Introduction: Navigating the Global Market for how to know if your starter relay is bad

When it comes to ensuring the reliability of your vehicle, understanding how to know if your starter relay is bad is crucial for international B2B buyers in the automotive sector. A malfunctioning starter relay can lead to costly downtime and disruptions in operations, particularly in regions like Africa, South America, the Middle East, and Europe, where vehicle reliability is paramount. This comprehensive guide delves into the various types of starter relays and solenoids, their applications in different vehicle models, and the telltale signs of failure, empowering you to make informed purchasing decisions.

In addition to identifying symptoms of a bad starter relay, this guide covers essential aspects such as supplier vetting, cost considerations, and maintenance practices. We provide insights into sourcing high-quality replacement parts that meet international standards, ensuring that your fleet remains operational and efficient. By equipping you with the knowledge to assess the functionality of starter relays and solenoids, this resource not only helps in minimizing repair costs but also enhances the overall performance of your vehicles.

Navigating the global market for automotive components can be challenging, but with the right information, you can confidently choose reliable suppliers and products that align with your operational needs. Whether you’re based in Brazil or Saudi Arabia, understanding these components will empower your business to maintain a competitive edge in the automotive industry.

Table Of Contents

- Top 3 How To Know If Your Starter Relay Is Bad Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to know if your starter relay is bad

- Understanding how to know if your starter relay is bad Types and Variations

- Key Industrial Applications of how to know if your starter relay is bad

- 3 Common User Pain Points for ‘how to know if your starter relay is bad’ & Their Solutions

- Strategic Material Selection Guide for how to know if your starter relay is bad

- In-depth Look: Manufacturing Processes and Quality Assurance for how to know if your starter relay is bad

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if your starter relay is bad’

- Comprehensive Cost and Pricing Analysis for how to know if your starter relay is bad Sourcing

- Alternatives Analysis: Comparing how to know if your starter relay is bad With Other Solutions

- Essential Technical Properties and Trade Terminology for how to know if your starter relay is bad

- Navigating Market Dynamics and Sourcing Trends in the how to know if your starter relay is bad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to know if your starter relay is bad

- Strategic Sourcing Conclusion and Outlook for how to know if your starter relay is bad

- Important Disclaimer & Terms of Use

Understanding how to know if your starter relay is bad Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electrical Testing | Utilizes multimeters or testers to check voltage levels | Automotive repair shops, wholesalers | Pros: Accurate diagnostics; Cons: Requires technical expertise. |

| Visual Inspection | Checks for physical damage or corrosion | Fleet management, vehicle maintenance | Pros: Quick assessment; Cons: May miss internal issues. |

| Click Sound Analysis | Listens for clicking noises during ignition | Automotive technicians | Pros: Easy to identify; Cons: Can be misleading if battery is weak. |

| Intermittent Starting Issues | Observes inconsistent starting behavior | Vehicle rental companies | Pros: Highlights underlying problems; Cons: May require extensive troubleshooting. |

| Relay Replacement Testing | Swaps out the relay to see if starting issues resolve | Parts suppliers, garages | Pros: Straightforward solution; Cons: May not address root causes. |

What Are the Key Features of Electrical Testing for Starter Relays?

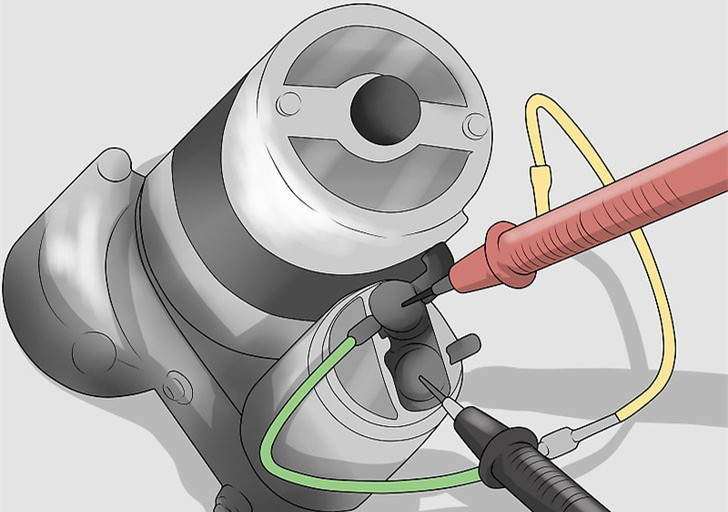

Electrical testing is an essential method for diagnosing a bad starter relay. By using multimeters or specialized testers, technicians can measure voltage levels and continuity within the starter circuit. This method is particularly suitable for automotive repair shops and wholesalers, as it allows for precise diagnostics. While it provides accurate results, it requires a certain level of technical expertise, which may necessitate additional training for staff or investment in specialized equipment.

How Does Visual Inspection Help in Identifying Starter Relay Issues?

Visual inspection involves checking the starter relay and its connections for signs of physical damage, corrosion, or loose wiring. This method is favored by fleet management and vehicle maintenance teams due to its speed and simplicity. While it allows for a quick assessment, it may not reveal internal issues within the relay itself, potentially leading to missed problems that could affect vehicle performance.

Why Is Click Sound Analysis Important for Diagnosing Starter Relays?

Click sound analysis is a straightforward diagnostic technique that involves listening for clicking noises when attempting to start the vehicle. This method is particularly useful for automotive technicians, as it can indicate whether the relay is attempting to engage but failing to do so. While this method is easy to identify, it can sometimes be misleading, especially if the battery is weak or other electrical issues are present.

What Are the Implications of Intermittent Starting Issues?

Intermittent starting issues can signal a failing starter relay, requiring careful observation of vehicle behavior. This type of analysis is particularly relevant for vehicle rental companies, where reliability is paramount. While it can highlight underlying problems, diagnosing intermittent issues may require extensive troubleshooting, which can be time-consuming and costly.

How Does Relay Replacement Testing Work as a Diagnostic Tool?

Relay replacement testing involves swapping out the suspected faulty relay with a new one to see if the starting issues resolve. This method is straightforward and commonly used by parts suppliers and garages. While it can provide a quick solution to starting problems, it may not address the root causes if other components are also failing, leading to potential future issues.

Key Industrial Applications of how to know if your starter relay is bad

| Industry/Sector | Specific Application of how to know if your starter relay is bad | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnosing starter issues in vehicles | Reduces downtime and repair costs for clients | Quality of diagnostic tools, availability of replacement parts |

| Transportation & Logistics | Ensuring fleet vehicles are operational | Maximizes fleet availability and efficiency | Reliability of components, supplier lead times |

| Construction Equipment | Maintenance of heavy machinery | Prevents costly breakdowns and project delays | Durability of parts, compatibility with various equipment models |

| Agricultural Equipment | Assessing starter relays in tractors and harvesters | Enhances productivity during critical seasons | Availability of specialized parts, local supplier networks |

| Marine & Offshore Operations | Troubleshooting starter systems in boats and vessels | Ensures safety and operational readiness | Compliance with maritime standards, robustness of components |

In the automotive repair sector, knowing how to diagnose a bad starter relay is crucial for service providers. When vehicles fail to start, mechanics can quickly identify the relay or solenoid as a potential culprit, preventing unnecessary replacement of more expensive components. This expertise not only enhances customer satisfaction but also streamlines operations, reducing labor costs and time spent on diagnostics.

For transportation and logistics companies, maintaining an operational fleet is essential for timely deliveries. Understanding starter relay issues allows fleet managers to implement preventive maintenance strategies, thereby minimizing unplanned breakdowns. This proactive approach can significantly enhance fleet reliability, ensuring that vehicles are always ready for service, which is particularly vital in competitive markets.

In the construction equipment industry, heavy machinery often faces harsh operating conditions. A malfunctioning starter relay can lead to equipment downtime, impacting project timelines. By being able to diagnose and address starter relay problems swiftly, construction companies can avoid costly delays and maintain productivity, especially during peak construction seasons when equipment demand is high.

For those in agricultural equipment, the ability to assess starter relay functionality is critical during planting and harvest periods. Equipment failures at these times can lead to significant financial losses. Farmers and agricultural businesses benefit from understanding these issues, as it allows them to ensure their machinery operates efficiently, maximizing yield and minimizing downtime during crucial operational windows.

Lastly, in marine and offshore operations, where safety and reliability are paramount, diagnosing starter relay problems is vital. A malfunctioning starter can leave vessels stranded or unable to start in emergency situations. By ensuring that starter systems are functioning correctly, operators can maintain compliance with safety regulations and ensure that their vessels are always ready for operation, thus protecting both personnel and investments.

3 Common User Pain Points for ‘how to know if your starter relay is bad’ & Their Solutions

Scenario 1: Difficulty Diagnosing Starter Relay Issues in Fleet Vehicles

The Problem:

For B2B buyers managing a fleet of vehicles, diagnosing issues related to the starter relay can be particularly challenging. A common pain point arises when a vehicle fails to start, and the fleet manager must quickly identify whether the problem lies with the starter relay, solenoid, or another electrical component. This uncertainty not only disrupts operations but can also lead to costly downtime. Fleet managers often lack the specialized training to differentiate between symptoms of a bad starter relay and other related issues, leading to misdiagnosis and unnecessary repairs.

The Solution:

To effectively diagnose starter relay issues, fleet managers should invest in comprehensive training for their maintenance teams focused on electrical systems and troubleshooting techniques. Implementing a systematic approach can significantly reduce misdiagnoses. Start by conducting a visual inspection of the starter relay and its connections, checking for corrosion or loose wiring. Utilize a multimeter to test the relay for continuity and voltage drop during operation. Educating the team on the symptoms—such as the absence of engine turnover or repeated clicking sounds—can help them accurately identify the starter relay as the issue. Establishing a clear protocol for diagnosing starting issues will streamline the repair process and minimize vehicle downtime.

Scenario 2: Inconsistent Starter Relay Performance Leading to Safety Concerns

The Problem:

B2B buyers in industries like logistics and transportation face severe safety concerns when vehicles exhibit intermittent starting issues due to faulty starter relays. An unreliable starting system not only jeopardizes the safety of drivers but also risks delays in deliveries and potential financial losses. The unpredictability of when a vehicle might fail to start can cause anxiety among drivers and operational headaches for managers, especially in high-stakes environments where timely deliveries are critical.

The Solution:

To address these safety concerns, businesses should implement a proactive maintenance schedule that includes regular inspections of starter relays and related components. Conducting routine electrical system diagnostics can help identify potential issues before they escalate. This could involve checking for signs of wear or damage in the wiring and connections associated with the starter relay. Additionally, consider investing in high-quality, OEM replacement relays that are specifically designed for your fleet vehicles. Using superior parts can enhance reliability and performance, reducing the likelihood of intermittent issues. Training drivers to report any starting irregularities immediately will also ensure that problems are addressed before they compromise safety.

Scenario 3: High Repair Costs Due to Ignoring Starter Relay Symptoms

The Problem:

Many B2B buyers underestimate the importance of addressing starter relay symptoms promptly, leading to escalated repair costs. When early signs—like a single click when turning the ignition—are ignored, the issue can progress to more severe electrical failures, potentially damaging other components like the starter motor itself. This oversight can result in significant expenses, as the costs of repairs and part replacements can compound quickly.

The Solution:

To mitigate repair costs, businesses should prioritize preventive maintenance and educate staff on recognizing early warning signs of starter relay failure. Implementing a scheduled maintenance program that includes checks for electrical system health can help catch issues before they worsen. Additionally, establishing a clear communication channel for mechanics and technicians to share observations and insights about vehicle performance will create a culture of vigilance. Investing in diagnostic tools that can quickly assess starter relay functionality will also enable quicker identification of potential failures, allowing for timely and cost-effective interventions. By addressing symptoms early, companies can avoid more extensive repairs and maintain a more efficient fleet operation.

Strategic Material Selection Guide for how to know if your starter relay is bad

What Materials Are Commonly Used in Starter Relays and Their Performance?

When assessing the materials used in starter relays, it’s essential to understand their properties, advantages, and limitations. This knowledge is crucial for B2B buyers who need reliable components that can withstand various environmental conditions and operational demands.

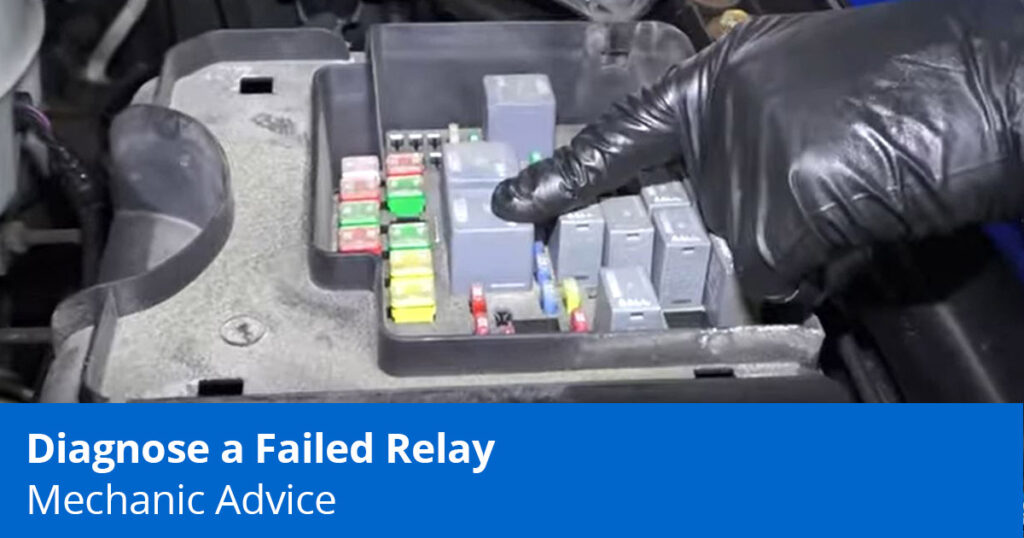

Illustrative image related to how to know if your starter relay is bad

What Are the Key Properties of Copper in Starter Relays?

Copper is widely used in electrical components, including starter relays, due to its excellent electrical conductivity and thermal properties. Its temperature rating can reach up to 200°C, making it suitable for high-performance applications. Copper also exhibits good corrosion resistance, although it can oxidize over time, leading to potential connectivity issues.

Pros: Copper is durable and highly conductive, ensuring efficient power transfer. It is relatively easy to manufacture and can be shaped into various forms.

Cons: The primary drawback is its cost, which can be higher than other materials like aluminum. Additionally, copper’s susceptibility to corrosion may require protective coatings, increasing manufacturing complexity.

Impact on Application: Copper’s compatibility with various electrical media makes it ideal for starter relays, where reliable electrical connections are critical.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, especially in regions like Europe and the Middle East, where quality assurance is paramount.

How Does Aluminum Compare as a Material for Starter Relays?

Aluminum is another common material used in starter relays, known for its lightweight and good conductivity, though not as high as copper. Its temperature rating typically caps around 150°C. Aluminum is naturally resistant to corrosion due to the formation of a protective oxide layer.

Pros: Aluminum is cost-effective and lightweight, making it easier to handle and install. It also offers good durability and resistance to environmental factors.

Cons: While aluminum is less expensive, its lower conductivity compared to copper can lead to efficiency losses in high-demand applications. Additionally, aluminum can be more challenging to weld or solder.

Impact on Application: Aluminum’s properties make it suitable for applications where weight savings are critical, but it may not be the best choice for high-performance starter relays.

Considerations for International Buyers: Buyers should ensure that the aluminum used meets relevant international standards, particularly in regions with strict manufacturing regulations like Europe.

What Role Does Plastic Play in Starter Relay Construction?

Plastics, particularly thermosetting and thermoplastic materials, are often used for the housing of starter relays. They can withstand temperatures up to 120°C and provide excellent insulation properties.

Pros: Plastics are lightweight, corrosion-resistant, and can be molded into complex shapes, allowing for versatile designs. They are also generally low-cost materials.

Cons: The main limitation is their lower thermal and mechanical strength compared to metals, which can affect durability in extreme conditions.

Impact on Application: Plastic housings are ideal for protecting internal components from environmental factors, but care must be taken to ensure they can handle the operational stresses of the application.

Considerations for International Buyers: Compliance with environmental regulations, such as RoHS in Europe, is critical for plastics, particularly for electronic components.

How Do Composite Materials Enhance Starter Relay Performance?

Composite materials, often a blend of metals and plastics, are increasingly used in starter relays to combine the benefits of both. They can withstand higher temperatures and offer excellent mechanical strength.

Pros: Composites provide a balance of strength, weight, and thermal resistance, making them suitable for high-performance applications. They can also offer improved electrical insulation.

Cons: The complexity of manufacturing composites can lead to higher costs and longer lead times.

Impact on Application: Composites are particularly beneficial in environments where both electrical performance and mechanical durability are required.

Considerations for International Buyers: Buyers should verify that composite materials meet industry standards for electrical components, particularly in regions with stringent regulations.

Summary Table of Material Selection for Starter Relays

| Material | Typical Use Case for how to know if your starter relay is bad | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections in starter relays | Excellent conductivity | Higher cost, corrosion risk | High |

| Aluminum | Lightweight relay housings | Cost-effective, lightweight | Lower conductivity | Medium |

| Plastic | Relay housings and insulation | Lightweight, corrosion-resistant | Lower thermal strength | Low |

| Composite | High-performance starter relays | Strength and thermal resistance | Higher manufacturing cost | High |

This analysis provides a comprehensive overview of material options for starter relays, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to know if your starter relay is bad

What Are the Main Stages of Manufacturing a Starter Relay?

When it comes to the manufacturing of starter relays, understanding the key stages involved is crucial for B2B buyers. The production process typically encompasses several phases, including material preparation, forming, assembly, and finishing. Each stage is essential to ensure the functionality and reliability of the final product.

How Is Material Prepared for Starter Relay Manufacturing?

The first step in manufacturing starter relays involves sourcing high-quality materials. Manufacturers often select materials such as copper, aluminum, and various plastics for their conductive and insulating properties. Quality assurance starts at this stage, where suppliers should provide certifications proving the materials meet international standards.

After sourcing, materials undergo processing, which may include cutting, shaping, and treating to enhance performance characteristics such as corrosion resistance. B2B buyers should inquire about the material specifications and certifications to ensure compliance with local and international regulations.

What Forming Techniques Are Used in Starter Relay Production?

Forming is the next critical stage, where the prepared materials are shaped into the components of the starter relay. Techniques like stamping, molding, and machining are commonly employed.

- Stamping involves using dies to cut out metal parts from sheets, ensuring precision and uniformity.

- Molding is often used for plastic components, where molten plastic is injected into molds to form the desired shapes.

- Machining processes may include drilling or milling to create precise dimensions and features on metal parts.

Each technique must adhere to strict tolerances to ensure the relay operates effectively. Buyers should evaluate suppliers based on their forming capabilities and the machinery used, which can indicate the quality and consistency of the products.

How Are Starter Relays Assembled?

Assembly is where the individual components come together to form the starter relay. This stage requires skilled labor and automated processes to ensure accuracy and efficiency. Key assembly methods include:

- Manual assembly for intricate components that require careful handling.

- Automated assembly lines for high-volume production, which enhance speed and reduce human error.

During assembly, quality checks are integrated to identify defects early, such as visual inspections and functional tests. B2B buyers should assess the assembly line setup and inquire about the operator training programs, as skilled labor is critical for maintaining high standards.

What Finishing Processes Are Involved in Starter Relay Manufacturing?

Finishing processes enhance the durability and aesthetics of starter relays. Common techniques include:

- Coating to provide insulation and protect against environmental factors.

- Heat treatment to improve mechanical properties and reduce brittleness.

- Labeling and packaging to ensure that relays are correctly identified and protected during shipping.

These finishing touches are essential for ensuring that the product can withstand operational stress and environmental conditions. B2B buyers should verify that the finishing processes align with the intended application of the relays.

What Quality Assurance Standards Are Relevant for Starter Relays?

Quality assurance is paramount in the manufacturing of starter relays, given their critical role in vehicle performance. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

Illustrative image related to how to know if your starter relay is bad

How Do Industry-Specific Certifications Impact Quality Control?

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for products used in oil and gas applications play a significant role in quality assurance. These certifications validate that products meet stringent safety and performance criteria.

B2B buyers should prioritize suppliers who possess relevant certifications, as this often reflects a commitment to quality and adherence to best practices.

What Are the Key Quality Control Checkpoints in Starter Relay Manufacturing?

Quality control (QC) is integrated at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. This may include measurements of critical dimensions and functional tests.

- Final Quality Control (FQC): Before products are shipped, a thorough inspection is conducted to ensure they meet all specifications and performance criteria.

These QC checkpoints are vital for maintaining the integrity of the starter relays. B2B buyers should request details on the QC processes of potential suppliers and understand how defects are handled.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of supplier quality control practices is essential for B2B buyers looking to ensure the reliability of starter relays. Here are several methods to consider:

- Audits: Conducting regular audits of suppliers allows buyers to assess compliance with quality standards and manufacturing practices.

- Quality Reports: Requesting quality reports can provide insights into the supplier’s performance, defect rates, and any corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and product quality.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding regional regulations and expectations for quality assurance can significantly impact supplier selection.

Illustrative image related to how to know if your starter relay is bad

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances when sourcing starter relays. Factors to consider include:

- Regulatory Compliance: Different regions may have specific regulations affecting product standards, such as environmental and safety requirements.

- Cultural Factors: Understanding cultural attitudes towards quality and manufacturing practices can help in selecting reliable suppliers.

- Logistics and Supply Chain: Quality assurance does not stop at manufacturing; shipping and handling processes can impact product integrity. Buyers should assess the entire supply chain.

By being informed about these nuances, B2B buyers can make more strategic decisions, ensuring they partner with manufacturers who meet their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if your starter relay is bad’

The following guide serves as a comprehensive checklist for B2B buyers looking to understand how to identify a faulty starter relay. This knowledge is essential for maintaining vehicle performance and ensuring operational efficiency.

Step 1: Identify Symptoms of a Bad Starter Relay

Begin by recognizing the common signs that indicate a starter relay issue. A vehicle that fails to start, produces a single click sound, or experiences intermittent starting problems may suggest a faulty relay. Understanding these symptoms can help in diagnosing the problem early, potentially saving costs on extensive repairs.

Step 2: Understand the Relay’s Role in the Starting System

Educate yourself about how the starter relay functions within the vehicle’s electrical system. The relay acts as a switch that allows a low-power signal from the ignition switch to control a high-power circuit needed for starting the engine. Knowing this can aid in troubleshooting and help you communicate more effectively with technicians or suppliers.

Step 3: Conduct Visual Inspections of the Relay

Physically inspect the starter relay and its connections. Look for signs of corrosion, damage, or loose wiring that may impede performance. A thorough visual check can often reveal issues that are easily rectifiable, reducing downtime and repair costs.

Step 4: Perform Electrical Tests on the Relay

Utilize a multimeter to test the relay for continuity and voltage. This step is crucial for confirming whether the relay is functioning correctly. If there is no continuity or the voltage readings are inconsistent, it may be time to replace the relay.

Illustrative image related to how to know if your starter relay is bad

Step 5: Evaluate Supplier Options for Replacement Parts

When sourcing replacement starter relays, it’s vital to evaluate multiple suppliers. Check for reliability, product quality, and warranty options. Ensure that the suppliers can provide parts compatible with your specific vehicle models, especially if you’re operating a fleet across diverse regions.

- Research Supplier Reputation: Look for customer reviews and case studies.

- Assess Product Range: Ensure they offer both relays and related components, such as solenoids.

Step 6: Verify Compliance with International Standards

Before finalizing your purchase, confirm that the starter relay meets international automotive standards. This is especially important when sourcing from suppliers in different regions like Africa, South America, or the Middle East, as compliance can affect both safety and performance.

Step 7: Establish a Relationship with Reliable Technicians

Cultivate relationships with qualified automotive technicians who can assist with installation and troubleshooting. A trusted technician can provide insights into the performance of the starter relay and help ensure that your vehicles are operating efficiently. Regular maintenance checks can also prevent future issues.

By following this structured checklist, B2B buyers can effectively assess and address issues related to starter relays, ensuring their vehicles remain in optimal condition.

Comprehensive Cost and Pricing Analysis for how to know if your starter relay is bad Sourcing

What Are the Key Cost Components in Sourcing Starter Relays?

When sourcing starter relays, several cost components play a critical role in determining the final price. These include:

-

Materials: The primary materials for starter relays often include copper, plastic, and various metals. The prices of these materials can fluctuate based on global market trends, affecting the overall cost.

-

Labor: Labor costs encompass the wages paid to workers involved in manufacturing and assembly. In regions with higher labor costs, such as parts of Europe, the total cost may increase significantly compared to regions with lower labor expenses.

-

Manufacturing Overhead: This includes costs related to factory utilities, equipment depreciation, and indirect labor. Efficient manufacturing processes can help reduce these overhead costs, contributing to a more competitive pricing structure.

-

Tooling: Initial tooling costs can be significant, especially for custom parts. If a buyer requires specialized tooling for unique specifications, this can lead to higher upfront costs, which should be factored into the total pricing analysis.

-

Quality Control (QC): Ensuring that starter relays meet the required specifications involves QC processes, which add to the cost. Buyers should consider the implications of QC standards on pricing, especially when sourcing from suppliers with different regulatory environments.

-

Logistics: Transporting starter relays to the buyer’s location includes shipping, customs duties, and handling fees. These logistics costs can vary widely depending on the shipping method and distance, impacting the overall cost structure.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and desired profitability. Understanding the industry standard margins can help buyers negotiate better deals.

How Do Price Influencers Affect the Sourcing of Starter Relays?

Several factors influence the pricing of starter relays, particularly in the international B2B market:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should inquire about MOQs and consider consolidating orders to maximize cost savings.

-

Specifications and Customization: Custom-designed relays may incur additional costs due to unique tooling and production processes. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: The quality of materials used in manufacturing starter relays can significantly affect pricing. Additionally, certifications (e.g., ISO, CE) that demonstrate compliance with international standards may also impact costs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality and timely delivery may charge a premium, but this can be justified by reduced risk and enhanced service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. They define responsibilities for shipping, insurance, and tariffs, which can significantly affect the overall cost.

What Are the Best Buyer Tips for Cost-Efficiency in Starter Relay Sourcing?

To optimize sourcing strategies, buyers should consider the following tips:

-

Negotiation: Engaging in negotiations with suppliers can yield better pricing and terms. Be prepared with market research and competitive quotes to strengthen your position.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost of ownership, which includes maintenance, warranty, and potential downtime. A lower initial price may not always equate to better value.

-

Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local market conditions, labor costs, and material availability. Buyers from Africa, South America, the Middle East, and Europe should be aware of these nuances when comparing quotes.

-

Disclaimer for Indicative Prices: It’s essential to note that prices can fluctuate based on market conditions and supplier negotiations. Always seek updated quotes and verify the terms before committing to a purchase.

By understanding these cost components, price influencers, and strategic tips, B2B buyers can make informed decisions when sourcing starter relays, ensuring they achieve the best possible value for their investment.

Alternatives Analysis: Comparing how to know if your starter relay is bad With Other Solutions

Exploring Alternatives for Diagnosing Starter Relay Issues

When it comes to identifying a faulty starter relay, various methods and technologies can be employed. Understanding these alternatives is essential for B2B buyers seeking effective solutions for automotive diagnostics. Each method has its advantages and drawbacks, making it crucial to assess them based on performance, cost, ease of implementation, maintenance, and their best use cases.

Illustrative image related to how to know if your starter relay is bad

Comparison Table

| Comparison Aspect | How To Know If Your Starter Relay Is Bad | Digital Multimeter | Automotive Diagnostic Scanner |

|---|---|---|---|

| Performance | Effective for immediate issues | High accuracy in voltage readings | Comprehensive diagnostics, including error codes |

| Cost | Low cost (basic tools) | Moderate (varies by model) | Higher initial investment, but can be cost-effective long-term |

| Ease of Implementation | Simple; requires basic knowledge | Requires understanding of electrical principles | User-friendly interfaces, but may need training |

| Maintenance | Minimal; occasional testing needed | Regular calibration may be needed | Software updates required for accurate diagnostics |

| Best Use Case | Quick checks in low-tech environments | Electrical system diagnostics | Comprehensive vehicle diagnostics in professional settings |

Detailed Breakdown of Alternatives

What Are the Benefits of Using a Digital Multimeter for Starter Relay Diagnosis?

A digital multimeter is a versatile tool that measures voltage, current, and resistance. It provides precise readings that can help diagnose electrical issues, including those related to the starter relay. The advantage of using a multimeter lies in its accuracy and ability to pinpoint specific electrical problems. However, it requires a certain level of technical knowledge to interpret the results effectively. For businesses with trained technicians, a multimeter can be an invaluable tool for detailed electrical diagnostics.

How Can an Automotive Diagnostic Scanner Enhance Vehicle Troubleshooting?

An automotive diagnostic scanner is a more advanced option that allows for comprehensive diagnostics of a vehicle’s electronic systems. These scanners can read error codes, monitor real-time data, and even suggest repairs. The primary advantage is the breadth of information provided, enabling technicians to identify not only starter relay issues but also a variety of other potential faults. However, the higher cost and need for software updates can be a barrier for smaller operations. For those looking to invest in long-term diagnostic capabilities, an automotive scanner can be a worthwhile investment.

Making the Right Choice: Which Solution Should You Choose?

When selecting the right method for diagnosing a bad starter relay, B2B buyers should consider their specific operational needs and budget constraints. For businesses seeking quick and straightforward solutions, a multimeter may suffice. However, for those looking for a comprehensive approach that can address multiple vehicle issues, an automotive diagnostic scanner offers greater value despite the higher initial cost. Ultimately, the choice should align with the technical expertise of the team and the complexity of the vehicles serviced.

Essential Technical Properties and Trade Terminology for how to know if your starter relay is bad

What Are the Key Technical Properties to Consider for a Starter Relay?

When assessing whether a starter relay is malfunctioning, several technical properties come into play. Understanding these specifications can help B2B buyers make informed purchasing decisions, ensuring they select reliable components that meet operational needs.

1. Current Rating (Amperage)

The current rating indicates the maximum electrical load that a starter relay can handle without failure. For automotive applications, typical ratings range from 30A to 200A. Knowing the required amperage is crucial; an undersized relay may lead to overheating and premature failure, while an oversized relay can be unnecessarily expensive.

2. Coil Voltage

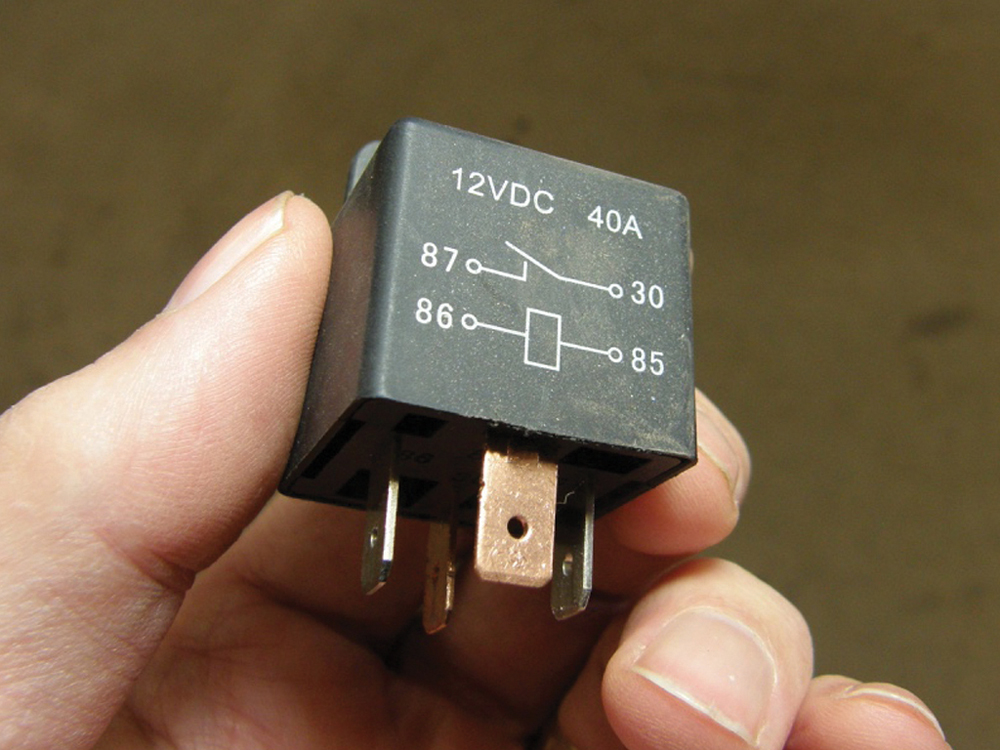

This specification refers to the voltage required to energize the relay’s coil. Common coil voltages include 12V and 24V, depending on the vehicle’s electrical system. Selecting a relay with the appropriate coil voltage ensures compatibility and functionality, preventing potential damage to both the relay and the vehicle’s electrical system.

3. Contact Configuration

The contact configuration defines how the relay connects within a circuit. Common configurations include normally open (NO) and normally closed (NC). Understanding this property is essential for ensuring that the relay functions correctly within the intended application, affecting the overall performance of the starting system.

4. Temperature Rating

Temperature ratings indicate the operational limits of a starter relay, typically ranging from -40°C to +85°C. This property is critical in regions with extreme climates, as operating outside of these limits can lead to reduced performance or failure. B2B buyers should consider the environmental conditions where the relay will be used to ensure durability.

5. Material Composition

The materials used in the relay’s construction, such as copper for contacts and thermoplastic for the housing, play a significant role in performance and longevity. High-quality materials can enhance corrosion resistance and thermal conductivity, leading to improved reliability. Buyers should prioritize relays made from materials suited to their specific application demands.

Illustrative image related to how to know if your starter relay is bad

6. Mounting Type

The mounting type of a starter relay can vary (e.g., plug-in, bolt-on). Understanding the mounting requirements is essential for compatibility with existing systems. This consideration can affect installation time and costs, making it an important factor for B2B buyers.

What Are the Common Trade Terms Relevant to Starter Relays?

Familiarity with industry terminology can enhance communication and negotiations in B2B transactions. Here are key terms related to starter relays:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the same company that manufactured the original components of a vehicle. For buyers, sourcing OEM starter relays can ensure compatibility and reliability, as these parts are designed to meet specific manufacturer standards.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to plan their inventory purchases effectively, ensuring they meet demand without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. Issuing an RFQ for starter relays allows buyers to compare prices and terms, facilitating better procurement decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping transactions. Familiarity with these terms can help B2B buyers understand shipping costs, risks, and obligations associated with purchasing starter relays from international suppliers.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For businesses relying on timely repairs or manufacturing schedules, understanding lead times for starter relays is crucial to maintaining operational efficiency.

6. Warranty

A warranty is a guarantee from the manufacturer regarding the quality and longevity of the product. Knowing the warranty terms for starter relays can provide buyers with assurance regarding their investment and potential recourse in case of defects.

By comprehending these technical properties and industry terms, B2B buyers can make more informed decisions when evaluating starter relays, ensuring optimal performance and reliability in their applications.

Navigating Market Dynamics and Sourcing Trends in the how to know if your starter relay is bad Sector

How Are Global Market Dynamics Influencing the Sourcing of Starter Relays?

The market for automotive components, including starter relays, is experiencing significant changes driven by technological advancements and evolving consumer demands. One notable trend is the increasing reliance on electronic systems in vehicles, which necessitates high-quality, reliable starter relays and solenoids. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate this landscape, they must pay close attention to quality assurance and supplier capabilities.

Emerging technologies, such as IoT and advanced manufacturing techniques, are reshaping the sourcing of starter relays. Suppliers are leveraging automation and predictive analytics to enhance production efficiency and reduce lead times, making it crucial for buyers to evaluate the technological prowess of potential suppliers. Additionally, the rise of e-commerce platforms has facilitated easier access to global suppliers, allowing buyers to compare options and negotiate better terms.

Furthermore, geopolitical factors and supply chain disruptions due to events like the COVID-19 pandemic have prompted buyers to diversify their sourcing strategies. This diversification can mitigate risks associated with single-source suppliers and improve supply chain resilience. In this context, B2B buyers should prioritize building relationships with multiple suppliers across different regions, ensuring a steady flow of quality components.

What Role Does Sustainability and Ethical Sourcing Play in the Starter Relay Market?

Sustainability is becoming a paramount concern for B2B buyers in the automotive sector. The environmental impact of sourcing practices, particularly in manufacturing starter relays, is under scrutiny as companies strive to meet regulatory requirements and consumer expectations for greener products. Buyers are increasingly seeking suppliers who adhere to sustainable practices, including the use of recycled materials and energy-efficient manufacturing processes.

Illustrative image related to how to know if your starter relay is bad

Ethical sourcing is equally critical, with a growing emphasis on transparency within supply chains. Buyers should prioritize suppliers who demonstrate a commitment to ethical labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can serve as indicators of a supplier’s dedication to sustainable practices.

By choosing to work with suppliers who prioritize sustainability and ethical sourcing, B2B buyers not only contribute to environmental protection but also enhance their own brand reputation. This can lead to improved customer loyalty and potentially open up new market opportunities, especially in regions where consumers are increasingly eco-conscious.

How Has the Starter Relay Market Evolved Over Time?

The evolution of the starter relay market reflects broader trends in automotive technology and consumer preferences. Initially, starter relays were simple electromagnetic switches designed to engage the starter motor with minimal complexity. However, as vehicles have become more advanced, so too have the components that support their operation.

In the last few decades, the shift towards electronic ignition systems has necessitated the development of more sophisticated starter relays capable of handling higher currents and providing enhanced reliability. This evolution has been driven by the need for improved vehicle performance, fuel efficiency, and compliance with emissions regulations. As a result, modern starter relays often incorporate smart technology that allows for better diagnostics and integration with vehicle control systems.

Illustrative image related to how to know if your starter relay is bad

This historical context is crucial for B2B buyers as they assess suppliers and products in today’s market. Understanding the technological advancements that have shaped starter relay design can inform purchasing decisions and help buyers identify suppliers that are at the forefront of innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of how to know if your starter relay is bad

-

1. How do I identify if my starter relay is malfunctioning?

To determine if your starter relay is faulty, listen for a single click sound when you attempt to start your vehicle. If the engine doesn’t turn over and you hear only a click, the relay may not be engaging properly. Additionally, check for intermittent starting issues—if your vehicle starts sometimes and not others, it could indicate a failing relay. Also, inspect for signs of electrical corrosion or damage to wiring, which can affect the relay’s performance. Testing with a multimeter can provide a definitive answer by measuring continuity and voltage. -

2. What signs indicate a bad starter solenoid?

Common signs of a faulty starter solenoid include the engine not starting at all, a single click sound from the engine compartment when turning the ignition, or the starter engaging without releasing when the key is turned. If you experience any of these symptoms, it’s essential to check the solenoid as it could lead to further damage to the starter motor. Intermittent starting can also be a sign of a bad solenoid, necessitating immediate inspection to prevent potential breakdowns. -

3. Are there specific tests I can perform to diagnose starter relay issues?

Yes, you can conduct several tests to diagnose starter relay issues. Start by checking for continuity using a multimeter; this will help confirm whether the relay is functioning. You can also swap the relay with a similar one in the fuse box to see if the problem resolves. Inspect the wiring for any corrosion or loose connections that might impede performance. If the relay fails to engage the starter after these tests, it likely needs replacement. -

4. What are the key factors to consider when sourcing starter relays internationally?

When sourcing starter relays internationally, consider factors such as the supplier’s reliability and reputation. Verify certifications and compliance with international quality standards to ensure product safety and reliability. Additionally, assess the supplier’s ability to provide customization options that meet your specific needs. Understanding logistics, including shipping times and costs, is crucial, as is evaluating payment terms and conditions to mitigate financial risks. -

5. How can I ensure the quality of starter relays from international suppliers?

To ensure quality, request samples from potential suppliers and perform thorough testing before placing large orders. Establish clear quality assurance protocols and consider third-party inspections to verify the manufacturing processes. Additionally, review the supplier’s track record and customer feedback to gauge their commitment to quality. Engaging in regular communication with the supplier can help address any concerns promptly and maintain product standards. -

6. What are typical minimum order quantities (MOQs) for starter relays?

Minimum order quantities (MOQs) for starter relays can vary widely based on the manufacturer and the specifics of the order. Generally, MOQs range from 100 to 1,000 units, but some suppliers may offer lower quantities for initial orders or samples. It’s advisable to negotiate MOQs based on your purchasing needs and to consider the potential for bulk discounts. Understanding the supplier’s production capabilities can also help in setting realistic expectations regarding order sizes. -

7. What payment terms should I negotiate with international suppliers?

When negotiating payment terms, aim for conditions that minimize risk while ensuring timely transactions. Common arrangements include partial payments upfront (e.g., 30-50%) with the remainder due upon delivery or after inspection. Consider using secure payment methods such as letters of credit or escrow services, which can provide additional protection. Clear documentation outlining terms is essential to prevent misunderstandings and ensure compliance from both parties. -

8. How can logistics impact my sourcing of starter relays?

Logistics plays a critical role in sourcing starter relays, affecting delivery times, costs, and overall supply chain efficiency. Factors such as shipping methods, customs regulations, and potential tariffs should be assessed to avoid delays and unexpected expenses. It’s advisable to collaborate with logistics partners who have experience in international shipping and can navigate complexities effectively. Establishing clear timelines and monitoring shipments closely can help ensure that your sourcing process remains on track and meets operational needs.

Top 3 How To Know If Your Starter Relay Is Bad Manufacturers & Suppliers List

1. Jeep – Patriot Starting Issue

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2008 Jeep Patriot; issue: car won’t start; symptoms: all lights and radio work, single click noise when attempting to start; potential problems: starter relay fuse or starter needing replacement.

2. Aliontimer – Essential Relay Solutions

Domain: aliontimer.com

Registered: 2016 (9 years)

Introduction: 1. Protection Relay – Critical Components of Electrical Power Grid 2. Floatless Relay – Automatic Water Supply and Drainage Control 3. Modular Timer Relay – Essential Part of Motor Control 4. Multifunction Timer Relay – Multi-range Timer Delay Relay

3. MGEXP – 30 Amp Starter Relay

Domain: mgexp.com

Registered: 2011 (14 years)

Introduction: Generic 30 amp starter relay, compatible with fog light or fan relay types. Can be cube-shaped with four spades usually marked 30, 87, 85, and 86. A common option is the 194 Signal-Stat relay rated at 40A. Available at local auto parts stores for $5-$6. Users recommend bringing the old relay for compatibility checks.

Strategic Sourcing Conclusion and Outlook for how to know if your starter relay is bad

As you assess the functionality of starter relays and solenoids, understanding the nuances of these components is crucial for effective decision-making in your sourcing strategy. Key indicators of a malfunctioning starter relay or solenoid include failure to start, unusual clicking sounds, and intermittent operation. Identifying these signs early can prevent costly downtimes and enhance the reliability of your fleet operations.

Strategic sourcing plays a vital role in ensuring that you acquire high-quality parts that meet industry standards. By partnering with reputable suppliers, you can ensure that your sourcing process is streamlined, cost-effective, and aligned with your operational needs. This is particularly important in regions like Africa, South America, the Middle East, and Europe, where diverse supply chain dynamics exist.

Looking ahead, prioritize building relationships with trusted suppliers who understand your specific requirements and can provide timely support. By doing so, you will not only enhance your operational efficiency but also position your business for sustainable growth in a competitive landscape. Take action today to evaluate your sourcing strategy and ensure your fleet remains operationally sound.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.