Introduction: Navigating the Global Market for car starter motor replacement

In the dynamic landscape of automotive parts sourcing, navigating the global market for car starter motor replacement poses a significant challenge for B2B buyers. Sourcing reliable starter motors that meet diverse application needs while balancing cost and quality is crucial for maintaining operational efficiency. This guide offers an in-depth exploration of the various types of starter motors, their applications across different vehicle makes and models, and essential criteria for vetting suppliers.

With a focus on the unique requirements of international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Vietnam—this comprehensive resource empowers businesses to make informed purchasing decisions. It addresses critical factors such as pricing variability, common issues affecting starter motors, and the importance of understanding local market dynamics.

Moreover, the guide emphasizes the significance of assessing supplier reliability and product quality, ensuring that buyers can confidently choose components that enhance their service offerings. By equipping B2B buyers with actionable insights and practical tips, this guide aims to streamline the sourcing process, ultimately leading to improved performance and customer satisfaction in the automotive sector. Whether you are an established distributor or a new market entrant, understanding these nuances is essential for thriving in the competitive automotive parts landscape.

Table Of Contents

- Top 4 Car Starter Motor Replacement Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car starter motor replacement

- Understanding car starter motor replacement Types and Variations

- Key Industrial Applications of car starter motor replacement

- 3 Common User Pain Points for ‘car starter motor replacement’ & Their Solutions

- Strategic Material Selection Guide for car starter motor replacement

- In-depth Look: Manufacturing Processes and Quality Assurance for car starter motor replacement

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car starter motor replacement’

- Comprehensive Cost and Pricing Analysis for car starter motor replacement Sourcing

- Alternatives Analysis: Comparing car starter motor replacement With Other Solutions

- Essential Technical Properties and Trade Terminology for car starter motor replacement

- Navigating Market Dynamics and Sourcing Trends in the car starter motor replacement Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car starter motor replacement

- Strategic Sourcing Conclusion and Outlook for car starter motor replacement

- Important Disclaimer & Terms of Use

Understanding car starter motor replacement Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Starter Motor | Basic design, typically used in most vehicles | General automotive repair shops | Pros: Cost-effective; widely available. Cons: Limited performance in high-demand applications. |

| High-Performance Starter | Enhanced torque and speed for racing or heavy-duty vehicles | Performance automotive shops | Pros: Superior starting power; ideal for high-performance applications. Cons: Higher cost; may require specialized installation. |

| Gear Reduction Starter | Compact design with reduced weight and increased torque | Off-road and racing vehicles | Pros: Lightweight; improved efficiency. Cons: May be more expensive; not suitable for all vehicle types. |

| Mini Starter | Smaller size, often used in retrofitted or custom vehicles | Custom automotive builds | Pros: Space-saving; lightweight. Cons: Limited compatibility; may require modifications. |

| Remanufactured Starter | Rebuilt starters with OEM specifications | Cost-sensitive repair shops | Pros: More affordable than new; often reliable. Cons: Warranty and quality can vary by supplier. |

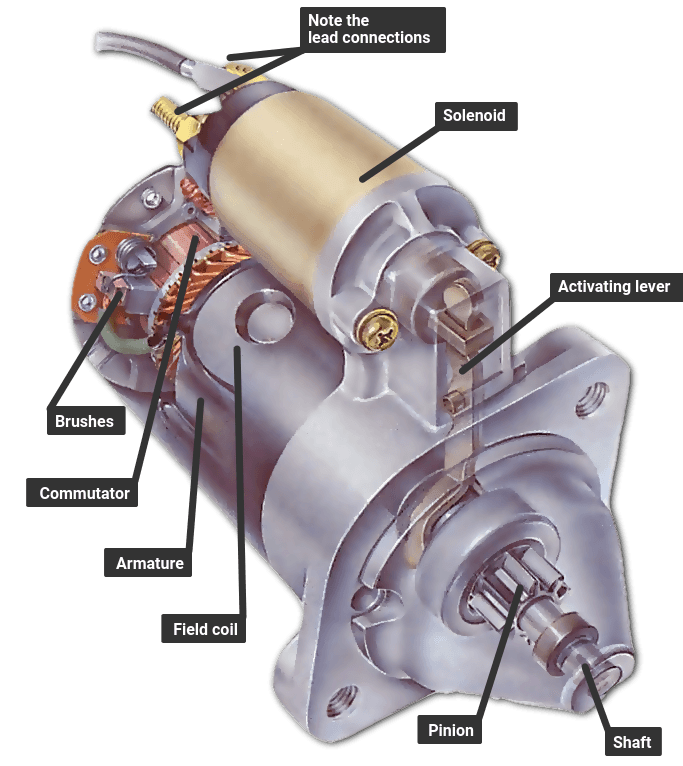

What are the Characteristics of Standard Starter Motors?

Standard starter motors are the most common type found in modern vehicles, utilizing basic electromagnetic principles to engage the engine. They are typically robust and designed for everyday driving conditions. B2B buyers should consider the availability of these starters, as they are widely stocked by suppliers, making them a go-to option for general repair shops. However, while they are cost-effective, their performance may not meet the demands of high-performance or heavy-duty applications.

How Do High-Performance Starters Differ from Standard Models?

High-performance starters are engineered for enhanced torque and speed, making them ideal for racing or heavy-duty vehicles. These starters often utilize advanced materials and designs to withstand extreme conditions. B2B buyers in performance automotive sectors should prioritize these models for their ability to improve engine responsiveness. However, the higher cost and potential need for specialized installation may require careful consideration of budget and expertise.

Why Choose Gear Reduction Starters for Off-Road Applications?

Gear reduction starters are designed to provide increased torque in a compact form, making them suitable for off-road and racing vehicles. Their lightweight design contributes to overall vehicle efficiency, which is crucial in high-demand environments. B2B buyers should assess the weight-to-performance ratio, especially when dealing with vehicles that require agility and speed. While they may come at a premium, their efficiency can justify the investment for performance-focused businesses.

What Advantages Do Mini Starters Offer in Custom Builds?

Mini starters are specifically designed for custom automotive builds and retrofitted vehicles, providing a space-saving solution without sacrificing performance. Their lightweight nature makes them appealing for projects where weight is a concern. B2B buyers involved in custom builds should ensure compatibility with specific vehicle models, as some may require modifications. While they offer unique advantages, the limited availability and potential extra costs for modifications should be factored into purchasing decisions.

Are Remanufactured Starters a Viable Option for Cost-Sensitive Buyers?

Remanufactured starters present a cost-effective alternative to new units, as they are rebuilt to OEM specifications, often providing reliable performance at a reduced price. They are particularly appealing to cost-sensitive repair shops seeking to manage expenses while maintaining quality service. B2B buyers should evaluate the warranty and reputation of the supplier, as the quality of remanufactured parts can vary significantly. This option is advantageous for those looking to balance budget constraints with the need for dependable components.

Key Industrial Applications of car starter motor replacement

| Industry/Sector | Specific Application of car starter motor replacement | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Replacement of starter motors for various vehicle types | Enhances customer satisfaction by ensuring reliable vehicle performance | Sourcing high-quality starters compatible with diverse vehicle models |

| Fleet Management | Regular replacement of starters in fleet vehicles | Minimizes downtime and maintenance costs, ensuring operational efficiency | Bulk purchasing agreements and reliability of suppliers |

| Transportation Services | Starter motor replacement for taxis and delivery vehicles | Reduces the risk of breakdowns, ensuring timely service delivery | Quick turnaround times for sourcing and installation |

| Construction Equipment | Replacement of starters in heavy machinery | Ensures uninterrupted operation on job sites, enhancing productivity | Compatibility with specific machinery models and availability of OEM parts |

| Agricultural Machinery | Starter motor replacements for tractors and harvesters | Guarantees reliable operation during critical farming periods | Access to durable starters suited for harsh environments |

How Are Automotive Repair Shops Utilizing Car Starter Motor Replacement?

Automotive repair shops frequently encounter vehicles with starter issues, making the replacement of starter motors a common service. By providing reliable replacements, these shops enhance customer satisfaction, ensuring vehicles operate smoothly. This is particularly important in regions where vehicle dependability is crucial, such as in Africa and South America, where transportation reliability can significantly impact daily operations. Repair shops must consider sourcing high-quality starter motors that are compatible with a variety of vehicle makes and models to cater to their diverse clientele.

Why is Fleet Management Dependent on Efficient Starter Motor Replacement?

In fleet management, the regular replacement of starter motors is vital for maintaining operational efficiency. A malfunctioning starter can lead to vehicle downtime, which is costly for businesses relying on transportation for logistics and service delivery. By ensuring that fleet vehicles are equipped with reliable starters, companies can minimize maintenance costs and maximize productivity. Buyers should look for suppliers that offer bulk purchasing agreements to secure better pricing, as well as dependable delivery schedules to ensure timely replacements.

How Do Transportation Services Benefit from Starter Motor Replacement?

Transportation services, including taxis and delivery vehicles, rely heavily on the functionality of their starter motors. A faulty starter can lead to service interruptions, affecting customer satisfaction and revenue. Regular replacement of starter motors helps mitigate the risk of breakdowns and ensures timely service delivery. For international buyers in regions like the Middle East and Europe, sourcing starters that offer quick turnaround times is essential to maintain service reliability and meet customer expectations.

What Role Does Starter Motor Replacement Play in Construction Equipment?

Heavy machinery used in construction is often subject to rigorous demands, making starter motor reliability crucial. Replacing starters in construction equipment ensures that machinery operates without interruption, enhancing overall productivity on job sites. Buyers in this sector should focus on sourcing starters that are compatible with specific machinery models and ensure they can withstand harsh operating conditions. Access to OEM parts can significantly improve the longevity and reliability of the equipment.

How is Car Starter Motor Replacement Critical for Agricultural Machinery?

In the agricultural sector, reliable starter motors are essential for tractors and harvesters, especially during peak farming periods. A malfunctioning starter can delay critical operations, impacting productivity and yields. Timely replacement of starter motors ensures that agricultural machinery runs smoothly, allowing farmers to maximize their output. Buyers must consider sourcing durable starters designed for harsh environments, ensuring they can withstand the rigors of agricultural use, particularly in regions with challenging climates like Africa and parts of South America.

3 Common User Pain Points for ‘car starter motor replacement’ & Their Solutions

Scenario 1: Difficulty in Identifying the Root Cause of Starting Issues

The Problem: Many B2B buyers, especially those managing fleets or automotive repair shops, often encounter vehicles that exhibit starting problems. However, pinpointing whether the issue lies with the starter motor, battery, or another electrical component can be quite challenging. This uncertainty can lead to unnecessary costs and extended downtime, impacting overall productivity and service efficiency.

The Solution: To effectively diagnose starting issues, implement a systematic troubleshooting approach. Begin by testing the battery’s voltage, ensuring it meets the minimum requirement of 12.4 volts. Check battery connections for corrosion and tightness. If the battery is functional, inspect fuses related to the starter and ignition systems. If these components check out, focus on the starter relay and listen for clicking sounds when attempting to start the vehicle. A methodical approach not only saves time but also minimizes costs associated with replacing unnecessary parts. Additionally, consider investing in diagnostic tools that can streamline this process, allowing for quicker assessments and informed decisions on whether to repair or replace the starter motor.

Scenario 2: High Cost of Starter Motor Replacement

The Problem: B2B buyers often face the challenge of high replacement costs for starter motors, particularly for luxury or less common vehicle models. The expenses can escalate when additional labor is required due to difficult accessibility or the need for specialized parts. This can strain budgets, especially for businesses operating on tight margins or those managing large fleets with varied vehicle types.

The Solution: To mitigate replacement costs, consider establishing relationships with multiple suppliers to secure competitive pricing on starter motors. Additionally, explore options for remanufactured or refurbished starters, which can significantly lower costs while still providing reliable performance. Ensure to verify the quality and warranty of these products to avoid future failures. Moreover, educating your mechanics on DIY replacement techniques can further reduce labor costs. Providing them with proper training and resources will empower them to execute replacements efficiently, thus saving both time and money in the long run.

Scenario 3: Inconsistent Quality of Replacement Parts

The Problem: Another prevalent issue is the inconsistency in quality among different brands and suppliers of starter motors. Poor-quality parts can lead to frequent breakdowns, resulting in increased maintenance costs and customer dissatisfaction. For businesses focused on maintaining a strong reputation, sourcing unreliable components can be detrimental.

The Solution: To ensure high-quality replacements, conduct thorough research on suppliers and manufacturers. Look for reputable brands known for their durability and reliability in the automotive sector. Utilize feedback from other B2B buyers and industry reviews to gauge the performance of various starter motors. Establish partnerships with suppliers that offer warranties and robust return policies, allowing for easy exchanges if quality issues arise. Additionally, consider implementing a quality control process that includes inspecting parts upon receipt and before installation. This proactive measure will help maintain high standards and minimize the risk of future failures, thereby enhancing customer trust and satisfaction.

Strategic Material Selection Guide for car starter motor replacement

What Are the Common Materials Used in Car Starter Motor Replacement?

When selecting materials for car starter motor replacements, it is essential to consider their properties, advantages, disadvantages, and suitability for different applications. The choice of material can significantly influence the performance, durability, and cost-effectiveness of the starter motor, especially for international B2B buyers operating in diverse markets.

What Are the Key Properties of Copper in Starter Motors?

Copper is widely used in car starter motors, particularly for electrical connections and windings due to its excellent electrical conductivity. It can withstand temperatures up to 200°C and has good corrosion resistance, especially when treated with coatings.

Pros: Copper’s high conductivity ensures efficient power transfer, enhancing the starter’s performance. It is also relatively easy to machine, making it suitable for complex designs.

Cons: The primary drawback of copper is its cost, which is higher compared to alternatives like aluminum. Additionally, copper can be prone to corrosion if not adequately protected, which can affect longevity.

Impact on Application: Copper’s compatibility with various electrical systems makes it suitable for a wide range of vehicles. However, buyers must consider local environmental conditions, as high humidity or saline environments can accelerate corrosion.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for electrical components, such as IEC or ANSI, to guarantee safety and reliability.

How Does Aluminum Compare as a Material for Starter Motors?

Aluminum is increasingly being used in starter motors, particularly for housings and casings. It has a lower density than copper, making it lightweight and ideal for applications where weight reduction is critical. Aluminum can withstand temperatures up to 150°C and offers decent corrosion resistance.

Pros: The lightweight nature of aluminum contributes to improved fuel efficiency in vehicles. It is also cost-effective compared to copper, making it a popular choice for manufacturers.

Cons: While aluminum is resistant to corrosion, it is less conductive than copper, which can lead to performance issues in high-demand applications. Additionally, it may require more complex manufacturing processes to achieve the desired strength.

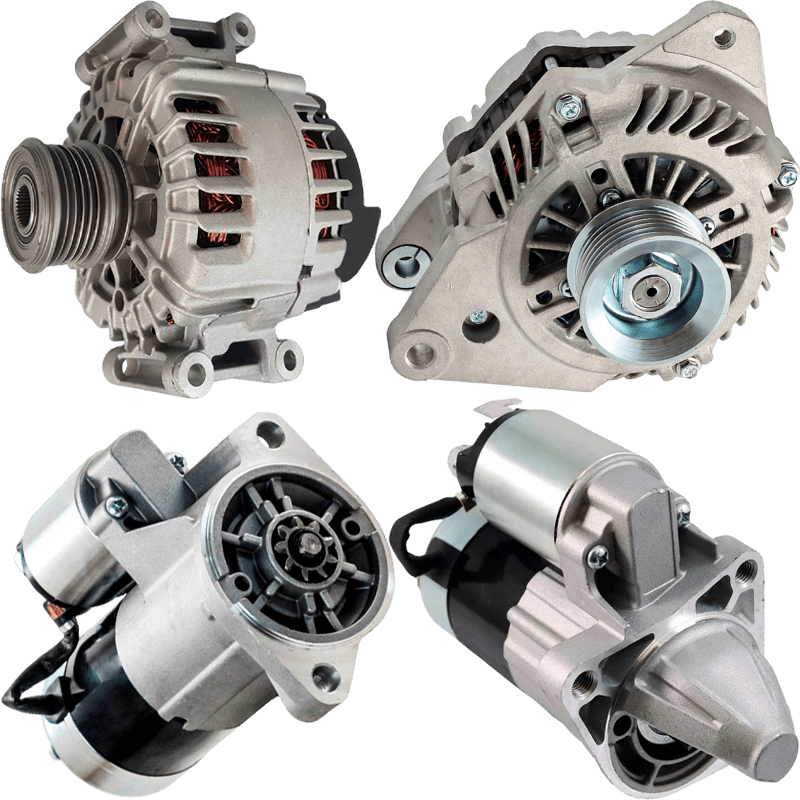

Illustrative image related to car starter motor replacement

Impact on Application: Aluminum is suitable for vehicles where weight is a priority, but its lower conductivity means it may not be ideal for high-performance starter motors.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of standards such as EN and ISO that govern aluminum use in automotive applications.

What Role Does Steel Play in Starter Motor Components?

Steel is often used for structural components of starter motors, such as the housing and drive gears. With a high tensile strength and the ability to withstand significant mechanical stress, steel is a reliable choice for durability.

Pros: Steel’s strength and durability make it suitable for heavy-duty applications. It is also relatively inexpensive, making it an attractive option for manufacturers.

Cons: Steel is heavier than aluminum and can be susceptible to rust if not properly treated. This can lead to performance issues in environments with high moisture levels.

Impact on Application: Steel components are ideal for vehicles that require robust performance but may not be suitable for lightweight applications.

Considerations for International Buyers: Buyers should ensure that steel components meet relevant standards, such as ASTM or JIS, to ensure quality and performance.

Illustrative image related to car starter motor replacement

How Is Composite Material Used in Starter Motors?

Composite materials, often a combination of plastics and metals, are increasingly being used in starter motors for non-structural components. They offer excellent resistance to heat and chemicals, making them suitable for harsh environments.

Pros: Composites can reduce weight and are resistant to corrosion, which enhances the longevity of starter motors. They can also be molded into complex shapes, allowing for innovative designs.

Cons: The main limitation is the cost, as composites can be more expensive than traditional materials. Additionally, their mechanical strength may not match that of metals, which can be a concern in high-stress applications.

Illustrative image related to car starter motor replacement

Impact on Application: Composites are ideal for applications where weight and corrosion resistance are critical, but their use may be limited in high-stress environments.

Considerations for International Buyers: Buyers should verify that composite materials comply with industry standards, particularly in regions with stringent automotive regulations.

Summary of Material Selection for Car Starter Motors

| Material | Typical Use Case for car starter motor replacement | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections and windings | Excellent electrical conductivity | Higher cost, prone to corrosion | High |

| Aluminum | Housings and casings | Lightweight, cost-effective | Lower conductivity, complex manufacturing | Medium |

| Steel | Structural components (housing, gears) | High strength and durability | Heavier, susceptible to rust | Low |

| Composite | Non-structural components | Corrosion-resistant, lightweight | Higher cost, lower mechanical strength | Medium |

This guide provides a comprehensive overview of the materials suitable for car starter motor replacements, offering B2B buyers critical insights for informed decision-making in diverse international markets.

Illustrative image related to car starter motor replacement

In-depth Look: Manufacturing Processes and Quality Assurance for car starter motor replacement

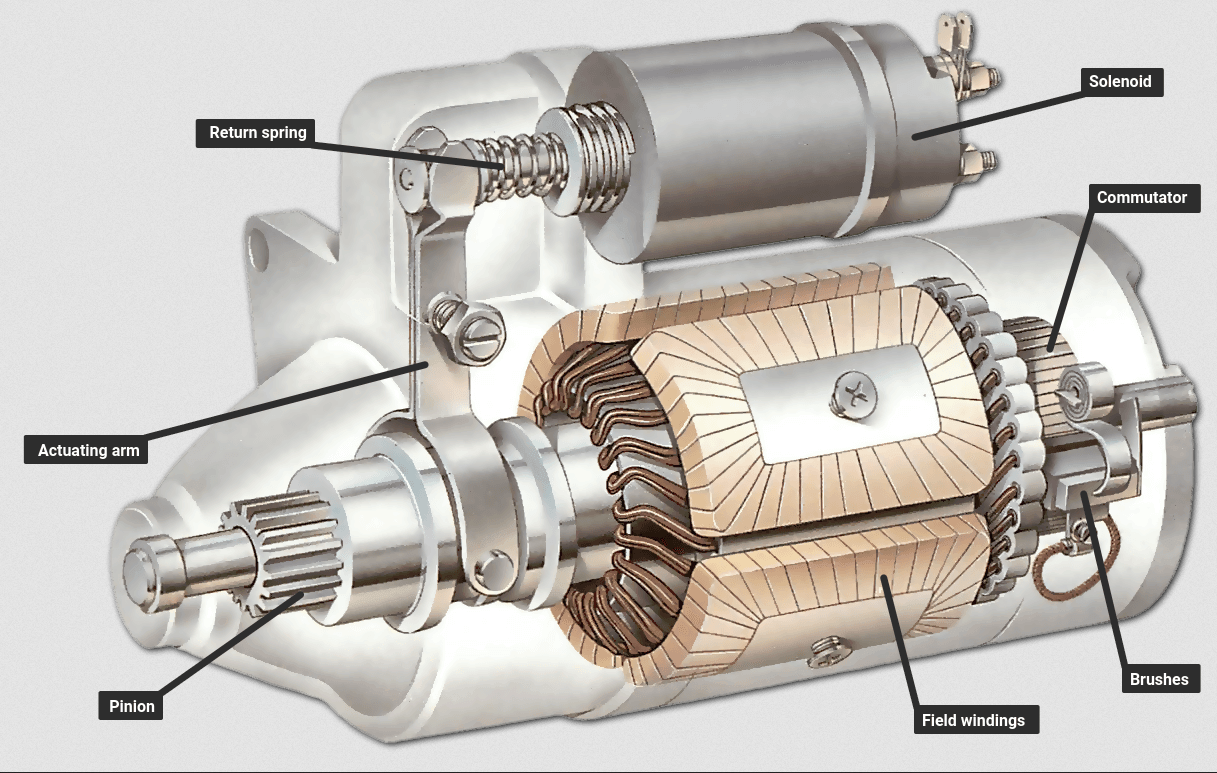

What Are the Key Manufacturing Processes for Car Starter Motors?

Manufacturing car starter motors involves a series of intricate processes designed to ensure reliability and performance. The main stages include material preparation, forming, assembly, and finishing. Each stage is crucial for producing a high-quality product that meets or exceeds industry standards.

How Is Material Prepared in Car Starter Motor Manufacturing?

Material preparation is the first step in the manufacturing process. High-grade materials, such as steel for the housing and copper for the windings, are selected based on their conductivity and durability. This stage also involves sourcing raw materials that comply with international quality standards. Suppliers must provide material certifications, ensuring that they meet the required specifications.

Once materials are sourced, they undergo processes like cutting, machining, and surface treatment. Machining is particularly critical, as it shapes components such as the armature and housing to precise dimensions. This precision is essential for the starter motor’s performance, as even minor deviations can lead to operational inefficiencies or failures.

What Techniques Are Employed in the Forming Process?

The forming stage encompasses various techniques that shape the components of the starter motor. Stamping, casting, and forging are commonly used methods. Stamping is particularly effective for creating flat parts such as brackets and covers, while casting is employed for complex shapes like the motor housing.

Illustrative image related to car starter motor replacement

Each technique must adhere to rigorous quality standards to ensure that the components can withstand the stresses of operation. For example, the armature must be carefully balanced to prevent vibrations during operation, which can lead to premature wear and failure.

How Are Components Assembled in Car Starter Motor Production?

Once individual components are formed, they proceed to the assembly stage. This process typically involves several key steps, including the installation of the armature, solenoid, and electrical connections. Each component must be carefully integrated to ensure optimal functionality.

Quality control at this stage is vital. Manufacturers often use automated assembly lines equipped with sensors to detect improper alignments or connections. Furthermore, skilled technicians conduct visual inspections to identify any potential defects that automated systems might miss.

What Finishing Processes Are Necessary for Starter Motors?

The finishing stage includes surface treatment, painting, and final inspections. Surface treatments such as anodizing or galvanizing protect metal parts from corrosion, which is particularly important for automotive applications exposed to harsh environments.

Painting not only enhances aesthetic appeal but also adds a layer of protection against wear and environmental factors. After finishing, a comprehensive final inspection (FQC) is performed to ensure that the starter motor meets all specifications before being packaged for shipment.

What Quality Assurance Standards Are Relevant for Car Starter Motors?

Quality assurance is critical in the manufacturing of car starter motors, particularly for international B2B transactions. Compliance with relevant standards, such as ISO 9001, is essential. This standard focuses on quality management systems and helps organizations demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are also important. These certifications indicate that products comply with European Union safety and environmental regulations, as well as industry-specific performance standards.

What Are the Key Quality Control Checkpoints in Starter Motor Manufacturing?

Quality control involves several checkpoints throughout the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This checkpoint assesses the quality of raw materials and components upon arrival. Suppliers are required to provide documentation certifying that their materials meet predetermined standards.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to ensure that manufacturing processes adhere to specifications. Techniques such as statistical process control (SPC) may be utilized to monitor production metrics and identify deviations in real time.

-

Final Quality Control (FQC): Before shipment, the final product undergoes a thorough inspection to verify that it meets all quality standards. This includes testing for electrical integrity, mechanical performance, and compliance with safety regulations.

What Common Testing Methods Are Used for Car Starter Motors?

Testing methods for car starter motors include functional testing, electrical testing, and environmental testing. Functional testing simulates actual operating conditions to ensure that the starter performs as expected under various scenarios.

Electrical testing checks parameters such as voltage, current, and resistance to verify that the starter motor operates efficiently. Environmental testing may involve subjecting the starter to extreme temperatures or humidity levels to assess its durability and reliability over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Buyers can conduct audits of potential suppliers to assess their manufacturing practices and quality assurance systems. During these audits, buyers should review documentation related to quality certifications, inspection reports, and testing results.

Additionally, third-party inspections can provide an unbiased assessment of a supplier’s quality practices. Buyers may also request samples of previous work or customer testimonials to gauge the supplier’s reliability and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges in quality control. Differences in regulatory standards and manufacturing practices can lead to complications in product consistency. Buyers should familiarize themselves with the relevant regulations in their region and ensure that suppliers can meet these requirements.

Moreover, language barriers and cultural differences may affect communication regarding quality expectations. Establishing clear channels of communication and documentation can help mitigate these issues, ensuring that both parties have a mutual understanding of quality standards.

Conclusion

Manufacturing and quality assurance for car starter motors involve complex processes designed to ensure reliability and performance. By understanding these processes and the associated quality control measures, B2B buyers can make informed decisions when sourcing starter motors from international suppliers. Emphasizing quality certifications, inspection methods, and effective communication will ultimately lead to successful partnerships and high-quality products that meet market demands.

Illustrative image related to car starter motor replacement

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car starter motor replacement’

Introduction

This sourcing guide provides a structured approach for B2B buyers looking to procure car starter motor replacements. Given the complexities involved in automotive parts sourcing, especially for diverse markets such as Africa, South America, the Middle East, and Europe, following this checklist will help ensure that you make informed decisions, secure quality products, and establish reliable supplier relationships.

Step 1: Define Your Technical Specifications

Before sourcing, clearly outline the technical specifications of the starter motors you need. This includes the make, model, year of the vehicle, and any specific performance requirements.

- Compatibility: Ensure that the starter motor matches the vehicle’s specifications to avoid compatibility issues.

- Quality Standards: Determine the quality standards that the parts must meet, including OEM or aftermarket specifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who can meet your needs. Utilize online platforms, trade shows, and industry directories to compile a list of candidates.

- Industry Experience: Look for suppliers with a proven track record in automotive parts, particularly in starter motors.

- Market Presence: Evaluate their market presence in your target regions, as local suppliers may better understand the specific needs and regulations.

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality assurances of your shortlisted suppliers. This step is crucial to ensure that you are dealing with reputable manufacturers.

- ISO Certifications: Check for ISO 9001 or other relevant quality certifications that demonstrate adherence to international quality management standards.

- Compliance with Local Standards: Ensure that the suppliers comply with local automotive regulations in your target markets.

Step 4: Request Samples and Specifications

Before finalizing your order, request samples of the starter motors along with their technical specifications. This is vital for assessing the quality and compatibility of the products.

- Testing: Conduct tests to ensure that the samples meet your performance criteria and are free from defects.

- Documentation: Ensure that the specifications include installation guidelines and warranty information.

Step 5: Negotiate Pricing and Terms

Once you are satisfied with the samples, initiate negotiations regarding pricing, payment terms, and delivery schedules. This step is essential to ensure that you receive a fair deal.

- Volume Discounts: Inquire about discounts for bulk purchases, as this can significantly reduce your overall costs.

- Lead Times: Discuss lead times for delivery to ensure that you can meet your operational timelines.

Step 6: Establish a Communication Plan

Set up a clear communication plan with your chosen supplier. Effective communication can help address any issues promptly and maintain a smooth working relationship.

- Regular Updates: Schedule regular check-ins to discuss order progress and any potential challenges.

- Feedback Mechanism: Establish a feedback mechanism to address quality concerns or improvements post-purchase.

Step 7: Implement Quality Control Measures

After procurement, implement quality control measures to ensure the starter motors meet your standards during installation and operation.

Illustrative image related to car starter motor replacement

- Inspection Protocols: Develop inspection protocols for incoming shipments to verify that the parts match the ordered specifications.

- Performance Monitoring: Monitor the performance of the starter motors in real-world conditions to identify any long-term issues.

By following this structured checklist, B2B buyers can streamline their sourcing process for car starter motor replacements, ensuring quality products and reliable supplier partnerships.

Comprehensive Cost and Pricing Analysis for car starter motor replacement Sourcing

What Are the Key Cost Components of Car Starter Motor Replacement?

When sourcing car starter motor replacements, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The raw materials used in manufacturing starter motors, such as metals (aluminum, copper) and plastics, significantly impact the overall cost. High-quality materials that meet specific performance standards may increase costs but enhance longevity and reliability.

-

Labor: Labor costs encompass both manufacturing and installation. Skilled labor is required for assembly and quality control, while installation costs can vary based on the complexity of the vehicle’s design. For instance, luxury or specialized vehicles may demand higher labor costs due to their intricate designs.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, including utilities, equipment maintenance, and salaries of non-production staff. Efficient manufacturing processes can help reduce overhead costs, which can be reflected in pricing.

-

Tooling: Custom tooling is often necessary for specific vehicle models, contributing to the initial setup costs. Suppliers may pass these costs on to buyers, particularly for low-volume orders.

-

Quality Control (QC): Rigorous QC processes are essential to ensure that starters meet safety and performance standards. This can include testing, inspections, and certifications, which add to the overall cost.

-

Logistics: Transportation and shipping costs are significant, especially for international buyers. Factors such as distance, shipping method, and customs duties can affect the final price.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market conditions, competition, and the perceived value of the product.

How Do Price Influencers Affect Car Starter Motor Replacement Costs?

Several factors can influence the pricing of car starter motors, particularly in the context of international B2B sourcing:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often yield better pricing due to economies of scale. Suppliers may offer discounts for bulk purchases, which can significantly reduce the per-unit cost.

-

Specifications and Customization: Custom-built starters or those with specific performance characteristics may incur additional costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Materials: The choice of materials directly impacts costs. Premium materials that enhance durability and performance may justify a higher price, particularly for high-end or commercial vehicles.

-

Quality and Certifications: Products that meet international quality standards (e.g., ISO certifications) may command higher prices. Buyers should consider whether these certifications are necessary for their market.

-

Supplier Factors: Reputation, reliability, and service levels of suppliers can affect pricing. Established suppliers may charge more due to their proven track record and customer support.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping and customs duties. Understanding these terms is essential for calculating the total cost.

What Are the Best Buyer Tips for Sourcing Car Starter Motors?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Wisely: Leverage volume purchases to negotiate better pricing. Establishing long-term relationships with suppliers can also provide opportunities for favorable terms.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, warranties, and potential failures. A cheaper starter may lead to higher TCO if it fails prematurely.

-

Understand Pricing Nuances: Be aware of regional market dynamics that may influence pricing. Factors such as local demand, currency fluctuations, and geopolitical conditions can affect costs.

-

Explore Multiple Suppliers: Diversifying your supplier base can provide competitive pricing and reduce risks associated with dependency on a single source.

-

Stay Informed on Market Trends: Keeping abreast of industry developments, such as changes in material costs or technological advancements in starter motors, can help buyers make informed sourcing decisions.

Disclaimer on Indicative Prices

Prices for car starter motor replacements can vary widely based on numerous factors, including vehicle type, geographic location, and market conditions. This analysis provides indicative pricing structures and should not be considered definitive. Always consult with suppliers for the most accurate and current pricing relevant to your specific sourcing needs.

Alternatives Analysis: Comparing car starter motor replacement With Other Solutions

Understanding Alternatives to Car Starter Motor Replacement

In the automotive industry, the need for reliable vehicle starting solutions is paramount, especially for businesses reliant on transportation. While car starter motor replacement is a common approach for resolving starting issues, there are viable alternatives worth considering. This analysis compares the traditional starter motor replacement with other methods, providing B2B buyers with actionable insights for informed decision-making.

Comparison Table

| Comparison Aspect | Car Starter Motor Replacement | Battery Replacement | Jump-Starting Solutions |

|---|---|---|---|

| Performance | Reliable, long-term solution | Improves starting but temporary | Immediate, but not permanent |

| Cost | $150 – $1,100 | $50 – $300 | Minimal (battery cables) |

| Ease of Implementation | Moderate (requires tools and skills) | Easy (can be DIY) | Very easy (no tools needed) |

| Maintenance | Low (once replaced) | Regular checks needed | Low (only for emergencies) |

| Best Use Case | Persistent starting issues | Weak battery symptoms | Temporary fix for dead battery |

Exploring Alternative Solutions

Battery Replacement

Battery replacement is often a straightforward alternative to starter motor replacement. If the vehicle shows signs of starting difficulties, such as dim lights or slow cranking, a battery issue may be the root cause. The costs range from $50 to $300, depending on the battery type and vehicle requirements. The ease of implementation is high, as many drivers can replace their batteries without professional help. However, regular maintenance checks are essential to ensure optimal battery performance over time. This method is best used when the battery is confirmed to be the issue, making it a cost-effective solution for minor starting problems.

Jump-Starting Solutions

Jump-starting a vehicle is a quick and often necessary solution when faced with a dead battery. This method involves connecting the vehicle to another with a functional battery, usually requiring minimal tools (just jumper cables). The cost is virtually negligible, making it an attractive option for immediate assistance. However, this is only a temporary fix and does not address underlying issues. Jump-starting is best suited for situations where a vehicle needs a quick restart without the intention of long-term reliability. While it provides immediate relief, it does not substitute for proper diagnostics and repairs.

Illustrative image related to car starter motor replacement

Conclusion: Choosing the Right Solution for Your Needs

When considering solutions for vehicle starting issues, it is essential for B2B buyers to evaluate their specific circumstances. Car starter motor replacement provides a long-term, reliable solution but can be costly and requires skilled labor. Battery replacement offers a practical and often more economical choice for businesses experiencing weak battery symptoms. Jump-starting, while quick and cost-effective, should only be seen as a stopgap measure. Ultimately, understanding the performance, cost, ease of implementation, and maintenance of each option will help buyers select the most appropriate solution tailored to their operational needs.

Essential Technical Properties and Trade Terminology for car starter motor replacement

What Are the Key Technical Properties of Car Starter Motors?

When considering car starter motor replacements, understanding critical specifications is essential for making informed purchasing decisions. Here are some key technical properties that B2B buyers should be aware of:

-

Material Grade

The material used in the construction of starter motors significantly affects durability and performance. Common materials include high-grade steel for the casing and copper for the wiring. Higher material grades can withstand extreme temperatures and provide better electrical conductivity, leading to improved reliability and longevity. For B2B buyers, sourcing starters made from premium materials can reduce the frequency of replacements and improve overall customer satisfaction. -

Torque Specifications

Torque specifications indicate the amount of rotational force that a starter motor can apply to the engine. This is crucial for ensuring the starter can effectively turn over the engine, particularly in larger vehicles or those with high-compression engines. Understanding torque requirements allows buyers to match starters with specific vehicle models, ensuring compatibility and optimal performance. -

Electrical Resistance

Electrical resistance is a critical factor that affects the efficiency of starter motors. Lower resistance generally leads to higher efficiency and faster engine cranking speeds, which is vital in cold weather conditions. Buyers should assess the electrical resistance ratings when sourcing starters, as this can impact the reliability of starting systems in diverse climates. -

Cranking Amperage

This specification measures the amount of current a starter motor draws during the initial engine cranking phase. Different vehicles require different cranking amperages based on engine size and design. For B2B buyers, understanding the cranking amperage is essential to ensure that the starter can handle the demands of the vehicle’s engine without failure. -

Operating Temperature Range

Starter motors operate in various environments, and knowing the operating temperature range is crucial. This specification indicates the temperatures at which the starter can function optimally without degrading. For international buyers, especially in regions with extreme climates, selecting starters with appropriate temperature ratings can prevent premature failures.

What Are Common Trade Terms in the Starter Motor Industry?

Familiarity with industry jargon can streamline the purchasing process and enhance communication between buyers and suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle’s original manufacturer. These parts are typically designed to meet the exact specifications of the vehicle, ensuring compatibility and performance. B2B buyers often prefer OEM parts for their reliability, although they may come at a premium compared to aftermarket options. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and avoid overstocking. Buyers should negotiate MOQs that align with their purchasing capacity and market demand. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. It’s a critical step in the procurement process, allowing buyers to compare prices and terms before making purchasing decisions. Properly structured RFQs can lead to better deals and stronger supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. They clarify who is responsible for shipping costs, insurance, and customs duties. Understanding Incoterms is vital for B2B buyers engaged in cross-border transactions, as it helps mitigate risks and ensures smoother logistics. -

Aftermarket

The aftermarket includes parts and accessories that are not sourced directly from the OEM. These products can offer cost-effective alternatives and may come with various performance benefits. B2B buyers should evaluate the quality and reliability of aftermarket parts to ensure they meet the needs of their customers.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions in the car starter motor replacement market, ultimately enhancing their operational efficiency and customer satisfaction.

Illustrative image related to car starter motor replacement

Navigating Market Dynamics and Sourcing Trends in the car starter motor replacement Sector

What Are the Key Market Dynamics Affecting Car Starter Motor Replacement?

The global car starter motor replacement market is influenced by several dynamic factors that international B2B buyers must navigate. One significant driver is the growing vehicle population, especially in emerging markets like Africa and South America, where increasing urbanization and disposable incomes are leading to higher vehicle ownership rates. This trend heightens the demand for replacement parts, including starter motors, as vehicles age and require maintenance.

Technological advancements are also reshaping the market landscape. The rise of electric vehicles (EVs) is introducing new sourcing challenges and opportunities. Traditional internal combustion engine vehicles still dominate, but the shift towards EVs will require suppliers to adapt to different starter technologies, such as integrated starter-generator systems. This transition is essential for suppliers to remain competitive and meet the evolving needs of the automotive industry.

Additionally, the current global supply chain disruptions due to geopolitical tensions and the COVID-19 pandemic have emphasized the importance of building resilient supply chains. Buyers are increasingly seeking suppliers who can ensure reliable delivery and quality, leading to a preference for local sourcing and partnerships with manufacturers that offer transparency in their operations.

How Important Is Sustainability and Ethical Sourcing in Car Starter Motor Replacement?

As environmental concerns continue to rise, sustainability and ethical sourcing have become critical considerations for B2B buyers in the car starter motor replacement sector. The automotive industry is under pressure to reduce its carbon footprint, and this extends to the sourcing of components. Buyers are increasingly evaluating suppliers based on their environmental practices, such as the use of sustainable materials and energy-efficient manufacturing processes.

The environmental impact of traditional starter motors, particularly those that rely on non-renewable resources, cannot be overlooked. The market is seeing a gradual shift towards ‘green’ certifications and materials, which include recyclable components and the use of renewable energy in production. Suppliers that prioritize sustainability can not only enhance their brand image but also meet the growing demand from environmentally conscious consumers and businesses.

Furthermore, ethical supply chains are gaining traction, with buyers keen on ensuring that their suppliers adhere to fair labor practices and environmentally sound operations. This focus on ethical sourcing helps mitigate risks associated with reputational damage and compliance issues, making it a vital aspect for international buyers looking to establish long-term partnerships.

Illustrative image related to car starter motor replacement

How Has the Car Starter Motor Replacement Sector Evolved?

The evolution of the car starter motor replacement sector has been marked by significant technological advancements and changing consumer expectations. Initially, starter motors were simple mechanical devices that relied on direct electrical connections to engage the engine. However, with the advent of electronic ignition systems and improved battery technologies, starter motors have become more sophisticated, integrating advanced features like solenoids and built-in diagnostics.

In recent years, the growth of electric and hybrid vehicles has further transformed the landscape. These vehicles require specialized starter systems, such as starter-generators, which combine the functions of starting the engine and generating electrical power. As a result, suppliers are now investing in research and development to innovate and produce components that meet the needs of modern vehicles.

The rise of e-commerce and digital platforms is also reshaping how B2B buyers source starter motors. Buyers can now access a wider range of products and suppliers online, facilitating comparison shopping and enhancing procurement efficiency. This evolution underscores the importance of staying informed about market trends and technological advancements for buyers seeking to make strategic sourcing decisions in the car starter motor replacement sector.

Frequently Asked Questions (FAQs) for B2B Buyers of car starter motor replacement

-

How do I identify a faulty starter motor?

To diagnose a faulty starter motor, begin by checking the battery condition, ensuring it has a charge of at least 12.4 volts. Inspect battery connections for corrosion or looseness, and test any related fuses. Common symptoms of a bad starter include unusual noises, erratic cranking, or a complete lack of response when attempting to start the vehicle. If the starter shows signs of wear or damage, it may require replacement. Consult a qualified mechanic if unsure, as they can perform detailed diagnostics to confirm the issue. -

What factors influence the cost of starter motor replacement?

The cost of replacing a starter motor can vary widely based on several factors, including the vehicle’s make, model, and year. Labor costs differ by region and the complexity of the starter’s location within the engine. Additionally, whether you choose to replace or rebuild the starter will affect pricing. For bulk purchases, consider negotiating with suppliers to get better rates. Always compare quotes and ensure the parts meet OEM specifications to maintain quality. -

What are the key components to consider when sourcing starter motors internationally?

When sourcing starter motors internationally, focus on the quality of components, compliance with international standards, and the supplier’s reputation. Verify that the parts are compatible with your specific vehicles and that they meet OEM specifications. Additionally, consider the supplier’s experience in international trade, delivery capabilities, and after-sales support. Assessing these factors will help ensure a reliable and consistent supply of quality starter motors. -

What is the minimum order quantity (MOQ) for starter motors from suppliers?

Minimum order quantities (MOQs) for starter motors can vary significantly depending on the supplier and the type of motor being ordered. Typically, MOQs range from 50 to 500 units for bulk orders. It’s advisable to discuss your requirements with potential suppliers to negotiate favorable terms, especially if you are looking to start with a smaller volume. Establishing a strong relationship with suppliers can also lead to flexibility in MOQs over time. -

What payment terms should I expect when sourcing starter motors from international suppliers?

Payment terms can vary widely among international suppliers. Common arrangements include advance payment, payment on delivery, or a letter of credit. It’s important to negotiate terms that protect your interests while also being acceptable to the supplier. Ensure clarity on currency, payment methods, and any potential fees. Establishing a good rapport with suppliers can lead to more favorable payment terms, such as extended credit or discounts for early payment. -

How do I ensure quality assurance for the starter motors I purchase?

To ensure quality assurance, request detailed product specifications and certifications from suppliers. Conduct regular audits of their manufacturing processes and ask for samples before committing to larger orders. Implement a quality control checklist that includes testing for performance, durability, and compliance with industry standards. Collaborating with third-party inspection services can also help verify product quality before shipment, reducing the risk of defects. -

What logistics considerations should I keep in mind when importing starter motors?

When importing starter motors, consider shipping methods, transit times, and customs regulations in your country. Choose a reliable freight forwarder familiar with automotive parts to streamline the process. Be aware of potential tariffs and duties that may apply, and ensure all paperwork is complete to avoid delays. Additionally, plan for warehousing and distribution logistics to efficiently manage inventory once the parts arrive. -

Can I customize starter motors to fit specific vehicle models?

Yes, many suppliers offer customization options for starter motors to fit specific vehicle models. This can include modifications to size, mounting configurations, and electrical connections. When discussing customization with potential suppliers, provide detailed specifications and requirements. Keep in mind that customized parts may have longer lead times and potentially higher costs. Collaborate closely with the supplier to ensure the final product meets your needs and quality expectations.

Top 4 Car Starter Motor Replacement Manufacturers & Suppliers List

1. Toyota – Starter Replacement Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2007 Toyota Corolla starter replacement; difficulty level: relatively simple depending on the car; parts needed: starter, possibly tools for removal; troubleshooting: check battery terminals before replacing starter; estimated cost for new starter: around $150.

2. Facebook – Car Repair Tips

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Car Repair Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Electric Starter – Heavy Duty Installation

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Project Duration: 1 to 2 hours; Skill Level: Intermediate; Starter Type: Electric starter (starter motor); Weight: 20 pounds or more; Special Requirements: Correct starter bolts (not regular grade 8 bolts); Tools Needed: Floor jack, jack stands, ramps or wheel cribs, wrenches, sockets, ratchet, extensions; Safety Precautions: Disconnect battery negative terminal, ensure vehicle is securely lifted;…

4. WikiHow – Car Starter Installation Guide

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: This article provides a step-by-step guide on how to install a car starter, including removing a faulty starter and installing a new one. Key steps include disconnecting the battery, locating the starter, removing the old starter, comparing the new starter to the old one, and securing the new starter in place. The guide emphasizes the importance of using common hand tools and ensuring the new star…

Strategic Sourcing Conclusion and Outlook for car starter motor replacement

In the dynamic landscape of automotive parts procurement, effective strategic sourcing for car starter motors is essential for international B2B buyers. Understanding the nuances of starter motor replacement—from cost variances influenced by vehicle type to identifying the signs of failure—empowers businesses to make informed purchasing decisions. By sourcing quality parts, whether through OEM or aftermarket channels, companies can enhance customer satisfaction and ensure vehicle reliability.

Moreover, as markets in Africa, South America, the Middle East, and Europe continue to evolve, the ability to adapt sourcing strategies to local conditions and supply chain challenges will be a key differentiator. Engaging with trusted suppliers who understand regional requirements can lead to reduced lead times and improved pricing, ultimately driving profitability.

Illustrative image related to car starter motor replacement

As we look to the future, proactive sourcing strategies that leverage technology and analytics will be paramount. B2B buyers are encouraged to explore partnerships with suppliers that offer transparency and innovation in their sourcing practices. By embracing these strategies, businesses can position themselves for success in the competitive automotive market, ensuring they meet both current demands and future growth opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.