Introduction: Navigating the Global Market for gear drive starter

In the rapidly evolving landscape of industrial machinery, sourcing a reliable gear drive starter can present significant challenges for international B2B buyers. Whether you are operating in the demanding environments of Africa, South America, the Middle East, or Europe, understanding the nuances of gear drive starters is essential for optimizing performance and ensuring operational efficiency. This guide serves as a comprehensive resource, exploring various types of gear drive starters, their applications across different sectors, and the key factors to consider during the supplier vetting process.

Throughout this guide, we will delve into critical aspects such as cost variations, performance metrics, and the latest technological advancements in gear drive starters. By equipping yourself with this knowledge, you can make informed purchasing decisions that align with your specific operational needs and budget constraints.

For B2B buyers in emerging markets like Brazil and Nigeria, where access to high-quality components can be limited, this guide will help you navigate the complexities of sourcing gear drive starters. It empowers you to identify trustworthy suppliers, evaluate product specifications, and ultimately select the right equipment that enhances your machinery’s performance. With the insights provided herein, you will be better positioned to secure durable, efficient, and cost-effective gear drive starters that meet your business objectives.

Table Of Contents

- Top 4 Gear Drive Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for gear drive starter

- Understanding gear drive starter Types and Variations

- Key Industrial Applications of gear drive starter

- 3 Common User Pain Points for ‘gear drive starter’ & Their Solutions

- Strategic Material Selection Guide for gear drive starter

- In-depth Look: Manufacturing Processes and Quality Assurance for gear drive starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘gear drive starter’

- Comprehensive Cost and Pricing Analysis for gear drive starter Sourcing

- Alternatives Analysis: Comparing gear drive starter With Other Solutions

- Essential Technical Properties and Trade Terminology for gear drive starter

- Navigating Market Dynamics and Sourcing Trends in the gear drive starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of gear drive starter

- Strategic Sourcing Conclusion and Outlook for gear drive starter

- Important Disclaimer & Terms of Use

Understanding gear drive starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gear Reduction Starter | Utilizes smaller, high-speed motors with a 4:1 ratio | Automotive, Heavy Machinery, Agricultural Equipment | Pros: Higher torque, compact size, efficiency. Cons: Generally more expensive; may require specialized parts. |

| Direct Drive Starter | Large, low-speed motor operating at a 1:1 ratio | Heavy-Duty Diesel Engines, Older Vehicles | Pros: Lower cost, simpler design. Cons: Heavier, less efficient compared to gear reduction. |

| Planetary Gear Starter | Employs planetary gears for compact design | Racing Vehicles, Performance Applications | Pros: Lightweight, high torque in small size. Cons: Complex design may lead to higher failure rates. |

| Spur Gear Starter | Uses spur gears with a direct connection | Industrial Equipment, Construction Machinery | Pros: Cost-effective and reliable. Cons: Bulkier, less torque compared to gear reduction starters. |

| High-Performance Starter | Designed for extreme conditions and high demands | Motorsports, Heavy-Duty Applications | Pros: Optimized for maximum power and durability. Cons: High initial investment, may require frequent maintenance. |

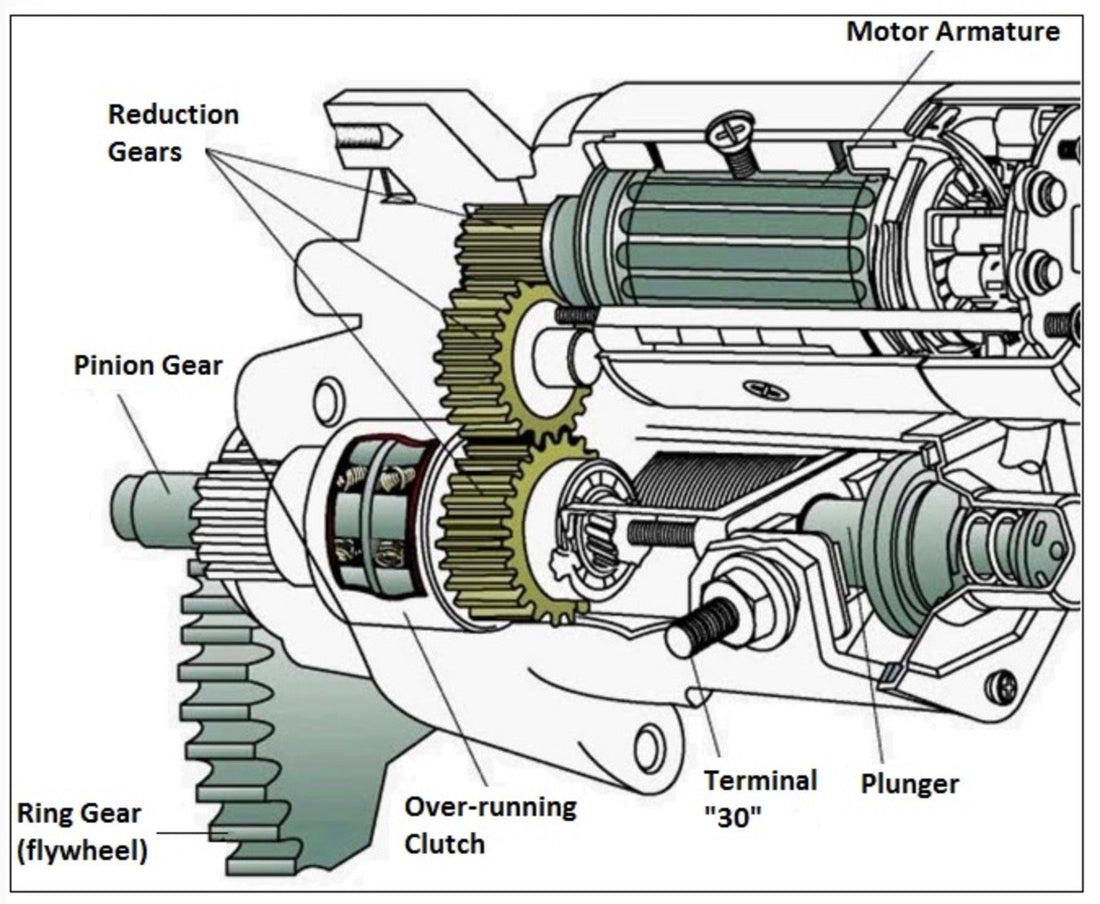

What Are Gear Reduction Starters and Their Applications?

Gear reduction starters are designed with smaller, high-speed motors that operate at a 4:1 gear ratio, allowing them to generate higher torque while consuming less power. This makes them ideal for applications in automotive, heavy machinery, and agricultural equipment, particularly where weight and space are critical. When considering a purchase, B2B buyers should evaluate the specific torque requirements and installation space, as well as the availability of replacement parts, which may vary by manufacturer.

How Do Direct Drive Starters Compare?

Direct drive starters feature a large, low-speed motor that drives the pinion gear in a 1:1 ratio. They are typically less expensive and simpler in design, making them suitable for heavy-duty diesel engines and older vehicles. However, their bulkier design and lower efficiency compared to gear reduction starters might deter buyers who prioritize performance. Buyers should weigh the cost savings against potential long-term efficiency losses when deciding on direct drive options.

What Are the Benefits of Planetary Gear Starters?

Planetary gear starters utilize a compact design that incorporates planetary gears, making them lightweight and capable of delivering high torque. They are often used in racing vehicles and performance applications where space and weight are at a premium. However, their complexity may lead to higher failure rates, so B2B buyers should consider the reliability of the manufacturer and the availability of service support when investing in these starters.

Why Choose Spur Gear Starters?

Spur gear starters are known for their straightforward design, making them a cost-effective choice for industrial and construction machinery. While they may not provide the same torque output as gear reduction starters, their reliability and ease of maintenance make them appealing for many businesses. Buyers should assess the balance between initial costs and long-term operational efficiency when selecting spur gear starters for their equipment.

What Should Buyers Know About High-Performance Starters?

High-performance starters are engineered to meet the demands of extreme conditions in motorsports and heavy-duty applications. They are optimized for maximum power and durability, but this often comes with a higher initial investment and the potential for more frequent maintenance. B2B buyers must evaluate the specific performance needs of their operations against the costs and maintenance requirements associated with these advanced starters, ensuring they make an informed decision that aligns with their operational goals.

Key Industrial Applications of gear drive starter

| Industry/Sector | Specific Application of gear drive starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Starter motors for passenger vehicles | Enhanced efficiency and torque, especially in cold weather conditions | Compatibility with vehicle models, voltage ratings, and torque specs |

| Agricultural Machinery | Tractors and heavy equipment starting systems | Improved starting reliability and reduced power consumption | Durability, resistance to environmental factors, and service support |

| Marine | Engine starting for boats and vessels | Compact design reduces weight, essential for space-constrained areas | Corrosion resistance, power requirements, and certification standards |

| Construction Equipment | Heavy machinery like excavators and bulldozers | Increased torque for reliable starts under heavy loads | Sourcing from reputable manufacturers and availability of spare parts |

| Renewable Energy | Wind turbine systems | Efficient motor performance leads to better energy capture | Specifications for environmental conditions and maintenance support |

How is the gear drive starter utilized in the automotive industry?

In the automotive sector, gear drive starters are critical for powering passenger vehicles, particularly in regions with extreme weather conditions. These starters utilize a gear reduction mechanism, allowing smaller, high-speed motors to produce significant torque while consuming less power. This efficiency is especially beneficial for cold-starting engines, where traditional starters may struggle. Buyers must consider compatibility with specific vehicle models, voltage ratings, and torque specifications to ensure optimal performance.

What role do gear drive starters play in agricultural machinery?

In agricultural applications, gear drive starters are employed in tractors and other heavy equipment, providing reliable engine starting capabilities. The gear reduction technology minimizes the current draw, allowing for more efficient operation, which is crucial during peak farming seasons when machinery is heavily relied upon. Buyers in this sector should prioritize durability against harsh environmental conditions, as well as ease of installation and maintenance, to ensure uninterrupted operation in the field.

How are gear drive starters beneficial for marine applications?

Marine engines benefit significantly from gear drive starters, which are designed to start boats and vessels efficiently. The compact design of these starters is essential for marine environments where space is at a premium. Additionally, their lightweight nature contributes to overall vessel performance. Buyers should focus on sourcing starters that are corrosion-resistant and comply with maritime standards to ensure reliability in harsh marine conditions.

Why are gear drive starters essential for construction equipment?

In the construction industry, gear drive starters are vital for heavy machinery like excavators and bulldozers. The higher torque output of gear reduction starters allows for reliable engine starts, even under heavy loads, which is critical for construction operations. When sourcing starters, businesses should consider the reputation of manufacturers, the availability of spare parts, and the ability to withstand the demanding conditions often found on construction sites.

How do gear drive starters contribute to renewable energy systems?

In renewable energy, particularly in wind turbine systems, gear drive starters are employed to initiate the turbine’s operation. Their efficient performance enhances energy capture, making them a valuable component in sustainable energy solutions. Buyers in this sector should ensure that starters meet specific environmental conditions and maintenance requirements, as well as adhere to industry certifications, to maintain optimal functionality and longevity.

3 Common User Pain Points for ‘gear drive starter’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Gear Drive Starters

The Problem: B2B buyers, especially those operating in regions with limited access to high-quality automotive parts, often struggle to find reliable gear drive starters. This challenge can lead to costly downtime, as unreliable products can result in frequent failures and the need for replacements. Buyers may face pressure from clients or internal stakeholders to minimize costs, but opting for cheaper, lower-quality products can compound issues, leading to a cycle of inefficiency and frustration.

The Solution: To effectively source reliable gear drive starters, buyers should prioritize partnerships with reputable suppliers who offer proven products and strong warranties. Conduct thorough research to identify manufacturers with a solid track record in the industry, particularly those that provide detailed specifications and performance data. Leveraging online platforms and industry forums can help gauge the reputation of suppliers based on peer reviews and experiences. Additionally, consider utilizing a mix of OEM and high-quality aftermarket parts to balance cost and reliability. Establishing long-term relationships with suppliers can also facilitate better support and access to exclusive products that meet specific operational needs.

Scenario 2: Incompatibility with Existing Equipment

The Problem: Another prevalent issue is the incompatibility of gear drive starters with existing machinery or vehicles. Buyers may find that the starter they purchase does not fit the specifications of their engines, leading to installation challenges and additional costs. This situation is particularly common when dealing with older models or specialized equipment, where specifications can vary significantly from standard offerings.

The Solution: To avoid compatibility issues, buyers should invest time in understanding the specific requirements of their equipment before making a purchase. This includes reviewing the manufacturer’s documentation for detailed specifications such as voltage, power rating, and rotation direction. Creating a comprehensive list of required features can help streamline the selection process. Furthermore, engaging directly with suppliers to discuss compatibility can provide insights into potential alternatives or modifications. Utilizing custom solutions, such as adapters or specialized mounts, can also be beneficial when standard parts do not fit.

Scenario 3: Performance Under Extreme Conditions

The Problem: Many B2B buyers operate in regions where extreme weather conditions can significantly affect the performance of gear drive starters. For example, in colder climates, traditional starters may struggle to provide sufficient power, leading to starting failures. This can be particularly problematic for businesses that rely on consistent operation, such as those in agriculture or construction, where equipment downtime can translate into lost revenue.

The Solution: To enhance performance in extreme conditions, buyers should consider gear drive starters specifically designed for high-torque applications and cold weather operation. Look for models that feature robust construction and higher power ratings, as these will typically perform better under load. Additionally, investing in regular maintenance checks can help ensure that all components, including batteries and electrical systems, are in optimal condition. Collaborating with suppliers to identify starters with advanced features, such as improved insulation and weatherproofing, can also mitigate performance issues. Finally, educating end-users on the importance of pre-heating engines in colder conditions can further improve starting reliability.

Strategic Material Selection Guide for gear drive starter

What Are the Key Materials Used in Gear Drive Starters?

When selecting materials for gear drive starters, it is essential to consider factors such as performance, durability, cost, and regional compliance. The following analysis explores four common materials used in gear drive starters: aluminum, steel, plastic composites, and copper.

How Does Aluminum Perform in Gear Drive Starters?

Aluminum is a lightweight and corrosion-resistant material that is often used in the construction of gear drive starters. Its key properties include a high strength-to-weight ratio and good thermal conductivity, making it suitable for applications where weight savings are critical.

Pros: Aluminum is highly resistant to corrosion, which is particularly advantageous in humid or coastal environments. Its lightweight nature reduces the overall weight of the starter, enhancing vehicle efficiency.

Cons: While aluminum is durable, it can be more expensive than other materials like steel. Additionally, its manufacturing complexity can increase production costs, especially in regions with less advanced manufacturing capabilities.

Impact on Application: Aluminum’s corrosion resistance makes it ideal for applications in harsh environments, such as those found in Africa and South America. However, buyers should ensure compliance with regional standards, such as ASTM or DIN, to guarantee material quality.

Why Choose Steel for Gear Drive Starters?

Steel is another common material for gear drive starters, known for its strength and durability. It typically has a higher temperature and pressure rating compared to aluminum.

Pros: Steel components are robust and can withstand high torque and stress, making them suitable for heavy-duty applications. They are also generally more cost-effective than aluminum.

Cons: The primary drawback of steel is its susceptibility to corrosion, which can lead to premature failure if not properly treated. Moreover, the heavier weight of steel components can negatively impact overall vehicle efficiency.

Impact on Application: Steel is widely accepted in various international markets, including Europe and the Middle East, where compliance with standards like JIS is crucial. Buyers should consider the need for protective coatings to enhance corrosion resistance.

What Role Do Plastic Composites Play in Gear Drive Starters?

Plastic composites are increasingly used in gear drive starters due to their lightweight and versatility. These materials often combine polymers with reinforcing fibers for enhanced strength.

Pros: Plastic composites are resistant to corrosion and can be molded into complex shapes, reducing manufacturing complexity. They are also lighter than both aluminum and steel, contributing to improved vehicle efficiency.

Cons: The main limitation of plastic composites is their lower temperature tolerance compared to metals, which may restrict their application in high-heat environments. Additionally, they can be more expensive than traditional materials.

Illustrative image related to gear drive starter

Impact on Application: In regions with lower manufacturing capabilities, such as parts of Africa, the cost of advanced composites may be a barrier. However, their lightweight properties make them attractive for applications where efficiency is paramount.

How Does Copper Contribute to Gear Drive Starters?

Copper is primarily used in electrical components of gear drive starters, such as windings and connectors, due to its excellent electrical conductivity.

Pros: Copper provides superior conductivity, which enhances the starter’s performance and efficiency. It is also resistant to corrosion, particularly when alloyed with other materials.

Cons: The primary drawback of copper is its high cost compared to other materials. Additionally, its weight can be a concern in applications where minimizing weight is critical.

Impact on Application: In international markets, the cost of copper can be a significant factor for buyers, particularly in regions like Brazil and Nigeria, where budget constraints may limit options. Compliance with electrical standards is also essential.

Summary Table of Material Selection for Gear Drive Starters

| Material | Typical Use Case for gear drive starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight starters for efficiency | Corrosion resistance | Higher cost and manufacturing complexity | Medium |

| Steel | Heavy-duty applications | Robust and cost-effective | Susceptible to corrosion | Low |

| Plastic Composites | Lightweight, complex designs | Molding flexibility and corrosion resistance | Lower temperature tolerance | High |

| Copper | Electrical components | Superior electrical conductivity | High cost and weight | High |

This guide provides actionable insights into material selection for gear drive starters, helping B2B buyers make informed decisions tailored to their specific regional needs and applications.

In-depth Look: Manufacturing Processes and Quality Assurance for gear drive starter

What Are the Key Stages in the Manufacturing Process of Gear Drive Starters?

The manufacturing process of gear drive starters involves several critical stages that ensure the final product meets performance and durability standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The foundation of a high-quality gear drive starter begins with the selection of raw materials. Typically, manufacturers utilize high-grade steel for the housing and gears due to its strength and durability. Components such as the armature and pinion gears are often made from materials that can withstand high torque and wear, such as nickel-chromium alloy steel. Advanced techniques like heat treatment may be applied to enhance the hardness and fatigue resistance of these materials.

-

Forming: This stage involves shaping the raw materials into the necessary components. Common techniques include forging, casting, and machining. For instance, the pinion gear may be forged to create a strong and lightweight component, while the housing is typically cast to achieve complex shapes with a high level of precision. CNC (Computer Numerical Control) machining is often employed to ensure that each part meets exact specifications, reducing tolerances and improving fit.

-

Assembly: Once individual components are formed, they proceed to the assembly stage. This process is critical, as the alignment and integration of gears, motors, and electrical components directly affect the starter’s performance. Automated assembly lines are increasingly common, allowing for rapid and precise assembly. Skilled technicians often oversee this process to ensure that each component is correctly fitted and secured.

-

Finishing: The final stage involves surface treatments to enhance durability and resistance to environmental factors. Techniques such as powder coating, anodizing, or plating are used to protect against corrosion and wear. Additionally, quality checks during this stage ensure that the finish does not compromise the performance characteristics of the starter.

How Is Quality Assurance Integrated into Gear Drive Starter Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process for gear drive starters, ensuring that each unit adheres to international standards and industry-specific regulations.

-

International Standards Compliance: Manufacturers typically align their QA processes with international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards assures B2B buyers of consistent quality and reliability in products. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the application of the gear drive starters.

-

Quality Control Checkpoints: Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival. Materials are tested for mechanical properties and compliance with specifications.

– In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to ensure that processes are within defined limits. This includes monitoring machining tolerances and assembly alignment.

– Final Quality Control (FQC): Before products are shipped, they undergo rigorous testing to verify functionality and performance. This may include load testing, electrical testing, and durability assessments. -

Common Testing Methods: Various testing methods are employed to ensure the reliability of gear drive starters. These may include:

– Torque Testing: Evaluating the starter’s ability to deliver the specified torque.

– Vibration Testing: Ensuring that the starter can withstand operational vibrations without failure.

– Thermal Cycling Tests: Assessing performance under extreme temperature variations to simulate real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

Illustrative image related to gear drive starter

-

Conducting Audits: Buyers can request to conduct on-site audits of the manufacturing facilities. This allows them to evaluate the supplier’s QA processes, equipment, and overall production environment. During these audits, buyers should focus on the adherence to international standards, the condition of machinery, and the qualifications of the workforce.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports that outline their testing methodologies, results, and compliance with relevant standards. Regularly updated reports can also indicate ongoing commitment to quality.

-

Third-Party Inspections: Engaging a third-party inspection agency can provide an unbiased assessment of the supplier’s quality control processes. These agencies can conduct inspections at various stages of the manufacturing process and provide comprehensive reports on compliance and quality.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing gear drive starters from international suppliers, B2B buyers must be aware of several quality control nuances:

-

Regulatory Compliance: Different regions have specific regulatory requirements. For example, products exported to Europe must comply with CE marking regulations, while products intended for the U.S. market may need to meet specific ANSI (American National Standards Institute) standards. Buyers should verify that suppliers understand and comply with these regulations.

-

Cultural and Regional Differences: Quality expectations may vary across regions. Buyers from Europe may have different quality standards compared to those in Africa or South America. Understanding these cultural nuances can aid in setting appropriate expectations and ensuring that suppliers meet the necessary quality standards.

-

Communication and Transparency: Effective communication with suppliers is essential. Buyers should establish clear lines of communication regarding quality expectations, testing protocols, and reporting requirements. Transparency in these areas can foster trust and ensure that quality remains a priority throughout the supply chain.

By understanding the manufacturing processes and quality assurance measures associated with gear drive starters, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only helps in identifying reliable partners but also ensures that the products procured meet the required performance and durability standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gear drive starter’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to procure gear drive starters. With the increasing demand for efficient and reliable starter motors in various applications, understanding the nuances of sourcing gear drive starters can significantly impact operational efficiency and cost-effectiveness. This checklist will guide you through the essential steps to ensure you select the right product and supplier for your needs.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. This includes the voltage (e.g., 12V), power rating (e.g., 1.4kw or 2.0kw), and rotation direction (left or right). Defining these parameters will help streamline the procurement process and ensure compatibility with your machinery.

- Consider application-specific needs: Different applications may require specific torque and efficiency levels.

- Evaluate environmental factors: If your equipment operates in extreme conditions, ensure the starter can perform reliably under such circumstances.

Step 2: Research Available Options

Conduct thorough research to identify various gear drive starter models available in the market. Compare features, price ranges, and specifications among different brands and models to find the best fit for your requirements.

Illustrative image related to gear drive starter

- Utilize online resources: Websites, forums, and industry publications can provide insights into the latest trends and innovations.

- Look for user reviews and testimonials: Gather feedback from other businesses that have purchased similar products to gauge performance and reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step ensures that you partner with a reputable supplier who can meet your needs.

- Check certifications and compliance: Ensure the supplier adheres to industry standards and regulations.

- Assess their after-sales support: Consider their warranty policies and availability of replacement parts.

Step 4: Request Samples or Prototypes

If possible, request samples or prototypes of the gear drive starters you are considering. This will allow you to evaluate the quality, performance, and compatibility with your existing equipment before making a bulk purchase.

- Test under real conditions: Evaluate the starter’s performance in your operational environment to identify any potential issues.

- Assess ease of installation: Ensure that the starter can be easily integrated into your current systems.

Step 5: Negotiate Pricing and Terms

Once you’ve shortlisted potential suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. This step is essential to ensure you receive the best value for your investment.

- Inquire about bulk purchase discounts: Many suppliers offer price reductions for larger orders.

- Clarify shipping and handling fees: Understand all costs associated with the purchase to avoid unexpected expenses.

Step 6: Finalize Your Order and Monitor Delivery

After agreeing on terms, finalize your order with the selected supplier. Monitor the delivery process closely to ensure that the gear drive starters arrive on time and in satisfactory condition.

- Document everything: Keep detailed records of your order, including invoices and shipping receipts.

- Inspect upon arrival: Immediately check the starters for any signs of damage or discrepancies in specifications.

Step 7: Conduct Post-Purchase Evaluation

After installation, assess the performance of the gear drive starters in your operations. This evaluation will provide insights into their reliability and efficiency, informing future purchasing decisions.

- Gather feedback from your team: Engage those who interact with the equipment to understand their experiences.

- Analyze performance metrics: Track performance indicators to evaluate whether the starters meet your operational goals.

By following this checklist, B2B buyers can navigate the complexities of sourcing gear drive starters effectively, ensuring they make informed decisions that enhance their operational capabilities.

Comprehensive Cost and Pricing Analysis for gear drive starter Sourcing

What Are the Key Cost Components of Gear Drive Starters?

When sourcing gear drive starters, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The quality of materials significantly influences the price. For instance, higher-grade metals and components may enhance durability and performance but also increase costs. Common materials include steel for housing, copper for windings, and various plastics for insulation.

-

Labor: Labor costs encompass assembly, quality control, and testing. Regions with lower labor costs may offer more competitive pricing, but this could impact the quality and reliability of the product.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, benefiting the overall pricing structure.

-

Tooling: Initial setup for production, including molds and specialized equipment, can be a significant upfront investment. This cost is typically spread over the production run, impacting unit pricing.

-

Quality Control (QC): Rigorous quality assurance processes ensure the reliability and longevity of gear drive starters. Companies that invest in extensive QC measures may have higher costs, which are often reflected in the final price.

-

Logistics: Transportation and shipping costs, especially for international buyers, can vary widely based on distance, mode of transport, and Incoterms. Understanding these costs is essential for calculating the total expense.

-

Margin: The profit margin applied by manufacturers or suppliers can vary based on their market positioning, brand reputation, and the competitive landscape.

How Do Pricing Influencers Affect Gear Drive Starter Costs?

Several factors can influence the pricing of gear drive starters, particularly in the international B2B market:

-

Volume/MOQ: Bulk orders typically qualify for lower pricing per unit. Buyers should consider their needs and negotiate minimum order quantities (MOQ) to optimize costs.

-

Specifications and Customization: Custom requirements (e.g., specific torque ratings, sizes, or configurations) can lead to higher costs. Standardized products are generally more cost-effective.

-

Material Quality and Certifications: Starters that meet specific industry standards or certifications may command higher prices. Buyers should assess whether such certifications are necessary for their applications.

-

Supplier Factors: Supplier reputation, experience, and location can influence pricing. Established suppliers may offer higher prices due to perceived reliability, while newer entrants might provide lower costs to gain market share.

-

Incoterms: The terms of trade (e.g., FOB, CIF) can impact total landed costs. Buyers should understand how these terms affect shipping responsibilities and costs.

What Tips Can Help Buyers Negotiate Better Prices for Gear Drive Starters?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies can lead to significant savings:

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes installation, maintenance, and operational costs. A slightly higher upfront investment in a quality product may result in lower long-term costs.

-

Conduct Market Research: Understanding market trends, average prices, and competitor offerings can empower buyers during negotiations. Researching various suppliers can also reveal pricing discrepancies and potential for negotiation.

-

Establish Long-term Relationships: Building rapport with suppliers can lead to better pricing and terms over time. Consider forming partnerships that benefit both parties, such as guaranteed purchase agreements.

-

Negotiate Payment Terms: Flexible payment options can improve cash flow. Negotiating favorable terms can also provide leverage in discussions around pricing.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing strategies based on local demand, currency fluctuations, and economic conditions. Stay informed about the market landscape in target sourcing regions like Brazil and Nigeria.

Disclaimer on Indicative Prices

While the prices for gear drive starters can range from approximately $160 to $195 for standard models, actual costs may vary based on the factors outlined above. Buyers should obtain quotes from multiple suppliers to ensure competitive pricing and accurate budgeting.

Alternatives Analysis: Comparing gear drive starter With Other Solutions

When considering the procurement of starter systems, it is essential for B2B buyers to evaluate various alternatives to gear drive starters. Understanding the strengths and weaknesses of different technologies can lead to informed decisions that align with specific operational needs and budget constraints.

| Comparison Aspect | Gear Drive Starter | Direct Drive Starter | Gear Reduction Starter |

|---|---|---|---|

| Performance | High torque, efficient under load | Lower torque, simple mechanism | Higher torque, efficient power use |

| Cost | Moderate to high ($160 – $195) | Generally lower cost | Higher initial investment |

| Ease of Implementation | Moderate installation complexity | Simple, direct installation | Moderate complexity, requires alignment |

| Maintenance | Moderate, parts may be harder to find | Low, straightforward repairs | Moderate, may require specialized knowledge |

| Best Use Case | High-performance applications | Cost-sensitive scenarios | Applications requiring high torque and efficiency |

How Does a Direct Drive Starter Compare to Gear Drive Starters?

Direct drive starters utilize a large, low-speed motor that engages the pinion gear in a 1:1 ratio. This simplicity allows for a cost-effective solution, making it an attractive option for buyers on a budget. However, the trade-off is a lower torque output compared to gear drive starters. Direct drive systems are typically easier to install and maintain, which is beneficial in environments where downtime must be minimized. They are well-suited for less demanding applications, such as certain agricultural machinery and older vehicle models.

What Advantages Do Gear Reduction Starters Offer Over Gear Drive Starters?

Gear reduction starters are a modern alternative that employs smaller, faster motors, producing higher torque while drawing less power. This efficiency is particularly advantageous in cold weather, as these starters can crank effectively even when battery power is reduced. However, gear reduction starters often come with a higher price tag and greater complexity in installation and maintenance. They are ideal for applications requiring robust performance, such as heavy-duty vehicles and machinery that demand reliable starting power under challenging conditions.

Conclusion: Which Starter Solution Is Right for Your Business Needs?

Choosing the right starter solution requires a careful assessment of your specific operational demands, budget, and the environmental conditions in which the starter will be used. Gear drive starters offer a balance of performance and efficiency for high-demand applications, while direct drive starters present a more economical option for less intensive needs. Gear reduction starters, although pricier, provide exceptional torque and efficiency, making them suitable for critical machinery. By evaluating these factors, B2B buyers can select a starter technology that not only meets their requirements but also enhances the overall efficiency and reliability of their operations.

Essential Technical Properties and Trade Terminology for gear drive starter

What Are the Key Technical Properties of Gear Drive Starters?

When evaluating gear drive starters, it’s crucial to understand their technical properties, as these specifications directly influence performance, reliability, and cost-effectiveness. Here are some essential properties to consider:

-

Power Rating (kW)

Gear drive starters typically come with power ratings such as 1.4 kW or 2.0 kW. A higher power rating means increased torque and better performance in demanding applications, especially in colder climates where battery efficiency can be compromised. For B2B buyers, selecting the appropriate power rating can impact the operational efficiency and longevity of machinery. -

Gear Reduction Ratio

The gear reduction ratio defines how much the starter motor’s speed is reduced while increasing torque. Common ratios are approximately 4:1 for gear reduction starters. This means that for every four rotations of the motor, the pinion gear turns once. Understanding this ratio helps buyers select starters that provide optimal torque without requiring excessive power, which is particularly important in high-load situations. -

Material Grade

The materials used in manufacturing gear drive starters, such as high-grade steel or aluminum, affect durability and weight. Higher-grade materials can withstand more wear and tear, leading to longer product life. B2B buyers should prioritize starters made from robust materials to minimize maintenance costs and downtime. -

Output Shaft Diameter

The diameter of the output shaft, often around 0.530 inches, is crucial for compatibility with the engine’s flywheel or flex plate. Ensuring the correct shaft diameter is critical to prevent installation issues and ensure reliable performance. This specification is particularly relevant for international buyers who may need to match starters with different engine types. -

Rotation Direction

Gear drive starters can be configured for either right-hand or left-hand rotation, which is essential for compatibility with various engine designs. This specification is vital for B2B buyers to ensure that the starter fits the intended application without modification. -

Amperage Draw

Gear reduction starters typically draw less current compared to direct drive starters. This lower amperage draw means that they can operate efficiently without straining the battery, which is especially beneficial in applications requiring prolonged cranking. Understanding amperage can help buyers assess battery compatibility and overall system efficiency.

What Are Common Trade Terms Related to Gear Drive Starters?

Familiarity with industry jargon can enhance communication and facilitate better purchasing decisions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. For gear drive starters, OEMs provide assurance of quality and compatibility with existing machinery. B2B buyers often seek OEM products to ensure reliability and performance. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory and costs effectively, especially in markets where bulk purchasing can lead to significant savings. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specified products or services. In the context of gear drive starters, submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers navigate shipping costs and responsibilities, ensuring smooth logistics and compliance in cross-border purchases. -

Aftermarket

The aftermarket refers to products sold after the original sale, including replacement parts like gear drive starters. B2B buyers often explore aftermarket options for cost-effective alternatives to OEM parts, but they should assess quality and compatibility to avoid issues. -

Warranty Period

The warranty period indicates the duration for which a manufacturer guarantees the performance of their product. Understanding warranty terms is crucial for B2B buyers, as it reflects the manufacturer’s confidence in their product and provides a safety net against defects or failures.

Understanding these properties and terms not only aids in making informed purchasing decisions but also helps build stronger relationships with suppliers, ensuring that businesses can maintain their operational efficiency and competitiveness in the market.

Navigating Market Dynamics and Sourcing Trends in the gear drive starter Sector

What Are the Key Trends Shaping the Global Gear Drive Starter Market?

The gear drive starter market is witnessing significant transformation driven by several global factors. As industries increasingly demand efficiency and performance, gear reduction technology has gained traction, primarily due to its ability to deliver higher torque with lower power consumption. This trend is particularly relevant in regions such as Africa, South America, the Middle East, and Europe, where energy costs are a growing concern. The shift from direct drive to gear reduction starters has been accelerated by advancements in manufacturing technology, leading to lighter, more compact designs that are easier to install.

Emerging B2B technologies, including automation and IoT integration, are also impacting sourcing strategies. Manufacturers are leveraging smart technologies to enhance product performance and reliability, which is crucial for sectors like automotive and heavy machinery. Furthermore, the rise of e-commerce platforms is transforming how international buyers source gear drive starters, providing greater access to competitive pricing and a wider array of products. Buyers in emerging markets are particularly benefitting from these trends as they seek cost-effective solutions without compromising on quality.

How Is Sustainability and Ethical Sourcing Influencing Gear Drive Starter Procurement?

Sustainability is becoming a critical factor in the procurement of gear drive starters, with many companies prioritizing environmentally friendly practices. The manufacturing process of these components often involves significant energy consumption and the use of raw materials that may not be sustainably sourced. As a result, buyers are increasingly seeking suppliers who demonstrate a commitment to reducing their environmental footprint through responsible sourcing and production methods.

Illustrative image related to gear drive starter

Ethical supply chains are also gaining importance, especially in regions where labor practices may not always meet international standards. B2B buyers are encouraged to conduct thorough due diligence on their suppliers, ensuring compliance with ethical labor practices and environmental regulations. Additionally, certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability.

As the demand for ‘green’ products rises, gear drive starter manufacturers are exploring the use of recyclable materials and eco-friendly manufacturing processes. This shift not only helps in reducing waste but also appeals to environmentally conscious buyers who prioritize sustainability in their purchasing decisions.

What Is the Historical Context Behind Gear Drive Starters?

The evolution of gear drive starters dates back to the 1960s when Chrysler first introduced gear reduction technology. This innovation significantly improved starter efficiency, enabling smaller motors to produce greater torque, thus facilitating easier engine cranking, especially in cold weather conditions. Over the years, gear drive starters have largely replaced traditional direct drive starters in many applications, owing to their advantages in weight, efficiency, and power consumption.

As the automotive and machinery industries have evolved, so too has the technology behind gear drive starters. The introduction of electronic controls and advanced materials has further enhanced performance and reliability, making gear drive starters a preferred choice for many manufacturers. Today, as global markets continue to expand, the demand for high-quality, efficient gear drive starters remains strong, underscoring their critical role in modern machinery and automotive applications.

Frequently Asked Questions (FAQs) for B2B Buyers of gear drive starter

-

How do I choose the right gear drive starter for my application?

Choosing the right gear drive starter depends on various factors including the engine size, application type, and specific performance requirements. Start by identifying the power rating needed—common options include 1.4kw and 2.0kw. Consider the rotation direction (right-hand or left-hand) based on your engine configuration. Additionally, evaluate the starter’s torque-to-weight ratio, especially for heavy-duty applications. It’s also wise to consult with suppliers about compatibility with your existing systems and any potential customization needs. -

What is the difference between gear drive and direct drive starters?

Gear drive starters utilize a gear reduction mechanism that allows smaller, faster motors to produce higher torque while consuming less power. This design is often more efficient and suitable for cold weather starts. In contrast, direct drive starters feature a 1:1 ratio and typically use larger, slower motors, making them cheaper but bulkier. For applications requiring high torque in a compact space, gear drive starters are usually the better choice despite their higher upfront cost. -

What are the minimum order quantities (MOQ) for gear drive starters?

Minimum order quantities can vary significantly based on the manufacturer and the specific starter model. Typically, MOQs range from 10 to 100 units for international buyers. If you’re sourcing from a supplier in regions like Africa or South America, it’s essential to discuss your needs upfront. Some suppliers may offer flexibility on MOQs for first-time buyers or bulk orders, which can help in managing inventory costs. -

How do I vet suppliers for gear drive starters?

When vetting suppliers, prioritize those with a proven track record in the industry. Check for certifications such as ISO or other relevant quality standards. Request references or case studies from previous clients, especially those in your region. Additionally, assess their responsiveness to inquiries and willingness to provide detailed product specifications. Visiting the supplier’s facility, if feasible, can also provide insights into their production capabilities and quality assurance processes. -

What payment terms should I expect when sourcing gear drive starters internationally?

Payment terms can vary widely depending on the supplier and the buyer’s negotiation power. Common terms include a deposit (often 30-50%) upfront, with the balance due upon delivery or after inspection. Some suppliers may offer letters of credit or payment through escrow services for added security. It’s advisable to clarify terms in writing and ensure they align with your cash flow management strategies, particularly when dealing with international shipments. -

How do I ensure quality assurance for gear drive starters?

To ensure quality assurance, request detailed product specifications and test reports from your supplier. Implement a quality control checklist that includes inspections at various production stages. Consider third-party inspection services to validate product quality before shipping. Establish clear communication with the supplier about your quality standards and expectations to prevent any discrepancies upon delivery. -

What logistics considerations should I keep in mind for international shipping of gear drive starters?

When planning logistics for international shipping, consider the shipping method (air freight vs. sea freight) based on urgency and budget. Evaluate customs regulations and import duties specific to your country to avoid unexpected costs. Ensure that your supplier provides all necessary shipping documentation, including invoices and certificates of origin. Collaborate with a reliable freight forwarder to streamline the logistics process and ensure timely delivery. -

Can gear drive starters be customized to fit specific applications?

Yes, many manufacturers offer customization options for gear drive starters to meet specific application needs. Customizations can include modifications in power ratings, rotation direction, and mounting configurations. Discuss your requirements with potential suppliers early in the sourcing process. Providing detailed specifications and operational conditions will help suppliers recommend the best solutions tailored to your unique needs.

Top 4 Gear Drive Starter Manufacturers & Suppliers List

1. Burris Racing – Replacement Gear Drive Starter Motor

Domain: burrisracing.com

Registered: 1996 (29 years)

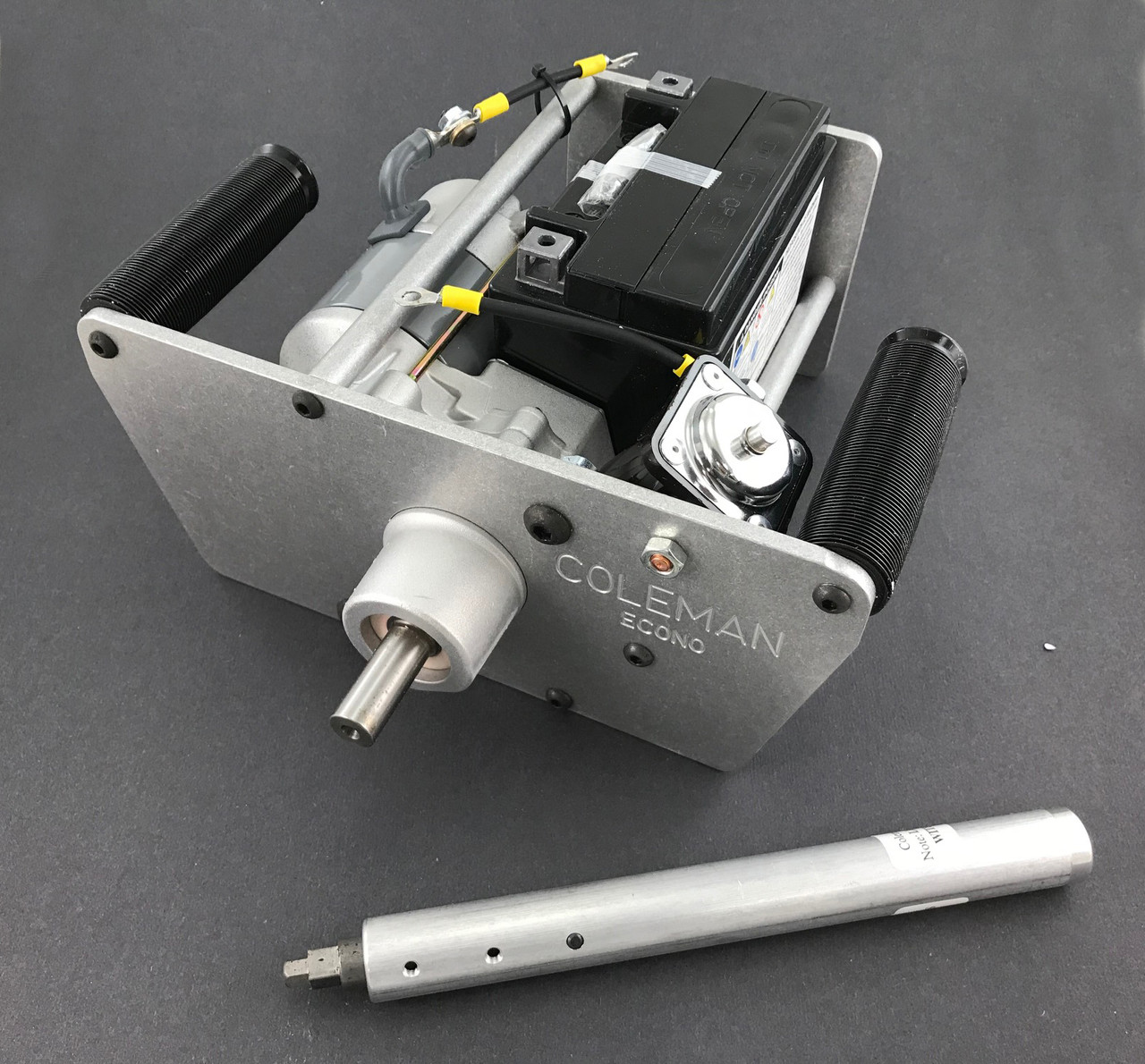

Introduction: Replacement gear drive starter motor from Burris Racing. Price range: $160.00 – $195.00. Available in multiple variants: Right Hand 1.4kw (Standard), Right Hand 2.0kw (upgrade), Left Hand (2.0kw ONLY). Output shaft diameter: .530″. Voltage: 12v.

2. Yesterday’s Tractors – Gear Reduction Starters

Domain: forums.yesterdaystractors.com

Introduction: Gear reduction starters are designed to allow the motor to turn the engine over while drawing less current and working less hard compared to direct drive starters. They typically feature a permanent magnet (PM) motor that spins at higher RPM than a series DC motor. Gear reduction starters are lighter, often made in China or India, and can be less reliable, with some users reporting issues with dur…

3. Delcore – 39MT™ Heavy Duty Gear Reduction Starter

Domain: delcoremy.com

Registered: 1998 (27 years)

Introduction: {‘name’: ’39MT™ Heavy Duty Gear Reduction Starter’, ‘application’: ‘Heavy duty truck and off highway applications’, ‘features’: [‘Electrical soft start for proper ring gear engagement’, ‘Sealed solid link solenoid to eliminate contact welding’, ‘Sealed noseless configuration to minimize debris accumulation’, ‘Over-crank protection’, ‘Rotatable flange design for service flexibility’, ‘Two sided cha…

4. CB Performance – WOSP Gear Drive Starter

Domain: cbperformance.com

Registered: 1996 (29 years)

Introduction: WOSP Gear Drive Starter – 6 Volt Gear

– Reliable, High-Torque Starts – Every Time

– Fast, dependable cranking power with less amperage draw and more torque than stock VW starters

– Ideal for engines running higher compression or smaller batteries

– Integrated front bearing eliminates the need for the fragile OE bronze bushing in the transmission housing

– Designed to outlast and outperform standa…

Strategic Sourcing Conclusion and Outlook for gear drive starter

In summary, the strategic sourcing of gear drive starters presents a compelling opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. As manufacturers increasingly shift towards gear reduction technology, these starters not only offer enhanced efficiency and torque-to-weight ratios but also align with the growing demand for sustainable and cost-effective solutions. Buyers should consider the long-term benefits of investing in gear drive starters, including lower power consumption and improved performance in challenging conditions.

When sourcing gear drive starters, it is essential to evaluate suppliers based on their ability to deliver high-quality products that meet international standards. Engaging with reputable manufacturers and aftermarket suppliers can yield significant savings while ensuring product reliability.

Looking ahead, the market for gear drive starters is poised for growth as technological advancements continue to evolve. We encourage buyers to explore partnerships with innovative suppliers that can provide tailored solutions to meet their unique operational needs. By doing so, businesses can enhance their competitive edge in an increasingly globalized market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to gear drive starter

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.