Introduction: Navigating the Global Market for stater price

Navigating the complexities of sourcing the right starter price can be a daunting task for international B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. With varying quality standards, fluctuating prices, and the need for reliable suppliers, companies face significant challenges in ensuring they make informed purchasing decisions. This guide is designed to demystify the global market for starters, providing a comprehensive overview of different types, applications, and the factors influencing their pricing.

From understanding the essential components of starters to evaluating the costs associated with replacement and repair, this resource empowers buyers with actionable insights. We delve into the intricacies of supplier vetting, highlighting best practices for selecting reliable partners who can meet specific operational needs. Additionally, we discuss regional pricing dynamics and how they can impact procurement strategies, particularly for businesses in countries like Nigeria and Brazil.

By equipping B2B buyers with the knowledge to navigate this market effectively, this guide aims to facilitate smarter decisions that drive operational efficiency and cost savings. Whether you’re sourcing for automotive applications or industrial machinery, understanding the nuances of starter pricing is crucial for optimizing your supply chain and ensuring seamless operations.

Table Of Contents

- Top 2 Stater Price Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for stater price

- Understanding stater price Types and Variations

- Key Industrial Applications of stater price

- 3 Common User Pain Points for ‘stater price’ & Their Solutions

- Strategic Material Selection Guide for stater price

- In-depth Look: Manufacturing Processes and Quality Assurance for stater price

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘stater price’

- Comprehensive Cost and Pricing Analysis for stater price Sourcing

- Alternatives Analysis: Comparing stater price With Other Solutions

- Essential Technical Properties and Trade Terminology for stater price

- Navigating Market Dynamics and Sourcing Trends in the stater price Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of stater price

- Strategic Sourcing Conclusion and Outlook for stater price

- Important Disclaimer & Terms of Use

Understanding stater price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| New Starters | Brand new, factory-manufactured components | Vehicle manufacturing, fleet maintenance | Pros: Reliable, warranty often included. Cons: Higher initial cost. |

| Rebuilt Starters | Refurbished using original parts, often cheaper | Auto repair shops, budget-conscious buyers | Pros: Cost-effective, good performance. Cons: Limited warranty, potential quality variability. |

| Aftermarket Starters | Third-party manufactured, may vary in quality | Independent repair shops, DIY mechanics | Pros: Wide range of options, potentially lower prices. Cons: Quality can be inconsistent, less reliable than OEM. |

| OEM Starters | Original Equipment Manufacturer parts | Authorized dealerships, high-end repairs | Pros: Perfect fit, high reliability. Cons: More expensive than alternatives. |

| Performance Starters | Enhanced starters designed for high-performance vehicles | Racing teams, performance vehicle upgrades | Pros: Improved power and reliability. Cons: Higher cost, may not be necessary for standard vehicles. |

What are the Characteristics of New Starters and Their Suitability for B2B Buyers?

New starters are factory-manufactured components that offer the highest reliability and performance. They are ideal for B2B applications where dependability is paramount, such as in vehicle manufacturing or fleet maintenance. Buyers should consider the initial cost, as new starters tend to be more expensive than alternatives, but the assurance of quality and warranty can justify the investment, particularly for businesses reliant on operational uptime.

How Do Rebuilt Starters Compare, and When Should Businesses Consider Them?

Rebuilt starters are refurbished units that use original parts, providing a cost-effective alternative for businesses looking to save money without sacrificing too much on performance. They are suitable for auto repair shops and budget-conscious buyers who need reliable components. When purchasing, businesses should evaluate the warranty offered, as it can vary significantly, and be cautious of quality, which may differ by supplier.

What Should B2B Buyers Know About Aftermarket Starters?

Aftermarket starters are produced by third-party manufacturers and are often less expensive than OEM options. They are popular among independent repair shops and DIY mechanics due to the variety of choices available. However, quality can be inconsistent, so buyers must conduct thorough research and possibly request samples or reviews to ensure reliability. Aftermarket starters can be a viable option for businesses that prioritize cost savings over brand loyalty.

Why Choose OEM Starters for Your Business Needs?

OEM starters are made by the original manufacturers and are designed to fit specific vehicle models perfectly. They are ideal for authorized dealerships and high-end repairs where quality and compatibility are essential. While they come at a higher price point, the assurance of performance and longevity can make them worth the investment for businesses that cannot afford downtime due to starter failures.

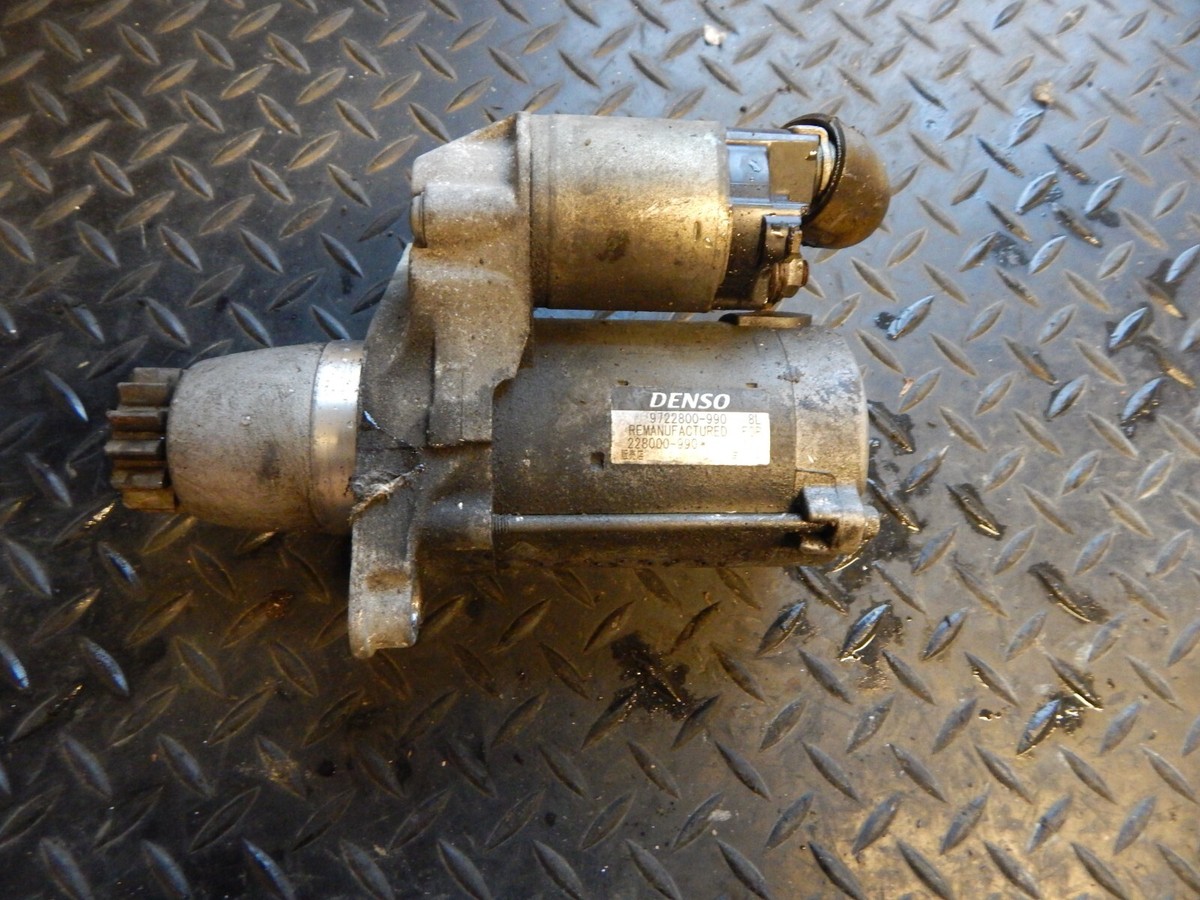

Illustrative image related to stater price

What Are Performance Starters and Who Should Use Them?

Performance starters are specialized units designed for high-performance vehicles and racing applications. They provide improved power and reliability, making them suitable for racing teams and businesses focused on performance upgrades. However, their higher cost may not be justified for standard vehicles, so companies should assess their specific needs and whether the enhanced capabilities align with their operational goals.

Key Industrial Applications of stater price

| Industry/Sector | Specific Application of stater price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Replacement of electric starters in vehicles | Enhances vehicle reliability and reduces downtime | Quality certification, compatibility with vehicle models, and warranty options. |

| Agriculture | Starters for agricultural machinery | Ensures efficient operation of critical farming equipment | Availability of parts, local supplier relationships, and lead times. |

| Construction Equipment | Starters for heavy machinery like excavators | Minimizes operational interruptions and boosts productivity | Durability of components, service support, and sourcing from trusted manufacturers. |

| Marine Industry | Starters for boats and marine engines | Increases reliability for critical marine operations | Resistance to corrosion, compliance with maritime regulations, and specialized parts availability. |

| Renewable Energy | Starters for wind turbines and solar trackers | Supports sustainable energy production and reduces costs | Technical specifications, compatibility with renewable systems, and after-sales support. |

How is ‘stater price’ Applied in the Automotive Repair Sector?

In the automotive repair industry, the price of starters is crucial for businesses that provide maintenance and repair services. Electric starters are essential components that allow vehicles to start efficiently. A reliable starter reduces the likelihood of vehicle breakdowns, ensuring that mechanics can offer better service to their clients. International buyers, particularly from regions like Africa and South America, should consider sourcing starters that meet local vehicle specifications and possess quality certifications to avoid compatibility issues and ensure durability.

What Role Does ‘stater price’ Play in Agriculture?

In agriculture, the price of starters is significant for the maintenance of machinery such as tractors and harvesters. A faulty starter can lead to delays in farming operations, impacting productivity and profitability. Businesses in this sector must source starters that are not only cost-effective but also durable enough to withstand harsh outdoor conditions. Buyers should prioritize local suppliers who can provide timely deliveries and support, especially in regions like Nigeria and Brazil, where agricultural machinery is critical for economic stability.

How is ‘stater price’ Relevant to Construction Equipment?

The construction industry relies heavily on heavy machinery, which often requires reliable starters for optimal performance. The price of starters impacts the overall maintenance costs of equipment like excavators and bulldozers. A dependable starter ensures that machinery operates without interruptions, which is vital for project timelines and budgets. Buyers should focus on sourcing high-quality starters that meet the rigorous demands of construction work, considering factors like service support and the availability of replacement parts from reputable manufacturers.

Why is ‘stater price’ Important in the Marine Industry?

In the marine industry, the price of starters directly affects the reliability of boats and marine engines. A malfunctioning starter can lead to significant operational downtime, which is particularly detrimental in commercial fishing or transportation sectors. Buyers in this industry must look for starters that are resistant to corrosion and compliant with maritime regulations. Ensuring compatibility with existing systems and having access to specialized parts can be crucial for maintaining operational efficiency in regions with extensive marine activities.

Illustrative image related to stater price

How Does ‘stater price’ Impact Renewable Energy Sectors?

The renewable energy sector increasingly relies on starters for wind turbines and solar trackers. The price of these components can influence the overall cost of energy production. Reliable starters are essential for the efficient operation of renewable systems, contributing to sustainable energy goals. International buyers should consider technical specifications and compatibility with existing renewable technologies when sourcing starters. Additionally, after-sales support is vital to ensure long-term operational success, particularly in regions focused on expanding their renewable energy infrastructure.

3 Common User Pain Points for ‘stater price’ & Their Solutions

Scenario 1: Unpredictable Pricing Variability in Starter Parts

The Problem: B2B buyers often face unpredictable pricing for starter parts, which can fluctuate significantly based on factors such as vehicle make and model, part availability, and regional market conditions. This unpredictability complicates budget planning for automotive repair shops or fleet operators, leading to potential losses if costs exceed estimates or quotes. For buyers in emerging markets in Africa or South America, exchange rate fluctuations can further exacerbate these pricing challenges, making it hard to maintain consistent pricing strategies.

The Solution: To mitigate the impact of pricing variability, B2B buyers should establish relationships with multiple suppliers to compare prices and ensure competitive sourcing. Investing in a robust inventory management system can also help track price changes and optimize purchasing schedules to take advantage of lower costs. Additionally, buyers should consider bulk purchasing agreements or long-term contracts with suppliers, which can lock in prices and reduce overall costs. Researching regional suppliers who understand local market conditions can also provide more stable pricing, reducing the unpredictability associated with global suppliers.

Scenario 2: Difficulty in Assessing Starter Quality

The Problem: Another common challenge for B2B buyers is the difficulty in assessing the quality of starter parts. Many suppliers may offer low prices, but this can often come at the expense of quality, leading to higher failure rates and subsequent replacement costs. Buyers in regions with less access to quality assurance standards may struggle to differentiate between reliable and subpar products, risking both financial losses and damage to their reputation if customers receive faulty parts.

The Solution: To address this quality concern, B2B buyers should prioritize sourcing from reputable manufacturers with established track records. Requesting detailed product specifications, performance certifications, and warranty information can help ensure quality. Additionally, conducting supplier audits and requesting samples for testing before making large purchases can provide deeper insights into the product’s reliability. Collaborating with industry associations or local automotive councils can also yield recommendations for trustworthy suppliers, ensuring that buyers are better equipped to make informed decisions.

Illustrative image related to stater price

Scenario 3: Lack of Technical Knowledge for Proper Starter Selection

The Problem: Many B2B buyers, particularly those new to the automotive parts industry, often lack the technical knowledge necessary to select the appropriate starter parts for specific vehicles. This lack of understanding can lead to purchasing incorrect parts, resulting in wasted resources, increased downtime, and customer dissatisfaction. In regions with a diverse range of vehicle types, such as the Middle East and Europe, the challenge is compounded by the need for compatibility with various makes and models.

The Solution: To overcome this knowledge gap, B2B buyers should invest in training for their staff to improve their understanding of starter systems and compatibility requirements. Providing access to resources such as online databases or software tools that offer detailed specifications for different vehicle models can also enhance decision-making. Additionally, establishing partnerships with technical experts or consultants in the automotive field can provide valuable insights and guidance when selecting starter parts. Suppliers that offer comprehensive support, including product knowledge and installation assistance, can also be invaluable resources for buyers looking to make informed purchases.

Strategic Material Selection Guide for stater price

What Are the Common Materials Used in Starter Production?

When selecting materials for starters, it is essential to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials used in starter manufacturing: steel, aluminum, copper, and composite materials. Each material has unique characteristics that influence its performance, cost, and applicability in various markets.

How Does Steel Perform as a Material for Starters?

Steel is a widely used material in starter production due to its strength and durability. It typically has a high-temperature rating and excellent corrosion resistance when treated properly. Steel starters can withstand significant mechanical stress, making them suitable for heavy-duty applications.

Pros: Steel is robust and can handle high pressures, making it ideal for demanding environments. It is also relatively cost-effective compared to other metals.

Cons: The weight of steel can be a disadvantage in applications where weight reduction is critical. Additionally, manufacturing complexity can increase if intricate designs are required.

Impact on Application: Steel starters are compatible with a variety of media, including gasoline and diesel engines. However, they may not be the best choice for applications requiring lightweight components.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should also consider local sourcing options to reduce costs.

What Role Does Aluminum Play in Starter Manufacturing?

Aluminum is another popular choice for starter components due to its lightweight nature and good corrosion resistance. It is particularly effective in applications where weight savings are essential, such as in automotive and aerospace industries.

Illustrative image related to stater price

Pros: Aluminum starters are lighter than their steel counterparts, improving fuel efficiency in vehicles. They also offer good thermal conductivity, which can enhance performance.

Cons: While aluminum is strong, it is not as durable as steel under high-stress conditions. The cost of aluminum can also be higher, depending on market fluctuations.

Impact on Application: Aluminum is suitable for applications that require reduced weight and good thermal performance. However, it may not be ideal for high-torque applications where durability is paramount.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local and international standards. In regions like Europe, adherence to environmental regulations regarding aluminum recycling is also important.

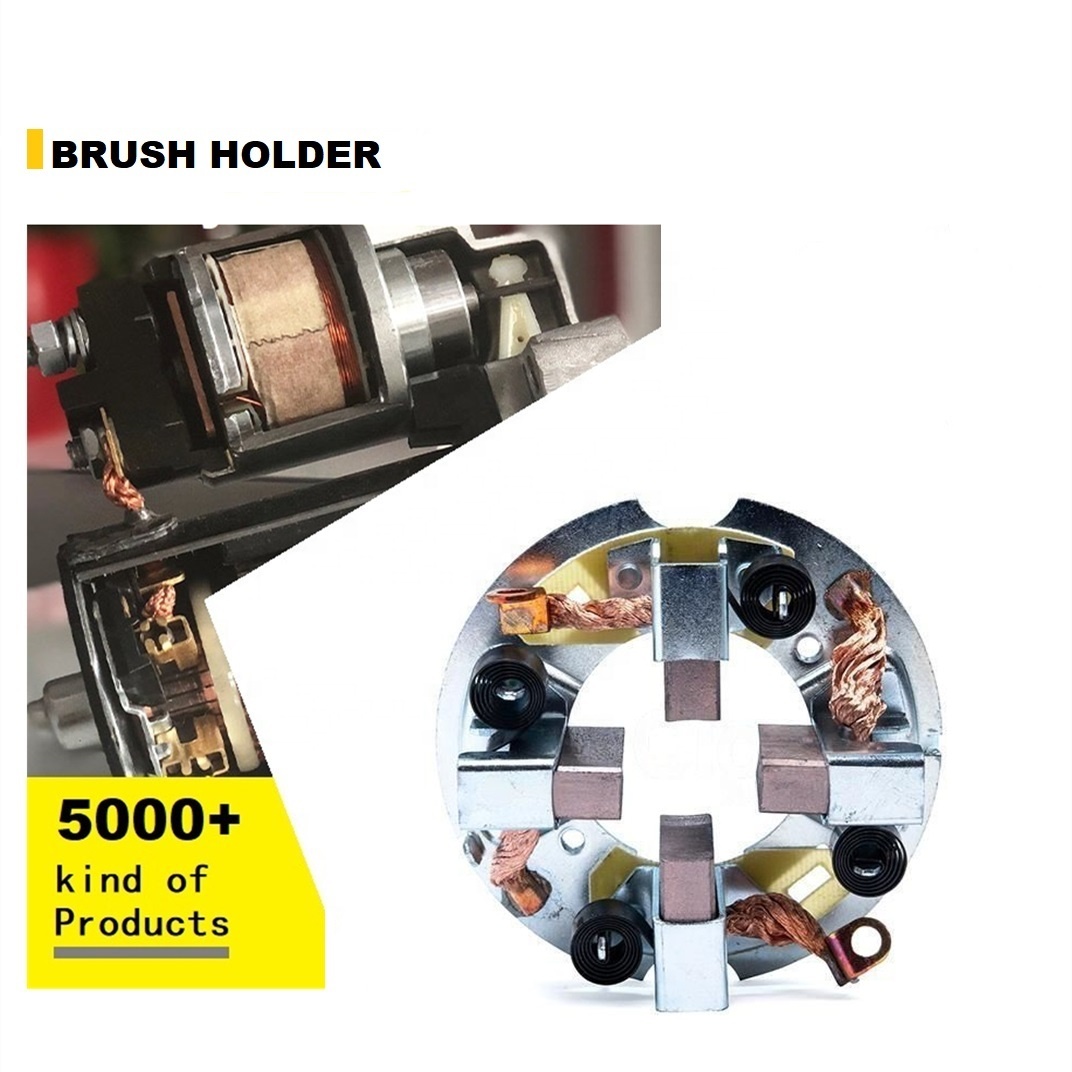

How Does Copper Enhance Starter Functionality?

Copper is primarily used in electrical components of starters, such as wiring and contacts, due to its excellent electrical conductivity. It has good thermal properties, which help in efficient energy transfer.

Pros: Copper’s high conductivity ensures optimal performance in electrical applications, reducing energy loss. It is also resistant to corrosion, especially when coated.

Cons: Copper is relatively expensive compared to other materials, which can increase overall costs. It is also heavier than aluminum, which may affect applications where weight is a concern.

Impact on Application: Copper is essential for any starter that requires reliable electrical connections. Its compatibility with various electrical systems makes it a preferred choice for many manufacturers.

Illustrative image related to stater price

Considerations for International Buyers: Buyers must consider the quality of copper used and its compliance with standards like JIS or ASTM. In regions with fluctuating copper prices, cost stability should be a key consideration.

What Advantages Do Composite Materials Offer in Starter Design?

Composite materials, often a blend of plastics and fibers, are gaining popularity in starter manufacturing due to their lightweight and versatile properties. They can be engineered to meet specific performance requirements.

Pros: Composites are lightweight and can be molded into complex shapes, allowing for innovative designs. They also offer good resistance to corrosion and chemicals.

Cons: The manufacturing process for composites can be complex and costly. Additionally, their mechanical strength may not match that of metals, limiting their use in high-stress applications.

Illustrative image related to stater price

Impact on Application: Composites are suitable for applications requiring weight reduction and corrosion resistance. They are particularly useful in environments where exposure to chemicals is a concern.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant standards and certifications. In regions like the Middle East, where temperatures can be extreme, thermal stability of composites must be verified.

Summary Table of Material Selection for Starters

| Material | Typical Use Case for stater price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty automotive starters | High strength and durability | Heavier weight, complex manufacturing | Medium |

| Aluminum | Lightweight automotive applications | Reduced weight, good thermal conductivity | Lower durability under high stress | High |

| Copper | Electrical components in starters | Excellent electrical conductivity | Higher cost, heavier than aluminum | High |

| Composite | Specialized lightweight starters | Lightweight, corrosion-resistant | Complex manufacturing, lower strength | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for stater price

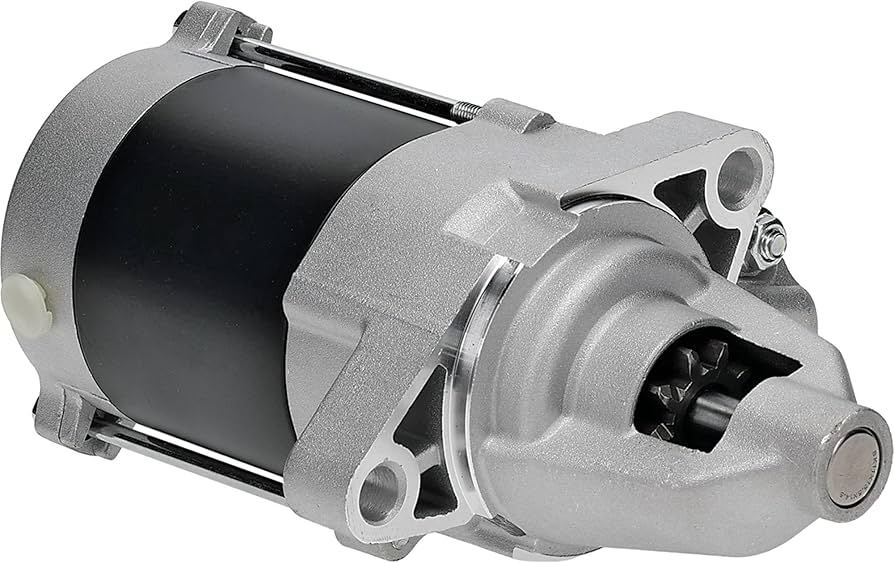

What Are the Key Stages in the Manufacturing Process of Starters?

The manufacturing process for automotive starters involves several critical stages, each designed to ensure the final product meets the necessary performance and quality standards. Understanding these stages can help B2B buyers assess supplier capabilities and product reliability.

Material Preparation: What Materials Are Used in Starter Manufacturing?

The first stage in starter manufacturing involves selecting high-quality materials that can withstand the operational demands of automotive applications. Common materials include:

Illustrative image related to stater price

- Copper for electrical components due to its excellent conductivity.

- Steel for the housing and internal components, providing durability and strength.

- Plastic or composites for insulation and lightweight structural elements.

Once materials are sourced, they undergo various treatments to enhance their properties, such as heat treatment for steel to improve hardness and wear resistance.

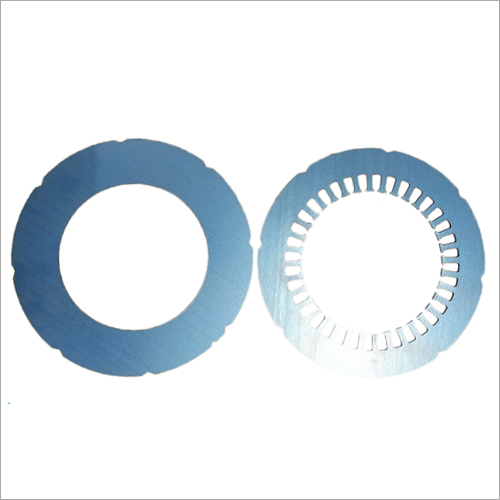

How Are Starters Formed and Assembled?

The forming process typically includes precision machining and stamping to create the individual components of the starter. Key techniques used during this stage include:

- CNC Machining: Used for creating intricate parts like the armature and solenoid, ensuring high tolerances and repeatability.

- Stamping: Employed to produce parts like the starter housing, allowing for efficient mass production.

- Injection Molding: Utilized for plastic components, ensuring consistency and reducing waste.

After forming, the components are assembled. This stage involves several sub-processes, such as:

- Winding the Armature: Copper wire is wound around the armature to create electromagnetic fields.

- Solenoid Assembly: The solenoid is carefully assembled to ensure proper engagement with the starter drive gear.

- Final Assembly: All components are brought together, and connections are made to form a complete starter unit.

What Finishing Processes Are Essential for Starters?

The finishing stage includes treatments that enhance the durability and aesthetic appeal of the starter. Common techniques include:

- Painting and Coating: Protective coatings are applied to prevent corrosion and improve aesthetics.

- Quality Inspections: Each finished starter undergoes rigorous testing to ensure functionality before shipment.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is a vital aspect of starter manufacturing, ensuring that products meet both international and industry-specific standards. B2B buyers should be familiar with the following standards:

- ISO 9001: This international standard focuses on quality management systems and is applicable to all organizations, including manufacturers. Compliance indicates a commitment to quality and continuous improvement.

- CE Marking: Essential for products sold in the European market, CE marking signifies that a product meets EU safety, health, and environmental protection standards.

- API Standards: Particularly relevant for starters used in specialized applications like marine or heavy-duty vehicles, API standards ensure reliability and performance.

What Are the Key Quality Control Checkpoints in Starter Manufacturing?

Quality control (QC) is implemented at various stages of the manufacturing process. Key QC checkpoints include:

Illustrative image related to stater price

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected to ensure they meet predefined specifications before production begins.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and ensure compliance with quality standards.

- Final Quality Control (FQC): This stage involves comprehensive testing of the finished starters, including electrical testing and performance assessments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing starters from international suppliers, B2B buyers must ensure robust quality control processes are in place. Here are effective ways to verify these practices:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and overall compliance with international standards.

- Quality Reports: Requesting detailed quality reports can provide insights into defect rates, corrective actions taken, and overall production performance.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices and product quality.

What Testing Methods Are Commonly Used for Starters?

Various testing methods are employed to ensure that starters perform reliably under different conditions. Common tests include:

- Electrical Testing: Measures the starter’s electrical performance, ensuring it operates within specified voltage and current ranges.

- Torque Testing: Assesses the starter’s ability to engage and disengage under load, ensuring it can handle the demands of engine cranking.

- Durability Testing: Simulates long-term use to evaluate wear and performance over time.

What Nuances Should International B2B Buyers Consider in Quality Control?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in starter manufacturing is crucial. Factors to consider include:

- Regulatory Compliance: Different regions may have specific regulations that must be adhered to. Understanding local compliance requirements can prevent costly delays and penalties.

- Cultural Differences in Quality Expectations: Expectations around quality and performance may vary by region. Engaging in open dialogue with suppliers can help align expectations and foster better partnerships.

- Logistical Challenges: Shipping and customs regulations can impact product delivery timelines and quality. Ensuring that suppliers have robust logistics and quality assurance processes can mitigate these risks.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance standards for starters can significantly impact purchasing decisions for B2B buyers. By focusing on material quality, assembly techniques, and rigorous testing methods, buyers can ensure they source reliable and compliant products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stater price’

In this guide, we aim to provide international B2B buyers with a structured approach to sourcing starter prices effectively. Understanding the nuances of procurement in different regions—especially in Africa, South America, the Middle East, and Europe—can help ensure that you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to clearly outline the technical requirements for the starters you need. This includes understanding the specifications of the vehicles or equipment they will be used for, such as voltage, size, and compatibility with existing systems. Precise specifications help avoid costly errors and ensure that the components meet operational needs.

Step 2: Research Market Prices

Conduct thorough market research to understand the typical price range for starters in your target regions. Prices can vary significantly based on factors like brand reputation, quality, and regional supply chains. Utilize online marketplaces and industry reports to gather data on current pricing trends and adjust your budget accordingly.

Illustrative image related to stater price

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record of reliability and quality, as this can save you time and money in the long run.

- Check Reviews and Ratings: Utilize platforms like Trustpilot or local business directories to gauge the supplier’s reputation.

- Request Samples: If possible, obtain samples to assess the quality of the products firsthand.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers have the necessary certifications and quality assurance processes in place. Certifications can indicate compliance with international standards and can significantly affect the reliability of the starters you source.

- ISO Certifications: Look for ISO 9001 or relevant industry-specific certifications.

- Warranty and Return Policies: Review these policies to ensure you are protected in case the products do not meet your expectations.

Step 5: Assess Logistics and Shipping Costs

Understanding the logistics involved in transporting starters from suppliers to your location is essential. Shipping costs can vary widely based on distance, shipping methods, and customs regulations.

- Inquire About Shipping Options: Discuss various shipping methods with suppliers to find the most cost-effective solution.

- Consider Local Suppliers: If possible, sourcing from local suppliers can reduce shipping times and costs.

Step 6: Negotiate Terms and Conditions

Once you have identified potential suppliers, it’s time to negotiate terms, including pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable payment conditions, which can enhance your cash flow.

Illustrative image related to stater price

- Discuss Volume Discounts: If you plan to order in bulk, inquire about volume pricing.

- Clarify Payment Methods: Ensure the payment methods align with your company’s financial practices.

Step 7: Finalize the Agreement

After negotiations, finalize the agreement and ensure all terms are documented in a formal contract. This protects both parties and provides a clear understanding of the expectations and deliverables.

- Review Legal Requirements: Ensure that the contract complies with local laws and regulations.

- Set Milestones for Deliverables: Establish clear timelines for delivery to monitor supplier performance effectively.

By following these steps, B2B buyers can navigate the complexities of sourcing starters more efficiently, ensuring they acquire high-quality products at competitive prices.

Comprehensive Cost and Pricing Analysis for stater price Sourcing

What Are the Key Cost Components in Stater Price Sourcing?

When analyzing the cost structure for stater price sourcing, several critical components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The primary materials involved in manufacturing starters typically include metals like aluminum and copper, as well as various plastics and rubber components. The choice of materials can significantly influence costs, especially if high-performance or specialized materials are required.

-

Labor: Labor costs vary by region and depend on the complexity of the starter design. Skilled labor for assembly and quality assurance can add substantial costs, particularly in areas with higher wage standards.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient production processes can help minimize overhead, impacting the overall cost of starters.

-

Tooling: Initial tooling costs can be significant, especially for custom starter designs. These costs are usually spread over larger production runs, making them more manageable for bulk orders.

-

Quality Control: Ensuring the reliability of starters requires rigorous QC processes, which can involve testing and certification. These additional steps, while essential for maintaining standards, can also raise costs.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. Factors like shipping distance, weight, and packaging can all affect logistics costs.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary widely based on market conditions and competition.

How Do Price Influencers Affect Stater Prices?

Several factors can influence the pricing of starters, which international buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract bulk pricing discounts. Buyers should assess their needs carefully to negotiate favorable terms.

-

Specifications and Customization: Custom starters or those with specific performance requirements can incur higher costs due to specialized manufacturing processes.

-

Material Selection: The choice of materials directly impacts price. High-quality materials may enhance performance but will increase costs.

-

Quality and Certifications: Products that meet specific industry certifications or quality standards may carry a premium price. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The supplier’s reputation, reliability, and location can all influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding shipping terms is essential for cost management. Different Incoterms can shift responsibilities and costs between buyers and sellers, affecting the total landed cost.

What Are the Best Negotiation Tips for International Buyers?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to enhance their negotiation power:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, repair, and operational costs over the product’s lifespan. This perspective can help justify a higher upfront cost if long-term savings are evident.

-

Leverage Volume Discounts: If feasible, consolidate orders across multiple purchases to meet MOQ thresholds, unlocking better pricing.

-

Research Market Prices: Conduct thorough research on current market prices and competitor offerings to establish a baseline for negotiation.

-

Build Relationships: Establishing a rapport with suppliers can lead to better terms and more favorable pricing structures over time.

-

Be Transparent About Budget Constraints: Sharing your budget limitations can encourage suppliers to offer tailored solutions or alternative products that meet your needs without compromising quality.

What Should International Buyers Know About Pricing Nuances?

For international buyers, understanding regional pricing nuances is vital. Currency fluctuations, tariffs, and trade agreements can all impact pricing. Buyers from Nigeria, Brazil, and similar markets should be aware of local economic conditions that might influence supplier pricing strategies. Additionally, familiarize yourself with local regulations and import duties that could affect the total cost of acquiring starters.

Illustrative image related to stater price

Disclaimer on Indicative Prices

Prices for starters can vary widely based on numerous factors, including specifications, supplier choices, and market conditions. The estimates provided in this analysis serve as a guideline and should be confirmed through direct supplier engagement for accurate quotes tailored to specific needs.

Alternatives Analysis: Comparing stater price With Other Solutions

In the competitive landscape of automotive solutions, understanding the various options available for starter replacement is crucial for B2B buyers. While the price of starters is a significant factor, considering alternatives can lead to more informed purchasing decisions. This section will compare the costs and benefits of using traditional starter replacements against two viable alternatives: starter repair kits and aftermarket starter components.

Comparison Table

| Comparison Aspect | Stater Price | Starter Repair Kits | Aftermarket Starter Components |

|---|---|---|---|

| Performance | Reliable, OEM quality | Varies by kit quality | Generally good, but quality varies |

| Cost | $80 – $350 | $50 – $150 | $60 – $300 |

| Ease of Implementation | Moderate (professional help often needed) | Moderate (requires some DIY skills) | Easy (plug-and-play for most models) |

| Maintenance | Low (typically long-lasting) | Moderate (depends on the kit) | Low to Moderate (varies by brand) |

| Best Use Case | Standard replacement needs | Budget-conscious repairs | Quick replacements for common models |

In-Depth Analysis of Alternatives

What Are Starter Repair Kits and Their Advantages?

Starter repair kits are designed for those who prefer to fix rather than replace their starter. These kits typically include essential components such as brushes, solenoids, and gears, allowing users to refurbish their existing starter. The primary advantage is cost savings; repair kits often range from $50 to $150, making them an appealing option for budget-conscious buyers. However, the effectiveness of these kits can vary significantly based on the manufacturer and the specific vehicle model. For businesses with skilled technicians, this can be a cost-effective solution, but it requires a certain level of mechanical expertise.

How Do Aftermarket Starter Components Compare?

Aftermarket starter components provide an alternative for businesses looking for a quick and often cheaper replacement. Priced between $60 and $300, these parts are typically designed to meet or exceed OEM specifications. They offer the advantage of accessibility and ease of installation, often requiring minimal tools and time. However, the quality can be inconsistent, and businesses must carefully evaluate the reliability of the suppliers. This option is best suited for companies that handle a high volume of repairs and need to maintain efficiency without sacrificing too much quality.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the right starter solution, B2B buyers should consider several factors, including budget, the skill level of their technicians, and the specific needs of their vehicle fleet. If reliability and OEM quality are paramount, investing in traditional starters may be the best approach. Conversely, if cost is a significant concern, starter repair kits and aftermarket components can provide viable alternatives. Ultimately, the choice will depend on the balance between cost, performance, and the operational capabilities of the buyer’s organization. By thoroughly evaluating these options, businesses can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for stater price

What Are the Key Technical Properties Relevant to Starter Price?

When evaluating starter prices in a B2B context, understanding specific technical properties is essential. These properties not only influence the performance of the starter but also affect the overall cost and reliability of the product. Here are some critical specifications to consider:

-

Material Grade

The material used in the construction of starters can significantly impact durability and performance. Common materials include high-strength steel and aluminum alloys. A higher material grade typically translates to better resistance to wear and tear, making it crucial for buyers seeking long-lasting components. -

Torque Rating

Torque rating is a measure of the rotational force that a starter can generate. This specification is vital as it determines the starter’s ability to crank the engine under various conditions. For buyers, understanding torque ratings helps ensure compatibility with specific vehicle models, preventing issues during installation or operation. -

Current Draw

The current draw, measured in amperes, indicates how much electrical power the starter consumes during operation. A lower current draw can lead to less strain on the vehicle’s electrical system, which is particularly important for companies managing fleets. Buyers should assess current draw to optimize energy efficiency and reduce potential electrical issues. -

Temperature Resistance

Starters are often exposed to extreme temperatures, both hot and cold. Evaluating the temperature resistance of a starter ensures that it will function reliably in various climates, a key consideration for international buyers in regions like Africa and South America. A starter with a higher temperature tolerance can minimize the risk of failure. -

Mounting Type

The mounting type refers to how the starter is installed in the vehicle, which can vary by make and model. Understanding the mounting specifications is crucial for ensuring that the starter fits correctly without the need for modifications. This can save time and costs during the installation process.

What Are Common Trade Terms Used in the Starter Price Industry?

Navigating the B2B landscape for starters requires familiarity with specific trade terminology. Here are some common terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to products made by the manufacturer that produced the original parts for a vehicle. OEM starters are often preferred for their guaranteed compatibility and quality. Buyers should consider OEM options when seeking reliable replacements to maintain vehicle performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers as it can affect inventory management and cost efficiency. Companies must evaluate their needs against supplier MOQs to ensure they are not overstocking or understocking. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities of products. This is a fundamental step in the procurement process, allowing buyers to compare costs and negotiate terms. Crafting a detailed RFQ can lead to better pricing and stronger supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand the logistics involved in purchasing starters, especially when dealing with international suppliers. -

Lead Time

Lead time refers to the amount of time it takes for an order to be fulfilled from the moment it is placed. Knowing the lead time is crucial for planning and inventory management, as it affects how quickly a company can respond to customer needs or repairs.

By understanding these technical properties and trade terms, B2B buyers can make informed purchasing decisions regarding starters, ensuring they select the right products for their operational needs.

Illustrative image related to stater price

Navigating Market Dynamics and Sourcing Trends in the stater price Sector

What Are the Current Market Dynamics and Key Trends in the Starter Price Sector?

The global starter price sector is experiencing a notable shift driven by several key factors. Increased vehicle ownership in emerging markets, particularly in Africa and South America, is propelling demand for automotive components, including starters. The rise of electric vehicles (EVs) is another significant driver, as these vehicles require different starter systems, leading to an evolving market landscape. Moreover, advancements in technology, such as smart manufacturing and IoT integration, are streamlining production processes and optimizing supply chains, which can lead to cost reductions for B2B buyers.

Emerging B2B tech trends are also influencing the starter price sector. The use of data analytics and AI in inventory management is helping suppliers predict demand more accurately, thereby minimizing excess stock and reducing costs. Furthermore, e-commerce platforms are facilitating easier access to a global marketplace, allowing buyers from regions like Nigeria and Brazil to source components directly from manufacturers. These trends present opportunities for international buyers to leverage competitive pricing and enhanced product availability.

Another notable trend is the growing emphasis on local sourcing. B2B buyers are increasingly prioritizing suppliers that can provide quicker turnaround times and lower shipping costs. This shift is particularly relevant in regions with logistical challenges, where establishing reliable local partnerships can significantly enhance supply chain efficiency.

How Is Sustainability and Ethical Sourcing Impacting the Starter Price Sector?

Sustainability and ethical sourcing are becoming critical components in the starter price sector, driven by increasing regulatory pressures and consumer demand for environmentally friendly practices. The environmental impact of traditional manufacturing processes, particularly regarding waste and carbon emissions, has prompted many companies to seek greener alternatives. B2B buyers are encouraged to consider suppliers that adopt sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing processes.

Ethical supply chains are also gaining prominence, with companies increasingly scrutinizing their sourcing strategies to ensure fair labor practices and transparency. Certifications like ISO 14001 and other ‘green’ standards are becoming essential for suppliers aiming to demonstrate their commitment to sustainability. B2B buyers should prioritize partnerships with manufacturers who can provide documentation of these certifications, as this not only aligns with corporate social responsibility goals but also enhances brand reputation.

Illustrative image related to stater price

In addition, the growing trend towards electric vehicles is pushing manufacturers to innovate sustainable starter solutions. For instance, starters designed for hybrid and electric vehicles often incorporate eco-friendly materials and technologies that reduce environmental impact. Buyers focusing on the starter price sector should keep an eye on these advancements, as they will likely influence future product offerings and pricing structures.

How Has the Starter Price Sector Evolved Over Time?

The starter price sector has evolved significantly from its early days, marked by the transition from manual crank starters to electric starters in the early 20th century. Initially, starters were a luxury feature, but as automotive technology advanced, they became standard equipment in all vehicles. Over the decades, innovations in starter design and materials have led to enhanced efficiency and reliability, directly impacting pricing strategies.

In recent years, the rise of electric and hybrid vehicles has catalyzed further evolution in starter technologies, necessitating new designs and manufacturing processes. The shift towards sustainable practices and ethical sourcing has also reshaped the landscape, as buyers increasingly seek suppliers who align with their environmental and social values. This evolution reflects a broader trend in the automotive industry, where the focus on innovation, efficiency, and sustainability continues to drive market dynamics and influence pricing.

Overall, international B2B buyers must remain vigilant and adaptable to these changes, leveraging emerging technologies and sustainable practices to navigate the complexities of the starter price sector effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of stater price

-

How do I determine the appropriate starter price for my vehicle?

To determine the appropriate starter price for your vehicle, start by identifying the make, model, and year of your vehicle. Prices can vary significantly based on these factors, as well as the starter’s brand and type (new or rebuilt). Research various suppliers and compare prices, keeping in mind that local market conditions, shipping costs, and import duties may affect the final price. Utilize online resources and automotive forums to gather insights on average prices and reliable suppliers. -

What is the best starter for a commercial vehicle?

The best starter for a commercial vehicle typically depends on the specific requirements of the engine and the vehicle’s intended use. Look for starters designed for high-torque applications, as they can handle the demands of larger engines. Brands known for durability and reliability, such as Bosch or Delco Remy, are often recommended. Ensure that the starter meets OEM specifications for optimal performance and longevity, and consult with suppliers who specialize in commercial vehicle parts for tailored recommendations. -

What factors should I consider when sourcing starters internationally?

When sourcing starters internationally, consider factors such as supplier reputation, product quality, compliance with international standards, and shipping logistics. It’s crucial to vet suppliers by checking their certifications, customer reviews, and references. Additionally, evaluate their ability to provide after-sales support, warranty terms, and return policies. Understanding the import regulations in your country, including tariffs and taxes, will also help you calculate the total cost of acquisition. -

What is the typical minimum order quantity (MOQ) for starters?

The typical minimum order quantity (MOQ) for starters can vary widely depending on the supplier and the type of starter. Generally, MOQs can range from 10 to 100 units. However, some manufacturers may offer flexible MOQs for new customers or bulk orders. Always inquire about the MOQ before placing an order to ensure it aligns with your purchasing strategy and inventory needs. Negotiating favorable terms with suppliers can also lead to better pricing and reduced MOQs. -

What payment terms are common when purchasing starters from suppliers?

Common payment terms when purchasing starters from suppliers include upfront payment, net 30, or net 60 days. Many international suppliers require a deposit (typically 30-50%) before manufacturing, with the balance due upon shipment or delivery. Always clarify payment terms in advance to avoid misunderstandings. Utilizing secure payment methods, such as letters of credit or escrow services, can help protect your financial interests in international transactions. -

How can I ensure the quality of the starters I source?

To ensure the quality of the starters you source, request samples before placing a bulk order. Verify that the starters meet industry standards and specifications, and consider suppliers that offer warranties or quality guarantees. Conduct thorough inspections upon receipt and consider third-party quality assurance services if necessary. Building a strong relationship with reputable suppliers can also foster trust and ensure consistent quality in your orders. -

What are the logistics considerations when importing starters?

Logistics considerations when importing starters include choosing the right shipping method (air or sea), understanding customs clearance processes, and estimating delivery times. Evaluate the costs associated with freight forwarding, insurance, and any import duties that may apply. Collaborating with a logistics provider experienced in automotive parts can streamline the import process and help you navigate potential challenges. Always plan for lead times and ensure that your supply chain can accommodate fluctuating demand. -

How do I handle customs and import duties for starter parts?

Handling customs and import duties for starter parts requires understanding the regulations of your country and the classification of the parts being imported. Consult with a customs broker to ensure compliance with local laws and to accurately calculate duties and taxes. Prepare all necessary documentation, including invoices, shipping labels, and certificates of origin. Staying informed about trade agreements between your country and the supplier’s country can also provide potential duty reductions.

Top 2 Stater Price Manufacturers & Suppliers List

1. Pull-A-Part – Used Starters for Sale

Domain: pullapart.com

Registered: 1999 (26 years)

Introduction: Used starters for sale at Pull-A-Part. A starter is a device that initiates the engine’s operation, also known as a starter motor or cranking motor. It typically measures 6 to 8 inches in length and weighs 2 to 5 pounds. Starters are usually located in the steering column or behind the dashboard on the driver’s side. When purchasing a used starter, check for intact casing, absence of rust or corro…

2. Compustar – 1-Way Remote Start System

Domain: bestbuy.com

Registered: 1994 (31 years)

Introduction: {“products”:[{“name”:”Compustar – 1-Way Remote Start System”,”rating”:”4.5 out of 5 stars”,”reviews”:”1025 reviews”,”price”:”$249.99″,”savings”:”Save $100″,”comp_value”:”$349.99″},{“name”:”Viper – DS4VB Remote Start System”,”rating”:”4.3 out of 5 stars”,”reviews”:”3314 reviews”,”price”:”$249.99″,”savings”:”Save $70″,”comp_value”:”$319.99″},{“name”:”Viper – 2-Way, 5-Button – Remote Start System”,”r…

Strategic Sourcing Conclusion and Outlook for stater price

In conclusion, the landscape of starter pricing and sourcing necessitates a strategic approach for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Key takeaways highlight the importance of understanding the intricate relationship between vehicle specifications and starter costs, as well as the significant variations in pricing depending on the make and model. By leveraging insights on parts availability and repair versus replacement considerations, buyers can enhance their procurement strategies, ensuring they secure the best value while maintaining operational efficiency.

Moreover, the strategic sourcing of starters not only involves cost considerations but also emphasizes the reliability and quality of the parts sourced. As markets evolve, staying ahead of trends in starter technology and pricing will be crucial for maintaining a competitive edge.

Looking ahead, we encourage international B2B buyers to actively engage with suppliers, explore innovative sourcing options, and leverage data-driven insights to optimize their purchasing decisions. By doing so, you can ensure that your business is well-equipped to navigate the complexities of starter pricing, ultimately driving greater value and sustainability in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to stater price

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.