Introduction: Navigating the Global Market for motor starter types

The diverse landscape of motor starter types presents a formidable challenge for international B2B buyers seeking to optimize their operations while ensuring safety and efficiency. As companies navigate the complexities of sourcing motor starters, understanding the nuances of various types—ranging from Direct-On-Line (DOL) starters to Variable Frequency Drives (VFDs)—is essential. Each motor starter type caters to specific applications and operational requirements, making it crucial for buyers to align their choices with their unique needs.

This comprehensive guide delves into the myriad types of motor starters, their applications across different industries, and factors influencing procurement, including supplier vetting and cost considerations. With insights tailored for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Brazil and Vietnam—this resource equips decision-makers with the knowledge to make informed purchasing decisions. By highlighting the importance of selecting the right motor starter, the guide not only addresses potential challenges but also empowers businesses to enhance their operational efficiency, prolong equipment life, and safeguard against electrical failures.

Navigating the global market for motor starters doesn’t have to be daunting; with the right information, international buyers can confidently select solutions that meet their performance needs while driving growth and innovation.

Table Of Contents

- Top 2 Motor Starter Types Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for motor starter types

- Understanding motor starter types Types and Variations

- Key Industrial Applications of motor starter types

- 3 Common User Pain Points for ‘motor starter types’ & Their Solutions

- Strategic Material Selection Guide for motor starter types

- In-depth Look: Manufacturing Processes and Quality Assurance for motor starter types

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘motor starter types’

- Comprehensive Cost and Pricing Analysis for motor starter types Sourcing

- Alternatives Analysis: Comparing motor starter types With Other Solutions

- Essential Technical Properties and Trade Terminology for motor starter types

- Navigating Market Dynamics and Sourcing Trends in the motor starter types Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of motor starter types

- Strategic Sourcing Conclusion and Outlook for motor starter types

- Important Disclaimer & Terms of Use

Understanding motor starter types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct On-Line (DOL) Starter | Connects motor directly to power supply; simple operation | Small pumps, fans, and compressors | Pros: Cost-effective, easy to install. Cons: High inrush current can damage motor. |

| Star-Delta Starter | Reduces starting current by switching from star to delta configuration | Large industrial motors | Pros: Low starting current, less mechanical stress. Cons: More complex wiring and control. |

| Soft Starter | Gradually increases voltage to motor for smooth acceleration | Conveyors, crushers, and mixers | Pros: Reduces mechanical stress, extends motor life. Cons: Higher initial cost compared to DOL. |

| Variable Frequency Drive (VFD) | Controls motor speed by varying frequency of supply voltage | HVAC systems, pumps, and fans | Pros: Energy-efficient, precise speed control. Cons: Higher upfront investment and complexity. |

| Reduced Voltage Starter | Lowers voltage at startup to minimize inrush current | High-power motors in industrial settings | Pros: Protects motor from damage, reduces voltage fluctuations. Cons: Limited to specific applications. |

What Are the Characteristics of Direct On-Line (DOL) Starters?

Direct On-Line (DOL) starters are the simplest type of motor starters, connecting the motor directly to the power supply. They are typically used for small motors, often under five horsepower. DOL starters are valued for their straightforward design and ease of installation, making them a popular choice for applications like water pumps and fans. However, they generate high inrush currents, which can lead to motor damage if not properly managed. B2B buyers should consider the motor’s specifications and the operational environment when choosing this starter type.

How Do Star-Delta Starters Work and Where Are They Used?

Star-Delta starters are designed to reduce starting currents in large motors by initially connecting the motor in a star configuration and then switching to a delta configuration for normal operation. This method is particularly effective for motors that require high torque at startup, such as in industrial applications. While they are beneficial for reducing electrical stress and mechanical wear, they involve more complex wiring and control mechanisms. Buyers should evaluate the motor’s size and application to determine if the Star-Delta starter is appropriate.

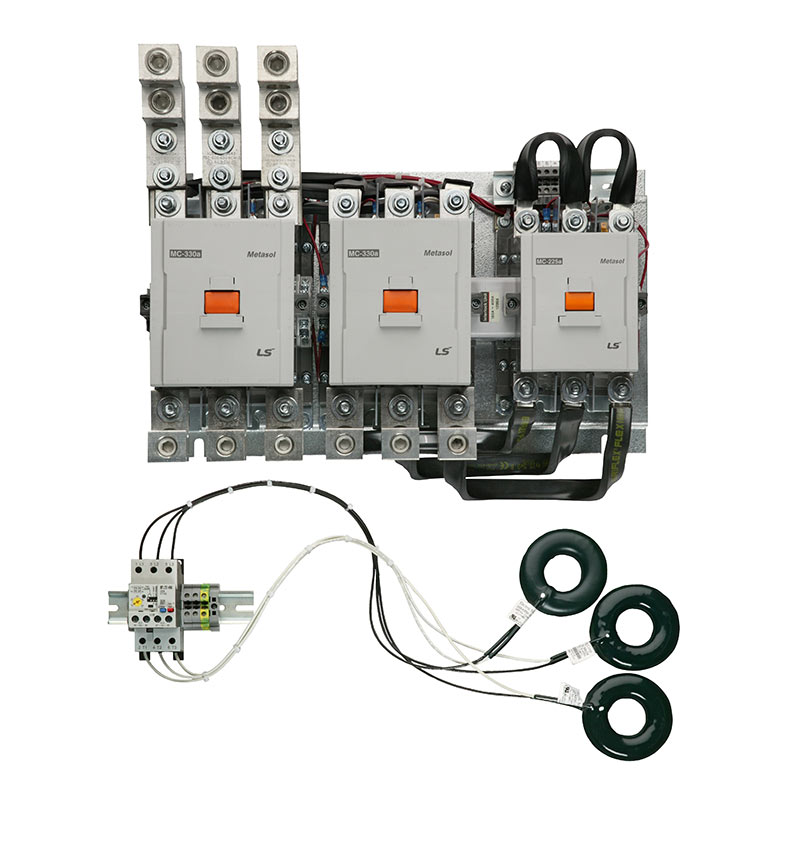

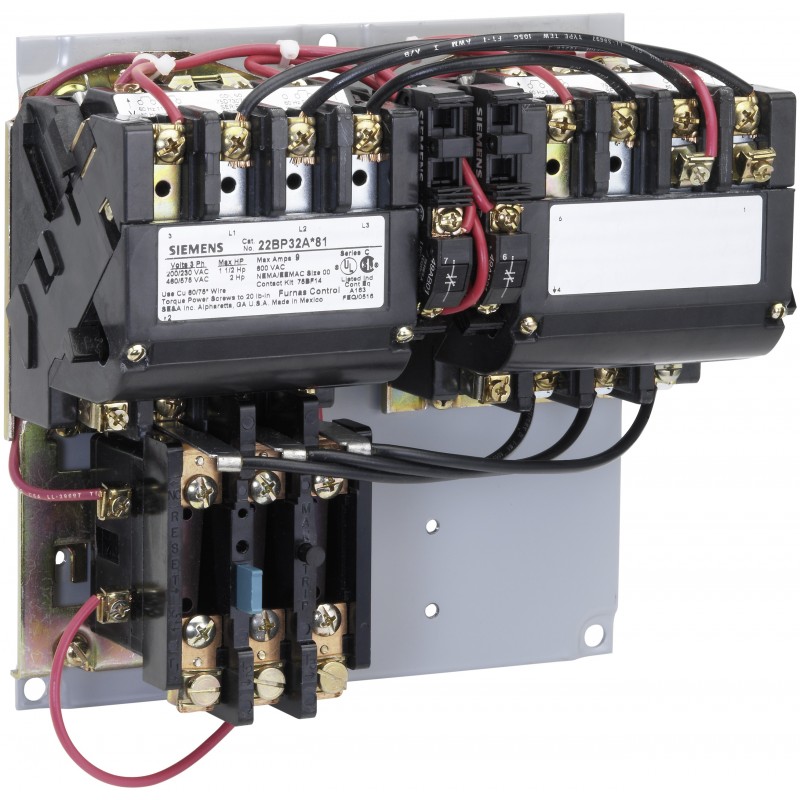

Illustrative image related to motor starter types

What Are the Benefits of Using Soft Starters?

Soft starters gradually increase the voltage supplied to the motor, facilitating a smooth start and reducing mechanical stress. This feature is particularly useful in applications where sudden starts can cause damage, such as in conveyors and crushers. While soft starters can be more expensive than DOL starters, their ability to extend motor life and reduce maintenance costs makes them a worthwhile investment for many businesses. Buyers should assess their operational needs and budget when considering this option.

Why Choose Variable Frequency Drives (VFDs)?

Variable Frequency Drives (VFDs) offer advanced control by varying the frequency of the power supply, enabling precise speed and torque management. This technology is ideal for applications requiring variable speed, such as HVAC systems and industrial pumps. Although VFDs typically have a higher initial cost and complexity, they provide significant energy savings and operational flexibility over time. Businesses should weigh the long-term benefits against the upfront costs when deciding on VFDs for their motor control solutions.

What Is the Role of Reduced Voltage Starters?

Reduced Voltage Starters are designed to lower the starting voltage supplied to the motor, minimizing inrush current and protecting the motor from damage during startup. This type of starter is commonly employed in high-power industrial motors, where voltage fluctuations can be detrimental. While they effectively safeguard motors, their use is limited to specific applications that require such protection. Buyers should consider the operational demands and compatibility with existing systems when selecting a reduced voltage starter.

Key Industrial Applications of motor starter types

| Industry/Sector | Specific Application of motor starter types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhanced efficiency and reduced downtime in production | Compatibility with existing systems and ease of integration |

| Water Treatment | Pump Control Systems | Reliable operation under varying load conditions | Durability in harsh environments and local support |

| Mining and Minerals | Heavy Equipment Operation | Protection from overload and improved safety | Robust design for extreme conditions and compliance with local regulations |

| Agriculture | Irrigation Systems | Energy savings and optimized water usage | Customization for specific crops and environmental conditions |

| HVAC | Chillers and Air Handling Units | Improved energy efficiency and reduced operational costs | Energy ratings and compliance with international standards |

How Are Motor Starter Types Used in Manufacturing Conveyor Systems?

In manufacturing, motor starters are critical for controlling conveyor systems, ensuring that motors start and stop safely and efficiently. These systems often operate continuously, making it essential to minimize downtime and enhance productivity. Full Voltage or Across-the-Line starters are commonly used due to their straightforward operation and reliability. Buyers should consider compatibility with existing equipment and the ability to handle the specific load requirements of their operations, especially in regions like Africa and South America where power supply stability can vary.

What Role Do Motor Starters Play in Water Treatment Pump Control Systems?

Motor starters in water treatment facilities manage the operation of pumps, which are crucial for maintaining water quality and supply. Reduced Voltage Starters are often employed to limit inrush current, protecting pumps from damage while ensuring reliable operation under fluctuating load conditions. This is particularly important in regions facing water scarcity, where efficient pump operation is vital. Buyers should focus on sourcing durable starters that can withstand harsh environmental conditions and ensure local support for maintenance and repairs.

How Are Motor Starters Essential for Heavy Equipment Operation in Mining?

In the mining industry, motor starters are pivotal for the operation of heavy equipment, such as drills and haul trucks. Starters like the Soft Starter and Variable Frequency Drive (VFD) provide essential protection against overloads and allow for better control of motor speeds, which is crucial in the dynamic mining environment. For international buyers, especially in the Middle East, sourcing robust and compliant starters that can endure extreme conditions is essential to ensure operational safety and efficiency.

What Benefits Do Motor Starters Provide in Agricultural Irrigation Systems?

Motor starters are increasingly used in agricultural irrigation systems to control the operation of pumps efficiently. By utilizing starters like the Star-Delta Starter, farmers can reduce starting torque and current, leading to significant energy savings and optimized water usage. In regions like Brazil and Vietnam, where agriculture is a primary economic driver, sourcing customizable motor starters that accommodate specific crop needs and local environmental conditions can greatly enhance productivity and sustainability.

How Do Motor Starters Improve HVAC Systems?

In HVAC applications, motor starters are essential for controlling chillers and air handling units. Soft Starters and VFDs allow for smooth acceleration and precise speed control, improving energy efficiency and reducing operational costs. Buyers in Europe and the Middle East should prioritize sourcing starters that meet energy efficiency standards and provide reliable performance in varying climate conditions, ensuring optimal indoor environments while minimizing energy consumption.

3 Common User Pain Points for ‘motor starter types’ & Their Solutions

Scenario 1: The Confusion Over Selecting the Right Motor Starter Type

The Problem: Many B2B buyers, especially those new to industrial motor applications, often struggle to differentiate between the various types of motor starters. This confusion can lead to selecting an inappropriate starter that does not meet the operational requirements of their machinery. For instance, a buyer might inadvertently choose a Direct-On-Line (DOL) starter for a high-power motor that would benefit from a Reduced Voltage Starter, leading to excessive inrush currents and potential damage to the motor and associated equipment. This not only increases operational costs but also risks downtime and maintenance expenses.

The Solution: To alleviate this pain point, buyers should conduct a thorough assessment of their motor specifications and operational requirements before making a purchase. Understanding the motor’s horsepower, application type, and environmental conditions is crucial. It is advisable to consult with manufacturers or distributors who can provide detailed specifications and recommendations tailored to the specific use case. Additionally, leveraging resources such as technical datasheets and industry guidelines can help in identifying the appropriate motor starter type. For instance, a Reduced Voltage Starter can be beneficial for high-power motors, minimizing inrush current and extending motor life.

Illustrative image related to motor starter types

Scenario 2: Overlooking Protection Features in Motor Starters

The Problem: A common oversight among B2B buyers is neglecting the protective features of motor starters. For example, a company may opt for a basic motor starter without considering overload protection, resulting in frequent motor failures and costly replacements. This issue can be particularly pronounced in regions with inconsistent electrical supply, where fluctuations can lead to low voltage and overcurrent situations. The lack of adequate protection mechanisms can not only cause equipment failure but also pose safety risks in the workplace.

The Solution: Buyers should prioritize motor starters with integrated protection features, such as overload relays and low-voltage protection circuits. When sourcing motor starters, it is essential to evaluate products that meet specific industry standards and provide comprehensive safety features. Companies should also consider the operating environment; for instance, in areas prone to voltage fluctuations, investing in starters that include automatic reset capabilities can enhance reliability. Furthermore, conducting regular maintenance and testing of the protection features can help ensure they are functioning correctly, thus safeguarding the equipment against potential damages.

Scenario 3: Difficulty in Implementing Advanced Motor Control Solutions

The Problem: As industries evolve, there is a growing need for advanced motor control solutions that offer precise speed and torque management. However, many B2B buyers face challenges when transitioning from traditional motor starters to more sophisticated options like Variable Frequency Drives (VFDs). This transition can be daunting due to the complexity of VFDs and the fear of increased installation costs or extended downtime during the implementation phase. For instance, a manufacturing plant might resist upgrading to a VFD due to concerns about the technical expertise required for installation and integration with existing systems.

Illustrative image related to motor starter types

The Solution: To successfully implement advanced motor control solutions, buyers should invest in proper training and support from the motor starter manufacturers. Engaging with suppliers who offer comprehensive training programs can empower staff to understand and manage these advanced systems effectively. Additionally, buyers should seek out vendors that provide installation services or technical support during the transition phase. It is also beneficial to conduct a pilot project using VFDs on a single motor to evaluate performance improvements and address any challenges before full-scale implementation. By taking a phased approach, companies can minimize risks while leveraging the enhanced efficiency and cost savings that advanced motor control solutions offer.

Strategic Material Selection Guide for motor starter types

What Materials Are Commonly Used in Motor Starters?

When selecting materials for motor starters, understanding the properties, advantages, and limitations of each material is crucial for ensuring optimal performance and longevity. Below, we analyze four common materials used in motor starters: steel, copper, aluminum, and plastic.

How Does Steel Contribute to Motor Starter Performance?

Steel is frequently utilized in the construction of motor starters due to its strength and durability. Key properties of steel include high tensile strength and excellent wear resistance, making it suitable for high-pressure and high-temperature environments. However, steel is prone to corrosion, which can be a significant drawback in humid or corrosive environments.

Pros: Steel’s durability offers long-term reliability, making it ideal for heavy-duty applications. Its cost is relatively low compared to other metals, which can be beneficial for budget-conscious buyers.

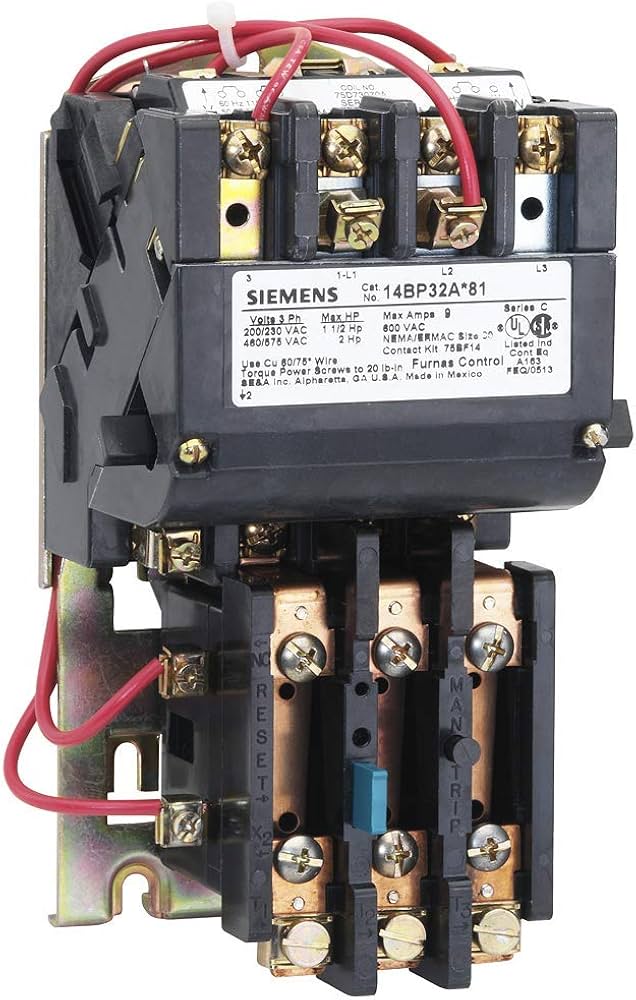

Illustrative image related to motor starter types

Cons: The susceptibility to rust necessitates protective coatings, which can increase manufacturing complexity and costs. Additionally, its weight can be a disadvantage in applications where lightweight materials are preferred.

Impact on Application: Steel is compatible with various media types but may require additional treatment or coatings for corrosive environments.

Considerations for International Buyers: Compliance with standards such as ASTM for material properties is essential. Buyers in regions like Africa and South America should consider local environmental conditions that may affect steel’s performance.

What Role Does Copper Play in Motor Starter Design?

Copper is another prevalent material used in motor starters, particularly for electrical contacts and windings. Its excellent electrical conductivity and thermal properties make it ideal for efficient energy transfer. Copper’s resistance to corrosion further enhances its suitability for various applications.

Pros: The high conductivity of copper ensures minimal energy loss, making it a preferred choice for high-performance starters. Its durability also contributes to a longer lifespan.

Cons: Copper is more expensive than steel and aluminum, which can be a limiting factor for large-scale applications. Additionally, it can be heavy, which may not be suitable for all designs.

Impact on Application: Copper is highly compatible with electrical systems and can handle high inrush currents effectively.

Considerations for International Buyers: Buyers should ensure that copper components meet international standards such as IEC or JIS. In regions like Europe, the recycling and environmental impact of copper must also be considered.

How Does Aluminum Compare in Terms of Motor Starter Applications?

Aluminum is increasingly being used in motor starters due to its lightweight and good conductivity. Its properties include a favorable strength-to-weight ratio and resistance to corrosion, making it suitable for various applications.

Pros: Aluminum is lighter than steel and copper, which can facilitate easier installation and lower shipping costs. Its corrosion resistance also reduces maintenance needs.

Illustrative image related to motor starter types

Cons: While aluminum has good conductivity, it is not as efficient as copper. Additionally, it may require thicker cross-sections to achieve the same strength as steel, potentially increasing material costs.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as portable equipment or overhead installations.

Considerations for International Buyers: Compliance with standards like ASTM and DIN is essential. Buyers should also consider the availability of aluminum in local markets, as it may vary by region.

Illustrative image related to motor starter types

What Advantages Do Plastics Offer in Motor Starter Manufacturing?

Plastics are often used in the insulation and housing of motor starters. Their key properties include excellent electrical insulation and resistance to corrosion and chemicals.

Pros: Plastics are lightweight and can be molded into complex shapes, allowing for versatile design options. They also provide good thermal insulation, which can enhance safety.

Cons: Plastics generally have lower mechanical strength compared to metals, which can limit their use in high-stress applications. Additionally, they may not withstand high temperatures as effectively as metals.

Impact on Application: Plastics are suitable for environments where electrical insulation is critical, but they may not be ideal for high-temperature or high-pressure applications.

Considerations for International Buyers: Buyers should ensure that plastic materials meet relevant safety and environmental standards, especially in regions with stringent regulations.

Summary Table of Material Selection for Motor Starters

| Material | Typical Use Case for motor starter types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and frames | High durability and strength | Prone to corrosion | Low |

| Copper | Electrical contacts and windings | Excellent conductivity | Higher cost than steel | High |

| Aluminum | Lightweight applications and casings | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Plastic | Insulation and housing | Good electrical insulation | Lower mechanical strength | Low |

By carefully considering these materials and their properties, international B2B buyers can make informed decisions that enhance the performance and longevity of motor starters in various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for motor starter types

What Are the Key Stages in the Manufacturing Process of Motor Starters?

Manufacturing motor starters involves a series of meticulously planned stages that ensure each component meets the required specifications. The typical stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Motor Starters?

The manufacturing process begins with the selection and preparation of raw materials. Common materials used in motor starters include:

- Copper and Aluminum: For electrical contacts and windings, chosen for their excellent conductivity.

- Steel and Plastic: Used for the housing and structural components, providing durability and protection.

- Insulating Materials: Such as rubber or thermoplastics to prevent electrical leakage and ensure safety.

Quality of these materials is critical, as it directly impacts the performance and longevity of the motor starters. Suppliers often need to provide certifications that confirm the material quality, such as material safety data sheets (MSDS).

How Are Components Formed During Manufacturing?

The forming stage involves several key techniques:

- Stamping and Cutting: Used to create metal components, such as contactors and terminals, from sheets of metal. Precision in this stage is essential to ensure parts fit together correctly during assembly.

- Injection Molding: Commonly used for creating plastic components, such as enclosures. This technique allows for complex shapes and designs that enhance functionality.

- Winding: For motor starters involving inductive components, winding copper wire around a core is crucial. Automated winding machines ensure consistency and precision in the number of turns and tension.

Each of these techniques requires skilled operators and advanced machinery to maintain quality standards.

What Does the Assembly Process Look Like?

During the assembly stage, all formed components come together. This process typically includes:

- Component Integration: Assembly lines where electrical contacts, overload protection circuits, and control elements are integrated into the starter unit.

- Soldering and Fastening: Connections are made using soldering techniques or mechanical fasteners, ensuring reliability and conductivity.

- Quality Assurance Checks: Throughout the assembly process, quality checks are conducted to identify defects early. This can include visual inspections and basic functionality tests.

Automation is often utilized to enhance efficiency and reduce human error, but manual inspection remains vital for quality assurance.

Illustrative image related to motor starter types

What Are the Final Finishing Techniques Applied?

Finishing processes enhance the durability and aesthetic appeal of motor starters:

- Surface Treatment: Components may undergo treatments such as galvanization or powder coating to prevent corrosion and wear.

- Labeling and Marking: Clear labeling is applied for identification, safety instructions, and compliance with regulatory standards.

- Final Inspection: Before packaging, a thorough inspection is performed to ensure that the motor starters meet all specifications and quality standards.

How Is Quality Assurance Managed in Motor Starter Manufacturing?

Quality assurance (QA) is a critical aspect of motor starter manufacturing, ensuring that each unit meets international and industry-specific standards.

What Are the Relevant International Standards for Motor Starters?

Motor starters must adhere to various international quality standards. Key certifications include:

- ISO 9001: Focuses on quality management systems. Manufacturers must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for motor starters used in the oil and gas industry, ensuring products meet specific operational requirements.

Obtaining these certifications involves rigorous audits and documentation to prove compliance.

What QC Checkpoints Are Commonly Used in Motor Starter Production?

Quality control checkpoints are critical throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify defects in real-time. This can include visual inspections and functional testing of components.

- Final Quality Control (FQC): Comprehensive testing of the completed motor starters, including performance tests and safety checks.

These checkpoints help manufacturers maintain high standards and reduce the risk of defective products reaching the market.

What Testing Methods Are Employed for Quality Assurance?

Common testing methods include:

- Electrical Testing: Ensures that the starter operates correctly under various load conditions. This can involve testing for inrush current, insulation resistance, and operational efficiency.

- Thermal Testing: Assesses the performance of the starter under different temperature conditions to ensure it can operate effectively in various environments.

- Durability Testing: Simulates prolonged use to evaluate the lifespan of the motor starter and its components.

These tests are often documented in quality assurance reports, which can be shared with B2B buyers for transparency.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should consider several strategies to verify the quality control processes of suppliers:

- Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing practices and adherence to quality standards. This can involve reviewing their quality management systems and inspecting their facilities.

- Request Quality Assurance Reports: Suppliers should be willing to provide documentation that outlines their quality control processes, including testing results and compliance with relevant standards.

- Engage Third-Party Inspectors: Independent inspections can provide an unbiased assessment of the supplier’s quality assurance practices. This is particularly important for international buyers who may not have the ability to conduct on-site audits.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges regarding quality control:

- Understanding Local Standards: Different regions may have varying regulatory requirements. Buyers should ensure that their suppliers are compliant with both local and international standards to avoid legal issues.

- Language Barriers: Clear communication is essential for quality assurance. Buyers should consider working with suppliers who can provide documentation and support in a common language.

- Cultural Differences: Variations in business practices and quality expectations can arise from cultural differences. Buyers should establish clear expectations and maintain open lines of communication to mitigate misunderstandings.

By understanding the manufacturing processes and quality assurance measures in motor starter production, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their operational needs and compliance requirements.

Illustrative image related to motor starter types

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motor starter types’

This guide serves as a comprehensive checklist for international B2B buyers looking to procure motor starters. By following these steps, you can ensure a strategic sourcing process that aligns with your operational requirements and safety standards.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline the technical requirements of the motor starters needed for your operations. Consider factors such as the type of motor (AC or DC), horsepower ratings, and specific applications. This clarity helps in selecting the right starter type—whether it’s a Direct On-Line (DOL), Soft Starter, or Variable Frequency Drive (VFD)—which ultimately impacts performance and efficiency.

Step 2: Assess Your Application Needs

Different applications require different motor starters. Evaluate the specific demands of your operations, such as the need for soft starting capabilities, reversing functions, or energy efficiency. This assessment will guide you in choosing between options like Reduced Voltage Starters for high-power motors or Multi-Speed Starters for applications needing variable speed control.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to gauge their reliability and expertise in motor starters. Look for company profiles, client testimonials, and case studies relevant to your industry. Ensure that the suppliers have experience with the specific starter types you need, which can be critical for successful implementation.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers hold relevant certifications, such as ISO 9001, which indicates a commitment to quality management. Additionally, check for compliance with international standards and regional regulations, particularly in markets like Europe and the Middle East, where adherence to safety and environmental standards is paramount.

Step 5: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that outline not just the pricing but also the specifications, warranty terms, and delivery timelines. A comprehensive quote allows for better comparison and helps identify any hidden costs or service terms that may affect your decision.

Step 6: Consider After-Sales Support and Service

Evaluate the level of after-sales support provided by the supplier. This includes installation assistance, troubleshooting, and access to replacement parts. Reliable support can significantly reduce downtime and ensure your operations run smoothly, particularly in regions where technical expertise may be limited.

Illustrative image related to motor starter types

Step 7: Plan for Long-Term Partnership

When selecting a supplier, consider the potential for a long-term partnership. Engaging with a supplier who understands your ongoing needs can lead to better pricing, tailored solutions, and improved service over time. This strategic approach can enhance your operational efficiency and reduce procurement costs in the long run.

By following this checklist, B2B buyers can navigate the complexities of sourcing motor starters effectively, ensuring they select the right products for their specific applications while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for motor starter types Sourcing

What Are the Key Cost Components for Motor Starter Types?

Understanding the cost structure of motor starters is essential for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The total cost of motor starters can be broken down into several key components:

-

Materials: The type and quality of materials used significantly influence the cost. For instance, high-grade copper for windings and robust plastic or metal for enclosures can increase costs but enhance durability and performance.

-

Labor: Labor costs vary based on the region and the complexity of the motor starter being manufactured. Skilled labor is often required for assembly and quality checks, which can drive up labor costs in countries with higher wage standards.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce these costs, impacting the final price of the motor starters.

-

Tooling: The initial setup cost for specialized tools and molds can be significant, especially for customized motor starters. These costs are typically amortized over production runs, which means larger orders can dilute tooling costs per unit.

-

Quality Control (QC): Effective quality assurance processes are essential for ensuring reliability and safety. The costs associated with testing and certification can vary widely, particularly if products require compliance with international standards.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as shipping method, distance, and import duties can influence overall costs.

-

Margin: Suppliers will typically add a profit margin to cover their expenses and risks. This margin can vary based on market demand and competition.

What Price Influencers Should Buyers Consider When Sourcing Motor Starters?

Several factors can influence the pricing of motor starters, which B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant cost savings. Suppliers often provide discounts for larger orders, making it beneficial for companies with high demand.

-

Specifications and Customization: Custom features tailored to specific applications may incur additional costs. Buyers should weigh the benefits of customization against the increased price.

-

Materials and Quality Certifications: Premium materials and certifications (such as ISO or CE) typically increase the cost but can enhance performance and reliability. Buyers should assess whether the added expense justifies the benefits.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers with a proven track record may charge more but offer better quality and service.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is crucial. These terms dictate who is responsible for shipping costs and risks, influencing the total cost of ownership.

What Are the Best Negotiation and Cost-Efficiency Tips for Buyers?

To maximize value when sourcing motor starters, international B2B buyers should consider the following strategies:

-

Negotiation: Building a strong relationship with suppliers can facilitate better pricing. Engage in discussions about volume discounts, payment terms, and delivery schedules to secure favorable terms.

-

Total Cost of Ownership (TCO): Assess the total cost of owning a motor starter, including purchase price, installation, maintenance, and operational costs. A lower initial price may not always equate to lower overall costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local market conditions that may impact pricing. Understanding the economic landscape of the supplier’s country can provide leverage in negotiations.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers can reduce logistics costs and lead times, potentially offsetting higher material costs.

Conclusion

In the complex landscape of motor starter sourcing, understanding the cost components and pricing influencers can empower B2B buyers to make informed decisions. By focusing on negotiation strategies and considering the total cost of ownership, buyers can optimize their procurement processes and enhance operational efficiency. Always remember that indicative prices may vary based on market conditions and specific project requirements, so thorough research and supplier engagement are essential.

Alternatives Analysis: Comparing motor starter types With Other Solutions

Understanding Alternatives to Motor Starter Types

In the realm of industrial motor control, selecting the right technology is essential for optimizing efficiency and ensuring reliability. While motor starters play a crucial role in safely starting and stopping motors, other solutions may offer similar benefits with varying performance characteristics and costs. This section evaluates motor starter types against viable alternatives, providing insights that can aid B2B buyers in making informed decisions.

| Comparison Aspect | Motor Starter Types | Variable Frequency Drives (VFDs) | Soft Starters |

|---|---|---|---|

| Performance | Reliable motor control and protection against faults | Provides precise speed and torque control, energy-efficient | Smooth acceleration, reduced mechanical stress |

| Cost | Moderate initial investment; long-term savings from efficiency | Higher upfront cost but potential for significant energy savings | Lower cost than VFDs, with a focus on starting current reduction |

| Ease of Implementation | Relatively straightforward installation | Requires programming and setup expertise | Simple to install and operate |

| Maintenance | Regular checks for overload protection | Requires periodic calibration and monitoring | Minimal maintenance required |

| Best Use Case | General-purpose applications with varied motor sizes | Applications needing variable speed control and energy savings | Applications requiring reduced starting current and torque |

What are the Advantages and Disadvantages of Variable Frequency Drives (VFDs)?

Variable Frequency Drives (VFDs) are advanced motor control solutions that adjust the frequency and voltage supplied to the motor, allowing for precise control over speed and torque. Their primary advantage lies in energy efficiency, especially in applications where motors run at variable speeds. However, they come with a higher initial cost and complexity in installation and programming. This makes them ideal for operations that can justify the investment through energy savings and enhanced process control, such as in HVAC systems or conveyor systems.

How Do Soft Starters Differ from Motor Starters?

Soft starters offer a unique approach by gradually increasing the voltage supplied to the motor, minimizing the inrush current and associated mechanical stress during startup. This capability can extend motor life and reduce the risk of damage. While soft starters are generally more affordable than VFDs, they do not provide the same level of control over speed or torque. Soft starters are best suited for applications where starting current reduction is critical, such as in fans or pumps that require a gentle start.

Conclusion: How Should B2B Buyers Choose Between Motor Starters and Alternatives?

When evaluating motor starters against alternatives like VFDs and soft starters, B2B buyers should assess their specific operational needs, budget constraints, and long-term goals. For applications requiring straightforward motor control with reliable protection, traditional motor starters may suffice. However, for operations that demand energy efficiency and speed control, investing in VFDs can yield substantial savings. Conversely, soft starters are ideal for reducing mechanical stress in applications with high starting currents. By considering these factors, buyers can select the most effective solution to meet their operational requirements and enhance their overall productivity.

Essential Technical Properties and Trade Terminology for motor starter types

What Are the Key Technical Properties of Motor Starters?

When evaluating motor starters, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that B2B buyers should consider:

1. Voltage Rating

Voltage rating indicates the maximum voltage that a motor starter can handle. It is critical to match the starter’s voltage rating with the motor’s operating voltage. A mismatch can lead to equipment failure or safety hazards. For instance, starters are commonly available in ratings such as 230V, 400V, or 690V, catering to different industrial applications. Ensuring compatibility protects the motor and extends its lifespan, making it a vital consideration for buyers.

2. Current Rating

Current rating specifies the maximum current the starter can manage. This is essential for preventing overheating and ensuring efficient motor operation. Buyers should select a starter with a current rating that exceeds the motor’s full-load current to accommodate inrush currents during startup. For example, a motor rated at 50A may require a starter rated for 60A or higher, depending on the application.

3. Protection Features

Motor starters often incorporate protection features such as overload relays, short-circuit protection, and phase failure detection. These features are crucial for safeguarding motors against damage caused by electrical faults. B2B buyers should look for starters with comprehensive protection mechanisms to ensure reliability and minimize downtime, which can be costly in industrial settings.

4. Control Type

The control type determines how the motor starter is operated. Options include manual, automatic, or programmable control. Understanding the control type is essential for ensuring that the starter fits the operational needs of the business. For example, a soft starter with programmable settings can provide smoother acceleration and deceleration, reducing mechanical stress on the motor.

5. Size and Mounting Options

Physical dimensions and mounting options can significantly impact installation and integration into existing systems. Buyers should consider the space available for installation and whether the starter can be mounted in a way that facilitates easy access for maintenance. Compact starters may be preferable in limited spaces, while larger units might offer more robust features.

6. Environmental Ratings

The environmental rating defines the suitability of a motor starter for various operating conditions, such as temperature, humidity, and exposure to dust or corrosive elements. Ratings like IP (Ingress Protection) indicate how well the starter can withstand environmental factors. For industries operating in harsh conditions, selecting a starter with appropriate environmental ratings is critical for ensuring longevity and performance.

What Are Common Trade Terms Associated with Motor Starters?

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to motor starters:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For motor starters, OEMs are crucial for ensuring compatibility and quality. Buyers often seek OEM products to guarantee that the components will function seamlessly with their existing machinery.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for B2B buyers, especially when managing inventory and budget. Suppliers may set MOQs based on production costs, and negotiating these terms can lead to more favorable pricing and order flexibility.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This is a critical step in procurement, allowing businesses to compare options and negotiate better deals. A well-prepared RFQ can streamline the buying process and ensure that all necessary specifications are communicated.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms helps B2B buyers navigate international transactions more effectively, ensuring clarity on costs and liabilities.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For motor starters, shorter lead times can significantly impact production schedules and operational efficiency. B2B buyers should discuss lead times with suppliers to ensure timely delivery aligns with their project timelines.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that optimize motor performance and safeguard their investments.

Navigating Market Dynamics and Sourcing Trends in the motor starter types Sector

What Are the Key Market Dynamics Influencing Motor Starter Types?

The global motor starter market is witnessing significant growth, driven by increasing industrial automation and the demand for energy-efficient solutions. In regions like Africa, South America, the Middle East, and Europe, the adoption of advanced motor control technologies is reshaping sourcing trends. B2B buyers are particularly interested in motor starters that offer energy savings, enhanced performance, and reliability. The rise of smart manufacturing and Industry 4.0 initiatives has led to a growing preference for Variable Frequency Drives (VFDs) and soft starters, which provide precise control over motor speed and torque.

Emerging technologies, such as IoT integration in motor control systems, are also impacting the market dynamics. These innovations enable predictive maintenance, reducing downtime and operational costs for manufacturers. Additionally, the growing focus on reducing carbon footprints is leading buyers to seek motor starters that comply with international energy efficiency standards. This shift is particularly pronounced in regions with stringent regulatory frameworks, such as Europe, where compliance with the Ecodesign Directive is essential.

Illustrative image related to motor starter types

B2B buyers must stay abreast of these trends to make informed sourcing decisions. Understanding the specific needs of their applications—be it for high-torque industrial motors or energy-efficient solutions for HVAC systems—will allow them to select the most suitable motor starter types. Collaborating with suppliers who offer comprehensive technical support and customization options will also enhance their competitive edge in an increasingly dynamic marketplace.

How Is Sustainability Shaping the Sourcing of Motor Starters?

Sustainability is becoming a critical factor in the sourcing of motor starter types, as companies worldwide recognize the environmental impact of their operations. The production and operation of motor starters can contribute to energy waste and increased carbon emissions, prompting B2B buyers to prioritize sustainable solutions. The emphasis on ethical sourcing has led to a growing demand for motor starters made from eco-friendly materials and those that achieve energy efficiency certifications.

Buyers are increasingly looking for suppliers who adhere to sustainability standards such as ISO 14001 or those offering products with green certifications, like Energy Star or CE marking. These certifications not only signify compliance with environmental regulations but also assure buyers of the product’s efficiency and minimal ecological impact. Furthermore, integrating sustainability into the supply chain can enhance brand reputation and customer loyalty, particularly in markets where consumers are increasingly eco-conscious.

In regions such as Africa and South America, where infrastructure development is critical, sustainable sourcing can also lead to cost savings in the long run. By investing in energy-efficient motor starters, businesses can reduce operational costs associated with energy consumption. This strategic approach to sourcing not only fulfills corporate social responsibility but also aligns with the global shift towards greener industrial practices.

What Is the Historical Evolution of Motor Starters Relevant to B2B Buyers?

The evolution of motor starters has been marked by significant technological advancements that directly impact B2B sourcing strategies. Initially, motor starters were rudimentary devices focused solely on switching motors on and off. However, as industrial processes grew more complex, the need for enhanced control mechanisms emerged. This led to the development of various types of motor starters, including Direct-On-Line (DOL), star-delta starters, and soft starters, each offering unique advantages for different applications.

The introduction of electronic controls in the late 20th century revolutionized the motor starter landscape. Variable Frequency Drives (VFDs) emerged as a game-changer, providing precise speed control and energy savings, which are now essential for modern industrial applications. As industries continue to prioritize efficiency and sustainability, understanding the historical context of motor starters can help B2B buyers appreciate the advancements in technology and the implications for their sourcing decisions.

In conclusion, staying informed about market trends, sustainability practices, and the historical evolution of motor starters will empower B2B buyers to make strategic sourcing choices that align with their operational goals and environmental commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of motor starter types

-

How do I choose the right motor starter for my application?

Choosing the right motor starter involves assessing several factors including the motor type (AC or DC), power rating, and application requirements. For high inrush current applications, consider using a soft starter or a variable frequency drive (VFD) to manage the starting current effectively. Additionally, evaluate the need for features like direction control and overload protection. Consulting with your motor supplier or an electrical engineer can provide insights tailored to your specific operational context. -

What is the best motor starter for high-power motors?

For high-power motors, a Reduced Voltage Starter or a Star-Delta Starter is often recommended. These starters help to minimize the inrush current and reduce mechanical stress on the motor during startup. A Variable Frequency Drive (VFD) is also an excellent option as it provides precise control over speed and torque, enhancing energy efficiency. Assess the specific power requirements and operational conditions before making a selection. -

What are the key features to look for in a motor starter supplier?

When vetting suppliers for motor starters, consider their experience in the industry, certification standards (such as ISO 9001), and product range. Look for suppliers who offer customization options to meet your specific needs and have a solid track record in quality assurance. Additionally, inquire about their support services, warranty policies, and lead times to ensure they can meet your operational demands. -

What are the typical minimum order quantities (MOQ) for motor starters?

Minimum order quantities can vary significantly among suppliers. Generally, MOQs may range from a few units to several hundred, depending on the manufacturer and the complexity of the motor starter. For customized solutions, suppliers might have higher MOQs. It’s advisable to discuss your requirements with potential suppliers to negotiate suitable terms that align with your purchasing strategy. -

What payment terms are commonly offered by motor starter suppliers?

Payment terms can vary widely based on the supplier and the buyer’s relationship. Common arrangements include payment in advance, net 30, or net 60 days. For international transactions, consider options like letters of credit or escrow services to secure the transaction. Always clarify payment terms before finalizing an order to avoid unexpected financial issues. -

How can I ensure quality assurance when sourcing motor starters?

To ensure quality assurance, request certification documents and compliance reports from your supplier, such as ISO certifications or safety standards relevant to your region. Conducting factory audits or requesting product samples can also help assess quality. Establishing a clear quality control process, including inspections upon delivery, can further safeguard against defects or subpar products. -

What are the logistics considerations when importing motor starters?

Logistics considerations include shipping methods, customs regulations, and import duties specific to your country. Choose a reliable freight forwarder experienced in handling industrial equipment to navigate customs efficiently. Consider the total landed cost, including shipping, insurance, and taxes, to accurately budget for your motor starter procurement. Timely communication with your supplier about shipping schedules can help prevent delays. -

How do I manage after-sales support for motor starters?

After-sales support is crucial for ensuring the long-term performance of motor starters. Verify that the supplier offers comprehensive support services, including installation assistance, troubleshooting, and warranty claims. Establish a clear communication channel for technical support and inquire about the availability of replacement parts. A supplier with a strong after-sales service can significantly enhance your operational efficiency and minimize downtime.

Top 2 Motor Starter Types Manufacturers & Suppliers List

1. North America Phase Converters – Electric Motor Starter Switches

Domain: northamericaphaseconverters.com

Registered: 2011 (14 years)

Introduction: Electric Motor Starter Switches – 3-Phase

– **Product Type**: Motor Starters

– **Price Range**: $119.00 – $179.00

– **Types of Motor Starters**:

– **Manual Motor Starters**: Operated manually, provide overload protection but no low-voltage protection. Suitable for low-power applications (10 horsepower or less).

– **Magnetic Motor Starters/Direct Online (DOL)**: Automatically break the control…

2. LinkedIn – Motor Starters

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: Motor starters are devices used to control the starting, stopping, and operation of electric motors, providing control over electrical power and protection against faults and overloads. Common types include: 1. Direct-On-Line (DOL) Starter: Simple, connects motor directly to power supply, suitable for small motors. 2. Star-Delta Starter: Reduces starting current by connecting motor in star configu…

Strategic Sourcing Conclusion and Outlook for motor starter types

Understanding the diverse types of motor starters is essential for optimizing operational efficiency in various industrial applications. Key takeaways include the importance of selecting the right starter to manage inrush currents, enhance motor protection, and facilitate energy savings. From Direct-On-Line (DOL) starters for simple applications to Variable Frequency Drives (VFDs) for advanced speed control, each type caters to specific operational needs.

Strategic sourcing plays a pivotal role in ensuring that businesses not only acquire the most suitable motor starters but also benefit from competitive pricing and reliable supply chains. As international B2B buyers from Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, leveraging local partnerships and understanding regional specifications will enhance procurement strategies.

Looking ahead, the demand for energy-efficient and technologically advanced motor starters is set to rise. Businesses are encouraged to stay informed about industry trends and innovations. By making informed choices today, buyers can ensure sustainable operations and a competitive edge in the global marketplace. Engage with reliable suppliers and explore the optimal motor starter solutions that meet your unique operational requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to motor starter types