Introduction: Navigating the Global Market for alternator car price

In the ever-evolving automotive landscape, understanding the intricacies of alternator car prices is essential for international B2B buyers. Sourcing the right alternator at a competitive price can be a daunting challenge, especially when navigating diverse markets across Africa, South America, the Middle East, and Europe. This guide is designed to empower you with actionable insights into the various types of alternators, their applications, and the factors influencing pricing.

From identifying the key components and functionalities of alternators to understanding the implications of faulty units on vehicle performance, this comprehensive resource covers it all. We delve into the nuances of supplier vetting, ensuring that you partner with reputable manufacturers who meet your quality and service expectations. Additionally, we examine the cost structures associated with alternators, including factors that can significantly affect your procurement budget, such as model specifications and regional variations.

By equipping you with this essential knowledge, this guide facilitates informed purchasing decisions, enabling you to secure the best alternator solutions for your business needs. Whether you’re operating in emerging markets or established economies like Vietnam and Germany, the insights provided will enhance your sourcing strategies and optimize your supply chain efficiency. Embrace the opportunity to navigate the global alternator market with confidence and precision.

Table Of Contents

- Top 2 Alternator Car Price Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator car price

- Understanding alternator car price Types and Variations

- Key Industrial Applications of alternator car price

- 3 Common User Pain Points for ‘alternator car price’ & Their Solutions

- Strategic Material Selection Guide for alternator car price

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator car price

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator car price’

- Comprehensive Cost and Pricing Analysis for alternator car price Sourcing

- Alternatives Analysis: Comparing alternator car price With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator car price

- Navigating Market Dynamics and Sourcing Trends in the alternator car price Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator car price

- Strategic Sourcing Conclusion and Outlook for alternator car price

- Important Disclaimer & Terms of Use

Understanding alternator car price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternators | Conventional design, typically 12V output | General automotive repair and fleet | Pros: Widely available, cost-effective. Cons: Limited power output for high-demand vehicles. |

| High-Output Alternators | Enhanced power capacity, designed for performance vehicles | Racing, heavy-duty applications | Pros: Supports additional electrical loads. Cons: Higher cost and may require modifications. |

| Remanufactured Alternators | Rebuilt using original parts, often with warranty | Budget-conscious fleets and workshops | Pros: Cost savings, reliable. Cons: May not last as long as new units. |

| Diesel Alternators | Specifically designed for diesel engines, higher durability | Commercial trucks, buses | Pros: Built for heavy-duty use. Cons: Typically higher initial investment. |

| Smart Alternators | Incorporates advanced electronics for efficiency and diagnostics | Modern vehicles with complex electrical systems | Pros: Improved performance and diagnostics. Cons: More expensive and requires specialized installation. |

What Are Standard Alternators and When Should B2B Buyers Consider Them?

Standard alternators are the most common type found in vehicles, providing a 12V output suitable for general automotive applications. These units are often cost-effective and easily sourced, making them ideal for general repairs and maintenance in workshops and fleet operations. When purchasing, B2B buyers should consider the vehicle’s electrical demands to ensure compatibility, as these alternators may not support high-output requirements for performance vehicles.

How Do High-Output Alternators Differ from Standard Models?

High-output alternators are engineered for performance vehicles and heavy-duty applications, offering greater power capacity to support additional electrical components. This makes them suitable for racing teams or commercial vehicles with extensive electronic systems. While they provide the necessary power for enhanced performance, buyers should weigh the higher costs and potential need for vehicle modifications against their specific electrical demands.

What Advantages Do Remanufactured Alternators Offer to Budget-Conscious Buyers?

Remanufactured alternators are rebuilt from original parts, offering a cost-effective solution for businesses looking to minimize expenses without sacrificing quality. These units often come with warranties, providing additional assurance for B2B buyers. However, it’s important to consider that while they can be reliable, they may not match the longevity of brand-new alternatives, which could affect long-term operational costs.

Why Are Diesel Alternators Essential for Heavy-Duty Applications?

Diesel alternators are specifically designed for diesel engines, featuring enhanced durability and performance to withstand the rigors of commercial use. They are essential for trucks and buses that require reliable electrical systems for various onboard functions. Buyers should consider the initial investment and ensure that the alternator meets the specific power needs of their diesel vehicles to optimize performance and longevity.

How Do Smart Alternators Enhance Vehicle Performance?

Smart alternators utilize advanced electronics to improve efficiency and provide diagnostic capabilities, making them ideal for modern vehicles with complex electrical systems. These units can adjust their output based on demand, optimizing battery charging and overall vehicle performance. While they offer significant advantages, B2B buyers should be prepared for higher costs and the necessity of specialized installation, which could impact overall project budgets.

Key Industrial Applications of alternator car price

| Industry/Sector | Specific Application of alternator car price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicles requiring reliable electrical systems | Ensures vehicle reliability and customer satisfaction | Quality standards, compatibility with various vehicle models, and warranty provisions. |

| Fleet Management | Maintenance of commercial vehicle fleets | Reduces downtime and repair costs, improving operational efficiency | Bulk purchasing discounts, availability of parts, and service agreements for quick replacements. |

| Renewable Energy | Integration of electric vehicles (EVs) into renewable energy systems | Supports sustainable transport and energy solutions | Compatibility with renewable charging systems and performance under varying environmental conditions. |

| Heavy Equipment | Powering electrical systems in construction machinery | Enhances machinery performance and reduces operational failures | Durability under harsh conditions, maintenance support, and sourcing from reputable manufacturers. |

| Export and Import Trade | Logistics companies managing vehicle imports/exports | Facilitates smoother operations in cross-border trade | Compliance with international regulations, cost-effectiveness, and reliable delivery timelines. |

How is ‘alternator car price’ utilized in the Automotive Manufacturing Sector?

In the automotive manufacturing sector, the alternator is crucial for ensuring the reliability of the vehicle’s electrical systems. A well-functioning alternator is essential for powering components such as the ignition system, lighting, and onboard computers. For international B2B buyers, especially those in regions like Africa and South America, sourcing high-quality alternators at competitive prices can significantly impact production costs. Buyers must consider compatibility with various vehicle models and the availability of warranties to ensure long-term reliability.

What role does ‘alternator car price’ play in Fleet Management?

For fleet management, the alternator is vital in maintaining the operational efficiency of commercial vehicles. A malfunctioning alternator can lead to vehicle downtime, which directly impacts productivity and profitability. By investing in reliable alternators, fleet managers can reduce repair costs and enhance vehicle uptime. Buyers should look for bulk purchasing options and service agreements that facilitate quick replacements, ensuring that their fleets remain operational without significant delays.

How is ‘alternator car price’ relevant to Renewable Energy Initiatives?

In the context of renewable energy, the integration of electric vehicles (EVs) necessitates a reliable alternator to support efficient energy conversion and storage. Businesses involved in renewable energy projects can benefit from sourcing high-quality alternators that meet the specific requirements of EVs. Key considerations include compatibility with charging systems and the ability to perform under various environmental conditions. This ensures that the vehicles can effectively contribute to sustainable transport solutions.

Why is ‘alternator car price’ important for Heavy Equipment?

Heavy equipment, such as construction machinery, relies on robust electrical systems powered by reliable alternators. These components must withstand demanding operational conditions, making durability a primary concern for B2B buyers in this sector. By selecting high-quality alternators, businesses can enhance machinery performance and reduce the likelihood of operational failures. Buyers should focus on sourcing from reputable manufacturers that provide maintenance support and can demonstrate the longevity of their products.

How does ‘alternator car price’ impact Export and Import Trade?

In the export and import trade, logistics companies managing vehicle imports and exports must ensure that their vehicles are equipped with reliable alternators to facilitate smooth operations. A malfunctioning alternator can lead to significant delays and increased costs in cross-border trade. B2B buyers should prioritize sourcing alternators that comply with international regulations and offer cost-effectiveness, ensuring reliable delivery timelines and minimizing disruptions in logistics operations.

3 Common User Pain Points for ‘alternator car price’ & Their Solutions

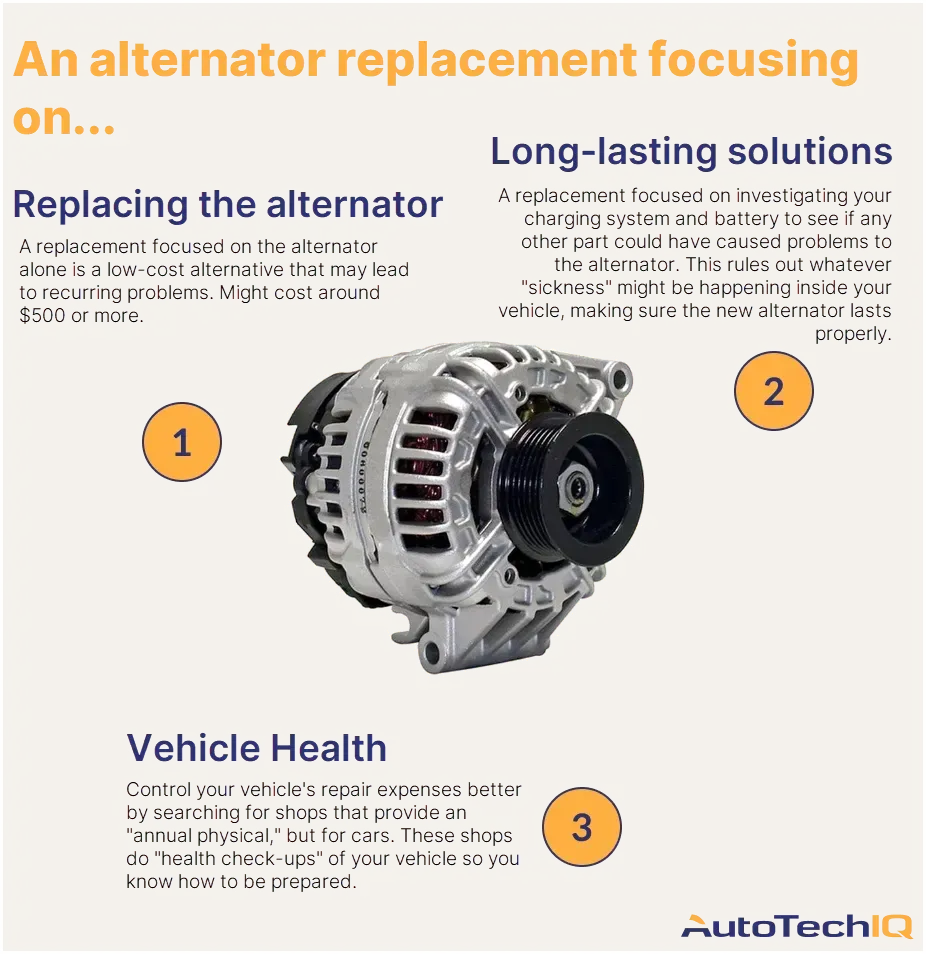

Scenario 1: Unpredictable Alternator Replacement Costs

The Problem: B2B buyers often face the challenge of unpredictable costs associated with alternator replacements. When managing a fleet or a large inventory of vehicles, the variability in alternator prices can significantly impact budgeting and financial forecasting. Factors such as vehicle make, model, and regional pricing differences can lead to considerable discrepancies in replacement costs, creating financial strain and complicating procurement strategies.

The Solution: To mitigate these cost uncertainties, B2B buyers should adopt a comprehensive procurement strategy. First, establish relationships with multiple suppliers to gain access to a range of pricing options. This includes both OEM (Original Equipment Manufacturer) and aftermarket alternators. Conduct thorough market research to understand price benchmarks for different vehicle types across various regions, particularly focusing on the specific markets of interest such as Africa, South America, the Middle East, and Europe. Additionally, consider negotiating bulk purchase agreements with suppliers, which can lead to significant discounts. Implementing a centralized inventory management system can also help track usage and replacement frequency, allowing for better forecasting and budget allocation.

Scenario 2: Difficulty in Sourcing Quality Alternators

The Problem: Sourcing high-quality alternators that meet the specific needs of different vehicle models can be a daunting task for B2B buyers. Many aftermarket parts come with varying levels of quality, and the risk of receiving subpar products can lead to operational disruptions and increased maintenance costs. This is particularly critical for international buyers who may not have direct access to reputable suppliers.

The Solution: To ensure the procurement of quality alternators, B2B buyers should prioritize due diligence in supplier selection. Start by vetting suppliers with established reputations and positive reviews in the automotive industry. Look for suppliers that offer warranties or guarantees on their products, as this can be an indicator of quality. Additionally, consider utilizing third-party testing services to verify the specifications and performance of the alternators before purchasing. Networking within industry forums or attending trade shows can also provide insights into reliable suppliers and innovative products. Implementing a standardized evaluation process for alternators can help maintain quality consistency across your fleet.

Scenario 3: Navigating Complex Import Regulations and Costs

The Problem: International B2B buyers often encounter complex import regulations and associated costs when sourcing alternators from different countries. Tariffs, customs duties, and compliance with local automotive regulations can add significant overhead to the already fluctuating prices of alternators. This complexity can lead to delays, unexpected expenses, and ultimately, operational inefficiencies.

The Solution: To navigate these challenges effectively, B2B buyers should invest time in understanding the import regulations of their target markets. Collaborating with local legal and trade experts can provide valuable insights into compliance requirements and potential cost-saving strategies. Additionally, consider leveraging local distributors who understand the regional market landscape and can handle logistics, thus simplifying the import process. Establishing a clear communication channel with suppliers regarding shipping terms and costs upfront can also prevent unexpected charges. Furthermore, utilizing trade agreements or partnerships with other businesses can facilitate smoother import processes and potentially lower tariffs. By proactively addressing these regulatory complexities, buyers can streamline their procurement process and better manage their total cost of ownership.

Strategic Material Selection Guide for alternator car price

What Are the Key Materials Used in Alternators for Automotive Applications?

When considering the materials used in alternators, B2B buyers need to focus on those that enhance performance, durability, and cost-effectiveness. Here, we analyze four common materials: aluminum, copper, steel, and plastic, which are integral to alternator construction and performance.

How Does Aluminum Impact Alternator Performance and Cost?

Aluminum is frequently used in the housing and components of alternators due to its lightweight and excellent thermal conductivity. Its temperature rating typically ranges from -40°C to 120°C, making it suitable for various automotive applications. The primary advantage of aluminum is its resistance to corrosion, which is essential for vehicles operating in humid or saline environments.

However, aluminum can be more expensive than other metals like steel, and its manufacturing process may involve complex machining, which can increase production costs. For international buyers, particularly in regions with high humidity such as Africa and South America, aluminum’s corrosion resistance is a significant advantage. Compliance with international standards like ASTM can also assure quality and performance.

What Role Does Copper Play in Alternator Efficiency?

Copper is a critical material for the windings and electrical connections within alternators. Known for its high electrical conductivity, copper ensures efficient energy transfer, which is crucial for the alternator’s performance. The material can withstand high temperatures (up to 200°C) and has excellent corrosion resistance when properly treated.

While copper enhances performance, it is also one of the more expensive materials, which can impact the overall cost of the alternator. Additionally, the weight of copper can be a disadvantage in applications where reducing weight is a priority. For buyers in Europe and the Middle East, where energy efficiency is paramount, investing in copper components can lead to long-term savings on energy consumption.

How Does Steel Contribute to the Durability of Alternators?

Steel is often used for structural components of alternators, such as the rotor shaft and mounting brackets. With a high tensile strength and good fatigue resistance, steel can endure the mechanical stresses encountered during operation. The typical temperature rating for steel components can range from -20°C to 150°C, depending on the alloy used.

The main drawback of steel is its susceptibility to corrosion, which can be mitigated through coatings or galvanization. For B2B buyers in regions with extreme weather conditions, such as the Middle East, selecting steel components that comply with international corrosion-resistant standards (like DIN) is crucial. While steel is generally less expensive than aluminum and copper, the added costs for protective treatments can affect the overall pricing.

What Advantages Does Plastic Offer in Alternator Manufacturing?

Plastic materials, particularly thermoplastics, are increasingly used in alternator components such as housings and insulators. They are lightweight, cost-effective, and can be molded into complex shapes, which simplifies manufacturing. Plastic components typically have a temperature resistance of up to 100°C, making them suitable for various automotive applications.

However, the main disadvantage of plastic is its lower mechanical strength compared to metals, which may limit its use in high-stress applications. For international buyers, especially in Europe, compliance with automotive-grade plastic standards is essential to ensure safety and performance. Additionally, the lower cost of plastic can be attractive for budget-conscious buyers in developing markets.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for alternator car price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and components | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Copper | Windings and electrical connections | High electrical conductivity | Expensive and heavier | High |

| Steel | Structural components | High tensile strength | Susceptible to corrosion | Low |

| Plastic | Housings and insulators | Lightweight and cost-effective | Lower mechanical strength | Low |

In conclusion, selecting the right materials for alternators is essential for ensuring performance, durability, and cost-effectiveness. International B2B buyers should consider the specific requirements of their markets, including compliance with local standards and the environmental conditions in which the vehicles will operate.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator car price

What Are the Main Stages of Manufacturing Alternators?

Manufacturing alternators involves a series of intricate processes designed to ensure high performance and reliability. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Alternator Manufacturing?

The manufacturing process begins with the selection and preparation of raw materials. High-grade steel and copper are the primary materials used in alternators due to their excellent electrical conductivity and strength. Steel plates are cut into specific shapes for the stator and rotor, while copper wires are insulated to prevent electrical shorting. Rigorous quality checks are conducted on raw materials to ensure they meet industry standards before they proceed to the forming stage.

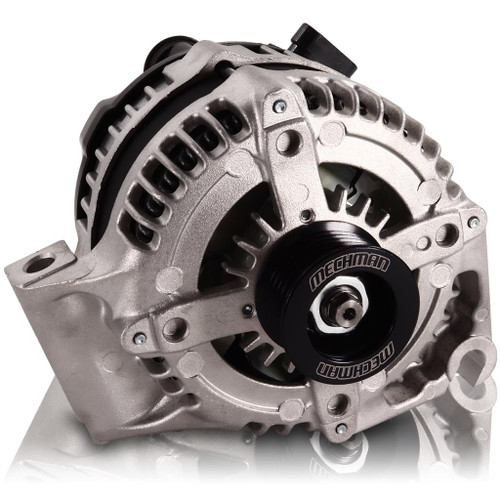

Illustrative image related to alternator car price

What Techniques Are Used in the Forming Stage of Alternator Production?

In the forming stage, the raw materials undergo various processes such as stamping, winding, and machining. The stator is formed by stamping steel sheets into precise shapes, which are then stacked and insulated. For the rotor, copper wires are wound around a steel core to create the excitation winding. Advanced techniques like laser cutting may be utilized to ensure precision, and CNC machines can be employed for machining components to exact specifications, enhancing the overall quality and performance of the alternator.

How Does the Assembly Process Work for Alternators?

Once the individual components are ready, they move to the assembly line. This stage involves the integration of the stator, rotor, and other electrical components, such as diodes and voltage regulators. Automated assembly systems are commonly used to ensure consistency and efficiency. Quality assurance checkpoints are integrated throughout this process, with inspections conducted after major assembly steps to identify defects early on.

What Finishing Processes Are Essential for High-Quality Alternators?

The finishing stage includes coating, painting, and final testing. Components are often coated with protective finishes to enhance durability and resist corrosion. Additionally, the assembled alternator undergoes rigorous testing to verify its functionality and performance metrics. This includes checking the voltage output and conducting stress tests to ensure it can handle the operational demands of various vehicles.

What Quality Assurance Standards Are Relevant for Alternator Manufacturing?

Quality assurance is critical in alternator manufacturing, particularly for international B2B buyers. Compliance with international standards, such as ISO 9001, ensures that the manufacturing process meets global quality benchmarks. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can be crucial for ensuring that products meet regional regulations and safety standards.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) checkpoints are vital to maintaining high standards throughout the manufacturing process. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Any materials that do not meet specifications are rejected and sent back to suppliers.

-

In-Process Quality Control (IPQC): During the production stages, IPQC involves regular inspections at key points in the assembly line to ensure that components are being manufactured correctly. This helps catch defects early, reducing waste and rework.

-

Final Quality Control (FQC): After assembly, the finished alternators undergo extensive testing to ensure they function according to specifications. This includes electrical tests and performance evaluations.

What Common Testing Methods Are Used in Alternator Quality Assurance?

Several testing methods are employed to guarantee the reliability of alternators:

-

Electrical Testing: This includes measuring voltage output and checking for short circuits or other electrical failures.

-

Mechanical Testing: Durability tests assess the physical integrity of the alternator under simulated operational conditions.

-

Thermal Testing: This evaluates how well the alternator performs under high temperatures, which is crucial given the heat generated during operation.

-

Vibration Testing: Alternators must withstand vibrations from the engine, so this testing ensures they remain functional under such conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some strategies to consider:

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing practices and adherence to quality standards. This includes reviewing their QC processes and certifications.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their QC measures, including inspection results and compliance with industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can help verify the quality of products before they are shipped. These services can conduct independent evaluations of manufacturing practices and product integrity.

What Are the QC and Certification Nuances for International Buyers?

When dealing with suppliers from regions like Africa, South America, the Middle East, and Europe, B2B buyers should be aware of specific nuances in quality control and certification:

-

Regional Standards Compliance: Different regions may have varying standards and certifications that must be adhered to. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural Differences in Quality Perception: Understanding that different regions may have different priorities regarding quality can help buyers navigate expectations and negotiations with suppliers.

-

Documentation and Traceability: Ensure that suppliers maintain thorough documentation of their QC processes and can provide traceability for materials used in production. This is vital for accountability and transparency.

In conclusion, understanding the manufacturing processes and quality assurance measures for alternators is crucial for B2B buyers looking to make informed purchasing decisions. By focusing on the main stages of production, relevant quality standards, and effective verification methods, buyers can ensure they procure high-quality alternators that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator car price’

Introduction

Navigating the procurement of automotive parts, specifically alternators, requires a strategic approach to ensure quality, compliance, and cost-effectiveness. This step-by-step checklist is designed to guide B2B buyers through the essential stages of sourcing alternators, focusing on factors that influence pricing and supplier reliability. By following these steps, you can make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of the alternators you need is crucial. This includes voltage output, compatibility with various vehicle models, and specific features such as size and type (e.g., diesel or petrol).

– Consider the application: Are you sourcing for commercial vehicles, luxury cars, or a fleet of standard models? Each may have different specifications.

– Document requirements: Create a detailed specification sheet to ensure all stakeholders are aligned on what is needed.

Step 2: Research Market Prices

Conduct thorough market research to understand the price range for alternators relevant to your specifications. This will help you set a realistic budget and identify potential suppliers.

– Compare prices across regions: Prices may vary significantly based on the supplier’s location and shipping costs, especially when sourcing internationally.

– Look for bulk pricing options: Many suppliers offer discounts for larger orders, which can significantly affect your overall cost.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Assess reliability: Look for suppliers with a proven track record and positive feedback from other businesses.

– Check for certifications: Ensure the supplier meets international quality standards, which can affect the performance and longevity of the alternators.

Step 4: Request Samples

Whenever possible, request samples of the alternators you plan to procure. This will allow you to assess the quality and ensure they meet your specifications before making a larger commitment.

– Test performance: Check for voltage output and overall functionality.

– Inspect for compatibility: Ensure that the alternators fit and operate correctly within your intended vehicle models.

Step 5: Negotiate Terms and Conditions

Once you have identified potential suppliers, it’s time to negotiate terms. This includes pricing, payment terms, delivery timelines, and warranty conditions.

– Be clear on expectations: Discuss lead times and confirm that they align with your business needs.

– Consider after-sales support: Ensure that the supplier provides adequate support for any issues that may arise post-purchase.

Step 6: Finalize the Purchase Agreement

After negotiations, draft a purchase agreement that outlines all terms and conditions agreed upon. This should include pricing, delivery schedules, and any warranties or guarantees.

– Ensure clarity: Both parties should understand their responsibilities to avoid disputes later.

– Include contingencies: Address potential issues such as delays or defects in the product.

Step 7: Monitor Delivery and Quality Assurance

After placing your order, monitor the delivery process to ensure that the alternators arrive as specified. Conduct a quality assurance check upon receipt.

– Inspect for damages: Check for any physical damage during transit.

– Verify specifications: Ensure the delivered items match the specifications agreed upon in the purchase agreement.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing alternators, ensuring they secure quality products at competitive prices while fostering strong supplier relationships.

Illustrative image related to alternator car price

Comprehensive Cost and Pricing Analysis for alternator car price Sourcing

What Are the Key Cost Components in Sourcing Alternators for Cars?

When sourcing alternators, understanding the cost structure is crucial for making informed purchasing decisions. The primary components of the cost include:

-

Materials: The choice of materials significantly impacts the cost. High-quality copper, steel, and electronic components are essential for durability and performance. The price of raw materials can fluctuate due to market conditions, so it’s advisable to stay updated on commodity prices.

-

Labor: Labor costs can vary widely based on the location of manufacturing. Regions with lower labor costs may offer competitive pricing, but this may come at the expense of quality. Understanding the labor market in the supplier’s country is essential.

-

Manufacturing Overhead: This includes costs related to the production facility, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these costs, so inquire about the supplier’s production efficiency.

-

Tooling: Custom tooling for specific alternator designs can be a significant upfront cost. If you require custom specifications, it’s essential to factor in these costs when negotiating prices.

-

Quality Control (QC): Implementing stringent quality control processes ensures the alternators meet required standards. While this adds to the cost, it can prevent expensive failures and recalls in the long run.

-

Logistics: Transportation costs can vary based on the distance from the manufacturer to your location. Consider factors such as shipping methods, insurance, and customs duties, especially for international shipments.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the average market margin can help you assess whether a quote is competitive.

What Factors Influence the Pricing of Alternators?

Several factors can influence the pricing of alternators:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Discussing your expected purchase volume with suppliers can help negotiate better pricing.

-

Specifications and Customization: Custom-designed alternators or those with specific features will generally incur higher costs. Be clear about your needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Alternators made from premium materials and those that meet specific quality certifications tend to cost more. Ensure that the materials align with your performance requirements.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, but they may also offer better service and quality assurance.

-

Incoterms: The chosen Incoterms can influence the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for calculating final costs.

How Can Buyers Negotiate and Optimize Costs When Sourcing Alternators?

Buyers can employ several strategies to optimize costs when sourcing alternators:

-

Negotiation: Leverage your purchasing power by negotiating terms such as pricing, payment terms, and delivery schedules. Be transparent about your budget constraints while seeking value-added services.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the initial purchase price. Consider factors such as reliability, maintenance costs, and warranty terms when evaluating suppliers.

-

International Pricing Nuances: For buyers in Africa, South America, the Middle East, and Europe, it’s vital to understand local market conditions, tariffs, and regulations that could impact pricing. Researching potential suppliers in different regions can reveal more competitive options.

-

Supplier Relationship Management: Building long-term relationships with suppliers can lead to better pricing, improved service, and exclusive access to new products or technologies.

What Should Buyers Keep in Mind About Indicative Prices?

It’s important to note that the prices for alternators can vary widely based on several factors, including market demand, supplier capabilities, and specific buyer requirements. Always ask for detailed quotes and be prepared for fluctuations in pricing due to economic conditions or changes in material costs. By understanding these dynamics, buyers can make more strategic sourcing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing alternator car price With Other Solutions

Understanding Alternatives to Alternator Car Price

In the automotive industry, the alternator is a crucial component for the electrical system of a vehicle. However, there are alternative solutions that can fulfill similar roles or mitigate the need for a traditional alternator replacement. This section explores viable alternatives, comparing their performance, costs, ease of implementation, maintenance requirements, and best use cases.

Comparison Table

| Comparison Aspect | Alternator Car Price | Battery Management Systems | Solar Power Systems |

|---|---|---|---|

| Performance | Converts mechanical energy to electrical power effectively; critical for vehicle operation | Regulates battery charge and discharge, optimizing battery lifespan and performance | Converts solar energy to electrical power, can supplement or replace alternator power in some applications |

| Cost | $350 – $900 for replacement, depending on vehicle model and labor | $200 – $600 for installation, plus ongoing monitoring costs | Initial setup costs range from $1,000 – $3,000, depending on system size and installation |

| Ease of Implementation | Moderate; requires mechanical skills or professional help for installation | Moderate; often requires professional installation, especially for complex systems | High; requires significant upfront investment and possibly structural modifications |

| Maintenance | Generally low; replacement every 7-10 years or as needed | Low to moderate; requires periodic monitoring and potential recalibration | Moderate; requires occasional cleaning of solar panels and battery checks |

| Best Use Case | Standard gasoline and diesel vehicles | Fleets or vehicles with high electrical demands | Off-grid applications or electric vehicles with solar integration |

Detailed Breakdown of Alternatives

1. Battery Management Systems (BMS)

Battery Management Systems are designed to optimize the performance and lifespan of batteries in vehicles, particularly electric and hybrid models. They ensure that batteries are charged efficiently and prevent overcharging or deep discharging, which can lead to battery failure. While the initial investment for a BMS can be lower than a full alternator replacement, ongoing monitoring and maintenance may be necessary. This system is ideal for businesses with fleets that have high electrical demands, as it maximizes battery efficiency and reduces long-term costs associated with battery replacements.

2. Solar Power Systems

Solar power systems can serve as an alternative to traditional alternators, particularly in off-grid or electric vehicle applications. These systems convert sunlight into electrical power, which can charge batteries directly. However, the initial setup cost can be significantly higher than that of an alternator, and they require careful planning and possibly modifications to the vehicle structure to install solar panels. While they offer sustainability benefits and can reduce reliance on traditional power sources, their effectiveness is contingent on weather conditions and geographic location, making them less practical for all business operations.

Illustrative image related to alternator car price

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right solution for vehicle power management, B2B buyers must consider their specific operational requirements and cost constraints. For traditional vehicles, maintaining or replacing the alternator may be the most straightforward and cost-effective approach. However, for fleets with significant electrical demands or businesses focused on sustainability, exploring battery management systems or solar power solutions could yield long-term savings and operational efficiencies. Each option presents unique advantages and drawbacks; thus, a thorough assessment of vehicle types, usage patterns, and budget will guide buyers to the most appropriate choice.

Essential Technical Properties and Trade Terminology for alternator car price

What Are the Key Technical Properties of Alternators That Affect Car Prices?

When assessing the price of alternators in the automotive market, several critical specifications come into play. Understanding these properties can help B2B buyers make informed purchasing decisions.

1. Amp Output Rating

The amp output rating of an alternator indicates its capacity to generate electrical current. Most modern vehicles require an alternator that produces between 70 to 150 amps. For B2B buyers, knowing the amp output is crucial; it directly impacts the vehicle’s electrical system performance and can influence the choice of alternator for specific vehicle models. Higher amp ratings may lead to increased costs but can be essential for vehicles with numerous electrical components.

2. Voltage Regulation

Voltage regulation is vital for maintaining a stable output voltage, typically between 13.8 to 14.6 volts in automotive applications. This property ensures that electrical devices function correctly without risking damage from voltage fluctuations. Buyers should pay attention to the type of voltage regulator (electronic vs. mechanical) since this can affect reliability and cost. A quality voltage regulation system can lead to lower long-term maintenance costs.

Illustrative image related to alternator car price

3. Material Composition

The materials used in the construction of an alternator, such as copper for windings and high-grade steel for the rotor and stator, can significantly influence its durability and performance. Alternators built with superior materials tend to have longer lifespans, which can reduce replacement frequency and costs for businesses managing fleets. Buyers should seek products with warranties that reflect the material quality.

4. Size and Weight

The size and weight of an alternator can affect compatibility with various vehicle models and installation processes. Larger or heavier alternators may require more robust mounting systems, which could increase installation costs. Understanding the dimensional specifications is crucial for B2B buyers looking to optimize inventory and reduce potential returns due to compatibility issues.

5. Temperature Rating

Alternators are designed to operate within specific temperature ranges. A high-temperature rating indicates that the alternator can withstand extreme conditions without failure. This is particularly important for vehicles operating in hot climates, as overheating can lead to premature failure. Buyers should consider temperature ratings when sourcing alternators for regions with extreme environmental conditions.

What Are Common Trade Terms Relevant to Alternator Pricing?

Familiarity with industry jargon can facilitate smoother negotiations and better purchasing decisions in the alternator market.

Illustrative image related to alternator car price

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are generally more expensive than aftermarket alternatives but are often preferred for their guaranteed compatibility and quality. B2B buyers should weigh the benefits of OEM parts against cost when sourcing alternators.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for B2B buyers to manage inventory effectively and negotiate favorable terms. Suppliers may offer lower prices for larger orders, so knowing the MOQ can help in strategic purchasing.

3. RFQ (Request for Quotation)

An RFQ is a standard business process in which a buyer requests pricing and terms from suppliers for specific products, like alternators. This process helps businesses compare options and make informed decisions. Crafting a clear and detailed RFQ can lead to better pricing and terms.

Illustrative image related to alternator car price

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping and delivery. For B2B buyers importing alternators, understanding these terms is critical for managing costs and logistics. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight), which clarify who pays for shipping and insurance.

5. Warranty Period

The warranty period indicates the length of time a manufacturer guarantees their product against defects. A longer warranty often signifies higher quality and can be a deciding factor for B2B buyers when comparing alternators. Buyers should thoroughly review warranty terms to ensure adequate protection against potential failures.

By understanding these technical properties and trade terms, B2B buyers can navigate the alternator market more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Illustrative image related to alternator car price

Navigating Market Dynamics and Sourcing Trends in the alternator car price Sector

What Are the Key Market Dynamics Affecting the Alternator Car Price Sector?

The global alternator market is influenced by several dynamic factors that international B2B buyers should consider. The automotive sector’s shift towards electric vehicles (EVs) and hybrids is a significant driver, as these vehicles often utilize advanced alternator technology for energy management. In markets like Europe and parts of Africa, government regulations promoting green technology are accelerating this transition, leading to increased demand for high-efficiency alternators. Additionally, supply chain disruptions caused by geopolitical tensions and the COVID-19 pandemic have highlighted the need for diversified sourcing strategies. Buyers must be agile, leveraging technologies such as blockchain for better supply chain visibility and predictive analytics to optimize inventory management.

Emerging sourcing trends include a growing preference for remanufactured alternators, which can provide cost-effective alternatives while addressing sustainability concerns. Furthermore, the trend towards just-in-time (JIT) inventory systems is reshaping how businesses procure alternators, emphasizing the importance of reliable suppliers who can ensure timely deliveries. In regions like South America and the Middle East, where local manufacturers are gaining traction, B2B buyers should evaluate partnerships that not only meet cost targets but also align with local market needs.

How Can Sustainability and Ethical Sourcing Enhance Your Business in the Alternator Sector?

Sustainability and ethical sourcing are increasingly vital considerations for B2B buyers in the alternator market. The automotive industry is under pressure to reduce its environmental footprint, and this extends to the sourcing of alternators. Buyers are encouraged to seek suppliers who demonstrate a commitment to reducing waste and using environmentally friendly materials in their products. For instance, companies that offer alternators made from recycled materials or those that adhere to eco-friendly manufacturing processes can provide a competitive edge.

Moreover, obtaining certifications like ISO 14001 for environmental management or using materials with lower carbon footprints can enhance brand reputation and customer loyalty. Ethical supply chains not only mitigate risks associated with sourcing from regions with lax labor standards but also resonate with increasingly conscientious consumers. By prioritizing suppliers with transparent practices, buyers can help foster a more sustainable automotive ecosystem while potentially reducing costs associated with waste and inefficiency.

What Is the Historical Context of the Alternator Market That Influences Current Trends?

The alternator has evolved significantly since its inception in the early 20th century, transitioning from simple mechanical systems to sophisticated electronic units critical for modern vehicles. Initially, vehicles relied on generators for power, but as electrical demands grew with the advent of advanced automotive technologies, the alternator emerged as a more efficient solution. This evolution was driven by the need for higher voltage outputs and better reliability, leading to innovations such as the integration of microprocessor controls in modern alternators.

As global automotive markets began to expand in the late 20th century, the alternator’s design and manufacturing processes underwent further refinement, including the use of lighter materials and advanced manufacturing techniques. This historical context informs current trends, emphasizing the need for ongoing innovation and adaptation in the alternator market. As international B2B buyers navigate the complexities of sourcing, understanding this evolution provides valuable insights into the factors shaping pricing and availability today.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator car price

-

How do I determine the fair market price for an alternator?

To ascertain a fair market price for an alternator, consider factors such as the make and model of the vehicle, the type of alternator (OEM vs. aftermarket), and current market trends. Research online marketplaces, automotive parts suppliers, and industry reports to compare prices. Additionally, engage with local distributors or manufacturers to obtain quotes. For international buyers, consider currency fluctuations and shipping costs that may affect the overall price. -

What are the key factors affecting alternator prices?

Alternator prices are influenced by several factors, including the vehicle’s specifications, brand reputation, and whether the alternator is new, refurbished, or remanufactured. The complexity of the alternator’s design, required amperage, and additional features (like integrated voltage regulators) also play a role. Lastly, regional market conditions and import duties can significantly impact the final cost for international buyers. -

How can I ensure the quality of the alternators I purchase?

To ensure quality, source alternators from reputable manufacturers and suppliers with a proven track record. Request certifications and quality assurance documentation, such as ISO certifications or warranty details. It’s also beneficial to conduct product testing or request samples before placing larger orders. Establishing long-term relationships with suppliers who provide reliable customer service and support can further enhance confidence in the quality of your purchases. -

What is the minimum order quantity (MOQ) for alternators?

The MOQ for alternators can vary significantly based on the supplier and the type of alternator. Some suppliers may offer flexible MOQs for smaller businesses, while others may require bulk purchases to optimize shipping costs. It’s advisable to inquire directly with potential suppliers about their MOQs and any associated pricing tiers to find the best fit for your purchasing needs. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms when sourcing alternators can differ widely among suppliers. Common terms include upfront payments, net 30 or net 60 days, and payment upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify the payment structure and ensure it aligns with your cash flow requirements before finalizing any agreements. -

How do I vet suppliers for alternators?

Vetting suppliers for alternators involves assessing their credibility, production capacity, and quality control measures. Start by reviewing their business history, customer testimonials, and industry certifications. Engage in direct communication to gauge their responsiveness and willingness to provide necessary documentation. If possible, conduct site visits or use third-party verification services to ensure the supplier meets your expectations regarding quality and reliability. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider shipping methods, customs regulations, and lead times. Choose a reliable logistics partner experienced in handling automotive parts to ensure timely delivery. Be aware of import duties and taxes that may apply, and factor these costs into your overall budget. Additionally, establish a clear communication plan with your supplier regarding shipping schedules and tracking to avoid unexpected delays. -

Can I customize alternators for specific applications?

Yes, many manufacturers offer customization options for alternators to meet specific application requirements. Customizations can include modifications to amperage ratings, housing designs, or connectors to fit unique vehicle specifications. Discuss your needs with potential suppliers and inquire about their capabilities for customization, including any associated costs and lead times. Ensure that any custom alternators maintain compliance with industry standards for quality and performance.

Top 2 Alternator Car Price Manufacturers & Suppliers List

1. JD Power – Alternator Replacement Costs

Domain: jdpower.com

Registered: 1995 (30 years)

Introduction: Alternator replacement costs range from $350 to $900, with average part costs between $100 to $350, and luxury models costing $500 to $700. Labor costs can add $350 to $500, and replacing the serpentine belt may add $20 to $50. Rebuilt alternators are available and should match or exceed the original amp rating. DIY installation can save on labor costs, but requires some skill and time.

2. Advance Auto Parts – Alternator

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: Alternator – Advance Auto Parts

– Discounts: 15% OFF orders $35+, 20% OFF $100+ (online only, use code BLACKFRIDAY, exclusions apply)

– Function: Part of the vehicle’s electrical charging system, converts mechanical energy to electricity, powers electrical system, maintains battery charge.

– Importance: A failing alternator leads to reliance on battery power, depleting it until the engine dies.

– …

Strategic Sourcing Conclusion and Outlook for alternator car price

In conclusion, understanding the dynamics of alternator pricing is crucial for B2B buyers navigating the automotive parts market. Key takeaways include recognizing the significant role of alternators in vehicle performance, the variance in costs depending on vehicle models, and the potential for savings through strategic sourcing, such as opting for remanufactured parts or conducting DIY installations.

By prioritizing strategic sourcing, businesses can not only manage costs effectively but also ensure the reliability and longevity of their fleet’s electrical systems. As markets in Africa, South America, the Middle East, and Europe continue to evolve, staying informed about pricing trends and supplier relationships will be vital.

Looking ahead, we encourage international buyers to leverage data-driven insights and build strong partnerships with reputable suppliers. By doing so, you can enhance your procurement strategies, ultimately leading to improved operational efficiency and cost-effectiveness. Engage with your suppliers today to explore the best options for your business needs in the automotive sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.