Introduction: Navigating the Global Market for starter motor solenoid problems

In today’s fast-paced automotive industry, addressing starter motor solenoid problems is crucial for maintaining operational efficiency and reducing downtime. International B2B buyers, particularly in emerging markets like Africa, South America, the Middle East, and Europe, face unique challenges when sourcing reliable components to ensure their vehicles perform optimally. This guide aims to demystify the complexities surrounding starter motor solenoids by providing in-depth insights into various types, applications, and common issues, as well as strategies for effective supplier vetting.

Throughout this comprehensive resource, we will explore the signs of malfunctioning solenoids, the implications for vehicle performance, and the potential impact on overall business operations. Additionally, we will outline critical factors to consider when evaluating suppliers, including quality assurance, pricing, and logistics. By equipping B2B buyers with actionable knowledge, this guide empowers them to make informed purchasing decisions that enhance reliability and minimize operational disruptions.

Whether you’re a fleet manager in Brazil navigating local supplier options or a distributor in Vietnam seeking to understand global sourcing trends, this guide will serve as an essential tool in your procurement strategy. With the right information at your fingertips, you can confidently address starter motor solenoid problems and secure the best solutions for your business needs.

Table Of Contents

- Top 3 Starter Motor Solenoid Problems Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter motor solenoid problems

- Understanding starter motor solenoid problems Types and Variations

- Key Industrial Applications of starter motor solenoid problems

- 3 Common User Pain Points for ‘starter motor solenoid problems’ & Their Solutions

- Strategic Material Selection Guide for starter motor solenoid problems

- In-depth Look: Manufacturing Processes and Quality Assurance for starter motor solenoid problems

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor solenoid problems’

- Comprehensive Cost and Pricing Analysis for starter motor solenoid problems Sourcing

- Alternatives Analysis: Comparing starter motor solenoid problems With Other Solutions

- Essential Technical Properties and Trade Terminology for starter motor solenoid problems

- Navigating Market Dynamics and Sourcing Trends in the starter motor solenoid problems Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter motor solenoid problems

- Strategic Sourcing Conclusion and Outlook for starter motor solenoid problems

- Important Disclaimer & Terms of Use

Understanding starter motor solenoid problems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Intermittent Engagement | Starts sometimes, fails at other times; erratic behavior. | Automotive repair shops, fleet services | Pros: Cost-effective repairs; Cons: Difficult to diagnose; may lead to unexpected downtime. |

| Single Click Issue | A single click sound with no engine start; solenoid trying to engage. | Automotive parts suppliers, workshops | Pros: Easy identification; Cons: Could indicate deeper electrical issues. |

| Continuous Crank | Starter engages but doesn’t disengage; potential engine damage. | Heavy machinery, automotive repair | Pros: Clear indication of solenoid failure; Cons: Risk of additional damage to starter motor. |

| No Response | No sound or movement when ignition is turned; complete failure. | Vehicle manufacturers, maintenance teams | Pros: Simple troubleshooting; Cons: May require full starter replacement, increasing costs. |

| Overheating | Solenoid becomes excessively hot during operation. | Automotive manufacturers, service centers | Pros: Identifies potential electrical issues; Cons: Can lead to rapid failure if not addressed. |

What Are the Characteristics of Intermittent Engagement Starter Solenoid Problems?

Intermittent engagement issues in starter solenoids are characterized by sporadic functionality, where the engine starts successfully at times but fails at others. This inconsistency can lead to significant downtime, particularly in fleet operations where reliability is crucial. B2B buyers should consider investing in diagnostic tools to pinpoint the exact cause, whether it’s a faulty solenoid or related electrical issues, to minimize repair costs and operational disruptions.

How to Identify the Single Click Issue in Starter Solenoids?

The single click issue occurs when the solenoid attempts to engage but fails to turn the engine over, typically producing a single clicking sound. This can indicate that the solenoid is malfunctioning or that there are underlying electrical problems. For B2B buyers, understanding this issue is essential for automotive repair shops to quickly diagnose and resolve the problem, as it allows for targeted repairs rather than unnecessary part replacements.

What Are the Risks of Continuous Crank Problems?

Continuous crank problems arise when the starter engages but fails to disengage after the ignition key is released. This can lead to severe damage to the starter motor and potentially the engine itself. For businesses dealing with heavy machinery or automotive repairs, recognizing this issue early can prevent costly repairs and ensure safety. Buyers should be aware of the risk of additional damage and consider purchasing high-quality solenoids to mitigate such failures.

How to Address No Response Issues in Starter Solenoids?

No response from the starter solenoid indicates a complete failure, where turning the ignition results in no sound or movement. This can be due to a failed solenoid or other electrical issues in the starting system. For vehicle manufacturers and maintenance teams, understanding this failure mode is crucial for effective troubleshooting. It often necessitates a complete starter replacement, so B2B buyers should evaluate the cost implications and the reliability of replacement parts.

What Causes Overheating in Starter Solenoids?

Overheating in starter solenoids is a concerning issue that can arise from excessive current draw or prolonged engagement. This condition can lead to premature failure of the solenoid and associated components. Automotive manufacturers and service centers should be aware of this risk, as it can signify larger electrical problems. Buyers should prioritize high-quality solenoids designed to handle thermal stress and consider regular maintenance checks to prevent overheating incidents.

Key Industrial Applications of starter motor solenoid problems

| Industry/Sector | Specific Application of Starter Motor Solenoid Problems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Quality Control in Starter Production | Ensures reliability and performance of starter motors, reducing warranty claims. | Look for suppliers with robust testing procedures and quality certifications. |

| Agriculture Equipment | Maintenance of Farm Machinery | Minimizes downtime of critical machinery like tractors, enhancing productivity. | Source durable solenoids suitable for harsh environments and high demand. |

| Transportation & Logistics | Fleet Vehicle Management | Reduces operational costs by preventing starter failures in fleet vehicles. | Consider suppliers that offer bulk purchasing options and quick delivery. |

| Mining Operations | Equipment Reliability | Ensures continuous operation of heavy machinery, preventing costly delays. | Evaluate suppliers based on their experience in high-performance solenoids. |

| Construction | Heavy Equipment Performance | Enhances the reliability of construction machinery, reducing project delays. | Seek suppliers with a strong track record in supplying construction-grade components. |

How Do Starter Motor Solenoid Problems Affect Automotive Manufacturing?

In automotive manufacturing, the quality control of starter motors is critical. Problems with solenoids can lead to defective products, resulting in increased warranty claims and customer dissatisfaction. Manufacturers must ensure that their starter motors are reliable, which involves sourcing solenoids that meet stringent performance standards. International buyers should prioritize suppliers that provide detailed testing procedures and quality certifications to mitigate risks associated with product failures.

What Role Do Starter Motor Solenoid Problems Play in Agriculture Equipment Maintenance?

In the agricultural sector, farm machinery such as tractors relies heavily on starter motors to operate efficiently. Solenoid issues can cause unexpected downtimes, directly impacting productivity during crucial farming periods. Businesses in this sector benefit from sourcing robust solenoids that can withstand harsh environmental conditions. International buyers should consider suppliers that offer specialized products designed for high-demand agricultural applications, ensuring that machinery remains operational when needed.

How Can Transportation & Logistics Benefit from Addressing Starter Motor Solenoid Problems?

For companies in transportation and logistics, managing a fleet of vehicles efficiently is paramount. Starter motor solenoid problems can lead to vehicle failures, resulting in increased operational costs and delays. By investing in high-quality solenoids, fleet managers can minimize the risk of unexpected breakdowns. Buyers in this sector should focus on suppliers that offer bulk purchasing options and quick delivery services to maintain fleet reliability and reduce downtime.

Why is Reliability Crucial in Mining Operations Concerning Starter Motor Solenoid Problems?

Mining operations depend on heavy machinery that requires continuous operation to avoid costly delays. Starter motor solenoid problems can disrupt these operations, leading to significant financial losses. Therefore, sourcing reliable solenoids is essential for maintaining equipment performance. Buyers from the mining sector should evaluate suppliers based on their experience in providing high-performance solenoids that can endure the demanding conditions of mining environments.

How Do Starter Motor Solenoid Problems Impact Construction Equipment Performance?

In construction, the reliability of heavy machinery is vital for meeting project deadlines. Problems with starter motors can lead to machinery failures, causing delays and increased project costs. By addressing solenoid issues proactively, construction companies can enhance machinery performance and reduce downtime. International buyers should seek suppliers with a proven track record in supplying components specifically designed for the construction industry, ensuring that their equipment operates efficiently under demanding conditions.

3 Common User Pain Points for ‘starter motor solenoid problems’ & Their Solutions

Scenario 1: Intermittent Starting Issues in Fleet Vehicles

The Problem: B2B buyers managing fleets often face the frustrating challenge of intermittent starting issues caused by faulty starter motor solenoids. Vehicles that sometimes fail to start can lead to operational inefficiencies, increased downtime, and potential loss of revenue. This inconsistency not only affects daily logistics but also impacts employee morale, as drivers may experience delays and uncertainties in their schedules.

The Solution: To address intermittent starting issues, it is crucial to implement a systematic diagnostic approach. Begin by regularly inspecting the starter solenoids in your fleet. Conduct tests to check for adequate voltage and continuity, which can help identify weak or failing solenoids. Additionally, consider investing in diagnostic tools that can provide real-time data on solenoid performance, allowing for proactive maintenance. When sourcing replacement solenoids, ensure you choose components that meet or exceed OEM specifications for durability and performance. Partnering with reputable suppliers who offer warranties and technical support can also mitigate risks associated with unreliable parts.

Scenario 2: Overheating and Melting of Starter Solenoids

The Problem: In regions with extreme temperatures, such as parts of Africa and the Middle East, starter motor solenoids are prone to overheating. This can lead to melting of the solenoid casing and subsequent failure, rendering vehicles inoperable. For businesses relying on transportation, such failures can severely disrupt operations and lead to costly repairs or replacements, not to mention potential safety hazards for drivers.

The Solution: To combat overheating issues, B2B buyers should focus on selecting starter solenoids specifically designed for high-temperature environments. When procuring solenoids, look for features such as heat-resistant materials and advanced cooling designs. Implementing a routine maintenance schedule that includes cleaning and inspecting solenoids for signs of wear or overheating can also be beneficial. Additionally, consider installing thermal management systems within vehicles to help regulate temperatures during operation. Investing in training for technicians on proper installation and maintenance of starter solenoids can further enhance reliability and performance.

Scenario 3: Difficulty in Identifying Related Electrical Issues

The Problem: B2B buyers often encounter the challenge of diagnosing starter motor solenoid problems that are actually symptoms of broader electrical issues. For instance, a vehicle may fail to start, leading managers to mistakenly attribute the problem solely to the solenoid. This misdiagnosis can result in unnecessary parts replacement and increased maintenance costs, alongside prolonged downtime for vehicles.

The Solution: To effectively address this challenge, it is essential to adopt a comprehensive electrical troubleshooting methodology. Begin by training technicians to evaluate the entire electrical system, including the battery, wiring, and alternator, before concluding that the solenoid is at fault. Utilize diagnostic equipment to check for voltage drops and continuity throughout the starter circuit. When sourcing parts, ensure compatibility and cross-reference specifications to prevent mismatches. Building a relationship with a knowledgeable supplier can provide access to technical resources and support, aiding in accurate diagnostics. By fostering a culture of thorough diagnostics and continuous learning, businesses can reduce costs and downtime associated with misdiagnosed solenoid issues.

Strategic Material Selection Guide for starter motor solenoid problems

What Are the Key Materials for Starter Motor Solenoid Problems?

When addressing starter motor solenoid problems, selecting the right materials is crucial for performance, durability, and compliance with international standards. Here, we analyze four common materials used in starter motor solenoids: copper, aluminum, steel, and plastic.

How Does Copper Perform in Starter Motor Solenoids?

Copper is widely recognized for its excellent electrical conductivity, making it a preferred choice for wiring and connections within solenoids. Its high thermal conductivity ensures efficient heat dissipation, which is vital in high-power applications. However, copper is prone to corrosion, especially in humid environments, which can lead to degradation over time.

Pros:

– High electrical and thermal conductivity.

– Good mechanical strength.

Cons:

– Susceptible to corrosion.

– Higher cost compared to alternatives.

For international buyers, particularly in regions like Africa and South America, sourcing high-quality copper that meets ASTM standards is essential to ensure reliability and longevity.

What Role Does Aluminum Play in Solenoid Design?

Aluminum is another popular material due to its lightweight nature and resistance to corrosion. It offers decent electrical conductivity, though not as high as copper. Aluminum is often used in the housing of solenoids, providing a balance between weight and strength.

Pros:

– Lightweight and corrosion-resistant.

– Cost-effective compared to copper.

Cons:

– Lower electrical conductivity than copper.

– May require additional treatments for high-temperature applications.

For B2B buyers in the Middle East and Europe, ensuring compliance with DIN standards is crucial for aluminum components in automotive applications.

Why is Steel Considered for Starter Motor Solenoids?

Steel is commonly used in the structural components of solenoids due to its high strength and durability. It can withstand significant mechanical stress, making it suitable for heavy-duty applications. However, steel is heavier and can be prone to rust if not properly coated or treated.

Pros:

– High strength and durability.

– Cost-effective for large-scale production.

Cons:

– Heavier than aluminum or plastic.

– Requires protective coatings to prevent rust.

International buyers should consider local environmental conditions when choosing steel components, as different regions may have varying levels of humidity and exposure to corrosive elements.

How Does Plastic Fit into the Material Selection for Solenoids?

Plastic materials, particularly thermoplastics, are often used for insulation and housing in solenoids. They provide excellent electrical insulation and are resistant to corrosion. However, plastics may not withstand high temperatures as well as metals, which can limit their use in certain applications.

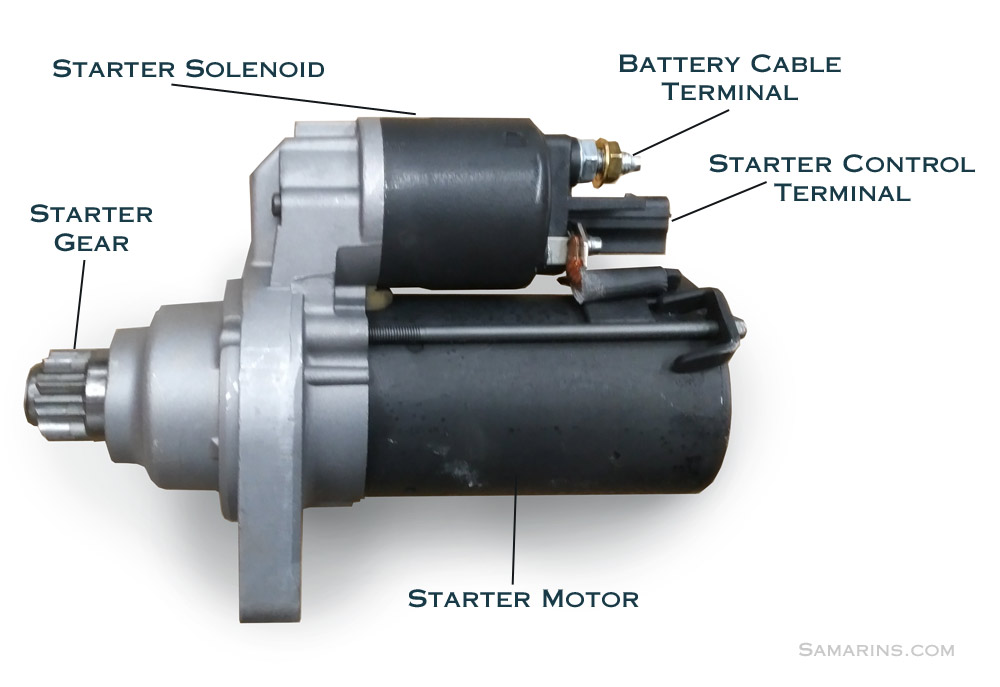

Illustrative image related to starter motor solenoid problems

Pros:

– Excellent electrical insulation properties.

– Lightweight and corrosion-resistant.

Cons:

– Limited temperature resistance.

– May not provide structural support in heavy-duty applications.

For B2B buyers in regions like Brazil and Vietnam, understanding the specific plastic grades and their compliance with JIS standards is essential for ensuring performance and safety.

Summary Table of Material Selection for Starter Motor Solenoid Problems

| Material | Typical Use Case for starter motor solenoid problems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and electrical connections in solenoids | High electrical and thermal conductivity | Susceptible to corrosion | High |

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Lower electrical conductivity | Medium |

| Steel | Structural components requiring high strength | High strength and durability | Heavier and requires protective coatings | Medium |

| Plastic | Insulation and housing for electrical components | Excellent electrical insulation | Limited temperature resistance | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that enhance the performance and reliability of starter motor solenoids.

In-depth Look: Manufacturing Processes and Quality Assurance for starter motor solenoid problems

What Are the Main Stages of Manufacturing Starter Motor Solenoids?

The manufacturing process of starter motor solenoids involves several critical stages, each designed to ensure high performance and reliability. Understanding these stages helps B2B buyers evaluate the quality of products they are sourcing.

How Is Material Prepared for Starter Motor Solenoids?

The first step in the manufacturing process is material preparation. Solenoids are typically made from various metals, including copper for electrical components and high-strength steel for structural parts. Suppliers must ensure that materials meet specific standards for conductivity, strength, and corrosion resistance.

Quality assurance begins at this stage, where incoming materials undergo rigorous inspection to verify their specifications. Buyers should inquire about the types of materials used and the standards adhered to, such as ASTM or ISO specifications, to ensure longevity and performance.

What Forming Techniques Are Used in Solenoid Manufacturing?

After material preparation, the forming stage begins. This typically involves techniques such as stamping, machining, and die-casting.

- Stamping: This process shapes metal sheets into the desired forms for solenoid housing or internal components. It is a high-speed process that allows for high precision and repeatability.

- Machining: Components may require additional machining to achieve tight tolerances. CNC (Computer Numerical Control) machines are commonly employed to ensure accuracy.

- Die-Casting: For components requiring intricate shapes, die-casting is often used. This method allows for the production of complex geometries while maintaining structural integrity.

These techniques can significantly impact the solenoid’s performance and reliability. Buyers should evaluate suppliers’ capabilities in these areas, as well as their ability to provide custom solutions when necessary.

How Are Starter Motor Solenoids Assembled?

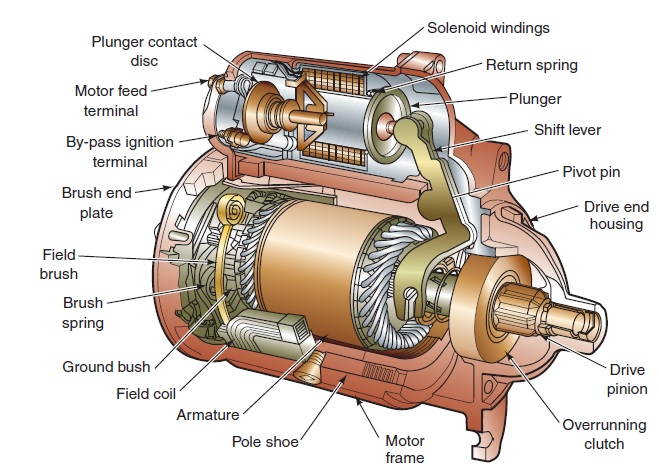

The assembly stage involves bringing together the various components produced in the earlier stages. Assembly can be manual, automated, or a combination of both, depending on the complexity of the solenoid and the production volume.

Automated assembly lines ensure consistency and reduce human error, while manual assembly may be necessary for intricate tasks that require a skilled technician’s attention. During this stage, components such as the solenoid coil, plunger, and housing are carefully fitted together to form a complete unit.

Buyers should consider the assembly techniques used by suppliers, as they can influence the overall quality and reliability of the solenoid.

What Finishing Processes Are Important for Quality?

Finishing processes are crucial for enhancing the solenoid’s performance and longevity. Common finishing techniques include:

- Coating: Applying protective coatings to prevent corrosion and wear.

- Heat Treatment: Strengthening metal components through processes like quenching and tempering.

- Testing: Conducting electrical tests to ensure functionality and performance under load.

These processes not only improve durability but also contribute to the solenoid’s efficiency in real-world applications. B2B buyers should ensure that suppliers perform thorough finishing processes and provide documentation of these practices.

Illustrative image related to starter motor solenoid problems

What International Quality Standards Should Buyers Look For?

Quality assurance in the manufacturing of starter motor solenoids is paramount, especially for international buyers. Several standards should be considered:

How Does ISO 9001 Impact Quality Control?

ISO 9001 is the international standard for quality management systems (QMS). Manufacturers adhering to ISO 9001 must demonstrate consistent quality in their products and services. This includes effective process management and continuous improvement practices.

Buyers should prioritize suppliers with ISO 9001 certification, as it reflects a commitment to quality and customer satisfaction.

What Industry-Specific Standards Are Relevant?

In addition to general quality standards, specific certifications may apply to starter motor solenoids. For instance:

Illustrative image related to starter motor solenoid problems

- CE Marking: Indicates compliance with European safety standards, essential for buyers in Europe.

- API Certification: Relevant for automotive components, ensuring they meet performance and safety benchmarks.

Understanding these certifications helps buyers assess the reliability and safety of the products they purchase.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. Common checkpoints include:

How Is Incoming Quality Control (IQC) Conducted?

Incoming Quality Control (IQC) involves inspecting raw materials upon receipt. This ensures that only materials meeting specified standards are used in production. Buyers should inquire about the IQC processes employed by suppliers to verify material quality.

What Is In-Process Quality Control (IPQC)?

In-Process Quality Control (IPQC) occurs during the manufacturing stages. This involves monitoring production processes and conducting tests to ensure that components meet design specifications. Regular checks at this stage help identify issues early, reducing waste and rework.

How Is Final Quality Control (FQC) Executed?

Final Quality Control (FQC) is the last checkpoint before products are shipped. This step includes comprehensive testing of finished solenoids to verify functionality, durability, and compliance with relevant standards. Buyers should request reports detailing FQC results to ensure product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure they are partnering with reliable manufacturers, B2B buyers should consider the following strategies:

What Role Do Audits Play in Supplier Evaluation?

Conducting audits of potential suppliers allows buyers to assess manufacturing practices and quality control measures directly. Audits can be performed by third-party inspectors or by the buyers themselves, providing insights into the supplier’s operations.

How Can Buyers Review Quality Reports?

Requesting quality reports from suppliers can help buyers understand their QC processes and outcomes. These reports should include details on testing methods, failure rates, and corrective actions taken for any identified issues.

What Are the Benefits of Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services often include detailed evaluations of manufacturing processes, materials, and compliance with international standards, offering buyers peace of mind.

Illustrative image related to starter motor solenoid problems

What Are the Unique QC Considerations for International Buyers?

International buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural Differences: Understanding local manufacturing practices and quality expectations is crucial when sourcing globally.

- Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Buyers should familiarize themselves with these requirements to avoid compliance issues.

- Supply Chain Transparency: Ensuring transparency throughout the supply chain is vital for maintaining quality. Buyers should engage suppliers who are open about their sourcing, manufacturing, and QC practices.

By focusing on these aspects, B2B buyers can make informed decisions when sourcing starter motor solenoids, ensuring they partner with manufacturers that prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor solenoid problems’

Introduction

This practical sourcing guide aims to assist B2B buyers in effectively addressing starter motor solenoid problems. Understanding the complexities of sourcing components like solenoids is crucial for ensuring operational efficiency and reliability in automotive applications. This checklist provides actionable steps to guide you through the procurement process, helping you make informed decisions.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it is essential to clearly outline your technical requirements. This includes voltage ratings, current capacity, and compatibility with specific engine types. Providing precise specifications will help suppliers deliver components that meet your operational needs and reduce the risk of purchasing unsuitable products.

Illustrative image related to starter motor solenoid problems

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers specializing in starter motor solenoids. Look for companies with a strong reputation in the industry, and consider their experience with international clients. Utilize platforms like trade directories, industry forums, and trade shows to gather a list of potential partners.

Step 3: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications and comply with industry standards. Certifications such as ISO 9001 indicate a commitment to quality management systems. Verify if they meet local and international regulations, particularly if you are sourcing from regions with stringent automotive standards.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the starter motor solenoids. Testing samples can help you evaluate the quality and performance of the components firsthand. Pay attention to factors such as durability, response time, and ease of installation to ensure they align with your operational requirements.

Step 5: Assess Pricing and Payment Terms

Engage suppliers in discussions about pricing models and payment terms. Compare quotes from different suppliers while considering the total cost of ownership, which includes shipping, tariffs, and potential duties. Ensure that the payment terms are flexible and align with your financial capabilities to maintain cash flow.

Step 6: Evaluate After-Sales Support and Warranty

Inquire about the after-sales support and warranty policies offered by potential suppliers. A robust warranty can indicate the supplier’s confidence in their products. Additionally, assess their customer service responsiveness, as timely support can be critical in resolving issues that arise post-purchase.

Step 7: Establish Long-Term Relationships

Consider establishing long-term relationships with suppliers who consistently meet your quality and service expectations. Building strong partnerships can lead to better pricing, priority service, and access to new product developments. Regular communication and feedback can enhance collaboration and ensure mutual growth.

By following this checklist, B2B buyers can navigate the complexities of sourcing starter motor solenoids effectively, ensuring they acquire high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for starter motor solenoid problems Sourcing

What Are the Key Cost Components for Sourcing Starter Motor Solenoid Solutions?

When evaluating the costs associated with sourcing solutions for starter motor solenoid problems, several key components contribute to the overall pricing structure:

-

Materials: The primary materials involved in manufacturing starter motor solenoids include copper for wiring, steel for housing, and various plastics for insulation. The quality of these materials can significantly impact the cost. High-grade materials may lead to increased durability but will also elevate the price.

-

Labor: Labor costs can vary widely depending on the region and the complexity of the manufacturing process. In countries with higher labor costs, such as those in Europe, the manufacturing expense may be higher compared to regions in Africa or South America, where labor costs are typically lower.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Overhead can vary based on the scale of operations and the efficiency of manufacturing processes.

-

Tooling: Tooling costs refer to the expenses incurred in creating molds, dies, and other equipment necessary for production. Custom tooling for specific designs can significantly increase upfront costs, making it essential for buyers to consider these expenses when determining the total cost of ownership.

-

Quality Control (QC): Ensuring product quality is crucial, especially for components like solenoids that are vital for vehicle operation. Investment in rigorous QC processes can add to costs but may prevent costly failures and enhance customer satisfaction in the long run.

-

Logistics: Shipping and handling costs, including freight, insurance, and customs duties, must be factored into the overall cost structure. The location of suppliers and the choice of transportation modes can influence these costs significantly.

-

Margin: Suppliers typically add a profit margin to the cost of production, which can vary based on market competition and perceived value. Understanding the supplier’s margin can help buyers negotiate better prices.

What Factors Influence Pricing for Starter Motor Solenoid Sourcing?

Several factors can influence the pricing of starter motor solenoid sourcing:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing can lead to significant discounts. Suppliers often have minimum order quantities, and meeting these can lower per-unit costs.

-

Specifications and Customization: Custom specifications may lead to higher costs due to additional engineering and production time. Buyers should evaluate whether they need custom solutions or can work with standard products to save costs.

-

Material Choices: The selection of materials directly impacts pricing. For instance, opting for lower-grade materials may reduce initial costs but could lead to higher long-term expenses due to potential failures or replacements.

-

Quality Certifications: Components that meet international quality standards (e.g., ISO certifications) may come at a premium. However, such certifications often justify the higher price due to increased reliability and safety.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers with proven track records may charge more but often provide better service and quality assurance.

-

Incoterms: Understanding the implications of Incoterms is critical for international buyers. Terms such as CIF (Cost, Insurance, and Freight) versus FOB (Free on Board) can affect the total landed cost and should be clarified before finalizing contracts.

What Are Essential Tips for Negotiating Prices for Starter Motor Solenoid Solutions?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation can lead to more favorable pricing structures:

-

Research and Benchmarking: Conduct thorough market research to understand average pricing and quality levels. This information can empower you during negotiations.

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, downtime, and potential replacements. Presenting a TCO analysis can strengthen your negotiation position.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing and favorable terms. Trust and reliability often translate into better deals.

-

Leverage Volume Discounts: If your operations allow for it, consolidate orders to take advantage of volume pricing. This strategy can lead to substantial savings.

-

Be Flexible on Specifications: If possible, consider flexibility in product specifications. Suppliers may have existing inventory that meets your needs at a lower cost.

Final Thoughts

While pricing for starter motor solenoid sourcing can vary significantly based on numerous factors, understanding the cost components and price influencers is vital for making informed purchasing decisions. By employing strategic negotiation techniques and focusing on total cost implications, buyers can enhance their procurement outcomes. As always, it’s essential to approach pricing discussions with a clear understanding of both the immediate and long-term impacts on your operations.

Alternatives Analysis: Comparing starter motor solenoid problems With Other Solutions

Understanding Alternative Solutions to Starter Motor Solenoid Problems

When faced with starter motor solenoid issues, businesses often seek alternative solutions that can effectively resolve their automotive challenges. Understanding these alternatives is crucial for B2B buyers in different regions, including Africa, South America, the Middle East, and Europe, as it enables them to make informed decisions tailored to their specific operational needs.

Comparison Table

| Comparison Aspect | Starter Motor Solenoid Problems | Alternative 1: Starter Relay Upgrade | Alternative 2: Smart Battery Management System |

|---|---|---|---|

| Performance | Often leads to intermittent starting issues and engine failures. | Increases reliability and reduces failure rates in the ignition system. | Enhances battery life and ensures optimal power delivery. |

| Cost | Replacement costs can be high depending on vehicle make and model. | Moderate cost; may require professional installation. | Higher initial investment but offers long-term savings. |

| Ease of Implementation | Typically requires professional service for replacement or repair. | Can be installed by a skilled technician; relatively straightforward. | Installation can be complex; may require specialized knowledge. |

| Maintenance | Limited maintenance; usually replaced when faulty. | Minimal maintenance; depends on relay quality. | Regular monitoring needed to ensure efficiency. |

| Best Use Case | Suitable for vehicles with traditional starter systems. | Ideal for modern vehicles requiring improved ignition reliability. | Best for fleets or vehicles with high battery usage and turnover. |

What Are the Advantages and Disadvantages of Upgrading to a Starter Relay?

Upgrading to a starter relay can mitigate many of the problems associated with starter motor solenoids. This solution offers enhanced reliability by ensuring that the ignition system can handle higher power demands without overheating or failing. However, while the cost of upgrading is moderate, it may still require professional installation, which can add to the overall expense. The relay’s performance is generally superior, but it is critical to ensure compatibility with the vehicle’s electrical system.

How Does a Smart Battery Management System Provide a Viable Alternative?

A Smart Battery Management System (BMS) represents a more advanced approach to managing vehicle power needs. By actively monitoring battery health and optimizing power distribution, a BMS enhances battery life and ensures that the starter receives sufficient power during ignition. Although the initial investment may be higher, the long-term savings on battery replacements and repairs can be significant. However, the complexity of installation and the need for specialized knowledge can be a barrier for some businesses.

Conclusion: How Should B2B Buyers Choose the Right Solution?

In evaluating the best solution for starter motor solenoid problems, B2B buyers should consider several factors, including vehicle type, operational demands, and budget constraints. For businesses operating older vehicles or those with simpler electrical systems, addressing solenoid issues directly may suffice. Conversely, companies managing modern fleets may benefit more from upgrading to a starter relay or implementing a Smart Battery Management System for enhanced reliability and efficiency. Ultimately, aligning the chosen solution with specific operational requirements will ensure optimal performance and reduced downtime.

Essential Technical Properties and Trade Terminology for starter motor solenoid problems

What Are the Critical Technical Properties of Starter Motor Solenoids?

Understanding the essential technical properties of starter motor solenoids is vital for B2B buyers, particularly when sourcing components for automotive applications. Here are some key specifications to consider:

1. Material Grade

The material used in the construction of a solenoid significantly affects its durability and performance. Common materials include copper for windings due to its excellent conductivity and various grades of steel for the housing. Choosing a high-grade material ensures that the solenoid can withstand heat and wear, which is crucial in high-demand environments.

2. Coil Resistance

Coil resistance is a critical parameter that influences the solenoid’s performance. Typically measured in ohms, the resistance should align with the vehicle’s electrical specifications. An appropriate resistance level ensures optimal power draw and prevents overheating, which can lead to solenoid failure. Understanding this helps in assessing compatibility with existing systems.

3. Voltage Rating

The voltage rating, usually specified in volts, indicates the maximum voltage the solenoid can handle. Most automotive solenoids operate at 12V, but some vehicles may require higher ratings. Selecting a solenoid with the correct voltage rating is crucial for ensuring reliable performance and preventing electrical failures.

4. Torque Output

Torque output measures the rotational force the solenoid can exert. This specification is critical in ensuring that the solenoid can effectively engage the starter motor under varying conditions. A higher torque output typically translates to a more reliable start, especially in cold weather or high-stress environments.

5. Operating Temperature Range

The operating temperature range defines the environmental conditions in which the solenoid can function effectively. Solenoids used in automotive applications must withstand extreme temperatures, both hot and cold. Understanding this property is essential for ensuring longevity and reliability in diverse climates, particularly in regions like Africa and the Middle East.

6. Duty Cycle

The duty cycle refers to the amount of time the solenoid can operate continuously without overheating. This property is crucial for applications requiring repeated engagements. A solenoid with a higher duty cycle is preferable for heavy-duty vehicles or in scenarios where frequent starts are necessary.

What Trade Terminology Should B2B Buyers Understand for Solenoid Procurement?

Knowledge of industry-specific terminology is essential for effective communication and negotiation in the procurement process. Here are some key terms relevant to starter motor solenoids:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold directly by vehicle manufacturers. B2B buyers often prefer OEM components for their reliability and compatibility with existing systems. Understanding OEM specifications helps in sourcing high-quality parts that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for inventory management and budgeting. It allows buyers to plan purchases effectively and avoid excess stock, which is particularly important for companies operating in regions with fluctuating demand.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. In the context of starter motor solenoids, issuing an RFQ helps buyers gather competitive offers and make informed decisions. Clarity in the RFQ can lead to better pricing and service agreements.

4. Incoterms

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping costs, risk transfers, and delivery points, ensuring smoother transactions, especially when importing from regions like Europe or South America.

5. Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. Knowing the lead time is crucial for planning and ensuring that components arrive when needed, particularly in industries where downtime can be costly.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing starter motor solenoids, ultimately leading to improved operational efficiency and reliability in their automotive applications.

Navigating Market Dynamics and Sourcing Trends in the starter motor solenoid problems Sector

What Are the Current Trends Impacting the Starter Motor Solenoid Problems Market?

The global market for starter motor solenoid solutions is being shaped by several key drivers, including the growing demand for efficient and reliable automotive components and the increasing prevalence of advanced vehicle technologies. With the rise of electric and hybrid vehicles, there is an emerging need for advanced starter systems that can handle new power requirements. Additionally, the automotive aftermarket is witnessing a surge in demand for replacement parts, driven by longer vehicle lifespans and increased vehicle ownership in developing regions like Africa and South America.

In terms of B2B tech and sourcing trends, digital transformation is playing a significant role. Companies are increasingly leveraging data analytics and IoT technology to enhance the performance and reliability of starter solenoids. For instance, predictive maintenance tools can help identify potential failures before they occur, reducing downtime and improving customer satisfaction. Furthermore, international buyers are increasingly looking to source products from manufacturers that provide comprehensive technical support and warranties, ensuring that they can maintain high operational standards.

Market dynamics also indicate a shift toward more competitive pricing models as manufacturers strive to offer cost-effective solutions without compromising quality. This is particularly relevant for international buyers, who are often navigating different market conditions and currency fluctuations. As a result, sourcing strategies must adapt to account for local economic factors and supply chain challenges, especially in regions like the Middle East and Europe, where trade regulations can vary significantly.

How Can Sustainability and Ethical Sourcing Practices Be Integrated into the Starter Motor Solenoid Supply Chain?

The environmental impact of automotive components, including starter motor solenoids, is a growing concern for businesses worldwide. The automotive industry is under increasing pressure to reduce its carbon footprint, prompting manufacturers to adopt sustainable practices. This includes the use of eco-friendly materials and processes that minimize waste and energy consumption.

For B2B buyers, the importance of ethical supply chains cannot be overstated. Partnering with suppliers that prioritize sustainability can enhance brand reputation and customer loyalty. Additionally, buyers should seek manufacturers who have obtained relevant ‘green’ certifications, such as ISO 14001 for environmental management, which can serve as a guarantee of the supplier’s commitment to sustainable practices.

Moreover, the trend toward circular economy principles is gaining traction. This involves designing starter motor solenoids that are easier to recycle or refurbish, thus extending the lifecycle of components and reducing landfill waste. By prioritizing suppliers who align with these values, international buyers can contribute to a more sustainable automotive ecosystem while meeting regulatory requirements and consumer expectations.

What Historical Developments Have Influenced the Starter Motor Solenoid Market?

The starter motor solenoid has evolved significantly since its introduction in the early 20th century. Initially, the solenoid served a basic function, acting as a switch to engage the starter motor. However, as automotive technology advanced, so too did the complexity and functionality of solenoids.

In the late 20th century, the incorporation of electronic controls transformed starter solenoids from purely mechanical devices to sophisticated electronic components. This evolution has enabled more precise control over engine starting processes, improving overall vehicle reliability. As vehicles have become more technologically advanced, the demand for high-quality starter solenoids has grown, prompting manufacturers to innovate continually.

Understanding this historical context is crucial for B2B buyers, as it highlights the importance of sourcing from manufacturers that are not only knowledgeable about current technologies but also adept at anticipating future trends. This foresight can lead to more strategic partnerships and better product offerings in a competitive market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of starter motor solenoid problems

-

1. How do I solve issues related to a bad starter motor solenoid?

To address problems with a starter motor solenoid, first diagnose the symptoms. Common signs include a failure to start, a single click sound, or intermittent starting issues. Ensure the battery is fully charged and check for blown fuses or corroded wiring. If the solenoid is faulty, it may need to be replaced. Consult a qualified technician to confirm the diagnosis and recommend the appropriate solution, which may involve replacing the solenoid or even the starter assembly, depending on the vehicle’s design. -

2. What is the best way to identify a reliable supplier for starter motor solenoids?

Identifying a reliable supplier involves several steps. Start by researching suppliers with a strong reputation in the automotive parts industry. Look for customer reviews, certifications, and industry experience. Request samples to assess product quality and compliance with international standards. Additionally, consider suppliers who offer warranties and have transparent return policies. Establishing direct communication can also provide insights into their reliability and customer service capabilities. -

3. What customization options should I consider when sourcing starter motor solenoids?

When sourcing starter motor solenoids, consider customization options that align with your specific needs, such as voltage ratings, housing materials, and connector types. Discuss potential modifications with suppliers to ensure compatibility with your vehicle models. Additionally, inquire about the possibility of branding or packaging customization to enhance your market presence. Custom solutions can help you differentiate your products and meet regional specifications effectively. -

4. What are the typical minimum order quantities (MOQs) for starter motor solenoids?

Minimum order quantities (MOQs) for starter motor solenoids can vary significantly among suppliers. Generally, MOQs range from 100 to 1,000 units, depending on the manufacturer and the complexity of the product. If you are a smaller business or just starting, discuss your needs with potential suppliers to negotiate lower MOQs. Some manufacturers may offer flexibility for first-time orders or sample runs, allowing you to test products without committing to large quantities. -

5. What payment terms are commonly offered by suppliers of starter motor solenoids?

Payment terms can vary widely based on the supplier’s policies and your business relationship. Common terms include upfront payment, a 30% deposit with the balance due upon shipment, or net 30/60 days after delivery. It is crucial to clarify payment methods accepted, such as bank transfers or letters of credit, to facilitate international transactions. Establishing favorable payment terms can help manage cash flow and reduce financial risk in international trade. -

6. How can I ensure quality assurance (QA) for starter motor solenoids?

To ensure quality assurance for starter motor solenoids, collaborate closely with your supplier to understand their QA processes. Request documentation on testing methods, material certifications, and compliance with international standards. Conduct regular inspections during production and before shipment. If possible, consider third-party inspections to verify product quality. Establishing a strong QA framework helps mitigate risks associated with defective parts and enhances customer satisfaction. -

7. What logistics considerations should I keep in mind when importing starter motor solenoids?

When importing starter motor solenoids, consider logistics factors such as shipping methods, customs clearance, and lead times. Choose a reliable freight forwarder experienced in handling automotive parts to ensure smooth transportation. Be aware of import regulations and tariffs in your country to avoid unexpected costs. Additionally, plan for potential delays due to customs inspections or shipping disruptions, and maintain open communication with your supplier to manage timelines effectively. -

8. What are the common issues to watch for when testing starter motor solenoids?

While testing starter motor solenoids, watch for common issues such as inadequate engagement, inconsistent operation, or overheating. Use a multimeter to check for proper voltage and continuity. Listen for unusual sounds, such as repeated clicking, which may indicate internal failures. Ensure all connections are secure and free from corrosion. Regular testing and maintenance can help identify potential problems early, reducing the risk of unexpected failures in the field.

Top 3 Starter Motor Solenoid Problems Manufacturers & Suppliers List

1. Eric’s Car Care – Starter Solenoid Solutions

Domain: ericscarcare.com

Registered: 2021 (4 years)

Introduction: This company, Eric’s Car Care – Starter Solenoid Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. PT Cruiser – Starter Solenoid Issues

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: 2002 PT Cruiser; starter solenoid issue; symptoms include solid clicking sound, starter not spinning; previous fixes involved tapping the solenoid; replaced starter with remanufactured unit; recurring problem after 2 months; new starter arrived with test report indicating solenoid failures.

3. Moss – Replacement Ignition Switch

Domain: mgexp.com

Registered: 2011 (14 years)

Introduction: 1967 MG MGB, replacement ignition switch from Moss, original Lucas ignition switch, starter solenoid, multimeter for testing voltage, battery voltage range 11.5V to 13V, troubleshooting steps for starter issues.

Strategic Sourcing Conclusion and Outlook for starter motor solenoid problems

As the automotive industry continues to evolve, addressing starter motor solenoid issues remains critical for operational efficiency. Understanding the signs of a failing solenoid—such as a complete lack of response, unusual clicking sounds, or intermittent starting problems—allows businesses to preemptively manage vehicle reliability and minimize downtime.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing becomes essential. Partnering with reliable suppliers who offer high-quality starter motor components can lead to better performance, reduced maintenance costs, and improved customer satisfaction.

Investing in advanced diagnostic tools and training for technicians can further enhance the ability to identify and resolve solenoid issues swiftly. As we look to the future, embracing technological advancements and fostering strong supplier relationships will be key to navigating the complexities of automotive components.

We encourage businesses to evaluate their sourcing strategies today—securing dependable parts and suppliers is not just a choice; it’s a competitive necessity. Reach out to trusted partners and invest in quality solutions to ensure your operations run smoothly and efficiently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.