что заказ может потребовать дополнительного времени на разработку и производство. Тесное сотрудничество с поставщиком на протяжении всего процесса может гарантировать, что конечный продукт будет соответствовать вашим ожиданиям.

Иллюстративное изображение, относящееся к компонентам генератора переменного тока

8. Какие ключевые факторы следует учитывать при выборе поставщиков компонентов генератора переменного тока?

При проверке поставщиков компонентов генератора учитывайте такие факторы, как опыт работы в отрасли, производственные возможности и качество продукции. Проверьте наличие сертификатов, таких как стандарты ISO, и поинтересуйтесь процессами контроля качества. Изучите структуру обслуживания клиентов и поддержки, поскольку надежная связь имеет решающее значение для успешной сделки. Наконец, оцените сроки поставки и логистические возможности компании, чтобы убедиться, что она сможет эффективно удовлетворить ваши потребности в цепочке поставок. Предварительные переговоры также могут дать представление об их отзывчивости и стремлении удовлетворить потребности клиентов.

Список 5 лучших производителей и поставщиков компонентов генератора

1. HowStuffWorks – Генераторы

Домен: auto.howstuffworks.com

Зарегистрирован: 1998 (27 лет)

Введение: Генераторы небольшие и легкие, размером примерно с кокос, с алюминиевым внешним корпусом для отвода тепла и немагнитности. Ключевые компоненты включают:

– Приводной шкив, прикрепленный к валу ротора, преобразующий механическую энергию в электрическую.

– Клеммы: клемма S (измеряет напряжение аккумулятора), клемма IG (выключатель зажигания для регулятора напряжения), клемма L (замыкает c…

2. АвтоЭлектро - Компоненты генератора

Домен: autoelectro.co.uk

Зарегистрирован: 1999 (26 лет)

Введение: Компоненты генератора переменного тока и их функции: 1. Регулятор: Контролирует распределение энергии от генератора к аккумулятору. 2. Выпрямитель: Преобразует переменный ток в постоянный во время зарядки. 3. Ротор: Вращающаяся масса, которая действует как вращающийся электромагнит. 4. Контактные кольца: Обеспечивают постоянный ток и питание ротора. 5. Торцевой подшипник контактного кольца: Поддерживает вращение вала ротора. 6. Статор: Катушки проволоки, вырабатывающие электрический...

3. Bermantec - Компоненты генератора

Домен: bermantec.com

Зарегистрирован: 2018 (7 лет)

Введение: Части генератора включают в себя: 1. Ротор - вращающееся магнитное поле, которое вращается, создавая электромагнитный поток. 2. Статор - статическая часть, состоящая из внешней рамы, сердечника статора и обмотки статора, которая вырабатывает переменный ток. 3. Выпрямитель - преобразует переменный ток в постоянный с помощью диодов, которые могут быть как положительной, так и отрицательной полярности. 4. Регулятор напряжения - поддерживает напряжение между 13,5 и 3...

4. Facebook - Компоненты генератора

5. Electude - Альтернатор

Домен: electude.com

Зарегистрирован: 2005 (20 лет)

Введение: Генератор переменного тока — важнейший автомобильный компонент, который преобразует механическую энергию в электрическую, генерируя энергию для электрических потребителей и аккумулятора автомобиля. Ключевые компоненты включают:

– Шкив: передает механическую энергию от двигателя.

– Ротор: создает магнитное поле для генерации переменного тока.

– Статор: статическая часть, в которой генерируется напряжение.

– Выпрямитель: …

Выводы и перспективы стратегического сорсинга для компонентов генератора переменного тока

Почему стратегический сорсинг необходим для компонентов генератора?

В условиях современной конкуренции стратегический поиск компонентов генератора переменного тока является жизненно важным для международных покупателей B2B. Ориентируясь на качественных поставщиков и надежные цепочки поставок, организации могут обеспечить надежность и производительность своих автомобильных приложений. Ключевые компоненты, такие как роторы, статоры, выпрямители и регуляторы напряжения, должны поставляться от надежных производителей, чтобы гарантировать долговечность и эффективность генераторов.

Кроме того, понимание тонкостей производства компонентов генератора позволяет покупателям согласовывать лучшие условия и оптимизировать свои стратегии закупок. Укрепляя прочные отношения с поставщиками в различных регионах, таких как Африка, Южная Америка, Ближний Восток и Европа, компании могут снизить риски, связанные с нарушениями в цепочке поставок, и обеспечить стабильный поток качественных компонентов.

На чем следует сосредоточиться покупателям B2B в будущем?

Заглядывая в будущее, мы видим, что спрос на инновационные и эффективные компоненты генераторов будет продолжать расти. Покупателям B2B рекомендуется опережать рыночные тенденции, инвестируя в передовые технологии и устойчивые методы поиска поставщиков. Такой проактивный подход не только повышает эффективность работы, но и соответствует мировым стандартам экологической ответственности.

В заключение следует отметить, что стратегический поиск компонентов генератора - это не просто задача закупок, а важнейший компонент бизнес-стратегии. Уделяя первостепенное внимание качеству, создавая прочные сети поставщиков и внедряя инновации, компании могут обеспечить себе успех на быстро развивающемся рынке. Обращайтесь к надежным партнерам уже сегодня, чтобы обеспечить себе конкурентное преимущество в цепочке поставок автомобильной техники.

Иллюстративное изображение, относящееся к компонентам генератора переменного тока

Важное предупреждение и условия использования

⚠️ Важное предупреждение

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой консультацией или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Рыночные условия, данные о компаниях и технические стандарты могут изменяться.

Покупатели B2B должны проводить собственную независимую и тщательную проверку прежде чем принимать какие-либо решения о покупке. Это включает в себя прямой контакт с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.