Introduction: Navigating the Global Market for is alternator part of the engine

In the ever-evolving landscape of the automotive industry, understanding whether the alternator is part of the engine is crucial for B2B buyers. This component plays a pivotal role in converting mechanical energy into electrical energy, ensuring that vehicles operate efficiently. However, sourcing the right alternator can present significant challenges, especially for international buyers navigating diverse markets in Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Brazil.

This comprehensive guide delves into the multifaceted world of alternators, offering insights into different types, applications, and the importance of robust supplier vetting processes. By examining cost considerations and the implications of quality on overall vehicle performance, this resource empowers B2B purchasers to make informed decisions. Whether you are looking to optimize your inventory, reduce operational costs, or ensure compliance with local regulations, our guide provides the essential knowledge needed to thrive in a competitive market.

In a landscape where every decision can impact the bottom line, understanding the role of the alternator in the engine and how to procure high-quality components is more important than ever. This guide serves as your roadmap, equipping you with the tools necessary to navigate the global market effectively, ensuring your business remains ahead of the curve.

Table Of Contents

- Top 4 Is Alternator Part Of The Engine Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for is alternator part of the engine

- Understanding is alternator part of the engine Types and Variations

- Key Industrial Applications of is alternator part of the engine

- 3 Common User Pain Points for ‘is alternator part of the engine’ & Their Solutions

- Strategic Material Selection Guide for is alternator part of the engine

- In-depth Look: Manufacturing Processes and Quality Assurance for is alternator part of the engine

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘is alternator part of the engine’

- Comprehensive Cost and Pricing Analysis for is alternator part of the engine Sourcing

- Alternatives Analysis: Comparing is alternator part of the engine With Other Solutions

- Essential Technical Properties and Trade Terminology for is alternator part of the engine

- Navigating Market Dynamics and Sourcing Trends in the is alternator part of the engine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of is alternator part of the engine

- Strategic Sourcing Conclusion and Outlook for is alternator part of the engine

- Important Disclaimer & Terms of Use

Understanding is alternator part of the engine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Alternator | Uses a rotating magnetic field and a set of diodes for output. | Automotive manufacturing, aftermarket replacements | Pros: Widely available, cost-effective. Cons: Limited efficiency at low RPMs. |

| High-Output Alternator | Designed to produce more power than standard alternators. | Performance vehicles, heavy-duty applications | Pros: Supports high electrical demand. Cons: Higher cost, may require modifications. |

| Smart Alternator | Integrates electronics for variable output based on demand. | Hybrid and electric vehicles, advanced automotive systems | Pros: Increased efficiency, reduces load on the engine. Cons: More complex, higher repair costs. |

| Brushless Alternator | Eliminates brushes, reducing maintenance and wear. | Commercial vehicles, industrial machinery | Pros: Longer lifespan, less maintenance. Cons: Higher initial cost, limited availability. |

| Dual-Voltage Alternator | Capable of producing two voltage outputs for different applications. | Specialty vehicles, emergency services | Pros: Versatile use, can power multiple systems. Cons: More complicated installation, costlier. |

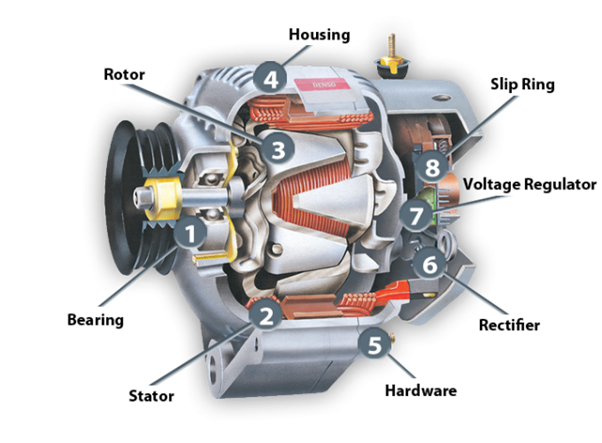

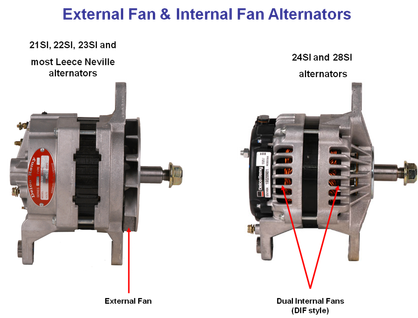

What are the characteristics of Conventional Alternators?

Conventional alternators are the most common type found in vehicles, utilizing a rotating magnetic field to generate electricity. They typically produce a fixed output and are designed for standard automotive applications. B2B buyers in the automotive manufacturing sector often prefer these for their cost-effectiveness and ease of installation. However, their performance can be limited at low RPMs, which may affect vehicles with high electrical demands.

How do High-Output Alternators cater to specific needs?

High-output alternators are engineered to deliver significantly more power than conventional models, making them ideal for performance vehicles or heavy-duty applications. These alternators are crucial for vehicles with numerous electrical accessories, such as sound systems or lighting. While they provide enhanced performance, buyers should consider the increased cost and potential need for modifications to the vehicle’s electrical system when purchasing.

What advantages do Smart Alternators offer in modern vehicles?

Smart alternators feature advanced electronics that allow them to adjust their output based on real-time electrical demand. This technology is particularly beneficial in hybrid and electric vehicles, where efficiency is paramount. B2B buyers focused on cutting-edge automotive technologies will find these alternators appealing due to their ability to reduce engine load and improve fuel efficiency. However, the complexity of these systems can lead to higher repair costs.

Why choose Brushless Alternators for industrial applications?

Brushless alternators are designed to minimize maintenance and wear by eliminating brushes, which are common failure points in traditional designs. They are particularly suited for commercial vehicles and industrial machinery, where reliability is essential. Buyers in these sectors will appreciate the longer lifespan and lower maintenance requirements, although the initial investment is typically higher compared to conventional models.

What makes Dual-Voltage Alternators suitable for specialty applications?

Dual-voltage alternators can produce two different voltage outputs, allowing them to power various systems within a vehicle simultaneously. This feature is especially useful in specialty vehicles or emergency services that require flexibility. While their versatility is a significant advantage, B2B buyers should consider the complexities of installation and the increased costs associated with these specialized units.

Key Industrial Applications of is alternator part of the engine

| Industry/Sector | Specific Application of is alternator part of the engine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Power generation for vehicle electrical systems | Ensures reliability of vehicles, reducing downtime | Quality certifications, compatibility with models |

| Heavy Machinery | Alternators in construction and mining equipment | Enhances operational efficiency and productivity | Durability under harsh conditions, voltage capacity |

| Marine | Power supply for boats and ships | Supports navigation and onboard electrical systems | Saltwater resistance, size and weight specifications |

| Agriculture | Alternators in agricultural machinery | Improves reliability of equipment, increasing yield | Power output requirements, environmental durability |

| Transportation | Alternators in public transport vehicles | Ensures safety and operational reliability | Compliance with local regulations, maintenance support |

How is the Alternator Integral to the Automotive Industry?

In the automotive sector, the alternator is crucial for generating electrical power to support vehicle systems such as lighting, infotainment, and safety features. A well-functioning alternator minimizes the risk of vehicle breakdowns due to electrical failures, which can significantly reduce maintenance costs and enhance customer satisfaction. For international buyers, sourcing alternators that meet specific vehicle compatibility and quality standards is essential to ensure long-term performance and reliability.

What Role Do Alternators Play in Heavy Machinery Applications?

In heavy machinery, such as construction and mining equipment, alternators are vital for converting mechanical energy into electrical energy to power various systems. A robust alternator enables machinery to operate efficiently, reducing the risk of downtime caused by electrical failures. Buyers in this sector should prioritize sourcing alternators that are durable, capable of withstanding harsh environmental conditions, and have adequate voltage capacity to meet the demands of heavy-duty applications.

How are Alternators Used in Marine Applications?

Marine applications rely on alternators to provide electrical power for navigation systems, lighting, and other essential onboard equipment. Given the unique challenges posed by saltwater environments, it is crucial to source alternators that are specifically designed for corrosion resistance and high performance. Buyers in this industry should consider the size and weight of alternators, as well as their power output capabilities, to ensure they fit within the constraints of marine vessels.

Why are Alternators Important in Agriculture?

In agriculture, alternators are employed in various machinery, including tractors and harvesters, to ensure reliable power for operations. A dependable alternator contributes to increased productivity by minimizing equipment failures during critical farming activities. Buyers should focus on sourcing alternators with the appropriate power output and environmental durability to withstand the rigors of agricultural work, ensuring that their machinery remains operational during peak seasons.

What is the Importance of Alternators in Transportation?

In the transportation sector, alternators are essential for public transport vehicles, providing the necessary electrical power for safety systems, lighting, and passenger comfort. Ensuring the reliability of these systems is critical for safety and operational efficiency. Buyers must consider compliance with local regulations and seek suppliers that offer strong maintenance support to keep their fleet running smoothly and safely.

3 Common User Pain Points for ‘is alternator part of the engine’ & Their Solutions

Scenario 1: Understanding the Role of an Alternator in Engine Functionality

The Problem: B2B buyers often encounter confusion regarding the alternator’s role within a vehicle’s engine system. This misunderstanding can lead to miscommunication with suppliers and mechanics, resulting in incorrect part specifications or unnecessary purchases. For example, an automotive parts retailer might receive orders for batteries when the actual issue lies with a malfunctioning alternator. This not only wastes time and resources but can also damage customer relationships when expectations are not met.

The Solution: To address this challenge, B2B buyers should invest time in understanding the alternator’s function as a critical component of the engine’s electrical system. Engaging in supplier training or workshops can enhance knowledge about the alternator’s role in converting mechanical energy from the engine into electrical energy, which is essential for charging the battery and powering electrical components. Additionally, creating detailed product specification sheets that outline the alternator’s characteristics, compatibility, and common issues can help ensure accurate orders and reduce miscommunication. Suppliers can also provide educational materials or online resources to clarify the distinctions between the alternator and other components, such as the battery and starter motor.

Scenario 2: Identifying Signs of Alternator Failure in Vehicles

The Problem: Automotive businesses, such as repair shops or fleet management companies, often face the challenge of diagnosing alternator issues promptly. Without a clear understanding of the signs of alternator failure, mechanics may misdiagnose problems, leading to unnecessary repairs and increased costs. For instance, if a fleet manager is unaware that dimming headlights or a battery warning light indicates alternator issues, they might replace batteries repeatedly without addressing the root cause.

The Solution: Implementing a systematic approach to vehicle diagnostics can significantly mitigate this issue. B2B buyers should encourage their teams to familiarize themselves with the common signs of alternator failure, such as flickering dashboard lights, strange noises, or electrical accessories functioning poorly. Conducting regular training sessions on vehicle electrical systems can empower staff to recognize these symptoms early. Additionally, investing in diagnostic tools that provide real-time data on vehicle performance can help technicians identify alternator-related issues more efficiently. By educating employees and providing the right tools, businesses can ensure timely repairs, thereby reducing operational costs and improving customer satisfaction.

Scenario 3: Sourcing Quality Alternator Parts for Different Engine Types

The Problem: When sourcing alternator parts, B2B buyers often struggle with finding high-quality components that are compatible with a diverse range of engine types. The global market presents an array of options, but not all suppliers meet the necessary quality standards. This inconsistency can lead to subpar replacements that fail prematurely, resulting in increased warranty claims and dissatisfied customers.

The Solution: To overcome this sourcing challenge, B2B buyers should establish relationships with reputable suppliers known for their quality and reliability. Conducting thorough due diligence, including checking reviews, certifications, and warranty policies, can help ensure that sourced alternators meet or exceed industry standards. Buyers can also create a standardized checklist for evaluating suppliers based on criteria such as production capabilities, quality assurance processes, and customer service responsiveness. Furthermore, leveraging technology to track supplier performance and product quality can provide valuable insights, enabling buyers to make informed decisions. By prioritizing quality over cost and establishing strong supplier relationships, businesses can enhance their product offerings and maintain customer loyalty.

Strategic Material Selection Guide for is alternator part of the engine

What Materials Are Commonly Used in Alternators and Their Properties?

When selecting materials for alternators, it’s essential to consider factors such as performance, durability, cost, and compliance with international standards. The following analysis covers four common materials used in alternators: aluminum, copper, steel, and plastic composites.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is widely used in alternator housings and components due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C, making it suitable for the high-temperature environments found in engine compartments.

Pros: Aluminum is durable, lightweight, and offers good thermal conductivity, which aids in heat dissipation. It is also relatively easy to manufacture and can be extruded or cast into complex shapes.

Cons: While aluminum is generally cost-effective, it can be more expensive than some steel options. Its mechanical strength is lower than steel, which may limit its use in high-stress applications.

Impact on Application: Aluminum’s corrosion resistance makes it ideal for vehicles operating in humid or coastal environments, common in regions like South America and the Middle East.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is crucial. Buyers should ensure that suppliers meet local regulations regarding material quality and environmental impact.

Copper: Superior Conductivity

Copper is primarily used in the windings of alternators due to its exceptional electrical conductivity. It operates effectively at temperatures up to 200°C and can handle high current loads without significant losses.

Pros: The high conductivity of copper improves the efficiency of the alternator, reducing energy losses. It is also highly durable and resistant to fatigue.

Cons: Copper is heavier than aluminum, which can affect the overall weight of the alternator. Additionally, it is more expensive, which may increase the overall cost of the alternator.

Impact on Application: Copper’s compatibility with high electrical loads makes it ideal for vehicles with advanced electrical systems, commonly found in European and Middle Eastern markets.

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM B170 for copper wire. In regions with high copper prices, alternative materials may be considered to manage costs.

Steel: Strength and Durability

Steel is often used for structural components of alternators, such as brackets and shafts, due to its high strength and durability. It can withstand high temperatures and pressures, making it suitable for demanding applications.

Pros: Steel’s strength allows for robust construction, reducing the likelihood of mechanical failures. It is also relatively inexpensive compared to other materials.

Cons: Steel is prone to corrosion if not properly treated, which can lead to premature failure in harsh environments. It is also heavier than aluminum, which can impact fuel efficiency.

Impact on Application: Steel is well-suited for heavy-duty applications, particularly in vehicles designed for rugged terrains, which are common in Africa and South America.

Considerations for International Buyers: Compliance with standards like ASTM A36 for structural steel is essential. Buyers should also consider local corrosion resistance treatments to enhance longevity.

Plastic Composites: Lightweight and Cost-Effective

Plastic composites are increasingly used in alternators for non-structural components, such as covers and insulators. They can operate effectively at temperatures up to 120°C.

Pros: Plastic composites are lightweight and can be molded into complex shapes, offering design flexibility. They are also resistant to corrosion and can be cost-effective.

Cons: While they are suitable for non-load-bearing applications, their mechanical properties may not be sufficient for high-stress components. They also have lower thermal conductivity compared to metals.

Impact on Application: Plastic composites are ideal for applications where weight savings are critical, such as in hybrid and electric vehicles, which are gaining traction in Europe and the Middle East.

Considerations for International Buyers: Compliance with standards such as ISO 9001 for quality management is important. Buyers should also assess the environmental impact of plastic materials in their markets.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for is alternator part of the engine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings and structural components | Lightweight and corrosion-resistant | Lower mechanical strength compared to steel | Medium |

| Copper | Windings and electrical connections | Superior electrical conductivity | Heavier and more expensive | High |

| Steel | Brackets and shafts | High strength and durability | Prone to corrosion | Low |

| Plastic Composites | Covers and insulators | Lightweight and cost-effective | Limited mechanical properties | Low |

This analysis provides a comprehensive overview of the materials commonly used in alternators, highlighting their properties, advantages, and considerations for international buyers. Understanding these factors can help B2B buyers make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for is alternator part of the engine

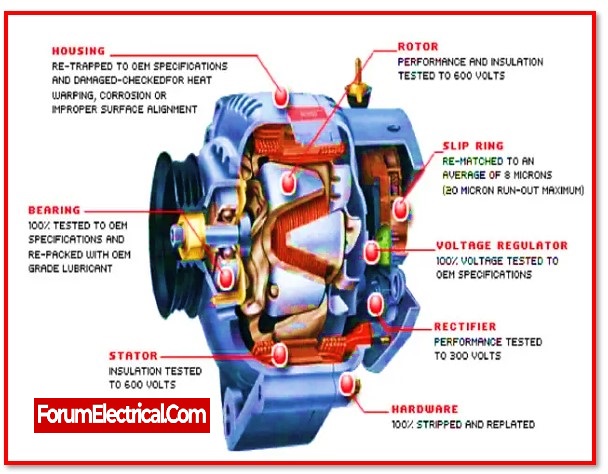

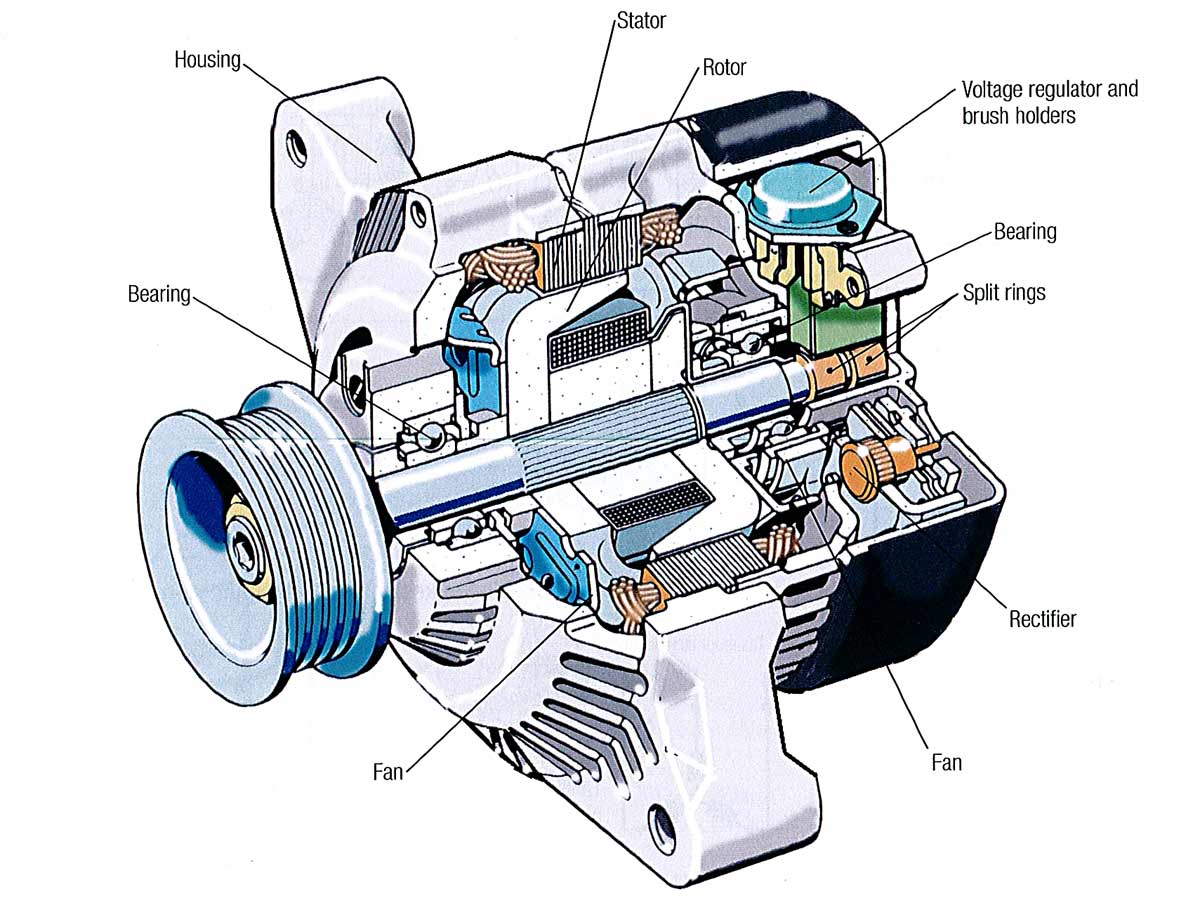

What Are the Key Stages in the Manufacturing Process of an Alternator?

The manufacturing process of an alternator involves several critical stages, each designed to ensure that the final product meets stringent performance and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to is alternator part of the engine

How Is Material Prepared for Alternator Manufacturing?

Material preparation begins with the selection of high-quality raw materials. For alternators, this typically includes copper for wiring, steel for the frame, and various alloys for internal components like the rotor and stator. Manufacturers often source materials that meet international standards to ensure durability and performance.

Once materials are sourced, they undergo rigorous inspection to verify their quality and specifications. This initial quality control (IQC) stage is vital in preventing defects that could compromise the alternator’s performance.

What Techniques Are Used in the Forming Stage of Alternator Production?

The forming stage involves shaping the raw materials into the necessary components of the alternator. Techniques such as stamping, machining, and die casting are commonly employed.

- Stamping is used to create flat components like the alternator housing from metal sheets.

- Machining processes, including CNC (Computer Numerical Control) machining, are used for precision parts like the rotor and stator, ensuring they fit together perfectly.

- Die casting is often utilized for creating complex shapes in aluminum or zinc, which are lightweight and resistant to corrosion.

Each of these techniques contributes to the overall efficiency and reliability of the alternator, making it essential for manufacturers to choose the right methods based on the design specifications.

Illustrative image related to is alternator part of the engine

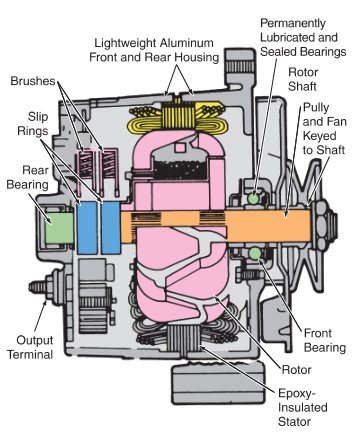

What Happens During the Assembly Phase of Alternator Manufacturing?

The assembly phase is where all the components come together to form a complete alternator. This process typically involves:

- Component Assembly: Individual components like the rotor, stator, voltage regulator, and bearings are assembled. Precision is critical here to ensure that all parts fit and function correctly.

- Electrical Connections: Wiring is installed to connect the electrical components, facilitating the conversion of mechanical energy into electrical energy.

- Quality Checks: Throughout assembly, manufacturers conduct in-process quality control (IPQC) checks to monitor the assembly’s adherence to specifications.

A well-structured assembly process minimizes the risk of errors and enhances product reliability.

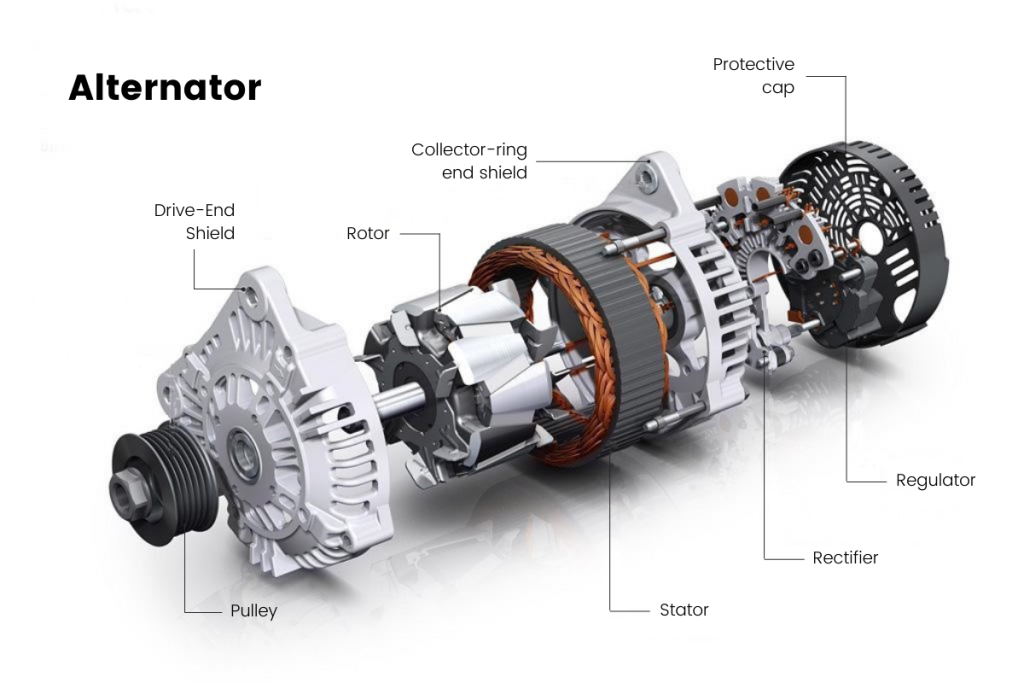

How Is the Finishing Stage Managed in Alternator Production?

The finishing stage involves applying protective coatings and conducting final inspections. Protective coatings may include paint or plating to prevent corrosion, particularly for alternators that will be used in challenging environments.

Final inspections are crucial and typically include visual checks and functional testing to ensure that the alternator operates correctly under various conditions. This stage may also involve testing for electrical output and mechanical integrity, ensuring compliance with international standards.

What Quality Assurance Measures Are Applied in Alternator Manufacturing?

Quality assurance in alternator manufacturing is governed by a series of international standards and industry-specific regulations.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems. Adhering to these standards ensures that manufacturers consistently produce high-quality products. Additionally, certifications like CE mark (Conformité Européenne) are crucial for products sold in European markets, indicating compliance with safety, health, and environmental protection standards.

For B2B buyers, understanding these standards is essential for assessing potential suppliers. It offers insights into their commitment to quality and reliability.

What Are the Key Quality Control Checkpoints in Alternator Production?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that the alternator meets all specifications.

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during assembly to identify any defects early in the process.

- Final Quality Control (FQC): This final checkpoint ensures that the assembled alternator meets all operational standards and is ready for market distribution.

These checkpoints help prevent defective products from reaching customers and maintain the manufacturer’s reputation for quality.

What Testing Methods Are Commonly Used for Alternators?

Testing methods for alternators include:

- Electrical Testing: Ensures that the alternator produces the correct voltage and current output.

- Mechanical Testing: Assesses the structural integrity of the alternator under various load conditions.

- Environmental Testing: Simulates conditions such as extreme temperatures and humidity to evaluate performance under stress.

By implementing these testing methods, manufacturers can ensure that their alternators will perform reliably in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital.

What Steps Can Buyers Take to Ensure Supplier Compliance?

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand.

- Requesting Quality Reports: Buyers can ask for detailed quality control reports that document testing results and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product reliability.

By taking these steps, buyers can mitigate risks and ensure that they source high-quality alternators that meet their operational needs.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must also navigate different regulatory environments and quality expectations.

- Cultural Differences: Understanding local manufacturing practices and cultural attitudes towards quality can influence supplier relationships.

- Regulatory Compliance: Different countries may have unique regulations regarding automotive components, making it essential for buyers to ensure that their suppliers comply with local laws.

- Shipping and Logistics: Quality assurance does not end at the factory. Ensuring that products are transported and stored under optimal conditions is critical to maintaining quality.

By being aware of these nuances, B2B buyers can make informed decisions and establish successful partnerships with suppliers worldwide.

Illustrative image related to is alternator part of the engine

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for alternators not only aids buyers in making informed purchasing decisions but also enhances the overall reliability and performance of the products they procure.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘is alternator part of the engine’

Introduction

Navigating the procurement of automotive parts, particularly alternators, requires a structured approach to ensure you secure high-quality components that meet your operational needs. This guide provides a practical checklist for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, to facilitate informed sourcing decisions regarding alternators as integral parts of engine systems.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before sourcing alternators. Identify the specific vehicle types, engine configurations, and power requirements to ensure compatibility. This step helps streamline your search and reduces the risk of acquiring unsuitable components.

Illustrative image related to is alternator part of the engine

- Key Specifications to Consider:

- Voltage and amperage ratings

- Physical dimensions and mounting configurations

- Electrical connections and harness compatibility

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to gauge their reliability and reputation in the market. Look for suppliers with extensive experience in automotive components and a track record of quality.

- Where to Look:

- Industry trade shows and exhibitions

- Online B2B marketplaces and directories

- Recommendations from industry peers

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications ensures that the alternators meet international quality and safety standards. Look for ISO certifications or specific automotive industry standards, which indicate a commitment to quality manufacturing processes.

- Certification Types to Look For:

- ISO 9001 for quality management

- IATF 16949 for automotive quality management

- CE marking for compliance with EU standards

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the alternators to evaluate their quality firsthand. Testing the samples allows you to assess performance, durability, and compatibility with your vehicles.

- What to Test:

- Electrical output under various loads

- Physical durability and resistance to environmental factors

- Noise levels during operation

Step 5: Analyze Pricing and Payment Terms

Understanding the pricing structure and payment terms is vital for maintaining budget control. Compare quotes from multiple suppliers while considering additional costs such as shipping, customs, and duties.

- Key Considerations:

- Bulk order discounts

- Payment terms (e.g., upfront payment, credit terms)

- Warranty and return policies

Step 6: Assess After-Sales Support and Warranty

Reliable after-sales support is essential for addressing any issues that may arise post-purchase. Ensure the supplier offers comprehensive warranty coverage and accessible customer support.

- What to Look For:

- Length and terms of the warranty

- Availability of technical support and troubleshooting assistance

- Return and exchange policies for defective products

Step 7: Finalize Your Order and Monitor Delivery

Once you select a supplier, finalize the order with clear communication regarding delivery timelines and expectations. Monitor the shipment process to ensure timely delivery and adherence to agreed-upon terms.

- Delivery Monitoring Tips:

- Use tracking services provided by the supplier

- Communicate regularly for updates on shipping status

- Prepare for customs clearance processes if applicable

By following this step-by-step checklist, B2B buyers can effectively navigate the procurement process for alternators, ensuring they acquire high-quality components that support their engine systems efficiently.

Comprehensive Cost and Pricing Analysis for is alternator part of the engine Sourcing

Understanding the cost structure and pricing analysis for alternators, a crucial component of the engine, is essential for B2B buyers in various international markets, including Africa, South America, the Middle East, and Europe. This comprehensive breakdown will help buyers make informed purchasing decisions while considering the unique factors that influence pricing.

What Are the Key Cost Components for Alternators?

When sourcing alternators, several cost components must be considered:

-

Materials: The primary materials used in alternator production include copper, aluminum, and steel, which contribute significantly to the overall cost. The quality and sourcing of these materials can vary, impacting the final price.

-

Labor: Labor costs are influenced by the region of manufacturing and the complexity of the assembly process. Countries with lower labor costs may offer more competitive pricing but could compromise on quality.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and operational management. High overhead can lead to increased prices, so it’s essential to evaluate the manufacturer’s efficiency.

-

Tooling: Specialized equipment for production can be a significant upfront cost. Suppliers may pass these costs onto buyers, particularly for custom or low-volume orders.

-

Quality Control (QC): Quality assurance processes are crucial for ensuring that alternators meet performance standards. Manufacturers with robust QC practices may charge higher prices, but this can lead to lower failure rates and reduced warranty claims.

-

Logistics: Shipping and handling fees can vary widely based on the shipping method, distance, and Incoterms used. Buyers should account for these costs when calculating the total price.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding market standards for margins can help buyers negotiate better deals.

What Influences the Price of Alternators?

Several factors can influence the price of alternators:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that allow for cost savings while meeting their needs.

-

Specifications and Customization: Custom-built alternators designed for specific applications or vehicles may incur higher costs. Buyers should weigh the benefits of customization against the additional expense.

-

Material Quality and Certifications: Alternators that meet specific industry standards or certifications (such as ISO or SAE) may carry a premium price. Buyers should consider the long-term value of investing in certified products.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers with a track record of quality may charge more but offer better support and warranty options.

-

Incoterms: The choice of Incoterms affects the total landed cost of the product. Buyers must understand their responsibilities regarding shipping, insurance, and duties to avoid unexpected expenses.

What Are the Best Practices for Buyers When Sourcing Alternators?

To maximize value when sourcing alternators, B2B buyers should adopt the following strategies:

-

Negotiate Effectively: Leverage volume purchases and long-term contracts to negotiate better prices and terms. Building a relationship with suppliers can also lead to more favorable conditions.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, warranty claims, and potential downtime. Investing in higher-quality alternators may reduce overall TCO.

-

Understand Pricing Nuances in International Markets: Different regions may have unique pricing structures influenced by local economic conditions, tariffs, and import duties. Conduct thorough market research to ensure competitive pricing.

-

Evaluate Supplier Capabilities: Assess suppliers not only on price but also on their ability to deliver quality products consistently. Request samples or case studies to verify their performance.

In conclusion, understanding the intricate cost components and pricing influencers for alternators is essential for B2B buyers. By applying strategic sourcing practices and considering the total cost of ownership, buyers can make informed decisions that align with their operational needs and budget constraints. Always remember to verify prices and terms with suppliers, as costs can fluctuate based on various factors.

Illustrative image related to is alternator part of the engine

Alternatives Analysis: Comparing is alternator part of the engine With Other Solutions

Understanding Alternatives to the Alternator in Engine Applications

When evaluating the role of an alternator as part of an engine’s functionality, it’s crucial to explore alternative solutions that can fulfill similar needs. The alternator is primarily responsible for converting mechanical energy from the engine into electrical energy, thus powering the vehicle’s electrical systems. However, various technologies can achieve the same goal, each with unique advantages and disadvantages. This analysis will compare the traditional alternator with two viable alternatives: alternating current (AC) generators and battery electric systems.

Comparison Table

| Comparison Aspect | Is Alternator Part Of The Engine | Alternative 1: AC Generator | Alternative 2: Battery Electric System |

|---|---|---|---|

| Performance | Reliable electrical output under varying RPMs | High efficiency in constant speed applications | Excellent energy storage and delivery, instant power |

| Cost | Moderate initial and replacement costs | Typically higher due to complexity | Higher upfront cost; lower operational costs |

| Ease of Implementation | Standard integration in combustion vehicles | Requires specialized installation | Complex integration, especially in existing systems |

| Maintenance | Regular checks needed; wear and tear over time | Lower maintenance but may need periodic servicing | Minimal maintenance; battery replacement required |

| Best Use Case | Conventional combustion engine vehicles | Industrial applications with steady power needs | Electric vehicles and hybrid systems |

In-Depth Analysis of Alternatives

What Are AC Generators and Their Benefits?

AC generators serve a similar function to alternators but are often used in settings where a steady power supply is needed, such as industrial applications. These generators convert mechanical energy into electrical energy through electromagnetic induction.

Pros: AC generators can achieve higher efficiency rates in constant speed applications, making them ideal for power plants or stationary engines. They often have lower maintenance needs compared to traditional alternators.

Cons: The initial cost can be higher due to the complexity of the system, and they may not perform well in variable speed applications, limiting their use in automotive contexts.

How Do Battery Electric Systems Work as an Alternative?

Battery electric systems utilize rechargeable batteries to store energy, which can then be used to power the vehicle’s electric systems. This technology is prevalent in electric and hybrid vehicles.

Pros: The main advantage of battery electric systems is their ability to provide instant power and energy storage, making them suitable for electric vehicles. They also have lower operational costs over time since they require less maintenance than traditional combustion engines.

Cons: The initial investment in battery technology can be significant, and existing vehicles may require extensive modifications for integration. Additionally, battery lifespan and replacement can be a concern for long-term operational costs.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between an alternator, AC generator, or battery electric system, B2B buyers must consider several factors specific to their operational needs. For businesses focused on conventional combustion engine vehicles, the alternator remains a reliable choice due to its established performance and integration ease. In contrast, industries requiring steady power supply might benefit from AC generators, while companies looking to invest in future-proof electric or hybrid vehicle technologies should explore battery electric systems. Evaluating the total cost of ownership, maintenance requirements, and performance in specific applications will guide buyers to the most appropriate solution for their operational objectives.

Illustrative image related to is alternator part of the engine

Essential Technical Properties and Trade Terminology for is alternator part of the engine

What Are the Key Technical Properties of an Alternator?

Understanding the technical properties of an alternator is crucial for B2B buyers, especially when selecting components for vehicle manufacturing or repair. Here are essential specifications that define alternators:

-

Power Output (Voltage and Amperage)

The power output of an alternator is typically measured in volts and amps. Standard automotive alternators generate between 12 to 14.5 volts, with amperage ranging from 40 to over 200 amps, depending on the vehicle’s electrical demands. For B2B buyers, selecting an alternator with the appropriate power output ensures compatibility with the vehicle’s electrical system, preventing potential failures and ensuring reliability. -

Efficiency Rating

Efficiency ratings indicate how effectively an alternator converts mechanical energy into electrical energy. Higher efficiency means less wasted energy, which can lead to better fuel economy and reduced engine load. For manufacturers, prioritizing high-efficiency alternators can enhance the overall performance of the vehicle, making it more appealing to end consumers. -

Material Grade

The construction materials of an alternator, such as the rotor, stator, and housing, significantly impact durability and performance. Common materials include aluminum and copper, which are chosen for their electrical conductivity and resistance to corrosion. B2B buyers should consider material grades to ensure longevity and resistance to environmental factors, particularly in regions with harsh climates. -

Operating Temperature Range

Alternators are designed to operate within specific temperature ranges, often between -40°C to 125°C. This range is critical for ensuring consistent performance under various conditions. For international buyers, understanding the operating temperature is vital, especially when considering regions with extreme temperatures, as it can affect warranty claims and maintenance schedules. -

Regulatory Compliance

Alternators must comply with various industry standards and regulations, such as ISO and SAE specifications. These standards ensure safety, quality, and interoperability with other vehicle systems. B2B buyers should verify compliance to avoid legal issues and ensure product reliability in different markets. -

Lifespan and Maintenance Requirements

Most alternators have a lifespan of around 100,000 to 150,000 miles but can vary based on use and conditions. Understanding maintenance needs, such as regular inspections and potential replacements of brushes and bearings, is crucial for fleet operators and manufacturers to minimize downtime and maintain efficiency.

What Are Common Trade Terms Related to Alternators?

Familiarity with industry jargon is essential for effective communication in the B2B marketplace. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the same manufacturer that produced the original part for the vehicle. B2B buyers often prefer OEM parts due to their guaranteed compatibility and quality, ensuring that replacements perform identically to the original components. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units a supplier is willing to sell in a single order. For B2B buyers, understanding MOQ is crucial for inventory management and cost-effectiveness, especially when planning purchases for large-scale production. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. In the context of alternators, submitting an RFQ allows buyers to compare pricing and specifications, facilitating informed purchasing decisions. -

Incoterms

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers for the delivery of goods. Understanding these terms helps B2B buyers manage shipping costs, risks, and logistics when sourcing alternators from international suppliers. -

Warranty Coverage

Warranty coverage specifies the terms under which a supplier will repair or replace defective products. B2B buyers should carefully review warranty terms for alternators to ensure adequate protection against potential failures, which can affect operational costs. -

Aftermarket Parts

Aftermarket parts are replacements made by manufacturers other than the original manufacturer. While often more affordable, B2B buyers should weigh the pros and cons of aftermarket versus OEM parts to ensure quality and compatibility with their vehicles.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing alternators, ultimately enhancing their product offerings and ensuring customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the is alternator part of the engine Sector

What Are the Current Market Dynamics Influencing the Alternator Sector?

The global alternator market is experiencing robust growth driven by several factors, including increasing vehicle production, the rise of electric and hybrid vehicles, and advancements in automotive technology. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware that the demand for alternators is expected to increase as automotive manufacturers focus on enhancing fuel efficiency and reducing emissions. This shift is largely influenced by government regulations pushing for greener technologies, which in turn drives the need for efficient electrical systems in vehicles.

Emerging trends in B2B sourcing highlight the importance of integrating advanced technologies such as IoT and AI in manufacturing processes. These technologies are enhancing the efficiency of alternator production and allowing for real-time monitoring of component performance. For buyers, this means a greater emphasis on sourcing from manufacturers who can provide not just traditional parts, but also smart alternators equipped with monitoring capabilities that can predict failures before they occur. Furthermore, global supply chain dynamics are evolving, with a focus on local sourcing to mitigate risks associated with international logistics and tariffs.

How Is Sustainability Shaping the Sourcing of Alternators?

Sustainability is becoming a cornerstone of B2B purchasing decisions in the alternator sector. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to seek suppliers that prioritize sustainable practices. This includes the use of recyclable materials in alternator production and adherence to ‘green’ certifications, which validate environmentally responsible practices.

Ethical sourcing is equally important, as businesses aim to ensure that their supply chains do not contribute to environmental degradation or exploitative labor practices. Buyers are encouraged to partner with manufacturers who demonstrate transparency in their sourcing processes and utilize eco-friendly materials. The adoption of renewable energy sources in manufacturing facilities is also gaining traction, aligning with the global push towards carbon neutrality. By focusing on sustainability, B2B buyers can enhance their brand reputation while also meeting the increasing consumer demand for environmentally responsible products.

What Is the Historical Context of the Alternator’s Development?

The alternator has evolved significantly since its inception in the early 20th century. Originally designed to provide power to vehicles, alternators have transformed from simple mechanical devices to sophisticated electrical components integral to modern automotive systems. The shift from direct current (DC) generators to alternating current (AC) alternators around the 1960s marked a pivotal change, enabling greater efficiency and reliability.

As vehicles have become more complex, so too have alternators, which now incorporate advanced technologies such as integrated voltage regulators and intelligent control systems. This evolution not only reflects advancements in automotive engineering but also the growing demand for higher energy efficiency and performance. For B2B buyers, understanding the historical context of alternators can provide valuable insights into their technical specifications and performance capabilities, aiding in informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of is alternator part of the engine

-

How does an alternator function within a vehicle’s engine system?

An alternator is a key component of a vehicle’s electrical system, converting mechanical energy from the engine into electrical energy. It works by using a rotating magnetic field to produce alternating current (AC), which is then converted to direct current (DC) to charge the car battery and power electrical components. Understanding this function is essential for buyers looking to source alternators, as it highlights their critical role in vehicle performance and reliability. -

What are the signs that an alternator may be failing?

Common indicators of a failing alternator include dimming headlights, a battery warning light on the dashboard, and electrical malfunctions within the vehicle. Buyers should consider sourcing alternators that come with warranties or guarantees, as these can provide added security against premature failures. Additionally, ensuring that the supplier offers quality assurance checks can help mitigate risks associated with faulty parts. -

What should I consider when sourcing alternators for international trade?

When sourcing alternators internationally, it’s vital to consider the supplier’s reputation, quality certifications, and compliance with international standards. Buyers should also evaluate the supplier’s experience in exporting automotive parts to ensure they understand the complexities of international shipping, tariffs, and regulations specific to their region, whether in Africa, South America, the Middle East, or Europe. -

How can I vet suppliers of alternators effectively?

To vet suppliers effectively, request detailed company profiles, including their manufacturing processes, quality control measures, and customer testimonials. It’s also beneficial to ask for references from other B2B buyers who have sourced alternators from them. Conducting factory visits, if possible, can provide firsthand insights into their operations and reliability. -

What are typical payment terms for purchasing alternators in bulk?

Payment terms can vary widely, but common practices include upfront payments, letters of credit, or staggered payments based on shipment milestones. Buyers should negotiate terms that align with their cash flow while ensuring the supplier’s financial stability. Clear agreements on payment schedules can help prevent misunderstandings and ensure smooth transactions. -

What are the minimum order quantities (MOQs) for alternators?

Minimum order quantities for alternators often depend on the manufacturer and the specific model. Many suppliers set MOQs to ensure production efficiency and cost-effectiveness. Buyers should inquire about the possibility of lower MOQs, especially when testing new markets or during initial orders, to minimize risk and investment. -

How can I customize alternators to meet specific market needs?

Customization options for alternators may include variations in voltage output, size, and connector types. When engaging with suppliers, clearly communicate your requirements and target market specifications. Some manufacturers may offer tailored solutions to meet unique demands, such as those arising from different vehicle models or regional electrical standards. -

What logistics considerations should I keep in mind when importing alternators?

Logistics play a crucial role in importing alternators, including shipping methods, customs clearance, and delivery timelines. Buyers should work with logistics partners experienced in automotive parts to navigate potential challenges. It’s essential to understand the shipping costs, potential duties, and local regulations to ensure timely and cost-effective delivery to your destination.

Top 4 Is Alternator Part Of The Engine Manufacturers & Suppliers List

1. Reddit – Vehicle Electrical Systems

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Vehicle Electrical Systems, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Endurance Warranty – Alternator Insights

Domain: endurancewarranty.com

Registered: 2009 (16 years)

Introduction: An alternator is an electrical generator in a vehicle that converts mechanical energy to electrical energy, keeping the car battery charged and the electrical system running. Signs of a bad alternator include a battery light on the dashboard, dim or flickering headlights, a dead battery, strange noises, a burning smell, slow electrical accessories, difficulty starting the car, and stalling while d…

3. Kia – Alternator

Domain: kia.com

Registered: 1996 (29 years)

Introduction: An alternator is an integral part of every combustion engine vehicle, responsible for converting chemical energy to electrical energy to charge and replenish the battery and other electrical components in a car. The vehicle’s charging system consists of a car battery, voltage regulator, and alternator. The alternator converts mechanical energy to electrical energy with alternating current (AC), wh…

4. Jack’s OK Tire – Alternators

Domain: jacksoktire.com

Registered: 2001 (24 years)

Introduction: Alternators are a part of the vehicle’s charging system, which includes the battery, voltage regulator, and alternator itself. They generate electrical currents to power various electrical components in the car, such as headlights and dashboard lights. Located towards the front of the engine, alternators are powered by the engine’s serpentine belt and utilize the crankshaft’s power to create elect…

Strategic Sourcing Conclusion and Outlook for is alternator part of the engine

What Are the Key Insights for Sourcing Alternators in Global Markets?

In conclusion, understanding the role of the alternator as an essential component of the engine is crucial for international B2B buyers. The alternator’s primary function is to convert mechanical energy from the engine into electrical energy, powering various vehicle systems and ensuring optimal performance. Given its critical nature, sourcing high-quality alternators is not only about securing a reliable part but also about minimizing potential downtime and repair costs.

Illustrative image related to is alternator part of the engine

Strategic sourcing plays a pivotal role in this process. By establishing relationships with reputable suppliers, buyers can ensure access to durable, cost-effective alternators that meet specific market needs. Additionally, considering the geographic diversity of buyers from Africa, South America, the Middle East, and Europe, it is essential to evaluate suppliers based on their ability to provide timely delivery and localized support.

As the automotive industry evolves, the demand for reliable alternators will continue to grow. International buyers are encouraged to proactively engage with suppliers, explore innovative sourcing strategies, and invest in quality components that enhance vehicle performance. Embrace the opportunity to streamline your sourcing processes and position your business for success in the competitive automotive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.