Introduction: Navigating the Global Market for how much to replace alternator

In today’s competitive automotive market, understanding the nuances of how much to replace an alternator can significantly impact your bottom line. For international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—navigating the complexities of sourcing, cost analysis, and supplier reliability is crucial. This guide offers an in-depth exploration of alternator replacement, addressing various types, applications, and the intricacies of pricing across different vehicle models.

As alternators play a pivotal role in a vehicle’s electrical system, ensuring their optimal performance is essential for safety and functionality. This comprehensive resource not only outlines the average costs associated with alternator replacement but also examines factors influencing these costs, including labor, parts, and regional variances. Furthermore, we delve into strategies for vetting suppliers, understanding warranty options, and making informed purchasing decisions that can lead to cost savings and enhanced operational efficiency.

By equipping B2B buyers with actionable insights and data-driven recommendations, this guide empowers organizations to make informed decisions in their procurement processes. Whether you’re looking to source reliable parts or negotiate better pricing, our expertise will help you navigate the global market effectively, ensuring your business remains competitive and well-equipped to meet customer demands.

Table Of Contents

- Top 2 How Much To Replace Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much to replace alternator

- Understanding how much to replace alternator Types and Variations

- Key Industrial Applications of how much to replace alternator

- 3 Common User Pain Points for ‘how much to replace alternator’ & Their Solutions

- Strategic Material Selection Guide for how much to replace alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how much to replace alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much to replace alternator’

- Comprehensive Cost and Pricing Analysis for how much to replace alternator Sourcing

- Alternatives Analysis: Comparing how much to replace alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how much to replace alternator

- Navigating Market Dynamics and Sourcing Trends in the how much to replace alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much to replace alternator

- Strategic Sourcing Conclusion and Outlook for how much to replace alternator

- Important Disclaimer & Terms of Use

Understanding how much to replace alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternator | Basic design, typically 12V output, used in most vehicles | General automotive maintenance | Pros: Cost-effective, widely available. Cons: Limited power for high-demand vehicles. |

| High-Output Alternator | Higher amp output, designed for vehicles with enhanced electrical needs | Performance vehicles, custom builds | Pros: Supports more electrical accessories. Cons: Higher cost and may require modifications. |

| Remanufactured Alternator | Rebuilt with new components, often with a warranty | Fleet operations, cost-sensitive buyers | Pros: Cost-effective, reliable. Cons: Quality can vary by manufacturer. |

| Diesel Alternator | Specifically designed for diesel engines, robust construction | Heavy-duty trucks, industrial machinery | Pros: Durable, high efficiency. Cons: Higher initial investment. |

| Digital Alternator | Advanced technology for better efficiency and performance | Electric vehicles, hybrid systems | Pros: Enhanced performance, energy-efficient. Cons: Higher complexity may require specialized service. |

What Are the Characteristics of a Standard Alternator?

The standard alternator is the most common type found in vehicles, typically providing a 12V output. It is designed to meet the basic electrical needs of most cars, making it a cost-effective choice for general automotive maintenance. B2B buyers should consider the vehicle’s electrical demands before opting for this type, as it may not support high-load applications. Despite its affordability, it may not be suitable for vehicles with extensive electronic accessories.

How Do High-Output Alternators Differ?

High-output alternators are engineered to deliver increased amperage, making them ideal for performance vehicles or those with numerous electrical components. They are often used in custom builds or modified vehicles where additional power is necessary. B2B buyers should evaluate their specific electrical requirements and consider the potential need for modifications, as these alternators can be more expensive than standard options.

What Benefits Do Remanufactured Alternators Offer?

Remanufactured alternators provide a cost-effective solution for businesses looking to maintain their fleets without overspending. These units are rebuilt using original equipment parts and often come with a warranty, ensuring reliability. However, B2B buyers should carefully assess the quality of the remanufacturer, as this can vary significantly between suppliers. This type is particularly advantageous for fleet operations where cost control is critical.

What Are the Key Features of Diesel Alternators?

Diesel alternators are specifically designed for heavy-duty applications, providing robust performance for trucks and industrial machinery. They are built to withstand the demands of diesel engines and often feature higher efficiency and durability. B2B buyers should consider the initial investment, as these alternators tend to be pricier, but the long-term reliability and performance benefits can justify the cost for businesses relying on heavy machinery.

How Do Digital Alternators Enhance Performance?

Digital alternators incorporate advanced technology for improved efficiency and performance, making them suitable for electric and hybrid vehicles. They provide precise voltage regulation and can adapt to the vehicle’s electrical demands dynamically. For B2B buyers, investing in digital alternators may lead to lower energy consumption and enhanced vehicle performance. However, their complexity may necessitate specialized servicing, which should be factored into the overall cost of ownership.

Key Industrial Applications of how much to replace alternator

| Industry/Sector | Specific Application of how much to replace alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Replacement for assembly line vehicles | Ensures operational efficiency and minimizes downtime | Supplier reliability, part compatibility, and cost-effectiveness |

| Transportation & Logistics | Fleet vehicle maintenance and repair | Reduces operational disruptions and enhances safety | Warranty terms, availability of parts, and service support |

| Construction Equipment | Alternator replacement in heavy machinery | Maintains productivity and reduces equipment failure | Quality of components, lead times, and local regulations |

| Renewable Energy | Alternator use in wind turbines | Optimizes energy conversion and reliability | Technical specifications, sourcing from certified manufacturers, and compliance with industry standards |

| Mining Operations | Alternators in mining vehicles and equipment | Ensures continuous operation in challenging environments | Durability of components, supplier expertise, and support services |

How is ‘how much to replace alternator’ applied in the Automotive Manufacturing sector?

In the automotive manufacturing sector, the cost of replacing an alternator is critical for maintaining assembly line vehicles. A malfunctioning alternator can halt production, leading to significant financial losses. Businesses in this sector must ensure they source reliable suppliers who provide compatible parts at competitive prices. Additionally, they should consider the warranty and support services offered, as these can significantly affect long-term operational efficiency.

What is the significance of alternator replacement in Transportation & Logistics?

In the transportation and logistics industry, fleet vehicle maintenance hinges on the timely replacement of alternators. A well-functioning alternator is essential for vehicle safety and performance. Companies must evaluate the total cost of ownership, including part replacement and labor, to minimize operational disruptions. Key sourcing considerations include the availability of parts and the reputation of suppliers, as these factors directly impact fleet reliability and safety.

How does alternator replacement affect Construction Equipment operations?

For construction equipment, the alternator is vital for powering machinery. A faulty alternator can lead to equipment failure, causing delays and increased costs. Businesses must prioritize sourcing high-quality components that can withstand harsh working conditions. Additionally, understanding local regulations and compliance requirements is crucial for international buyers in the construction sector, particularly in regions like Africa and South America.

Why is alternator replacement important in Renewable Energy?

In the renewable energy sector, particularly with wind turbines, the alternator plays a key role in energy conversion. Replacing an alternator ensures optimal performance and reliability, essential for maximizing energy output. Businesses should focus on sourcing from certified manufacturers to guarantee compliance with industry standards. Technical specifications and the ability to handle varying environmental conditions are also critical considerations for international buyers.

How does alternator replacement impact Mining Operations?

In mining operations, vehicles and equipment rely heavily on alternators for consistent power supply. The harsh environments can lead to frequent failures, necessitating timely replacements. Companies must consider the durability of components when sourcing alternators, as well as the expertise of suppliers in understanding the specific challenges faced in mining. Reliable support services are also crucial to minimize downtime and maintain productivity.

3 Common User Pain Points for ‘how much to replace alternator’ & Their Solutions

Scenario 1: Understanding the Cost Variability of Alternator Replacement in Different Markets

The Problem: B2B buyers often face significant challenges when attempting to understand the cost of alternator replacement across various markets. For instance, a buyer in Brazil may encounter higher parts costs due to import taxes and shipping fees, while a buyer in Saudi Arabia might benefit from lower local labor rates but face inflated part prices. This inconsistency can lead to confusion during budgeting and cost estimation, making it difficult to provide accurate quotes to clients or plan for maintenance effectively.

The Solution: To navigate these challenges, B2B buyers should conduct thorough market research to understand the local cost dynamics. This includes gathering data on local suppliers and comparing pricing for both parts and labor. Establishing relationships with multiple vendors can provide insights into competitive pricing and potential discounts for bulk purchases. Additionally, buyers should leverage online platforms to access price benchmarks and user reviews, which can aid in making informed decisions. Implementing a cost-analysis tool can also help in forecasting expenses based on historical data, thus enabling more accurate budget planning for alternator replacements across different regions.

Illustrative image related to how much to replace alternator

Scenario 2: Identifying Quality Parts Amidst Price Competition

The Problem: In the competitive automotive parts market, B2B buyers are often inundated with options ranging from OEM (Original Equipment Manufacturer) to aftermarket and rebuilt alternators, each with varying price points and quality. This abundance can create a dilemma: opting for cheaper parts to save costs might lead to poor performance and higher failure rates, while choosing premium parts could strain budgets. Such decisions not only affect immediate costs but can also impact long-term customer satisfaction and trust.

The Solution: To ensure quality without overspending, B2B buyers should prioritize establishing robust supplier relationships that emphasize quality assurance. Engaging with suppliers who offer warranties or guarantees on their products can provide peace of mind regarding their durability. Conducting a comparative analysis of parts based on performance reviews and user feedback can also help in selecting the right alternator. Additionally, buyers should consider investing in training programs for their teams to better understand the differences between OEM and aftermarket parts, empowering them to make informed purchasing decisions based on quality versus cost.

Scenario 3: Managing Customer Expectations During Replacement

The Problem: When dealing with alternator replacements, B2B buyers often face the challenge of managing customer expectations regarding costs and timelines. Clients may have unrealistic expectations based on general market prices or previous experiences, which can lead to dissatisfaction if actual costs exceed estimates or if there are delays in service. This issue is compounded in regions with limited access to parts, where delays can be frequent, leading to potential conflicts between buyers and their customers.

The Solution: To effectively manage customer expectations, clear communication is paramount. B2B buyers should develop detailed quotes that outline not only the parts and labor costs but also the potential for additional expenses related to unforeseen issues during replacement. Providing a timeline for the process, including potential delays due to parts availability, will help set realistic expectations. Additionally, establishing a proactive customer service approach, where regular updates are given throughout the replacement process, can enhance customer satisfaction. Offering alternative solutions, such as temporary fixes or rental equipment during downtime, can further demonstrate a commitment to customer service and reliability.

Strategic Material Selection Guide for how much to replace alternator

What Materials Are Commonly Used in Alternator Replacement?

When considering the replacement of alternators, the materials used in their construction significantly impact performance, durability, and overall cost. Here, we analyze four common materials: aluminum, steel, copper, and plastic composites.

How Does Aluminum Impact Alternator Performance?

Aluminum is frequently used in alternator housings due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C, making it suitable for automotive applications where heat dissipation is crucial. The primary advantage of aluminum is its strength-to-weight ratio, which enhances fuel efficiency by reducing overall vehicle weight.

However, aluminum can be more expensive than other materials, and its manufacturing process can be complex, requiring specialized techniques like die casting. For international buyers, particularly in regions like Europe and the Middle East, compliance with automotive standards such as DIN and ISO is essential to ensure quality and safety.

Illustrative image related to how much to replace alternator

What Role Does Steel Play in Alternator Construction?

Steel is another common material, particularly in the internal components of alternators, such as the rotor and stator. It offers high strength and durability, withstanding significant mechanical stress and temperature variations. Steel components can typically handle temperatures up to 200°C, making them suitable for high-performance vehicles.

The downside of steel is its susceptibility to corrosion unless treated or coated. This can lead to higher maintenance costs over time, especially in humid or corrosive environments, which are prevalent in parts of Africa and South America. Buyers in these regions should consider the cost of protective coatings or rust-resistant treatments.

Why Is Copper Essential for Alternator Functionality?

Copper is a critical material in alternators, primarily used in windings due to its excellent electrical conductivity. It allows for efficient energy transfer, which is vital for the alternator’s performance. Copper can withstand high temperatures, typically up to 250°C, making it ideal for electrical components.

However, copper is one of the more expensive materials, which can increase the overall cost of the alternator. Additionally, its weight can contribute to the vehicle’s overall mass, potentially impacting fuel efficiency. International buyers should be aware of fluctuating copper prices and consider sourcing options that may offer better cost stability.

Illustrative image related to how much to replace alternator

How Do Plastic Composites Enhance Alternator Design?

Plastic composites are increasingly being used in non-structural components of alternators, such as covers and insulators. These materials are lightweight and offer good electrical insulation properties, which can enhance the safety and efficiency of the alternator. They typically have a temperature rating of around 120°C, making them suitable for various automotive applications.

While plastic composites are generally less expensive and easier to manufacture, they may not provide the same level of durability as metals. In regions with extreme temperatures or harsh environmental conditions, the longevity of plastic components can be a concern. Buyers from regions like Saudi Arabia and Brazil should carefully evaluate the suitability of plastic materials for their specific applications.

Summary Table of Material Selection for Alternator Replacement

| Material | Typical Use Case for how much to replace alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings and structural components | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Steel | Rotor and stator components | High strength and durability | Susceptible to corrosion | Medium |

| Copper | Electrical windings | Excellent electrical conductivity | High cost and added weight | High |

| Plastic Composites | Covers and insulators | Lightweight and good insulation | Less durable in extreme conditions | Low |

This strategic material selection guide aims to provide international B2B buyers with insights into the materials used in alternator replacements, helping them make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how much to replace alternator

What Are the Main Stages of the Manufacturing Process for Alternators?

The manufacturing process for alternators involves several critical stages, each designed to ensure that the final product meets rigorous performance and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing alternators.

Material Preparation: What Raw Materials Are Used in Alternator Production?

The first step in manufacturing alternators is material preparation. High-grade materials are essential for ensuring durability and performance. Typically, manufacturers use:

- Steel and Copper: These materials are crucial for the stator and rotor components. Copper is used for winding, while steel forms the structural components.

- Insulation Materials: Insulation is vital for electrical components to prevent short circuits and ensure safety.

- Bearings and Bushings: These components reduce friction and wear, contributing to the longevity of the alternator.

Manufacturers often source these materials from reputable suppliers, ensuring they meet international quality standards. This is particularly important for B2B buyers who may require specific certifications.

How Is the Forming Process Conducted in Alternator Manufacturing?

After preparing the materials, manufacturers proceed with the forming process. This stage typically includes:

- Stator and Rotor Fabrication: The steel plates for the stator are stamped into shape, and copper wires are wound around them. The rotor is crafted by shaping the steel shaft and attaching the excitation windings.

- Assembly of Components: Once the individual components are ready, they are assembled. This involves fitting the rotor into the stator, attaching the voltage regulator, and installing the bearings.

Advanced techniques like automated winding machines and CNC machining are commonly employed to enhance precision and efficiency during this stage.

What Quality Control (QC) Measures Are in Place for Alternator Manufacturing?

Quality assurance is critical in alternator production, ensuring that each unit functions optimally and safely. International standards and industry-specific certifications guide these quality control measures.

Which International Standards Govern Alternator Quality?

One of the primary standards relevant to alternator manufacturing is ISO 9001, which outlines a framework for a quality management system. Compliance with ISO 9001 demonstrates a commitment to consistent quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE marking (indicating compliance with European safety standards) and API certifications (for automotive parts) are also significant. These certifications ensure that the alternators meet safety, health, and environmental protection standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control in alternator manufacturing typically involves several checkpoints:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet specified standards. This is crucial for preventing defects in the final product.

- In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are performed to catch any deviations from quality standards early on. This may include monitoring the accuracy of machining and assembly processes.

- Final Quality Control (FQC): Once the alternators are assembled, they undergo final testing to ensure functionality and performance. This includes electrical testing, load testing, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to ensure quality control. Buyers can:

- Schedule On-Site Audits: Visiting the manufacturing facility allows buyers to see the QC processes firsthand and assess the overall production environment.

- Request Documentation: Suppliers should provide detailed quality control reports, including results from IQC, IPQC, and FQC stages. Reviewing these documents helps buyers gauge the supplier’s commitment to quality.

How Important Are Third-Party Inspections in the QC Process?

Engaging third-party inspection services can further enhance confidence in supplier quality. These independent entities can conduct audits and tests, providing an unbiased assessment of the manufacturer’s quality assurance processes. This is particularly beneficial for buyers who may not have the resources to conduct comprehensive audits themselves.

Illustrative image related to how much to replace alternator

What Testing Methods Are Commonly Used in Alternator Quality Assurance?

Various testing methods are employed to ensure alternators meet quality and performance standards:

- Electrical Testing: This involves measuring the output voltage and current to ensure the alternator performs within specified ranges.

- Load Testing: Alternators are subjected to different loads to evaluate performance under realistic conditions. This helps identify potential issues before the product reaches the market.

- Durability Testing: Manufacturers may conduct tests that simulate long-term use to ensure the alternator can withstand the rigors of everyday operation.

How Do Quality Control Nuances Affect International B2B Buyers?

Understanding the nuances of quality control is crucial for international B2B buyers. Different regions may have varying standards and expectations regarding quality assurance. For example:

- Regulatory Compliance: Buyers in Europe may prioritize CE marking, while those in the Middle East might focus on compliance with local standards.

- Cultural Differences: Business practices related to quality assurance can vary significantly by region. Building relationships and understanding local expectations can facilitate smoother transactions.

By taking these factors into account, B2B buyers can make more informed decisions when sourcing alternators, ensuring they choose suppliers that adhere to stringent quality standards and practices.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much to replace alternator’

Introduction

This practical sourcing guide provides a step-by-step checklist for B2B buyers looking to procure services related to alternator replacement. Understanding the costs and components involved is essential for making informed decisions that can impact both operational efficiency and financial planning. By following this guide, buyers can ensure they select the right suppliers and services that align with their business needs.

Step 1: Assess Your Vehicle’s Requirements

Before engaging suppliers, determine the specific alternator type needed for your fleet. Different vehicles have unique specifications, including power requirements and compatibility. This initial assessment helps streamline your sourcing process and prevents miscommunication with potential suppliers.

Step 2: Research Market Prices

Investigate the current market prices for alternator replacement services and parts. Understanding the average costs—typically ranging from $350 to $900—will give you a baseline for negotiations. Keep in mind that prices can vary significantly based on vehicle type and location, so gather data from multiple regions if applicable.

Illustrative image related to how much to replace alternator

Step 3: Identify Qualified Suppliers

Compile a list of potential suppliers specializing in alternator replacement. Look for vendors with a proven track record and positive customer reviews. Consider factors such as:

– Experience: Suppliers with extensive industry knowledge are more likely to provide reliable services.

– Certifications: Verify any industry certifications or affiliations that indicate professionalism and adherence to quality standards.

Step 4: Evaluate Supplier Offerings

Examine the range of services each supplier offers, including parts availability and warranty terms. A supplier that provides both new and remanufactured alternators may offer more flexibility and cost savings. Additionally, consider any value-added services such as installation and diagnostics.

Step 5: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotes that itemize all costs associated with the alternator replacement. Look for transparency in pricing, including labor, parts, and any additional fees. This step is crucial for budget planning and ensures no hidden costs arise later in the process.

Step 6: Check References and Reviews

Before finalizing a supplier, check their references and read reviews from previous clients. This feedback can provide insights into the supplier’s reliability, quality of work, and customer service. Engage with other businesses in your industry to gather firsthand experiences and recommendations.

Illustrative image related to how much to replace alternator

Step 7: Negotiate Terms and Conditions

Finally, engage in negotiations with your selected supplier to discuss terms and conditions. This may include payment schedules, warranty agreements, and service timelines. Clear agreements can prevent misunderstandings and ensure both parties are aligned on expectations.

By following this checklist, B2B buyers can navigate the complexities of procuring alternator replacement services effectively, ensuring they make informed choices that contribute to the overall success of their operations.

Comprehensive Cost and Pricing Analysis for how much to replace alternator Sourcing

When considering the replacement of an alternator, B2B buyers must navigate a multifaceted cost structure that encompasses various components. Understanding these elements is crucial for informed sourcing decisions.

What Are the Key Cost Components Involved in Alternator Replacement?

-

Materials: The primary material cost involves the alternator itself, which can range from $100 to $700 depending on the vehicle type and alternator specifications. Rebuilt or remanufactured alternators may offer a more cost-effective alternative, typically priced lower than new units.

-

Labor: Labor costs can vary significantly based on the complexity of the installation and regional labor rates. In many markets, labor charges can add an additional $200 to $500 to the total replacement cost, particularly if performed by dealerships.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and administrative support. These costs are typically factored into the alternator’s price, influencing the overall cost structure.

-

Tooling: Initial tooling costs for specialized manufacturing processes can affect pricing. Suppliers may pass these costs onto buyers, particularly for custom or high-specification alternators.

-

Quality Control (QC): Ensuring that alternators meet specific performance standards incurs additional costs. Buyers should look for suppliers with robust QC processes, as this can impact long-term reliability and maintenance costs.

-

Logistics: Shipping and handling can significantly affect total costs, especially for international transactions. Import duties and freight costs must be considered, particularly for buyers in regions like Africa and South America.

-

Margin: Suppliers typically include a margin that reflects their operational costs and profit targets. Understanding the margin is essential for assessing whether a quote is competitive.

What Price Influencers Should Buyers Consider?

-

Volume/MOQ: Bulk purchases often lead to discounts. Understanding the minimum order quantities (MOQs) can help in negotiating better pricing, especially for fleet operations.

-

Specifications and Customization: Custom alternators designed for specific vehicles may incur additional costs. Buyers should clearly define their needs to avoid unexpected charges.

-

Materials Quality and Certifications: The use of high-quality materials and adherence to certifications (such as ISO standards) can influence pricing. Investing in certified components can enhance performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can significantly affect pricing. Established suppliers may offer better warranties and after-sales support, which can justify higher costs.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is critical for managing logistics costs. These terms dictate who bears the cost at different stages of shipping and can affect the total landed cost.

What Are the Best Buyer Tips for Cost-Efficiency in Alternator Replacement?

-

Negotiate: Engage in discussions with suppliers to negotiate better terms, especially for bulk purchases. Leveraging multiple quotes can help identify competitive pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase price, consider long-term maintenance costs, warranty coverage, and potential downtime due to alternator failure.

-

Understand Pricing Nuances for International Buyers: For buyers in regions like Saudi Arabia, Brazil, and others, be aware of local market conditions, potential tariffs, and the impact of currency fluctuations on pricing.

-

Seek Local Suppliers: Where possible, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall supply chain efficiency.

-

Assess Warranty and Support: Opt for suppliers that provide comprehensive warranties and support services. This can save costs in the event of a defective alternator.

Disclaimer for Indicative Prices

The pricing information provided is indicative and may vary based on market conditions, vehicle specifications, and supplier agreements. Always consult with multiple suppliers to obtain the most accurate and competitive quotes tailored to your specific needs.

Alternatives Analysis: Comparing how much to replace alternator With Other Solutions

Exploring Alternatives for Alternator Replacement: A Comprehensive Comparison

When faced with a faulty alternator, businesses often consider the option of replacing it outright. However, there are several alternative solutions available that may provide similar benefits at different costs and levels of complexity. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational needs and budgets.

| Comparison Aspect | How Much To Replace Alternator | Rebuilt Alternator | Battery Replacement |

|---|---|---|---|

| Performance | High; restores electrical functionality | High; comparable to new parts | Moderate; may not resolve all electrical issues |

| Cost | $350 – $900 | $100 – $250 | $100 – $300 |

| Ease of Implementation | Moderate; requires professional installation | Moderate; can be DIY or professional | Easy; often DIY-friendly |

| Maintenance | Standard; may require future checks | Standard; similar to new alternators | Low; typically straightforward upkeep |

| Best Use Case | When full functionality is required | Budget-conscious scenarios | When battery issues are suspected |

In-Depth Analysis of Alternatives

What Are the Benefits of Choosing a Rebuilt Alternator?

Opting for a rebuilt alternator can be a cost-effective solution. Rebuilt units are composed of original parts that have been refurbished, making them a reliable alternative to new units. They often come with warranties, providing additional peace of mind. However, one drawback is that the performance may not fully match that of a new alternator, particularly if the rebuild process did not replace all critical components. This option is ideal for businesses looking to balance cost and performance while maintaining reliability.

How Does Battery Replacement Compare?

In some cases, the issue may stem from a failing battery rather than the alternator itself. Replacing the battery is generally more straightforward and less expensive, making it an attractive option for businesses on a tight budget. However, if the alternator is indeed the root cause of electrical issues, merely replacing the battery will not resolve the underlying problem. This solution is best suited for businesses that suspect battery failure and want a quick fix without the need for extensive diagnostics.

Making the Right Choice for Your Business Needs

Choosing between replacing an alternator and considering alternatives requires a thorough assessment of your business’s specific situation. Factors such as the vehicle’s age, the frequency of use, and budget constraints should all play a role in your decision-making process. If reliability and performance are paramount, investing in a new alternator might be the best route. Conversely, if cost savings are a priority and the vehicle is not heavily relied upon, a rebuilt alternator or battery replacement could serve your needs adequately.

Ultimately, the right solution will depend on a careful evaluation of both the immediate needs and long-term operational goals of your business. By weighing these options, you can make a decision that not only addresses your current challenges but also supports your overall operational efficiency.

Essential Technical Properties and Trade Terminology for how much to replace alternator

What Are the Key Technical Properties of an Alternator Replacement?

When considering the replacement of an alternator, several critical specifications should be evaluated to ensure compatibility and performance. Here are the essential properties to consider:

-

Voltage Output

The standard voltage output for a modern alternator ranges between 13.8 to 14.6 volts. This specification is crucial as it directly affects the charging efficiency of the vehicle’s battery and the performance of electrical systems. A consistent voltage output ensures that all electrical components, from lights to infotainment systems, function correctly. For B2B buyers, understanding voltage output can prevent costly electrical failures. -

Amp Rating

The amp rating indicates the electrical current the alternator can produce. Alternators typically range from 60 to 220 amps. Higher amp ratings are essential for vehicles equipped with numerous electronic devices or heavy-duty applications. For businesses involved in vehicle maintenance or parts distribution, knowing the appropriate amp rating helps in selecting the right alternator for diverse vehicle models. -

Material Grade

The construction materials of an alternator, such as the rotor and stator, impact its durability and efficiency. Common materials include copper for windings and high-grade steel for the casing. B2B buyers should prioritize alternators made from high-quality materials to ensure longevity and minimize the frequency of replacements, which can affect operational costs. -

Compatibility and Fitment

Ensuring that an alternator is compatible with specific vehicle models is critical. This involves checking dimensions, mounting points, and electrical connections. Understanding these specifications is vital for businesses that offer vehicle repair services, as it reduces the risk of returns and enhances customer satisfaction. -

Warranty Period

A robust warranty indicates the manufacturer’s confidence in their product. Warranties typically range from one year to a lifetime, depending on the brand and model. For B2B buyers, evaluating the warranty can provide insights into the quality and reliability of the alternator, influencing purchasing decisions.

What Common Trade Terms Should B2B Buyers Know When Replacing an Alternator?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms related to alternator replacement:

Illustrative image related to how much to replace alternator

-

OEM (Original Equipment Manufacturer)

OEM parts are produced by the vehicle’s manufacturer or a designated supplier. These components are designed to meet specific performance standards. For businesses, sourcing OEM alternators ensures compatibility and reliability, which can enhance service offerings. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to manage inventory levels effectively and minimize excess stock, especially when dealing with alternator replacements. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. When planning to replace alternators, submitting an RFQ can help buyers compare costs and terms from different suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

Incoterms are a series of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is vital for B2B transactions involving alternators, as they dictate costs, risks, and logistics responsibilities across borders. -

Remanufactured Alternator

This term refers to alternators that have been restored to working condition using a combination of reused and new parts. Remanufactured alternators can be a cost-effective alternative, and understanding this option can help businesses offer more budget-friendly solutions to their customers. -

Aftermarket Parts

Aftermarket parts are components made by companies other than the OEM. These parts can vary in quality and price, and familiarity with aftermarket options allows businesses to cater to a wider range of customer needs and budgets when replacing alternators.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ultimately leading to better procurement strategies and customer satisfaction in the automotive sector.

Navigating Market Dynamics and Sourcing Trends in the how much to replace alternator Sector

What Are the Key Drivers Influencing the Alternator Replacement Market?

The global alternator replacement market is experiencing dynamic shifts driven by several key factors. Increased vehicle production, particularly in emerging markets like Brazil and Saudi Arabia, is amplifying demand for alternators. Additionally, the rising awareness of vehicle maintenance and safety standards is prompting B2B buyers to prioritize timely alternator replacements to avoid costly repairs associated with electrical failures.

In terms of technology, the growing trend toward electric and hybrid vehicles is reshaping the alternator landscape. These vehicles often require more sophisticated alternators that can handle higher electrical loads. As a result, suppliers must adapt their offerings to include advanced alternator types that meet these new demands, creating opportunities for B2B buyers to invest in high-quality, reliable products.

Another emerging trend is the rise of digital platforms for sourcing auto parts, allowing international buyers to compare prices, quality, and supplier reputations more effectively. This trend is particularly relevant in regions like Africa and the Middle East, where access to reliable parts can be challenging. By leveraging these digital tools, buyers can enhance their procurement strategies, making informed decisions that align with their operational needs.

How Is Sustainability Shaping Sourcing Practices in the Alternator Market?

The focus on sustainability is becoming increasingly important in the alternator replacement sector. B2B buyers are now more aware of the environmental impacts of their sourcing decisions, including the carbon footprint associated with manufacturing and transporting auto parts. This has led to a demand for suppliers who prioritize sustainable practices, such as using recycled materials and reducing waste in production processes.

Ethical sourcing is also gaining traction, with businesses seeking suppliers who adhere to fair labor practices and responsible sourcing of raw materials. Certifications like ISO 14001 for environmental management and ISO 26000 for social responsibility are becoming critical factors for B2B buyers when evaluating potential suppliers. By choosing suppliers with these certifications, companies can align their sourcing practices with corporate social responsibility goals, fostering a positive brand image and customer loyalty.

Moreover, the push for “green” technologies, including energy-efficient alternators, is prompting suppliers to innovate. Buyers should consider seeking out products that not only meet performance requirements but also contribute to overall environmental goals. This shift towards sustainable and ethical sourcing is not just a trend but a strategic move that can enhance long-term viability in the competitive automotive parts market.

What Is the Historical Context of Alternator Development for B2B Buyers?

The development of alternators has evolved significantly over the decades, shaped by advancements in automotive technology and changing consumer needs. Initially, vehicles were equipped with generators that provided insufficient power for the growing number of electrical components. The introduction of the alternator in the 1960s marked a pivotal shift, allowing for more efficient energy conversion and improved reliability.

Illustrative image related to how much to replace alternator

As vehicles became more complex, the demand for higher-capacity alternators grew. Modern alternators are designed to support a wide array of electrical systems, from infotainment units to advanced safety features. This evolution is particularly relevant for B2B buyers who must stay informed about the latest advancements and specifications in alternators to ensure compatibility with contemporary vehicle models.

Understanding this historical context not only provides insight into the functionality of alternators but also highlights the importance of selecting the right supplier who can offer products that meet current and future automotive needs. By partnering with manufacturers that are aligned with technological advancements, B2B buyers can ensure they are sourcing high-quality alternators that enhance vehicle performance and reliability.

Frequently Asked Questions (FAQs) for B2B Buyers of how much to replace alternator

-

How can I determine the cost of replacing an alternator for my fleet?

To estimate the cost of replacing alternators for your fleet, consider factors such as the type of vehicles, the specific alternator models required, and the supplier pricing. Generally, parts range from $100 to $700, depending on vehicle specifications. Additionally, factor in labor costs, which can vary by region and service provider. Obtaining quotes from multiple suppliers can help in budgeting effectively and identifying competitive pricing options. -

What should I look for when sourcing alternators from international suppliers?

When sourcing alternators internationally, prioritize suppliers with a strong reputation, verified certifications, and a history of reliability. Check for quality assurance processes and inquire about warranties. Additionally, assess their capacity for fulfilling large orders and their compliance with international shipping regulations. Establish communication to ensure they can meet your specific requirements, including customization options and delivery timelines. -

What are the common payment terms for purchasing alternators in bulk?

Payment terms can vary widely among suppliers, but common options include upfront payments, net 30/60 terms, and letters of credit for larger transactions. It’s essential to negotiate terms that align with your cash flow and operational needs. Ensure you understand any potential fees associated with currency exchange, international transactions, or payment processing, especially when dealing with suppliers from different regions. -

How can I ensure the quality of alternators from overseas suppliers?

To ensure quality, request samples before placing large orders, and conduct thorough inspections upon receipt. Verify that the suppliers adhere to international quality standards, such as ISO certifications. Consider implementing a quality assurance (QA) process that includes regular audits of the supplier’s production and testing practices. Additionally, establishing a strong relationship with your supplier can enhance transparency regarding quality control measures. -

What are the logistics considerations when importing alternators?

Logistics for importing alternators involve several key considerations, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling automotive parts to streamline the process. Be aware of any import duties, taxes, and compliance with local regulations in your country. Planning for potential delays and ensuring proper documentation will help avoid disruptions in your supply chain. -

What are the minimum order quantities (MOQs) for alternators?

Minimum order quantities (MOQs) can vary significantly among suppliers based on their production capabilities and inventory policies. Some manufacturers may require MOQs of 50 units or more, while others might be more flexible, especially for new customers. When negotiating with suppliers, communicate your needs clearly and explore options for smaller trial orders to assess quality before committing to larger quantities. -

Can I customize alternators for specific vehicle models?

Yes, many suppliers offer customization options for alternators to fit specific vehicle models or performance requirements. This may include modifications to amp ratings, voltage outputs, or physical dimensions. When discussing customization, provide detailed specifications and any unique requirements your vehicles may have. Ensure that the supplier has the capability and experience to deliver the customized alternators within your desired timeframe. -

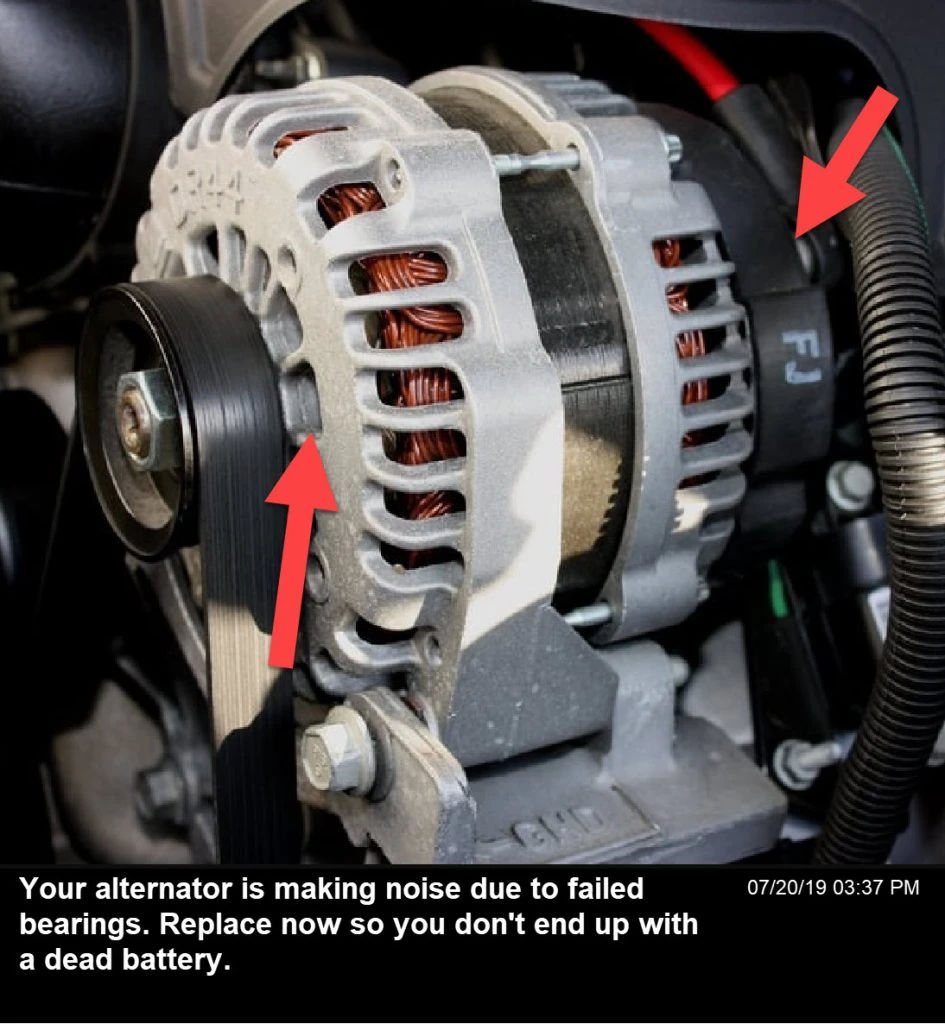

What are the signs that I need to replace an alternator in my fleet vehicles?

Common signs that indicate an alternator may need replacement include dimming headlights, electrical issues, or warning lights on the dashboard. Additionally, if vehicles frequently experience difficulty starting or show signs of battery failure, it may be time to inspect the alternators. Regular maintenance checks and diagnostics can help identify potential issues early, reducing downtime and ensuring the reliability of your fleet operations.

Top 2 How Much To Replace Alternator Manufacturers & Suppliers List

1. JD Power – Alternator Replacement Costs

Domain: jdpower.com

Registered: 1995 (30 years)

Introduction: Alternator replacement costs range from $350 to $900, with average parts costing $100 to $350, and luxury models costing $500 to $700. Labor costs can add $350 to $500 if performed by a dealership. Rebuilt alternators are available and should have the same or higher amp rating as the original. DIY installation can save on labor costs, though it requires some skill and time.

2. CarTalk – Alternator Replacement Costs

Domain: cartalk.com

Registered: 1995 (30 years)

Introduction: The cost to replace an alternator ranges from $600 to $1,500. An alternator is a critical component that converts mechanical energy into electrical energy, powering the engine, lights, and charging the battery. Signs of a failing alternator include a check engine light, dimming headlights, and the need for jump starts. Alternators can fail due to mechanical wear or electrical component failure. Ne…

Strategic Sourcing Conclusion and Outlook for how much to replace alternator

In the realm of automotive maintenance, understanding the intricacies of alternator replacement is vital for B2B buyers. The cost of replacing an alternator can range significantly based on vehicle type, with average expenses falling between $350 to $900, and potentially exceeding $1,000 for luxury models. Strategic sourcing of alternators—whether opting for OEM, aftermarket, or remanufactured units—can lead to substantial cost savings and ensure reliability in vehicle performance.

Key considerations include the longevity of the alternator, typically lasting between 7 to 10 years, and the importance of regular maintenance checks to avoid unexpected breakdowns. International buyers should prioritize sourcing high-quality parts that align with local market demands, ensuring compatibility and performance standards are met.

As the automotive landscape evolves, so does the opportunity for strategic partnerships in sourcing. By establishing strong relationships with reliable suppliers and understanding regional market dynamics, B2B buyers can enhance operational efficiency and reduce total ownership costs. Embrace this opportunity to optimize your procurement strategies and secure your position in the competitive automotive industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how much to replace alternator