Introduction: Navigating the Global Market for litens alternator

In the rapidly evolving automotive landscape, sourcing high-quality Litens alternators can be a daunting challenge for international B2B buyers. As manufacturers and suppliers strive to meet the demands of diverse markets across Africa, South America, the Middle East, and Europe, understanding the nuances of alternator technology becomes crucial. This guide is designed to provide comprehensive insights into Litens alternators, including their various types, applications, and the benefits of integrating advanced features like the Overrunning Alternator Decoupler (OAD).

International buyers will find critical information on supplier vetting processes to ensure reliability and quality, alongside a detailed analysis of cost factors that influence purchasing decisions. As the automotive sector becomes increasingly competitive, leveraging this guide will empower B2B buyers to make informed choices that enhance operational efficiency and vehicle performance. With a focus on practical applications and market-specific considerations, this resource serves as an invaluable tool for those navigating the complexities of sourcing Litens alternators in diverse global markets. By understanding the benefits and implications of their products, buyers can confidently align their procurement strategies with industry advancements and ultimately drive business success.

Table Of Contents

- Top 2 Litens Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for litens alternator

- Understanding litens alternator Types and Variations

- Key Industrial Applications of litens alternator

- 3 Common User Pain Points for ‘litens alternator’ & Their Solutions

- Strategic Material Selection Guide for litens alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for litens alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘litens alternator’

- Comprehensive Cost and Pricing Analysis for litens alternator Sourcing

- Alternatives Analysis: Comparing litens alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for litens alternator

- Navigating Market Dynamics and Sourcing Trends in the litens alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of litens alternator

- Strategic Sourcing Conclusion and Outlook for litens alternator

- Important Disclaimer & Terms of Use

Understanding litens alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Overrunning Alternator Decoupler (OAD) | Advanced torsion spring design, reduces noise and vibrations | Automotive aftermarket, fleet maintenance | Pros: Increases belt life, quieter operation. Cons: Higher upfront cost compared to standard pulleys. |

| Litens Monster OAD | Designed for large alternators in heavy-duty applications | Buses, commercial vehicles | Pros: Enhanced durability, suitable for high loads. Cons: May require specialized installation. |

| Hellraiser OAD | Optimized for high-performance vehicles, increases boost safely | Performance automotive markets | Pros: Boosts engine performance, tailored for high-stress applications. Cons: Limited to specific vehicle types. |

| Timing Belt Tensioners | Ensures synchronized performance, patented design | Automotive manufacturing, repair shops | Pros: Critical for engine performance, reliable. Cons: Replacement intervals can vary significantly. |

| Hybrid Drive Tensioners | Specifically designed for hybrid vehicles, addresses unique challenges | Hybrid vehicle manufacturers, aftermarket suppliers | Pros: Improves hybrid efficiency, tailored for specific needs. Cons: Niche application, may limit buyer pool. |

What Are the Key Characteristics of the Overrunning Alternator Decoupler (OAD)?

The Overrunning Alternator Decoupler (OAD) is engineered to enhance the performance of the engine’s accessory drive system. Its unique torsion spring design absorbs engine vibrations and mitigates belt tension fluctuations, resulting in a quieter and smoother operation. B2B buyers in the automotive aftermarket and fleet maintenance sectors will find the OAD particularly advantageous due to its ability to extend the life of belts and tensioners by up to two times. When considering procurement, businesses should weigh the initial investment against the long-term benefits of reduced maintenance costs and enhanced vehicle performance.

How Does the Litens Monster OAD Cater to Heavy-Duty Applications?

The Litens Monster OAD is tailored for large alternators found in buses and commercial vehicles, designed to withstand the rigors of heavy-duty applications. Its robust construction ensures it can handle high loads, making it ideal for B2B buyers in the transportation sector. While it offers exceptional durability and performance, prospective buyers should consider the potential need for specialized installation, which may incur additional labor costs. This product is a strategic investment for companies focused on maintaining fleet reliability and efficiency.

What Makes the Hellraiser OAD a Game-Changer for Performance Vehicles?

The Hellraiser OAD is specifically designed for high-performance vehicles, allowing for increased boost pressure while maintaining engine safety. This product is particularly relevant for B2B buyers in the performance automotive market, where enhancing vehicle output is a priority. The Hellraiser OAD’s bespoke design caters to high-stress environments, offering significant performance benefits. However, buyers should note that its application is limited to specific vehicle types, which may restrict its marketability in broader automotive sectors.

Why Are Timing Belt Tensioners Important for Engine Performance?

Timing Belt Tensioners are crucial for ensuring synchronized performance in an engine, preventing slippage and misalignment. This product is widely used in automotive manufacturing and repair shops, making it a staple for B2B buyers focused on engine reliability. While the benefits of improved engine performance and longevity are clear, buyers must consider the varying replacement intervals, which can affect inventory management and operational costs. Ensuring that the right timing belt tensioners are used is vital for maintaining vehicle performance.

How Do Hybrid Drive Tensioners Address Unique Challenges?

Hybrid Drive Tensioners are specifically designed to meet the challenges presented by hybrid vehicles, ensuring efficiency and reliability in a dual-power system. B2B buyers in the automotive industry, particularly those focusing on hybrid vehicle manufacturing and aftermarket services, will find these tensioners essential for optimizing performance. While they offer tailored solutions, the niche application may limit the buyer pool, necessitating targeted marketing strategies to reach potential customers effectively. Investing in hybrid drive tensioners can significantly enhance the overall efficiency of hybrid vehicles, making them a valuable addition to any product lineup.

Key Industrial Applications of litens alternator

| Industry/Sector | Specific Application of litens alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Integration in electric and hybrid vehicle systems | Enhances energy efficiency and reduces emissions | Ensure compatibility with vehicle models and local regulations |

| Commercial Transportation | Use in buses and heavy-duty trucks | Increases reliability and decreases maintenance costs | Look for high durability and performance under extreme conditions |

| Agricultural Machinery | Application in farming equipment | Improves operational efficiency and reduces downtime | Consider environmental factors and availability of local support |

| Construction Equipment | Utilization in heavy machinery | Enhances power supply stability and reduces noise levels | Source parts that meet specific machinery requirements |

| Renewable Energy Systems | Deployment in wind and solar energy systems | Increases system reliability and optimizes energy output | Assess compatibility with existing energy systems and local needs |

How is the Litens Alternator Used in Automotive Manufacturing?

In the automotive manufacturing sector, the Litens alternator is crucial for electric and hybrid vehicle systems. Its advanced Overrunning Alternator Decoupler (OAD) technology synchronizes the belt drive, enhancing energy efficiency while minimizing noise and vibration. This is particularly important for manufacturers aiming to meet stringent emissions regulations in markets like Europe and South America. B2B buyers must ensure that the alternator is compatible with various vehicle models and adheres to local environmental standards.

What Role Does the Litens Alternator Play in Commercial Transportation?

In commercial transportation, particularly in buses and heavy-duty trucks, the Litens alternator significantly contributes to vehicle reliability. The OAD technology allows for smoother operation, reducing wear on other components and ultimately lowering maintenance costs. This is vital for fleet operators who depend on high uptime. When sourcing, businesses should prioritize durability and performance, especially in regions like Africa and the Middle East where operating conditions can be harsh.

How is the Litens Alternator Beneficial for Agricultural Machinery?

The agricultural sector utilizes the Litens alternator in various farming equipment to enhance operational efficiency. The OAD feature helps manage engine vibrations and tension fluctuations, thus minimizing downtime during critical farming seasons. For international buyers, particularly in regions like South America, it is essential to consider the local climate and terrain when selecting alternators, ensuring they can withstand specific environmental challenges.

In What Ways Does the Litens Alternator Enhance Construction Equipment?

In construction equipment, the Litens alternator plays a vital role in ensuring stable power supply and reducing noise levels during operation. This is essential for machinery that often operates in populated areas or sensitive environments. B2B buyers should focus on sourcing alternators that meet the specific requirements of heavy machinery and consider the availability of local support and parts for maintenance.

How Does the Litens Alternator Contribute to Renewable Energy Systems?

In renewable energy systems, such as wind and solar installations, the Litens alternator improves reliability and optimizes energy output. The OAD technology allows for better management of energy fluctuations, which is crucial for maintaining system performance. Buyers in this sector should assess compatibility with existing systems and consider local energy needs when sourcing these alternators to ensure maximum efficiency and reliability.

3 Common User Pain Points for ‘litens alternator’ & Their Solutions

Scenario 1: Difficulty in Ensuring Component Compatibility

The Problem: B2B buyers often face the challenge of ensuring that the alternator components they purchase are compatible with the specific vehicle models they are servicing. This is especially crucial in international markets where vehicle specifications can vary widely. Incompatible parts can lead to increased downtime and unnecessary costs, as mechanics may need to reorder the correct components or make modifications, frustrating both the service providers and their customers.

The Solution: To mitigate compatibility issues, B2B buyers should utilize Litens’ comprehensive catalog of Overrunning Alternator Decouplers (OAD) and other components. Each product is designed to meet the original equipment manufacturer (OEM) specifications, ensuring that they fit seamlessly with a wide range of vehicles. Buyers should invest time in verifying the specific part numbers and model specifications before making a purchase. Additionally, leveraging Litens’ customer support can provide insights into the correct part for particular vehicle applications, reducing the risk of costly errors.

Scenario 2: Concerns Over Product Durability and Performance

The Problem: A common pain point for B2B buyers in the automotive sector is the concern over the durability and performance of alternator components. Many aftermarket parts may not match the quality and reliability of OEM products, leading to potential failures and increased maintenance costs. Buyers in regions with harsh climates, such as Africa and the Middle East, are particularly sensitive to this issue, as extreme conditions can exacerbate wear and tear on automotive components.

The Solution: Litens stands out by offering products that are not only OEM-equivalent but also designed with advanced technology to enhance performance. The patented internal spring and clutch system of the Litens OAD provides superior shock absorption and reduces noise, vibration, and harshness (NVH), which is crucial for long-term reliability. B2B buyers should emphasize sourcing from trusted suppliers like Litens that guarantee quality through extensive testing and warranties. Additionally, implementing a regular maintenance schedule can help extend the life of these components, ensuring optimal performance even in challenging environments.

Scenario 3: Challenges in Installation and Maintenance

The Problem: For many B2B buyers, particularly those in emerging markets, the complexity of installing and maintaining alternator systems can be a significant barrier. Inadequate training or lack of technical resources can lead to improper installation, resulting in premature failure of the components and increased operational costs. This issue can be particularly acute in regions where skilled labor is scarce or where training resources are limited.

The Solution: To address installation challenges, buyers should prioritize sourcing from manufacturers that provide comprehensive installation instructions and support. Litens not only includes detailed installation guides with their OAD products but also offers online resources for troubleshooting and maintenance. Investing in training for technicians can also prove invaluable; partnering with Litens can facilitate access to technical workshops or webinars. Additionally, creating a streamlined process for inspecting and replacing worn components can minimize downtime and ensure that installations are performed correctly the first time, enhancing overall operational efficiency.

Strategic Material Selection Guide for litens alternator

What Materials Are Commonly Used in Litens Alternators?

When selecting materials for Litens alternators, it is essential to consider their properties, advantages, and limitations. The materials used directly affect performance, durability, and compatibility with various applications, especially in diverse international markets.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is often used in the construction of various components of alternators due to its lightweight nature and excellent corrosion resistance. It can withstand moderate temperature ranges, making it suitable for automotive applications.

Pros: Aluminum’s low weight contributes to fuel efficiency, while its corrosion resistance prolongs the lifespan of alternator components. It is also relatively easy to machine and form, which simplifies manufacturing processes.

Cons: While aluminum is durable, it may not be as strong as steel under high-stress conditions. Additionally, it can be more expensive than some alternatives, which may impact overall production costs.

Impact on Application: Aluminum is compatible with various automotive fluids, ensuring that it does not degrade over time. However, international buyers must ensure that the aluminum grades meet specific standards, such as ASTM or DIN, to ensure reliability.

Steel: Strength and Durability

Steel is another common material used in alternator components, particularly for parts that require high strength and durability, such as shafts and pulleys. It offers excellent temperature resistance and can handle high-stress applications.

Pros: Steel’s strength makes it ideal for high-load applications, providing long-lasting performance. It is also more cost-effective than aluminum, particularly for bulk manufacturing.

Illustrative image related to litens alternator

Cons: The primary drawback of steel is its susceptibility to corrosion, which can be mitigated through coatings but may add to the manufacturing complexity. Additionally, steel components are heavier, which can negatively impact fuel efficiency.

Impact on Application: Steel components are suitable for high-temperature environments but may require regular maintenance to prevent rust, especially in humid regions. Buyers in Africa and South America should consider the local climate when selecting steel parts.

Plastic: Lightweight and Cost-Effective

Plastic materials, particularly reinforced polymers, are increasingly used in alternator components due to their lightweight and cost-effectiveness. They are suitable for non-load-bearing parts, such as housings and covers.

Pros: Plastics can be molded into complex shapes, reducing manufacturing complexity and costs. They are also resistant to corrosion and can withstand a variety of chemicals.

Cons: While lightweight, plastics generally do not have the same strength as metals, which limits their use in high-stress applications. They may also have lower temperature resistance, which could affect performance in extreme conditions.

Impact on Application: Plastics are compatible with various automotive fluids, but their performance can vary with temperature and exposure to UV light. Buyers should ensure that the selected plastic materials comply with international standards for automotive applications.

Composite Materials: Advanced Performance

Composite materials, which combine different substances to enhance performance, are gaining traction in the automotive industry. They offer a balance of strength, weight, and resistance to environmental factors.

Pros: Composites can provide superior performance characteristics, such as high strength-to-weight ratios and excellent corrosion resistance. They can also be engineered for specific applications, making them highly versatile.

Cons: The main limitation of composites is their higher manufacturing costs and complexity. They may require specialized processes for production and repair, which could impact lead times.

Impact on Application: Composites are suitable for high-performance applications but may not be widely available in all regions. International buyers should check for compliance with local standards and availability of suppliers.

Illustrative image related to litens alternator

Summary Table

| Material | Typical Use Case for litens alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and non-load-bearing parts | Lightweight and corrosion-resistant | Less strong under high stress | Medium |

| Steel | Shafts and pulleys | High strength and durability | Susceptible to corrosion | Low |

| Plastic | Covers and housings | Cost-effective and easy to mold | Lower strength and temperature resistance | Low |

| Composite | High-performance components | Superior performance characteristics | Higher manufacturing complexity | High |

This material selection guide aims to provide B2B buyers with valuable insights into the materials used in Litens alternators, helping them make informed decisions that align with their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for litens alternator

What Are the Key Stages in the Manufacturing Process of Litens Alternators?

The manufacturing process of Litens alternators is a multifaceted operation that emphasizes precision, reliability, and efficiency. The production typically unfolds in several key stages, each designed to uphold the highest standards of quality.

Material Preparation: What Raw Materials Are Used?

The first stage involves careful selection and preparation of raw materials. Litens utilizes high-grade steel and advanced composites for the construction of their alternator components. Materials are sourced from reputable suppliers who meet stringent quality criteria. Once received, materials undergo inspection to verify their compliance with technical specifications, ensuring only the best materials make it to the production line.

Forming: How Are Components Shaped?

The forming stage is where raw materials are transformed into functional components. Techniques such as forging, machining, and stamping are employed to create the intricate parts of the alternator. For instance, the Overrunning Alternator Decoupler (OAD) features a sophisticated internal spring and clutch system that necessitates precise machining. Advanced CNC machines are utilized to achieve the exact tolerances required, ensuring that every component fits perfectly and operates smoothly.

Assembly: What Techniques Ensure Quality?

In the assembly stage, skilled technicians bring together all the individual components. This process often employs automated assembly systems to enhance efficiency while maintaining quality control. Each assembly line is designed to minimize human error and maximize consistency. Technicians conduct visual inspections and functional tests during assembly to ensure that components are correctly installed and operational.

Finishing: How Is the Product Prepared for Market?

The finishing stage includes surface treatments and coatings to enhance durability and performance. Components may undergo processes such as anodizing or powder coating to provide corrosion resistance and improve aesthetics. Final inspections are performed to ensure the alternators meet both aesthetic and functional standards before packaging for distribution.

What Quality Assurance Measures Are Implemented in Litens Alternators?

Quality assurance is paramount in the production of Litens alternators, ensuring that each unit meets rigorous international and industry-specific standards.

What International Standards Govern Quality Assurance?

Litens adheres to ISO 9001, a globally recognized standard for quality management systems. This certification demonstrates Litens’ commitment to consistent quality, customer satisfaction, and continual improvement. Compliance with ISO standards is essential for international B2B transactions, providing buyers with the assurance that products are manufactured in a controlled environment.

Illustrative image related to litens alternator

Which Industry-Specific Standards Are Relevant?

In addition to ISO 9001, Litens products often comply with industry-specific standards such as CE marking for European markets and API specifications for automotive components. These certifications further validate the quality and safety of the products, making them suitable for various international markets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that every alternator meets the highest standards.

What Are Incoming Quality Control (IQC) Procedures?

Incoming Quality Control (IQC) is the first line of defense in quality assurance. During this phase, raw materials are inspected upon arrival. Testing may include dimensional checks, material composition analysis, and physical property evaluations. Only materials that pass these stringent tests are allowed into the production process.

How Is In-Process Quality Control (IPQC) Conducted?

In-Process Quality Control (IPQC) involves monitoring the manufacturing process at various stages. Technicians perform regular checks to ensure that machinery is functioning correctly and that the manufacturing process adheres to established protocols. This includes monitoring temperatures, pressures, and other critical parameters that can affect product quality.

What Is Final Quality Control (FQC) Like?

Final Quality Control (FQC) is conducted once the alternators are fully assembled. This stage includes comprehensive testing of the finished products. Common testing methods include functional tests, load tests, and durability assessments to ensure that the alternators perform as expected under real-world conditions.

Illustrative image related to litens alternator

How Can B2B Buyers Verify the Quality Control Practices of Litens Suppliers?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

What Role Do Audits Play in Supplier Verification?

Conducting audits is one of the most effective methods for verifying a supplier’s quality control practices. Buyers can request periodic audits of the manufacturing facilities to assess compliance with both international standards and internal quality protocols. These audits can be carried out by third-party organizations specializing in quality assurance.

How Important Are Quality Reports and Certifications?

Buyers should also request quality reports and certifications from suppliers. These documents provide detailed insights into the quality assurance processes, testing results, and compliance with standards. Suppliers should be able to furnish documentation that demonstrates adherence to ISO 9001 and any relevant industry-specific certifications.

What Are the Nuances for International B2B Buyers?

International buyers must be aware of regional regulations and standards that may impact their purchasing decisions. For instance, products sold in Europe must comply with CE marking requirements, while those in the Middle East may need to meet specific local standards. Understanding these nuances can help buyers make informed decisions and avoid compliance issues.

Conclusion: Why Quality Assurance Matters in B2B Transactions

In conclusion, the manufacturing processes and quality assurance measures implemented by Litens in the production of alternators are crucial for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed purchasing decisions that align with their operational needs and regulatory requirements. This knowledge not only enhances buyer confidence but also contributes to the overall success of their business operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘litens alternator’

This guide aims to equip B2B buyers with a practical checklist for sourcing Litens alternators, specifically the Overrunning Alternator Decoupler (OAD). By following these steps, buyers can ensure they are making informed purchasing decisions that align with their operational needs and standards.

Step 1: Define Your Technical Specifications

Understanding the exact requirements for the alternator is crucial before initiating the procurement process. Specifications such as the vehicle model, engine type, and compatibility with existing systems will influence your choice. This clarity helps in identifying the right Litens OAD that meets performance expectations while ensuring compatibility with your fleet.

Step 2: Research Supplier Backgrounds

Before engaging in negotiations, thoroughly research potential suppliers of Litens products. Investigate their market presence, years of operation, and reputation within the automotive industry. This information can often be found through industry reviews, testimonials, and case studies, which will provide insight into their reliability and service quality.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that suppliers hold necessary certifications and comply with international quality standards. Look for ISO certifications or other relevant industry accreditations that indicate a commitment to quality and performance. This step ensures that the components you procure are manufactured under rigorous quality control processes.

Step 4: Request Samples and Technical Documentation

Before placing a bulk order, request samples of the Litens OAD along with detailed technical documentation. This will allow you to assess the quality and suitability of the product for your needs. Pay attention to installation guides, warranty details, and maintenance recommendations to understand the product’s lifecycle and support.

Illustrative image related to litens alternator

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that the terms are favorable and align with your budget and operational timelines. Discuss bulk purchase discounts and any additional services, such as warranty extensions or technical support.

Step 6: Assess After-Sales Support and Warranty

Inquire about the after-sales support offered by the supplier, including warranty conditions and service agreements. A robust after-sales service can save costs and time in the long run, especially when dealing with technical issues or product replacements. Ensure that the warranty covers defects and provides adequate coverage for your operations.

Step 7: Monitor Market Trends and Innovations

Stay informed about industry trends and technological advancements related to alternators and power transmission products. Engaging in forums, subscribing to industry publications, and attending trade shows can provide valuable insights that may influence future sourcing decisions. Understanding innovations can help you maintain a competitive edge and optimize your operations.

By following these steps, B2B buyers can streamline the sourcing process for Litens alternators, ensuring they select high-quality products that enhance their vehicle performance and reliability.

Comprehensive Cost and Pricing Analysis for litens alternator Sourcing

What Are the Key Cost Components Involved in Sourcing Litens Alternators?

When sourcing Litens alternators, understanding the comprehensive cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: The quality of raw materials used in manufacturing Litens alternators significantly influences the final price. High-grade steel and patented designs are integral to ensuring durability and performance, directly affecting material costs.

-

Labor: Labor costs encompass the wages of skilled workers involved in the manufacturing process. Given the complexity of the alternator components, skilled labor is essential to maintain quality standards.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Specialized tools and machinery required for production add to the overall cost. The investment in advanced tooling is necessary for the precision engineering of Litens products.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure that every alternator meets the required specifications. This adds to the cost but is vital for maintaining the brand’s reputation.

-

Logistics: Transportation and shipping costs can vary based on the destination. For international buyers, understanding these costs is essential for accurate pricing.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and investment in technology. Understanding this can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Litens Alternators?

Several factors influence the pricing of Litens alternators, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchases can significantly reduce the per-unit cost. Suppliers often offer discounts based on Minimum Order Quantity (MOQ), making it beneficial for buyers to consolidate their orders.

-

Specifications and Customization: Custom specifications can lead to higher costs due to the need for tailored manufacturing processes. Buyers should assess their needs carefully to avoid unnecessary expenses.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., ISO standards) often come at a premium. However, investing in certified products can lead to lower Total Cost of Ownership (TCO) in the long run due to enhanced durability and efficiency.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can impact pricing. Established suppliers like Litens may command higher prices due to their proven track record but often deliver better quality and support.

-

Incoterms: Understanding the shipping terms (Incoterms) is crucial for pricing transparency. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of products.

What Are the Best Negotiation Tips for International Buyers of Litens Alternators?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating favorable terms is essential:

-

Research and Benchmarking: Conduct thorough market research to understand the average pricing and features of Litens alternators. This knowledge will empower you during negotiations.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Trust can result in more favorable negotiations.

-

Focus on Total Cost of Ownership (TCO): Emphasize the long-term benefits of investing in quality products. Highlighting the cost savings from reduced maintenance and extended lifespan can justify a higher upfront price.

-

Be Open to Alternative Proposals: Suppliers may offer different options or packages that can provide better value. Being flexible can lead to mutually beneficial agreements.

-

Understand Local Market Dynamics: Factors like currency fluctuations, tariffs, and trade agreements can impact pricing. Being aware of these can help in negotiating better terms.

What Are Some Pricing Nuances for International B2B Buyers?

International buyers should be mindful of several pricing nuances:

-

Currency Exchange Rates: Fluctuations in currency can significantly affect the cost. Consider negotiating prices in a stable currency to mitigate risks.

-

Import Duties and Taxes: Understand the import regulations and potential duties that may apply to your country. These can add considerable costs to the final price.

-

Shipping Times and Costs: Factor in the logistics of shipping, as longer lead times can affect your operations. Negotiate shipping terms that align with your supply chain needs.

-

Warranty and After-sales Support: Ensure that warranty terms are clearly defined. A strong warranty can provide peace of mind and reduce potential future costs.

By understanding these elements, international buyers can navigate the complexities of sourcing Litens alternators more effectively, ensuring they make informed purchasing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing litens alternator With Other Solutions

Introduction: Understanding Alternatives for Alternator Solutions

When evaluating automotive alternators, it’s essential to consider various options that can meet the diverse needs of vehicles and their operators. The Litens alternator, particularly its Overrunning Alternator Decoupler (OAD) technology, offers unique advantages, but alternative solutions may also provide viable benefits. This analysis will compare Litens’ offering with other technologies, aiding B2B buyers in making informed decisions.

Comparison Table

| Comparison Aspect | Litens Alternator | Alternator with Standard Pulley | Brushless Alternator |

|---|---|---|---|

| Performance | High efficiency; reduces noise and vibration | Moderate; can lead to increased wear | Very high; efficient under various loads |

| Cost | Premium pricing, reflecting quality | Lower initial cost | Higher upfront cost, but lower long-term operational costs |

| Ease of Implementation | Direct replacement, easy to install | Simple to install, but may require more frequent replacements | More complex installation; may require specialized tools |

| Maintenance | Low maintenance; designed for longevity | Higher maintenance due to wear | Minimal maintenance due to fewer moving parts |

| Best Use Case | Ideal for standard and hybrid vehicles needing quieter operation | Suitable for older vehicles with less demanding requirements | Best for high-performance or electric vehicles requiring efficiency |

Detailed Breakdown of Alternatives

Alternator with Standard Pulley

Alternators equipped with standard pulleys are common in older vehicle models. They typically come at a lower initial cost and are simpler to install. However, the performance can suffer due to increased noise, vibration, and wear over time. These units may require more frequent replacements, leading to higher long-term costs and potential disruptions in operations. They are best suited for vehicles with less demanding electrical needs and where budget constraints are a priority.

Illustrative image related to litens alternator

Brushless Alternator

Brushless alternators represent a technological advancement in automotive power systems. They operate with fewer moving parts, which translates to increased efficiency and reduced maintenance requirements. While the upfront cost is higher compared to both the Litens alternator and standard pulley systems, the long-term operational savings can be significant, especially in high-performance or electric vehicles. Installation may be more complex, requiring specialized tools or expertise, making them less accessible for all repair shops. They are ideal for businesses focusing on high-efficiency applications and advanced vehicle technologies.

Conclusion: Choosing the Right Alternator Solution

For B2B buyers, selecting the right alternator solution involves balancing performance, cost, and ease of maintenance against the specific requirements of their vehicle fleet. The Litens alternator stands out for its advanced design and long-term reliability, making it a strong choice for those prioritizing performance and reduced operational noise. In contrast, standard pulley systems may appeal to budget-conscious buyers with older vehicles, while brushless alternators are suited for businesses looking to invest in high-efficiency solutions for modern vehicles. Understanding these alternatives enables buyers to align their choices with their operational goals and vehicle specifications, ensuring optimal performance and cost-effectiveness.

Essential Technical Properties and Trade Terminology for litens alternator

What Are the Key Technical Properties of Litens Alternators?

When evaluating Litens alternators, it is essential to consider several critical specifications that contribute to their performance and reliability in various applications. Below are the key properties:

Illustrative image related to litens alternator

-

Material Grade

– Litens alternators are constructed from high-grade steel and reinforced plastic, ensuring durability and resistance to wear. The choice of materials impacts the longevity of components, which is crucial for B2B buyers looking for reliable products that minimize maintenance costs. -

Tolerance Levels

– Precision engineering in Litens products involves strict tolerance levels, typically within ±0.01 mm. This precision ensures that the alternator operates smoothly, preventing premature failure or excessive noise, thus enhancing overall vehicle performance. -

Grooved Running Surface

– The alternators feature a V-ribbed grooved contact surface that increases friction and enhances power transmission efficiency. This design is essential for ensuring smooth operation and minimizing energy loss, which can directly affect fuel efficiency. -

Decoupling Mechanism

– The patented Overrunning Alternator Decoupler (OAD) system allows the alternator to free-wheel during sudden deceleration. This mechanism reduces tension peaks in the belt, protecting the engine’s accessory drive system and contributing to quieter operation and improved engine efficiency. -

Installation Specifications

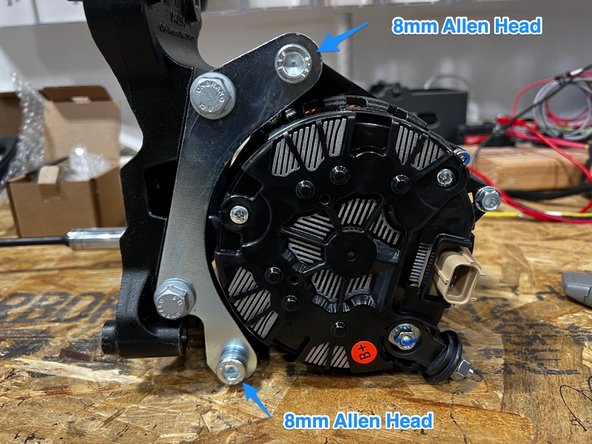

– Installation of the Litens alternator typically requires specific tools and methods, such as an impact gun with a 17mm hex driver. Understanding installation requirements is vital for B2B buyers to ensure proper fitting and functionality in their applications. -

Warranty and Replacement Cycles

– Litens offers a warranty that typically covers one year for defects, with a recommended replacement cycle of 45,000 to 75,000 miles under normal driving conditions. This information is crucial for buyers assessing long-term value and planning maintenance schedules.

What Are Common Trade Terms Related to Litens Alternators?

Familiarity with industry jargon is crucial for B2B buyers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to products made by the original manufacturer of the vehicle. Litens products are designed to match OEM specifications, ensuring compatibility and performance, which is critical for buyers who prioritize quality. -

MOQ (Minimum Order Quantity)

– MOQ denotes the minimum number of units a buyer must purchase in a single order. Understanding MOQ is essential for businesses aiming to manage inventory costs effectively while ensuring they meet supplier requirements. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request pricing and terms from suppliers. It is a vital tool for B2B transactions, enabling companies to compare options and negotiate favorable terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

– These are internationally recognized terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps businesses navigate international trade logistics efficiently. -

Aftermarket Parts

– These are components not made by the OEM but designed to fit and function like the original parts. Understanding the aftermarket landscape is vital for buyers looking to balance cost with quality and performance. -

Belt Drive System

– This term describes the mechanism that transfers power from the engine to various components via belts. Knowledge of belt drive systems is essential for buyers to understand the integration and performance of alternators within the larger vehicle system.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing Litens alternators, ensuring they meet their operational needs and quality expectations.

Navigating Market Dynamics and Sourcing Trends in the litens alternator Sector

What Are the Current Market Dynamics and Key Trends in the Litens Alternator Sector?

The global automotive market is witnessing a paradigm shift driven by technological advancements, evolving consumer preferences, and stringent regulatory frameworks. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. A significant driver is the push for improved fuel efficiency and reduced emissions, compelling manufacturers to adopt advanced components like the Litens Overrunning Alternator Decoupler (OAD). This technology not only enhances engine efficiency but also minimizes noise and vibration, aligning with the demands of modern vehicles.

Emerging trends in sourcing include the increasing reliance on digital platforms for procurement, which enables buyers to access a broader range of products and suppliers, streamlining the purchasing process. Additionally, there’s a growing emphasis on quality assurance, with buyers seeking original equipment (OE) components to ensure compatibility and reliability. The Litens OAD, recognized for its patented design and superior performance, positions itself as a preferred choice among B2B buyers seeking high-quality, durable parts that meet OE specifications.

Moreover, economic conditions in regions like Africa and South America influence buyer behavior, with many companies focusing on cost-effective solutions without compromising quality. As such, suppliers that offer transparent pricing and robust warranties are likely to gain a competitive edge. The global shift towards electric vehicles (EVs) is another critical factor, prompting suppliers to innovate and adapt their product lines to meet the evolving market demands.

Illustrative image related to litens alternator

How Is Sustainability and Ethical Sourcing Shaping the Litens Alternator Sector?

In today’s market, sustainability and ethical sourcing have become paramount concerns for B2B buyers. The environmental impact of automotive components, including those used in alternators, has led to an increased demand for suppliers that prioritize sustainable practices. The Litens alternator, particularly with its OAD technology, exemplifies this shift by enhancing fuel efficiency, thereby contributing to lower carbon emissions over the vehicle’s lifecycle.

B2B buyers are increasingly scrutinizing their supply chains for ethical practices. This includes sourcing materials responsibly and ensuring that manufacturing processes adhere to environmental regulations. Certifications such as ISO 14001 for environmental management and partnerships with organizations focused on sustainability can enhance a supplier’s credibility. Litens, recognized as a leader in the OE aftermarket parts sector, has made significant strides in this area, focusing on innovation that reduces waste and improves the overall efficiency of automotive systems.

Furthermore, as the global market leans toward green technologies, suppliers who can demonstrate their commitment to sustainability are likely to attract more business. This shift not only aligns with the values of environmentally conscious consumers but also positions companies favorably in a competitive landscape increasingly influenced by corporate social responsibility.

Illustrative image related to litens alternator

What Is the Evolution and Historical Context of the Litens Alternator Sector?

The Litens brand has a storied history that dates back to 1979, when it first revolutionized automotive performance with the introduction of the automatic tensioner for the Ford Mustang. Over the decades, the company has evolved into a major player in the automotive aftermarket, specializing in power transmission products. Today, Litens is recognized as the largest supplier of OE components, with a portfolio that includes advanced technologies like the OAD.

This historical context is essential for B2B buyers as it highlights Litens’ commitment to quality and innovation. The company’s extensive patent portfolio, which includes over 2,000 patents, underscores its focus on developing cutting-edge solutions that meet the changing demands of the automotive industry. By choosing Litens, buyers can leverage a legacy of engineering excellence and a deep understanding of market needs, ensuring they source products that not only perform but also align with the latest industry standards.

Frequently Asked Questions (FAQs) for B2B Buyers of litens alternator

-

How can I ensure the quality of Litens alternators when sourcing?

To ensure quality, request certification documents from your supplier, such as ISO 9001, which indicates adherence to international quality management standards. Conduct a background check on the supplier, including their reputation in the market and any customer reviews. Additionally, consider requesting product samples for a thorough inspection and testing before making a bulk order. Engaging with suppliers who provide a warranty or guarantee on their products can also be a strong indicator of quality assurance. -

What are the typical lead times for ordering Litens alternators internationally?

Lead times can vary significantly based on your location, order volume, and the supplier’s inventory. Generally, for international orders, you can expect lead times ranging from 4 to 12 weeks. It’s important to communicate your timelines clearly to your supplier and inquire about expedited shipping options if needed. Ensure that your supplier has a reliable logistics partner to prevent delays, especially if your order is time-sensitive. -

What are the minimum order quantities (MOQ) for Litens alternators?

Minimum order quantities (MOQ) can vary among suppliers, but they typically range from 50 to 200 units for Litens alternators. It’s advisable to discuss your specific needs with potential suppliers, as some may offer flexibility based on your business relationship or order history. Additionally, consider the impact of MOQ on your inventory management and cash flow, especially if you are entering a new market or testing demand. -

What payment terms should I expect when sourcing Litens alternators?

Payment terms can differ widely depending on the supplier’s policies and your negotiation skills. Common terms include a deposit upfront (usually 30% to 50%) with the balance due upon shipment or delivery. Some suppliers may offer net terms (e.g., 30, 60, or 90 days) for established customers. Always clarify payment options in advance and consider using secure payment methods like letters of credit for larger transactions to mitigate risks. -

How can I vet suppliers for Litens alternators effectively?

Start by checking the supplier’s business credentials, including their registration and compliance with local regulations. Request references from previous clients, and conduct online research to find reviews or testimonials. Additionally, consider visiting the supplier’s facility if possible, or ask for virtual tours. Engaging with suppliers who are recognized for their commitment to quality and customer service will enhance the reliability of your sourcing process. -

What logistics considerations should I keep in mind when importing Litens alternators?

When importing, consider shipping methods, customs regulations, and potential tariffs or duties that may apply. It’s essential to select a logistics partner experienced in handling automotive parts to ensure timely and safe delivery. Additionally, factor in the costs associated with insurance and warehousing if needed. Being aware of local regulations in your country regarding automotive parts will also help streamline the import process. -

Can Litens alternators be customized for specific applications?

Litens offers various products tailored to different vehicle models and requirements, but customization options may be limited. If you require specific features or modifications, it’s best to discuss your needs directly with the supplier. Some suppliers may accommodate custom orders for bulk purchases, but be prepared for longer lead times and potential additional costs. Clear communication of your specifications will be key to achieving the desired outcome. -

What warranty options are available for Litens alternators?

Most reputable suppliers offer warranties that typically range from 1 to 3 years, covering defects in materials and workmanship. When sourcing, always inquire about the specific warranty terms and conditions, including the process for claims. Understanding the warranty policy will provide peace of mind and protect your investment, especially when dealing with international purchases where returns can be complex and costly.

Top 2 Litens Alternator Manufacturers & Suppliers List

1. Litens Automotive – Overrunning Alternator Decoupling Pulley

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: {‘part_number’: ‘920810A’, ‘warranty’: ‘1 YEAR REPLACEMENT IF DEFECTIVE’, ‘manufacturer’: ‘Litens Automotive’, ‘description’: ‘Overrunning Alternator Decoupling (OAD) Pulley – Original Equipment Quality’, ‘compatibility’: ‘Designed for Chrysler/Dodge/Jeep’, ‘features’: [‘Patented Original Equipment Design’, ‘Protects the alternator and other front-end accessory drive components’, ‘Installation ins…

2. Litens – OAD™ Decoupler Pulleys

Domain: decouplerpulley.com

Registered: 2009 (16 years)

Introduction: Litens OAD™ Decoupler Pulleys are designed for vehicles equipped with an Overrunning Alternator Decoupler (OAD™) pulley, which is essential for synchronizing the belt drive system. Using the correct OAD™ pulley is crucial to prevent severe damage to a vehicle’s belt drive system. The OAD™ pulley offers a 1.5% to 2% fuel economy improvement and reduces parasitic losses in accessory drives through a…

Strategic Sourcing Conclusion and Outlook for litens alternator

In today’s competitive automotive market, strategic sourcing of Litens alternators and related components is essential for enhancing operational efficiency and product reliability. The advanced engineering behind Litens’ Overrunning Alternator Decoupler (OAD) not only extends the lifespan of drive systems but also mitigates noise and vibration, ultimately contributing to improved vehicle performance. By opting for Litens, buyers can ensure they are investing in original equipment quality that meets the rigorous demands of diverse markets, including those in Africa, South America, the Middle East, and Europe.

Strategic sourcing is not just about cost savings; it also involves securing high-quality components that foster customer satisfaction and loyalty. With Litens’ commitment to innovation and quality, international buyers can confidently integrate these products into their offerings, knowing they are backed by over four decades of engineering excellence and a vast patent portfolio.

As the automotive landscape continues to evolve, now is the time for B2B buyers to leverage the advantages of Litens products. By prioritizing quality and performance, businesses can position themselves for success in their respective markets. Explore how Litens can enhance your product line today, and take a proactive step towards a more efficient future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to litens alternator

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.