Introduction: Navigating the Global Market for how much is a starter replacement

In the complex landscape of automotive maintenance, understanding how much a starter replacement costs is crucial for businesses that rely on transportation for their operations. Whether you are a fleet manager in Nigeria or a logistics company in Germany, the implications of starter failure can lead to unexpected downtime and increased operational costs. This guide aims to navigate the intricacies of starter replacement, providing a comprehensive overview of factors that influence pricing, such as vehicle type, labor costs, and the choice between new and remanufactured starters.

Our guide will delve into the various types of starters available in the global market, explore applications across different vehicle categories, and offer insights on how to effectively vet suppliers. By addressing the key challenges associated with sourcing and pricing, we empower B2B buyers from Africa, South America, the Middle East, and Europe to make informed purchasing decisions. This resource will not only clarify the cost structure involved in starter replacements but will also highlight best practices for selecting quality parts and reputable service providers. Ultimately, our goal is to enable businesses to optimize their vehicle maintenance strategies, reduce expenses, and enhance operational efficiency.

Table Of Contents

- Top 5 How Much Is A Starter Replacement Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much is a starter replacement

- Understanding how much is a starter replacement Types and Variations

- Key Industrial Applications of how much is a starter replacement

- 3 Common User Pain Points for ‘how much is a starter replacement’ & Their Solutions

- Strategic Material Selection Guide for how much is a starter replacement

- In-depth Look: Manufacturing Processes and Quality Assurance for how much is a starter replacement

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is a starter replacement’

- Comprehensive Cost and Pricing Analysis for how much is a starter replacement Sourcing

- Alternatives Analysis: Comparing how much is a starter replacement With Other Solutions

- Essential Technical Properties and Trade Terminology for how much is a starter replacement

- Navigating Market Dynamics and Sourcing Trends in the how much is a starter replacement Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much is a starter replacement

- Strategic Sourcing Conclusion and Outlook for how much is a starter replacement

- Important Disclaimer & Terms of Use

Understanding how much is a starter replacement Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Economy Starters | Aftermarket, budget-friendly options typically priced lower. | Small repair shops and budget-conscious fleets. | Pros: Cost-effective, accessible. Cons: Shorter lifespan, potential reliability issues. |

| OEM Starters | Original Equipment Manufacturer parts ensuring fit and performance. | Authorized dealerships, fleet management. | Pros: High reliability, warranty coverage. Cons: Higher cost, limited availability. |

| High-Performance Starters | Specialty parts for enhanced performance in specific vehicles. | Performance automotive shops, racing teams. | Pros: Superior durability, optimized for high performance. Cons: Very high cost, niche market. |

| Remanufactured Starters | Rebuilt starters using refurbished components, more affordable. | Independent garages, budget fleets. | Pros: Cost savings, environmentally friendly. Cons: Shorter lifespan, potential quality variability. |

| DIY Starter Kits | Parts sold separately for self-installation by skilled mechanics. | DIY enthusiasts, small repair shops. | Pros: Significant labor cost savings. Cons: Requires expertise, risk of improper installation. |

What Are Economy Starters and When Should You Consider Them?

Economy starters are aftermarket parts designed for budget-conscious buyers. Priced between $75 and $200, they serve well for compact vehicles or older models where cost savings are paramount. B2B buyers in regions with high competition or budget constraints may find these options appealing. However, it’s essential to consider their shorter lifespan and potential reliability issues, which can lead to repeated replacements.

Why Choose OEM Starters for Your Fleet?

OEM starters are manufactured by the original vehicle makers, ensuring compatibility and performance. Typically ranging from $150 to $400, these parts are ideal for authorized dealerships or businesses managing large fleets. The benefits include higher reliability and warranty coverage, which can mitigate long-term costs. However, B2B buyers must weigh these advantages against the higher upfront costs and limited availability in some markets.

How Do High-Performance Starters Fit into Specialized Applications?

High-performance starters, priced from $300 to over $1,000, are designed for vehicles requiring enhanced performance. These starters are essential for performance automotive shops and racing teams that prioritize durability and efficiency. While they offer superior performance, their niche market and high costs can be a barrier for general B2B buyers. Consideration should be given to the specific needs of the vehicle and the potential return on investment.

What Are the Benefits of Remanufactured Starters?

Remanufactured starters provide a balance between cost and reliability, typically priced between $50 and $300. They are an attractive option for independent garages and budget fleets looking to minimize expenses. While they are more affordable and environmentally friendly, buyers should be cautious of the potential variability in quality and lifespan compared to new parts.

When to Consider DIY Starter Kits?

DIY starter kits allow skilled mechanics to purchase parts separately for self-installation, offering significant savings on labor costs. These kits are suitable for DIY enthusiasts and small repair shops equipped with the necessary expertise. However, the risk of improper installation and potential electrical damage should be carefully considered, making this option more suitable for those with a solid understanding of automotive repairs.

Key Industrial Applications of how much is a starter replacement

| Industry/Sector | Specific Application of how much is a starter replacement | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Replacement services for personal and commercial vehicles | Ensures vehicle reliability and minimizes downtime | Quality of parts, warranty, local labor rates |

| Transportation & Logistics | Fleet management for commercial transport | Reduces operational disruptions and maintenance costs | Availability of parts, bulk purchasing options |

| Agriculture | Agricultural machinery maintenance | Enhances equipment performance and productivity | Compatibility with different machinery models |

| Construction | Heavy equipment starter replacements | Improves uptime and efficiency on job sites | Access to specialized starters for various equipment |

| Mining | Starter replacements for mining vehicles | Ensures consistent operation in challenging environments | Ruggedness of parts, supplier reliability |

How is ‘how much is a starter replacement’ Relevant in the Automotive Repair Industry?

In the automotive repair sector, understanding the cost of starter replacement is crucial for workshops and service centers. These businesses need to provide accurate estimates to customers while ensuring quality service. By sourcing reliable starter motors, they can enhance customer satisfaction and loyalty. Additionally, businesses must consider labor costs and the complexity of the vehicle model when pricing services. This knowledge helps in building a transparent pricing model that can attract more clients, particularly in regions with varying economic conditions like Africa and South America.

What is the Impact of Starter Replacement Costs in Transportation & Logistics?

In the transportation and logistics industry, fleet operators face the challenge of maintaining multiple vehicles. The cost of starter replacement directly affects operational budgets and efficiency. By investing in quality starters and understanding the cost implications, fleet managers can minimize vehicle downtime and reduce maintenance expenses. Sourcing parts in bulk can also yield cost benefits. International buyers, particularly from Europe and the Middle East, should prioritize suppliers that offer warranties and reliable delivery times to ensure fleet readiness.

How Does Starter Replacement Affect Agricultural Operations?

Agricultural machinery relies heavily on functional starters for optimal performance. In this sector, the cost of starter replacement can significantly influence overall productivity during planting and harvesting seasons. Farmers and agricultural businesses must ensure they have access to compatible and durable starter motors for their equipment. Understanding the replacement costs allows them to budget effectively and minimize equipment downtime, which is critical in time-sensitive agricultural operations, especially in regions with limited access to parts.

Why is Starter Replacement Important in Construction?

In the construction industry, heavy machinery often requires immediate attention when issues arise. The cost of starter replacements can impact project timelines and budgets. Construction companies must ensure that their equipment is operational to avoid delays. This necessitates sourcing high-quality starters that can withstand tough conditions. By understanding the cost implications, construction firms can make informed decisions about maintenance schedules and budgeting, which is vital for projects in developing regions like Africa.

How Do Mining Operations Benefit from Understanding Starter Replacement Costs?

Mining operations depend on the reliability of their vehicles and machinery, where the cost of starter replacement plays a critical role. A faulty starter can halt operations, leading to significant financial losses. Mining companies must prioritize sourcing rugged and durable starters that can withstand harsh environments. By budgeting for these costs, they can maintain operational efficiency and ensure the safety of their workforce. Moreover, international buyers should consider the reputation of suppliers and the availability of parts in remote locations to mitigate risks associated with downtime.

3 Common User Pain Points for ‘how much is a starter replacement’ & Their Solutions

Scenario 1: Navigating Cost Variability in Starter Replacement

The Problem: B2B buyers often face confusion when trying to estimate the cost of starter replacement for their fleet vehicles. With a wide range of factors influencing pricing—such as vehicle make and model, the choice between OEM and aftermarket parts, and local labor rates—buyers may struggle to get an accurate quote. This uncertainty can lead to budgeting issues, unexpected costs, and difficulties in making timely repair decisions, ultimately affecting operational efficiency.

The Solution: To navigate this variability effectively, B2B buyers should establish a comprehensive understanding of their vehicle specifications and the average costs associated with starter replacements. Start by compiling data on the make and model of each vehicle in your fleet, and consult reliable automotive resources or service providers for detailed cost breakdowns. Engage with multiple suppliers to compare prices for both OEM and aftermarket starters, and consider the potential need for additional repairs that could arise from a failing starter. This proactive approach allows for better budgeting and helps identify the most cost-effective options for your fleet’s needs.

Scenario 2: Balancing Quality with Cost in Starter Choices

The Problem: B2B buyers often grapple with the dilemma of choosing between lower-cost aftermarket starters and higher-priced OEM parts. While budget constraints may push them towards cheaper alternatives, there is a risk of compromising on quality and longevity. A poor-quality starter could lead to more frequent failures, resulting in additional costs and downtime, which can severely impact business operations, especially in sectors reliant on transportation.

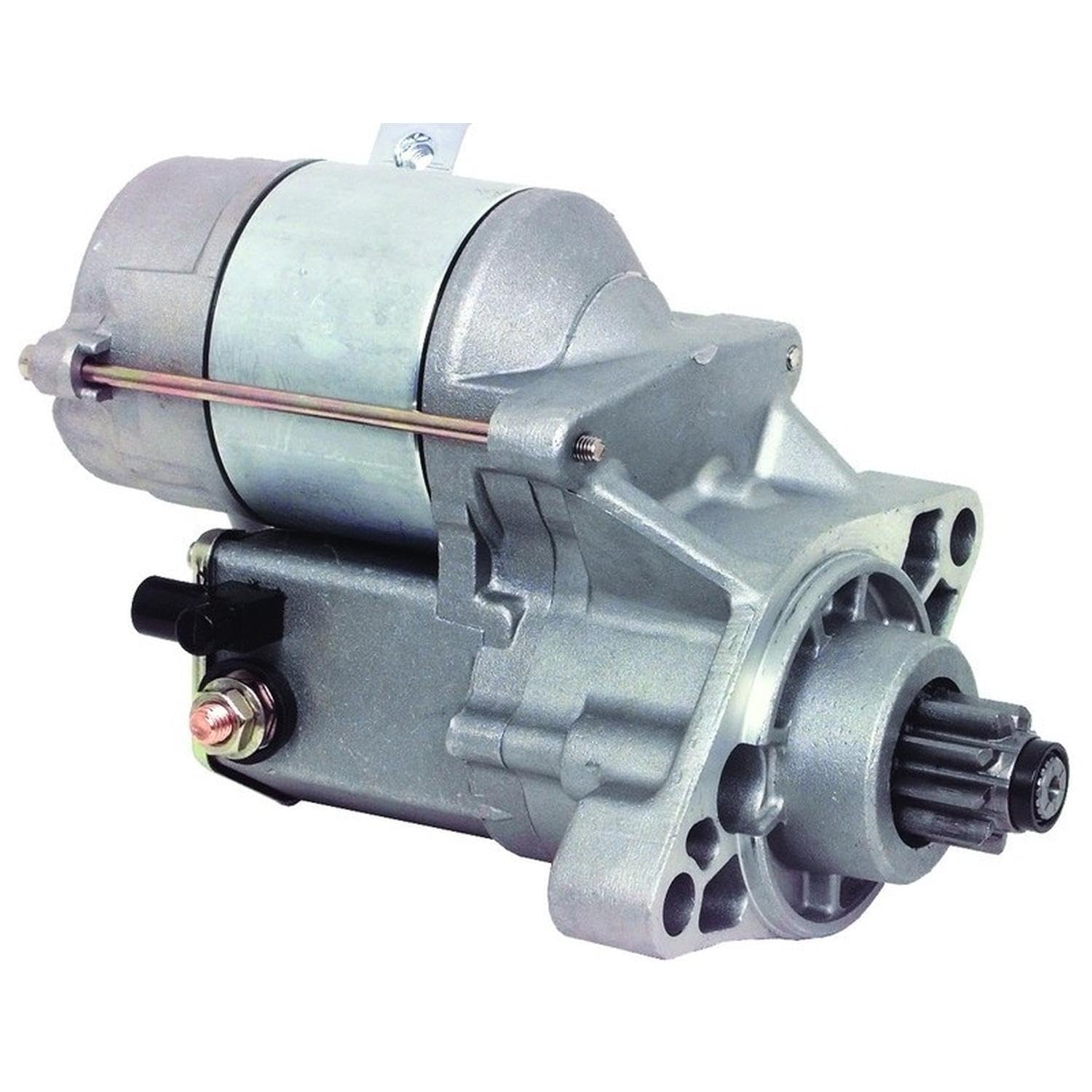

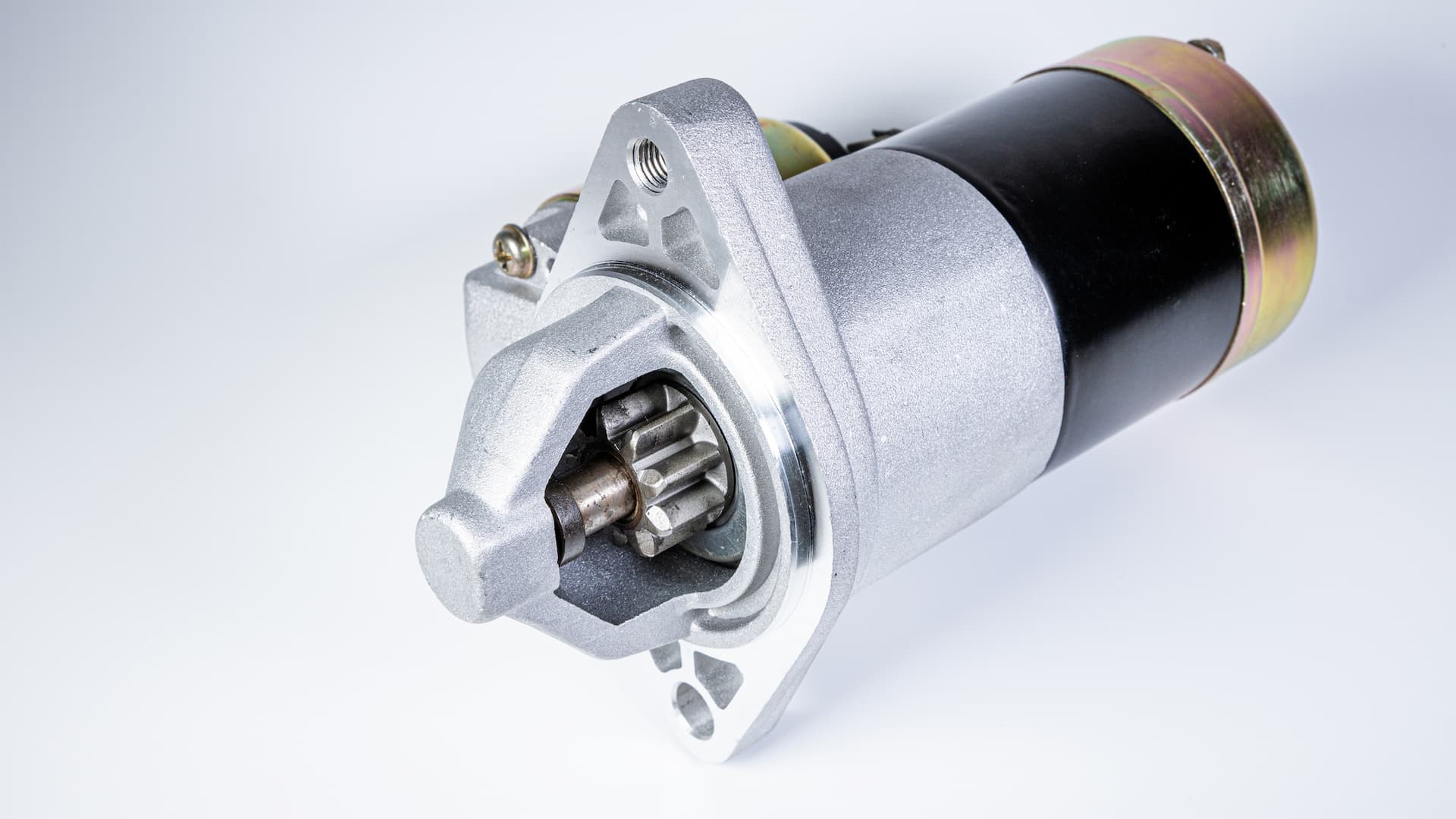

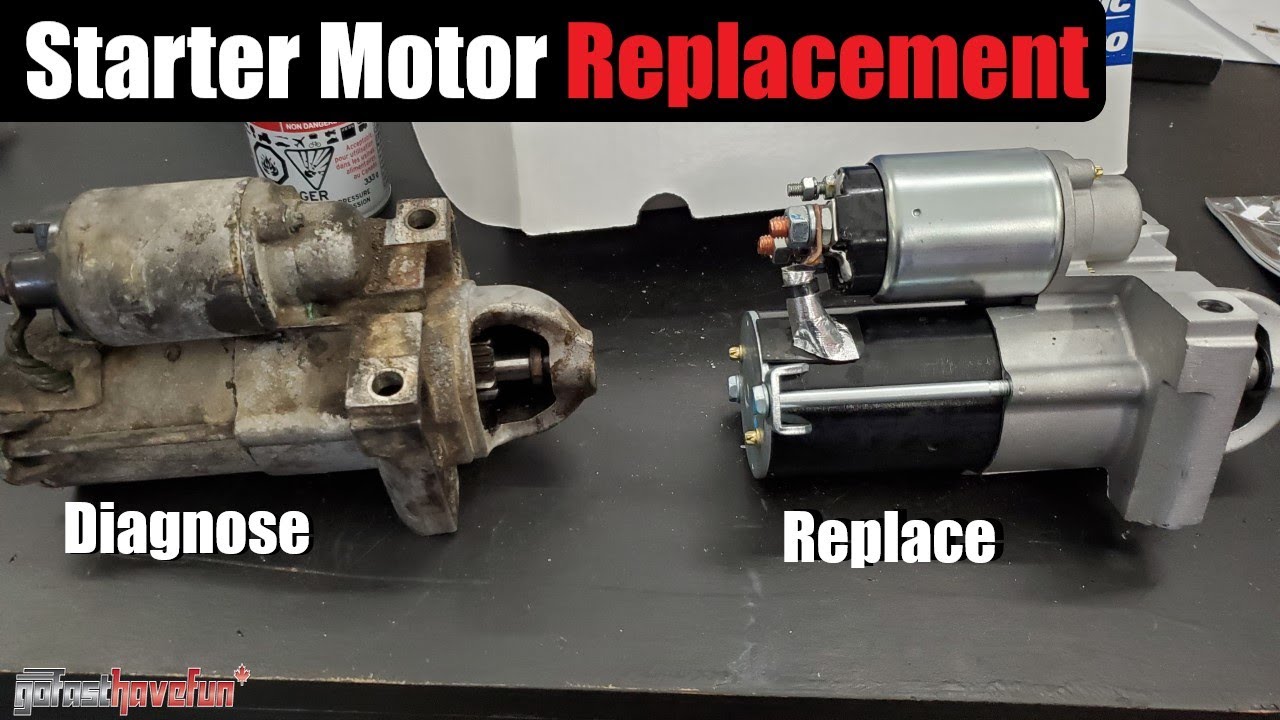

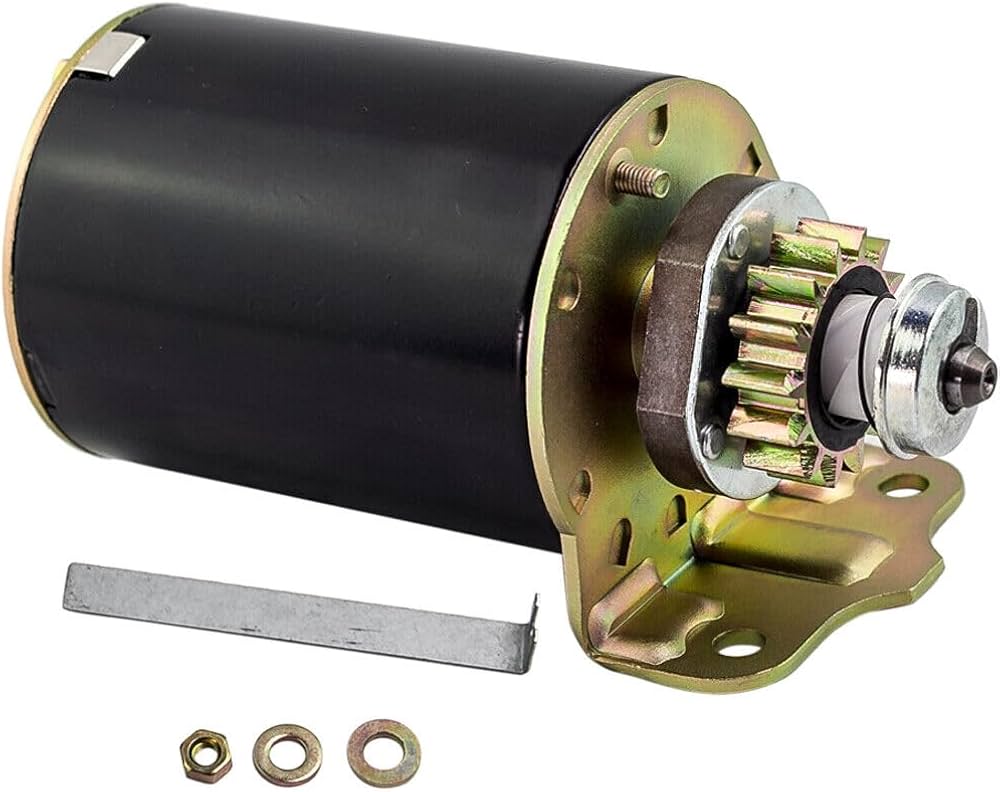

Illustrative image related to how much is a starter replacement

The Solution: To make informed decisions, B2B buyers should conduct a thorough analysis of the long-term implications of their starter choices. Create a cost-benefit analysis that includes factors such as the expected lifespan of the starter, warranty coverage, and the potential cost of future replacements or repairs. Additionally, seek out reviews and testimonials from other businesses regarding the performance of specific starter brands. By prioritizing quality alongside cost, buyers can select starters that not only fit their budget but also enhance the reliability of their fleet, ultimately reducing operational disruptions.

Scenario 3: Managing Labor Costs and Downtime During Starter Replacement

The Problem: When a starter fails, the time taken to replace it can vary greatly, leading to unexpected labor costs and vehicle downtime. B2B buyers may find it challenging to anticipate these costs, especially when dealing with complex installations in high-end vehicles or when parts are difficult to access. This unpredictability can disrupt schedules and lead to lost revenue, particularly for businesses that rely on a fleet of vehicles for service delivery.

The Solution: To mitigate the risks associated with labor costs and downtime, B2B buyers should implement a structured maintenance schedule and develop relationships with reliable auto repair shops that specialize in their specific vehicle types. Consider negotiating service agreements that include fixed labor rates and prioritized service for your fleet. Furthermore, train your in-house maintenance team to recognize early signs of starter failure, enabling timely interventions before complete breakdowns occur. By being proactive about maintenance and establishing clear communication with service providers, businesses can reduce both downtime and unexpected expenses associated with starter replacements.

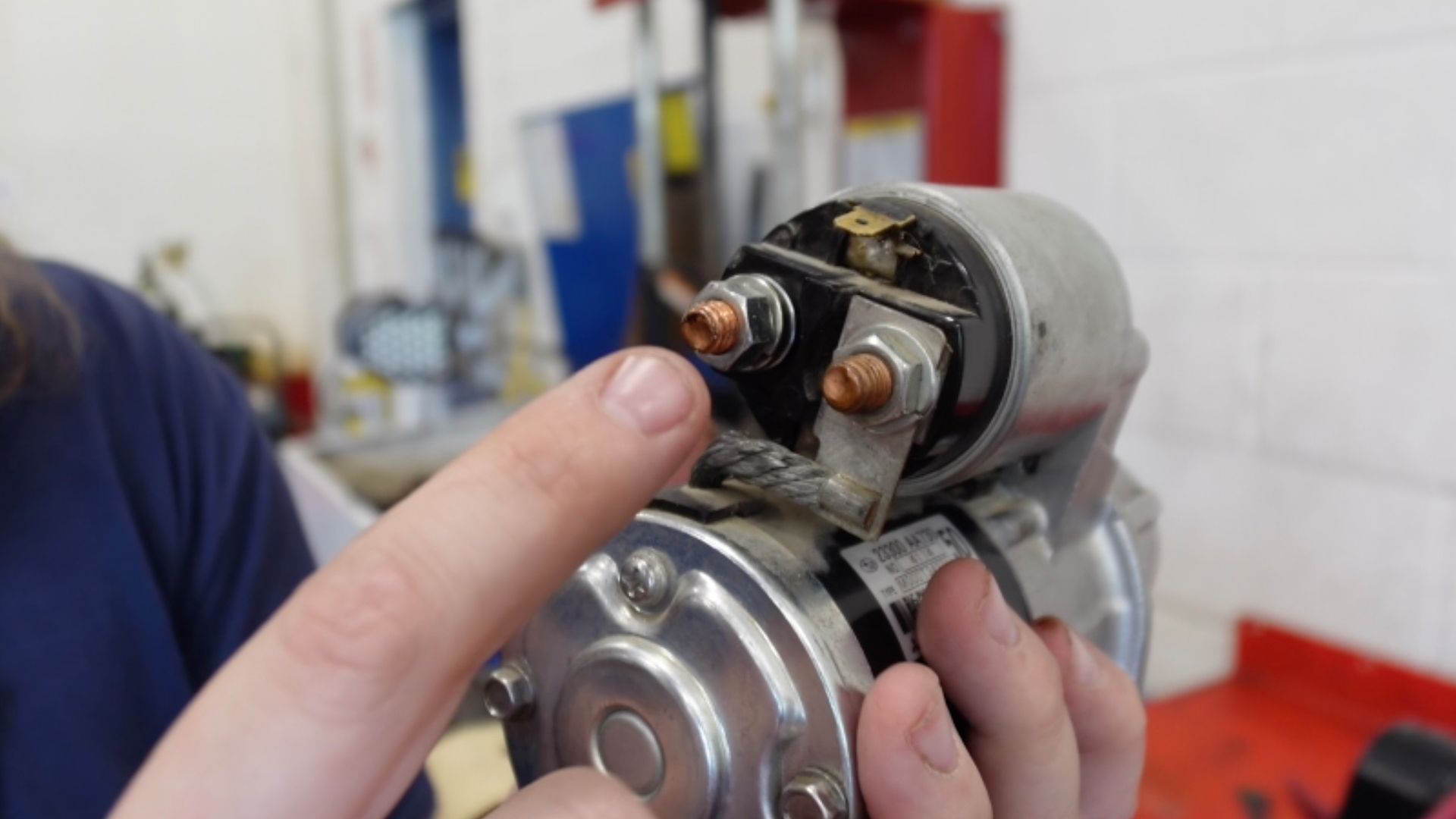

Illustrative image related to how much is a starter replacement

Strategic Material Selection Guide for how much is a starter replacement

What Materials Are Commonly Used in Starter Replacement Components?

When considering starter replacement, the materials used in the construction of starter motors and related components significantly influence performance, durability, and cost. Below, we analyze four common materials utilized in starter replacements: aluminum, steel, copper, and plastic.

How Does Aluminum Impact Starter Replacement Performance?

Aluminum is widely used in starter housings due to its lightweight and corrosion-resistant properties. It typically has a good temperature rating, making it suitable for high-heat environments, which is essential for automotive applications.

Pros: Aluminum’s lightweight nature contributes to overall vehicle efficiency, and its resistance to corrosion ensures longevity, reducing the frequency of replacements. Additionally, aluminum is relatively easy to manufacture, allowing for complex shapes that can enhance performance.

Cons: While aluminum is durable, it can be more expensive than other materials like steel. Its lower tensile strength compared to steel may also limit its application in high-stress environments.

Impact on Application: Aluminum’s compatibility with various automotive fluids makes it an excellent choice for starter components, ensuring no adverse reactions occur.

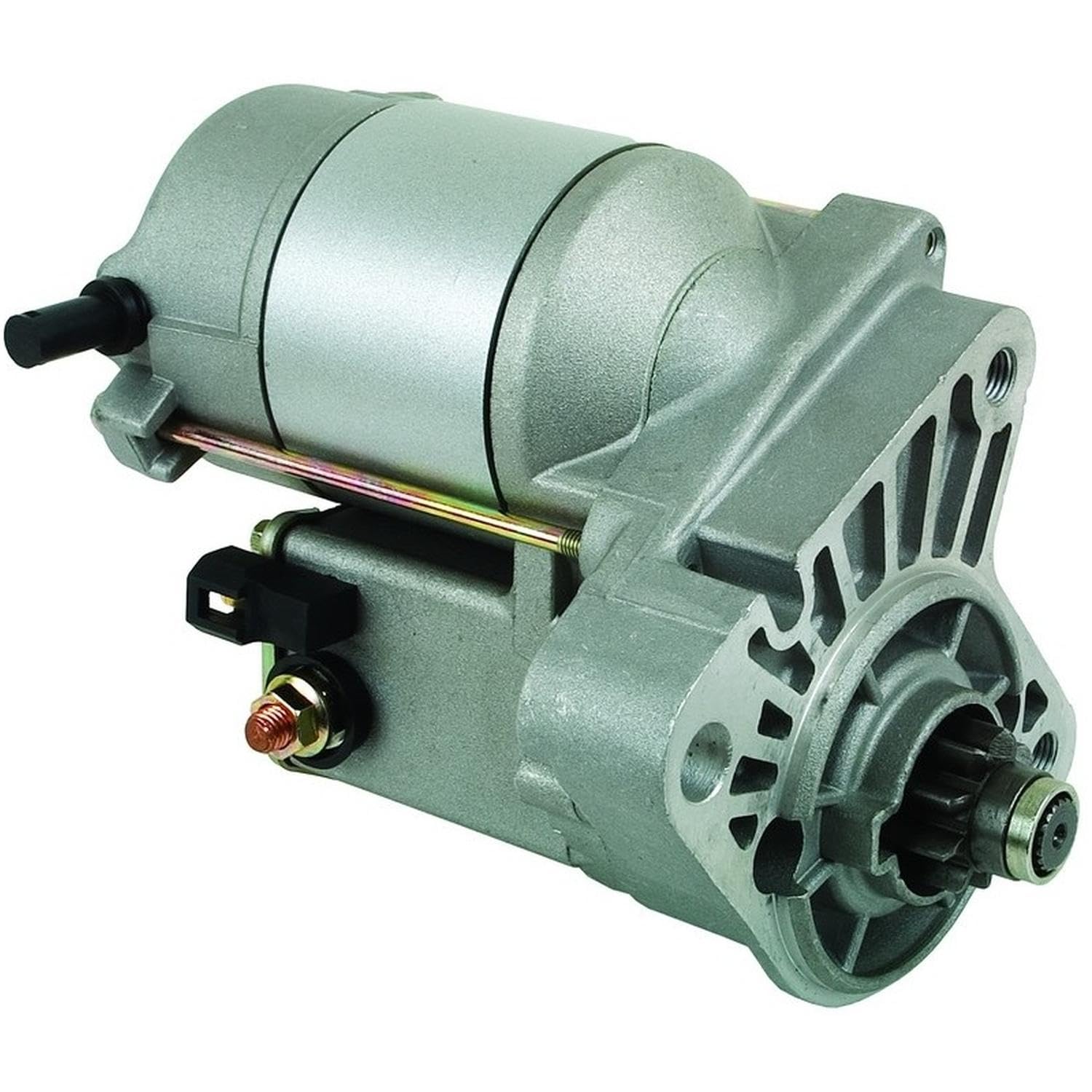

Illustrative image related to how much is a starter replacement

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that aluminum components meet local standards for automotive parts, such as compliance with ISO or ASTM specifications.

What Role Does Steel Play in Starter Replacement Durability?

Steel is another common material in starter motors, particularly for internal components like gears and shafts. Its high tensile strength and durability make it ideal for parts that undergo significant wear and tear.

Pros: Steel’s robustness ensures that components can withstand high pressure and stress, extending the lifespan of the starter. It is also generally more cost-effective than aluminum.

Illustrative image related to how much is a starter replacement

Cons: Steel is heavier than aluminum, which may impact overall vehicle weight and efficiency. Additionally, it is prone to rust and corrosion if not properly treated.

Impact on Application: Steel’s compatibility with high torque applications makes it suitable for heavy-duty starters used in trucks and SUVs.

Considerations for International Buyers: Buyers should verify that steel components comply with local standards, such as DIN in Germany or JIS in Japan, to ensure quality and safety.

How Does Copper Enhance Electrical Performance in Starters?

Copper is primarily used in electrical connections and windings within starter motors due to its excellent conductivity and thermal properties.

Pros: The high electrical conductivity of copper ensures efficient power transfer, which is critical for starter performance. Its thermal conductivity also helps dissipate heat, reducing the risk of overheating.

Illustrative image related to how much is a starter replacement

Cons: Copper can be expensive compared to alternatives like aluminum, and it is susceptible to corrosion if not properly insulated.

Impact on Application: Copper’s ability to handle high electrical loads makes it essential for reliable starter operation, particularly in high-performance vehicles.

Considerations for International Buyers: Buyers should ensure that copper components meet international standards for electrical safety and performance, such as IEC standards.

What Advantages Does Plastic Offer in Starter Replacement Components?

Plastic is often used for insulation and housing components in starters, providing a lightweight and cost-effective solution.

Illustrative image related to how much is a starter replacement

Pros: Plastic is lightweight, which can help reduce the overall weight of the starter assembly. It is also resistant to corrosion and can be molded into complex shapes, facilitating design flexibility.

Cons: Plastic is generally less durable than metals, especially in high-temperature environments. It may also degrade over time when exposed to automotive fluids.

Impact on Application: Plastic’s insulation properties make it suitable for protecting electrical components from short circuits and environmental damage.

Considerations for International Buyers: Buyers should check that plastic materials comply with relevant automotive standards, ensuring they can withstand the operating conditions in their specific regions.

Summary Table of Material Selection for Starter Replacement

| Material | Typical Use Case for how much is a starter replacement | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Starter housings | Lightweight and corrosion-resistant | Lower tensile strength than steel | Medium |

| Steel | Internal gears and shafts | High durability and cost-effective | Prone to rust if untreated | Low |

| Copper | Electrical connections and windings | Excellent conductivity | Expensive and corrosion-susceptible | High |

| Plastic | Insulation and housing components | Lightweight and moldable | Less durable in high temperatures | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in starter replacements, helping them make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for how much is a starter replacement

What Are the Main Stages of Manufacturing Processes for Starter Replacement?

The manufacturing process of starter motors involves several critical stages, each ensuring the final product meets both performance and durability standards. For B2B buyers, understanding these stages can help assess the quality and reliability of the components they are considering for procurement.

Material Preparation: What Raw Materials Are Used in Starter Manufacturing?

The first stage in the manufacturing process is material preparation. Common materials include high-grade steel for the housing, copper for the windings, and various alloys for components such as the armature and solenoid. Suppliers often source materials from certified vendors to ensure they meet industry standards. Buyers should inquire about the material specifications and the origin of the materials, as this can significantly impact the performance and longevity of the starters.

Forming: How Are Starter Components Shaped and Assembled?

Following material preparation, components undergo forming processes such as stamping, machining, and die casting. Stamping is used for creating flat parts like housings, while machining is essential for precision components like gears and shafts. Advanced techniques like injection molding may also be employed for producing plastic parts.

Once formed, components are often assembled using automated systems to ensure consistent quality and efficiency. Some manufacturers utilize robotic arms for precision assembly, which minimizes human error and enhances production speed. B2B buyers should evaluate the technology used in the forming and assembly processes, as this can influence the quality and cost of the starters.

What Quality Assurance Standards Are Relevant for Starter Production?

Quality assurance (QA) is paramount in the manufacturing of starter motors, given their critical role in vehicle performance. B2B buyers should be aware of the international standards and industry-specific certifications that govern quality in starter production.

How Does ISO 9001 Ensure Quality in Starter Manufacturing?

ISO 9001 is a widely recognized quality management standard that emphasizes a process approach to quality. Companies that are ISO 9001 certified demonstrate their commitment to consistent quality and customer satisfaction. This certification requires manufacturers to establish a quality management system (QMS) that includes process mapping, risk management, and continuous improvement practices.

B2B buyers can request ISO certification documentation from suppliers to verify their compliance. This documentation should outline the supplier’s quality policies, objectives, and procedures, ensuring that the manufacturing process aligns with international best practices.

What Industry-Specific Certifications Should Buyers Look For?

In addition to ISO 9001, certain industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for ensuring that starters meet regional and application-specific requirements. CE marking indicates compliance with European health, safety, and environmental protection standards, while API certification is vital for parts used in automotive applications, ensuring they meet rigorous performance criteria.

Buyers should ensure that their suppliers possess relevant certifications that align with the markets they serve, as this can impact product acceptance and regulatory compliance.

What Are the Key Quality Control Checkpoints in Starter Production?

Quality control (QC) is integrated throughout the manufacturing process to identify and rectify defects early. B2B buyers should understand the various QC checkpoints that manufacturers implement.

How Are Incoming Quality Control (IQC) Measures Implemented?

Incoming Quality Control (IQC) is the first checkpoint in the QC process. It involves inspecting raw materials and components upon arrival at the manufacturing facility. This step ensures that all incoming materials meet specified standards before they are used in production. Buyers can request IQC reports from suppliers to confirm that the materials used in starter production are of high quality.

What Is In-Process Quality Control (IPQC) and Its Importance?

In-Process Quality Control (IPQC) involves monitoring the manufacturing process in real time. This can include regular inspections of components during assembly and testing of electrical systems to ensure they meet performance specifications. Manufacturers often use statistical process control (SPC) methods during this stage to identify trends and variances that may indicate potential defects.

B2B buyers can inquire about the frequency and methods of IPQC checks, as well as the qualifications of personnel involved in these inspections.

Illustrative image related to how much is a starter replacement

What Role Does Final Quality Control (FQC) Play in Ensuring Product Reliability?

Final Quality Control (FQC) is the last checkpoint before products are packaged and shipped. This stage includes comprehensive testing of completed starters to ensure they function correctly under various conditions. Common tests include electrical load tests, vibration tests, and durability assessments.

B2B buyers should request FQC documentation, which should detail the testing procedures, results, and any corrective actions taken for non-conforming products. This documentation serves as evidence of the supplier’s commitment to delivering reliable products.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Ensuring that suppliers maintain high-quality standards is essential for B2B buyers looking to procure starter motors. Here are some strategies to verify QC processes effectively.

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control practices. Audits can be performed by the buyer or third-party inspectors and should evaluate the supplier’s QMS, manufacturing processes, and compliance with international standards. Buyers should establish a clear audit checklist that includes key areas such as material sourcing, manufacturing processes, and quality control practices.

How Can Third-Party Inspection Services Assist Buyers?

Third-party inspection services offer an unbiased evaluation of a supplier’s manufacturing and quality assurance processes. These services can conduct random inspections at different stages of production and provide detailed reports on compliance with industry standards. Engaging third-party inspectors can add an extra layer of confidence for buyers, especially in international transactions where direct oversight may be limited.

Illustrative image related to how much is a starter replacement

What Nuances Should International Buyers Consider in Quality Control?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control.

How Do Regional Regulations Impact Quality Assurance?

Different regions have varying regulations and standards that affect the quality assurance of automotive components. For instance, European buyers must consider the CE marking, while buyers in Africa may need to be aware of local automotive standards. Understanding these regional nuances is crucial for compliance and successful market entry.

What Are the Common Challenges in Verifying Supplier Quality Across Borders?

Cross-border transactions can complicate the verification of supplier quality. Language barriers, different time zones, and varying levels of regulatory enforcement can create challenges. B2B buyers should establish clear communication channels with suppliers and consider leveraging technology, such as digital platforms for documentation and real-time updates, to streamline the verification process.

By understanding the manufacturing processes and quality assurance measures in starter motor production, B2B buyers can make informed decisions that align with their needs and expectations, ultimately leading to more reliable and efficient procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is a starter replacement’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to understand the costs associated with starter replacement and to procure the necessary components effectively. Knowing how to navigate this process is essential for making informed purchasing decisions, optimizing supply chain management, and ensuring operational efficiency.

Illustrative image related to how much is a starter replacement

Step 1: Identify Your Vehicle Specifications

Understanding the specific make and model of the vehicle in need of a starter replacement is crucial. Different vehicles may require unique starter designs and specifications, which directly influence the cost and availability of parts. Ensure you have the vehicle identification number (VIN) at hand, as this will help suppliers provide accurate pricing and compatibility information.

Step 2: Research Market Prices

Before engaging with suppliers, conduct thorough market research to gauge the average costs of starter replacements. This includes both parts and labor. Prices can vary significantly based on geographical location and vehicle type, so it’s beneficial to compare multiple sources to establish a baseline for negotiations.

Step 3: Evaluate Supplier Options

When sourcing starters, it’s important to vet potential suppliers. Look for companies that specialize in automotive parts, particularly those that offer a range of options, from OEM to aftermarket parts. Request company profiles, product catalogs, and references from similar industries to assess their reliability and quality.

- Consider the Supplier’s Reputation: Check online reviews and testimonials.

- Inquire About Warranty Policies: A solid warranty can indicate confidence in the product quality.

Step 4: Assess Quality of Components

Not all starters are created equal; the quality can vary based on manufacturer and specifications. Determine whether you need a new or remanufactured starter based on your budget and the vehicle’s requirements. New starters typically offer longer lifespans but at a higher cost, while remanufactured starters can be more economical but may have a shorter operational life.

Step 5: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that break down all associated costs. This should include the price of the starter, labor costs, and any additional fees such as shipping or handling. A transparent quote allows for better budget planning and can highlight any potential hidden costs.

Step 6: Negotiate Terms and Conditions

After receiving quotes, engage in negotiations to secure favorable terms. This may involve discussing payment terms, bulk purchasing discounts, or warranty coverage. Establishing clear terms at the outset can help mitigate risks and ensure a smoother transaction process.

Step 7: Plan for Installation and Additional Repairs

Finally, consider the logistics of installation and any potential additional repairs. Assess whether your team will handle installation or if professional services are required. Additionally, be aware of any related issues that may arise, such as battery or wiring problems, that could increase overall repair costs.

By following this checklist, B2B buyers can streamline the sourcing process for starter replacements, ensuring they make informed decisions that align with their operational needs and budgets.

Comprehensive Cost and Pricing Analysis for how much is a starter replacement Sourcing

When assessing the costs associated with starter replacements, it is essential to understand the various components that contribute to the overall pricing structure. This analysis will help international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

What Are the Key Cost Components for Starter Replacement?

-

Materials Costs

The primary material cost is the starter motor itself, which can vary significantly depending on whether it is an aftermarket, OEM, or high-performance part. Generally, aftermarket starters can range from $75 to $200, while OEM parts can cost between $150 and $400. High-performance options may exceed $1,000. Additional materials, such as wiring and fasteners, can also contribute to the total cost. -

Labor Costs

Labor costs are influenced by the complexity of the installation. Basic starter replacements may incur labor charges of $100 to $250, while more complex installations, especially for luxury or performance vehicles, can range from $300 to $600. The regional labor rates also play a crucial role in determining these costs, with variations observed between different countries and cities. -

Manufacturing Overhead and Tooling

Manufacturing overhead includes costs associated with production facilities, equipment maintenance, and workforce training. Tooling costs can be significant, especially for custom or specialized starter designs. These factors are often absorbed into the pricing of the starter units. -

Quality Control (QC)

Investing in quality control measures is critical for ensuring the reliability of starter replacements. Quality certifications, such as ISO standards, can add to the overall cost but are essential for maintaining product integrity and customer satisfaction. -

Logistics and Shipping

Logistics costs encompass warehousing, transportation, and customs duties, particularly for international transactions. These costs can vary widely based on the shipping method, distance, and any applicable tariffs or duties. -

Margin

The profit margin added by suppliers will depend on market conditions, competition, and the perceived value of the product. Generally, margins can range from 20% to 40%, but this can fluctuate based on demand and supply dynamics.

What Influences Pricing for Starter Replacements?

Several factors can influence the price of starter replacements, including:

- Volume/MOQ: Bulk purchases typically offer significant discounts. Negotiating minimum order quantities (MOQ) can provide cost benefits.

- Specifications and Customization: Custom-designed starters tailored to specific vehicle models or performance standards may incur higher costs.

- Materials Quality and Certifications: Higher-quality materials and certifications can lead to increased pricing but often result in better longevity and reliability.

- Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers may charge a premium for their products due to brand trust.

- Incoterms: The chosen Incoterms can influence logistics costs and risks. Understanding who is responsible for shipping, insurance, and duties is vital for cost management.

What Tips Can Help Buyers Navigate Starter Replacement Costs?

-

Negotiate Effectively: Leverage volume purchases or long-term agreements to negotiate better pricing and terms. Establishing a relationship with suppliers can also lead to more favorable deals.

-

Focus on Total Cost of Ownership (TCO): Consider not just the upfront costs but also the potential long-term savings from higher-quality starters that may require fewer replacements and repairs.

-

Understand Pricing Nuances for International Buyers: Buyers from different regions should be aware of local market conditions, currency fluctuations, and import duties that can affect the final price. For example, sourcing from suppliers in Europe may differ significantly in cost and logistics compared to sourcing from local manufacturers in Africa or South America.

-

Request Detailed Quotes: Ensure that quotes from suppliers include a breakdown of all cost components, allowing for easier comparison and analysis.

Disclaimer on Indicative Prices

The prices provided in this analysis are indicative and may vary based on specific market conditions, supplier pricing strategies, and individual buyer negotiations. It is advisable to conduct thorough market research and obtain multiple quotes to ensure competitive pricing and quality.

Alternatives Analysis: Comparing how much is a starter replacement With Other Solutions

Exploring Alternatives for Starter Replacement Solutions

When considering the costs associated with starter replacement, it’s essential to explore alternative solutions that may offer similar functionalities or benefits. This analysis will compare traditional starter replacement with alternative methods such as battery replacement and the use of jump-start devices. By examining these alternatives, B2B buyers can make informed decisions that suit their operational needs and budget constraints.

Illustrative image related to how much is a starter replacement

Comparison Table

| Comparison Aspect | How Much Is A Starter Replacement | Battery Replacement | Jump-Start Device |

|---|---|---|---|

| Performance | High, crucial for ignition | Moderate, only if the starter is faulty | Variable, provides temporary power |

| Cost | $250 – $1,000+ | $50 – $300 | $50 – $150 |

| Ease of Implementation | Requires professional installation | Often DIY, simple process | Easy to use, portable |

| Maintenance | Low, once replaced | Moderate, battery lifespan varies | Low, requires periodic charging |

| Best Use Case | Persistent starting issues | Weak battery symptoms | Emergency situations |

Understanding Battery Replacement as an Alternative

Battery replacement is a viable alternative when the starting issues stem from a weak or failing battery rather than a faulty starter. The cost of a new battery typically ranges from $50 to $300, making it a more budget-friendly option. The ease of implementation is another advantage, as many vehicle owners can replace a battery themselves with minimal tools. However, it is crucial to note that if the starter is indeed the root of the problem, merely replacing the battery will not solve the starting issue, potentially leading to further complications down the line.

Evaluating Jump-Start Devices

Jump-start devices, often referred to as battery jump-starters, provide a portable solution for starting vehicles without requiring another vehicle’s assistance. Priced between $50 and $150, these devices can be a lifesaver in emergency situations. Their ease of use and portability are significant advantages, allowing users to quickly address starting problems. However, they serve only as a temporary fix; if the starter is malfunctioning, relying on a jump-start device repeatedly may not be sustainable in the long term. Furthermore, regular charging of the jump-starter is necessary to ensure readiness.

Conclusion: How to Choose the Right Solution for Your Needs

For B2B buyers evaluating their options regarding starter replacement, understanding the specific circumstances surrounding the starting issues is vital. If the vehicle consistently fails to start due to a malfunctioning starter, investing in a full replacement may be the most reliable solution. Conversely, if the problems are linked to battery health, a battery replacement could suffice and save costs. For emergency scenarios, having a jump-start device on hand can provide immediate assistance. Ultimately, the right choice depends on a thorough assessment of vehicle performance, budget, and operational requirements, ensuring that the selected solution aligns with the buyer’s strategic objectives.

Essential Technical Properties and Trade Terminology for how much is a starter replacement

What Are the Key Technical Properties of Starter Replacement Components?

When considering starter replacement, understanding the technical properties of the components involved is crucial for B2B buyers. These properties can impact the performance, durability, and cost-effectiveness of the replacement parts.

1. Material Grade

The material grade of a starter motor is vital as it determines the component’s strength, durability, and resistance to wear and tear. High-grade materials, such as steel or specialized alloys, are essential for longevity, especially in demanding environments. For B2B buyers, investing in high-grade materials can lead to reduced maintenance costs and longer operational lifespans.

Illustrative image related to how much is a starter replacement

2. Torque Specifications

Torque specifications refer to the amount of rotational force the starter motor can generate to crank the engine. This is crucial for ensuring that the starter can effectively start the engine under various conditions. Buyers should consider the torque requirements based on the vehicle’s engine size and type to ensure compatibility and performance.

3. Tolerance Levels

Tolerance levels are the permissible limits of variation in a physical dimension or measured value. In starter motors, tight tolerances ensure that components fit together correctly, enhancing performance and reducing the likelihood of failure. For B2B procurement, selecting parts with precise tolerances can minimize the risk of operational issues and improve reliability.

4. Electrical Resistance

The electrical resistance of a starter motor affects its efficiency and power consumption. A lower resistance typically results in better performance, as it allows more current to flow through the motor. B2B buyers must evaluate the electrical specifications to ensure that the starter is efficient and compatible with the vehicle’s electrical system.

Illustrative image related to how much is a starter replacement

5. Power Rating

The power rating, usually expressed in volts and amps, indicates the electrical power required for the starter to operate effectively. Understanding power ratings is essential for ensuring that the starter motor is compatible with the vehicle’s battery and electrical system. For international buyers, this specification can also influence the choice of starters that are suitable for different voltage standards.

What Are Common Trade Terms Related to Starter Replacement?

Familiarity with industry terminology can greatly facilitate the procurement process. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts that are made by the manufacturer of the original vehicle components. These parts are typically higher in quality and fit, ensuring compatibility. B2B buyers often prefer OEM parts for their reliability and performance, especially in critical applications.

Illustrative image related to how much is a starter replacement

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers, as it can impact inventory management and cost-effectiveness. Buyers should negotiate MOQs to align with their purchasing needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process is essential for B2B transactions, allowing buyers to compare offers and select the best supplier based on quality and cost.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is crucial for international B2B transactions, as they clarify who is responsible for shipping, insurance, and tariffs, ensuring smooth logistics and minimizing misunderstandings.

5. Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of a product. For B2B buyers, understanding warranty terms is important as it affects the long-term cost of ownership and the risk associated with potential failures.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding starter replacements, ensuring they choose the right components for their operational needs.

Illustrative image related to how much is a starter replacement

Navigating Market Dynamics and Sourcing Trends in the how much is a starter replacement Sector

What Are the Key Trends Affecting the Starter Replacement Market?

The global starter replacement market is currently experiencing significant shifts influenced by several key drivers. One of the primary factors is the increasing vehicle population, especially in emerging markets such as Africa and South America. As more vehicles take to the roads, the demand for starter replacements rises, particularly for older models that may require more frequent maintenance. Additionally, the ongoing technological advancements in vehicle design and manufacturing are leading to more sophisticated starters, which can be costlier to replace but offer improved reliability.

Emerging B2B tech trends, such as digital platforms for sourcing automotive parts, are transforming how international buyers procure starter replacements. Platforms that aggregate multiple suppliers and provide comparative pricing, inventory availability, and reviews can streamline the purchasing process. The rise of e-commerce in automotive parts is particularly noticeable in regions like Europe and the Middle East, where buyers are increasingly comfortable making purchases online.

Market dynamics are also shaped by regional variations in labor costs and the availability of skilled technicians. In countries like Germany, where labor costs are higher, buyers may lean towards OEM parts for quality assurance, while in markets like Nigeria, the demand for cost-effective aftermarket solutions is prevalent. Understanding these dynamics is crucial for B2B buyers when making purchasing decisions, ensuring they can source the right components at competitive prices.

How Is Sustainability Influencing the Starter Replacement Sector?

Sustainability is becoming a critical consideration in the starter replacement sector, as environmental concerns gain prominence among B2B buyers. The production and disposal of automotive parts, including starters, can have a considerable environmental impact. As a result, many companies are focusing on ethical sourcing practices and the use of sustainable materials in their manufacturing processes.

Incorporating ‘green’ certifications and materials can enhance a supplier’s appeal to conscious buyers. For instance, manufacturers that utilize recycled materials in their starter production or implement energy-efficient processes may gain a competitive edge. Furthermore, the demand for remanufactured starters is on the rise, as they offer a more sustainable alternative to new parts, reducing waste and conserving resources.

Illustrative image related to how much is a starter replacement

B2B buyers are increasingly prioritizing suppliers who can demonstrate a commitment to sustainability and ethical practices. This trend not only helps companies meet regulatory requirements but also aligns with consumer expectations, driving brand loyalty and market competitiveness.

What Is the Historical Context of Starter Replacement?

The evolution of starter replacement can be traced back to the early 20th century when electric starters replaced hand cranks, significantly improving vehicle usability. Initially, starters were simple devices, but as automotive technology advanced, the complexity of starters increased, necessitating more sophisticated replacement parts.

In recent decades, the market has seen a shift from purely mechanical starters to electronic systems, which are more efficient but also more challenging to replace. This evolution has led to a diversification of starter types, including high-performance and specialized starters, catering to a wide range of vehicle models. Understanding this historical context is essential for B2B buyers as it informs them about the ongoing developments in starter technology and the implications for sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of how much is a starter replacement

-

How much does it cost to replace a starter in different regions?

The cost of starter replacement can vary significantly based on the region. In Europe, prices generally range from €150 to €600, influenced by labor rates and vehicle types. In Africa and South America, costs can be lower, typically between $100 and $400, depending on local market conditions. It’s important to account for additional shipping and import duties when sourcing parts internationally, as these can affect the overall cost. -

What factors influence the price of a starter replacement?

Several key factors influence the cost of starter replacement. The type of vehicle (compact cars generally have cheaper starters), the quality of the starter (OEM vs. aftermarket), and labor costs play significant roles. Additionally, geographical location can impact pricing due to variations in labor rates and the availability of parts. B2B buyers should consider these factors when negotiating with suppliers. -

How can I ensure the quality of starters when sourcing internationally?

To ensure quality, B2B buyers should conduct thorough supplier vetting. This includes checking for certifications, reviewing past performance, and requesting samples. Engage in direct communication with suppliers to discuss quality assurance processes, warranty terms, and product testing methods. Utilizing third-party inspection services before shipment can further assure the quality of the parts being sourced. -

What is the minimum order quantity (MOQ) for starter parts?

Minimum order quantities (MOQs) for starter parts can vary widely among suppliers. Many manufacturers set MOQs based on production costs and inventory management strategies, often ranging from 50 to 500 units. B2B buyers should clarify MOQs during initial discussions and negotiate terms that align with their purchasing capabilities, especially if they are looking to test new suppliers or markets. -

What payment terms are typically offered for starter replacements?

Payment terms for starter replacements can vary depending on the supplier and the buyer’s relationship. Common terms include net 30, net 60, or even cash on delivery. B2B buyers should negotiate favorable terms that allow for financial flexibility while ensuring timely payments. Additionally, consider utilizing secure payment methods such as letters of credit or escrow services to mitigate risks in international transactions. -

How do I handle logistics for sourcing starters from abroad?

Handling logistics involves planning the shipment process from the supplier to your location. B2B buyers should select reliable freight forwarders who understand customs regulations and can handle documentation efficiently. It’s essential to factor in shipping times, insurance, and possible delays when sourcing internationally. Establishing a clear logistics plan helps ensure that starter parts arrive on time and in good condition. -

What are the common signs that a starter needs to be replaced?

Common indicators of a failing starter include difficulty in starting the vehicle, a clicking noise when attempting to start, or intermittent starting issues. If these symptoms are present, it is advisable to source a replacement promptly to avoid further complications. For B2B buyers, understanding these signs can help in timely procurement and reduce downtime for their fleets or clients. -

Can I customize starter parts for specific vehicle models?

Many manufacturers offer customization options for starter parts to fit specific vehicle models. B2B buyers should inquire about customization capabilities, including specifications, design alterations, and branding options. Providing detailed requirements will help suppliers deliver tailored solutions that meet your needs. Customization can enhance compatibility and performance, making it a valuable option for businesses with unique vehicle requirements.

Top 5 How Much Is A Starter Replacement Manufacturers & Suppliers List

1. Starter Replacement – Cost Overview

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Starter replacement, labor charges, diagnostics, OEM starter pricing, price variations by location, markup on parts.

2. Last Chance Auto Repairs – Starter Replacement Cost Guide

Domain: lastchanceautorepairs.com

Registered: 2009 (16 years)

Introduction: Starter Replacement Cost Breakdown: 1. Cost of the Starter Motor: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. 2. Labor Costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Factors affecting cost: Vehicle type & model, New vs Re-Manufactured starters, Additional repairs. DIY Starter Replacement Costs: Part…

3. Facebook – Car Repair Costs

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: cost to get car to the shop and replace starter

4. Tundras – Starter Replacement Analysis

Domain: tundras.com

Registered: 2000 (25 years)

Introduction: Starter replacement for a 2007 Toyota Tundra; quoted cost: $1500 (labor: $900, part: $650); part number: Denso 428000-4640; vehicle mileage: 174,000; mechanic shop: Brakes Plus; discussion on whether the price is reasonable; mention of potential battery issues instead of starter failure; advice on DIY replacement and varying labor costs.

5. CarTalk – Starter Replacement Costs

Domain: cartalk.com

Registered: 1995 (30 years)

Introduction: Cost to replace a starter: $600 to $900 for common vehicles; $900 to $1,400 for luxury models. Factors affecting cost include labor and accessibility of the starter. Symptoms of a failing starter include clicking sounds, screeching noises, and intermittent functionality. Options for replacement include new, remanufactured, or repaired starters, with remanufactured starters being common. Modern veh…

Strategic Sourcing Conclusion and Outlook for how much is a starter replacement

In summary, understanding the costs associated with starter replacement is essential for B2B buyers in diverse markets. The price can fluctuate significantly based on factors such as vehicle type, starter quality, and labor costs. For businesses, investing in high-quality OEM parts may ensure longer-lasting performance, thereby reducing the frequency of replacements and associated labor costs. Moreover, recognizing the signs of a failing starter early can prevent more extensive damage, leading to cost savings over time.

Strategic sourcing plays a pivotal role in managing these costs effectively. By establishing reliable supplier relationships and leveraging bulk purchasing, businesses can negotiate better pricing and ensure timely access to essential components. This approach not only enhances operational efficiency but also contributes to overall business sustainability.

As you navigate the complexities of starter replacement costs, consider the long-term benefits of strategic sourcing. Whether you are operating in Africa, South America, the Middle East, or Europe, aligning with trusted suppliers can empower your business to optimize expenditures. Take proactive steps today to secure quality starter components and streamline your procurement processes for a more resilient future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.