Introduction: Navigating the Global Market for pure energy alternator reviews

Navigating the global market for pure energy alternators can be a daunting task for B2B buyers, especially when sourcing reliable and high-quality products. With a multitude of suppliers and varying specifications, ensuring that you choose the right alternator for your business needs is crucial. This guide offers a comprehensive review of pure energy alternators, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

By delving into detailed reviews and analyses, this resource empowers international B2B buyers from regions like Africa, South America, the Middle East, and Europe—countries including Saudi Arabia and Brazil—to make informed purchasing decisions. Understanding the nuances of different alternator models, including their performance ratings and compatibility with various applications, will help you avoid common pitfalls that can lead to costly mistakes.

Furthermore, the guide emphasizes best practices for supplier selection, enabling you to identify trustworthy partners who can deliver quality products consistently. As the global energy market evolves, being well-informed about the latest trends and innovations in pure energy alternators will position your business for success. Equip yourself with the knowledge and insights necessary to navigate this complex landscape confidently, ensuring that your energy solutions are both efficient and cost-effective.

Table Of Contents

- Top 4 Pure Energy Alternator Reviews Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pure energy alternator reviews

- Understanding pure energy alternator reviews Types and Variations

- Key Industrial Applications of pure energy alternator reviews

- 3 Common User Pain Points for ‘pure energy alternator reviews’ & Their Solutions

- Strategic Material Selection Guide for pure energy alternator reviews

- In-depth Look: Manufacturing Processes and Quality Assurance for pure energy alternator reviews

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pure energy alternator reviews’

- Comprehensive Cost and Pricing Analysis for pure energy alternator reviews Sourcing

- Alternatives Analysis: Comparing pure energy alternator reviews With Other Solutions

- Essential Technical Properties and Trade Terminology for pure energy alternator reviews

- Navigating Market Dynamics and Sourcing Trends in the pure energy alternator reviews Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pure energy alternator reviews

- Strategic Sourcing Conclusion and Outlook for pure energy alternator reviews

- Important Disclaimer & Terms of Use

Understanding pure energy alternator reviews Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternator | Basic design, typically 12V or 24V with internal regulators | General automotive, light commercial | Pros: Cost-effective, easy to find parts; Cons: Limited power output for heavy-duty applications. |

| High-Output Alternator | Increased amperage (above 100A), designed for high-performance | Racing, heavy machinery, commercial vehicles | Pros: Supports high power demands; Cons: Higher cost, may require modifications for installation. |

| Marine Alternator | Corrosion-resistant materials, designed for marine environments | Boat manufacturing, marine repairs | Pros: Durable against harsh conditions; Cons: Often more expensive than standard alternators. |

| Brushless Alternator | No brushes, reduced maintenance, longer lifespan | Renewable energy systems, electric vehicles | Pros: Higher efficiency, less wear; Cons: Higher initial investment, specialized applications. |

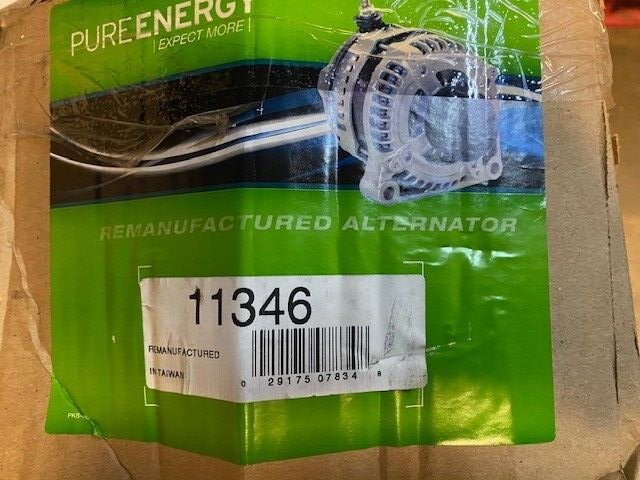

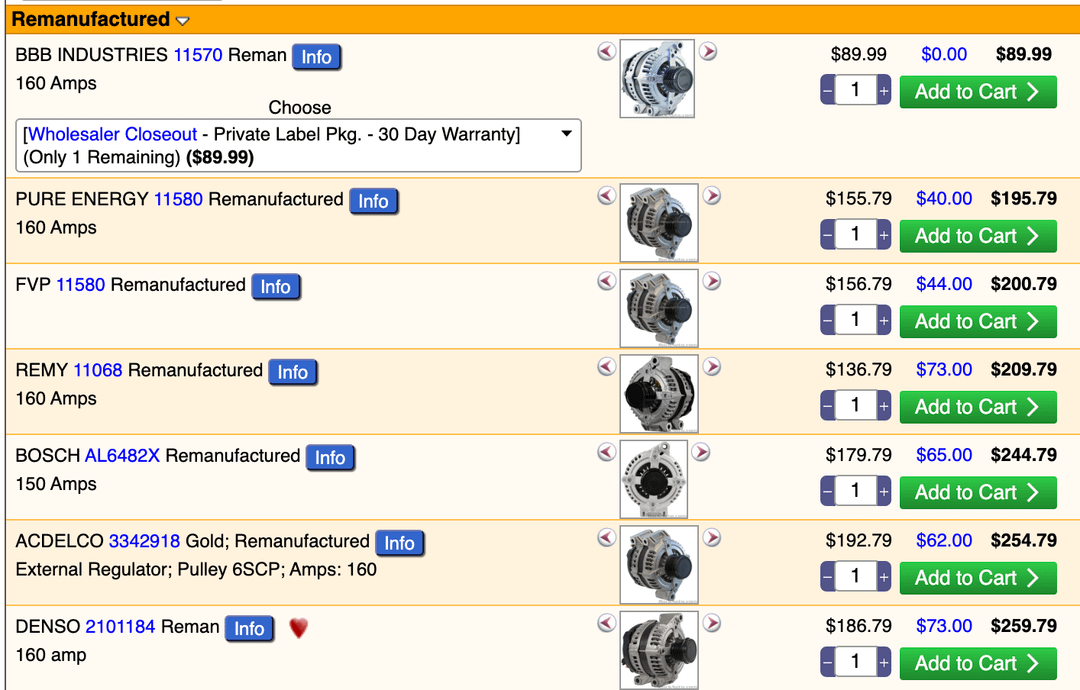

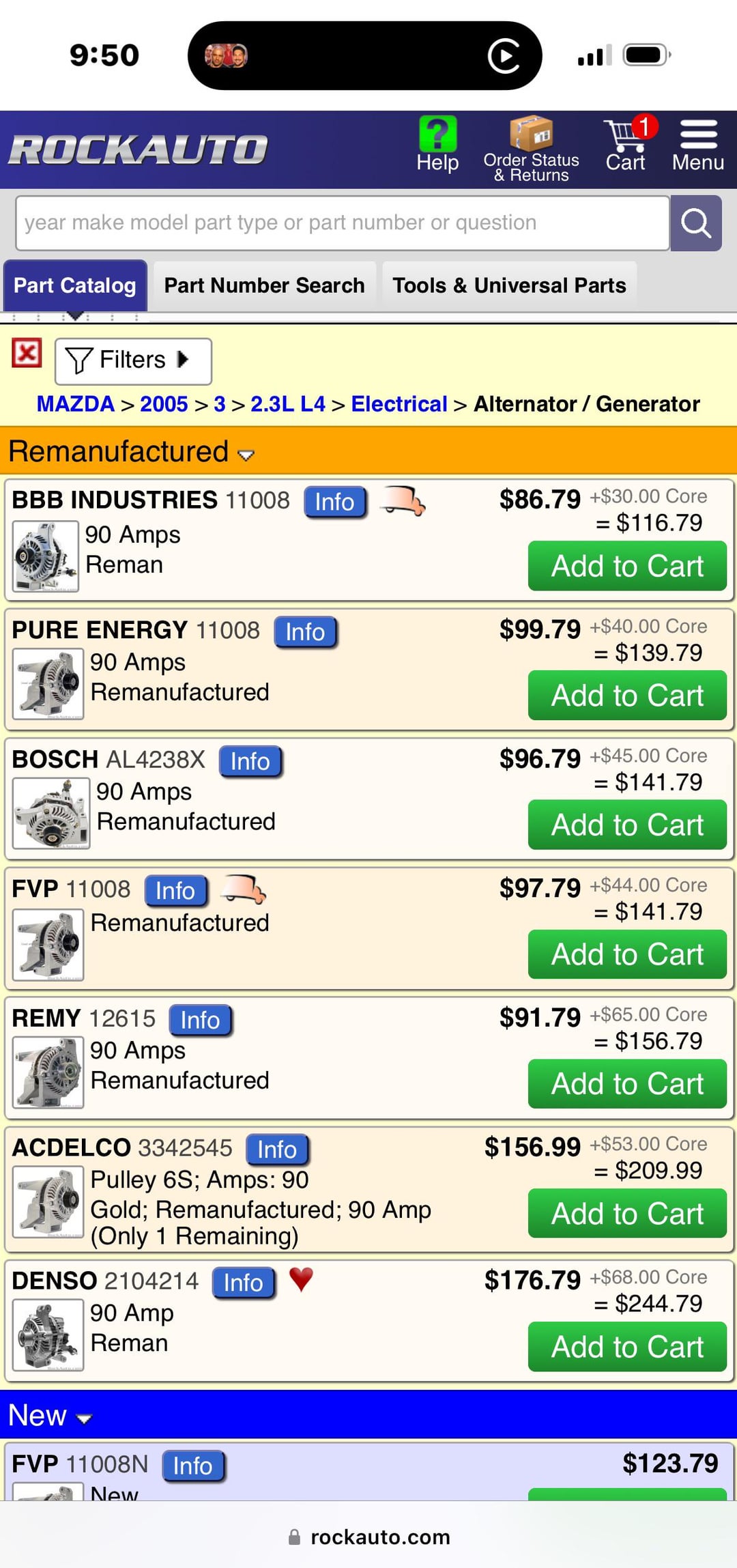

| Remanufactured Alternator | Rebuilt from used parts, often tested for quality | Cost-sensitive projects, fleet maintenance | Pros: Affordable, eco-friendly option; Cons: Potential variability in quality, limited warranty. |

What Are the Characteristics of Standard Alternators?

Standard alternators are the backbone of automotive electrical systems, typically operating at 12V or 24V with internal voltage regulators. They are suitable for general automotive use and light commercial applications, making them widely available and cost-effective. For B2B buyers, the primary consideration is ensuring compatibility with vehicle specifications, as they are easy to source and replace but may not meet the power demands of heavier vehicles.

How Do High-Output Alternators Differ from Standard Models?

High-output alternators are engineered to provide greater amperage, often exceeding 100A, making them ideal for high-performance applications like racing or heavy machinery. B2B buyers in industries requiring significant electrical power should consider these units for their ability to support advanced electrical systems. However, the increased cost and potential need for installation modifications are important factors to evaluate.

Illustrative image related to pure energy alternator reviews

Why Choose Marine Alternators for Maritime Applications?

Marine alternators are specifically designed to withstand the corrosive environments of marine applications, incorporating materials that resist saltwater and humidity. These units are crucial for boat manufacturers and marine repair services. While they offer durability and reliability, the higher price point is a consideration for buyers operating under tight budgets.

What Advantages Do Brushless Alternators Offer?

Brushless alternators eliminate the need for brushes, which reduces maintenance needs and extends lifespan. They are particularly suited for renewable energy systems and electric vehicles, where efficiency is paramount. B2B buyers should weigh the initial investment against the long-term savings in maintenance and operational efficiency, especially in specialized applications.

How Do Remanufactured Alternators Provide Value?

Remanufactured alternators are rebuilt from used parts, allowing for a more affordable option for businesses, especially those managing fleet maintenance or cost-sensitive projects. They often come with testing to ensure quality but may vary in reliability compared to new units. Buyers should consider the warranty and the supplier’s reputation to mitigate risks associated with potential quality variability.

Key Industrial Applications of pure energy alternator reviews

| Industry/Sector | Specific Application of pure energy alternator reviews | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Replacement for commercial vehicle alternators | Ensures reliable vehicle operation and reduced downtime | Compatibility with vehicle models and local regulations |

| Renewable Energy | Integration in solar and wind energy systems | Enhances energy efficiency and sustainability | Voltage requirements and environmental certifications |

| Agriculture | Power supply for farm machinery | Increases productivity and reduces operational costs | Durability in harsh conditions and maintenance support |

| Construction | Backup power for equipment and tools | Minimizes project delays and enhances safety | Load capacity and reliability under various conditions |

| Marine | Power generation for boats and ships | Ensures uninterrupted power supply in remote locations | Resistance to corrosion and water ingress protection |

How Are Pure Energy Alternator Reviews Used in the Automotive Industry?

In the automotive sector, pure energy alternators are crucial for powering commercial vehicles. Reviews help buyers identify reliable models that meet specific amperage and compatibility requirements. For international buyers, particularly in regions like Africa and South America, understanding local vehicle specifications and sourcing options is vital. Issues such as faulty alternators can lead to significant downtime, so selecting a well-reviewed product can ensure operational efficiency and minimize repair costs.

What Role Do Pure Energy Alternators Play in Renewable Energy Systems?

Pure energy alternators are increasingly used in renewable energy systems, such as solar and wind power installations. Reviews provide insights into the most efficient models that can convert energy effectively, thereby enhancing the overall system performance. Buyers must consider voltage requirements, environmental certifications, and integration capabilities with existing systems. This is especially important in regions like the Middle East, where renewable energy is a growing focus, and reliability is paramount.

Illustrative image related to pure energy alternator reviews

How Are Pure Energy Alternators Beneficial in Agriculture?

In agriculture, pure energy alternators supply power to various farm machinery, ensuring that operations run smoothly. Reviews assist businesses in identifying alternators that can withstand the rigors of outdoor environments, thus improving productivity and reducing operational costs. Buyers in agricultural sectors, particularly in developing regions, should focus on durability, ease of maintenance, and support from local suppliers to ensure long-term reliability.

Why Are Pure Energy Alternators Important for Construction?

Construction sites often require backup power for tools and equipment, making pure energy alternators a critical component. Reviews help project managers select alternators that provide reliable power, minimizing delays and enhancing safety on site. Key considerations for buyers include load capacity and reliability under varying environmental conditions, which are especially relevant in diverse climates across Europe and South America.

How Do Marine Applications Benefit from Pure Energy Alternators?

In marine applications, pure energy alternators are essential for generating power on boats and ships, particularly in remote locations where access to shore power is limited. Reviews guide buyers in selecting models that offer resistance to corrosion and water ingress, ensuring longevity and reliability. For international marine operations, understanding local maritime regulations and sourcing quality components is crucial for maintaining operational efficiency and safety.

3 Common User Pain Points for ‘pure energy alternator reviews’ & Their Solutions

Scenario 1: Confusion Over Product Specifications

The Problem: B2B buyers often face challenges when the specifications of pure energy alternators received do not match what was ordered. For instance, a buyer might order a specific alternator with a defined amperage and internal regulator position, only to receive a product that looks different or does not function as expected. This can lead to operational delays, as the buyer may need to return the product and reorder, causing significant downtime and potential loss of revenue.

The Solution: To mitigate this issue, buyers should ensure they thoroughly cross-reference specifications before placing an order. It is advisable to use detailed comparison charts or databases that include images and technical specifications. Additionally, when sourcing from suppliers, establishing direct communication to clarify any uncertainties about product specifications can prevent misorders. Buyers should also consider investing in a robust vendor management system that tracks the history of orders and specifications to streamline the purchasing process. By keeping meticulous records, buyers can expedite the resolution of any discrepancies.

Scenario 2: Reliability of Product Performance

The Problem: Another common pain point is the uncertainty regarding the reliability and performance of pure energy alternators. After reading mixed reviews, buyers may struggle to determine which products will truly meet their operational needs. A product that fails to perform as expected can result in increased maintenance costs, operational inefficiencies, and even damage to other equipment.

The Solution: To address concerns about product performance, buyers should look for suppliers that provide comprehensive performance testing data alongside customer reviews. Engaging with other businesses in the same industry can yield valuable insights about specific models and their long-term reliability. Additionally, requesting samples or trial periods for new alternators can allow buyers to assess performance firsthand before committing to larger orders. Lastly, maintaining a feedback loop with technical support teams can help buyers troubleshoot issues quickly and improve the overall reliability of their operations.

Scenario 3: Difficulty in Finding Local Support and Service

The Problem: B2B buyers may find it challenging to locate local service providers or support for pure energy alternators, especially in regions where certain products are not widely available. This can lead to extended downtimes when repairs are needed, as buyers might have to wait for parts to be shipped or for technicians to become available.

The Solution: To overcome this challenge, buyers should prioritize sourcing alternators from manufacturers that have established networks of local distributors or service centers. Conducting thorough market research to identify companies with a presence in targeted regions can save time and reduce dependency on long shipping times for repairs. Additionally, forming partnerships with local repair shops or service providers that specialize in alternators can create a more responsive support system. Buyers may also benefit from training their own technicians on basic maintenance and repair procedures for pure energy alternators, which can significantly reduce reliance on external support and improve operational efficiency.

Strategic Material Selection Guide for pure energy alternator reviews

What Are the Key Materials Used in Pure Energy Alternators?

When selecting materials for pure energy alternators, several factors come into play, including performance, durability, and cost. Understanding the properties and applications of common materials can help international B2B buyers make informed decisions. Here, we analyze four prevalent materials used in alternator construction: aluminum, copper, steel, and plastic composites.

How Does Aluminum Perform in Pure Energy Alternators?

Aluminum is widely used in alternator housings due to its lightweight and excellent corrosion resistance. Its key properties include a temperature rating up to 150°C and a pressure tolerance suitable for automotive applications. The primary advantage of aluminum is its low weight, which contributes to improved fuel efficiency in vehicles. However, its lower tensile strength compared to steel may limit its use in high-stress applications.

For B2B buyers in regions like Africa and South America, where harsh environmental conditions may be prevalent, aluminum’s corrosion resistance is a significant benefit. Compliance with international standards such as ASTM and DIN is essential, as it ensures the material meets safety and performance criteria.

What Role Does Copper Play in Pure Energy Alternators?

Copper is crucial for electrical components within alternators, particularly in windings and connectors. Its high electrical conductivity (approximately 59% IACS) and excellent thermal conductivity make it ideal for efficient energy transfer. The primary advantage of copper is its ability to reduce energy losses, enhancing the alternator’s overall performance.

However, copper is more expensive than aluminum and can be prone to corrosion if not properly coated. For international buyers, particularly in the Middle East and Europe, understanding the local market for copper pricing and sourcing is vital. Compliance with standards such as JIS for electrical components can also affect procurement decisions.

Why Is Steel Used in Pure Energy Alternators?

Steel is often employed in the structural components of alternators, including the frame and rotor. Its high tensile strength and durability make it suitable for high-load applications. Steel can withstand extreme conditions, with temperature ratings often exceeding 200°C. The main advantage of steel is its robustness, ensuring long-term reliability.

On the downside, steel is heavier than aluminum and can be susceptible to rust if not adequately treated. For buyers in regions with high humidity, such as parts of Brazil, selecting steel with appropriate coatings or treatments is essential to prevent corrosion. Compliance with international standards ensures that the steel used meets the necessary mechanical properties.

How Do Plastic Composites Benefit Pure Energy Alternators?

Plastic composites are increasingly used in alternators for non-structural components, such as housings and insulators. These materials offer excellent electrical insulation properties and are lightweight, which can contribute to overall efficiency. The key advantage of plastic composites is their resistance to corrosion and chemical exposure.

However, they may have lower thermal and mechanical performance compared to metals, which can limit their use in high-stress environments. For B2B buyers, particularly in Europe, understanding the specific grades of plastic composites that meet industry standards is crucial for ensuring compatibility with other materials.

Summary Table of Material Selection for Pure Energy Alternators

| Material | Typical Use Case for pure energy alternator reviews | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Copper | Electrical windings and connectors | High electrical and thermal conductivity | Higher cost and corrosion potential | High |

| Steel | Frame and rotor components | High strength and durability | Heavier and rust-prone | Medium |

| Plastic Composites | Non-structural components like housings and insulators | Corrosion-resistant and lightweight | Lower thermal/mechanical performance | Low |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed choices that align with their operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for pure energy alternator reviews

What Are the Key Stages in the Manufacturing Process of Pure Energy Alternators?

The manufacturing process of pure energy alternators involves several critical stages that ensure the final product meets both performance and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing alternators.

Material Preparation

The first stage involves selecting high-quality materials essential for the durability and efficiency of the alternators. Manufacturers typically use copper for windings due to its excellent electrical conductivity, while high-grade aluminum or steel is chosen for the casing to ensure strength and corrosion resistance. Material inspection is crucial at this stage, where suppliers must provide certification for the raw materials used, ensuring compliance with industry standards.

Forming

Once the materials are prepared, the next step is forming. This involves cutting, stamping, or machining the metal components to specific dimensions. Techniques such as die-casting may be employed for aluminum components, while CNC machining is often used for precision parts. This stage is critical for ensuring that all components fit together seamlessly, reducing the likelihood of failures during operation.

Assembly

After forming, the assembly stage begins. This involves integrating various components, such as rotors, stators, and voltage regulators. Skilled technicians often conduct this process, using specialized tools to secure each part effectively. Assembly lines may employ automation to enhance efficiency, but human oversight remains vital to ensure quality. Each alternator should undergo a pre-assembly inspection to verify that all parts conform to specifications.

Finishing

The final manufacturing stage is finishing, which includes processes like painting, coating, and packaging. Finishing not only enhances the aesthetic appeal of the alternators but also provides protective layers against environmental factors. Manufacturers may use powder coating or anodizing to prevent corrosion, especially for products intended for markets with harsh climates, such as parts of Africa and the Middle East.

How Is Quality Assurance Integrated into the Manufacturing of Pure Energy Alternators?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that every alternator meets the required performance standards before reaching the market. B2B buyers should be aware of the various QA measures in place.

What International Standards Are Relevant for Quality Control?

Manufacturers of pure energy alternators often adhere to international quality standards like ISO 9001, which outlines criteria for a quality management system. This certification ensures that a company consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking in Europe or API standards for products intended for the oil and gas sector can also be significant indicators of quality.

What Are the Key Quality Control Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process, commonly referred to as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

IQC: This involves inspecting raw materials and components upon arrival at the manufacturing facility. Ensuring that materials meet specified standards is crucial for preventing defects in the final product.

-

IPQC: During the assembly and manufacturing stages, ongoing inspections help identify any issues early on. This stage may include measurements and tests to confirm that components are being assembled correctly and function as intended.

-

FQC: The final inspection occurs before packaging and shipping. This step ensures that the alternators function correctly and meet all specifications, including electrical output and physical integrity.

What Common Testing Methods Are Used?

Various testing methods are employed to verify the performance and reliability of pure energy alternators. Common tests include:

-

Electrical Testing: This checks the output voltage and current under different load conditions to ensure that the alternator meets its rated specifications.

-

Mechanical Testing: This evaluates the physical integrity of the alternator, including vibration tests and thermal cycling tests to assess durability under stress.

-

Environmental Testing: This ensures that the alternator can withstand various environmental conditions, such as extreme temperatures, humidity, and dust exposure.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial. Here are some actionable steps:

Conduct Supplier Audits

Regular supplier audits can provide insights into manufacturing processes and quality control measures. Buyers should look for suppliers who are open to audits, allowing for a thorough examination of their facilities, processes, and quality management systems.

Request Quality Assurance Reports

Buyers should request detailed quality assurance reports from suppliers. These reports should include information on testing results, certifications, and any corrective actions taken in response to previous quality issues. This documentation can provide reassurance regarding the supplier’s commitment to quality.

Engage Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These services can conduct inspections at various stages of the manufacturing process, ensuring compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the specific quality control nuances for different regions is essential for B2B buyers. For instance, buyers in Europe may prioritize CE marking, while those in the Middle East may look for compliance with local regulations and standards. Buyers should also be aware of logistical considerations, such as shipping and handling, which can impact product integrity during transit.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for pure energy alternators empowers B2B buyers to make informed decisions. By focusing on material quality, rigorous manufacturing techniques, and robust quality control practices, buyers can secure reliable alternators that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pure energy alternator reviews’

Introduction

This practical sourcing guide provides B2B buyers with a systematic approach to procuring ‘pure energy alternators.’ Whether you are operating in Africa, South America, the Middle East, or Europe, understanding the key steps in sourcing and evaluating alternators will ensure you make informed purchasing decisions that meet your operational requirements.

Illustrative image related to pure energy alternator reviews

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before initiating the sourcing process. Identify the specific requirements for the alternators, such as amperage ratings, internal or external regulators, and compatibility with existing systems. This helps to streamline the selection process and avoid mismatches that could lead to operational inefficiencies.

Step 2: Research Reputable Suppliers

Take the time to identify and research potential suppliers of pure energy alternators. Look for companies that have a proven track record in your region and offer reliable products. Investigate their reputation through customer reviews, industry forums, and case studies to ensure they have the necessary experience and credibility.

- Key indicators of a reputable supplier:

- Positive customer testimonials and case studies.

- Established presence in the local market.

Step 3: Evaluate Supplier Certifications

Before making any purchases, verify that your chosen suppliers hold the necessary certifications. Look for certifications that indicate compliance with international quality standards, such as ISO 9001 or specific automotive industry standards. This ensures that you are sourcing products that meet safety and reliability benchmarks.

- What to check:

- Certificates of compliance with relevant industry standards.

- Documentation supporting quality assurance processes.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the alternators for testing. This step is crucial as it allows you to evaluate the quality and performance of the products firsthand. Ensure that the samples match the specifications you defined earlier, and conduct thorough testing to assess functionality and durability.

Step 5: Assess Warranty and After-Sales Support

When sourcing alternators, inquire about warranty terms and after-sales support provided by the supplier. A robust warranty policy is a strong indicator of product quality and supplier confidence. Additionally, ensure that the supplier offers adequate technical support to address any issues that may arise post-purchase.

- Considerations:

- Length and coverage of warranty.

- Availability of customer support and technical assistance.

Step 6: Negotiate Pricing and Terms

Engage in negotiations with your chosen suppliers to secure favorable pricing and payment terms. This is particularly important for bulk purchases, where even small discounts can lead to significant cost savings. Be transparent about your budget and seek a win-win scenario that fosters a long-term business relationship.

Step 7: Finalize the Purchase Agreement

After agreeing on the terms, finalize the purchase agreement with clear documentation. Ensure that the contract outlines all specifications, pricing, delivery timelines, and payment terms. This protects both parties and establishes accountability, reducing the risk of misunderstandings in the future.

Following these steps will enable B2B buyers to make informed decisions when sourcing pure energy alternators, ensuring that the products meet their operational needs and contribute to business success.

Comprehensive Cost and Pricing Analysis for pure energy alternator reviews Sourcing

What Are the Key Cost Components in Sourcing Pure Energy Alternators?

When sourcing pure energy alternators, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of raw materials, such as copper for windings, aluminum for housings, and other components, significantly impacts pricing. Higher-grade materials often lead to improved performance and longevity, which can justify a higher initial cost.

-

Labor: Labor costs can vary widely based on geographical location and the skill level of workers. In regions with higher labor costs, such as parts of Europe, sourcing may come with a premium. However, countries with lower labor costs might provide an opportunity for savings, albeit potentially at the expense of quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Manufacturers often factor these costs into their pricing models, which can vary based on production efficiency and technology used.

-

Tooling: Initial tooling costs can be significant, especially for custom alternators. Buyers should consider whether they require specialized designs, as custom tooling can increase costs but may be necessary for specific applications.

-

Quality Control (QC): Investing in robust QC processes ensures that alternators meet necessary performance standards. However, enhanced QC measures can raise costs, so buyers should weigh the benefits of quality assurance against potential savings from less stringent processes.

-

Logistics: Shipping and handling are crucial elements, especially for international transactions. Costs can fluctuate based on distance, mode of transport, and any tariffs or duties applicable in the buyer’s country.

-

Margin: Supplier margins can vary based on market conditions and competition. Understanding how much margin is built into the price can provide insight into whether there is room for negotiation.

How Do Price Influencers Affect Pure Energy Alternator Sourcing?

Several factors can influence the pricing of pure energy alternators:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their purchasing strategy to maximize cost efficiency.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected price hikes and ensure compatibility with existing systems.

-

Materials and Certifications: Higher-quality materials and certifications (like ISO or CE) can increase prices. However, they often correlate with improved reliability and performance, which may reduce long-term costs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their experience and trustworthiness, while emerging suppliers might offer competitive rates to gain market share.

-

Incoterms: Understanding the terms of trade, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential. These terms dictate who bears the cost and risk at various stages of shipping, affecting the total cost of ownership.

What Are Effective Buyer Tips for Sourcing Pure Energy Alternators?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiate Prices: Always engage in price negotiations. Suppliers often have flexibility in their pricing, especially for bulk orders or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): While the upfront cost is important, consider long-term factors such as maintenance, durability, and efficiency. A lower-cost alternator may result in higher operational costs over time.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, sourcing from a local supplier in Brazil may be more cost-effective due to lower shipping costs compared to importing from Europe.

-

Request Multiple Quotes: Solicit quotes from multiple suppliers to compare prices and terms. This not only provides leverage in negotiations but also helps identify the best value for your needs.

-

Stay Informed on Market Trends: Keeping abreast of market conditions can provide insights into pricing fluctuations and help anticipate potential increases or decreases in costs.

By understanding these cost components and price influencers, B2B buyers can make informed decisions when sourcing pure energy alternators, ensuring they achieve the best value for their investment.

Illustrative image related to pure energy alternator reviews

Alternatives Analysis: Comparing pure energy alternator reviews With Other Solutions

Understanding Alternatives in the Pure Energy Alternator Market

When considering energy solutions for automotive needs, it is essential to explore various alternatives to pure energy alternators. These alternatives may offer different performance characteristics, costs, and maintenance requirements, influencing the decision-making process for B2B buyers. This analysis will compare pure energy alternator reviews against two other viable options: rebuilt alternators and high-efficiency alternators.

Comparison Table

| Comparison Aspect | Pure Energy Alternator Reviews | Rebuilt Alternators | High-Efficiency Alternators |

|---|---|---|---|

| Performance | Reliable for standard applications | Varies based on quality of rebuild | Higher output with improved efficiency |

| Cost | Moderate to high price range | Generally lower, but quality varies | Higher upfront cost, potential for long-term savings |

| Ease of Implementation | Straightforward installation | May require skilled labor for installation | Easy installation but may require specific mounts |

| Maintenance | Low maintenance requirements | Depends on rebuild quality | Minimal maintenance, designed for longevity |

| Best Use Case | Standard vehicles and applications | Vintage or specific model restorations | Performance-focused applications needing higher output |

Evaluating Rebuilt Alternators as an Alternative

Rebuilt alternators can be a cost-effective alternative for businesses looking to replace faulty units. They are often less expensive than new units, making them an attractive option for budget-conscious buyers. However, the quality of rebuilt alternators can vary significantly based on the supplier and the components used. This inconsistency can lead to performance issues or shorter lifespans compared to new products. Rebuilt alternators are best suited for vintage vehicles or specific models that may not have readily available new replacements.

Analyzing High-Efficiency Alternators

High-efficiency alternators are designed to provide greater output while consuming less energy. These units often come at a higher initial cost, but they offer long-term savings through improved performance and reduced fuel consumption. Businesses that operate vehicles requiring consistent power for advanced electrical systems, such as commercial fleets or specialized machinery, may find high-efficiency alternators to be the most beneficial. Their installation is typically straightforward, but it may necessitate specific mounting configurations, which could complicate the process for some users.

Illustrative image related to pure energy alternator reviews

Conclusion: Making the Right Choice for Your Business Needs

In conclusion, choosing the right energy solution depends on your specific requirements and constraints. Pure energy alternators are ideal for standard applications where reliability is paramount. In contrast, rebuilt alternators may serve as an economical choice for niche vehicles, while high-efficiency alternatives cater to performance-driven applications. B2B buyers should evaluate their operational needs, budget constraints, and the specific applications of their vehicles to determine the best fit. Careful consideration of these factors will lead to a more informed decision, optimizing both performance and cost-effectiveness in their operations.

Essential Technical Properties and Trade Terminology for pure energy alternator reviews

What Are the Key Technical Properties of Pure Energy Alternators?

When evaluating pure energy alternators, understanding their technical specifications is crucial for B2B buyers to make informed purchasing decisions. Here are some essential properties to consider:

-

Amp Rating

The amp rating of an alternator indicates its maximum electrical output. Common ratings range from 40 amps to over 150 amps. This specification is vital for determining whether the alternator can meet the power demands of the vehicle or equipment it will be used in. A higher amp rating is often required for vehicles with additional electrical components or heavy-duty applications. -

Regulator Type

Alternators can be equipped with either internal or external voltage regulators. The internal regulator is more common in modern designs and simplifies installation by reducing wiring complexity. Understanding the type of regulator is important for maintenance and compatibility, especially when considering replacements or upgrades. -

Material Composition

The materials used in the construction of the alternator, such as aluminum or high-grade steel, affect its durability and performance. A robust material composition can lead to longer service life and better resistance to environmental factors. For B2B buyers, choosing an alternator with quality materials can reduce long-term costs associated with repairs and replacements. -

Size and Mounting Configuration

The physical dimensions and mounting configuration are critical for compatibility with specific vehicle models. Buyers should ensure that the alternator fits within the designated space and aligns with existing mounting points. Incorrect sizing can lead to installation challenges and operational inefficiencies. -

Operating Temperature Range

Alternators are designed to operate within specific temperature ranges. Understanding this specification is essential, especially for applications in extreme climates. An alternator that can withstand higher temperatures will perform reliably and reduce the risk of overheating. -

Warranty and Service Life

A manufacturer’s warranty can provide insights into the expected service life and reliability of the alternator. Longer warranties often indicate confidence in the product’s durability. B2B buyers should assess warranty terms to gauge potential long-term value.

What Are Common Trade Terms Related to Pure Energy Alternators?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some common terms relevant to pure energy alternators:

-

OEM (Original Equipment Manufacturer)

OEM parts are made by the same manufacturer that produced the original components for a vehicle. In the context of alternators, OEM products are often preferred for their guaranteed compatibility and reliability. B2B buyers should look for OEM certifications to ensure product authenticity. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is crucial for procurement planning, especially for businesses looking to maintain inventory levels without overstocking. -

RFQ (Request for Quotation)

An RFQ is a document that companies use to solicit price quotes from suppliers for specific products or services. B2B buyers should prepare a detailed RFQ for alternators to ensure they receive accurate pricing and terms, which helps in budgeting and decision-making. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, such as shipping and delivery responsibilities. Knowing the relevant Incoterms can help B2B buyers understand their obligations and manage logistics effectively. -

Aftermarket

The aftermarket refers to all parts and accessories that are not sourced from the original manufacturer. For alternators, aftermarket options can provide cost-effective alternatives, but buyers should assess quality and compatibility before making a purchase. -

Lead Time

Lead time is the period from placing an order to delivery. Understanding lead time is essential for planning purposes, particularly in industries with tight production schedules. Buyers should inquire about lead times when negotiating with suppliers to avoid disruptions.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing pure energy alternators more effectively, ensuring they select the best products for their needs.

Navigating Market Dynamics and Sourcing Trends in the pure energy alternator reviews Sector

What Are the Key Drivers Shaping the Pure Energy Alternator Market?

The pure energy alternator market is experiencing significant growth driven by several global factors. The increasing demand for renewable energy sources, particularly in regions like Africa and South America, is prompting investments in energy-efficient technologies. This shift is underscored by a growing emphasis on sustainability and reducing carbon footprints, which aligns with international regulations aimed at combating climate change. Additionally, the rise of electric vehicles and hybrid systems is catalyzing the development of advanced alternator technologies, resulting in enhanced performance and energy efficiency.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are influencing sourcing trends. These technologies enable better inventory management, predictive maintenance, and optimized supply chain logistics, which are crucial for international B2B buyers. The ability to track and manage products in real-time can significantly enhance operational efficiency and reduce costs. Furthermore, buyers are increasingly looking for suppliers who can provide comprehensive product reviews and performance data, ensuring informed decision-making.

Market dynamics are also shifting due to the evolving supplier landscape. Traditional manufacturers are facing competition from new entrants offering innovative solutions, particularly in regions with burgeoning markets. Buyers are encouraged to explore local suppliers who can offer tailored solutions and faster response times, thereby enhancing their supply chain resilience.

How Can Sustainability and Ethical Sourcing Influence the B2B Purchasing Decisions for Pure Energy Alternators?

Sustainability is becoming a paramount concern for international B2B buyers, especially in regions such as the Middle East and Europe, where regulatory pressures are high. The environmental impact of sourcing and manufacturing alternators is under scrutiny, and businesses are increasingly expected to adopt ethical supply chain practices. This includes ensuring that materials used in alternators are sourced responsibly and that manufacturing processes minimize waste and pollution.

Buyers should prioritize suppliers who hold green certifications and demonstrate a commitment to sustainable practices. Certifications such as ISO 14001 for environmental management systems can serve as indicators of a supplier’s dedication to sustainability. Additionally, the use of recycled materials in the production of alternators not only reduces environmental impact but can also resonate with consumers increasingly focused on eco-friendly products.

Moreover, ethical sourcing can enhance brand reputation and customer loyalty. Companies that transparently communicate their sustainability efforts are likely to gain a competitive advantage. This trend aligns with the growing consumer demand for environmentally responsible products, further driving the need for B2B buyers to consider sustainability in their purchasing decisions.

What Is the Historical Context Behind the Pure Energy Alternator Sector?

The evolution of the pure energy alternator sector can be traced back to the early 20th century when the demand for reliable electrical systems began to grow alongside advancements in automotive technology. Initially, alternators were used primarily in vehicles, but as the importance of electrical systems expanded into various industries, so did the applications of alternators.

Over the decades, technological advancements have led to more efficient and compact designs, allowing for better performance and integration with modern energy systems. The late 20th century marked a significant shift towards renewable energy sources, spurring innovation in alternator technology to support wind and solar applications. Today, the focus is on enhancing energy efficiency and sustainability, reflecting broader societal trends towards greener energy solutions.

In summary, understanding the historical context of pure energy alternators provides valuable insights for B2B buyers navigating the current market dynamics. This knowledge can inform sourcing strategies, ensuring that businesses are aligned with both technological advancements and evolving consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of pure energy alternator reviews

-

How do I solve compatibility issues with a pure energy alternator?

When faced with compatibility issues, first verify the specifications of the alternator you intend to purchase, including amp rating and regulator type. Cross-reference these specifications with your vehicle’s requirements. If the alternator received differs from what was ordered, consult the supplier for clarification or consider returning it for a compatible model. Additionally, working with a local mechanic or specialist can help assess the situation and provide alternatives, such as rebuilding your original alternator or sourcing a reliable replacement. -

What is the best pure energy alternator for high-performance vehicles?

For high-performance vehicles, look for pure energy alternators that offer higher amperage outputs and advanced features like built-in voltage regulators. Models specifically designed for performance applications are often equipped with better cooling systems and durability enhancements. Reviews and testimonials from other B2B buyers can provide insights into reliability and efficiency. It’s advisable to source from reputable suppliers who specialize in high-performance automotive parts to ensure quality and compatibility. -

What should I consider when sourcing pure energy alternators internationally?

When sourcing internationally, consider factors such as compliance with local regulations, shipping costs, and potential tariffs. Verify the supplier’s credibility by checking their certifications and past customer reviews. Understand the lead times for shipping and the logistics involved, especially if you are ordering in bulk. It’s also beneficial to establish clear communication channels with suppliers to address any concerns regarding product specifications and after-sales support. -

What are the typical minimum order quantities (MOQs) for pure energy alternators?

Minimum order quantities (MOQs) for pure energy alternators can vary significantly based on the supplier and the specific model. Typically, MOQs range from 10 to 100 units. Discussing MOQs with potential suppliers before placing an order is crucial, especially if you’re testing a new product line. Some suppliers may offer lower MOQs for first-time buyers or for specific models, so negotiating terms could lead to more favorable purchasing conditions. -

How can I ensure the quality of pure energy alternators before purchasing?

To ensure quality, request detailed product specifications and certifications from your supplier. Conducting a factory audit or visiting the manufacturing site can provide insights into their production processes and quality control measures. Additionally, consider ordering samples for testing before committing to larger quantities. Checking for warranties and return policies can also safeguard your investment in case the products do not meet your expectations. -

What payment terms are commonly offered by suppliers of pure energy alternators?

Payment terms vary widely among suppliers, but common options include net 30, net 60, or upfront payment for first-time buyers. Some suppliers may offer discounts for early payments or flexible terms for repeat customers. It’s advisable to establish clear payment expectations in your initial discussions, considering the impact of currency fluctuations in international transactions. Using secure payment methods can also mitigate risks associated with international trade. -

What logistics considerations should I keep in mind when importing alternators?

Logistics considerations include selecting reliable shipping methods and understanding customs regulations in your country. Work with freight forwarders experienced in handling automotive parts to navigate the complexities of international shipping. Ensure that you have all necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. Planning for potential delays in transit and having contingency measures in place can also be beneficial. -

How can I customize pure energy alternators to meet specific needs?

Customizing pure energy alternators typically involves collaborating directly with manufacturers to discuss specific requirements such as voltage output, size, and design features. Suppliers may offer customization options such as branding, color, or specific technical enhancements. It’s essential to communicate your needs clearly and request prototypes or samples to ensure the final product meets your expectations. Establishing a strong partnership with your supplier can facilitate smoother customization processes and lead to better outcomes.

Top 4 Pure Energy Alternator Reviews Manufacturers & Suppliers List

1. Alternator – Buying Guide for 2000 Toyota Camry XLE

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: When buying and replacing an alternator for a 2000 Toyota Camry XLE, consider the following: 1. Brand recommendations include AC Delco and Bosch. 2. Evaluate the price difference between online purchases and local auto parts stores, factoring in shipping costs and core return policies. 3. Look for warranties that may be easier to handle with brick-and-mortar stores.

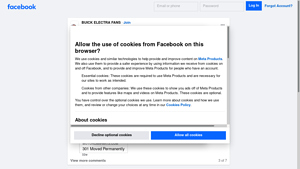

2. Pure Energy – Alternator

Domain: clublexus.com

Registered: 1998 (27 years)

Introduction: Pure Energy Alternator; Price: $126 (including shipping); Warranty: 1 year; User feedback: Mixed reviews, with some users expressing skepticism about the brand and quality, suggesting alternatives like Denso Remanufactured alternators for better reliability.

3. AcDelco – New Alternator

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: new alternator, preferably from AcDelco

4. Pure Energy – Premium Replacement Parts

Domain: motorcarparts.com

Registered: 2000 (25 years)

Introduction: Pure Energy offers premium-quality replacement parts for cars and light trucks, designed for durability and performance. Key product categories include: Starters, Alternators, Master Cylinders, Hub Assemblies and Bearings, Brake Power Boosters, Rotors, Brake Pads and Shoes, and Calipers. All parts are manufactured to high-quality standards, undergo rigorous reliability testing, and are 100% End-of…

Strategic Sourcing Conclusion and Outlook for pure energy alternator reviews

In the evolving landscape of pure energy alternators, strategic sourcing remains paramount for international B2B buyers. By focusing on reliable suppliers and conducting thorough product evaluations, businesses can mitigate risks associated with inconsistencies and ensure they receive quality products tailored to their specific needs. The experiences shared by users highlight the importance of verifying product specifications and the potential challenges posed by variations in design and functionality.

Understanding these dynamics empowers buyers to make informed decisions, ultimately enhancing operational efficiency and minimizing downtime. As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for dependable energy solutions will only intensify.

Looking ahead, international buyers should prioritize building strong relationships with reputable manufacturers and distributors, embracing digital tools for better transparency and sourcing agility. This proactive approach not only secures quality products but also positions businesses to thrive in a competitive marketplace. Engage with your suppliers, ask the right questions, and explore opportunities that align with your energy needs to ensure sustainable growth in your operations.

Illustrative image related to pure energy alternator reviews

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.