Introduction: Navigating the Global Market for parts of a alternator

In today’s global market, sourcing high-quality parts of an alternator poses a significant challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As the demand for reliable electrical power generation continues to rise, understanding the intricacies of alternator components—such as rotors, stators, rectifiers, and voltage regulators—becomes crucial. This guide offers a comprehensive overview of these essential parts, their applications, and the latest industry trends, enabling businesses to make informed purchasing decisions.

Navigating the complexities of supplier vetting, pricing structures, and compatibility issues is vital for international buyers seeking to enhance their operational efficiency. With an emphasis on quality and performance, this resource addresses common pain points, including the identification of reputable suppliers and the assessment of component durability and functionality. By delving into these aspects, B2B buyers can effectively mitigate risks associated with procurement and ensure the longevity of their equipment.

Furthermore, this guide not only outlines the technical specifications and applications of alternator parts but also explores emerging markets and innovative solutions tailored to diverse regional needs. Empowering businesses with actionable insights, it serves as an essential tool for strategic sourcing and effective supply chain management, ultimately fostering growth and competitiveness in an ever-evolving marketplace.

Table Of Contents

- Top 5 Parts Of A Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts of a alternator

- Understanding parts of a alternator Types and Variations

- Key Industrial Applications of parts of a alternator

- 3 Common User Pain Points for ‘parts of a alternator’ & Their Solutions

- Strategic Material Selection Guide for parts of a alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for parts of a alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a alternator’

- Comprehensive Cost and Pricing Analysis for parts of a alternator Sourcing

- Alternatives Analysis: Comparing parts of a alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for parts of a alternator

- Navigating Market Dynamics and Sourcing Trends in the parts of a alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts of a alternator

- Strategic Sourcing Conclusion and Outlook for parts of a alternator

- Important Disclaimer & Terms of Use

Understanding parts of a alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotor | Rotating component with electromagnetic field generation | Automotive manufacturing, repair | Pros: Efficient power generation; Cons: Requires precise fitting to stator. |

| Stator | Stationary part with insulated windings for AC generation | Electric vehicle components, generators | Pros: Durable and long-lasting; Cons: High-voltage insulation may increase costs. |

| Voltage Regulator | Balances voltage supply, essential for stable operation | Automotive, industrial machinery | Pros: Protects electrical systems; Cons: Complexity can lead to higher failure rates. |

| Rectifier | Converts AC to DC, crucial for automotive applications | Automotive, renewable energy systems | Pros: Essential for battery charging; Cons: Can be a point of failure if not maintained. |

| Clutch Pulley | Connects rotor to engine via drive belt, allows for smooth operation | Heavy machinery, automotive | Pros: Enhances energy efficiency; Cons: May add complexity to installation. |

What are the Characteristics and Suitability of Alternator Rotors for B2B Buyers?

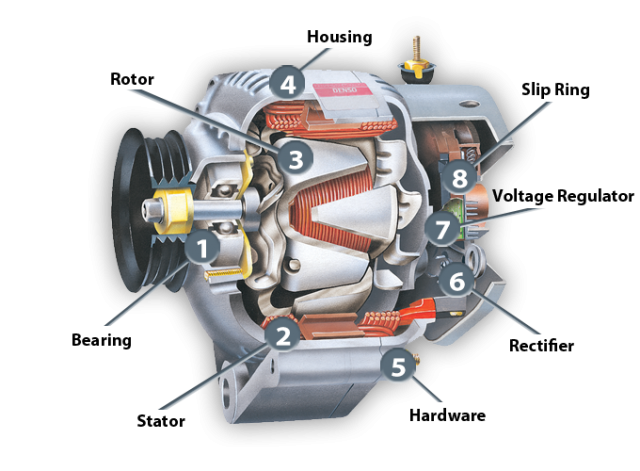

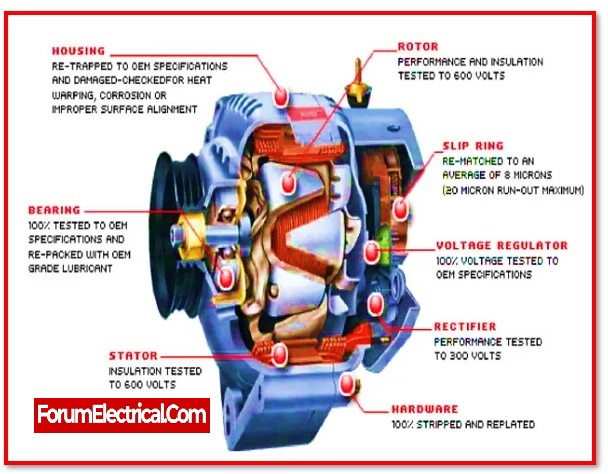

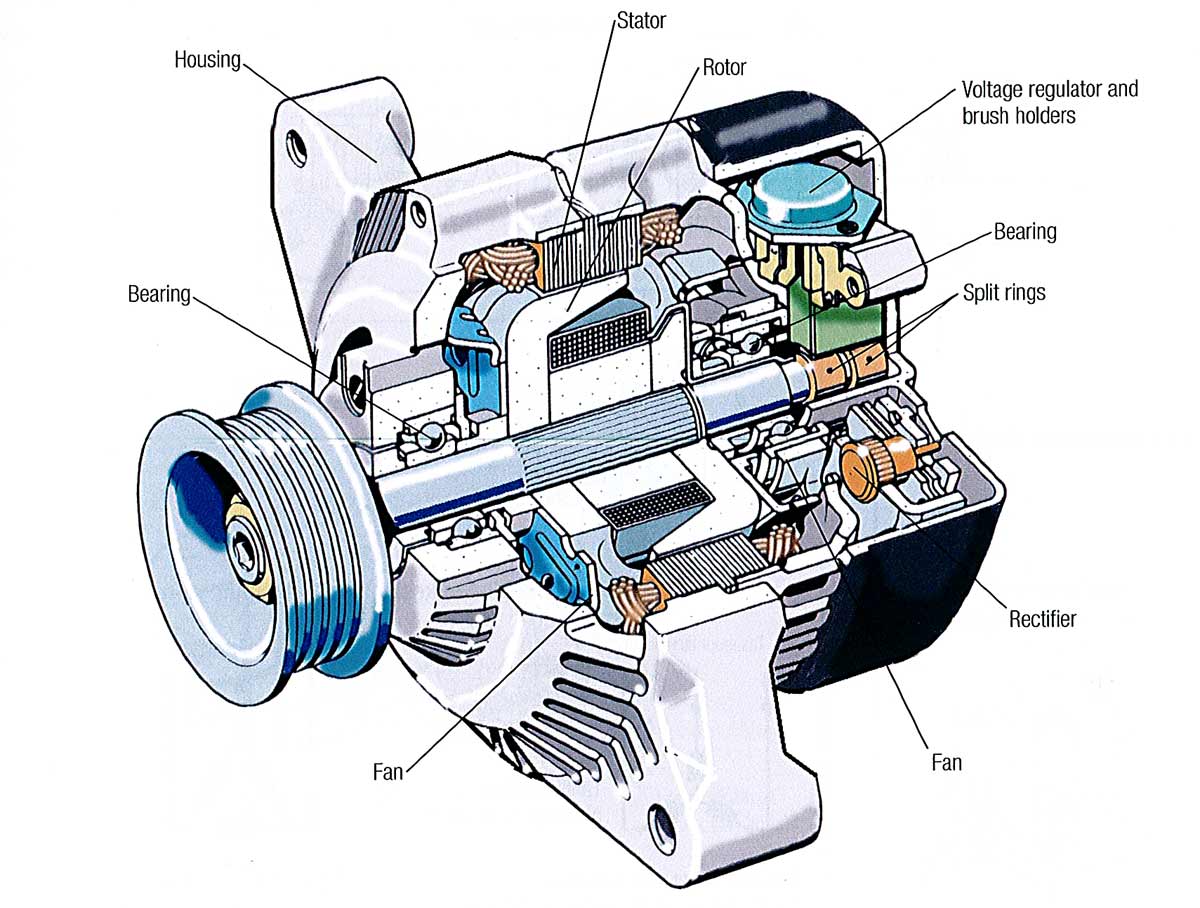

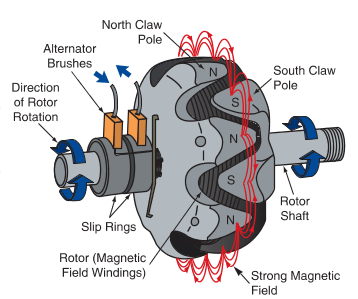

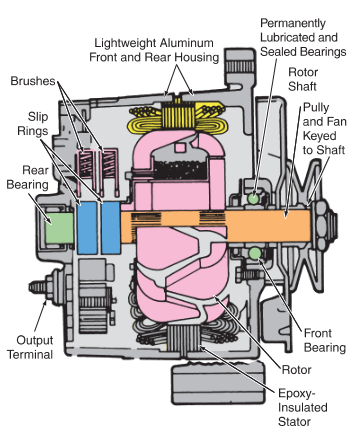

The rotor is a crucial component of an alternator, responsible for generating the electromagnetic field necessary for power production. Typically made from lightweight materials, rotors rotate at high speeds, converting mechanical energy from the engine into electrical energy. B2B buyers in the automotive manufacturing sector should consider the rotor’s compatibility with their specific engine designs, as precise fitting is essential for optimal performance. Additionally, the rotor’s efficiency can significantly impact the overall energy output, making it a vital area for investment.

Why is the Stator Important in Alternators for Industrial Applications?

The stator, being the stationary part of the alternator, houses insulated windings that interact with the rotor to produce alternating current (AC). Its durability and high-voltage insulation make it suitable for various applications, including electric vehicles and industrial generators. B2B buyers should focus on the stator’s quality and insulation properties, as these factors directly influence the longevity and reliability of the alternator. Investing in high-quality stators can lead to reduced maintenance costs and improved efficiency in electrical systems.

How Does the Voltage Regulator Enhance Alternator Performance for Businesses?

The voltage regulator plays a pivotal role in maintaining a consistent voltage output from the alternator, ensuring that electrical systems operate smoothly. This component is particularly important in automotive and industrial machinery applications, where fluctuations in voltage can lead to system failures. B2B buyers should evaluate the regulator’s specifications, as a reliable voltage regulator can protect other electrical components from damage, ultimately reducing downtime and repair costs. However, the complexity of these devices may increase their failure rates, necessitating careful selection and maintenance.

What Role Does a Rectifier Play in Automotive and Renewable Energy Systems?

The rectifier is essential for converting the alternating current (AC) generated by the alternator into direct current (DC), which is necessary for battery charging in automotive applications. Its importance extends to renewable energy systems, where efficient power conversion is crucial. B2B buyers should prioritize high-quality rectifiers that offer reliable performance, as they are often a point of failure in alternator systems. While rectifiers are vital for functionality, their maintenance and replacement should also be factored into the overall cost of ownership.

How Does a Clutch Pulley Contribute to Energy Efficiency in Heavy Machinery?

The clutch pulley connects the alternator’s rotor to the engine via a drive belt, facilitating smooth operation and energy transfer. This component is particularly beneficial in heavy machinery and automotive applications, where energy efficiency is paramount. B2B buyers should consider the clutch pulley’s design and compatibility with existing systems, as its integration can enhance overall operational efficiency. However, its complexity may complicate installation, making it essential to work with experienced technicians to ensure optimal performance and longevity.

Key Industrial Applications of parts of a alternator

| Industry/Sector | Specific Application of parts of a alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Replacement parts for vehicle alternators | Ensures reliable vehicle performance and reduces downtime. | Quality certification, compatibility with various models. |

| Renewable Energy | Alternators in wind turbine systems | Converts mechanical energy from wind into electrical power. | Durability, efficiency ratings, and local environmental conditions. |

| Agriculture | Alternators in farm machinery (e.g., tractors) | Powers essential equipment, improving productivity and efficiency. | Robustness for harsh conditions and availability of parts. |

| Marine | Alternators in boats and ships for electrical systems | Provides reliable power for navigation and onboard systems. | Corrosion resistance, size specifications, and power output. |

| Industrial Equipment | Alternators in generators for backup power solutions | Ensures continuous operation during power outages. | Voltage regulation, load capacity, and service support. |

How Are Parts of an Alternator Used in the Automotive Industry?

In the automotive sector, alternator components such as the rotor, stator, and voltage regulator play a crucial role in vehicle functionality. These parts convert mechanical energy into electrical power, charging the battery and powering electrical systems. Reliable performance is vital; thus, sourcing high-quality parts is essential to minimize vehicle downtime. Buyers should prioritize compatibility with various vehicle models and seek certifications to ensure quality.

What Role Do Alternators Play in Renewable Energy Applications?

In renewable energy, particularly in wind turbines, alternators convert the mechanical energy generated by wind into electrical energy. Components like the rotor and rectifier are essential for efficient energy conversion and distribution. Businesses in this sector benefit from sourcing durable and efficient alternators that can withstand varying environmental conditions. Buyers should consider the energy output efficiency and maintenance support when sourcing these components.

How Are Alternators Beneficial in Agriculture Machinery?

In agriculture, alternators are integral to powering machinery such as tractors and harvesters. The rotor and stator generate the necessary electrical power to run essential equipment, enhancing productivity on the farm. Buyers in this sector must focus on sourcing robust components that can endure harsh agricultural conditions, ensuring minimal downtime. Availability of replacement parts and local sourcing can also be significant factors in decision-making.

What Are the Applications of Alternators in Marine Industries?

Marine applications rely on alternators to provide essential electrical power for navigation and onboard systems. Components like the voltage regulator and diode rectifier ensure efficient power distribution, critical for safe operations at sea. Buyers should prioritize sourcing corrosion-resistant parts that meet specific size and power output requirements. Additionally, understanding local marine regulations can guide sourcing decisions.

How Do Industrial Equipment Manufacturers Utilize Alternators?

In industrial settings, alternators are used in generators to provide backup power solutions during outages. The rectifier and voltage regulator are crucial for maintaining stable power output. Businesses benefit from reliable power continuity, which is essential for operational efficiency. When sourcing alternator parts, companies should consider load capacity and the availability of service support to ensure long-term reliability.

3 Common User Pain Points for ‘parts of a alternator’ & Their Solutions

Scenario 1: Sourcing Quality Alternator Components for Reliable Performance

The Problem: Many B2B buyers face challenges when sourcing parts for alternators due to the vast number of suppliers and varying quality standards. In regions like Africa and South America, where supply chains may be less robust, buyers often receive subpar components that fail prematurely, leading to costly downtime and repair expenses. Additionally, understanding which suppliers provide genuine parts can be daunting, especially for buyers who may not have established relationships in the market.

The Solution: To overcome this sourcing dilemma, buyers should prioritize establishing partnerships with reputable suppliers who have a proven track record in the industry. Conducting thorough research and seeking out suppliers with positive reviews and certifications can help ensure quality. It’s also beneficial to request samples or conduct quality checks before placing bulk orders. Leveraging local trade shows or industry expos can provide opportunities to connect with trustworthy manufacturers. Furthermore, engaging in forums or online platforms dedicated to automotive parts can yield recommendations and insights from other businesses that have faced similar challenges.

Scenario 2: Understanding the Technical Specifications of Alternator Parts

The Problem: A common issue for B2B buyers is a lack of understanding regarding the technical specifications of alternator components, such as voltage regulators and rectifiers. This lack of knowledge can lead to incorrect orders, resulting in incompatible parts that do not fit the alternator models being serviced. For buyers in regions with diverse vehicle types, this problem is exacerbated by the need to cater to varying standards and specifications.

The Solution: Buyers should invest in training or resources that provide in-depth knowledge about the components of alternators, including their functions and specifications. Collaborating with suppliers who offer technical support can also be invaluable. When placing orders, it’s advisable to provide detailed information about the vehicle models and the specific requirements for the alternator parts needed. Utilizing a comprehensive parts catalog or database that includes specifications can help streamline the ordering process. Engaging with automotive engineers or consultants can further enhance understanding and ensure that the correct parts are sourced.

Scenario 3: Managing Supply Chain Disruptions for Alternator Parts

The Problem: Supply chain disruptions have become increasingly common, especially in the wake of global events. B2B buyers often find themselves facing delays in receiving critical alternator parts, which can halt operations and affect customer satisfaction. This issue is particularly pronounced in regions like the Middle East and Europe, where reliance on international shipping can lead to unpredictability.

The Solution: To mitigate the risks associated with supply chain disruptions, buyers should adopt a proactive approach to inventory management. Maintaining a buffer stock of essential alternator parts can prevent operational delays during shortages. Establishing relationships with multiple suppliers can also provide alternative options when one source is unavailable. Additionally, implementing an inventory management system that tracks usage patterns and forecasts demand can aid in making informed purchasing decisions. Buyers should also consider local suppliers or manufacturers to reduce dependency on international shipping, thereby improving lead times and reliability. Engaging in regular communication with suppliers about potential delays can further enhance transparency and allow for better planning.

Strategic Material Selection Guide for parts of a alternator

When selecting materials for alternator components, it is essential to consider their properties, performance, and suitability for specific applications. This analysis focuses on four common materials used in alternator parts: aluminum, copper, steel, and plastic. Each material has unique attributes that influence its performance and application in various environments, particularly in the international markets of Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum in Alternator Manufacturing?

Aluminum is widely used for the outer housing of alternators due to its lightweight nature and excellent thermal conductivity. It does not magnetize, which is crucial for heat dissipation during operation. Aluminum can withstand moderate temperatures, typically up to 150°C, making it suitable for most automotive applications.

Pros: Aluminum is durable, resistant to corrosion, and easy to machine, which simplifies manufacturing processes. It is also cost-effective compared to other metals.

Cons: While it performs well under normal conditions, aluminum may not be suitable for high-stress applications due to its lower tensile strength compared to steel.

Impact on Application: Aluminum’s lightweight properties enhance fuel efficiency, making it a preferred choice for automotive manufacturers. However, buyers should ensure compliance with international standards such as ASTM and DIN.

How Does Copper Enhance Electrical Conductivity in Alternators?

Copper is primarily used in the wiring and windings of alternators due to its superior electrical conductivity. It can handle high temperatures (up to 200°C) and has excellent corrosion resistance when properly coated.

Pros: Copper’s high conductivity allows for efficient power transfer, which is critical for the performance of alternators. It also has a long lifespan when used in electrical applications.

Cons: The primary drawback of copper is its relatively high cost compared to aluminum and its susceptibility to oxidation if not adequately protected.

Impact on Application: In regions with high humidity or corrosive environments, such as coastal areas in South America or the Middle East, using coated copper can mitigate corrosion issues. Buyers should consider local environmental conditions when selecting copper components.

What Role Does Steel Play in the Structural Integrity of Alternators?

Steel is often used for the rotor and stator cores due to its high strength and magnetic properties. It can withstand high temperatures and mechanical stress, making it ideal for heavy-duty applications.

Pros: Steel’s durability ensures long-term reliability, and its magnetic properties enhance the efficiency of the alternator.

Cons: Steel is heavier than aluminum, which can impact fuel efficiency. Additionally, it is prone to corrosion if not treated or coated properly.

Impact on Application: In markets like Europe, where stringent regulations on emissions and fuel efficiency exist, the weight of steel components may be a concern. Buyers should evaluate the balance between strength and weight when selecting steel parts.

How Does Plastic Contribute to Weight Reduction in Alternator Design?

Plastic is increasingly used in non-structural components of alternators, such as housings for electrical terminals and insulation materials. It offers a lightweight alternative to metals and can be engineered for specific thermal and electrical properties.

Pros: Plastic is lightweight, cost-effective, and can be molded into complex shapes, which simplifies manufacturing.

Cons: While plastic is resistant to corrosion, it may not withstand high temperatures or mechanical stress as well as metals.

Impact on Application: In regions with extreme temperatures, such as parts of Africa and the Middle East, selecting high-temperature resistant plastics is crucial. Compliance with international standards for plastics, such as ISO and ASTM, should also be considered.

Summary Table of Material Selection for Alternator Parts

| Material | Typical Use Case for parts of a alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Outer housing | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Copper | Wiring and windings | Superior electrical conductivity | High cost and oxidation risk | High |

| Steel | Rotor and stator cores | High strength and magnetic properties | Heavier and prone to corrosion | Medium |

| Plastic | Non-structural components | Lightweight and moldable | Limited high-temperature resistance | Low |

This material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of common materials used in alternators. Understanding these factors will help in making informed decisions that align with specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of a alternator

What Are the Key Stages in the Manufacturing Process of Alternator Parts?

The manufacturing of alternator parts involves a series of well-defined stages, ensuring precision and quality. Each stage contributes to the overall performance and reliability of the final product.

Illustrative image related to parts of a alternator

1. Material Preparation: What Materials Are Used in Alternator Parts?

The foundation of any high-quality alternator begins with the selection of materials. Typically, manufacturers use aluminum for the outer housing due to its lightweight and non-magnetic properties, which enhance heat dissipation. Other components, such as the rotor and stator, are often made from high-grade steel and copper. The preparation process includes:

- Sourcing Raw Materials: Suppliers must provide materials that meet specific industry standards.

- Material Inspection: Incoming Quality Control (IQC) checks are essential to ensure that materials meet specified requirements.

2. Forming: How Are Alternator Components Shaped?

The forming stage involves shaping the raw materials into the required components. This includes:

- Casting and Machining: The aluminum housing is often cast and then machined to precise dimensions, ensuring a perfect fit for internal components. CNC (Computer Numerical Control) machining is commonly employed for its accuracy.

- Stamping and Molding: Components like the stator and rotor may be stamped or molded, depending on design specifications. This method ensures consistency across large production runs.

What Assembly Techniques Are Used in the Production of Alternators?

Once individual components are prepared, they move to the assembly stage.

- Automated Assembly Lines: Many manufacturers utilize automated systems to streamline the assembly process. This includes robotic arms that can accurately place and secure components, reducing human error.

- Manual Assembly: Certain parts, such as the brushes and slip rings, might require manual assembly to ensure proper alignment and connection. Skilled workers are essential in this stage to maintain quality.

How Is Finishing Achieved in Alternator Manufacturing?

The finishing stage is crucial for enhancing the durability and aesthetic appeal of alternator parts.

- Surface Treatments: Components are often treated with coatings to prevent corrosion and wear. Anodizing aluminum parts increases their resistance to oxidation.

- Final Inspection: Before packaging, each part undergoes a thorough inspection to ensure it meets the required specifications.

What International Standards Should B2B Buyers Consider for Quality Assurance?

Quality assurance is vital in the manufacturing of alternator parts, especially for international B2B buyers. Adhering to recognized standards can significantly enhance product reliability.

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring consistent quality across all processes.

- CE Marking: Particularly relevant for the European market, CE marking indicates that products meet safety and environmental requirements.

- API Standards: The American Petroleum Institute (API) provides standards that may apply to alternators used in specific industries, such as oil and gas.

What Are the Key Quality Control Checkpoints in Alternator Manufacturing?

Quality control is integrated into every stage of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet established standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify issues early. Techniques such as visual inspections, measurements, and functional tests are employed.

- Final Quality Control (FQC): Once assembly is complete, final inspections confirm that the alternator parts meet all specifications before shipping.

What Testing Methods Are Commonly Used for Alternator Parts?

Testing is crucial for ensuring the performance and reliability of alternator components. Common methods include:

- Electrical Testing: This includes testing the output voltage, current, and overall electrical performance under load conditions.

- Thermal Testing: Components are tested for their ability to dissipate heat, simulating real-world conditions.

- Mechanical Testing: This involves checking the durability and strength of components, often through stress testing and fatigue analysis.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing process and quality control measures in place.

- Quality Reports: Requesting detailed quality reports can help assess the supplier’s adherence to international standards.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the manufacturing and quality assurance processes.

What Are the Unique Quality Control Nuances for International B2B Buyers?

When sourcing alternator parts internationally, buyers must be aware of specific quality control nuances:

- Regulatory Compliance: Different regions have various regulations regarding manufacturing standards. Understanding these regulations is crucial for compliance.

- Cultural Differences in Quality Perception: Quality expectations may vary by region; thus, clear communication with suppliers regarding standards is vital.

- Logistical Considerations: Quality can be affected by transportation and handling. Buyers should ensure that suppliers have protocols in place to mitigate risks during shipping.

Conclusion

Understanding the manufacturing processes and quality assurance practices for alternator parts is essential for international B2B buyers. By focusing on material preparation, forming techniques, assembly methods, and rigorous quality control measures, buyers can ensure they source high-quality components that meet their operational needs. Engaging with suppliers who adhere to international standards and maintaining thorough oversight can lead to successful partnerships and reliable product performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a alternator’

When sourcing parts for an alternator, especially in international markets like Africa, South America, the Middle East, and Europe, it’s essential to follow a systematic approach. This checklist will guide you through the critical steps to ensure you procure high-quality components efficiently and effectively.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline the technical specifications for each alternator part you need. This includes dimensions, material requirements, and compatibility with existing systems. A well-defined specification ensures that the parts you order will meet your operational needs and reduces the likelihood of costly errors.

- Identify the specific parts: Rotor, stator, rectifier, voltage regulator, etc.

- Consider performance requirements: Voltage ratings, current capacity, and durability standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in alternator parts. Look for manufacturers with a solid reputation and proven experience in the industry. This step is crucial as reliable suppliers can significantly impact your supply chain’s efficiency and the quality of the parts.

- Utilize online platforms: Explore B2B marketplaces and industry-specific directories.

- Check industry forums: Engage with communities to gather feedback about suppliers.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. Certifications such as ISO 9001 for quality management can indicate a supplier’s commitment to maintaining high standards in their manufacturing processes.

- Request documentation: Ask for copies of certifications and quality assurance processes.

- Assess compliance with regional standards: Ensure the supplier adheres to regulations applicable in your market.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the alternator parts. Testing samples allows you to verify the quality and compatibility of the components with your systems. This step can prevent future issues related to performance and reliability.

- Conduct performance tests: Evaluate the samples under real-world conditions.

- Assess fit and compatibility: Ensure the parts work seamlessly with existing equipment.

Step 5: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery timelines. Effective negotiation can lead to favorable terms that enhance your overall procurement strategy.

- Consider bulk order discounts: Leverage the volume of your order for better pricing.

- Discuss payment options: Establish terms that align with your cash flow requirements.

Step 6: Establish a Quality Control Process

Implement a quality control process to monitor the parts received from suppliers. This step is vital to maintaining the integrity of your products and ensuring that only high-quality components are used in your operations.

- Set quality benchmarks: Define what constitutes acceptable quality for each part.

- Plan for inspections: Schedule regular inspections upon receipt of goods to catch any discrepancies early.

Step 7: Build Long-term Relationships with Suppliers

Fostering strong relationships with your suppliers can lead to better communication, improved service, and potential cost savings over time. A collaborative approach can also provide you with insights into new products and technologies that may benefit your operations.

Illustrative image related to parts of a alternator

- Engage in regular communication: Keep an open line for feedback and suggestions.

- Consider joint ventures: Explore opportunities for collaborative projects or bulk purchasing agreements.

By following this checklist, B2B buyers can streamline their procurement process for alternator parts, ensuring they receive quality components that meet their technical and operational needs.

Comprehensive Cost and Pricing Analysis for parts of a alternator Sourcing

What Are the Key Cost Components in Alternator Parts Sourcing?

When sourcing parts for alternators, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The bulk of costs come from raw materials such as aluminum for housing, copper for windings, and specialized components like rectifiers and voltage regulators. Fluctuations in commodity prices can significantly impact overall costs.

-

Labor: Labor costs vary based on geographic location. Regions with lower labor costs may offer more competitive pricing, but this often comes with trade-offs in quality or lead times.

-

Manufacturing Overhead: This includes the costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can lead to lower overhead costs, which can be reflected in the pricing of parts.

-

Tooling: For custom or specialized parts, tooling costs can be substantial. This is especially true for unique designs or higher volumes that require dedicated molds or machines.

-

Quality Control (QC): Ensuring that components meet international standards involves rigorous testing and inspections, which add to the overall cost. Certifications such as ISO or TS16949 can also influence pricing.

-

Logistics: Shipping costs, customs duties, and insurance play a vital role in the total cost structure. The choice of Incoterms can either mitigate or exacerbate these expenses.

-

Margin: Suppliers will include a profit margin that reflects their operational costs and market positioning. This can vary widely based on competition and demand.

How Do Price Influencers Affect Alternator Parts Costs?

Several factors can influence pricing beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize pricing.

-

Specifications and Customization: Custom components often come with higher costs due to specialized manufacturing processes. Clearly defining specifications can help avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certification compliance can increase costs but may lead to better performance and reliability, justifying the investment.

-

Supplier Factors: The reputation and reliability of the supplier can significantly affect pricing. Established suppliers with a track record of quality may charge more, but they often provide better warranties and support.

-

Incoterms: Understanding the implications of Incoterms (e.g., FOB, CIF) is essential for managing logistics costs. The choice of Incoterms can impact overall pricing due to differing responsibilities for shipping, insurance, and customs clearance.

What Are Essential Tips for Negotiating Alternator Parts Pricing?

When negotiating prices for alternator components, international buyers should consider the following strategies:

-

Leverage Total Cost of Ownership (TCO): Emphasize the long-term value and savings associated with higher-quality parts. Demonstrating how superior components can lead to lower maintenance costs can strengthen your negotiating position.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and terms. Suppliers are more likely to offer favorable conditions to trusted partners.

-

Be Aware of Regional Variations: Understand the economic conditions in the supplier’s region, as these can impact pricing. For instance, suppliers in regions with high tariffs or shipping costs may require more negotiation flexibility.

-

Explore Multiple Quotes: Don’t settle for the first offer. Gathering quotes from various suppliers can provide leverage in negotiations and help identify the best overall value.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations and payment terms, as these can significantly affect costs for buyers from Africa, South America, the Middle East, and Europe.

Disclaimer on Indicative Prices

Prices for alternator parts can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and engage in direct negotiations with suppliers to obtain the most accurate and competitive pricing tailored to their specific requirements.

Alternatives Analysis: Comparing parts of a alternator With Other Solutions

Exploring Alternatives to Alternator Parts for Electrical Power Generation

In the automotive and industrial sectors, the alternator is a critical component for converting mechanical energy into electrical energy. However, several alternative technologies can achieve similar goals, each with its own advantages and disadvantages. Understanding these alternatives can help B2B buyers make informed decisions based on their specific requirements and operational contexts.

Comparison Table

| Comparison Aspect | Parts of an Alternator | Flywheel Energy Storage | Fuel Cell Technology |

|---|---|---|---|

| Performance | High efficiency; reliable output | Moderate efficiency; energy loss during conversion | High efficiency; continuous power generation |

| Cost | Moderate initial cost; low operational costs | High initial investment; low operational costs | High initial investment; ongoing fuel costs |

| Ease of Implementation | Simple integration with combustion engines | Requires specialized installation | Complex integration with infrastructure |

| Maintenance | Regular maintenance required for brushes and diodes | Low maintenance; minimal wear | Moderate maintenance; depends on fuel supply |

| Best Use Case | Automotive applications, reliable power for accessories | Energy storage in vehicles, regenerative braking | Sustainable power for vehicles and stationary applications |

Detailed Breakdown of Alternatives

Flywheel Energy Storage

Flywheel energy storage systems utilize a rotating mass to store kinetic energy. As energy is applied, the flywheel spins faster, storing energy that can be released when needed. This method is particularly effective for applications requiring rapid bursts of power, such as in electric vehicles during acceleration.

Pros: Flywheels offer low maintenance due to fewer moving parts and can provide high power output over short durations. They are also more environmentally friendly, as they do not rely on fossil fuels.

Cons: The initial investment is typically high, and the efficiency can be moderate due to energy losses during the conversion process. Additionally, specialized installation may be required, which can complicate deployment in certain environments.

Fuel Cell Technology

Fuel cells convert chemical energy from hydrogen or other fuels directly into electricity through a chemical reaction, offering a clean and efficient power source. They are increasingly used in electric vehicles and stationary power applications.

Pros: Fuel cells provide high efficiency and can generate power continuously as long as fuel is supplied. They also produce minimal emissions, contributing to a cleaner environment.

Cons: The initial setup costs can be significant, and ongoing fuel supply expenses can add to operational costs. Integration with existing infrastructure may be complex, requiring careful planning and execution.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between alternator parts and alternative technologies, B2B buyers should consider factors such as performance requirements, budget constraints, and the specific application context. For automotive applications, traditional alternators remain a reliable choice due to their proven efficiency and ease of integration. However, for innovative projects emphasizing sustainability and advanced energy management, exploring options like flywheel energy storage or fuel cell technology may yield long-term benefits. Ultimately, the right choice will depend on the unique demands of each business scenario.

Essential Technical Properties and Trade Terminology for parts of a alternator

What Are the Key Technical Properties of Alternator Parts?

Understanding the technical properties of alternator components is essential for B2B buyers looking to source high-quality parts. Here are several critical specifications that should be taken into account:

-

Material Grade: Most alternators use aluminum for the outer housing due to its lightweight and non-magnetic properties. The grade of aluminum affects its durability, resistance to corrosion, and thermal conductivity. For buyers, selecting the right material grade is vital for ensuring longevity and performance under varying environmental conditions.

-

Tolerance Levels: Tolerances refer to the allowable variations in dimensions of alternator components, such as the rotor and stator. Precise tolerances are crucial for ensuring that parts fit together correctly and function efficiently. Inaccurate tolerances can lead to mechanical failures, increased wear, and decreased efficiency. Buyers must understand these specifications to avoid costly replacements.

-

Electrical Ratings: Key electrical properties, such as voltage and current ratings, define how much electrical power an alternator can handle. These ratings are critical for ensuring compatibility with the vehicle’s electrical system. For B2B buyers, knowing the specific electrical ratings helps in sourcing alternators that meet the operational requirements of different vehicle models.

-

Cooling Efficiency: The design and efficiency of the cooling system within an alternator directly impact its performance. Efficient cooling mechanisms, such as internal fans or vents, reduce the risk of overheating, which can lead to premature failure. Buyers should prioritize alternators with superior cooling features to ensure reliability in demanding applications.

-

Winding Configuration: Alternators utilize different winding configurations, such as delta or wye, which influence their efficiency and output characteristics. Understanding these configurations helps buyers select the right alternator for specific applications, particularly in regions with varying electrical demands.

-

Bearing Types: The type of bearings used in an alternator affects its operational smoothness and lifespan. Quality bearings reduce friction and wear, enhancing overall performance. B2B buyers should inquire about bearing specifications to ensure optimal function and longevity.

What Are Common Trade Terms Used in the Alternator Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several common terms:

Illustrative image related to parts of a alternator

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts that are used in the assembly of vehicles. For B2B buyers, sourcing OEM parts often guarantees quality and compatibility with existing systems, making it a preferred choice for many businesses.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory levels effectively and to negotiate bulk purchasing advantages.

-

RFQ (Request for Quotation): An RFQ is a formal request sent to suppliers asking for their pricing and terms for specific products. This process is critical for buyers to assess costs and make informed purchasing decisions.

-

Incoterms (International Commercial Terms): Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. B2B buyers should be well-versed in Incoterms to avoid misunderstandings in international transactions.

-

Aftermarket Parts: These are components made by manufacturers other than the OEM. While often less expensive, the quality can vary significantly. Buyers should carefully evaluate aftermarket options to ensure they meet performance standards.

-

Lead Time: This refers to the time it takes from placing an order to receiving the goods. Understanding lead times helps buyers plan their procurement and inventory strategies more effectively, especially in regions where supply chains may be less predictable.

In conclusion, a comprehensive understanding of both the technical properties of alternator parts and the relevant trade terminology is essential for B2B buyers. This knowledge enables informed purchasing decisions, enhances supplier negotiations, and ultimately leads to better operational outcomes.

Navigating Market Dynamics and Sourcing Trends in the parts of a alternator Sector

What Are the Current Trends in the Global Parts of an Alternator Market?

The global market for alternator parts is shaped by several key dynamics. One significant driver is the growing automotive industry, particularly in emerging markets like Africa and South America, where increased vehicle ownership is translating into higher demand for vehicle maintenance and parts replacement. Additionally, the shift towards electric and hybrid vehicles is influencing sourcing trends, as manufacturers are adapting their product lines to accommodate new technologies. This transition requires parts that are not only efficient but also lightweight and durable, with materials like aluminum becoming increasingly prevalent.

Emerging technologies in the B2B space, such as digital supply chain management and e-procurement platforms, are also transforming how international buyers source alternator components. These technologies facilitate better inventory management, reduce lead times, and enhance transparency in the procurement process. Buyers from regions like the Middle East and Europe are increasingly leveraging data analytics to forecast demand and optimize sourcing strategies, ensuring that they remain competitive in a rapidly evolving marketplace.

As the market evolves, international buyers are also paying closer attention to supplier capabilities, quality certifications, and after-sales support. With the integration of Industry 4.0 practices, the focus is on sourcing from suppliers who can provide innovative solutions and maintain high standards of quality assurance.

How Is Sustainability Shaping Sourcing Decisions in the Parts of an Alternator Sector?

Sustainability has become a pivotal consideration for B2B buyers in the alternator parts sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, is prompting companies to seek out suppliers who prioritize ethical and sustainable practices. This shift is particularly pronounced in regions like Europe, where regulatory frameworks and consumer expectations are driving a push for greener supply chains.

Buyers are increasingly looking for suppliers who can demonstrate their commitment to sustainability through certifications such as ISO 14001, which focuses on effective environmental management systems. The use of recycled materials in the production of alternator parts, along with energy-efficient manufacturing processes, is becoming a critical factor in sourcing decisions. Additionally, the demand for “green” materials, such as biodegradable lubricants and eco-friendly packaging, is on the rise.

Ethical sourcing practices also enhance brand reputation and consumer trust, particularly in markets where corporate social responsibility is valued. By partnering with manufacturers who adhere to ethical labor practices and environmental stewardship, international buyers can not only mitigate risks but also contribute positively to the global supply chain.

How Has the Parts of an Alternator Market Evolved Over Time?

The alternator parts market has undergone significant transformations over the decades, evolving from basic mechanical components to sophisticated electronic systems. Early alternators were primarily used in combustion engines, relying on simple electromechanical principles to generate electrical power. As automotive technology advanced, so did the complexity of alternators, incorporating features such as integrated voltage regulators and diode rectifiers to enhance efficiency and reliability.

Illustrative image related to parts of a alternator

The introduction of hybrid and electric vehicles has further accelerated this evolution, necessitating the development of lighter, more efficient alternator components that can support advanced energy management systems. This shift not only reflects changes in consumer preferences but also emphasizes the importance of innovation in the parts supply chain. Today, B2B buyers are faced with a diverse array of alternator components that are engineered for performance, sustainability, and adaptability to emerging automotive technologies.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of a alternator

1. How do I choose the right alternator parts for my vehicle?

To select the appropriate alternator parts, start by identifying the specific model and make of your vehicle. Check the vehicle’s manual for part numbers and specifications. Consider sourcing parts from reputable suppliers who provide detailed product descriptions, compatibility information, and quality certifications. Additionally, inquire about the materials used in manufacturing to ensure durability and performance. Lastly, consult with industry professionals or mechanics for recommendations tailored to your specific needs and regional conditions.

2. What are the most common issues with alternator components?

Common issues with alternator components include wear and tear on brushes and slip rings, which can lead to poor electrical contact and decreased performance. Voltage regulators may fail, causing inconsistent power output, while rectifiers can develop faults, affecting the conversion of AC to DC. Additionally, overheating due to insufficient cooling can damage internal parts. Regular maintenance and quality sourcing can mitigate these issues, ensuring longevity and reliability of the alternator.

3. How do I vet suppliers of alternator parts for quality?

To vet suppliers, first, check for industry certifications such as ISO or TS16949, which indicate adherence to quality management standards. Request samples to evaluate the quality of the parts directly. Review customer testimonials and case studies to gauge the supplier’s reliability and service history. Additionally, consider their response time and customer service during initial interactions as indicators of professionalism. Conducting a background check on their financial stability can also provide insight into their capability to fulfill large orders.

4. Can I customize alternator parts for specific applications?

Yes, many suppliers offer customization options for alternator parts to meet specific application needs. This may include variations in size, material, or electrical specifications. When discussing customization, provide detailed requirements and specifications to the supplier. Be prepared for potential minimum order quantities (MOQs) and lead times associated with custom orders. Collaborating closely with the supplier during the design phase can ensure that the final product meets your operational standards.

5. What are the typical minimum order quantities (MOQs) for alternator parts?

Minimum order quantities (MOQs) for alternator parts can vary widely depending on the supplier and the specific components. Generally, MOQs can range from 100 to 1000 units. It’s advisable to discuss your needs with the supplier upfront, as many are willing to negotiate MOQs based on your purchasing power and the potential for long-term partnership. Smaller orders may be subject to higher per-unit costs, while bulk orders can offer significant savings.

6. What payment terms should I expect when sourcing alternator parts internationally?

Payment terms for international sourcing can vary, but common practices include upfront deposits (typically 30-50%) with the balance due upon delivery or before shipping. Some suppliers may offer net payment terms (e.g., net 30 or net 60) based on your creditworthiness. It’s essential to clarify these terms during negotiations and consider using secure payment methods such as letters of credit for large transactions to mitigate risks associated with international trade.

7. How do I ensure quality assurance (QA) for alternator parts?

To ensure quality assurance for alternator parts, request detailed quality control documentation from your supplier, including inspection reports and certifications. Establish clear specifications and testing protocols that all parts must meet before shipment. Consider third-party inspection services to verify quality before accepting delivery. Additionally, implementing a return policy and warranty agreements can safeguard your investment, allowing for recourse in case of defective parts.

8. What logistics considerations should I be aware of when importing alternator parts?

When importing alternator parts, consider shipping methods (air vs. sea), transit times, and costs. Ensure compliance with customs regulations in your region, which may involve tariffs and import duties. Partnering with a reliable freight forwarder can streamline the logistics process, helping to navigate documentation and customs clearance. Additionally, plan for potential delays and inventory management strategies to minimize disruptions to your operations.

Top 5 Parts Of A Alternator Manufacturers & Suppliers List

1. HowStuffWorks – Alternators

Domain: auto.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Alternators are small and lightweight, roughly the size of a coconut, constructed with an aluminum outer housing for heat dissipation. Key components include:

– Drive pulley attached to the rotor shaft, converting mechanical energy to electrical power.

– Several terminals: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L terminal (closes circuit to warn…

2. Electude – Alternator

Domain: electude.com

Registered: 2005 (20 years)

Introduction: An alternator is a crucial automotive component that converts mechanical energy into electrical energy, generating power for the vehicle’s electrical consumer units and battery. Key components include:

– Pulley: Transfers mechanical energy from the engine.

– Rotor: Creates the magnetic field for generating alternating current.

– Stator: The static part where voltage is generated.

– Rectifier: …

3. AutoElectro – Alternators

Domain: autoelectro.co.uk

Registered: 1999 (26 years)

Introduction: Alternators generate energy to feed the electrical system and charge the battery in a vehicle. They work by converting alternating current (AC) generated by the rotation of the pulley into direct current (DC) using a rectifier. Key components include:

– Regulator: Controls power distribution and charging process.

– Rectifier: Converts AC to DC.

– Rotor: Spinning mass that acts as a spinning ele…

4. Facebook – Parts of Alternator

5. HC Cargo – Alternator Parts

Domain: hc-cargo.com

Registered: 2009 (16 years)

Introduction: {“category”:”Alternator Parts”,”description”:”Comprehensive range of spare parts for alternators covering a large proportion of vehicles in the European market, including cars, commercial vehicles, agricultural machinery, marine, and off-road applications. All parts are OE compatible and undergo rigorous testing for quality and fit.”,”components”:[{“name”:”Carbon Brush”,”trade_number”:”H26″,”condu…

Strategic Sourcing Conclusion and Outlook for parts of a alternator

As the global market for automotive components continues to evolve, the strategic sourcing of alternator parts presents significant opportunities for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the essential components—such as the rotor, stator, rectifier, and voltage regulator—is crucial for informed purchasing decisions. These parts not only contribute to the efficiency and reliability of automotive systems but also influence the overall performance of vehicles in diverse environments.

By prioritizing strategic sourcing, buyers can leverage supplier relationships to enhance quality, reduce costs, and ensure timely delivery of critical components. Engaging with manufacturers and suppliers who demonstrate a commitment to innovation and sustainability can further optimize procurement strategies.

Looking ahead, the demand for advanced alternator technologies and environmentally friendly manufacturing practices will shape the market landscape. International buyers are encouraged to stay informed about industry trends and foster partnerships that align with their operational goals. Embrace this opportunity to enhance your supply chain and drive value in your automotive offerings. Your proactive approach to sourcing can set you apart in a competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to parts of a alternator

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.