Introduction: Navigating the Global Market for start motoren

In the ever-evolving landscape of global commerce, sourcing reliable starter motors can pose a significant challenge for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. The demand for high-quality start motoren—essential components that facilitate engine ignition—continues to rise as industries seek efficiency and reliability in their operations. This guide aims to demystify the complexities of the starter motor market by providing an in-depth exploration of various types, applications, and technologies available today.

Within these pages, you will find comprehensive insights into the different configurations of starter motors, their specific applications, and essential criteria for supplier vetting. Additionally, we will delve into cost considerations, ensuring you are equipped to make informed purchasing decisions that align with your business needs. Whether you are a manufacturer, distributor, or service provider, understanding the intricacies of starter motors will empower you to navigate this crucial market with confidence.

By leveraging the knowledge presented in this guide, international buyers will not only enhance their operational efficiency but also ensure the longevity and reliability of their machinery. The goal is to facilitate smarter sourcing strategies that meet the demands of your specific market, ultimately driving success in your business endeavors.

Table Of Contents

- Top 4 Start Motoren Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for start motoren

- Understanding start motoren Types and Variations

- Key Industrial Applications of start motoren

- 3 Common User Pain Points for ‘start motoren’ & Their Solutions

- Strategic Material Selection Guide for start motoren

- In-depth Look: Manufacturing Processes and Quality Assurance for start motoren

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘start motoren’

- Comprehensive Cost and Pricing Analysis for start motoren Sourcing

- Alternatives Analysis: Comparing start motoren With Other Solutions

- Essential Technical Properties and Trade Terminology for start motoren

- Navigating Market Dynamics and Sourcing Trends in the start motoren Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of start motoren

- Strategic Sourcing Conclusion and Outlook for start motoren

- Important Disclaimer & Terms of Use

Understanding start motoren Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Starter Motor | Uses a solenoid to engage the pinion gear; high torque for brief periods. | Automotive, small machinery | Pros: Reliable, widely available. Cons: Limited lifespan, can drain battery if faulty. |

| High Torque Starter Motor | Designed for heavy-duty applications; provides higher torque output. | Trucks, construction equipment | Pros: Suitable for demanding environments. Cons: Higher cost, may require more maintenance. |

| Gear Reduction Starter Motor | Incorporates a gear reduction mechanism to enhance torque while reducing size. | Performance vehicles, racing | Pros: Compact design, improved efficiency. Cons: More complex installation, potential for gear wear. |

| Permanent Magnet Starter | Uses permanent magnets instead of field windings; lightweight and efficient. | Electric vehicles, hybrids | Pros: Energy-efficient, compact. Cons: Higher initial cost, sensitive to heat. |

| Integrated Starter Generator (ISG) | Combines starter and generator functions; often used in hybrid systems. | Hybrid and electric vehicles | Pros: Enhances fuel efficiency, reduces emissions. Cons: Complex technology, higher replacement cost. |

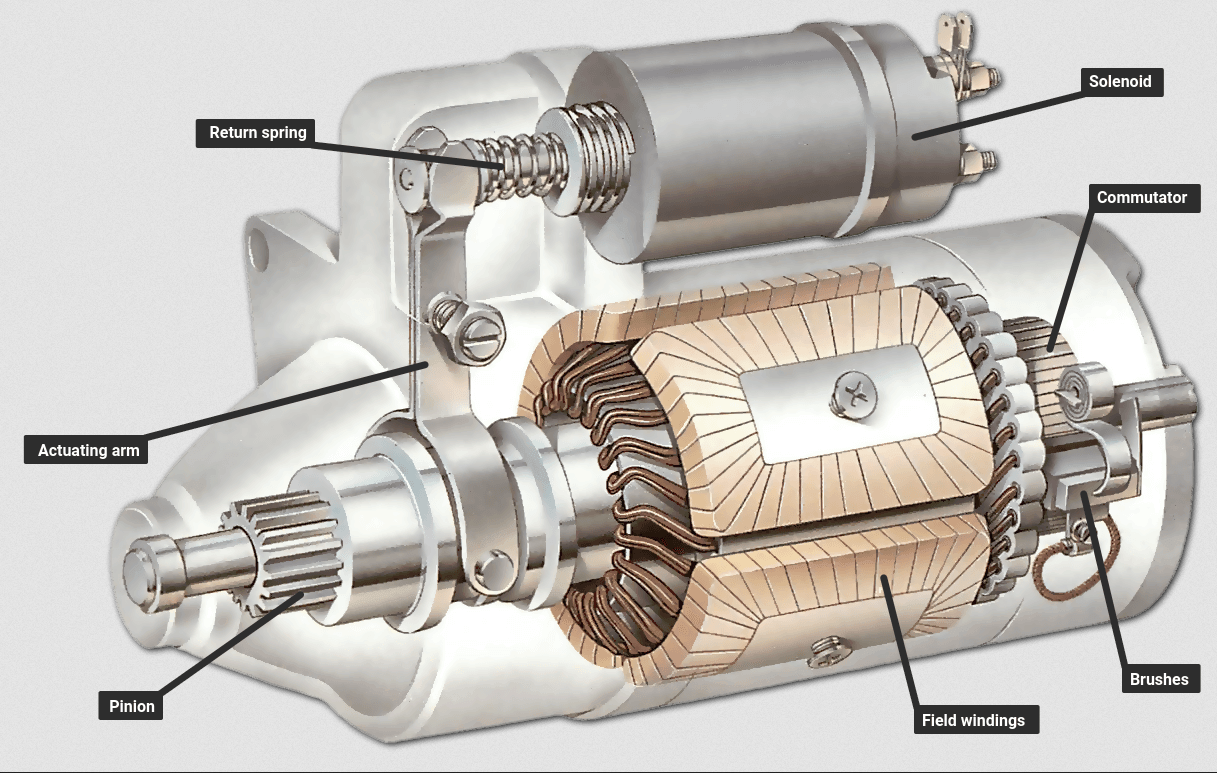

What Are the Characteristics of Conventional Starter Motors?

Conventional starter motors are the most common type found in vehicles, utilizing a solenoid to engage the pinion gear. They are designed to provide high torque for short bursts, enabling the engine to crank and start. These motors are widely used in automotive applications and small machinery due to their reliability and ease of replacement. When purchasing, buyers should consider factors like compatibility with vehicle models, as well as the potential for battery drain if the motor malfunctions.

How Do High Torque Starter Motors Differ?

High torque starter motors are engineered for heavy-duty applications, such as trucks and construction equipment, where greater starting power is necessary. They deliver a higher torque output compared to conventional starters, making them ideal for engines that require more effort to start. Buyers should evaluate the specific torque requirements of their machinery and consider the potential for increased maintenance due to the higher demands placed on these motors.

What Benefits Do Gear Reduction Starter Motors Offer?

Gear reduction starter motors feature a gear mechanism that amplifies torque while minimizing the size of the motor. This design is particularly beneficial in performance vehicles and racing applications, where space is limited and efficiency is crucial. While they offer improved performance, buyers must be aware of the more complex installation process and the possibility of gear wear over time.

Why Choose Permanent Magnet Starter Motors?

Permanent magnet starter motors utilize permanent magnets instead of traditional field windings, making them lighter and more energy-efficient. They are increasingly used in electric and hybrid vehicles, where weight reduction is critical. While these motors provide excellent efficiency and compactness, buyers should consider their higher initial cost and sensitivity to heat, which may impact their longevity in certain environments.

What Are Integrated Starter Generators (ISG) and Their Applications?

Integrated Starter Generators combine the functions of a starter and a generator, primarily used in hybrid and electric vehicles. This technology enhances fuel efficiency and reduces emissions by allowing the vehicle to utilize energy more effectively. However, the complexity of ISG systems may lead to higher replacement costs and necessitate specialized knowledge for repairs. Buyers should assess the long-term benefits against the initial investment and maintenance considerations when opting for this advanced technology.

Key Industrial Applications of start motoren

| Industry/Sector | Specific Application of start motoren | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine Start Systems | Reliable engine ignition, improving vehicle uptime | Compatibility with various engine types, voltage ratings, and torque requirements |

| Agriculture | Tractors and Harvesters | Enhanced operational efficiency in farming tasks | Durability in harsh environments, resistance to dust and moisture |

| Manufacturing | Conveyor Systems | Smooth operation and reduced downtime | Load capacity, speed control, and integration with existing systems |

| Mining | Heavy Equipment Start-Up | Quick mobilization of machinery, minimizing delays | Robustness for extreme conditions, safety certifications |

| Energy Production | Wind Turbines and Generators | Efficient energy conversion, supporting renewable energy initiatives | Compliance with energy standards, efficiency ratings |

How Are Starter Motors Used in the Automotive Industry?

In the automotive sector, starter motors are critical for engine ignition systems. They provide the necessary torque to turn the engine over, ensuring reliable starts under various conditions. For international buyers, especially from regions like Africa and South America, understanding the specific voltage ratings and compatibility with different engine types is essential. Furthermore, sourcing high-quality starter motors can prevent costly downtimes due to engine start failures, thereby enhancing vehicle uptime and operational efficiency.

What Role Do Starter Motors Play in Agriculture?

In agriculture, starter motors are commonly employed in tractors and harvesters. These motors enable the machinery to start efficiently, allowing farmers to maximize productivity during peak seasons. Buyers in this sector should consider the durability of starter motors, as agricultural equipment often operates in challenging environments filled with dust and moisture. Selecting robust starter motors can significantly reduce maintenance costs and equipment failures, leading to smoother farming operations.

How Are Starter Motors Essential in Manufacturing?

Manufacturing industries utilize starter motors to control conveyor systems and other automated machinery. They ensure smooth operation and facilitate quick startup and shutdown processes, which are crucial for maintaining production lines. Businesses should focus on sourcing starter motors that can handle specific load capacities and speed control requirements. Additionally, compatibility with existing systems is vital to ensure seamless integration and minimize operational disruptions.

Why Are Starter Motors Important in Mining Operations?

In the mining industry, starter motors are vital for the start-up of heavy equipment such as excavators and haul trucks. These motors provide quick mobilization of machinery, which is critical for minimizing delays in operations. When sourcing starter motors for this sector, buyers must prioritize robustness and safety certifications to withstand extreme conditions. Reliable starter motors can significantly enhance operational efficiency and ensure the safety of mining operations.

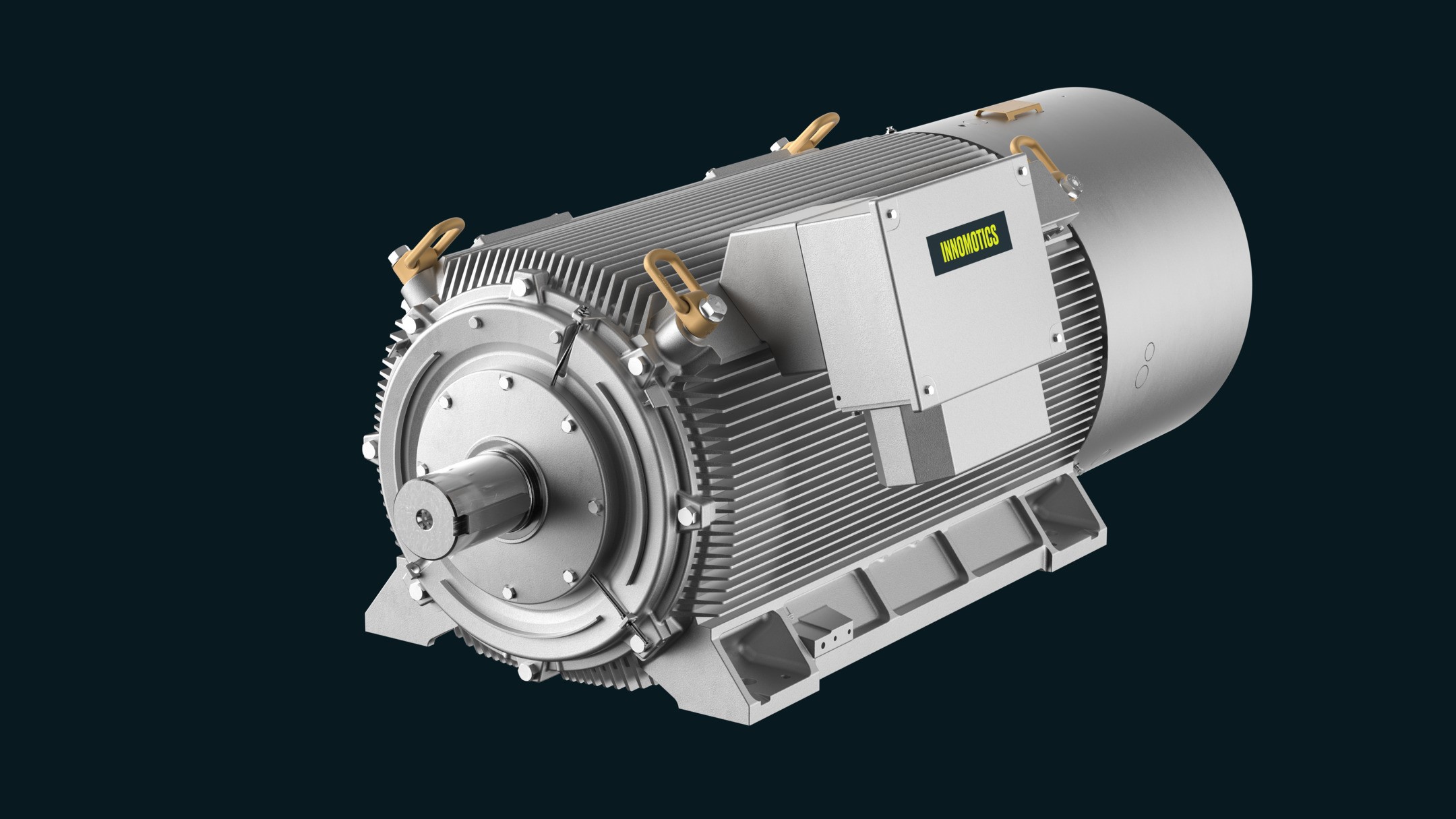

Illustrative image related to start motoren

How Do Starter Motors Support Energy Production?

In energy production, particularly in wind turbines and generators, starter motors facilitate the efficient conversion of kinetic energy into electrical energy. They play a crucial role in the startup sequence of these systems, ensuring optimal performance. International buyers should focus on compliance with energy standards and efficiency ratings when sourcing starter motors for energy applications. This focus not only supports renewable energy initiatives but also enhances the overall reliability of energy production systems.

3 Common User Pain Points for ‘start motoren’ & Their Solutions

Scenario 1: Navigating Starter Motor Compatibility Issues

The Problem: A common challenge faced by B2B buyers is ensuring compatibility between starter motors and their existing machinery or vehicle systems. When sourcing starter motors, many buyers find that specifications vary widely among manufacturers, which can lead to mismatches. This issue is particularly pronounced in regions with diverse vehicle makes and models, where specific starter motors may not be readily available. As a result, organizations may experience delays in production or costly downtime due to incompatible components.

The Solution: To mitigate compatibility issues, buyers should conduct thorough research on the specifications of the starter motors they intend to purchase. This includes understanding the voltage, torque requirements, and physical dimensions of the starter motor. Engaging with suppliers who offer comprehensive technical support can also be beneficial. It’s advisable to request detailed product datasheets and compatibility charts before making a purchase. Additionally, consider investing in a universal starter motor that is designed to fit multiple applications, reducing the need for inventory diversification. This proactive approach can enhance operational efficiency and minimize downtime.

Scenario 2: Addressing Starter Motor Failures and Downtime

The Problem: Frequent starter motor failures can severely disrupt business operations, leading to costly downtime and repair expenses. B2B buyers often struggle to diagnose whether the issue lies with the starter motor itself or ancillary components like the battery or electrical system. Misdiagnosis can lead to unnecessary replacement costs and prolonged service interruptions, which are particularly detrimental in industries reliant on continuous operation.

The Solution: Implementing a systematic approach to troubleshooting can significantly reduce downtime associated with starter motor failures. Begin by training maintenance personnel to conduct thorough diagnostics, focusing on the entire electrical system, including battery health and connections. Regular maintenance schedules should include testing the starter motor under load conditions to identify early signs of wear or malfunction. Additionally, establishing relationships with reliable suppliers who provide diagnostic tools can facilitate quick assessments and repairs. Utilizing predictive maintenance technologies can also help in anticipating failures before they occur, ensuring that businesses remain operational and minimizing unexpected costs.

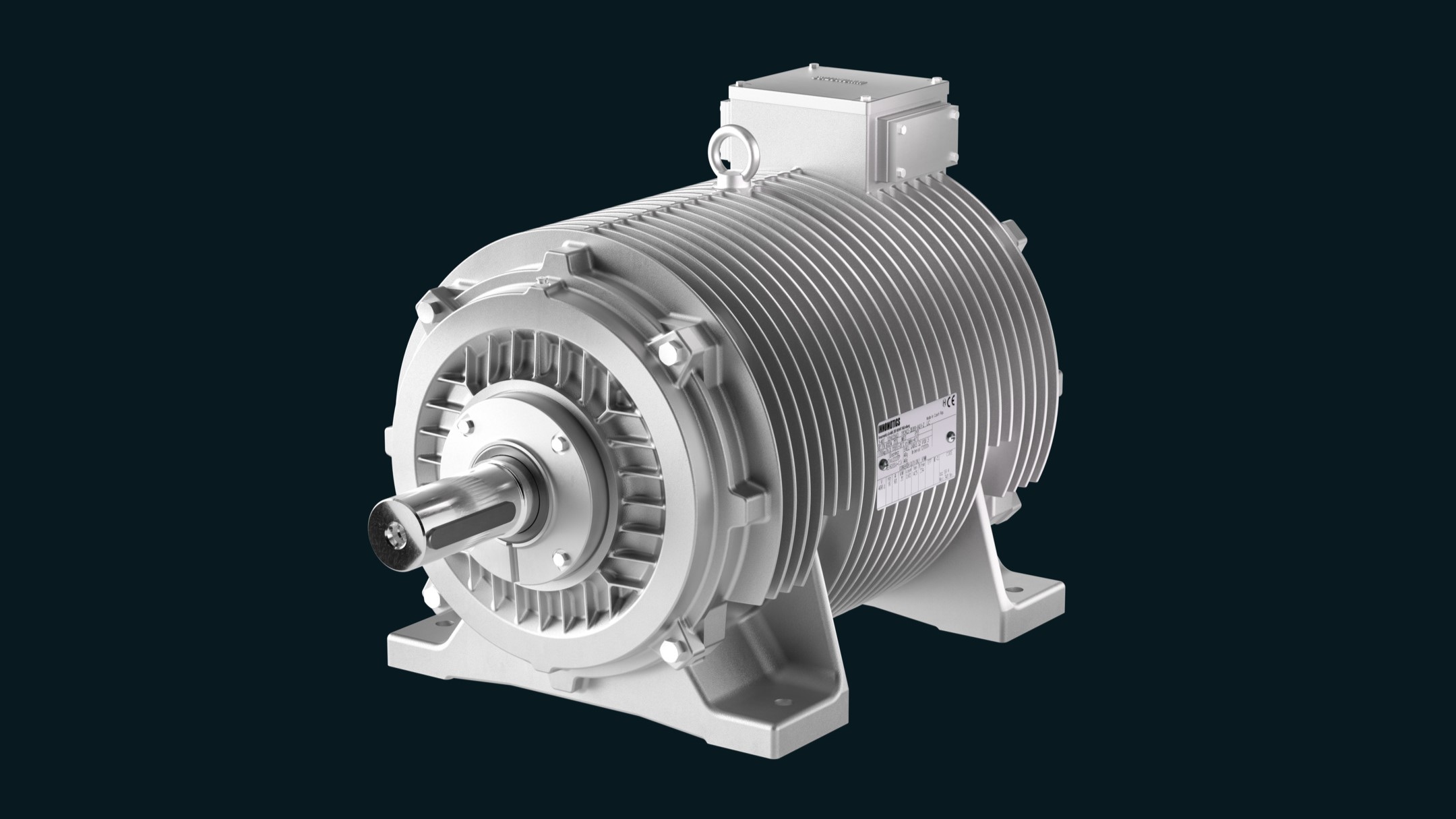

Illustrative image related to start motoren

Scenario 3: Overcoming Sourcing Challenges in Emerging Markets

The Problem: B2B buyers in emerging markets often face sourcing challenges for starter motors due to limited availability of high-quality products and reliable suppliers. This situation can lead to substandard components entering the supply chain, which may not perform reliably or may have shorter lifespans. Consequently, businesses risk facing frequent repairs and replacements, affecting overall productivity and profitability.

The Solution: To overcome sourcing challenges, B2B buyers should establish partnerships with reputable manufacturers or distributors known for quality assurance and reliability. Conducting supplier audits and requiring certifications can help ensure that sourced products meet industry standards. Buyers should also explore local manufacturing options, which may provide better access to quality starter motors tailored to specific regional needs. Furthermore, engaging in bulk purchasing agreements can improve negotiation power, leading to better pricing and guaranteed product quality. Finally, leveraging online platforms that connect buyers with verified suppliers can streamline the sourcing process and enhance the chances of acquiring high-quality starter motors suited for their operational requirements.

Strategic Material Selection Guide for start motoren

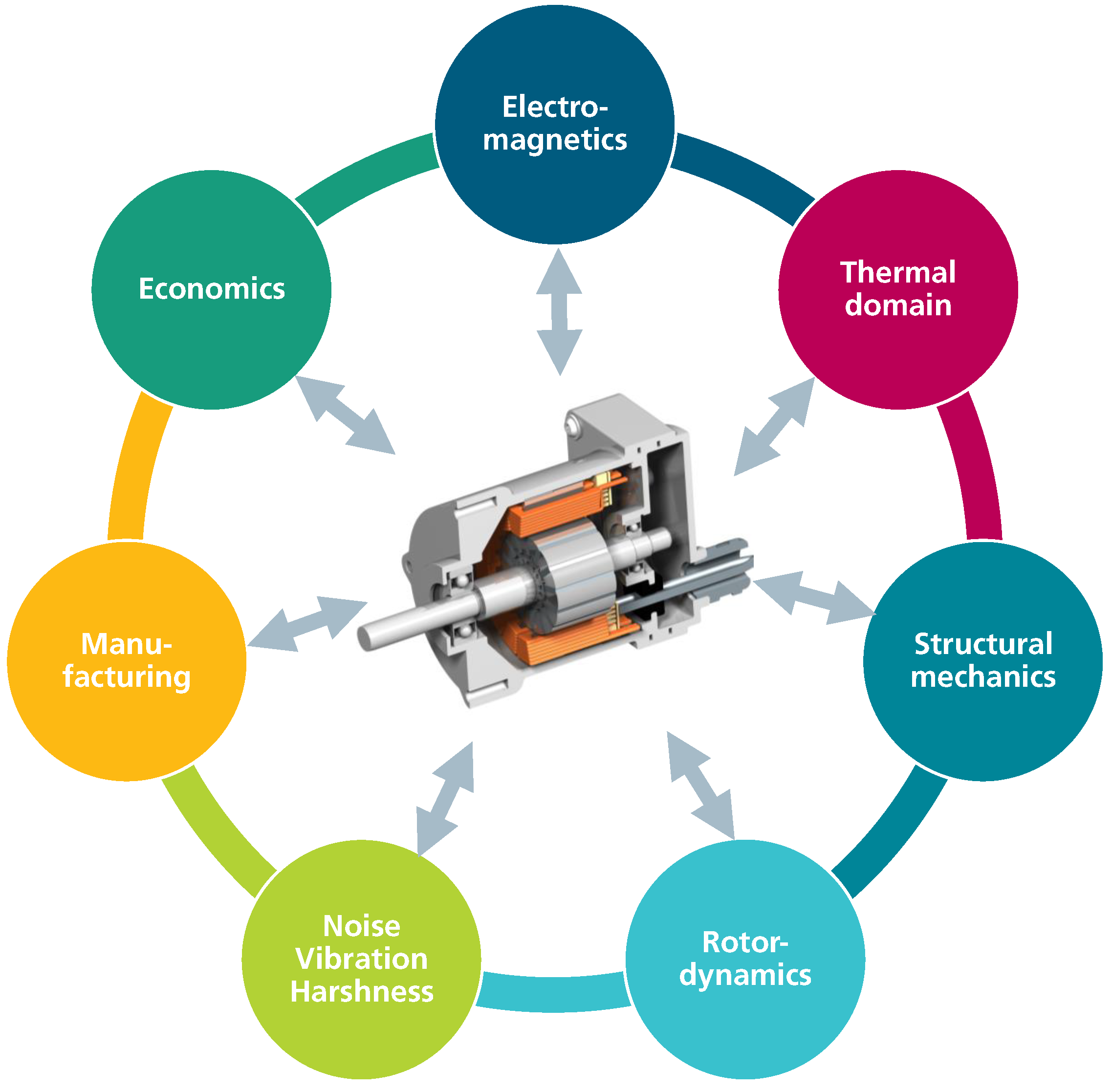

What Are the Key Materials Used in Starter Motors?

When selecting materials for starter motors, it is essential to consider properties that directly impact performance, durability, and overall functionality. Below are analyses of four common materials used in starter motor construction, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it an excellent choice for components that experience significant mechanical stress. It typically has good temperature resistance and can withstand high pressures.

Pros & Cons:

Steel offers excellent durability and is cost-effective, which makes it a popular choice in starter motor applications. However, it is susceptible to corrosion, which can lead to failure in harsh environments unless adequately treated or coated.

Impact on Application:

Steel is compatible with various media and can handle the mechanical demands of starter motors. However, its vulnerability to rust necessitates protective coatings, especially in humid or corrosive environments.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM or DIN, particularly regarding corrosion resistance treatments. Preference may be given to stainless steel or galvanized options in coastal areas.

2. Copper

Key Properties:

Copper is an excellent conductor of electricity, boasting high electrical and thermal conductivity. It also has good corrosion resistance, particularly when alloyed with other metals.

Pros & Cons:

The primary advantage of copper is its superior electrical conductivity, which enhances the efficiency of starter motors. However, copper is more expensive than steel and can be less durable under mechanical stress, making it more suitable for specific components rather than structural parts.

Impact on Application:

Copper is ideal for electrical connections and components within starter motors, ensuring efficient energy transfer. Its compatibility with various electrical systems is a significant advantage.

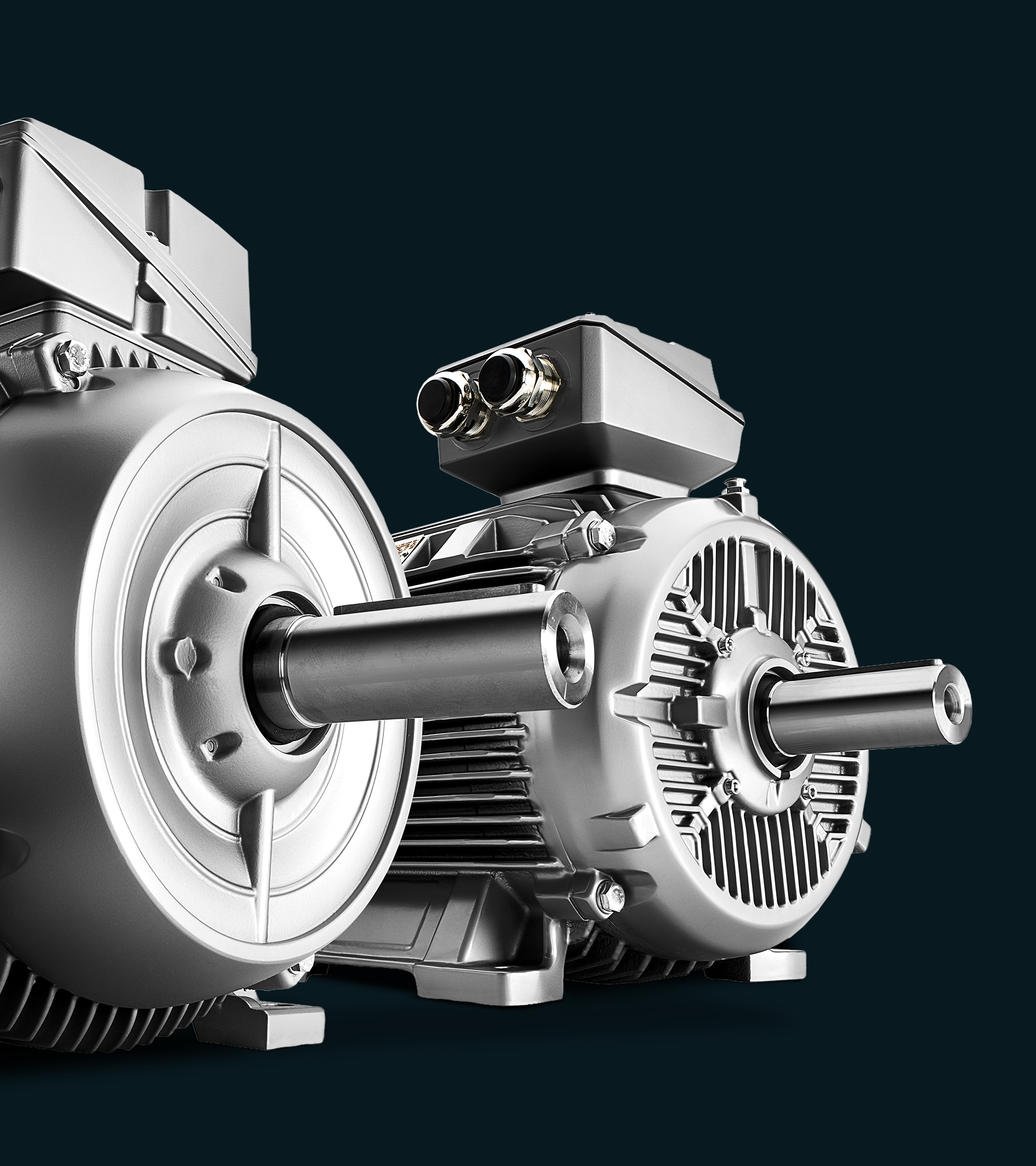

Illustrative image related to start motoren

Considerations for International Buyers:

In regions with stringent electrical standards, such as Europe, the use of copper may be preferred for its conductivity. Buyers should also consider the fluctuating costs of copper and potential supply chain issues.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, making it suitable for applications where weight reduction is essential. It also possesses decent thermal and electrical conductivity.

Pros & Cons:

Aluminum’s lightweight nature can lead to improved fuel efficiency in vehicles. However, it is less strong than steel and may not withstand high mechanical stresses as effectively, leading to potential durability concerns.

Impact on Application:

Aluminum is often used in starter motor housings and components where weight savings are critical. Its corrosion resistance makes it suitable for various environments, but its mechanical properties may limit its use in high-stress applications.

Considerations for International Buyers:

In regions like the Middle East, where temperatures can be extreme, the thermal properties of aluminum can be beneficial. Buyers should ensure compliance with local manufacturing standards to guarantee quality and performance.

Illustrative image related to start motoren

4. Composites

Key Properties:

Composite materials can be engineered to provide specific properties, such as high strength-to-weight ratios and excellent corrosion resistance. They can also be designed to withstand extreme temperatures.

Pros & Cons:

The primary advantage of composites is their versatility and ability to be tailored for specific applications, offering potential weight savings and enhanced performance. However, they can be more expensive and complex to manufacture compared to traditional materials.

Impact on Application:

Composites are ideal for specialized components in starter motors, particularly in high-performance applications. Their resistance to corrosion and temperature extremes makes them suitable for a variety of environments.

Illustrative image related to start motoren

Considerations for International Buyers:

Buyers should be aware of the certification requirements for composite materials in their respective regions, as standards can vary significantly. Understanding local preferences for material types can also influence purchasing decisions.

Summary Table of Material Selection for Starter Motors

| Material | Typical Use Case for start motoren | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and housings | High durability and cost-effectiveness | Susceptible to corrosion without treatment | Low |

| Copper | Electrical connections and windings | Superior electrical conductivity | Higher cost and lower mechanical strength | High |

| Aluminum | Lightweight housings and components | Reduced weight and good corrosion resistance | Less strong under high stress | Medium |

| Composites | Specialized components in high-performance applications | Tailored properties for specific needs | Higher manufacturing complexity and cost | High |

This strategic material selection guide provides B2B buyers with actionable insights into the materials best suited for starter motors, considering performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for start motoren

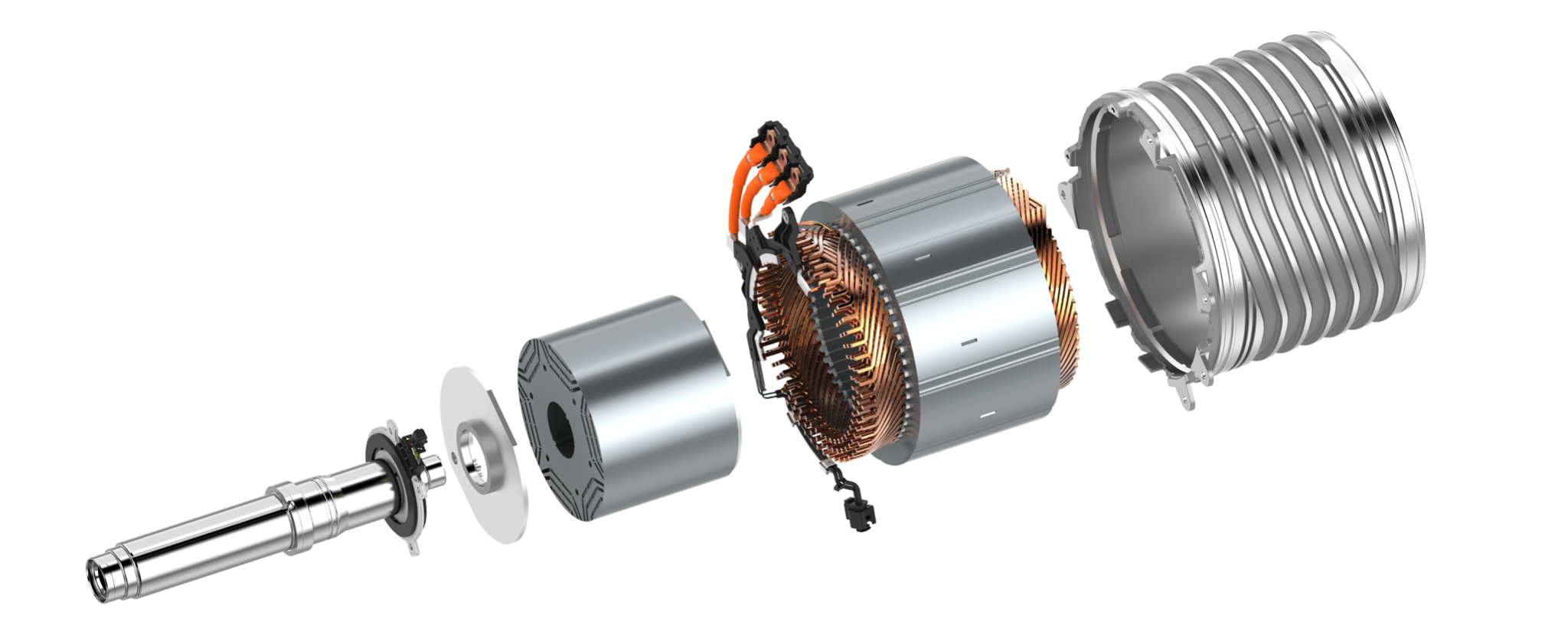

What Are the Key Stages in the Manufacturing Process of Starter Motors?

The manufacturing of starter motors involves several critical stages that ensure the final product meets the required performance and reliability standards. Each stage plays a vital role in determining the overall quality and functionality of the starter motor.

How Is Material Prepared for Starter Motor Production?

The first step in manufacturing starter motors is material preparation, which includes sourcing high-grade metals and components. Common materials used include copper for windings, steel for the casing, and high-quality alloys for gears and internal mechanisms. Suppliers must conduct thorough inspections of raw materials to ensure they meet the required specifications.

Additionally, materials undergo processes such as cutting, shaping, and treating to enhance their durability and performance. Techniques such as heat treatment may be employed to increase the hardness of steel components, ensuring they can withstand the mechanical stresses encountered during operation.

Illustrative image related to start motoren

What Are the Main Techniques Used in Forming Starter Motors?

Once materials are prepared, the forming stage commences, which typically involves processes like stamping, casting, and machining. Stamping is commonly used to create the starter motor casing, while casting may be employed for complex internal components. Machining processes, such as CNC (Computer Numerical Control) turning and milling, are crucial for creating precise dimensions and ensuring proper fitting of parts.

Magnetic components are also formed during this stage, where coils are wound with copper wire to create the necessary electromagnetic properties. Advanced automation technologies are often integrated to enhance precision and efficiency in forming processes.

How Is the Assembly of Starter Motors Conducted?

The assembly stage is where the various components come together to form the finished starter motor. This stage typically involves the following steps:

-

Component Assembly: Key components such as the motor housing, armature, solenoid, and pinion gear are assembled. This requires skilled labor to ensure that parts fit correctly and operate smoothly.

-

Wiring and Connections: Electrical connections are made, including soldering wires to terminals and ensuring the solenoid engages properly with the motor.

-

Testing During Assembly: In-process quality checks (IPQC) are performed at various points during assembly to identify issues early. This may involve functional tests of the solenoid and electrical connections.

What Finishing Techniques Are Applied to Starter Motors?

The final stage of manufacturing involves finishing processes that enhance the durability and aesthetics of the starter motor. This may include:

-

Surface Treatment: Processes such as plating, painting, or anodizing are employed to protect against corrosion and wear.

-

Final Assembly Checks: After finishing, a thorough inspection is conducted to ensure all components are secure and the motor meets design specifications.

-

Quality Assurance Testing: Before packaging, each starter motor undergoes rigorous testing to ensure it meets performance standards. This includes load testing and operational checks under simulated conditions.

What International Standards Govern Quality Assurance for Starter Motors?

Quality assurance in starter motor manufacturing is governed by several international standards, with ISO 9001 being one of the most recognized. This standard focuses on quality management systems and continuous improvement, ensuring that manufacturers maintain consistent quality throughout their processes.

Illustrative image related to start motoren

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for automotive applications may also apply. These certifications assure buyers that the products comply with safety and performance regulations.

How Are Quality Control Checkpoints Integrated into Manufacturing?

Quality control (QC) is an integral part of the manufacturing process, with several checkpoints established to monitor quality at different stages:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon receipt. Suppliers must provide documentation of material certifications, which should be verified by the manufacturer.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are performed to ensure that assembly and machining processes are within acceptable tolerances. This helps to catch defects early and reduce waste.

-

Final Quality Control (FQC): The final inspection involves comprehensive testing of completed starter motors. Parameters such as torque output, electrical resistance, and operational soundness are measured to ensure compliance with specifications.

What Testing Methods Are Commonly Used in Starter Motor Quality Assurance?

Testing methods used in quality assurance for starter motors include:

-

Functional Testing: Verifying that the motor engages and operates correctly under load conditions.

-

Electrical Testing: Assessing the electrical resistance and current draw of the starter motor to ensure it meets design specifications.

-

Durability Testing: Subjecting the starter motor to cyclic loading to simulate real-world conditions and measure performance over time.

-

Environmental Testing: Evaluating the motor’s performance under extreme temperatures and humidity to ensure reliability in various operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to source starter motors should take several steps to verify supplier quality control practices:

Illustrative image related to start motoren

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess manufacturing processes, quality control measures, and adherence to international standards.

-

Requesting Quality Reports: Buyers should request documentation of quality control processes, including inspection reports and test results for previous batches.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product reliability.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding these regulations can help avoid compliance issues and ensure market acceptance.

-

Cultural Considerations: Communication styles and business practices can differ across cultures, impacting negotiations and expectations regarding quality. Establishing clear specifications and expectations upfront is crucial.

-

Logistics and Supply Chain Factors: Buyers should consider the logistics of sourcing components and finished products, including lead times, transportation risks, and potential delays that could affect quality and delivery.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing starter motors, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘start motoren’

In the competitive landscape of international B2B procurement, sourcing starter motors requires a strategic approach to ensure quality, reliability, and compliance with specific operational needs. This checklist is designed to guide buyers through the critical steps necessary for successful procurement of starter motors, particularly for industries in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Identify the specific requirements for the starter motors based on the machinery or vehicles they will be used with. Consider factors such as voltage ratings, torque requirements, and operational environment (e.g., temperature, humidity).

– Tip: Consult technical manuals or industry standards to ensure all necessary parameters are included.

Step 2: Research Supplier Options

A thorough market analysis will help you identify potential suppliers. Look for manufacturers with a solid reputation in the starter motor industry and experience relevant to your needs.

– Tip: Utilize online directories, trade shows, and industry publications to compile a list of candidates.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international standards. Look for ISO certifications or any other industry-specific qualifications that ensure the quality and reliability of their products.

– Tip: Request copies of certifications and check for customer reviews or testimonials that reflect their adherence to quality standards.

Step 4: Assess Product Quality and Testing Procedures

Understanding the quality control measures in place is essential for ensuring the performance and longevity of the starter motors. Inquire about the testing procedures used to evaluate their products before they reach the market.

– Tip: Ask for documentation regarding testing results, including any third-party testing certifications.

Step 5: Request Samples or Prototypes

Whenever possible, request samples or prototypes of the starter motors you are considering. This step allows you to evaluate the physical attributes and performance of the product before making a larger commitment.

– Tip: Assess the sample in the intended operational context to observe how it performs under real conditions.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, initiate negotiations on pricing and terms of service. Discuss bulk purchase discounts, warranty provisions, and delivery timelines to ensure favorable conditions.

– Tip: Be prepared to compare offers from multiple suppliers to secure the best deal while considering total cost of ownership.

Step 7: Establish a Long-term Relationship

After selecting a supplier, focus on building a long-term partnership. Regular communication and feedback can help ensure ongoing quality and service, paving the way for future orders and collaborations.

– Tip: Schedule periodic reviews to discuss performance metrics and address any potential issues proactively.

Illustrative image related to start motoren

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing starter motors more effectively, ensuring that they select the right products and suppliers to meet their operational demands.

Comprehensive Cost and Pricing Analysis for start motoren Sourcing

What Are the Key Cost Components in Starter Motor Sourcing?

When sourcing starter motors, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The cost of raw materials such as copper for windings, steel for housing, and various plastics for components can fluctuate based on market demand and availability. High-quality materials often lead to increased durability and performance, impacting the overall price.

-

Labor: Labor costs vary significantly by region and manufacturing capabilities. Skilled labor is often required for assembly, testing, and quality assurance processes. In regions with lower labor costs, such as parts of Asia, prices may be more competitive.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, which may be passed on to buyers.

-

Tooling: Initial costs for molds, dies, and other manufacturing tools can be substantial, especially for custom or specialized starter motors. These costs are amortized over production runs, so high-volume orders can benefit from lower per-unit tooling costs.

-

Quality Control (QC): Ensuring that starter motors meet industry standards often requires rigorous testing and inspection processes. These QC measures are crucial for preventing failures in the field but can add to the overall cost.

-

Logistics: Shipping and handling costs are influenced by the weight and size of the starter motors, distance from the manufacturer, and chosen shipping methods. Incoterms also play a significant role in determining who bears these costs.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market competition, exclusivity of the product, and the relationship between buyer and supplier.

What Influences the Pricing of Starter Motors?

Several factors can influence the pricing of starter motors, particularly for international B2B buyers:

Illustrative image related to start motoren

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while considering potential savings.

-

Specifications and Customization: Custom starter motors designed to meet specific application needs can incur higher costs. Buyers should clearly define their requirements to receive accurate quotes.

-

Material Quality and Certifications: Higher quality materials and adherence to industry certifications (e.g., ISO, CE) can increase costs but may provide better performance and reliability, justifying the investment.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Established suppliers may charge a premium for their reputation, while emerging manufacturers might offer lower prices to gain market share.

-

Incoterms: The terms of shipment dictate responsibility for costs and risks during transportation. Understanding Incoterms can help buyers make informed decisions and avoid unexpected expenses.

What Are the Best Practices for Negotiating Starter Motor Prices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, here are some valuable tips for negotiating starter motor prices:

-

Conduct a Total Cost of Ownership Analysis: Look beyond the initial purchase price. Consider factors such as maintenance costs, warranty terms, and potential downtime. This holistic view can help justify higher upfront costs for better quality products.

-

Leverage Relationships: Building a strong relationship with suppliers can lead to better pricing and more favorable terms. Long-term partnerships often yield benefits such as priority production and exclusive discounts.

-

Explore Multiple Suppliers: Obtaining quotes from several suppliers allows for comparison and can provide leverage during negotiations. This practice helps ensure competitive pricing and terms.

-

Understand Market Trends: Staying informed about market trends and material costs can empower buyers during negotiations. Knowledge of the current landscape can help in making compelling arguments for price adjustments.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow and reduce financial strain. Discussing options such as extended payment periods or discounts for upfront payments can be advantageous.

Conclusion

Sourcing starter motors requires a keen understanding of the cost structure and pricing influences. By considering material costs, labor, manufacturing overhead, and logistics, as well as negotiating effectively, international buyers can make informed purchasing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing start motoren With Other Solutions

Introduction: Understanding Alternatives to Start Motoren

In the quest for effective engine starting solutions, businesses often seek alternatives to traditional starter motors. These alternatives can range from advanced technologies to alternative methods of initiating engine operation. This analysis will compare starter motors with two prominent alternatives: Integrated Starter-Generator Systems and Pneumatic Starters. Each solution has unique advantages and disadvantages that B2B buyers must consider based on their specific operational requirements.

Illustrative image related to start motoren

Comparison Table

| Comparison Aspect | Start Motoren | Integrated Starter-Generator Systems | Pneumatic Starters |

|---|---|---|---|

| Performance | High torque for brief periods | Continuous operation, high efficiency | Quick start capability |

| Cost | Moderate initial investment | Higher upfront costs | Generally lower costs |

| Ease of Implementation | Standard installation process | Requires specific vehicle configurations | Simplified installation |

| Maintenance | Regular checks needed | Low maintenance due to fewer parts | Requires periodic inspections |

| Best Use Case | Conventional gasoline engines | Hybrid and electric vehicles | Heavy machinery and large engines |

Detailed Breakdown of Alternatives

Integrated Starter-Generator Systems

Integrated starter-generator systems combine the functions of a starter motor and generator into a single unit, often used in hybrid and electric vehicles. These systems provide high efficiency and can operate continuously, offering power assistance during acceleration and regenerative braking. While they significantly improve fuel efficiency and reduce emissions, the initial investment is generally higher, and their installation may require specific vehicle configurations. This makes them ideal for manufacturers focusing on sustainability and performance.

Pneumatic Starters

Pneumatic starters utilize compressed air to start engines, making them especially suitable for heavy machinery and large engines found in industrial applications. Their primary advantage is the quick start capability, allowing for immediate engine engagement without the electrical demands associated with starter motors. Pneumatic starters are typically less expensive and easier to install in certain setups. However, they may require additional infrastructure for air compression, and regular maintenance is necessary to ensure the air supply is consistent and functional.

Conclusion: Choosing the Right Solution for Your Business Needs

When evaluating starter motor alternatives, B2B buyers should carefully consider the specific operational context and requirements of their applications. Starter motors remain a reliable choice for conventional engines, while integrated starter-generator systems provide advanced efficiency for hybrid and electric applications. Pneumatic starters offer a cost-effective solution for heavy machinery but may necessitate additional infrastructure. Ultimately, the decision should align with the organization’s long-term goals regarding performance, cost-effectiveness, and maintenance capabilities. By weighing these factors, businesses can select the most suitable starting solution to enhance their operational efficiency and reliability.

Essential Technical Properties and Trade Terminology for start motoren

What Are the Key Technical Properties of Starter Motors?

Understanding the technical properties of starter motors is crucial for B2B buyers, particularly when sourcing components for automotive or industrial applications. Here are some essential specifications that can influence purchasing decisions:

-

Torque Rating

Torque is the rotational force that the starter motor can produce. It is usually measured in Newton-meters (Nm). A higher torque rating ensures that the motor can effectively turn over an engine, especially in cold conditions or when the engine is under load. For B2B buyers, selecting a starter motor with the appropriate torque rating is vital for ensuring reliable engine starts, reducing wear on components, and maintaining operational efficiency. -

Voltage Rating

Starter motors typically operate at specific voltage levels, most commonly 12V or 24V. The voltage rating affects the motor’s performance and compatibility with the electrical system of the vehicle or machinery. Buyers must ensure that the starter motor’s voltage aligns with the application to avoid malfunctions or damage. -

Durability and Material Grade

The materials used in starter motor construction, such as steel for the housing and copper for windings, determine its durability and efficiency. Motors made from high-grade materials can withstand harsh environmental conditions, reducing the frequency of replacements. This is particularly important for international buyers in regions with extreme temperatures or challenging conditions. -

Engagement Mechanism

The engagement mechanism, often a solenoid, allows the starter motor to connect to the engine flywheel. A reliable engagement system ensures that the motor operates smoothly and disengages correctly after starting. Buyers should be aware of the different engagement types (e.g., pre-engaged or direct drive) to choose a starter that fits their specific needs. -

Current Draw

The amount of current a starter motor requires during operation is another critical property, often expressed in amperes (A). High current draw can lead to battery drain, particularly in vehicles with limited battery capacity. For B2B buyers, understanding the current requirements is essential for ensuring compatibility with existing electrical systems and preventing potential failures. -

Temperature Range

Starter motors are rated for specific operating temperature ranges, which indicate the conditions under which they can function optimally. Motors designed for extreme temperatures are essential in regions prone to heat or cold. Buyers should consider this property to avoid premature failures in adverse environments.

What Are Common Trade Terms Related to Starter Motors?

Familiarity with industry terminology can enhance communication and efficiency in procurement processes. Here are several key terms relevant to starter motors:

Illustrative image related to start motoren

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts used in the assembly of new vehicles or machinery. When sourcing starter motors, B2B buyers may prefer OEM parts for their guaranteed compatibility and quality assurance. Understanding whether a part is OEM can significantly influence purchasing decisions. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers when negotiating bulk purchases of starter motors, as it can affect inventory costs and supply chain management. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing information from suppliers for specific products, including starter motors. This term is essential for initiating procurement discussions and ensuring that buyers receive competitive pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping responsibilities, costs, and risk management when importing starter motors. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for planning and ensuring that projects remain on schedule. -

Aftermarket

Aftermarket refers to parts and accessories that are not sourced from the original manufacturer but are designed to fit and function like OEM products. B2B buyers may explore aftermarket options for cost savings, availability, or specific performance enhancements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they select the right starter motors for their applications while effectively navigating the procurement landscape.

Navigating Market Dynamics and Sourcing Trends in the start motoren Sector

What Are the Key Drivers Shaping the Starter Motor Market?

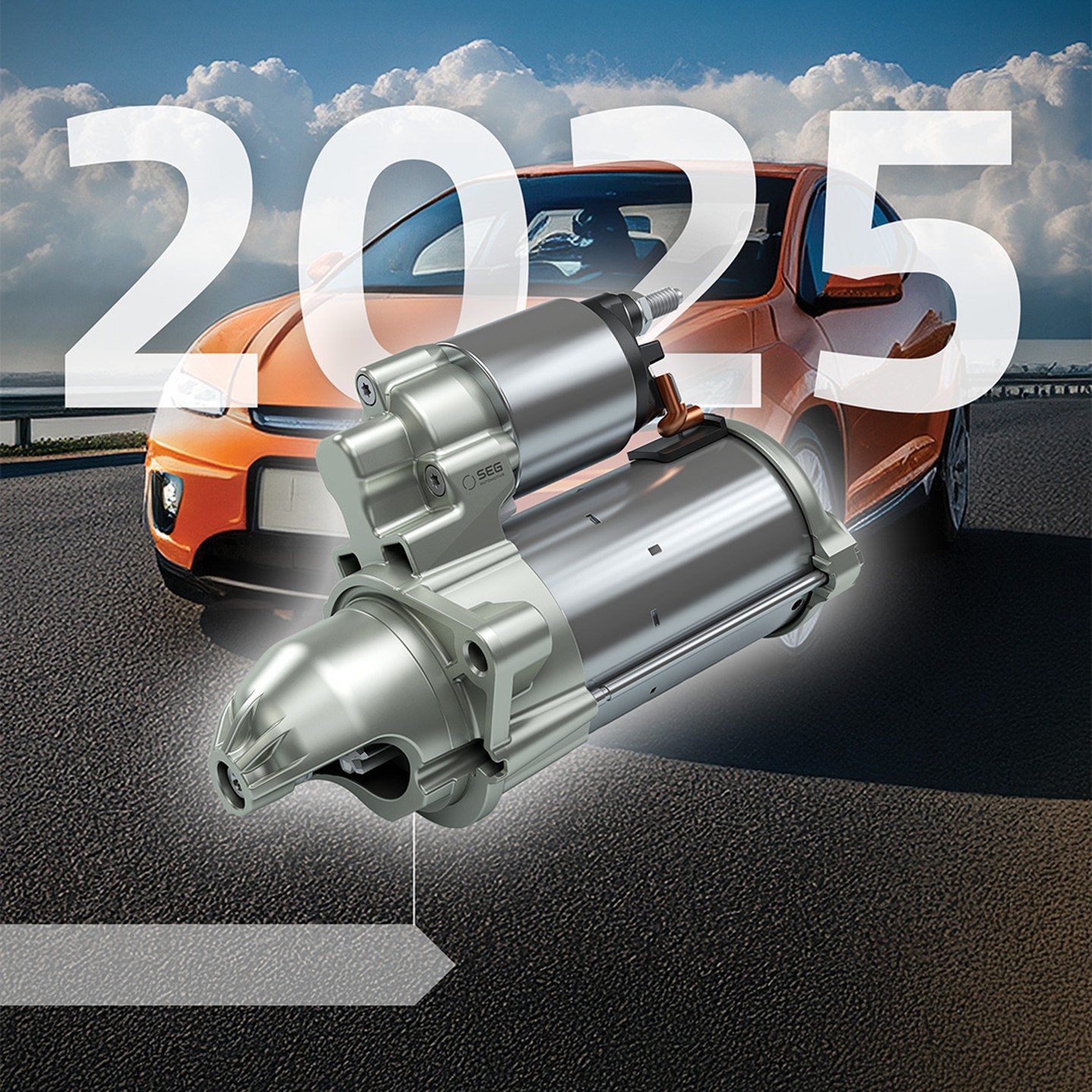

The global starter motor market is experiencing significant growth, driven by advancements in automotive technology and increasing demand for reliable vehicle performance. Key drivers include the rise in vehicle production and sales, particularly in emerging markets like Brazil, Vietnam, and various African countries. Additionally, the shift toward electric and hybrid vehicles is influencing starter motor design, necessitating innovative solutions that cater to these evolving technologies.

Current trends in B2B sourcing reflect a growing emphasis on automation and smart technology integration. Companies are increasingly adopting advanced motor starter systems that enhance operational efficiency, reduce energy consumption, and improve overall performance. Moreover, the rise of Industry 4.0 is prompting manufacturers to invest in digital solutions that facilitate real-time monitoring and predictive maintenance, which are crucial for minimizing downtime and optimizing supply chains.

International buyers are also navigating market dynamics shaped by geopolitical factors and trade regulations. For instance, fluctuating raw material costs and supply chain disruptions due to global events can impact sourcing strategies. Buyers in Africa, South America, the Middle East, and Europe must stay agile and informed about these changes to leverage opportunities and mitigate risks in the starter motor sector.

Illustrative image related to start motoren

How Is Sustainability Influencing Starter Motor Sourcing Decisions?

Sustainability has become a pivotal consideration in B2B sourcing strategies within the starter motor industry. The environmental impact of production processes and the lifecycle of products are increasingly scrutinized. Companies are prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and minimizing waste.

Ethical sourcing is also gaining traction, with buyers looking for transparency in their supply chains. This includes ensuring that raw materials are sourced responsibly and that labor practices adhere to international standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for suppliers aiming to attract conscientious buyers.

Furthermore, the adoption of ‘green’ materials in manufacturing starter motors is on the rise. This includes using recyclable components and biodegradable materials, which can enhance a company’s brand reputation and appeal to environmentally conscious consumers. By aligning with sustainability goals, B2B buyers can not only improve their supply chain resilience but also contribute positively to global environmental efforts.

What Is the Historical Evolution of Starter Motors and Its Relevance Today?

The starter motor has evolved significantly since its invention by Charles Kettering in 1911. Initially integrated with the ignition system, the starter motor’s role was to provide the necessary torque to crank the engine. Over the decades, advancements in materials and technology have led to the development of more efficient and reliable starter motors, including the emergence of integrated starter-generator systems in hybrid and electric vehicles.

Illustrative image related to start motoren

This historical evolution is relevant for B2B buyers today as it highlights the importance of innovation in sourcing decisions. Understanding the technological advancements and historical context can help buyers identify suppliers who are at the forefront of these developments. By investing in modern starter motor solutions, companies can enhance vehicle performance, reduce maintenance costs, and align with current automotive trends, ultimately leading to a competitive advantage in their respective markets.

Conclusion

The starter motor sector is characterized by rapid change and innovation, driven by market dynamics and the growing emphasis on sustainability. For international B2B buyers, particularly in diverse regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions. By prioritizing ethical supply chains and embracing technological advancements, companies can navigate the complexities of this evolving market landscape effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of start motoren

-

How do I troubleshoot a starter motor that won’t engage?

To troubleshoot a starter motor that won’t engage, first check the battery voltage to ensure it is fully charged. Inspect all connections for corrosion or looseness, as these can impede electrical flow. If the battery is fine, listen for a clicking sound when turning the key; if present, it may indicate a faulty solenoid or starter. Testing the starter motor at an auto parts store can also help determine if it is malfunctioning. If issues persist, consider consulting a professional mechanic for a thorough diagnosis. -

What is the best type of starter motor for heavy-duty applications?

For heavy-duty applications, gear reduction starter motors are often the best choice due to their ability to provide high torque while consuming less current. These starters are designed to handle the demands of larger engines and can offer improved durability and reliability. Additionally, consider the environmental conditions where the motor will operate, as some starters are specifically designed for extreme temperatures or adverse conditions, making them suitable for industrial applications. -

What factors should I consider when sourcing starter motors internationally?

When sourcing starter motors internationally, consider factors such as supplier reputation, product quality, compliance with international standards, and warranty options. Evaluate the supplier’s experience in the industry, as well as their capacity to meet your order volumes. Additionally, investigate logistics, including shipping costs and timelines, and whether the supplier offers support for customs clearance. Finally, ensure they provide after-sales support to address potential issues post-purchase. -

What are the minimum order quantities (MOQs) for starter motors?

Minimum order quantities (MOQs) for starter motors can vary significantly depending on the manufacturer and the type of starter being ordered. Typically, MOQs range from 50 to several hundred units. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing a new market or product line. Some suppliers may offer lower MOQs for initial orders to build a relationship, while others may require larger quantities for cost-effective pricing. -

What payment terms are common in international B2B transactions for starter motors?

Common payment terms in international B2B transactions for starter motors include letters of credit, advance payments, and net terms (e.g., net 30 or net 60). Letters of credit provide security for both the buyer and seller, while advance payments can expedite order processing. Net terms allow for post-delivery payment, which can be beneficial for cash flow. Always ensure that the payment terms are clearly defined in the contract to avoid disputes. -

How can I ensure quality assurance when sourcing starter motors?

To ensure quality assurance when sourcing starter motors, request product samples before placing a bulk order to evaluate quality firsthand. Look for certifications such as ISO or CE, which indicate compliance with international quality standards. Additionally, consider implementing a third-party inspection service to conduct quality checks during manufacturing and before shipment. Establishing clear specifications and quality benchmarks in your purchase agreement can also help safeguard against receiving subpar products. -

What are the logistics considerations when importing starter motors?

Logistics considerations when importing starter motors include understanding shipping options (air vs. sea freight), customs regulations, and potential tariffs or duties. Evaluate the total landed cost, including shipping, insurance, and handling fees, to ensure budget adherence. Partnering with a reliable freight forwarder can simplify the process, helping you navigate paperwork and compliance. Also, consider the lead times associated with shipping to plan your inventory needs effectively. -

What should I do if I receive defective starter motors?

If you receive defective starter motors, first document the issues with photos and detailed descriptions. Contact the supplier promptly, providing evidence of the defects and requesting a resolution, which may include replacements or refunds. Familiarize yourself with the supplier’s return policy and warranty terms before engaging. If the supplier is unresponsive or unwilling to resolve the issue, consider escalating the matter through formal channels or seeking legal advice, especially if significant financial losses are involved.

Top 4 Start Motoren Manufacturers & Suppliers List

1. Haynes – Starter Motor

Domain: us.haynes.com

Registered: 1996 (29 years)

Introduction: This company, Haynes – Starter Motor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Facebook – Starter Motor

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Starter Motor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. The Engineering Mindset – Starter Motors

Domain: theengineeringmindset.com

Registered: 2015 (10 years)

Introduction: Starter motors are essential components in combustion engine vehicles, converting electrical energy from the battery into mechanical energy to start the car engine. Key parts include the solenoid, drive end frame, rotor (armature), commutator plates, brushes, stator (permanent magnets or field windings), and an overrunning clutch. The solenoid activates the motor by allowing a large electrical cur…

4. MTech Control – Motor Starter Solutions

Domain: mtechcontrol.com

Registered: 2009 (16 years)

Introduction: Motor Starter: An electrical device used to start & stop a motor safely, providing thermal overcurrent protection. Main functions include safely starting/stopping a motor, reversing motor direction, and protecting against low voltage & overcurrent. Components: Contactor (makes/breaks current) and Overload Relay (prevents overheating). Circuits: Power Circuit (passes main voltage) and Control Circu…

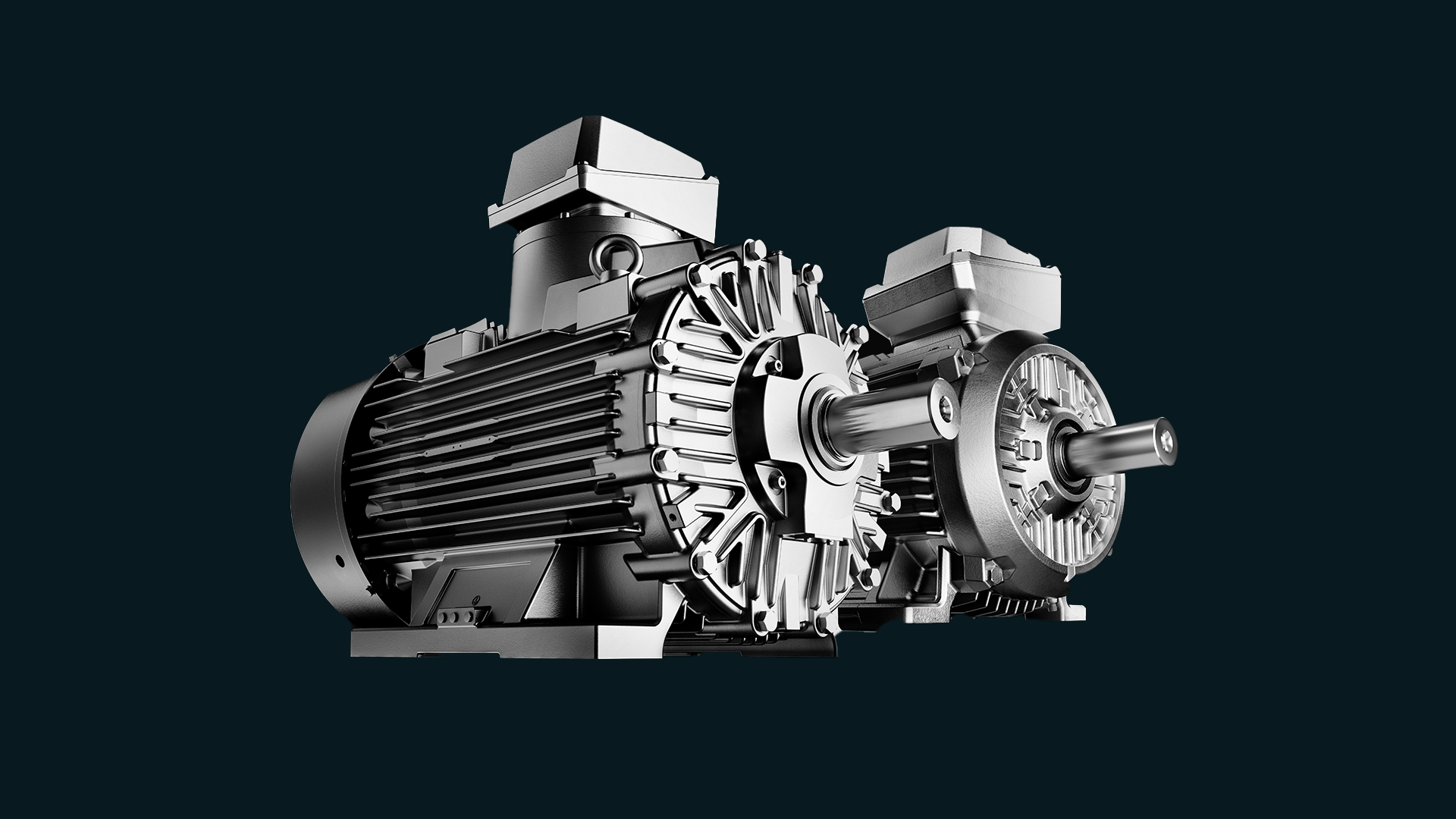

Strategic Sourcing Conclusion and Outlook for start motoren

What Are the Key Takeaways for Sourcing Starter Motors?

In the dynamic landscape of starter motor procurement, B2B buyers must prioritize strategic sourcing to enhance operational efficiency and reduce costs. Understanding the intricacies of starter motor functionality, including the importance of reliable torque and the mechanisms involved in engagement and disengagement, is crucial. Buyers should also consider the varying types of starter motors and their specific applications to ensure optimal performance in their respective industries.

How Can Strategic Sourcing Enhance Your Business Operations?

By leveraging strategic sourcing, businesses can mitigate risks associated with starter motor failures, such as battery drainage and mechanical breakdowns. Establishing strong relationships with reputable manufacturers and suppliers ensures access to high-quality products and timely support, which is vital for maintaining equipment reliability. Moreover, as industries increasingly shift towards automation and remote operation, sourcing advanced starter motor technologies can provide a competitive edge.

What’s Next for International Buyers in Emerging Markets?

As the demand for efficient motor control solutions rises in regions like Africa, South America, the Middle East, and Europe, international buyers should proactively explore partnerships with innovative suppliers. Investing in quality starter motors today will not only enhance operational efficiency but also future-proof your business against evolving market demands. Take the next step in your sourcing strategy by engaging with trusted manufacturers and exploring the latest advancements in starter motor technology.

Illustrative image related to start motoren

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.