Introduction: Navigating the Global Market for how long does it take to replace a alternator

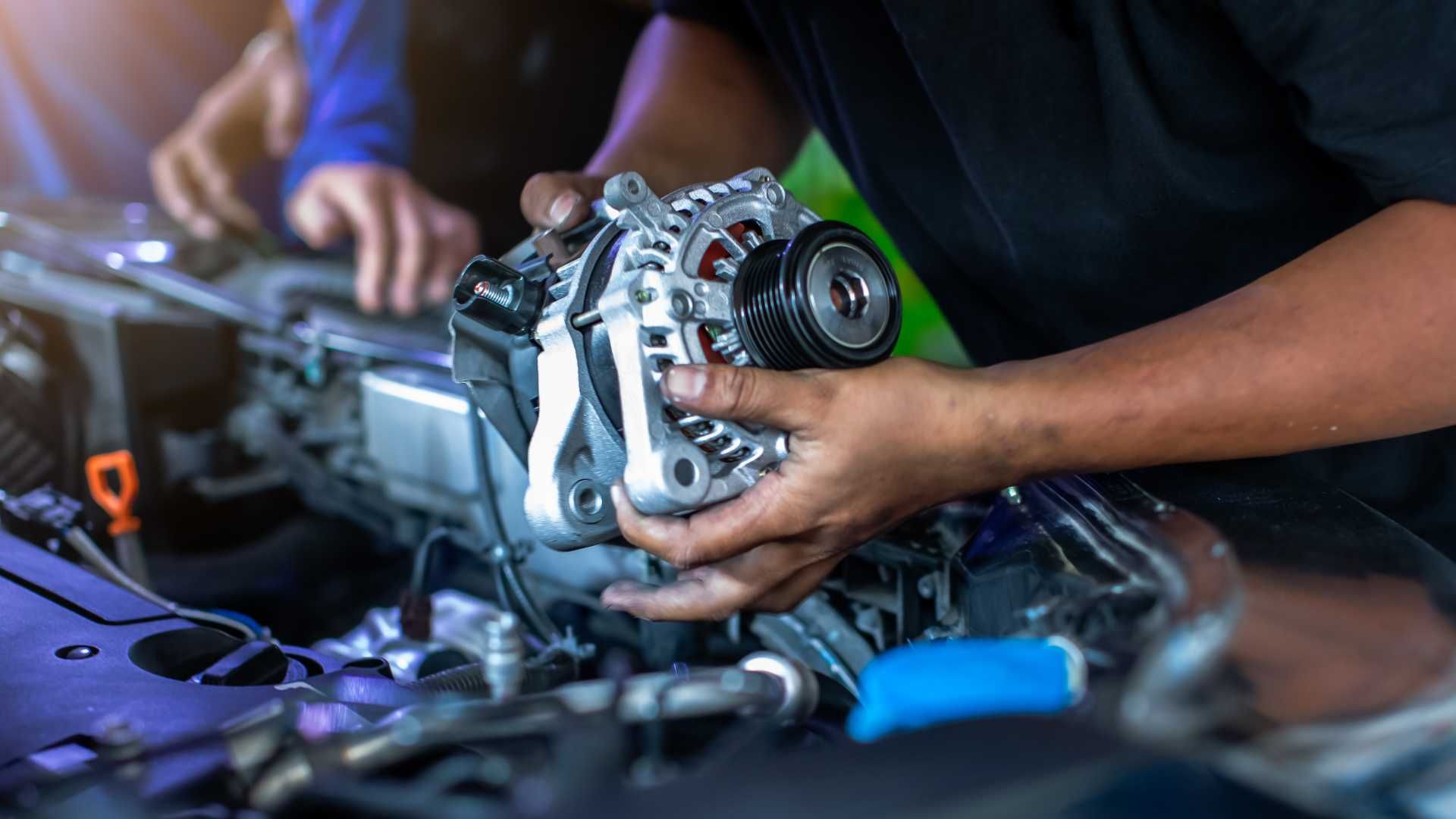

In today’s fast-paced automotive industry, understanding how long it takes to replace an alternator is crucial for B2B buyers, especially those operating across diverse markets such as Africa, South America, the Middle East, and Europe. The typical labor time for this essential service ranges from one to three hours, depending on vehicle type and accessibility. However, varying regional practices, supply chain logistics, and the availability of skilled labor can significantly impact these timelines.

This comprehensive guide delves into the intricacies of alternator replacement, covering different vehicle types, applications, and the implications of geographical factors on service times. It also provides insights on supplier vetting, ensuring that buyers can identify reliable partners capable of delivering quality parts and services efficiently. Furthermore, we will discuss cost considerations that can affect overall project budgets, enabling informed purchasing decisions.

By equipping international B2B buyers with actionable insights into the alternator replacement process, this guide empowers organizations to streamline their operations, reduce downtime, and enhance customer satisfaction. Whether you’re sourcing parts for a fleet or seeking reliable repair services, understanding these dynamics will help you navigate the global market effectively, ensuring that your business remains competitive and responsive to customer needs.

Table Of Contents

- Top 3 How Long Does It Take To Replace A Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long does it take to replace a alternator

- Understanding how long does it take to replace a alternator Types and Variations

- Key Industrial Applications of how long does it take to replace a alternator

- 3 Common User Pain Points for ‘how long does it take to replace a alternator’ & Their Solutions

- Strategic Material Selection Guide for how long does it take to replace a alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how long does it take to replace a alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does it take to replace a alternator’

- Comprehensive Cost and Pricing Analysis for how long does it take to replace a alternator Sourcing

- Alternatives Analysis: Comparing how long does it take to replace a alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how long does it take to replace a alternator

- Navigating Market Dynamics and Sourcing Trends in the how long does it take to replace a alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long does it take to replace a alternator

- Strategic Sourcing Conclusion and Outlook for how long does it take to replace a alternator

- Important Disclaimer & Terms of Use

Understanding how long does it take to replace a alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Passenger Vehicles | Typically 1-2 hours for replacement; accessible designs | Automotive repair shops, fleet management | Pros: Quick turnaround; Cons: Varies by model |

| Heavy-Duty Trucks | 2-4 hours, often requires specialized tools; complex access | Commercial transportation, logistics companies | Pros: Durable; Cons: Longer labor time |

| Luxury & Performance Vehicles | 2-3 hours; intricate wiring and components | High-end automotive service centers | Pros: High-quality parts; Cons: Higher costs |

| Electric & Hybrid Vehicles | 1-3 hours; requires specific knowledge of electrical systems | Eco-friendly vehicle repair shops | Pros: Growing market; Cons: Specialized training |

| Older Model Vehicles | 1-2 hours; simpler designs, often easier access | Classic car restoration, vintage vehicle shops | Pros: Easier repairs; Cons: Parts availability |

What are the Characteristics of Standard Passenger Vehicles in Alternator Replacement?

Standard passenger vehicles typically require 1-2 hours for alternator replacement, making them suitable for general automotive repair shops. The accessibility of the alternator in many models allows for a quicker turnaround, which is essential for businesses focused on customer satisfaction and efficiency. B2B buyers should consider the varying designs of different models that may impact labor time, as some vehicles may require additional steps to access the alternator.

How Do Heavy-Duty Trucks Differ in Alternator Replacement Time?

Heavy-duty trucks often take 2-4 hours for alternator replacement due to their complex designs and the necessity for specialized tools. This is particularly relevant for businesses in the transportation and logistics sectors, where downtime can significantly impact operations. B2B buyers should factor in the need for skilled technicians familiar with heavy-duty systems, and the potential for higher service costs due to extended labor times.

What Should B2B Buyers Know About Luxury & Performance Vehicles?

For luxury and performance vehicles, the alternator replacement process generally takes 2-3 hours. These vehicles often have intricate wiring and components that require specialized knowledge and tools. B2B applications for this type of service include high-end automotive service centers. Buyers should be aware that while the quality of parts is usually superior, the costs can also be significantly higher, impacting overall service budgets.

Why are Electric & Hybrid Vehicles Unique in Alternator Replacement?

Electric and hybrid vehicles typically require 1-3 hours for alternator replacement, but the process necessitates a specific understanding of electrical systems. As the market for eco-friendly vehicles expands, so does the need for specialized repair services. B2B buyers should consider the importance of ensuring that technicians are trained in the unique aspects of electric and hybrid vehicles, as this can affect both service quality and safety.

What are the Advantages of Replacing Alternators in Older Model Vehicles?

Older model vehicles generally allow for easier alternator replacement, typically taking about 1-2 hours. The simpler designs often lead to straightforward access, making them ideal for classic car restoration businesses. B2B buyers should keep in mind that while repairs may be simpler, the availability of parts can be a challenge, potentially leading to delays in service.

Key Industrial Applications of how long does it take to replace a alternator

| Industry/Sector | Specific Application of how long does it take to replace a alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Estimating repair time for fleet maintenance | Optimizes scheduling and resource allocation | Availability of parts and skilled technicians |

| Transportation and Logistics | Managing downtime for delivery vehicles | Reduces operational disruptions and improves efficiency | Access to reliable suppliers and quick turnaround times |

| Heavy Equipment Manufacturing | Planning maintenance for construction machinery | Enhances productivity and minimizes equipment downtime | Compatibility of parts with various machinery models |

| Automotive Parts Retail | Informing customers about repair timelines | Builds trust and transparency in customer service | Stock levels of alternators and related components |

| Electric Vehicle Charging Stations | Assessing maintenance needs for service vehicles | Ensures operational readiness and reliability of service fleets | Knowledge of EV-specific components and repair processes |

How Do Automotive Repair Shops Utilize Replacement Time Estimates for Alternators?

In automotive repair, knowing how long it takes to replace an alternator is crucial for efficient scheduling. Repair shops can estimate labor costs and time for customers, which enhances transparency and builds trust. This is particularly important for international buyers who may seek to understand local labor costs and service timelines. Fleet management companies benefit from this knowledge as it allows them to minimize vehicle downtime and optimize maintenance schedules, ensuring their operations run smoothly.

What is the Importance of Timely Repairs in Transportation and Logistics?

In the transportation and logistics industry, understanding the time required to replace an alternator can significantly impact delivery schedules. Quick repairs mean less downtime for delivery vehicles, which is essential for maintaining service level agreements. For international buyers, especially in regions like Africa and South America, reliable sourcing and timely repairs can enhance competitiveness. Ensuring that parts are readily available and that technicians are trained to handle repairs efficiently is vital for operational success.

How Does Heavy Equipment Manufacturing Benefit from Accurate Repair Time Estimates?

For heavy equipment manufacturers, knowing how long it takes to replace an alternator helps in planning maintenance schedules for construction machinery. This is critical as equipment downtime can lead to significant productivity losses on job sites. International buyers must consider sourcing parts that are compatible with various machinery models and ensuring that technicians are equipped to perform repairs swiftly. This proactive approach not only maintains operational efficiency but also safeguards project timelines.

Why is Knowledge of Repair Timelines Essential for Automotive Parts Retailers?

Automotive parts retailers can leverage knowledge of alternator replacement times to enhance customer service. By providing accurate estimates, they can help customers make informed decisions about repairs and maintenance. This is especially important in international markets, where customers may have varying expectations regarding service timelines and costs. Retailers should focus on maintaining adequate stock levels of alternators and related components to meet demand promptly, thereby improving customer satisfaction.

Illustrative image related to how long does it take to replace a alternator

How Do Electric Vehicle Charging Stations Assess Maintenance Needs?

Electric vehicle charging stations also benefit from understanding the time it takes to replace alternators in their service vehicles. Timely maintenance ensures that service fleets remain operational and ready to assist customers. For international buyers, particularly in regions investing in EV infrastructure, sourcing components that are compatible with electric vehicles is critical. Knowledge of specific repair processes and timelines can help these businesses maintain high service levels and operational reliability.

3 Common User Pain Points for ‘how long does it take to replace a alternator’ & Their Solutions

Scenario 1: Delays Due to Part Availability

The Problem: For B2B buyers managing fleets or automotive repair shops, one of the most pressing challenges is the unexpected delay in part availability when replacing an alternator. Often, mechanics may not have the specific alternator model in stock, leading to extended downtimes for vehicles. This can significantly affect operational efficiency, especially in industries reliant on transportation, as vehicles are essential for logistics and service delivery. The uncertainty regarding how long it will take to replace the alternator can further complicate scheduling and resource allocation.

The Solution: To mitigate these delays, B2B buyers should establish robust relationships with multiple suppliers to ensure a steady supply of alternators. Implementing a just-in-time inventory system can help maintain essential parts on hand without overstocking. Additionally, utilizing data analytics tools can assist in forecasting part demand based on historical usage patterns, allowing for better planning and procurement strategies. When requesting estimates from suppliers, be specific about the vehicle models and alternator types to minimize miscommunications and ensure faster delivery times.

Scenario 2: Miscommunication with Mechanics

The Problem: A common issue arises when B2B buyers are not fully informed about the expected labor time to replace an alternator, leading to miscommunication with mechanics or service providers. This situation can cause frustration, as clients may receive inflated time estimates or feel pressured to approve costly repairs without understanding the actual needs. Such miscommunication can erode trust and lead to disputes over service charges, ultimately affecting long-term relationships with repair shops.

The Solution: To address this, B2B buyers should equip themselves with knowledge regarding the typical timeframes for alternator replacement. Understanding that the process usually takes between 1 to 3 hours depending on vehicle make and model allows buyers to have informed discussions with mechanics. Additionally, buyers can request detailed breakdowns of the repair process from service providers, ensuring transparency. Regular training sessions or workshops can also be organized for buyers to familiarize them with common automotive maintenance procedures, enhancing their negotiation power and fostering clearer communication with service providers.

Scenario 3: Variability Across Vehicle Models

The Problem: B2B buyers often encounter challenges due to the variability in alternator replacement times across different vehicle models. While some vehicles may allow for straightforward access, others may require extensive disassembly of surrounding components, significantly increasing labor time. This inconsistency can lead to unexpected costs and scheduling issues, as buyers may not anticipate the complexities involved in certain models, leading to budget overruns and project delays.

The Solution: To navigate this complexity, B2B buyers should conduct thorough research on the specific vehicles in their fleet. Utilizing resources such as manufacturer service manuals or industry-standard labor time guides can provide accurate estimates for alternator replacement. Additionally, establishing a standardized protocol for vehicle maintenance can help streamline processes. For instance, creating a checklist that includes the average labor times for various models can assist in planning and budgeting for repairs. Collaborating with experienced mechanics to develop a knowledge base of common pitfalls associated with different models can also enhance efficiency and reduce variability in repair times.

Strategic Material Selection Guide for how long does it take to replace a alternator

What Materials Are Commonly Used for Alternator Replacement?

When considering the replacement of an alternator, the choice of materials plays a crucial role in determining the efficiency, longevity, and overall performance of the component. Here, we analyze four common materials used in alternator manufacturing and replacement, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Aluminum: A Lightweight and Corrosion-Resistant Option

Key Properties: Aluminum is known for its excellent corrosion resistance, lightweight nature, and good thermal conductivity. It typically withstands temperatures up to 150°C and has a high strength-to-weight ratio.

Pros & Cons: The primary advantage of aluminum is its lightweight characteristic, which contributes to reduced overall vehicle weight and improved fuel efficiency. However, it can be more expensive than steel and may require more complex manufacturing processes, which could increase lead times.

Impact on Application: Aluminum’s corrosion resistance makes it suitable for diverse environments, particularly in regions with high humidity or salt exposure, such as coastal areas in Africa and South America.

International Considerations: Buyers should ensure compliance with international standards such as ASTM and JIS for aluminum quality. Additionally, understanding regional preferences for aluminum versus steel can influence purchasing decisions.

Steel: The Traditional Choice for Durability

Key Properties: Steel is renowned for its high tensile strength and durability, with a temperature rating that can exceed 200°C. It is less resistant to corrosion unless treated or coated.

Pros & Cons: Steel’s primary advantage is its robustness, making it ideal for heavy-duty applications. However, its weight can negatively impact fuel efficiency and handling. The manufacturing process for steel components is generally simpler and less costly than that for aluminum.

Illustrative image related to how long does it take to replace a alternator

Impact on Application: Steel is well-suited for environments where mechanical stress is a concern, such as in heavy machinery or vehicles operating in rugged terrains.

International Considerations: Compliance with standards like ASTM A36 for structural steel is essential. Buyers in regions with stringent environmental regulations may need to consider the impact of corrosion and the necessity for protective coatings.

Copper: Essential for Electrical Conductivity

Key Properties: Copper is an excellent conductor of electricity and has a high melting point of around 1,085°C. It is also resistant to corrosion, especially when treated.

Pros & Cons: The primary advantage of copper is its superior electrical conductivity, which enhances alternator efficiency. However, it is more expensive than aluminum and steel, which can affect overall project budgets.

Impact on Application: Copper is critical in the wiring and connections of alternators, particularly in high-performance vehicles or applications requiring efficient energy transfer.

International Considerations: Buyers should be aware of copper’s fluctuating market prices and ensure compliance with international standards like ASTM B170 for copper wire. Additionally, regions with high copper theft rates may face supply chain challenges.

Plastic Composites: A Modern Alternative

Key Properties: Plastic composites are lightweight and can be engineered to provide specific properties, such as resistance to heat and chemicals. They typically withstand temperatures up to 120°C.

Pros & Cons: The major advantage of plastic composites is their lightweight nature and resistance to corrosion, making them suitable for various applications. However, they may not offer the same level of durability as metals and can be more susceptible to damage under mechanical stress.

Illustrative image related to how long does it take to replace a alternator

Impact on Application: Composites can be used in non-structural components of alternators, such as housings and covers, where weight savings are critical.

International Considerations: Buyers should ensure that plastic materials meet relevant standards such as ISO 9001 for quality management. Understanding the local market’s acceptance of composite materials is also vital.

Summary Table of Material Selection for Alternator Replacement

| Material | Typical Use Case for how long does it take to replace a alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight alternator housings in passenger vehicles | Excellent corrosion resistance | Higher cost and complex manufacturing | Medium |

| Steel | Heavy-duty alternators for trucks and machinery | High durability | Heavier, impacting fuel efficiency | Low |

| Copper | Electrical connections in performance vehicles | Superior electrical conductivity | Higher cost | High |

| Plastic Composites | Non-structural components in modern alternators | Lightweight and corrosion-resistant | Less durable under stress | Medium |

This analysis provides actionable insights for international B2B buyers, helping them navigate the complexities of material selection for alternator replacements while considering regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how long does it take to replace a alternator

What Are the Key Stages in the Manufacturing Process of Alternators?

The manufacturing of alternators involves several critical stages that ensure the final product meets performance and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing alternators from international suppliers.

Material Preparation: What Materials Are Used in Alternator Manufacturing?

The manufacturing process begins with the selection of high-quality materials, which typically include:

- Copper and Aluminum: Used for windings and conductors due to their excellent electrical conductivity.

- Steel and Iron: Commonly used for the housing and rotor components to ensure durability and strength.

- Magnetic Materials: Such as ferrite or neodymium for rotor assembly, essential for efficient magnetic field generation.

Once materials are sourced, they undergo quality checks to confirm compliance with industry standards, ensuring that only the best materials proceed to the next stage.

How Is the Forming Process Conducted for Alternators?

During the forming stage, materials are shaped into the necessary components of the alternator. This involves several techniques:

Illustrative image related to how long does it take to replace a alternator

- Stamping: Sheet metal is stamped into specific shapes for the housing and brackets.

- Machining: Components are machined for precise dimensions and fit, particularly for the rotor and stator.

- Winding: Copper wire is wound around the stator core, a critical step that directly affects the alternator’s efficiency.

Each of these processes must be conducted with precision to ensure that components fit together seamlessly, minimizing the risk of operational failure.

What Does the Assembly Process Entail for Alternators?

Once the components are formed, the assembly process begins. This includes:

- Component Assembly: Individual parts like the rotor, stator, and housing are assembled using automated and manual techniques.

- Electrical Connections: Proper electrical connections are made to ensure functionality. This is where quality assurance plays a significant role.

- Integration of Accessories: Additional components such as voltage regulators and diodes are integrated to complete the assembly.

The assembly line is designed to minimize errors, with workers trained to follow stringent guidelines to ensure that every alternator meets the required specifications.

How Is the Finishing Process Carried Out in Alternator Manufacturing?

The finishing stage involves several critical steps:

- Surface Treatment: Components may undergo surface treatments such as painting or coating to prevent corrosion and enhance appearance.

- Final Assembly Check: A thorough inspection is conducted to ensure all components are properly assembled and secured.

- Testing: Each alternator is subjected to rigorous testing to confirm functionality, performance, and durability.

This stage is crucial as it ensures that the alternators will perform reliably in real-world conditions, which is particularly important for B2B buyers concerned about product longevity and reliability.

What Quality Assurance Practices Are Essential in Alternator Manufacturing?

Quality assurance (QA) in alternator manufacturing is vital for ensuring that the end product meets international standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding relevant international standards can be crucial in supplier selection. Key standards include:

- ISO 9001: This standard ensures that manufacturers have a quality management system in place, focusing on continuous improvement and customer satisfaction.

- CE Marking: Particularly relevant for European markets, CE marking indicates that the product complies with EU safety and environmental requirements.

- API Standards: For alternators used in specific industrial applications, API standards may also apply, ensuring quality and performance.

These certifications can serve as a benchmark for evaluating potential suppliers.

What Are the Key Quality Control Checkpoints in Alternator Manufacturing?

Quality control checkpoints are integral to maintaining standards throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify defects early in the production process.

- Final Quality Control (FQC): The final product undergoes rigorous testing to ensure it meets all performance and safety standards.

B2B buyers should inquire about these checkpoints when evaluating suppliers to ensure that the manufacturing process includes thorough quality assurance.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure the reliability of suppliers, B2B buyers can undertake several verification steps:

- Conduct Audits: Regular audits of supplier facilities can provide insights into their manufacturing processes and quality assurance practices.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes and results from testing.

- Engage Third-Party Inspectors: Utilizing third-party services can offer an unbiased assessment of a supplier’s quality control measures.

For international buyers, especially those in regions like Africa, South America, the Middle East, and Europe, understanding these aspects can significantly influence the procurement process.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when sourcing alternators, including differing quality expectations and regulatory requirements.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have specific regulations that affect quality standards. For instance:

- Local Certifications: Buyers should be aware of any local certifications that may be required in their region.

- Cultural Differences in Quality Expectations: Understanding the local market’s quality expectations can help buyers negotiate better and make more informed purchasing decisions.

What Should Buyers Consider Regarding Logistics and Supply Chain Management?

Logistics also plays a vital role in quality assurance. B2B buyers must consider:

- Lead Times: Understand the typical lead times for sourcing alternators and factor in potential delays.

- Shipping Conditions: Ensure that suppliers adhere to proper shipping conditions to prevent damage during transport.

By considering these factors, international buyers can enhance their procurement strategies and ensure they receive high-quality alternators that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does it take to replace a alternator’

To assist B2B buyers looking to understand the process and time involved in replacing an alternator, this guide provides a practical step-by-step checklist. Knowing how long it takes to replace an alternator can help businesses plan for vehicle maintenance, manage downtime, and budget appropriately.

Step 1: Understand the Average Time Required

Recognizing that the typical time frame for alternator replacement ranges from 1 to 3 hours is crucial. This timeframe can vary based on vehicle make and model, accessibility, and the mechanic’s expertise. Knowing this helps in planning and scheduling the service efficiently.

Step 2: Identify Vehicle-Specific Requirements

Different vehicles may have unique requirements or complexities involved in alternator replacement. It’s essential to consult the vehicle’s service manual or manufacturer specifications to understand any special tools or procedures needed. This step ensures that the right approach is taken, minimizing unforeseen delays.

Step 3: Define Your Technical Specifications

Specify the type of alternator required for your vehicles, including voltage, amperage, and mounting style. Clear technical specifications help suppliers provide the correct parts and avoid compatibility issues. This reduces the risk of extended downtime due to incorrect part orders.

Step 4: Source Reliable Suppliers

Finding trustworthy suppliers is essential for acquiring quality alternators. Look for suppliers with a good reputation, verified customer reviews, and a proven track record in your region. Reliable suppliers will often provide warranties and customer support, ensuring peace of mind in your purchase.

Illustrative image related to how long does it take to replace a alternator

- Research Supplier Credentials: Verify industry certifications, such as ISO standards, to ensure quality and reliability.

- Request References: Ask for case studies or testimonials from similar businesses to gauge supplier performance.

Step 5: Evaluate Cost Estimates

Request detailed quotes from multiple suppliers to understand the pricing landscape. Ensure that the estimates include all associated costs, such as shipping and taxes, to avoid surprises. This transparency is vital for effective budgeting.

Step 6: Plan for Downtime and Labor Costs

Consider the labor costs involved in the alternator replacement process. If outsourcing, inquire about the hourly rates and estimated time for the job. Planning for this downtime is crucial to minimize disruption to operations.

Step 7: Confirm Warranty and Return Policies

Before finalizing any purchase, review the warranty and return policies offered by your suppliers. A solid warranty protects your investment against defects and ensures that you have recourse if the part fails prematurely. Understanding these policies can save costs and headaches in the long run.

By following this checklist, B2B buyers can effectively navigate the process of sourcing alternators and planning for their replacement, ensuring a smooth operation and minimal downtime.

Comprehensive Cost and Pricing Analysis for how long does it take to replace a alternator Sourcing

What Are the Key Cost Components for Replacing an Alternator?

When considering the costs associated with replacing an alternator, several key components come into play. Understanding these elements helps international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

-

Materials: The primary material cost for alternator replacement includes the alternator itself, which can vary significantly based on brand and specifications. New alternators range from $100 to $600, while remanufactured units may offer cost savings between $50 and $300. Additional materials, such as belts or connectors, may also be necessary, especially if they show signs of wear.

-

Labor: Labor costs typically range from $50 to $150 per hour, depending on the region and the mechanic’s expertise. The time required to replace an alternator generally falls between one to three hours, influenced by the vehicle’s make and model, accessibility, and the technician’s efficiency.

-

Manufacturing Overhead: This encompasses the costs related to production facilities, utilities, and administrative expenses. For B2B buyers, understanding the manufacturer’s operational efficiency can provide insights into pricing.

-

Tooling and Equipment: Specialized tools may be required for certain vehicles, adding to the overall cost. This is particularly relevant for businesses operating in regions where access to such tools may be limited.

-

Quality Control (QC): Ensuring the alternator meets specific performance and safety standards incurs additional costs. High-quality alternators often come with certifications that can influence pricing but provide value in reliability and warranty options.

-

Logistics: Shipping costs can vary widely based on the supplier’s location and the buyer’s destination. International shipping may involve customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers will add a margin to cover their risks and operational costs. Understanding the competitive landscape can help buyers negotiate better pricing.

What Influences the Pricing of Alternator Replacement?

Several factors influence the pricing of alternator replacement, which are crucial for B2B buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can significantly reduce per-unit costs. Suppliers often offer discounts for larger orders, making it advantageous for businesses with high vehicle turnover or fleet operations.

-

Specifications and Customization: Customized alternators or those with advanced features may come at a premium. Buyers should assess whether the additional cost aligns with their operational needs.

-

Material Quality and Certifications: Higher quality materials and certifications can lead to increased costs but often translate to enhanced durability and performance. Buyers should weigh the benefits against the price.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers with a proven track record may charge more but offer better service and support.

-

Incoterms: The terms of trade (Incoterms) agreed upon can impact costs. Buyers should clarify who is responsible for shipping, insurance, and import duties to avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Better Prices?

B2B buyers can employ several strategies to secure favorable pricing:

-

Conduct Market Research: Understanding the market rates for alternators can empower buyers during negotiations. Knowing competitor pricing helps establish a benchmark.

-

Leverage Total Cost of Ownership (TCO): Emphasizing the long-term benefits of quality parts can justify higher upfront costs. Buyers should consider durability, maintenance, and warranty when evaluating options.

-

Be Transparent About Needs: Clear communication regarding volume needs and specifications can help suppliers provide tailored pricing. Building a strong relationship can lead to better deals.

-

Explore Local Suppliers: For international buyers, sourcing from local suppliers can reduce logistics costs and lead times, making it a viable option for urgent repairs.

-

Negotiate Payment Terms: Flexible payment options can provide cash flow benefits and might influence the supplier’s willingness to offer discounts.

Disclaimer on Pricing

Prices mentioned are indicative and may vary based on local market conditions, specific vehicle models, and supplier negotiations. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure competitive pricing for alternator replacement.

Alternatives Analysis: Comparing how long does it take to replace a alternator With Other Solutions

Introduction: Understanding Alternatives in Alternator Replacement

When considering the process of replacing an alternator, it’s crucial for B2B buyers to evaluate various alternatives that can achieve similar outcomes. This analysis compares the traditional method of alternator replacement with other viable solutions, such as upgrading to a high-efficiency alternator and utilizing mobile repair services. Each alternative presents distinct benefits and challenges, which can impact operational efficiency, cost-effectiveness, and serviceability.

Comparison Table

| Comparison Aspect | How Long Does It Take To Replace An Alternator | Upgrade to High-Efficiency Alternator | Mobile Repair Services |

|---|---|---|---|

| Performance | 1-2 hours | 1-3 hours (including installation) | 1-2 hours on-site |

| Cost | Moderate (parts + labor) | Higher initial investment | Variable (depends on distance) |

| Ease of Implementation | Moderate (requires skilled labor) | Moderate (requires skilled labor) | Easy (convenience of service) |

| Maintenance | Standard (regular checks needed) | Lower (better durability) | Standard (based on service) |

| Best Use Case | Routine vehicle maintenance | High-demand applications | Emergency repairs |

Detailed Breakdown of Alternatives

1. Upgrade to High-Efficiency Alternator

Upgrading to a high-efficiency alternator can offer significant advantages, particularly for businesses relying on heavy machinery or vehicles with high electrical demands. These alternators are designed to produce more power while consuming less energy, which can enhance overall vehicle performance. However, the initial investment is generally higher than a standard alternator, which may deter cost-sensitive buyers. Additionally, while the installation process is similar to a standard alternator replacement, it may require specialized knowledge or tools, adding to labor costs.

2. Mobile Repair Services

Mobile repair services provide a convenient alternative for businesses that require quick turnaround times for vehicle repairs. By bringing the service directly to the location of the vehicle, these services can minimize downtime, which is critical for companies dependent on their fleets. The time taken for mobile services typically ranges from 1-2 hours, similar to traditional replacement methods. However, costs can vary based on the technician’s travel distance and labor rates. While the convenience is a significant advantage, the availability of mobile services might be limited in some regions, particularly in remote areas.

Conclusion: Making the Right Choice for Your Business Needs

When selecting the appropriate solution for alternator replacement, B2B buyers should weigh the specific needs of their operations against the advantages and disadvantages of each alternative. Factors such as performance requirements, budget constraints, and the urgency of repairs will influence the decision. For businesses focused on long-term savings and efficiency, investing in high-efficiency alternators might be beneficial. Conversely, for those needing immediate solutions with minimal downtime, mobile repair services could be the ideal choice. Ultimately, understanding these alternatives will empower buyers to make informed decisions that align with their operational objectives.

Illustrative image related to how long does it take to replace a alternator

Essential Technical Properties and Trade Terminology for how long does it take to replace a alternator

Understanding the Key Technical Properties Related to Alternator Replacement Time

When considering the duration required for replacing an alternator, several technical properties are crucial for B2B buyers to understand. These properties can influence both the efficiency of the replacement process and the overall cost.

-

Labor Time Specification

Labor time is typically specified in hours and represents the estimated duration for a mechanic to complete the alternator replacement. This time can range from 1 to 3 hours, depending on vehicle make and model, the mechanic’s experience, and the accessibility of the alternator. For buyers, understanding labor time helps in budgeting for repairs and in negotiating service costs. -

Accessibility Rating

Accessibility refers to how easily a mechanic can reach the alternator for replacement. This can vary significantly between different vehicle models. For example, some cars may require the removal of underbody panels or other components to access the alternator. Knowing the accessibility rating can help buyers anticipate potential additional labor costs and time delays. -

Parts Availability

The availability of the alternator and related components affects replacement time. If a part needs to be ordered, this can delay the repair process significantly. Buyers should inquire about the local stock status of alternators to minimize downtime. Establishing relationships with reliable suppliers can also ensure quicker access to necessary parts. -

Cooling Time Requirement

After the engine has been running, it may require a cooling period before a mechanic can safely handle the alternator. This cooling time can add to the overall labor time. Buyers should factor this into their timelines, especially if they are coordinating repairs with logistics or operational schedules. -

OEM vs. Aftermarket Parts

Original Equipment Manufacturer (OEM) parts are designed to meet the specifications of the vehicle, while aftermarket parts may vary in quality and compatibility. Using OEM parts can streamline the replacement process, as they are often easier to install and come with warranties. Buyers should weigh the pros and cons of each option, as this can affect replacement time and long-term reliability.

Common Trade Terminology for Alternator Replacement

Understanding industry-specific terminology is essential for B2B buyers involved in automotive repairs or parts sourcing. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are designed to fit and function exactly like the original components. Buyers often prefer OEM parts for their reliability and compatibility, which can reduce installation time. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For alternators, understanding MOQ can help buyers manage inventory costs, especially if they are purchasing for a fleet or repair shop. Higher MOQs might lead to excess stock, while lower ones could limit purchasing flexibility. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific parts or services. For alternator replacements, submitting an RFQ can help buyers compare costs and services from different suppliers, ensuring they receive competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers sourcing alternators globally, as they dictate shipping costs, risk, and delivery responsibilities. -

Warranty Period

The warranty period refers to the time during which a product is guaranteed against defects. For alternators, warranties can vary between OEM and aftermarket parts. Buyers should consider warranty terms as they can impact long-term operational costs and the decision to replace or repair. -

Service Level Agreement (SLA)

An SLA is a contract that outlines the expected service level between a provider and a customer. For businesses relying on vehicle uptime, having a clear SLA with repair service providers can ensure timely alternator replacements and minimize disruptions to operations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding alternator replacements, ultimately leading to cost-effective and efficient operations.

Navigating Market Dynamics and Sourcing Trends in the how long does it take to replace a alternator Sector

Market Overview & Key Trends in Alternator Replacement

The global automotive industry is experiencing significant shifts, particularly regarding the replacement of critical components like alternators. On average, the time required to replace an alternator ranges from one to three hours, depending on vehicle make, model, and accessibility. This variability is driven by the complexity of modern vehicle designs, which can significantly affect labor costs and service time for B2B buyers. In regions such as Africa, South America, the Middle East, and Europe, the demand for efficient service turnaround is increasing, urging suppliers and service centers to adopt more streamlined processes.

Emerging trends in B2B sourcing indicate a shift towards the use of advanced technologies such as diagnostic software and automated inventory management systems. These tools not only enhance the speed of diagnosis but also ensure that the necessary parts are readily available, reducing wait times for customers. Additionally, the rise of e-commerce platforms has empowered international buyers to source parts directly, fostering competitive pricing and improved service levels.

Another critical market dynamic is the growing emphasis on transparency in repair practices. B2B buyers are increasingly seeking detailed information on service times and labor costs to avoid unexpected expenses. This demand for transparency is pushing repair shops to standardize their pricing models and provide upfront estimates, making it easier for businesses to budget for repairs.

How Does Sustainability & Ethical Sourcing Impact the Alternator Replacement Sector?

The automotive sector is under increasing pressure to adopt sustainable practices, and the alternator replacement market is no exception. The environmental impact of automotive repairs, particularly regarding waste management and resource consumption, is prompting B2B buyers to prioritize suppliers that implement eco-friendly practices. This includes the use of recycled materials in alternator manufacturing and the responsible disposal of old components.

Ethical sourcing is also becoming paramount, as businesses seek partnerships with manufacturers that adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are increasingly sought after by B2B buyers as indicators of a supplier’s commitment to sustainability. Furthermore, the integration of “green” materials and technologies in the production of automotive parts not only helps reduce the carbon footprint but also meets the growing consumer demand for environmentally responsible products.

By investing in sustainable practices, businesses can not only improve their brand image but also potentially reduce costs through efficient resource management. As the global market continues to evolve, B2B buyers must consider the sustainability credentials of their suppliers as a key factor in their purchasing decisions.

Illustrative image related to how long does it take to replace a alternator

Brief Evolution/History of Alternator Replacement Practices

Historically, the replacement of alternators has evolved alongside advancements in automotive technology. In the early days of the automotive industry, alternators were relatively simple devices, making replacement a straightforward process that typically required minimal tools and time. However, as vehicles have become more complex, so too have the alternators themselves, often integrating advanced electronic features that require specialized knowledge and tools for replacement.

In recent decades, the introduction of diagnostic tools has further transformed the alternator replacement process. Technicians can now quickly assess the health of an alternator and related electrical systems, significantly reducing the time required for diagnosis and repair. This evolution has led to a more efficient service model, particularly important for B2B buyers who rely on quick turnaround times to maintain their fleets and customer satisfaction.

As the automotive industry continues to innovate, the practices surrounding alternator replacement will likely adapt, emphasizing efficiency, sustainability, and transparency—key considerations for modern B2B buyers navigating this dynamic market landscape.

Illustrative image related to how long does it take to replace a alternator

Frequently Asked Questions (FAQs) for B2B Buyers of how long does it take to replace a alternator

-

How long does it typically take to replace an alternator?

Replacing an alternator usually takes between one to three hours, depending on the vehicle make and model. The process involves removing the drive belt, disconnecting electrical connectors, and unbolting the alternator from its bracket. Accessibility can vary; some models allow easy access while others may require additional components to be removed. It’s wise to account for potential delays such as part delivery, particularly in regions where parts may not be readily available. -

What factors influence the time required for alternator replacement?

Several factors can affect the time needed for an alternator replacement, including the vehicle’s design, the technician’s experience, and the availability of necessary tools. Some vehicles have a more complex layout, making access to the alternator more challenging. Additionally, if diagnostic checks are required to confirm the alternator’s failure, this can extend the repair time. Understanding these variables can help B2B buyers set realistic timelines for repairs. -

What should I consider when sourcing alternators for my fleet?

When sourcing alternators, consider the quality and compatibility with your fleet vehicles. Look for suppliers who provide detailed specifications, warranties, and customer service. Additionally, evaluate the supplier’s reputation and their ability to meet your volume needs, especially if your operations require bulk purchases. Establishing relationships with reliable suppliers can streamline your procurement process and reduce downtime for your fleet. -

How do I vet suppliers for alternator parts?

To vet suppliers, assess their industry reputation, certifications, and experience in providing automotive components. Request references or case studies from similar businesses to gauge their reliability and quality. Additionally, inquire about their compliance with international standards and regulations, particularly if you are importing parts. Conducting site visits or audits can also provide insights into their operational capabilities and quality control measures. -

What is the typical minimum order quantity (MOQ) for alternators?

Minimum order quantities for alternators can vary significantly based on the supplier and the type of alternator. Some suppliers may offer flexible MOQs for smaller businesses, while others may require bulk orders to reduce costs. It’s essential to clarify MOQ terms during negotiations, especially if you’re looking to establish a long-term supply relationship. Understanding these terms can help you manage inventory and cash flow effectively. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms can vary widely among suppliers, but common practices include payment in advance, net 30, or letter of credit arrangements. It’s crucial to establish clear payment terms upfront to avoid misunderstandings. Consider factors like currency fluctuations and additional costs such as shipping and tariffs when negotiating terms. A clear understanding of these elements can help mitigate financial risks in international transactions. -

How can I ensure quality assurance for alternators purchased overseas?

To ensure quality assurance, request samples or conduct quality checks before making bulk purchases. Work with suppliers who provide detailed specifications and certifications for their products. Implement regular audits and establish clear quality control processes to monitor product standards. Collaborating with third-party inspection services can also provide an extra layer of assurance regarding the quality of alternators sourced from international suppliers. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider shipping methods, lead times, and customs regulations in your country. Evaluate the costs associated with freight, insurance, and duties to ensure a comprehensive understanding of total expenditure. Establishing relationships with reliable logistics partners can facilitate smoother operations and minimize delays. Additionally, maintaining clear communication with your supplier regarding shipping schedules and documentation is crucial to avoid complications at customs.

Top 3 How Long Does It Take To Replace A Alternator Manufacturers & Suppliers List

1. Honda Civic – Alternator Replacement Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Alternator replacement for a 2009 Honda Civic; user has little experience and is seeking advice on how much time to allocate for the task.

2. Facebook – Alternator Replacement Guide

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Alternator Replacement Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Autodoc – Alternator Replacement Time

Domain: autodoc.co.uk

Registered: 2011 (14 years)

Introduction: This company, Autodoc – Alternator Replacement Time, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how long does it take to replace a alternator

In the realm of automotive maintenance, understanding the time required to replace an alternator is crucial for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. Typically, the replacement process ranges from one to three hours, depending on the vehicle model and accessibility. Factors such as the need for additional repairs or part availability can also influence this timeframe, underscoring the importance of strategic sourcing for automotive components.

For international buyers, leveraging strategic sourcing not only ensures timely access to high-quality alternators but also fosters strong relationships with suppliers who understand local market dynamics. This approach can lead to cost savings, improved service delivery, and enhanced operational efficiency.

As the automotive industry continues to evolve, staying informed about maintenance timelines and sourcing strategies will be paramount. We encourage B2B buyers to engage with reliable suppliers and invest in partnerships that offer transparency and support. By doing so, you can enhance your procurement processes and ensure your fleet remains operational, contributing to your overall business success.

Illustrative image related to how long does it take to replace a alternator

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.